SUMMARY

This document outlines a comprehensive practical approach to a laboratory quality management system (QMS) by describing how to operationalize the management and technical requirements described in the ISO 15189 international standard. It provides a crosswalk of the ISO requirements for quality and competence for medical laboratories to the 12 quality system essentials delineated by the Clinical and Laboratory Standards Institute. The quality principles are organized under three main categories: quality infrastructure, laboratory operations, and quality assurance and continual improvement. The roles and responsibilities to establish and sustain a QMS are outlined for microbiology laboratory staff, laboratory management personnel, and the institution's leadership. Examples and forms are included to assist in the real-world implementation of this system and to allow the adaptation of the system for each laboratory's unique environment. Errors and nonconforming events are acknowledged and embraced as an opportunity to improve the quality of the laboratory, a culture shift from blaming individuals. An effective QMS encourages “systems thinking” by providing a process to think globally of the effects of any type of change. Ultimately, a successful QMS is achieved when its principles are adopted as part of daily practice throughout the total testing process continuum.

KEYWORDS: quality management system, ISO standard, quality system essentials, continual improvement, quality indicators, ISO 15189, QMS

INTRODUCTION

The role of the clinical microbiology laboratory is rapidly evolving as the delivery of health care undergoes drastic changes. Laboratories are no longer revenue-generating centers. Now they are considered cost centers that must justify their existence by demonstrating added quality and safety to improve patient care. Laboratories are no longer silos of information but integrated into the quality framework to provide patient-focused services. With this evolution, laboratory staff require an introduction into how their processes and procedures should align with their organization's quality management system (QMS). The purpose of this document is to educate clinical microbiologists about the fundamental quality elements and provide practical guidance on how to meet and sustain these QMS requirements. Although there are several QMS models to follow, this document primarily addresses the standards described in ISO document 15189 (2012), Medical Laboratories—Requirements of Quality and Compliance, of the International Organization for Standardization, which is universally recognized throughout the world (1). This document complements published guidelines, translates for the reader how to operationalize each of the management and technical requirements described in the ISO 15189 standard, and crosswalks these with the 12 quality system essentials (QSEs) delineated by the Clinical and Laboratory Standards Institute (CLSI) (2). This document includes suggested roles and responsibilities of the clinical microbiology laboratory staff, laboratory management personnel, and the organization to operate under a QMS.

HOW TO USE THIS DOCUMENT

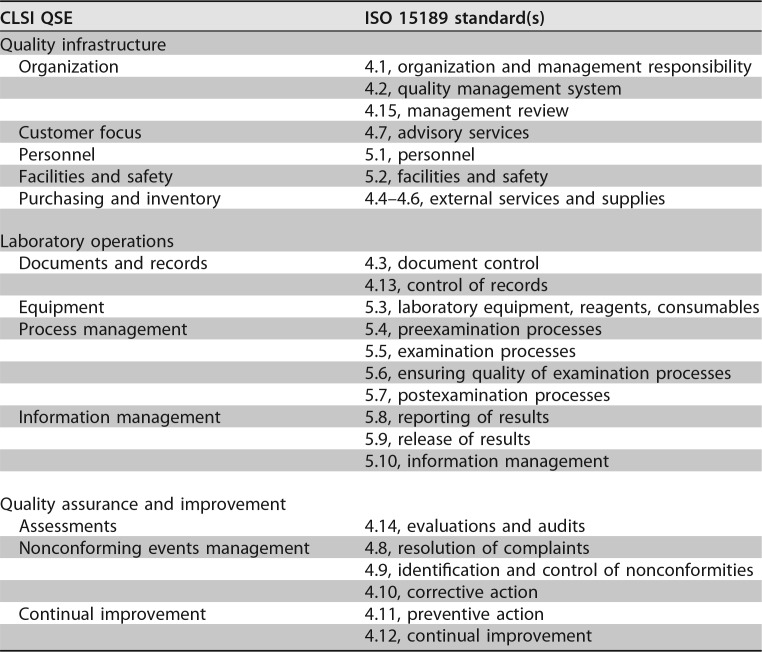

The laboratory quality standards are divided into three overarching areas: the infrastructure of the quality system, the laboratory operations, and the activities under quality assurance and continual improvement (CI). For those beginning to learn about a QMS, it may be easier to assimilate and apply the 12 quality system essentials defined by the CLSI (2) than the 10 management and 15 technical standards described in the ISO 15189 document. Table 1 is a crosswalk linking each CLSI quality system essential to an ISO 15189 requirement.

TABLE 1.

Crosswalk of CLSI quality system essentials and ISO 15189 standards

It is critical that the reader recognize the distinction between the verbs “shall” and “should” as used in this document and in concordance with ISO terminology. When something is a requirement and must be performed to achieve or remain in compliance, the verb “shall” is used. If the statement is a recommendation and a laboratory may opt out, or modify, what is prescribed, then the verb “should” is used.

Each laboratory has a unique organizational structure. Some may have laboratory directors, section directors, supervisors, and managers, while smaller laboratories may consolidate these responsibilities. In the tables listing potential roles and responsibilities for the institution, laboratory management, and staff, the reader may modify these roles and responsibilities according to how they apportion duties within their structure.

A glossary of terms guides the reader in the language of quality management (see the Appendix). Examples of policies, processes, procedures, and forms appear as figures to enable the reader to apply them to their laboratories. This document serves as a guideline only, and the sample procedures and forms are not meant to be prescriptive and may be adapted to each laboratory's practices. Publications that are referenced throughout the document provide excellent starting points to learn more about QMS standards and guidance that currently exist for clinical laboratories.

WHAT IS A QMS?

A laboratory quality management system is a systematic, integrated set of activities to establish and control the work processes from preanalytical through postanalytical processes, manage resources, conduct evaluations, and make continual improvements to ensure consistent quality results. Approaches to quality management in clinical microbiology were described previously by Bartlett et al. (3) and Schifman et al. (4). Government regulations of laboratory practices and the establishment of quality management have been debated vigorously over the decades. Laboratories improve their processes to be cost-effective and scientifically sound and effect a positive outcome for patient care. Process improvement typically occurs as laboratories adopt new technologies. Having a quality system to guide the laboratory in the implementation of new processes and procedures ensures that all elements will be considered prior to adopting a new practice or modifying a current one.

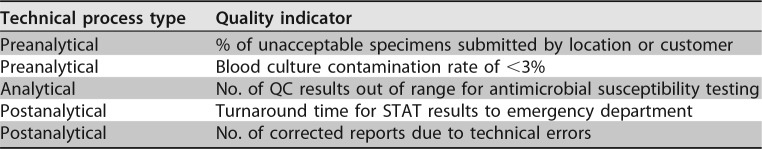

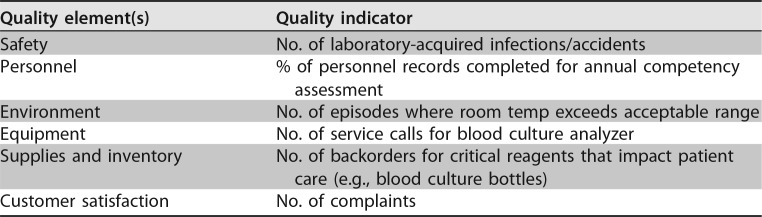

Clinical microbiology laboratories perform quality control (QC) for their analytical test methods, which is the initial level of controlling a procedure. QC requirements are mandated by regulatory agencies and specified in package inserts by the manufacturers of commercially prepared products. The next level of quality oversight is quality assurance (QA), where quality controls and quality indicators are tracked and trends are analyzed. QA includes monitoring supplies, equipment calibration and maintenance, procedures, personnel competency, proficiency testing (PT), specimen collection and transport, and accuracy and timeliness of result reporting.

Working under a true QMS broadens the scope of quality activities to be considered to obtain the highest level of quality in the product produced or service rendered. A QMS integrates all the quality elements into the work process. When a new test is initiated, the laboratory considers not only the QC and QA activities but also the purchasing and inventory processes, personnel training, test system assessment, instrument qualification, information technology support, and document control (and so forth). In a QMS, deviations from the expected performance, known as nonconforming events (NCEs), are reviewed by a higher level of management so that cross-cutting problems, such as specimen transport delays, can be resolved at the institutional level. Nonconforming events are addressed in Quality Assurance and Continual Improvement, below.

It is imperative that a laboratory review all regional and national regulatory requirements for a quality system since they may differ from the ISO standard. The most stringent requirements are the ones that must be followed to ensure compliance. For U.S. laboratories, a QMS is a requirement of the Clinical Laboratory Improvement Amendment (CLIA) (5). Laboratories have written policies and procedures to implement and monitor their quality for all phases of the testing process and general laboratory systems. A QMS meets the basic requirements defined in CLIA regulations and goes beyond the minimum requirements of the CLIA to enable continual quality improvement. In addition to meeting the requirements of regulatory authorities and accrediting bodies, a QMS focuses on exceeding the expectations of an organization's external and internal customers and encouraging the best use of resources.

At whatever level the QMS is implemented, either across the entire organization or within the laboratory system, leadership must be engaged and supportive of the QMS in order for it to succeed. The quality policy and standards shall be established at the highest organizational level, and the laboratory shall align with the organization's quality goals and objectives. How to operationalize the quality policy and standards varies according to the unique technical procedures, equipment, and personnel requirements within the laboratory. The goal is to produce a consistent, accurate, and reliable service or product for patient care. A QMS consists of tracking where inconsistencies occur, uncovering the root causes of why they happened, and correcting the system to prevent them from recurring.

QUALITY INFRASTRUCTURE

In this overarching section, we describe the CLSI QSEs that form the foundational building blocks for the quality management system. These five QSEs include (i) organization and management responsibilities, (ii) commitment to customers, (iii) personnel, (iv) provisions for adequate facilities and safety, and (v) purchasing and inventory.

Organization and Management Responsibility

Management shall visibly endorse and support the establishment of the QMS in order for the culture to change and the QMS to function successfully. Leadership shall demonstrate their commitment to the implementation of a QMS by providing the necessary budgetary resources, communications, personnel, and environment (6). Leadership shall establish the overarching quality policy and standards, which are defined in a quality manual. The quality policy should be widely communicated and understood by all laboratory personnel. Quality objectives for the laboratory should align with the organization's quality policy and standards and be specific, measurable, achievable, realistic, and time bound. Responsibilities for meeting the quality objectives shall be clearly defined within the laboratory organization. To be effective across the organization, communications shall be consistent, frequent, and delivered by multiple methods (e.g., all-hands meetings, one-on-one meetings, e-mails, and newsletters). Minutes for work group and committee meetings should be recorded and published, as appropriate, to ensure transparency and coordination of activities.

All personnel shall follow the organization's code of ethical conduct. The laboratory director shall be competent and fulfill his or her responsibilities. The laboratory director may delegate responsibilities for individual specialty areas (e.g., chemistry, microbiology, and molecular testing); however, the laboratory director is ultimately responsible for the successful completion of the activities and documentation of records.

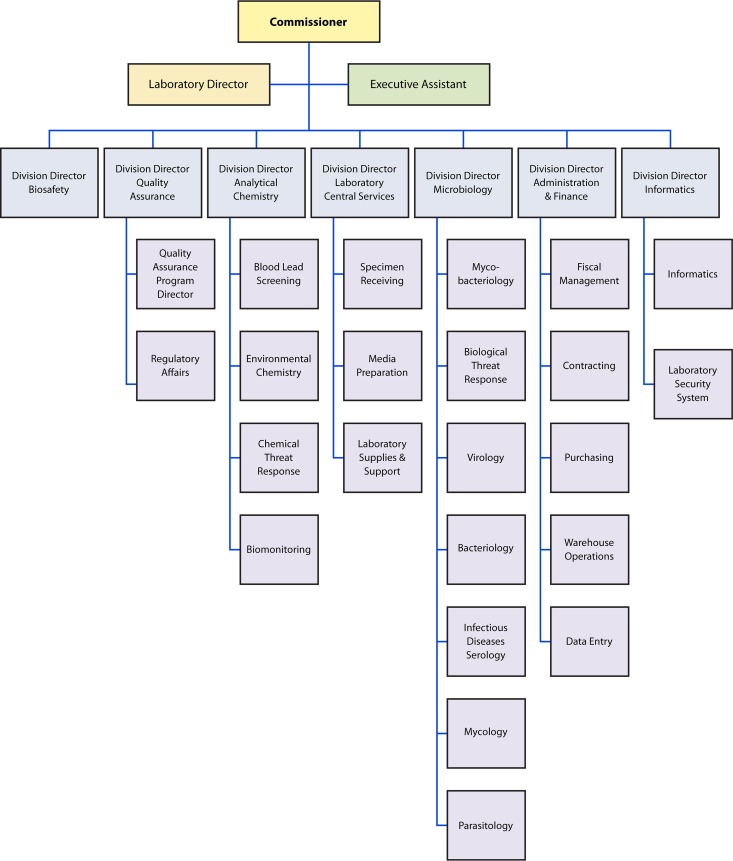

A quality manager should be appointed to oversee the processes needed and to ensure that the QMS is established, maintained, and evaluated for its effectiveness. There is a role for everyone in the QMS. It is not the sole responsibility of the quality manager. A laboratory organizational chart should be created and published so that everyone knows how they align in the organization and the supervisory chain of command. An example of an organization chart for a public health laboratory is shown in Fig. 1. Suggested roles and responsibilities for key activities are listed in Table 2.

FIG 1.

Sample organization chart for a public health laboratory system. The organizational chart demonstrates the chain of command. Organizational charts will vary based on areas of responsibility and disciplines covered.

TABLE 2.

Roles and responsibilities for the organization

| Activity | Role(s) and/or responsibility(ies) |

||

|---|---|---|---|

| Institution | Microbiology laboratory management | Microbiology staff | |

| Organizational commitment to the QMS | Provide commitment and resources | Adhere to quality policy and standards | Describe the principles of the QMS |

| Ensure that QMS elements are considered in all work practices | |||

| Communication of quality policy and objectives | Establish quality policy and standards | Provide timely and transparent communications regarding quality | Read the quality manual and adhere to QMS policies |

| Responsibilities for the QMS | Define roles for all personnel | Create a quality team to accomplish quality objectives | Perform duties as assigned to ensure quality |

| Participate as a leader of a quality team | Participate as a member of a quality team | ||

| Coordinate quality activities | Participate in management review | Appoint a quality manager | Participate in quality initiatives |

| Work closely with the quality manager to achieve the laboratory's quality objectives | |||

Quality management system.

Documentation serves as evidence of what is required and if the requirements are being met. For the QMS, this includes the quality policy, quality objectives, the quality manual, all procedures and records, and the applicable regulations and standards. The documentation may be in electronic or hard-copy format and shall be communicated to laboratory staff and management. It is the responsibility of each laboratory section to contribute to the development of quality indicators and objectives. The quality manual should be created at the highest level in the organization participating in the QMS. It is the responsibility of the personnel to read and understand the contents of the quality manual since continual improvement is a process that involves all staff.

The laboratory director and management team shall determine the processes that enable their laboratory to meet institutional quality standards. The laboratory is responsible for processes and procedures for their methods, operational controls, and resources. The laboratory shall monitor these processes, such as the turnaround time for reporting positive blood cultures, and continue to look for opportunities for improvement. The roles and responsibilities for the QMS are listed in Table 3.

