A Cu-catalyzed Sommelet–Hauser rearrangement for the synthesis of spiro-indolines is reported, where the reactivity was significantly improved by molecular torsional strain.

A Cu-catalyzed Sommelet–Hauser rearrangement for the synthesis of spiro-indolines is reported, where the reactivity was significantly improved by molecular torsional strain.

Abstract

A Cu-catalyzed Sommelet–Hauser dearomatization of dihydrophenanthridine and diazo compounds is reported for the synthesis of spiro-indolines. A spiro-structure with adjacent quaternary and tertiary carbon centers was constructed in one step as a single isomer. Increasing steric hindrance by introducing ortho-substituents dramatically improved substrate reactivity in this transformation.

Introduction

Dearomatization is a robust method for the construction of polyfunctionalized cyclic compounds; it can generate quaternary carbon centers and multi-substituted C C double bonds in one or two steps. Due to the high stabilization of aromaticity, dearomatization reactions are traditionally performed under harsh conditions, such as oxidation in the presence of hypervalent iodine,1 Birch reduction,2 enzymatic conditions,3 or other conditions.4 Dearomatization has recently been achieved using photochemistry and transition metal catalysis. In particular, catalytic asymmetric dearomatization (CADA) has attracted substantial attention, such as from the You group, for constructing optically pure molecules from arenes.5

The Sommelet–Hauser reaction is an intramolecular rearrangement of benzyl ammonium salts to give ortho-substituted benzylamines (Scheme 1a, path A).6–8 Sommelet–Hauser dearomatization can efficiently generate valuable three-dimensional compounds bearing quaternary carbon centers if the two ortho positions have non-hydrogen substituents (Scheme 1b). In a variation known as thio-Sommelet rearrangement, dearomatized compounds bearing thioether functionalities can be prepared by replacing the ammonium ylides with sulfur ylides.9,10

Scheme 1. The Sommelet–Hauser rearrangement.

A challenge to exploiting the Sommelet–Hauser reaction is preventing competitive Stevens rearrangement,11,12 in which formal intramolecular nucleophilic attack at the benzylic position affords 2-phenylethanamine analogues (Scheme 1a, path B). Singleton has argued that these two types of rearrangements compete dynamically because they can occur via the same transition state.13

Sommelet–Hauser rearrangement can be used to produce spiro-compounds from benzocyclic ammonium salts, but the reported reactions usually give low yields and wide product distribution.14 For example, the reaction usually produces two regioisomers together with ring-enlarged products from Stevens rearrangement (Scheme 1c). Ring strain in seven- and eight-membered structures lowers the rearrangement rate, significantly increasing the yields of desilylation by-products C. In addition, the requirement for pre-synthesized ammonium salts considerably limits the substrate scope of the reaction. Third, the Sommelet–Hauser rearrangement appears incompatible with ammonium salts with fewer than seven members. As a result, the reaction cannot generate rings smaller than six-membered N-heterocycles (Scheme 1c).

Herein we report the copper-catalyzed generation of nitrogen ylide intermediates capable of Sommelet–Hauser rearrangement, in which N-containing six-membered rings efficiently participate. We further report that molecular torsional strain in biaryl substrates increases their reactivity in this rearrangement.

We wondered whether we could adapt dearomatization via Sommelet–Hauser rearrangement to generate the important spirocyclohexaneindoline structural motif, found in several natural products including gelsemine,15 21-oxogelsemine16 and koumine (Fig. 1).17 It also comprises the core structural unit of various biologically active molecules.18

Fig. 1. Natural products containing a spirocyclohexaneindoline skeleton.