TABLE 3.

Roles and responsibilities for establishing a quality management system

| Document or activity | Role(s) and/or responsibility(ies) |

||

|---|---|---|---|

| Institution | Microbiology laboratory management | Microbiology staff | |

| Quality manual | Develop, approve, distribute, and periodically review, e.g., every 1–3 yr | Read and ensure that laboratory staff are aware of content | Read the quality manual |

| Quality policy and standards | Establish, communicate, and periodically review, e.g., every 1–3 yr | Establish or contribute to development of quality policy and standards | Adhere to policy and standards |

| Read, adhere to, and openly endorse policy and standards | |||

| Quality objectives | Evaluate for effectiveness | Establish specific, measurable, achievable, realistic, and time-bound quality objectives | Work to achieve objectives as applicable for the level of responsibility |

| Laboratory procedures, forms, and records | None | Write and approve procedures and related forms | Follow procedures as written Complete forms as required Maintain all documents and records Provide input where changes could improve the process, procedure, or form or where job aids could be beneficial |

| Educate staff on content | |||

| Provide training to perform procedures | |||

| Review documents annually and revise if needed | |||

| Retain documents and records for the prescribed period of time | |||

| Regulations | Comply with federal, state, local, and other regulatory requirements | Comply with federal, state, local, and other regulatory requirements | Adhere to all regulatory policies and procedures |

| Educate staff on all regulations that apply to the science and operation of the microbiology laboratory | |||

Management review.

Management review is an essential step for having an effective quality management system. The review should occur as a planned activity at a designated frequency throughout the year. The review should occur at least semiannually when the quality management system is newly created. Once a system is mature, an annual review may be sufficient. The data for the review may be collated by microbiology laboratory management and merged into an overall laboratory services report. Items to include in the review may be set by those higher in the organization and focus on risk management, which affects the financial and legal health of the organization (7). The review should be conducted by a management review committee comprised of higher-level laboratory leadership, such as the director of clinical pathology, the vice president of laboratory services, and directors and supervisors of the laboratory sections, to determine the continued suitability, adequacy, and effectiveness of the policies, processes, and procedures that support patient care.

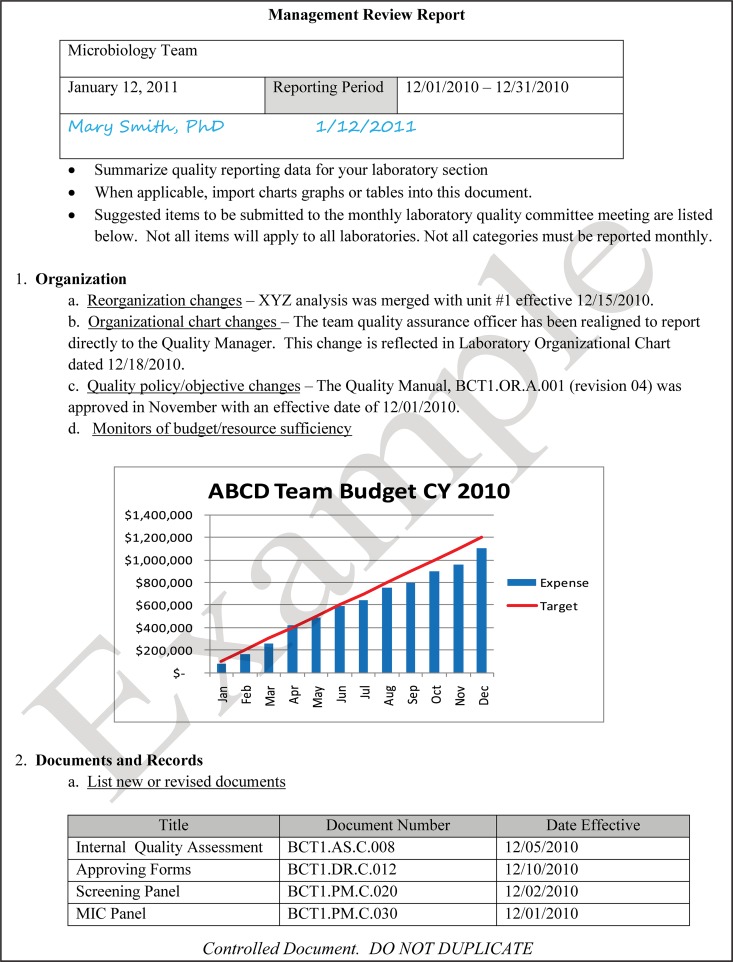

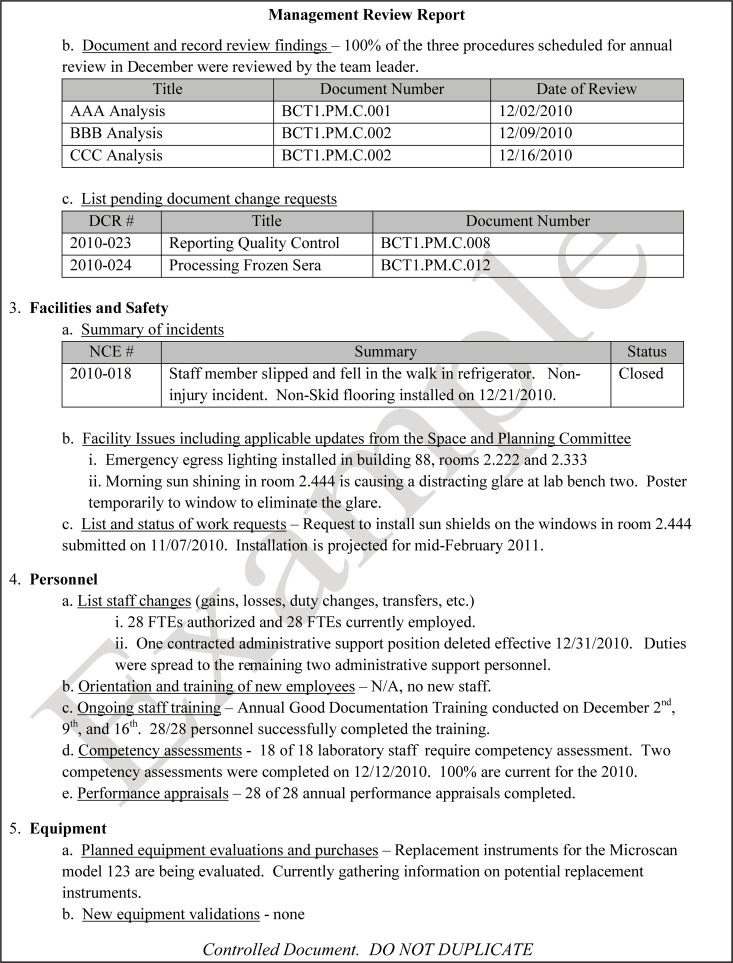

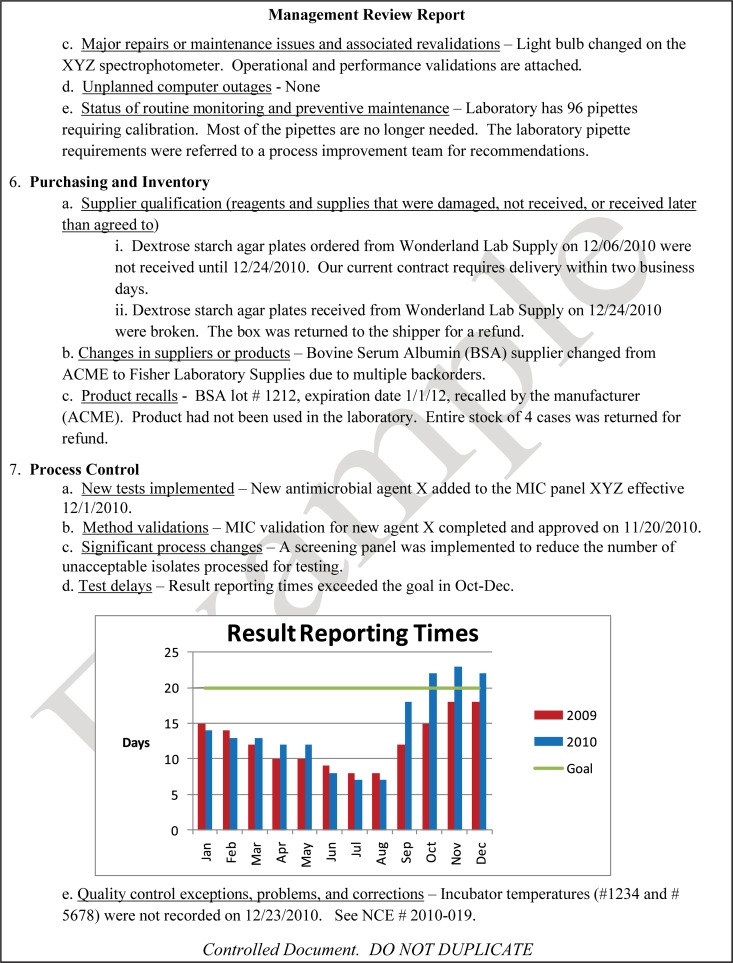

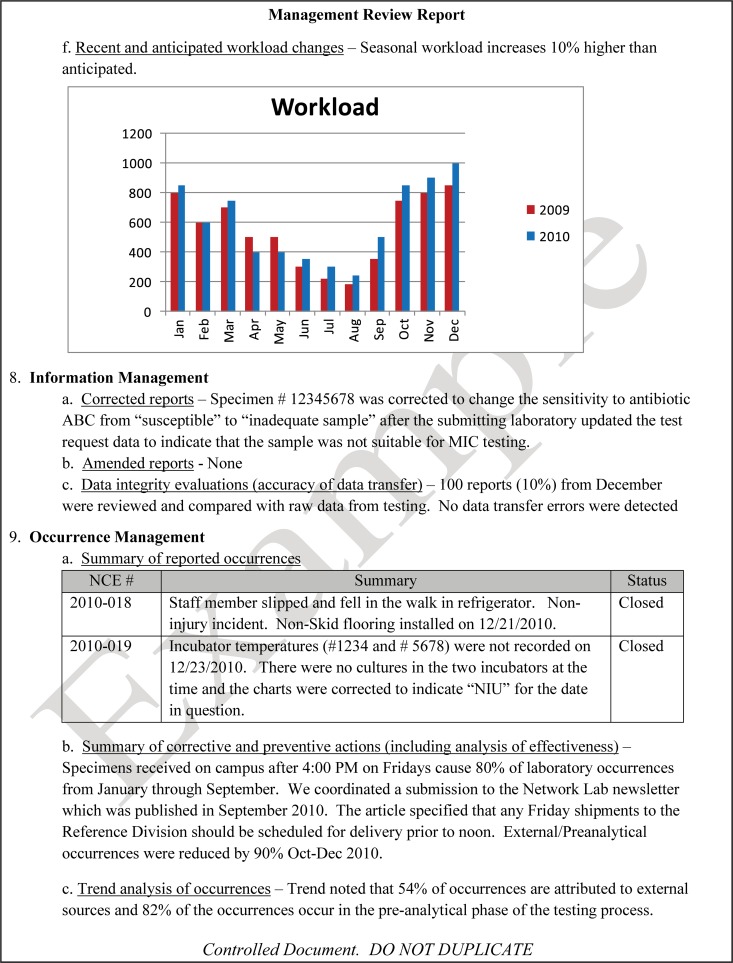

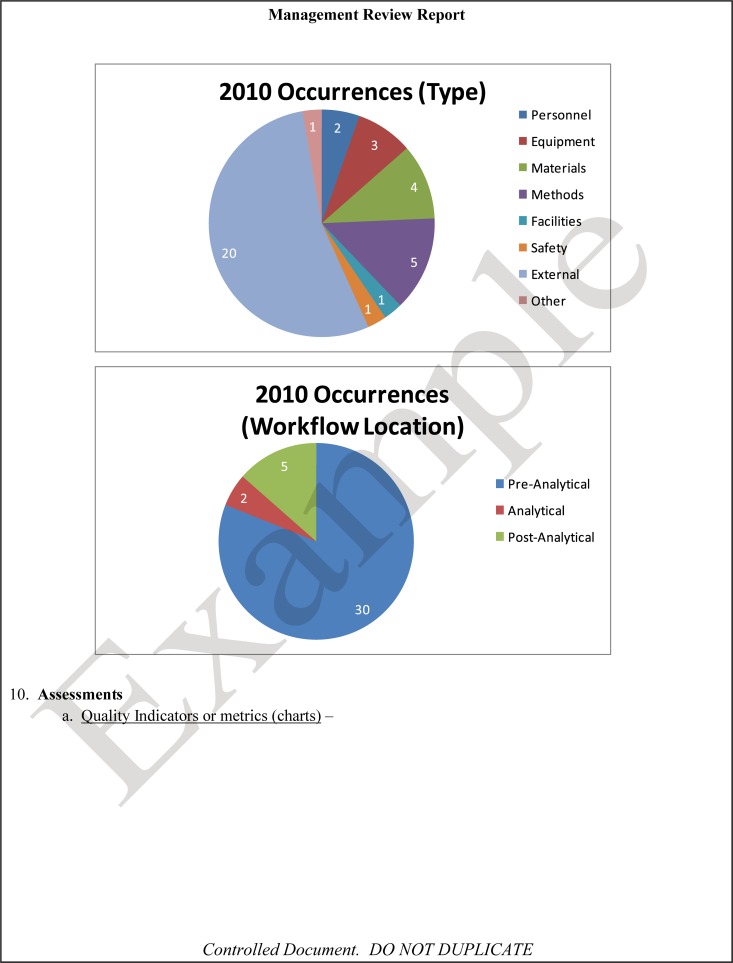

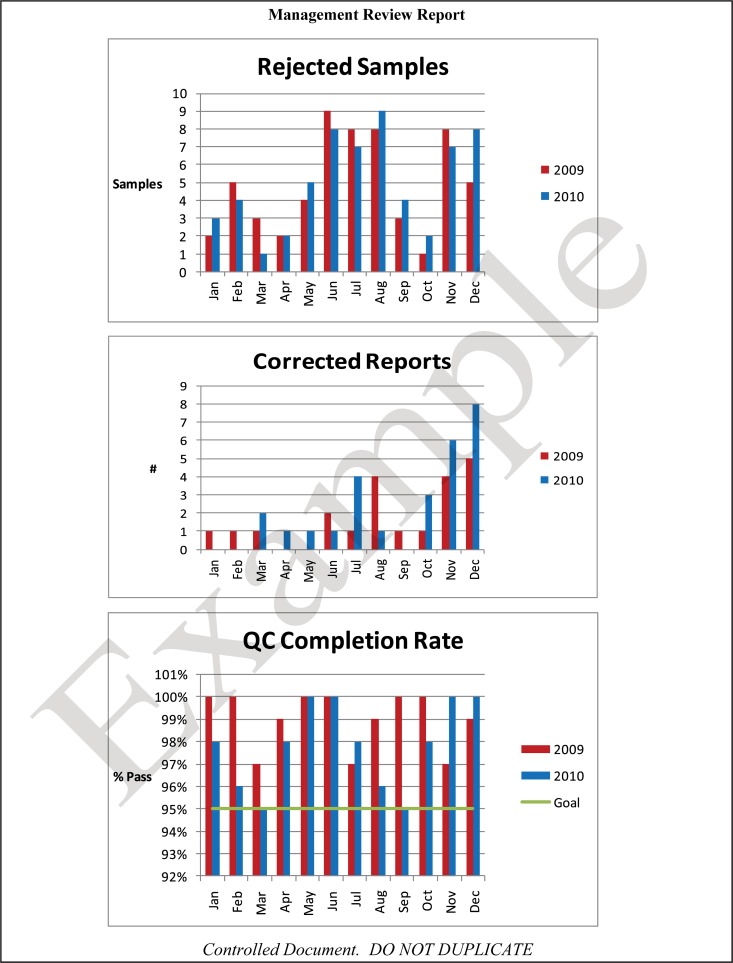

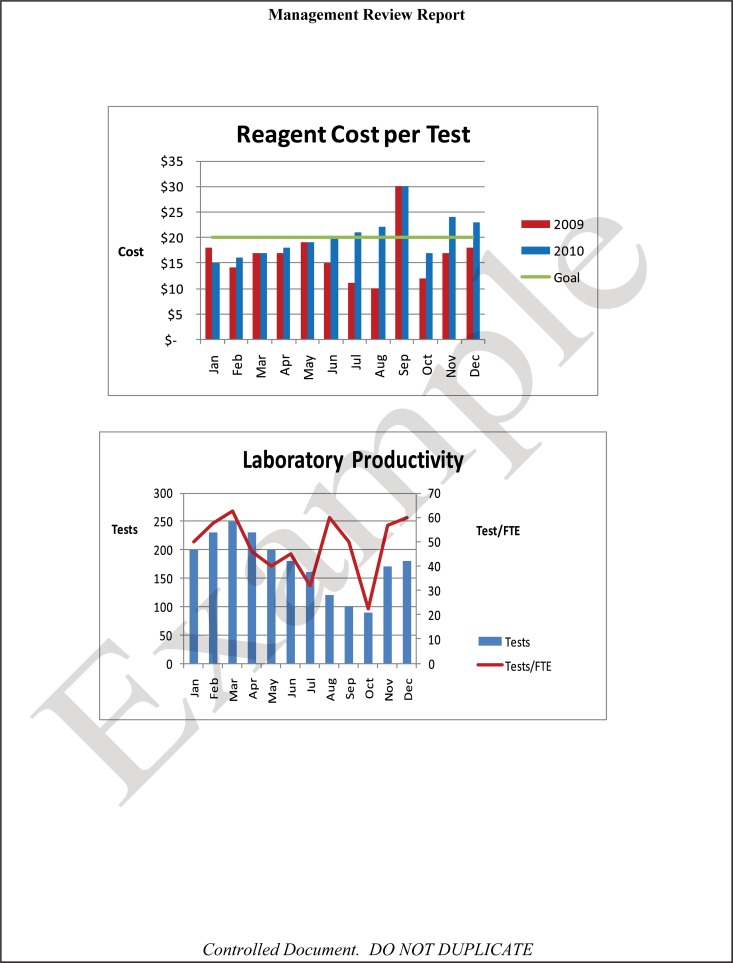

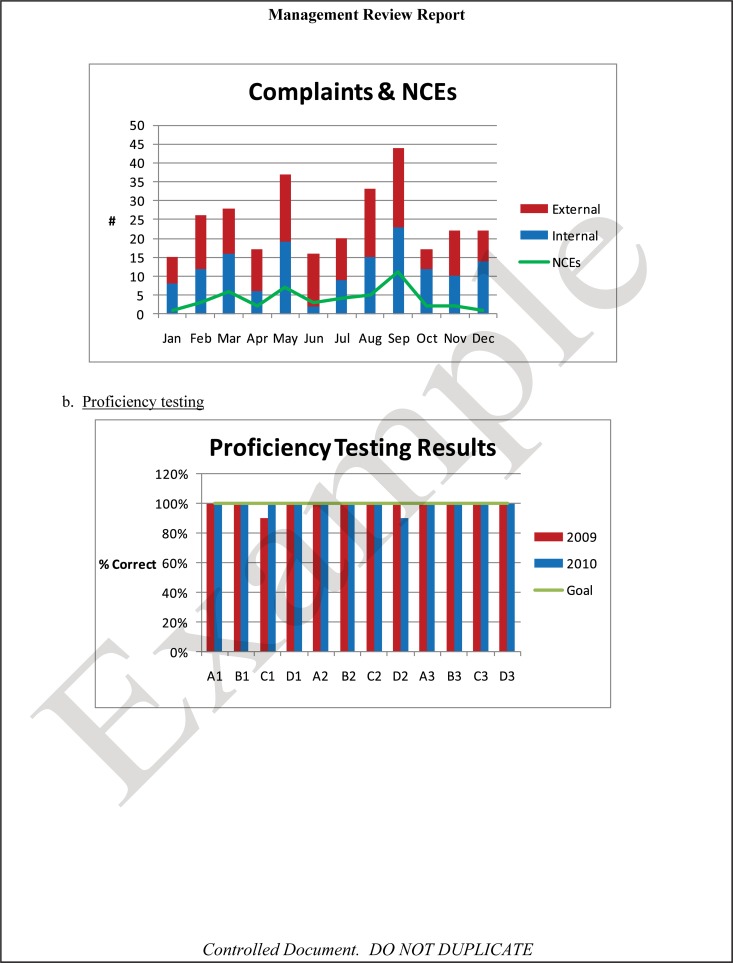

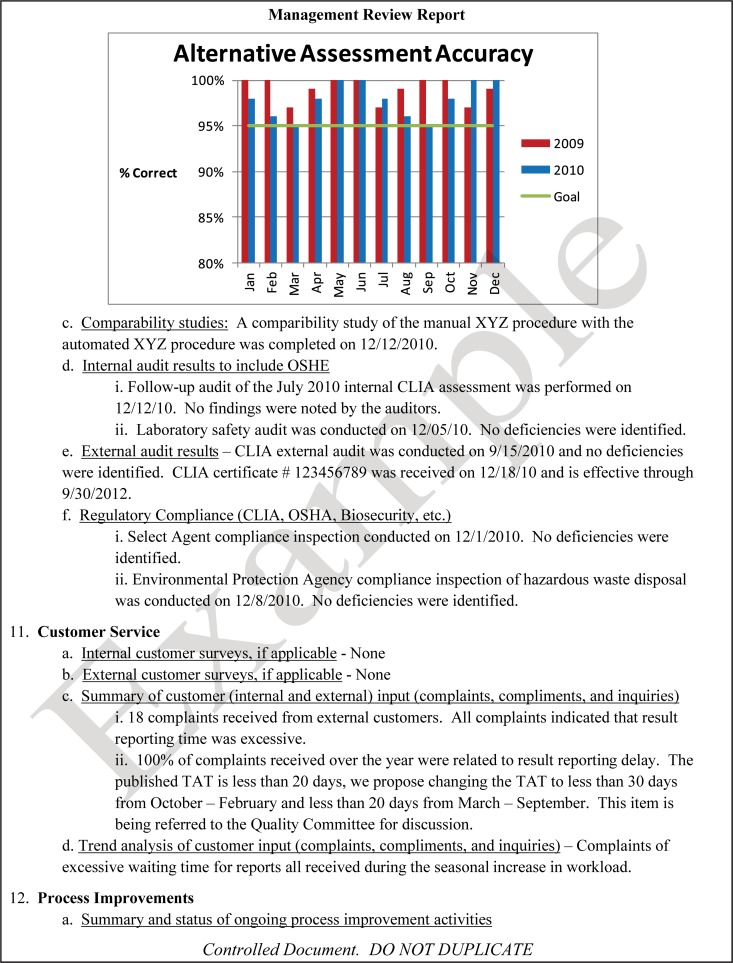

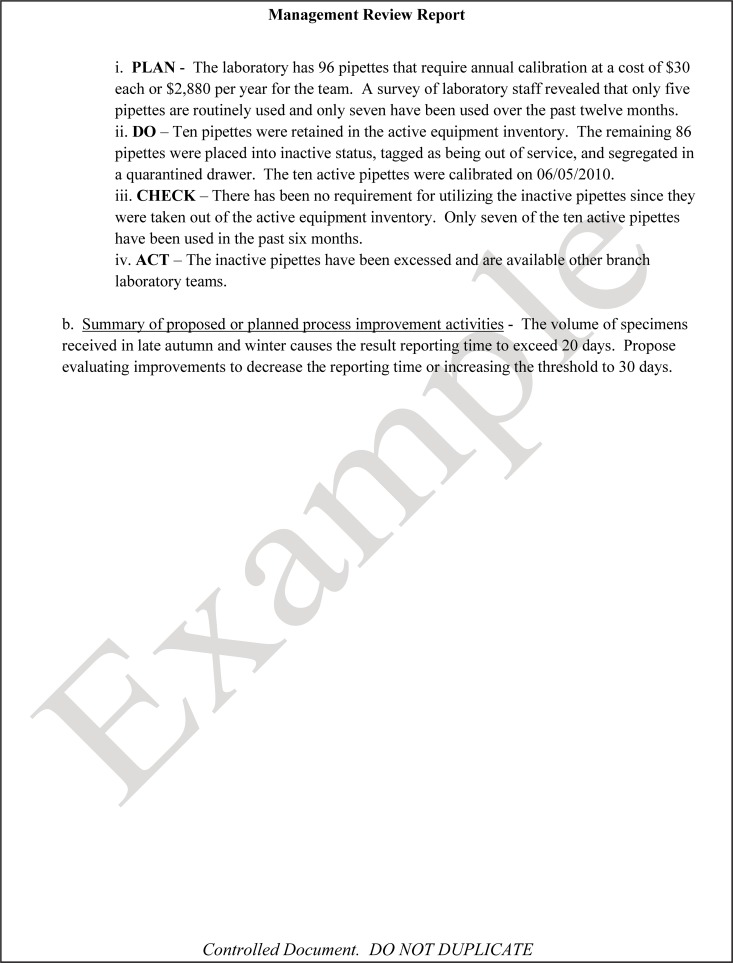

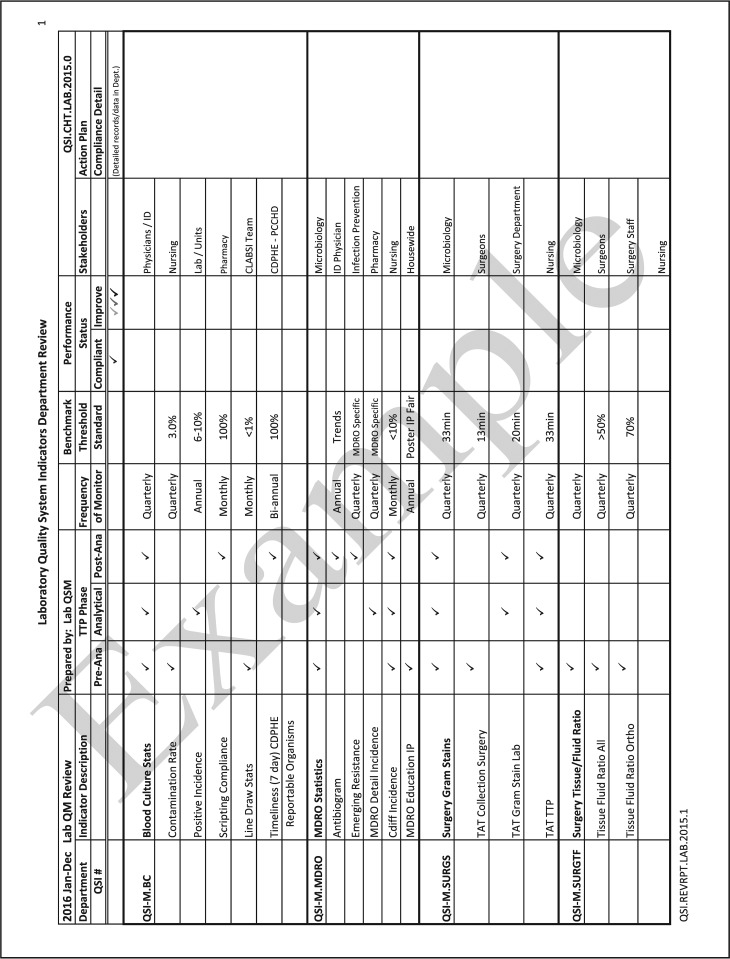

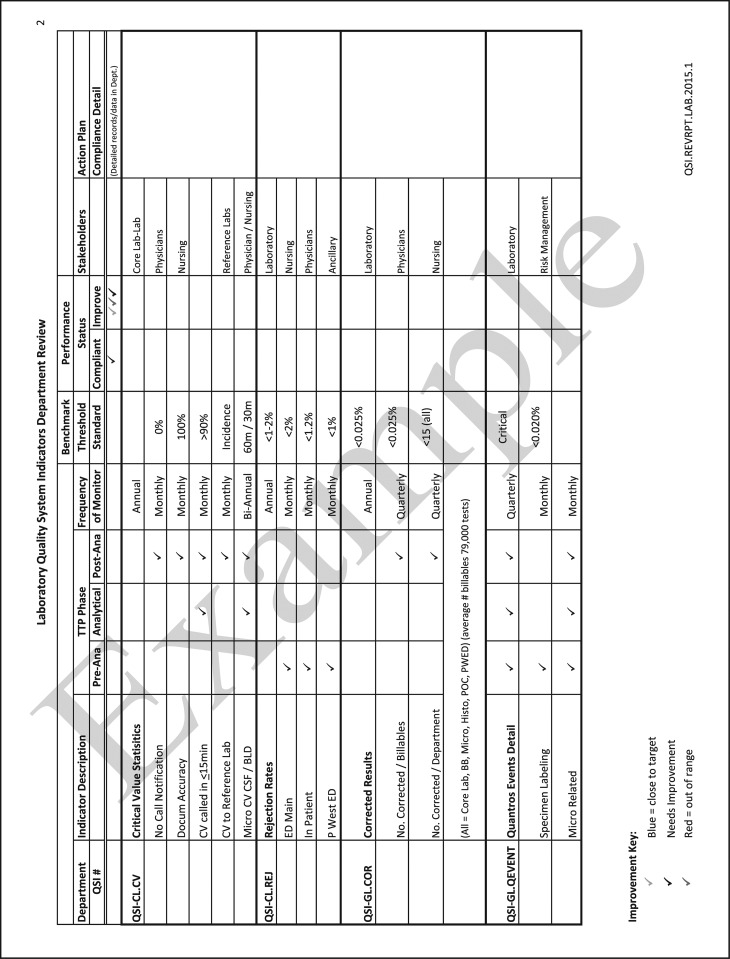

The quality and appropriateness of the laboratory's contribution to patient care should be objectively evaluated. Management review should include a review of the quality policy and quality goals and objectives annually. Individual laboratory sections, such as microbiology, serology, and molecular pathology, etc., should collect data throughout the year, which can be consolidated into an overarching report. As data are filtered upward, less detail is required for higher-level review; for example, documentation of contaminated purchased media at the technical level may contain details of the manufacturer, lot numbers, and types of contaminants, while the report to the vice president of laboratory services may have data on the impact on budget and patient services. All quality system elements should be covered in the annual review; however, data do not have to be collected from each area every month or quarter. Wherever possible, data should be presented graphically to track and analyze patterns and trends to highlight activities that require corrective or preventive action. A visual dashboard may be created to highlight specific issues for process improvement. A sample management review report, shown in Fig. 2, outlines the quality system elements to include and graphic presentations of data that allow performance comparisons over time and across laboratory sections.