Results and discussion

Optimization

We were unable to dearomatize biaryl compound 1a using diazo compound 2a in the presence of silver, rhodium or gold salts as catalysts, which are frequently used in reactions involving carbene (Table 1, entries 1–3). We were pleased to find that 1a reacted with 2a in the presence of Cu(OTf) 0.5PhH at 90 °C to give 27% of spiro product 3a as a single isomer, along with a small amount of 4a (entry 4). The reaction generated a spiro-structure with adjacent quaternary and tertiary carbon centers in one step. Screening of copper salts showed Cu(acac)2 to perform the best in terms of yield and reaction time (entries 5–9). Lowering the reaction temperature increased the selectivity for 3a over the Stevens rearrangement product 4a, improving the isolated yield of 3a to 72% (entry 10). Solvent screening identified methyl tert-butyl ether (MTBE) as the best (entries 11–13). The reaction proceeded smoothly with only 5 mol% of Cu(acac)2, albeit with a slightly lower yield (entry 14).

Table 1. Optimization of reaction conditions a .

| |||||

| Entry | Catalyst | Solvent | T/°C | Yield of 3a/% | Yield of 4a/% |

| 1 | Rh2(OAc)4 (5 mol%) | Toluene | 90 | <5 | — |

| 2 | (Ph3P)AuCl | Toluene | 90 | – b | — |

| 3 | AgOTf | Toluene | 90 | NR | — |

| 4 | Cu(OTf) 0.5PhH | Toluene | 90 | 27 | <5 |

| 5 | Cu(OTf)2 | Toluene | 90 | NR | — |

| 6 | Cu(MeCN)4PF6 | Toluene | 90 | 32 | <5 |

| 7 | CuTC | Toluene | 90 | 47 | <5 |

| 8 | Cu(acac)2 | Toluene | 90 | 63 | <5 |

| 9 | Cu(hfacac)2 | Toluene | 90 | <5 | — |

| 10 | Cu(acac)2 | Toluene | 50 | 72 | — |

| 11 | Cu(acac)2 | MTBE | 50 | 83 | — |

| 12 | Cu(acac)2 | DCE | 50 | 53 | — |

| 13 | Cu(acac)2 | THF | 50 | 72 | — |

| 14 | Cu(acac)2 (5 mol%) | MTBE | 50 | 79 | — |

aUnless stated otherwise, the reaction was conducted with 1a (0.10 mmol), 2a (0.20 mmol), and a metal catalyst (10 mol%).

bAn unidentified product was formed.

Substrate scope

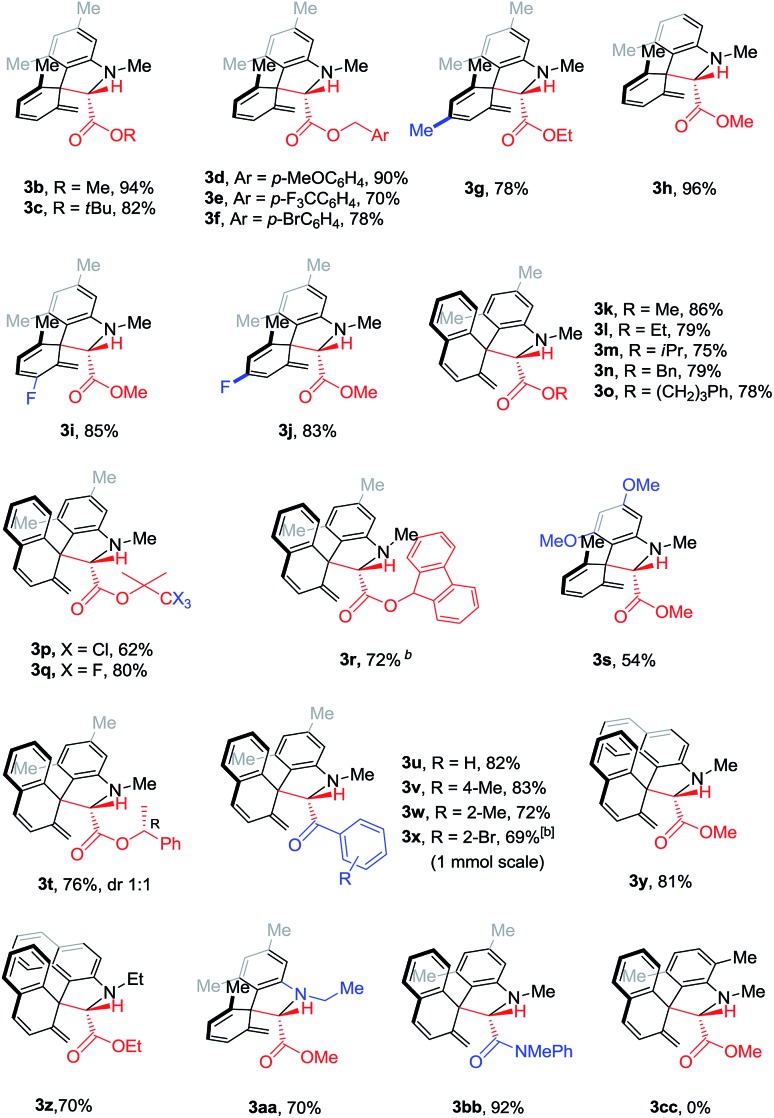

With the optimal conditions in hand, we tested the generality of this Cu(acac)2-catalyzed Sommelet–Hauser rearrangement. Diazo compounds with different ester groups, such as methyl, tert-butyl and substituted benzyl esters, reacted smoothly (3b–f). A diazo substrate with an electron-withdrawing group (CF3) led to a slightly lower yield (3e). The reaction tolerated additional methyl groups, a fluorine atom and methoxyl groups in the biaryl aniline skeleton (3g–3j, 3t). Naphthalene-based substrates and a binaphthalene derivative reacted uneventfully to give the spiro compounds in decent to excellent yields (3k–3r, 3t–3z and 3bb). Stereoinduction did not occur with the (R)-1-phenylethanol-derived diazo compound, such that a pair of diastereoisomers was isolated in a 1 : 1 ratio (3t). This rearrangement was compatible with ketones and amides, which afforded the desired products in decent to good yields (3u–3x). Introducing a methyl group adjacent to the C–N bond completely inhibited this transformation (3cc). The reaction tolerated an aryl-Br bond. Scale-up also proved possible, with compound 3x isolated in 69% yield on the 1.0 mmol scale.

The two ortho-substituents (R1 and R2 in Table 2) strongly influenced the efficiency of the Sommelet–Hauser reaction and selectivity for this type of rearrangement over Stevens rearrangement (Scheme 2). For example, under the standard conditions at 50–90 °C, the conversions of 5 were less than 55%, while isolated yields of 6 were no more than 35%. Product 6 was much less stable during purification than products 3a–3bb. Performing the reaction at higher temperature in toluene gave Stevens rearrangement product 7 as the major product, with 5 recovered at 55% yield.

Table 2. Substrate scope a .

|

|

aThe reaction was conducted with 1 (0.10 mmol), diazo compound 2 (0.20 mmol), and Cu(acac)2 (0.005 mmol, 5 mol%) in MTBE at 50 °C.

bThe reactions were performed in toluene.

Scheme 2. Substituent effects.

Synthetic applications

Preliminary synthetic studies were performed to demonstrate the utility of this rearrangement. Under 1 atm H2, the diene compound 3k underwent chemoselective 1,4-hydrogenation in the presence of Pd/C to give 8k in 83% yield, whose structure was unambiguously confirmed by single-crystal X-ray diffraction analysis. The N-methyl group could be further modified via rhodium-catalyzed C–H functionalization to afford 9k. Finally, the ester functionality could be reduced to the corresponding alcohol using DIBAL-H at –78 °C without eliminating the diene moiety. The diene was further cyclized in the presence of the MeNHOH·HCl catalyst to yield polycyclic compound 10k in 57% yield (Scheme 3).

Scheme 3. Control experiment and synthetic applications.