FIG 2.

Sample monthly management review report for the microbiology laboratory. The report is meant to highlight trends and changes in each quality area. It is intended to be visual and not contain unnecessary explanatory text. FTEs, full-time employees; N/A, not applicable; TAT, turnaround time.

All recommendations of the management review committee and follow-up actions shall be documented in writing, which serves as a formal record of review. Evaluation of the follow-up actions shall be performed in subsequent reviews to ensure that actions have addressed the problem as intended. The recommendations and action items from the management review should be shared with the laboratory staff so that they are aware of improvement initiatives and how they may contribute to the improvement process. Examples of topics where information may be collected and shared in a report for management review are shown in Table 4. Suggested roles and responsibilities across the organization and the microbiology laboratory for management review are outlined in Table 5.

TABLE 4.

Some suggested topics for management review and evaluation

| Topic area | Item(s) for evaluation |

|---|---|

| Changes in technical or procedural process | Addition or deletion of tests |

| Changes in scope of work or workload | |

| New regulatory requirements for technical procedures | |

| Purchasing and inventory | Problems with suppliers of critical materials |

| Equipment | Equipment failures or need for preventive maintenance contracts |

| Customer feedback | Customer surveys |

| Staff suggestions | |

| Monitoring and resolving complaints | |

| Nonconforming events | Analysis of nonconformities and near misses |

| Personnel | Competency assessments completed |

| Vacancies or scheduling issues | |

| Evaluations and audit reports | Performance in proficiency testing events |

| Inspections by external organizations | |

| Reports from internal audits | |

| Risk management and safety reviews | |

| Overarching laboratory systems | Follow-up actions from previous management reviews |

| Quality indicators being monitored | |

| Results of continuous improvement efforts, including the status of corrective and preventive actions |

TABLE 5.

Roles and responsibilities for management review

| Activity(ies) | Role(s) and/or responsibility(ies) |

||

|---|---|---|---|

| Institution | Microbiology laboratory management | Microbiology staff | |

| Determine quality topics and timeline for management review | Senior management decides what topics and level of detail should be presented | Suggest key areas important for management review | Provide suggestions to laboratory management |

| Responsible for scheduling planned meetings to review reports | |||

| Collect and analyze data for reports | Decide presentation format that would be most beneficial to capture data | Collate monthly data into comprehensive data that can be presented graphically over time | Assist in the completion of records that will be used to document quality issues |

| Conduct periodic management review | Hold the meeting as scheduled | Attend management review meeting | Understand what process improvements are in progress |

| Record minutes of the meeting, including recommendations made and follow-up actions Monitor the effectiveness of action plans for their efficacy and revise plans as needed |

Share outcome of management review meeting with laboratory staff Complete follow-up actions as requested Monitor the effectiveness of recommendations that pertain to the microbiology laboratory |

||

Customer Focus—Advisory Services

The microbiology laboratory provides the content expertise and leadership in infectious disease diagnosis, pathogen discovery, antibiogram, biosafety, and biosecurity areas. As such, the microbiology laboratory partners with any discipline or person in the health care system that requires their expertise to address current and changing needs. The microbiology laboratory is responsible for advising on the total testing process, including the preanalytical process (e.g., advising on the appropriate test for accurate diagnosis and providing instruction on ordering and collecting the optimal specimen), the analytical process (e.g., selecting the optimum methods and technologies used), and the postanalytical process (e.g., reporting final results and providing interpretations and data analyses). Clear and timely communication of this information is essential for successful consultation in microbiology. Miscommunication or inadequate communication is often at the heart of errors. Therefore, it is paramount for the microbiology laboratory to develop effective communication strategies to avoid misinterpretations that may compromise patient care.

The microbiology laboratory shall establish how to communicate its advice to users and have the input of its stakeholders (e.g., infection prevention, pharmacy, and infectious diseases) for the message that is being delivered. Communication may be in a written or electronic format to provide guidance, such as the names of tests performed that are clearly linked to reimbursement codes, a periodic antibiogram, specimen collection instructions, interpretive comments on patient reports, or alerts on antimicrobial resistance or notification of circulating influenza viruses. Timely communication may also be verbal, such as a phone call to the physician for a critical test result. In-person teleconferences on novel pathogens or staff in-services when a new blood culture instrument is instituted are also good forms of communication. Where appropriate, communications should be saved, archived, and readily available for future reference and can be used as evidence of advisory services for audit purposes.

In order to contact the laboratory for advice, key information should include the hours of operation of the microbiology laboratory and contact information during and after normal hours of operation. This may require creating and disseminating on-call schedules for accessing medical/scientific consultation and logistic or laboratory operations advisory services.

In addition to the advice provided directly to individuals, the microbiology laboratory should play a meaningful role in the planning and development of new services and facilities as well as strategic planning for the organization. Laboratory leadership together with the organization's leadership should collaborate to align the laboratory's vision with the needs of the patients, their health care providers, and the organization. Microbiology is currently undergoing a revolution in testing technologies and instrumentation that needs to be communicated effectively to the organization in order to secure the resources to implement these new changes. Poor communication could result in the failure to meet current standards of care if the organization's leadership is not kept abreast of new advancements in diagnostics. Similarly, to maintain high standards of care, the expertise of microbiologists is a great resource to inform policies and decisions regarding emerging infectious diseases, biosafety and biosecurity in all laboratories, infection prevention and control across the organization, antimicrobial stewardship programs, and other institutional programs. Table 6 outlines specific advisory services that shall be addressed by the microbiology laboratory and how these services may be shared or delegated.

TABLE 6.

Roles and responsibilities for advisory services and consultation

| Activity | Role(s) and/or responsibility(ies) |

||

|---|---|---|---|

| Institution | Microbiology laboratory management | Microbiology staff | |

| Advising on selection of tests and services | May provide resource support for the creation and accessibility of advisory services | Create the test menu and counsel on choice and use of services | Follow and enforce the policies and procedures that govern the criteria for appropriate choice and use of microbiology services |

| Write, promote, and enforce the policies and procedures that govern the criteria for appropriate choice and use of microbiology services | |||

| Advising on clinical cases for treatment or infection control | None | Consult on individual cases | Provide initial advice on testing based on policies and procedures |

| Facilitate contacting the appropriate personnel to respond to request for advice | |||

| Advise infection preventionists | |||

| Professional judgments on the interpretation of results | None | Counsel on the interpretation of results | Provide initial interpretations based on policies and procedures |

| Promoting effective utilization of laboratory services | Support and promote the effective utilization of laboratory services across the institution | Select, create, promote, and enforce policies and procedures that govern effective utilization of laboratory services | Identify, follow, and enforce laboratory utilization policies and procedures |

| Consulting on scientific and logistic matters | None | Counsel on clinical and technical matters and operational logistic matters | Provide initial advice based on standard operating policies and procedures |

| Strategic planning | Collaborate with laboratory leadership to consider patients, health care providers, and the organization in creating new directions | Collaborate with organization leadership to consider patients, health care providers, and the microbiology laboratory in creating new directions | Follow the new directions |

Personnel

The laboratory's human resources are its most valuable asset. Therefore, the tasks of hiring, orienting, training, and managing staff within a supportive working environment are critical for maintaining high-quality work.

As part of the hiring process, the institution shall provide clear job descriptions that specify the desired qualifications and competencies. In some jurisdictions, national or regional requirements, as defined by the U.S. Centers for Medicare and Medicaid CLIA laboratory program (5) or the Canadian body, the Institute for Quality Management in Healthcare (IQMH) (8), specify qualifications and competencies for laboratory directors, supervisors, and clinical consultants that comprise microbiology laboratory management as well as the microbiology laboratory staff who are the testing personnel. Requirements may include licensure for personnel who perform laboratory testing and oversight. The job description should detail the skills, knowledge, behaviors or attitudes, and experience that are required as well as the level of authority of the position and the chain of command (9). The description should be specific and comprehensive so that there is no ambiguity in the expectations of employment. This ensures that all tasks in the laboratory are completed by the appropriate personnel (10).

Orientation and training.

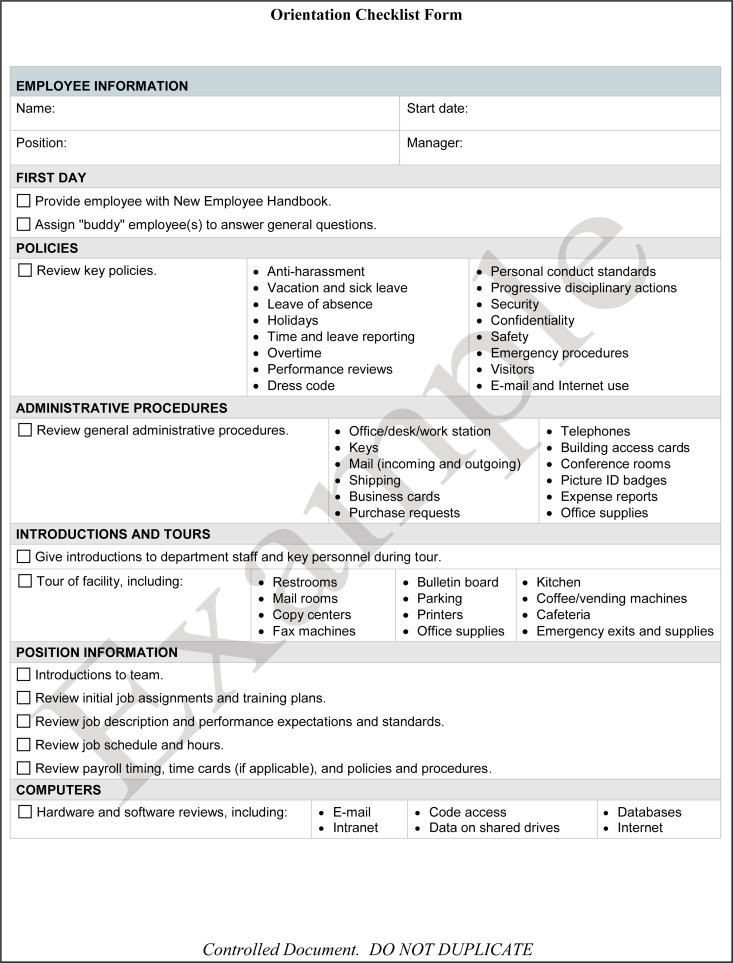

Laboratory management shall provide new staff members orientation to the organization. This includes familiarizing new staff with personnel policies (e.g., dress code, ethics, compensation, and vacation and sick days), all relevant staff facilities (e.g., personal lockers and lounges), biosafety risks, occupational health and safety requirements (e.g., workplace hazardous materials information system [WHMIS], safety data sheets [SDSs], and fire and emergency), and occupational health services. The World Health Organization (WHO) orientation checklist (11) in Fig. 3 is an example of items that should be included in the initial personnel orientation.

FIG 3.

World Health Organization new personnel orientation checklist.

An effective training program equips new staff with the knowledge, skills, and attitude required to meet the job description expectations. Currently, many microbiology laboratories are undergoing technical evolution, and new equipment, assays, and workflow processes are being introduced. Ongoing training of personnel is critical for retaining high-quality outcomes in an ever-changing laboratory environment. The training program shall be planned, documented, and evaluated periodically for its effectiveness and revised based on the feedback and needs of the staff to meet institutional and regulatory requirements. Direct observation is essential to ensure competency for high-quality independent work, especially for tasks that have a high impact on patient outcomes. Training programs should be inclusive of the specific tasks and duties reflected in the job description. Additional areas of training should include ethics, patient privacy, information technology systems, biosafety and biosecurity, occupational health and safety, as well as the QMS of the organization.

Competency assessment.