Mechanistic studies

In a plausible catalytic cycle (Scheme 4), the reaction begins when copper salt interacts with the diazo compound to give copper–carbene complex D, releasing one molecule of nitrogen gas. The subsequent reaction of the copper–carbene complex with amine 1 affords the ylide E. Intramolecular nucleophilic attack in E delivers the spiro product 3 either before or after dissociation of the copper catalyst. To obtain structural information about ammonium salt E and explain the different reactivity between 1 and 5, two ammonium compounds F and G were synthesized and analyzed by single-crystal X-ray diffraction. The torsional angle (C5–C6/C7–C13) was around 41° in F and 29° in G.19 Steric repulsion between the two ortho-substituents increased the distortion in the biaryl structure. We reasoned that the two ortho-substituents in E should distort its structure to a similar extent as in F. As a result, the relatively high-energy intermediate E undergoes a rapid intramolecular nucleophilic reaction to deliver spiro compounds. Alternatively, the increased torsion reduces the delocalization of the aniline lone-pair, which increases the basicity and accelerates the ammonium formation. Substituents on the substrates strongly influence the ratio of the [2,3]-rearrangement product to the Stevens rearrangement product;13 the latter rearrangement usually proceeds via a bi-radical pathway under thermal conditions.20 These considerations imply that less distorted substrates such as 5 generate lower-energy ylide intermediates, which therefore must overcome a higher activation barrier to give spiro products. Consistent with this, compound 5 was associated with lower conversion rates under the similar conditions.

Scheme 4. Plausible mechanism.

Conclusions

We have reported a copper-catalyzed Sommelet–Hauser rearrangement to construct spiroindoline compounds bearing adjacent quaternary and tertiary carbon centers. Increasing the torsional strain in the biaryl substrate increases its reactivity in this transformation. This is, to our knowledge, the first report in which Sommelet–Hauser rearrangement was used to generate spiro compounds bearing five-membered N-heterocycles.

Conflicts of interest

There are no conflicts to declare.

Supplementary Material

Acknowledgments

This work was supported by the NSFC (21622206, 21472179), ‘973’ project from the MOST of China (2015CB856600), the Strategic Priority Research Program of the Chinese Academy of Sciences (XDB20000000), and the Fundamental Research Funds for the Central Universities (WK2060190086).

Footnotes

†Electronic supplementary information (ESI) available. CCDC 1836413, 1836416 and 1836417. For ESI and crystallographic data in CIF or other electronic format see DOI: 10.1039/c8sc01657g

References

- (a) Yoshimuar A., Zhdankin V. V. Chem. Rev. 2016;116:3328. doi: 10.1021/acs.chemrev.5b00547. [DOI] [PubMed] [Google Scholar]; (b) Richardson R. D., Wirth T. Angew. Chem., Int. Ed. 2006;45:4402. doi: 10.1002/anie.200601817. [DOI] [PubMed] [Google Scholar]; (c) Uyanik M., Ishihara K. ChemCatChem. 2012;4:177. [Google Scholar]; (d) Dohi T., Kita Y. Chem. Commun. 2009:2073. doi: 10.1039/b821747e. [DOI] [PubMed] [Google Scholar]

- Rabideau P. W., Marcinow Z. Org. React. 1992;42:1–334. [Google Scholar]

- (a) Sono M., Roach M. P., Coulter E. D., Dawson J. H. Chem. Rev. 1996;96:2841. doi: 10.1021/cr9500500. [DOI] [PubMed] [Google Scholar]; (b) Harvey R. G. Acc. Chem. Res. 1981;14:218. [Google Scholar]; (c) Hudlicky T., Gonzalez D., Gibson D. T. Aldrichimica Acta. 1999;32:35. [Google Scholar]; (d) Ortiz F. L., Iglesias M. J., Fernández I., Sánchez C. M. A., Gómez G. R. Chem. Rev. 2007;107:1580. doi: 10.1021/cr030207l. [DOI] [PubMed] [Google Scholar]

- For some typical examples:; (a) Barluenga J., Trabanco A. A., Flórez J., García-Granda S., Martín E. J. Am. Chem. Soc. 1996;118:13099. [Google Scholar]; (b) García-Fortanet J., Kessler F., Buchwald S. L. J. Am. Chem. Soc. 2009;131:6676. doi: 10.1021/ja9025193. [DOI] [PMC free article] [PubMed] [Google Scholar]; (c) Shen C., Liu R.-R., Fan R.-J., Li Y.-L., Xu T.-F., Gao J.-R., Jia Y.-X. J. Am. Chem. Soc. 2015;137:4936. doi: 10.1021/jacs.5b01705. [DOI] [PubMed] [Google Scholar]; (d) Nan J., Zuo Z., Luo L., Bai L., Zheng H., Yuan Y., Liu J., Luan X., Wang Y. J. Am. Chem. Soc. 2013;135:17306. doi: 10.1021/ja410060e. [DOI] [PubMed] [Google Scholar]; (e) Seoane A., Casanova N., Quiñones N., Mascareñas J. L., Gulías M. J. Am. Chem. Soc. 2014;136:7607. doi: 10.1021/ja5034952. [DOI] [PMC free article] [PubMed] [Google Scholar]; (f) Pigge F. C., Coniglio J. J., Dalvi R. J. Am. Chem. Soc. 2006;128:3498. doi: 10.1021/ja058342y. [DOI] [PubMed] [Google Scholar]; (g) Bai L., Yuan Y., Liu J., Wu J., Han L., Wang H., Wang Y., Luan X. Angew. Chem., Int. Ed. 2016;55:6946. doi: 10.1002/anie.201601570. [DOI] [PubMed] [Google Scholar]; (h) Zuo Z., Wang H., Fan L., Liu J., Wang Y., Luan X. Angew. Chem., Int. Ed. 2017;56:2767. doi: 10.1002/anie.201612127. [DOI] [PubMed] [Google Scholar]

- (a) You S. and You S.-L., Asymmetric Dearomatization Reactions, Wiley-VCH, 2016. [Google Scholar]; (b) Zheng C., You S.-L. Chem. 2016;1:830. [Google Scholar]; (c) Zhuo C.-X., Zheng C., You S.-L. Acc. Chem. Res. 2014;47:2558. doi: 10.1021/ar500167f. [DOI] [PubMed] [Google Scholar]

- (a) Sommelet M. C. R. Hebd. Seances Acad. Sci. 1937;205:56–58. [Google Scholar]; (b) Kantor S. W., Hauser C. R. J. Am. Chem. Soc. 1951;73:4122–4131. [Google Scholar]

- Tayama E. Chem. Rec. 2015:789–800. doi: 10.1002/tcr.201500009. [DOI] [PubMed] [Google Scholar]

- (a) Tayama E., Sato R., Takedachi K., Iwamoto H., Hasegawa E. Tetrahedron. 2012;68:4710. [Google Scholar]; (b) Tayama E., Kimura H. Angew. Chem., Int. Ed. 2007;46:8869. doi: 10.1002/anie.200703832. [DOI] [PubMed] [Google Scholar]; (c) Tayama E., Orihara K., Kimura H. Org. Biomol. Chem. 2008;6:3673. doi: 10.1039/b811162f. [DOI] [PubMed] [Google Scholar]; (d) Tayama E., Watanabe K., Matano Y. Eur. J. Org. Chem. 2016:3631. [Google Scholar]; (e) Tayama E., Watanabe K., Sotome S. Org. Biomol. Chem. 2017;15:6668–6678. doi: 10.1039/c7ob01391d. [DOI] [PubMed] [Google Scholar]

- (a) Lee T.-J., Holtz W. J. Tetrahedron Lett. 1983;24:2071. [Google Scholar]; (b) Berger R., Ziller J. W., Van Vranken D. L. J. Am. Chem. Soc. 1998;120:841. [Google Scholar]; (c) Li Y., Shi Y., Huang Z., Wu X., Xu P., Wang J., Zhang Y. Org. Lett. 2011;13:1210. doi: 10.1021/ol200091k. [DOI] [PubMed] [Google Scholar]

- For a reaction involving Sommelet-Hauser rearrangement: Gassman P. G., van Bergen T. J., Gilbert D. P., Jr Cue B. W., J. Am. Chem. Soc., 1974, 96 , 5495 –5517 . [Google Scholar]