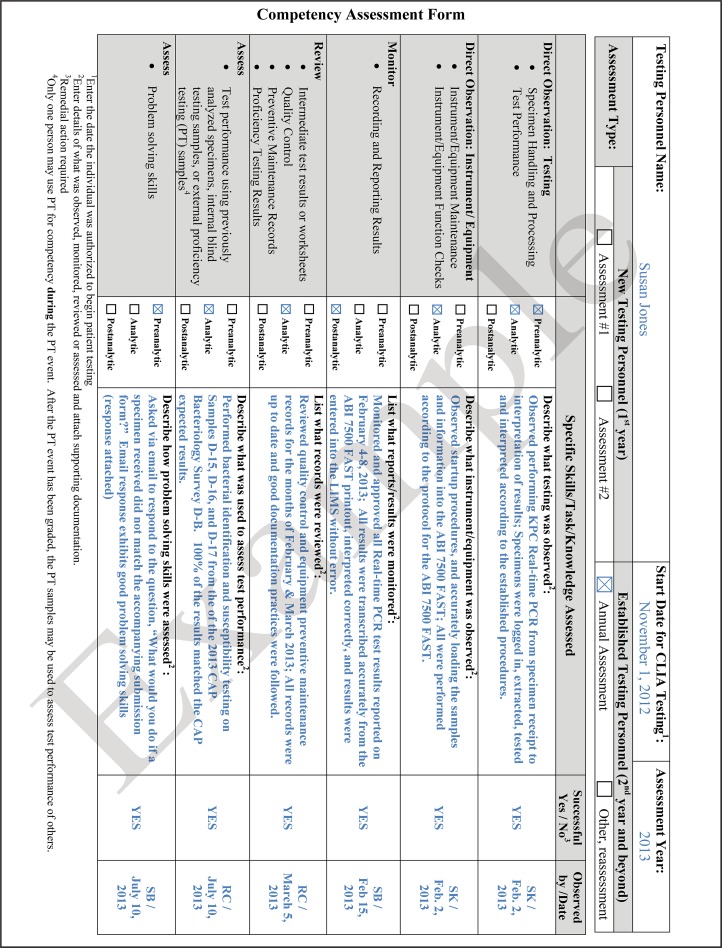

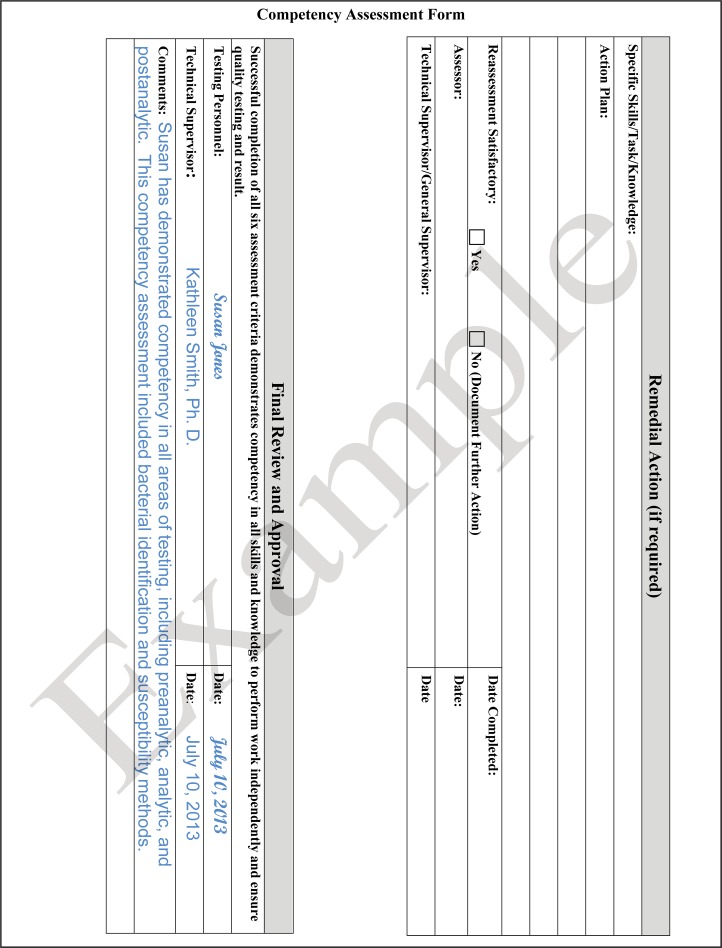

Competency testing of all technical and managerial staff shall be conducted and documented after training at the time of hiring and regularly thereafter. The frequency of competency assessments will depend on the skill or task and may be dictated by the laboratory's regulatory or accrediting body; e.g., the CLIA requires annual competency testing for personnel. The evaluations shall be objective and consistent to eliminate any assessment bias between employees. Laboratories should assess their technical staff throughout the year for the tests that they may perform. Suggested types of examinations are written or multiple-choice tests, direct observations, review of records, or testing of blind samples. The assessments should be diverse and address the knowledge, skills, or attitude that is expected of the staff member. Examples of technical skills to be assessed include the interpretation of Gram-stained smears or performance of antimicrobial susceptibility testing. Problem-solving skills could also be assessed, for example, by requesting staff to write an approach for troubleshooting a freezer or incubator whose temperature is out of range. Other types of monitoring may include a review of the records of equipment maintenance or direct observation of equipment function checks. Any observed deficiencies should be addressed, with appropriate retraining as necessary, to avoid any adverse patient care outcomes. Deficiencies may be used as the basis for continuous quality improvement (12). Competency guidelines for public health laboratory professionals have been published and may be used for those in the clinical laboratory as well (13). An example of a competency assessment form for laboratory personnel is shown in Fig. 4. The form can be duplicated to document competency assessment for multiple specialty areas where the staff is authorized to perform patient testing.

FIG 4.

Sample of a competency assessment form that may be used to meet Clinical Laboratory Improvement Amendment (CLIA) personnel requirements.

Performance reviews conducted by laboratory management or human resources shall be performed regularly, at least annually, to complement the competency assessments. They should address both the individual's and the laboratory's needs and expectations in order to maintain a healthy working environment and high-quality service. If issues arise in the employee's performance or behavior, they should be addressed in a timely manner as appropriate, and discussion and documentation, if required, should not be delayed until the annual review. Feedback from personnel should be encouraged regularly during laboratory meetings and one-on-one informal exchanges or by having an open-door policy and not just during annual reviews. Addressing staff concerns and desires as they arise can help to motivate and retain personnel and avoid high personnel turnover rates. Personnel retention is desirable to maintain continuity, efficiency, and expertise.

The employer shall provide opportunities for every staff member to enhance their supervisory and/or technical skills, and staff shall participate in professional-development or continuing-education programs. These activities can take many forms based on the needs and resources available. Examples include attending local microbiology journal clubs, webinars, or conferences and participating in interactive online courses, invited lectures, and study groups. To determine their effectiveness, these programs shall be reviewed routinely and revised accordingly. Continuing staff development, periodic assessments, and program evaluations may be achieved by (i) monitoring the percentage or number of staff participating, (ii) assessing participants' knowledge improvement with a posttest, (iii) monitoring the level of satisfaction with the professional-development or continuing-education program, and (iv) changing laboratory practices in response to continuing education, such as updating the breakpoints for antimicrobial agents. The latter two may be captured in course evaluations that specifically ask about the participant's satisfaction and how likely the course would change their practice.

Maintaining up-to-date personnel records is a shared responsibility between the staff, who provide the required documentation, and management, who record and maintain the records with the highest confidentiality and storage security. Electronic document control systems provide an efficient and secure method to maintain up-to-date records that are accessible to the required parties. An electronic system may reduce the duplication of documents that may otherwise be housed in several areas and permit the efficient storage of archived records. Personnel roles and responsibilities should include, but are not limited to, those listed in Table 7. Microbiology laboratory management should contribute to the development of these relevant documents for all microbiology personnel. Table 7 outlines possible activities that could contribute to the development and oversight of personnel records for microbiology laboratory staff. The medical and scientific staff also require similar documents and records for their jobs as well; however, this usually falls outside the scope of microbiology management and resides with human resources and/or other institutional administrators. Records of professional-development activities, competency, and licensure are fundamental requirements of the professional licensing and regulatory bodies for medical or scientific staff. These records shall be maintained up to date as proof of competency. Each institution should decide with whom the responsibility resides.

TABLE 7.

Roles and responsibilities for personnel

| Document(s) and/or activity(ies) | Role(s) and/or responsibility(ies) |

||

|---|---|---|---|

| Institution | Microbiology laboratory management | Microbiology staff | |

| Educational and professional qualifications | Request and maintain up-to-date records | Request and maintain up-to-date records | Provide proof of education and professional qualifications |

| Request and maintain copies of transcript or diploma | |||

| Copy of certification or license | Maintain up-to-date records for each staff member | Request and maintain copies from each staff member and acknowledge receipt | Provide copy and record of annual renewal |

| Previous work experience | Request and maintain records at the time of hiring | Request and maintain records of previous work experience at the time of hiring | Provide documentation of work experience |

| Job description | Establish job description standards | Contribute to the creation of microbiology job descriptions | Perform job responsibilities as described |

| Assign job descriptions to each staff member | |||

| Introduction of new staff to the laboratory environment | Create and maintain records of orientation to the institution | Develop the orientation program for the microbiology laboratory | Participate in the orientation of new laboratory staff |

| Orient new staff to the microbiology laboratory (e.g., checklist orientation) | |||

| Maintain records of microbiology orientation | |||

| Evaluate effectiveness of the orientation plan | |||

| Training in current job tasks | Review assessments as needed | Contribute to the development of the training program | Competently complete training in current job tasks |

| Maintain records of training | |||

| Create and update training checklist for each job task | |||

| Evaluate its effectiveness | |||

| Competency assessments | Review assessments as needed | Create competency assessments for microbiology personnel | Complete competency assessments for assigned job |

| Evaluate testing personnel for their competency for their assigned job tasks in the laboratory | Retrain where weaknesses are noted | ||

| Maintain records of competency assessments | |||

| Records of continuing education and achievements | Review records as needed Provide resources for continuing-education opportunities for employees |

Facilitate educational activities and achievements Maintain records of continuing education and achievements Establish personnel competencies where continuing education and training may be appropriate |

Identify gaps and interests in microbiology Request continuing professional and education development program activities Provide documentation of achievements Evaluate effectiveness of continuing-education programs |

| Reviews of staff performance | Maintain documentation of staff performance | Conduct staff performance reviews | Participate in peer or manager performance review as applicable |

| Maintain documentation of staff performance | |||

| Reports of accidents and exposure to occupational hazards | Maintain individual records of accident and exposure for human resources and/or occupational health | Maintain records of accidents and exposures | Report any incidents or exposures to microbiology laboratory management and occupational health |

| Complete an incident report for any laboratory accident or exposure | |||

| Track accidents or exposures and retrain employees where applicable | |||

| Immunization status, relevant to assigned duties | Maintain individual records in human resources and/or occupational health records | Ensure that laboratory staff are aware of pertinent vaccines, such as Neisseria meningitidis or hepatitis B vaccines | Maintain immunization status per institutional policies |

| Require evidence of vaccination where applicable to the task | |||

Facilities and Safety

Managing the facilities.

The laboratory's sample collection and testing sites, as well as point-of-care testing locations, shall have sufficient space to perform quality work and ensure patient, staff, and visitor safety. The laboratory shall evaluate and determine the adequacy of the space for both equipment and personnel. Special attention should be paid to the provision of a safe environment. Although specific safety standards are not included in ISO 15189, they are specified in the related ISO 15190 document (14). Safety must be an integral part of a good quality management system. A full discussion of biosafety levels, personal protective equipment, and facility and engineering controls is beyond the scope of this document. There are several excellent reference documents for consideration (15–17).

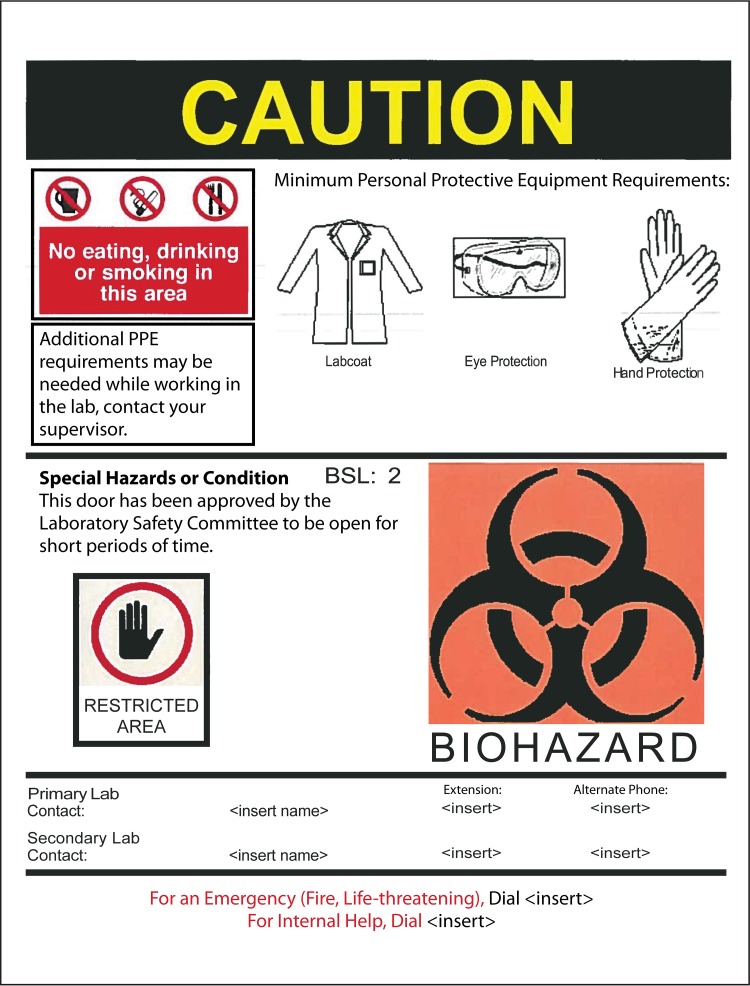

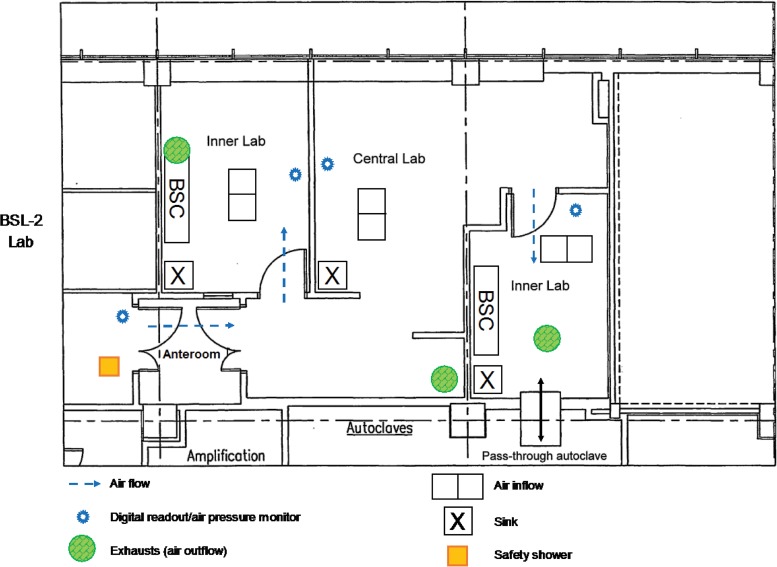

The laboratory shall have controlled access, with the level of access being based upon biological, chemical, and radiation hazards; biosecurity; and confidentiality. The levels of access can vary from space to space within the laboratory and should be restricted in areas where testing is performed at biosafety level 2 (BSL-2) or higher. In addition, signs identifying the hazards within should be posted at the entrance to and exit from the laboratory. Entrance signs for microbiology laboratories should identify the biohazard, and contact information shall be displayed in case of emergency. See Fig. 5 for an example of appropriate signage for a laboratory door. Access controls, such as key pads or double-door, locked anterooms, provide limited access to laboratories operating at BSL-3, such as mycobacteriology laboratories (16). See Fig. 6 for an example of a BSL-3 laboratory suite floor plan.

FIG 5.

Example of a door sign for a microbiology laboratory, indicating the level of biosafety, proper work practices, and type of personal protective equipment (PPE) required.

FIG 6.

Sample floor plan for a biosafety level 3 laboratory suite located within a larger BSL-2 central laboratory. The two inner BSL-3 laboratories are separate rooms with negative air flow to contain microorganisms or their molecular components. BSC, biological safety cabinet.

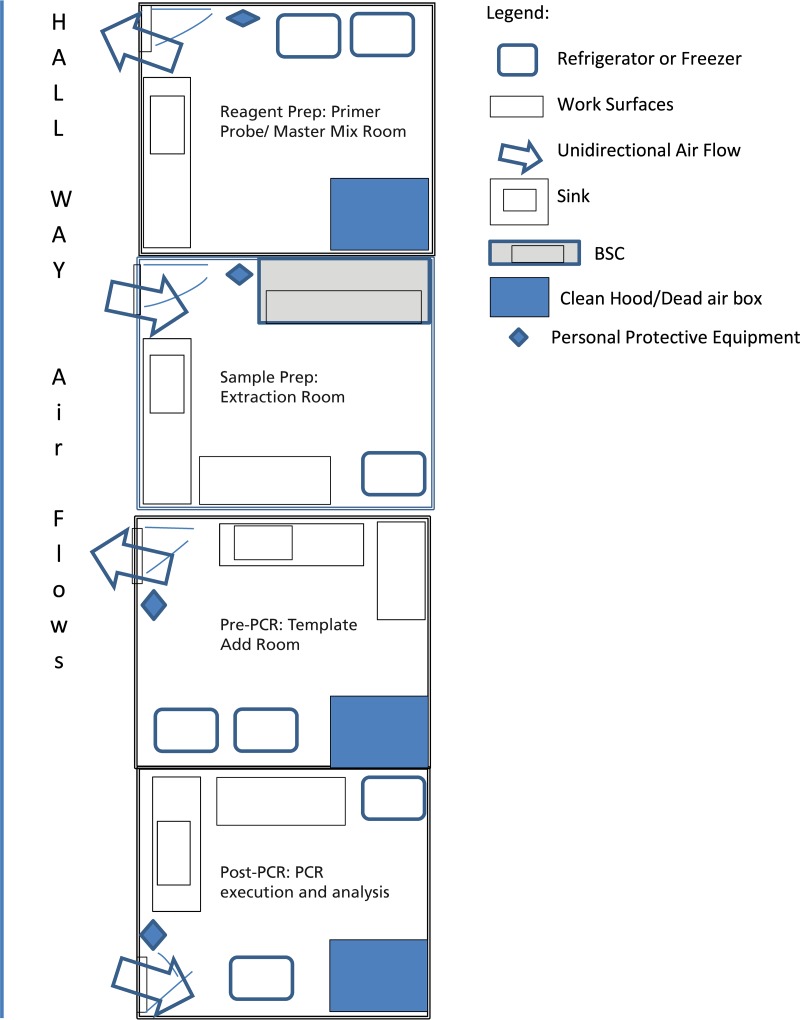

Of special note, laboratories performing molecular testing using a platform where reactions occur in an open system should limit access not only for biosafety purposes but also for decreasing the likelihood of amplicon contamination. Amplicon contamination is reduced through the use of separate work areas; engineering controls, such as dead-air boxes and unidirectional workflow; as well as stringent chemical and/or enzymatic decontamination. See Fig. 7 for a sample floor plan for molecular testing with unidirectional airflow. Although commercially available, molecular testing may be performed in a closed system; concern for contamination is still paramount throughout the testing process. Additional guidance for molecular testing in clinical laboratory environments has been reported (18).

FIG 7.

Sample floor plan for a molecular laboratory to ensure the segregation of specimens and high-amplicon material from clean reagents and PCR tubes. BSC, biological safety cabinet.

The laboratory environment shall be in compliance with federal, state, and local building codes. All areas and surfaces in the laboratory, including work benchtops, floors, ceilings, and walls, shall be clean and well maintained. Ideally, these surfaces are nonporous in order to be easily decontaminated. Laboratories shall never be carpeted in areas where testing is performed. The work environment, both the laboratory and office space, shall be ergonomically designed to prevent the occurrence of work-related musculoskeletal distress. In addition, there should be adequate separation of spaces between incompatible work environments. For example, biosafety cabinets (BSCs) should be located away from traffic flow and air ventilation systems in order to maintain proper function, and areas with potential amplicon contamination should be separate from molecular reagent and master mix preparation areas. Dedicated sinks for reagent preparation and equipment cleaning shall be available, and separate dedicated hand-washing sinks shall be hands-free and not utilized for other purposes. Additional environmental conditions that may affect the quality of the results that shall be monitored, recorded, and adjusted accordingly and include lighting, noise, vibrations, dust levels, fumes, radiation, electrical supply, temperature, and humidity.

In addition to the environment, the facility shall have adequate infrastructure for the tasks performed. Water of the type required for patient testing that meets the standards for clinical laboratory reagent water (CLRW) shall be available (19). Some laboratory procedures (e.g., molecular testing and virus culture media) require water of a purity higher than CLRW. Manufacturer specifications for the quality of water shall be followed. Electrical power with sufficient numbers of regular and emergency-backup outlets for the size and complexity of the laboratory shall be available. Multiple outlet adaptors and the use of extension cords should be limited to emergency situations only. Consideration of which critical instrumentation requires connection to emergency power shall be established; for example, automated blood culture instruments should be connected to emergency power.

Laboratory ventilation shall be monitored and adjusted to meet the air exchange, humidity, and temperature requirements of all areas. Ventilation can be affected by the configuration of the room, the location of heat-generating equipment (e.g., blood culture instruments) and ventilation equipment (e.g., biosafety cabinets and chemical fume hoods), and traffic patterns. Whenever possible, airflow should be in an inward direction from corridors into the laboratory space. Negative air pressure with adequate frequent air exchanges shall be used for mycobacteriology, mycology, and virology laboratories. In general, the acceptable frequency of air exchanges is between 3 and 15 air changes per h for BSL-2, which is generally more frequent in areas with higher concentrations of chemicals or hazards, such as mycobacteriology laboratories. Gas and vacuum lines should be available as applicable and clearly marked. Gas cylinders shall be secured in an upright fashion at all times, preferably mounted onto a solid surface, such as a wall, and placed away from flammable material. Valve safety covers shall be in place when valves are not in use.

An adequate storage facility of the appropriate size, temperature, and humidity to maintain the integrity of reagents, samples, equipment, supplies, documents, and records shall be available. Equipment and reagents may have manufacturer-specified temperature and humidity requirements that must be met. The temperature must be maintained under the required conditions 24 h per day and not altered for energy savings during off-peak hours. Sample storage space should be chosen to eliminate the potential for cross-contamination.

Safety programs.

The laboratory shall develop and implement a comprehensive safety program. The program typically includes biosafety, biosecurity, blood-borne pathogens, the transportation of dangerous goods, and the use of personnel protective equipment. A laboratory safety program shall also address fire safety; chemical hygiene; safe practices associated with electrical hazards, radiation, and hazardous waste; accessibility to first aid; and ergonomics.

The safety program shall be based upon workplace regulatory requirements and a thorough risk assessment. Safety training that should include the direct observation of safety practices shall be provided and documented as part of staff competency. Laboratory personnel shall follow guidelines for biosafety laboratory compliance (20), and management shall provide the resources to protect staff from occupationally acquired infections (21). To ensure compliance with the safety program, all facility administrative levels shall be involved, as outlined in Table 8.

TABLE 8.

Roles and responsibilities for facilities and safety

| Activity | Role(s) and/or responsibility(ies) |

||

|---|---|---|---|

| Institution | Microbiology laboratory management | Microbiology staff | |

| Controlled access to laboratory | Provide engineering controls to limit access | Encourage limited access | Monitor nonlaboratory personnel |

| Adequate work environment | Provide work environment with clean, well-maintained floor, ceiling, and walls and adequate lighting, water, ventilation, power, and communication | Advise as to accommodations and environmental-condition requirements | Inform when accommodations and environmental conditions are unsatisfactory or unsafe |

| Report accidents, incidents, or near misses | |||

| Monitor environmental conditions | |||

| Safety program | Provide resources and oversight for institutional safety program | Perform a risk assessment | Comply with safety program |

| Designate biosafety and safety officer(s) | Advise of unsafe conditions | ||

| Develop a comprehensive safety program to meet all requirements | Report accidents, incidents, or near misses | ||

| Adequate safety facility and supplies | Provide adequate safety supplies in close proximity | Be aware of and advise as to safety requirements and appropriate engineering controls | Utilize appropriate personal protective equipment and engineering controls |

| Provide appropriate safe engineering controls | Inform when supplies or engineering controls are unsafe, inadequate, or unusable | ||

| Report accidents or incidents | |||

| Occupational health | Provide occupational health services adequate for level of services provided | Advise as to necessity for baseline immunity testing and provide vaccinations | Report any exposures Undergo monitoring for exposures (e.g., status of immunity, chest radiograph, or skin testing or interferon gamma release assay for tuberculosis) |

| Monitor for exposures and recommend prophylaxis or treatment as required | |||

| Receive vaccinations, prophylaxis, or treatments as recommended | |||

Safety supplies and storage shall be adequate and in close proximity to use. The safety supplies required are dependent upon the biosafety level of the laboratory as well as the chemical hazards present. Safety supplies are not limited to personal protective equipment but also include engineering controls, such as biosafety cabinets, centrifuges with safety cups and rotors with covers, pipetting aids, splash guards, and safe sharps containers. Biological and chemical spill kits shall be easily accessible in the respective areas and marked appropriately. Spill drills shall be conducted by the responsible safety official, and staff shall be knowledgeable of such practices. The performance of safety equipment (e.g., biosafety cabinets, showers, and eye washes) shall be monitored and recorded regularly. Occupational health services shall be available to staff for any hazardous workplace exposure. In particular, occupational health services shall monitor for and respond to laboratory-acquired infections and provide preventative vaccines where applicable, such as a hepatitis B vaccine to those handling human blood specimens.

Purchasing and Inventory

To ensure the use of only high-quality services and supplies, a multifaceted approach is required. Policies and procedures shall be in place in the laboratory for the selection and purchasing of services and supplies that affect the quality of the tests and/or calibrations. These quality requirements shall be detailed in standard operating procedures (SOPs), typically located under the “materials required” section of each procedure, and identify the appropriate minimum specifications when necessary. The laboratory shall maintain records on the experience with a product or vendor so that selection or rejection is based on data. Problems detected by staff shall be reported to laboratory supervisors and monitored or documented as a nonconforming event. Issues should be discussed with the vendor, and unresolved issues should be reported to the purchasing agents. The purchasing of external services and supplies is a collaborative effort between the institution's administration and the laboratory. The laboratory director should have final approval on all purchases and customarily designates laboratory staff to perform the processes. Examples of purchased external services include referral laboratory services, equipment maintenance, BSC certification, or off-site waste disposal.

Services agreements are used to document a transaction where the provider of a service performs the service for a user. Examples of professional services agreements that may be appropriate for the laboratory as a user are equipment maintenance, reference testing, pathology consulting, consultant management, and facilities management or services. The provider of the services may be internal to the user, such as facilities management, or external, such as an equipment manufacturer providing an annual service contract. Agreements to provide medical laboratory services are an essential component of a quality management system. The laboratory shall ensure that the service providers are able to perform the requested services and that they have sufficient resources to provide the services before entering into the agreement. A service-level agreement (SLA) is a contract between a service provider and the laboratory that defines the level of service expected from the service provider and the individual and shared responsibilities of each party. Examples of items covered in a SLA are security services for the laboratory, occupational health services for laboratory staff, housekeeping services, medical waste management, and preventive and scheduled maintenance services. Entering into a SLA takes a team approach to ensure that the level of service is met. Table 9 lists the functions of various members of the laboratory team to establish service agreements.

TABLE 9.

Roles and responsibilities for service agreements

| Activity | Role(s) and/or responsibility(ies) |

||

|---|---|---|---|

| Institution | Microbiology laboratory management | Microbiology staff | |

| Determine the need for service agreements | Provide the method to enter into a service agreement | Review operations to determine what service agreements are needed | Provide data to drive the decision for service agreements |

| Entering into service agreements | Maintain the system that allows procurement of service agreements and good relationships with providers | Work with business analyst to facilitate development of appropriate service agreements | Maintain detailed records of services provided |

| Identify expense budget for providing the services to ensure continuation of service agreements across fiscal years and budget periods, ensuring uninterrupted service coverage | |||

| Identify requirements to be provided by the service agreement | |||

| Monitoring service agreements | Ensure that service agreements are kept current, renewed, or cancelled | Review the service agreement to make certain that terms are met | Understand and adhere to the terms of the service agreement |

| Analyze data on the performance of the service agreement | |||

| Monitor the performance of the service agreement | |||

Contracting for referral laboratory services.

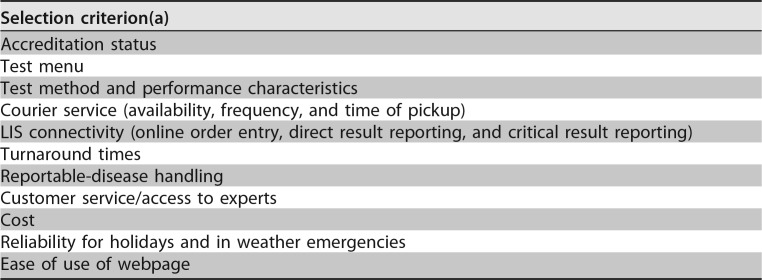

Because of the wide array of tests required and available for patient care, performing all requested tests in the institutional laboratory is unfeasible. A referral laboratory or reference laboratory is normally a large laboratory that performs testing not ordinarily found in a clinical laboratory. Examples of referral laboratories include commercial reference laboratories; academic medical centers; and national, state, local, or provincial public health laboratories. It is essential for every institution to have a contractual relationship with a referral laboratory, and rigorous analysis is needed before the selection of the referral laboratory is made. The laboratory director in consultation with the medical staff should determine which tests are referred and which tests are performed at the institution, also known as in-house testing. Institutions often use more than one referral laboratory. The selection of the referral laboratory is an important process that should be led by the laboratory director in collaboration with management.

The steps in the selection process may differ for each institution, but the process should start with the development of selection criteria, as outlined in Table 10. Microbiology management is integral for the preparation of the selection criteria. The selection of a reference laboratory is based on the desired services and performance standards required. Foremost in the criteria is the requirement that the referral laboratory meet accreditation standards. Laboratory management may write a request for information (RFI) or a request for proposal (RFP), to which potential referral laboratories respond in writing to bid for the contract. After the RFI or RFP is submitted, management compares the criteria to the responses of the referral laboratory candidates, analyzes and weighs the responses, and recommends the referral laboratory. While cost is a consideration, cost cannot be the only driver of the decision. The laboratory director should have the final word on the selection of a referral laboratory since that person is knowledgeable of the regulatory testing and reporting requirements that need to be met. The laboratory director shall also ensure that the selected laboratory meets all the accreditation qualifications and the required established criteria before the institution engages in a contractual relationship with the referral laboratory.

TABLE 10.

Elements of selection criteria for assessing referral laboratories

Laboratory management has the responsibility of establishing written procedures defining how to send specimens to the selected referral laboratory, and the laboratory director shall approve these procedures. Specimens shall be appropriately packaged for shipping. Requests for testing shall have the appropriate documentation accompanying the specimens. Staff shall be adequately trained on packaging, shipping, and order entry. Management shall monitor that these procedures are performed correctly and consistently so that test results are not compromised by sending specimens to an outside laboratory.

The referring laboratory shall ensure that the results reported are exactly as intended by the laboratory performing the testing. The results shall include any comments and interpretation that the reporting laboratory intended to be part of the report. While electronic reporting through laboratory information system (LIS) connectivity is preferred, manual reporting or reentry of results into the institution's LIS is acceptable if all results, comments, and interpretations are included. It is the responsibility of the institution to ensure that procedures for reportable diseases and requirements for the submission of specific pathogens for public health purposes, according to state code, are followed by the referral laboratory. Laboratory management shall communicate with the referral laboratory regarding whose responsibility it is to notify public health authorities of reportable information. The laboratory director shall ensure that a reliable system is in place and working as expected.

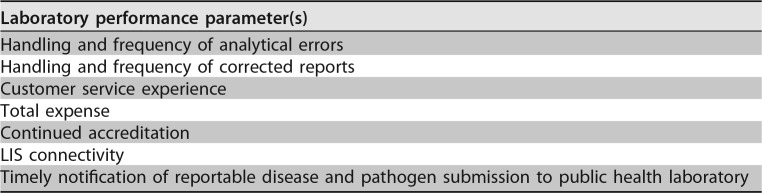

After the referral laboratory contract is established, the institution shall establish the performance monitoring process. This process should be incorporated into the laboratory's quality management system. The contracting institution should request and maintain a current copy of the accreditation documentation for the referral laboratory. Reports from the referral laboratory should be reviewed for accuracy of transmission. The performance of the referral laboratory should be monitored for several performance parameters, as defined in Table 11. Problems encountered with the referral laboratory should be well documented for tracking purposes. The laboratory management and technical staff are responsible for supplying accurate data, and the laboratory director should review the performance data and review cost benefits throughout the contract period.

TABLE 11.

Referral laboratory performance parameters

Purchasing services and supplies.