- (a) Jończyk A., Lipiak D. J. Org. Chem. 1991;56:6933–6937. [Google Scholar]; (b) Jończyk A., Lipiak D., Sienkiewicz K. Synlett. 1991:493–496. [Google Scholar]; (c) Zdrojewski T., Jonczyk A. J. Org. Chem. 1998;63:452. doi: 10.1021/jo961231k. [DOI] [PubMed] [Google Scholar]; (d) Harthong S., Bach R., Besnard C., Guénée L., Lacour J. Synthesis. 2013;45:2070. [Google Scholar]

- For some related reactions:; (a) Zhang Z., Sheng Z., Yu W., Wu G., Zhang R., Chu W.-D., Zhang Y., Wang J. Nat. Chem. 2017;9:970–976. doi: 10.1038/nchem.2789. [DOI] [PubMed] [Google Scholar]; (b) Soheili A., Tambar U. K. J. Am. Chem. Soc. 2011;133:12956. doi: 10.1021/ja204717b. [DOI] [PubMed] [Google Scholar]; (c) Zhou C.-Y., Yu W.-Y., Chan P. W. H., Che C.-M. J. Org. Chem. 2004;69:7072. doi: 10.1021/jo049540v. [DOI] [PubMed] [Google Scholar]; (d) Holzwarth M. S., Alt I., Plietker B. Angew. Chem., Int. Ed. 2012;51:5351–5354. doi: 10.1002/anie.201201409. [DOI] [PubMed] [Google Scholar]

- Biswas B., Collins S. C., Singleton D. A. J. Am. Chem. Soc. 2014;136:3740–3743. doi: 10.1021/ja4128289. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Narita K., Shirai N., Sato Y. J. Org. Chem. 1997;62:2544. doi: 10.1021/jo962226j. [DOI] [PubMed] [Google Scholar]

- (a) Sonnenschein F. L. Ber. Dtsch. Chem. Ges. 1876;9:1182–1186. [Google Scholar]; (b) Conroy H., Chakrabarti J. K. Tetrahedron Lett. 1959;1:6–13. [Google Scholar]; (c) Schun Y., Cordell G. A. J. Nat. Prod. 1985;48:969–971. doi: 10.1021/np50042a016. [DOI] [PubMed] [Google Scholar]; (d) Lovell F. M., Pepinsky R., Wilson A. J. C. Tetrahedron Lett. 1959;1:1–5. [Google Scholar]

- Schun Y., Cordell G. A., Garland M. J. Nat. Prod. 1986;49:483–487. doi: 10.1021/np50047a007. [DOI] [PubMed] [Google Scholar]

- Xu Y.-K., Yang L., Liao S.-G., Cao P., Wu B., Hu H.-B., Guo J., Zhang P. J. Nat. Prod. 2015;78:1511. doi: 10.1021/np5009619. [DOI] [PubMed] [Google Scholar]

- (a) Fensome A., Koko M., Wrobel J., Zhang P., Zhang Z., Cohen J., Lundeen S., Rudnick K., Zhu Y., Winneker R. Bioorg. Med. Chem. Lett. 2003;13:1317. doi: 10.1016/s0960-894x(03)00129-x. [DOI] [PubMed] [Google Scholar]; (b) Venkatesan H., Davis M. C., Altas Y., Snyder J. P., Liotta D. C. J. Org. Chem. 2001;66:3653. doi: 10.1021/jo0004658. [DOI] [PubMed] [Google Scholar]

- Zhao K., Duan L., Xu S., Jiang J., Fu Y., Gu Z. Chem. 2018;4:599–612. [Google Scholar]

- (a) Ollis W. D., Rey M., Sutherland I. O. J. Chem. Soc., Chem. Commun. 1975:543. [Google Scholar]; (b) Maeda Y., Sato Y. J. Chem. Soc., Perkin Trans. 1. 1997:1491. [Google Scholar]; (c) Ghigo G., Cagnina S., Maranzana A., Tonachini G. J. Org. Chem. 2010;75:3608. doi: 10.1021/jo100367z. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.