Purchasing external services and supplies is a three-step process that includes the prepurchase process, the actual purchase, and the postpurchase process. In the first step, the prepurchase process, the laboratory staff determines the quality requirements. In the second step of the purchasing process, the purchasing section of the institution negotiates price, places orders in a timely manner, and ensures that bills are paid. To achieve a successful collaboration, communication between purchasing agents and laboratory staff is critical. In the third step of the process, postpurchase, the laboratory staff who use the purchased items or services verify that the items or services meet the identified quality requirements. When those requirements are not met, the staff shall report the problems to the laboratory director, and these problems are communicated to the purchasing section.

The laboratory shall ensure that purchased supplies, reagents, and consumable materials that affect the quality of tests and/or calibrations are identified and that there is a process to ensure that only services and supplies of high quality are used. The laboratory should have representation on the product selection committee to balance cost with the best product performance for an optimal quality of clinical diagnostic services. The price of the product, memberships in buying groups, and cost containment efforts should not drive product selection decisions for instruments, media, test kits, and services purchased. In addition to cost and quality, selection shall also be based on reliable delivery and service, such as the ability of the provider to ship kits and reagents with a single lot within an order and with a long shelf-life.

Purchasing documents must be reviewed and approved for technical content prior to the placement of an order. Purchasing documents shall contain specific information describing the services and supplies ordered. The information may include precise identification such as type or class of service or grade of reagent; specifications; drawings; inspection instructions; and other technical data, including approval of test results, quality required, and the quality management system standard under which they were produced. Before substitutions are made, the purchasing agent shall contact the laboratory staff for approval. Communication on back orders and substitutions to the end user is critical.

Upon receipt of the purchase order, the laboratory staff shall review packing slips and the package contents and match them with the purchase request. A certificate of analysis (COA) shall be maintained on file after the COA is examined to ensure that the received item meets minimum specifications. Chemicals and reagents should be purchased with manufacturer certificates, where possible. When uncertified chemicals are purchased from ISO/IEC 17025- or ISO 9000-registered companies, records of action taken to check compliance shall be maintained. For examples, laboratories can use QC data to demonstrate the quality of supplies, reagents, and consumables.

All reagents and supplies shall be stored under the proper conditions (e.g., temperature, humidity, and light exposure) specified by the manufacturer. Inventory shall be controlled and monitored so that critical reagents and supplies are available and fit for use. Inventory items may be managed manually or with electronic control systems. Additional information on equipment and reagent inventory control is described in Laboratory Operations, below. Suggested roles and responsibilities for purchasing and inventory are outlined in Table 12.

TABLE 12.

Roles and responsibilities for purchasing services and supplies

| Activity | Role(s) and/or responsibility(ies) |

||

|---|---|---|---|

| Institution | Microbiology laboratory management | Microbiology staff | |

| Before decision to purchase products or services or renewal of an agreement | Negotiate best price, terms, and conditions | Establish criteria for the selection of quality products and services | Provide input into the level of quality required for products and services |

| Purchasing of products or services | Place orders accurately and promptly | Address deficiencies with vendors | Monitor inventory and place orders |

| Inform users of backorders or unavailability of products | |||

| After receipt of products or services | Timely payment of purchases | Document nonconformities Keep performance records to inform renewal or terminate agreements |

Inform management of incomplete orders or lack of service |

| Monitor quality of the products and services received | |||

LABORATORY OPERATIONS

This overarching section builds on the foundation and contains four QSEs that focus on routine laboratory operations. These QSEs include (i) the establishment and documentation of procedures and record retention, (ii) equipment qualification and maintenance, (iii) processes to manage the total testing pathway from preanalytical to postanalytical steps, and (iv) processes to manage information either electronically or manually.

Control of Documents and Records

Documents.

Documents may be electronic or paper based, but the principles of document control apply to all formats. All documents shall be uniquely identified with document and revision numbers to avoid the use of outdated documents. All documents shall be approved by the appropriate person who has the authority, as defined in a written procedure, before they are put into use. Documents may have different formats based on the purpose for communicating the information. These include policies, processes, SOPs, forms, and job aids.

A policy is a documented statement of the intentions or directions endorsed by management to provide efficiency and consistency. For example, the laboratory may have a written policy on attending continuing-education events locally or out of town or a policy regarding how holiday coverage is assigned.

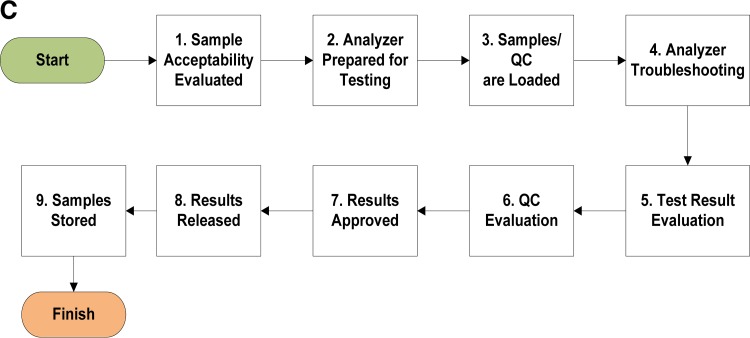

A process is a set of interrelated activities that transforms inputs into outputs. Steps in the overall process of culturing sputum would include specimen collection, transportation to the laboratory, accession into the information system, evaluation of the quality of the sample, inoculation into appropriate media, and interpretation of the culture result. There are several formats that can be used to display a process, such as flowcharts or process maps.

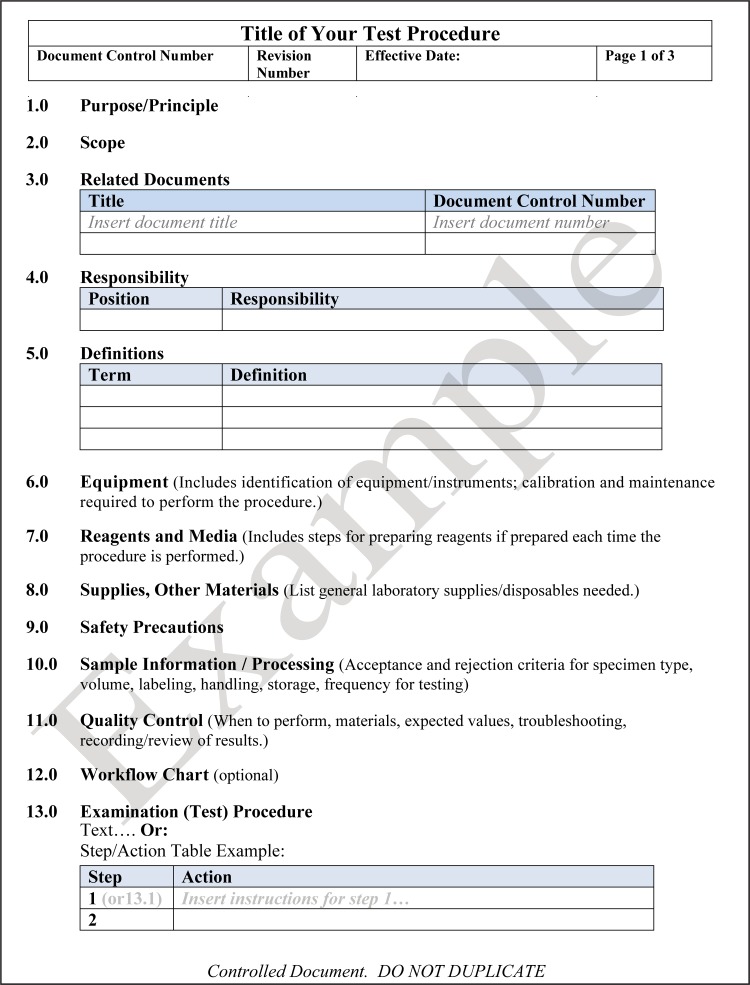

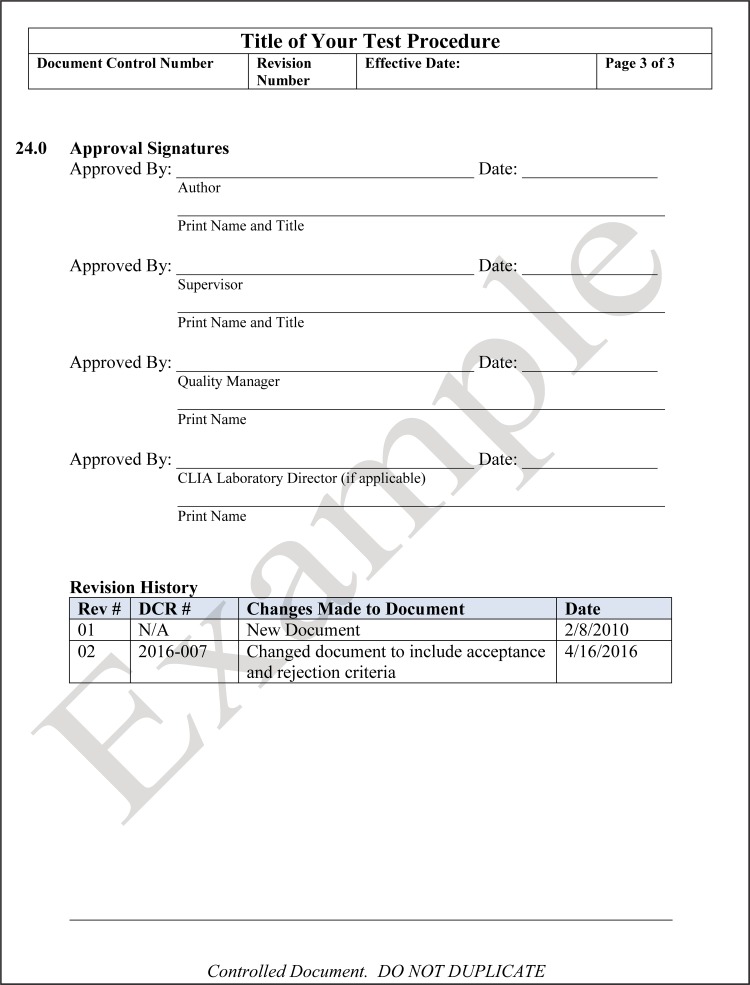

A SOP is a set of fixed instructions to carry out a routine activity or process. An example of a procedure would be a step-by-step description of how to perform a disk diffusion antimicrobial susceptibility test on a bacterial isolate. SOPs should have a consistent format and should be clear to all users so that the task being described is consistently performed. A template for writing a technical procedure is shown in Fig. 8.

FIG 8.

Template for writing a technical laboratory procedure. If a section is not applicable to a procedure, it is best not to delete the heading but to state “not applicable” in case the procedure should change and require this information in the future.

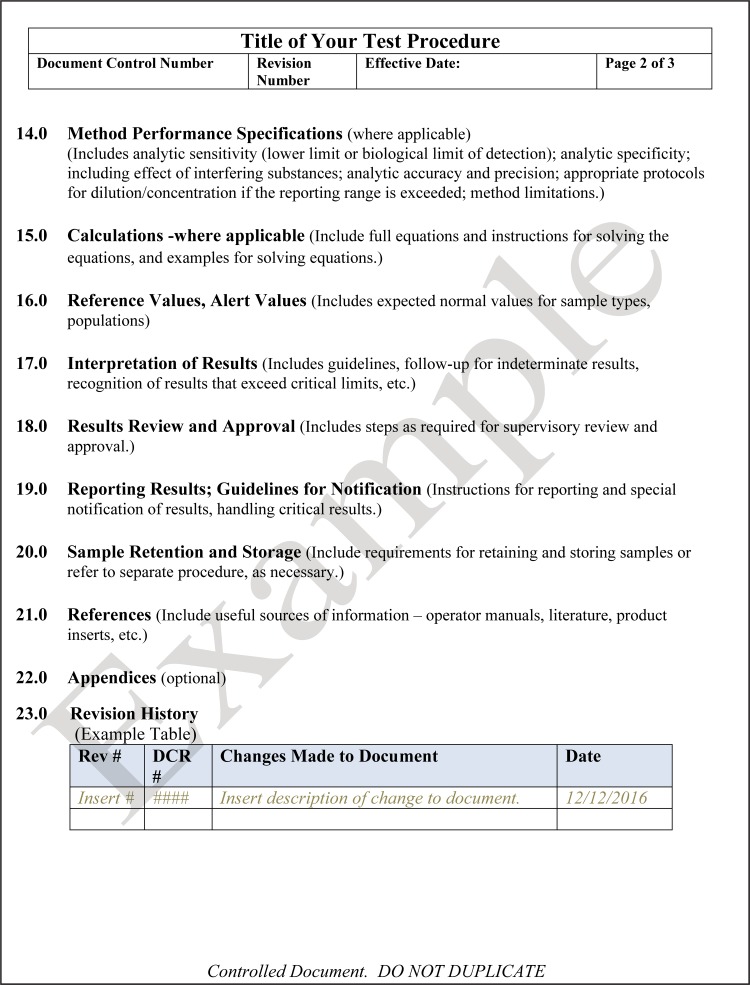

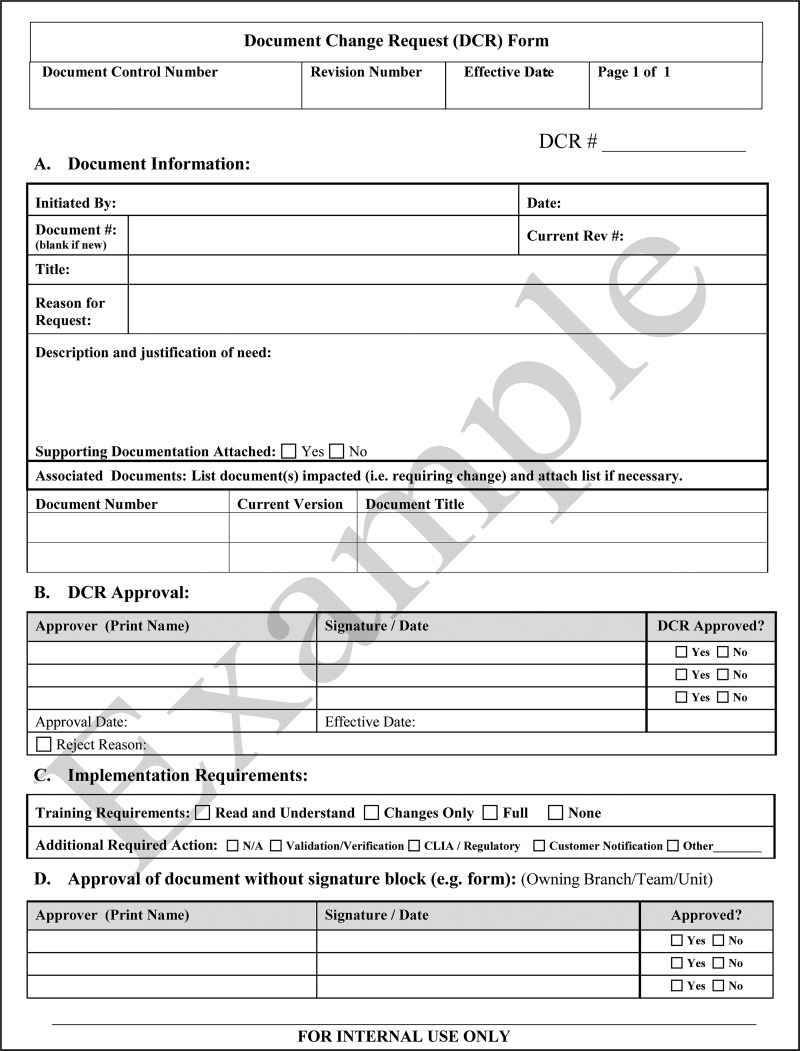

For changes to any document, there shall be a procedure that describes how to amend a document and who has authority to do so. A good practice may include the use of a “document change request” (DCR) form to initiate a change and to keep track of modifications in progress. A template for a DCR form is shown in Fig. 9.

FIG 9.

Template for writing a document change request (DCR). The DCR form allows traceability for amending or archiving technical or quality management policies and procedures.

Documentation of all changes shall be clearly recorded and should follow good documentation practices according to CLSI method QMS02-A6 (22). When making modifications, cross out original wording with a single line but allow it to remain legible. Never use correction fluid, and never delete the original information. Clearly state the revised wording. Ensure that an authorized person signs his or her initials and marks the date of the change. As soon as possible, update the revision history, assign the updated document a new revision number, and approve the document. Archive and appropriately retain outdated documents, including obsolete documents.

A form is a document to capture information, data, or test results. Examples include a communications log for inquiries and complaints, a form to capture the zone of inhibition for quality control organisms used in a disk diffusion test, or a form to document results observed for a lateral flow immunochromatographic test for Legionella antigen.

A job aid is an abbreviated set of instructions that briefly describes in words or pictures how to accomplish a task. An example of a job aid would be a diagram showing the order in which one should apply reagents for a Gram stain. It is not the complete SOP, but it indicates the necessary steps. All job aids should link to an approved SOP and should be signed and dated to ensure that the most recent SOP job aid is posted.

All documents, regardless of format, shall be reviewed periodically for their relevance. Some regulatory authorities or accrediting bodies set specific requirements for the frequency of review, which shall be observed to be in compliance.

Records.

A record is defined as documentation that provides evidence of results achieved or activity performed and can be either a hard copy or electronic. Forms become records after they are completed. The control of records applies to all technical and quality records. Technical records include observations, calculations, derived data, calibration records, instrument maintenance logbooks, spreadsheets used to calculate the accuracy and precision of instruments, sample logbooks, personnel records, and test reports. Quality management documentation includes audit reports, management review, preventive action taken, nonconforming events, and corrective action taken. A facility should develop a master index of records to provide order and structure to the record retention system.

The requirements for the control of records can originate from multiple sources, including compliance requirements of the accreditation agency, government regulations, and legal requirements. Customer requests shall be honored and may include requests from risk management to resolve legal inquires.

The “owner of the records,” sometimes known as the “records custodian,” is responsible for ensuring that records in the quality management system are handled in accordance with the stated requirements of the facility. This role can be served by the laboratory supervisor, the quality manager, or a person delegated for this function. The records custodian shall ensure that the records are properly indexed, stored on- or off-site, and maintained for the required retention period. It is the responsibility of all personnel to ensure that all records are legible and preserved for the retention process.

Records retention refers to how long the record is kept before it is either discarded or destroyed. The records custodian is required to ensure not only that the record is maintained for the required time but also that the confidentiality of any patient information is maintained. In the United States, the record retention period is based on local, state, or federal governmental regulations; the requirements of the compliance accrediting body, e.g., the College of American Pathologists (CAP) or the Joint Commission; and the procedures of the organization. There may be legal requirements depending on the type of testing performed by the laboratory. Records may be stored in the originating facility or sent off-site for long-term storage. Normally, records are retained on-site for the minimum retention time. Retention times for work area-specific records are determined by the laboratory and stated in their quality management system procedures. Suggested roles and responsibilities for controlling documents and records are listed in Table 13.

TABLE 13.

Roles and responsibilities associated with document control

| Activity(ies) | Role(s) and/or responsibility(ies) |

||

|---|---|---|---|

| Institution | Microbiology laboratory management | Microbiology staff | |

| Document creation | May provide a template for official documents | Establish a document control system that meets any institutional requirements | Inform supervisor if a new or revised document is needed |

| Prepare new or revised documents with the appropriate control and revision no. | |||

| Ensure that appropriate documents capture required information, data, and results to meet regulatory requirements | |||

| Approve and review documents as required | |||

| Document access and storage | Provide a system for adequate and accessible storage of electronic and hard-copy documents | Provide a secure system for accessing documents | Use current versions of processes and procedures |

| Determine if access to documents is appropriate for work | |||

| Instruct personnel on document location and editing rules | |||

| Determine the life span of a document according to regulations and standards | |||

| Archive obsolete documents | |||

| Record creation | None | Review records for completion and follow-up of outlying entries | Enter information on forms according to good laboratory practices |

| Sign and date records in a timely manner | |||

| Record access and retention | Provide a system for adequate storage of electronic and hard-copy records | Create a system for maintaining records for easy retrieval Ensure secure access to records Determine if access to records is appropriate for the work to be performed |

Follow policy for restricting access to and sharing records Maintain all records of work |

| Set institutional policy for record retention that complies with regulatory requirements | |||

| Store, archive, or discard records according to record retention policies | |||

Equipment and Reagents

Equipment.

The laboratory shall have the necessary equipment to provide services, including general office and laboratory-specific equipment, analytical instruments, computer hardware and software, and the LIS. There are multiple steps to qualify new equipment coming into the laboratory that encompass its selection, installation, operation, and performance before it may be used for testing.

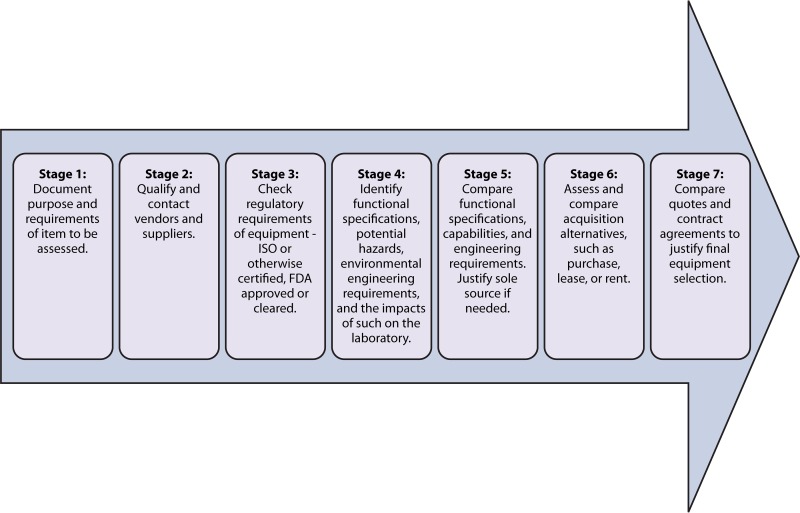

The laboratory shall have a process for identifying qualified suppliers from whom equipment purchases can be made. The laboratory shall follow approved procedures for the selection, purchase, and acquisition of equipment, including the preventive maintenance agreements for major equipment based on the manufacturer's requirements and the need for the equipment to perform reliably and safely throughout its life span of service. This initial process is known as “selection qualification” (SQ) and includes the steps outlined in Fig. 10. Note that the steps may not be followed necessarily in the particular order presented, and the ability to move to the next step is not contingent upon the completion of the prior step. Rather, Fig. 10 is a general guideline for SQ of equipment.

FIG 10.

Flow diagram for selection qualification of equipment. Each step does not necessarily need to be performed before others are completed. Some may be performed simultaneously.

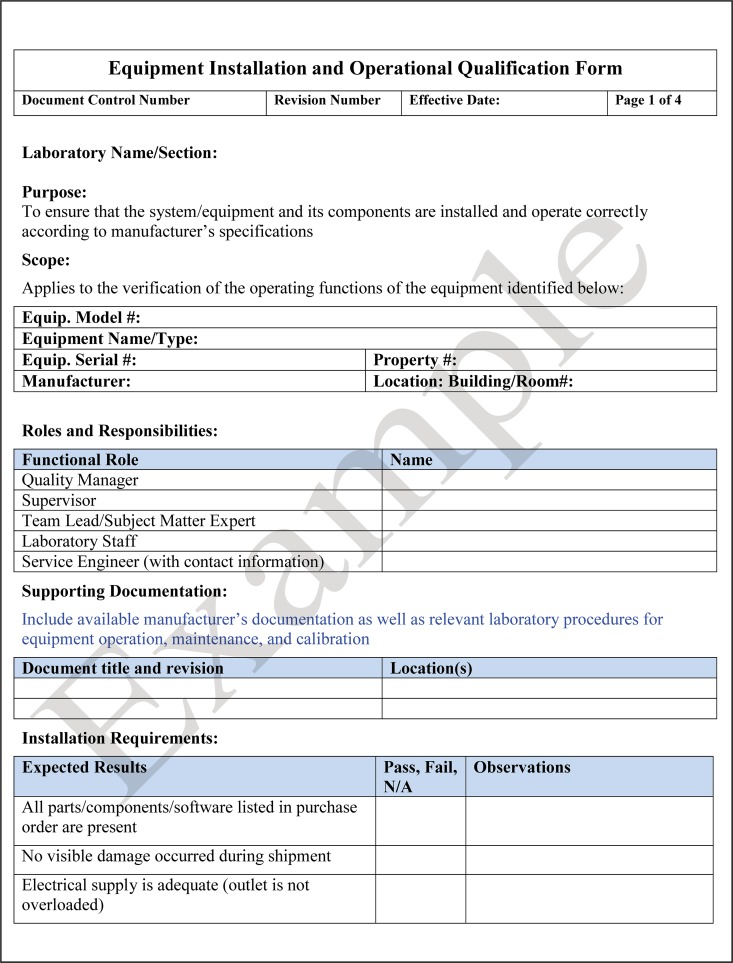

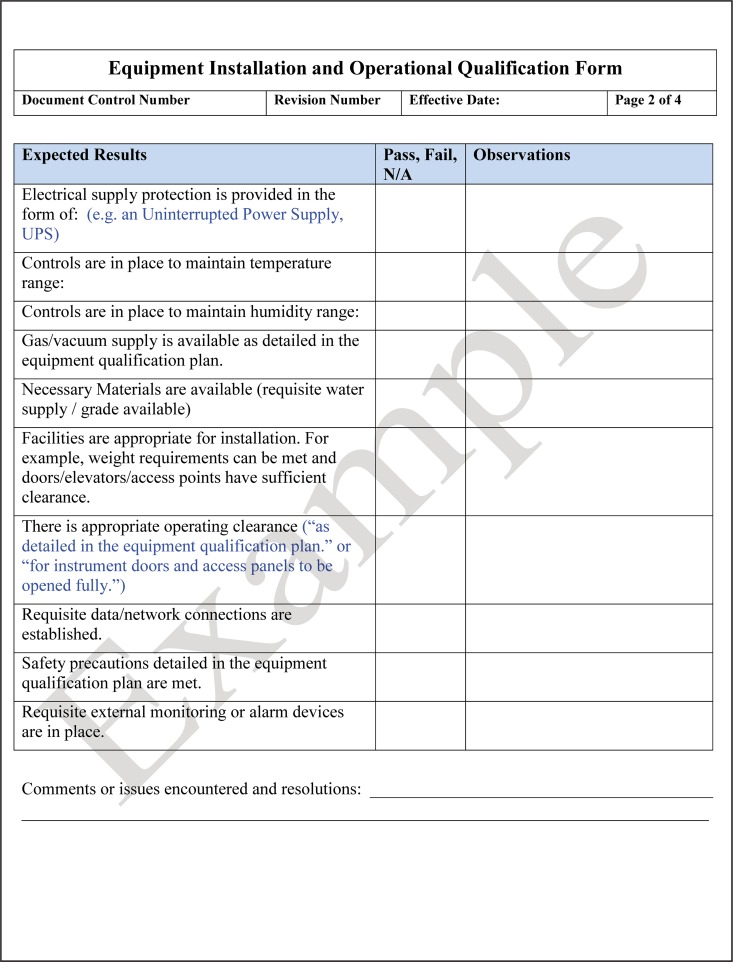

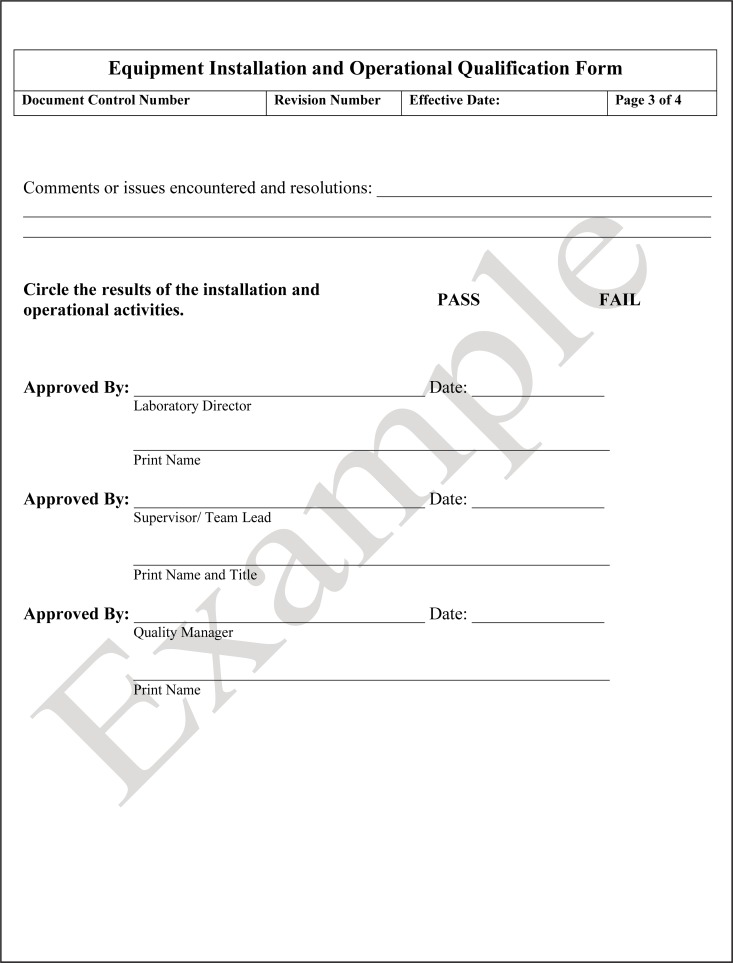

The second phase of equipment qualification is designated installation qualification (IQ). The laboratory shall have a process in place to ensure that equipment has been installed according to the manufacturer's requirements. The manufacturer or the vendor may perform this task and provide documentation showing that the equipment was correctly installed and has met the specific requirements.

Following installation, the equipment is qualified that it operates in accordance with the manufacturer's specifications, known as operational qualification (OQ). OQ includes activities such as power-up, initial calibration, and verification of functionality. The vendor or manufacturer may perform both the IQ and OQ on the instrument and provide the required documentation, but they may not perform the performance qualification (PQ). The laboratory personnel who will perform the testing going forward are the ones responsible for performing PQ testing. An example of a checklist for installation qualification and operation qualification is shown in Fig. 11.

FIG 11.

Template for an equipment installation qualification (IQ) and operation qualification (OQ) checklist. IQ and OQ are performed before the laboratory initiates the performance qualification (PQ) for an instrument.