Abstract

Background:

Prosthesis misfit plays an important role in complications such as occlusal and abutment screw loosening and fracture in implant restorations. Reproducing the intraoral relationship of implants through impression procedures is the first step in achieving an accurate, passively fitting prosthesis to ensure maximum accuracy. Hence, splinting of multiple implants with most accurate material may be a valid option.

Context:

The results of splinting multiple implants are always inconsistent, and there is limited literature available to compare the accuracy of impression techniques as well as materials. In such situation, more and more studies have to be done to prove the efficacy and accuracy of each splinting materials.

Aim:

The aim of the study was to evaluate the positional accuracy in multiple implants using acrylic resin, pattern resin, flowable composite, and bite registration paste.

Subjects and Methods:

An acrylic resin model was fabricated into which four implant analogs placed. The copings attached were splinted with dental floss onto which acrylic resin was added, which was sectioned and rewelded (Group A). Similarly, pattern resin, flowable composite, and bite registration material were added which were considered as Group B, C, and D, respectively. Impressions were made in vinyl polysiloxane and analogs were attached. The casts retrieved from each group were analysed for the positional accuracy of implants.

Statistical Analysis:

One-way ANOVA was done to analyze the significant difference between the four implant analogs of each group with the master model. The confidence interval was also calculated to assess the accuracy.

Results:

It was observed that all materials are equally effective for the accurate reproduction of implant positions. There was no significant difference between the centroids of implant analogues of master model and the mean of interimplant distance 1 and 2, 1 and 4, 3 and 4 and 2 and 4 in each group. The P-values were >0.05. The accuracy of splinting materials were analysed and it showed that splinting with flowable composite (Group C) as well as bite registration paste were in par with the conventionally used materials like pattern resin and acrylic resin.

Conclusions:

Results showed that flowable composite as well as bite registration material can be recommended as splinting material of choice for multiple implant cases, as these exhibited similar results like other groups (pattern resin and acrylic resin) which are conventionally used.

Keywords: Accuracy, acrylic resin, bite registration, dental implants, flowable composite, pattern resin

INTRODUCTION

Dental implants have been proven successful in the treatment of edentulism. Applications of implants in dentistry include restoration of partially edentulous, single-tooth, and implant overdenture treatments.[1] Most of the researchers reported the open-tray pick-up technique to be more precise and predictable than the closed tray technique using repositionable copings.[2] computer-aided design-computer-aided manufacturing technologies have been developed to fabricate a complete arch substructure for a fixed, screw-retained implant-supported prosthesis. However, because of certain technical aspects (errors include those caused by the computed tomography (CT) procedure, including the steps of image acquisition and data processing, potential mechanical errors, the radiation exposure during pre- and post-operative CT scanning, which is required to evaluate the precision of planned and placed implants, etc.) and the cost factor, these are yet to gain its popularity.[3,4,7]

The results of splinting multiple implants are not always consistent, and there is limited literature available to compare the accuracy of impression techniques as well as materials.[3,5,6] In certain studies, splinting with composite resin and acrylic resin did not present significant difference from the control model regardless of the implant inclination. This in vitro study aims at comparing the accuracy of different conventionally used splinting material with the flowable composite and bite registration paste as splinting materials as these are associated with minimal heat generation and negligible shrinkage.

SUBJECTS AND METHODS

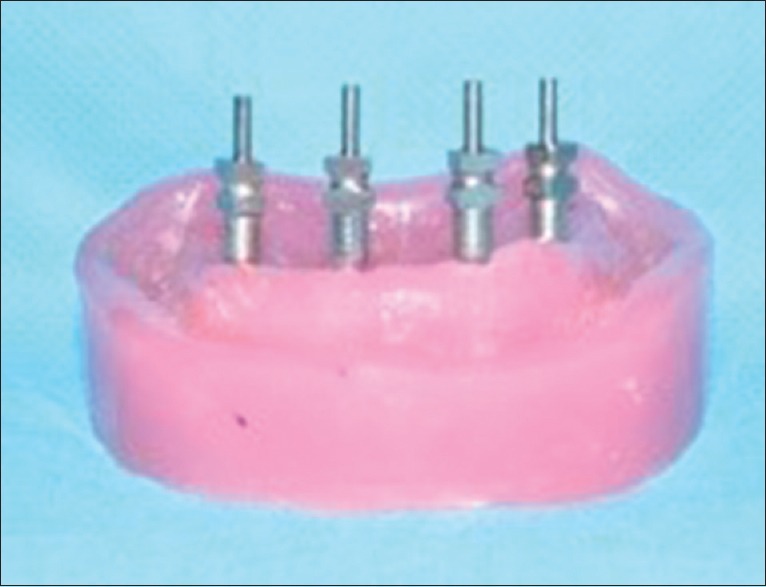

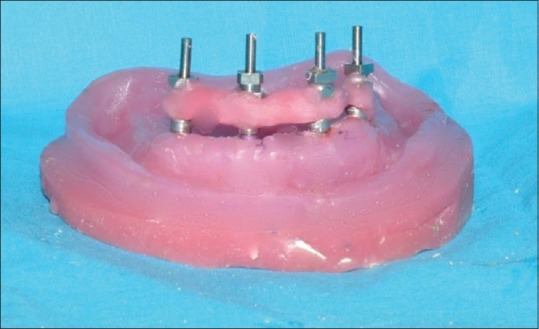

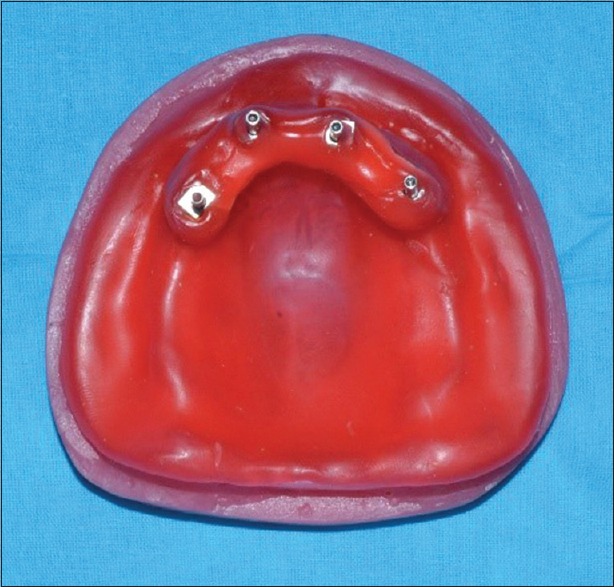

An acrylic resin model was fabricated with heat cure acrylic using a prefabricated rubber mold [Figure 1]. Drilling of four parallel holes at A, B, D, and E positions were done using pilot drill of milling machine. Four 3.75-mm diameter implant analogs with internal hex were placed in the acrylic model. Then, sequential drilling was carried on. The implants analogs, fixed in these sites in the acrylic resin model were sequentially numbered as 1, 2, 3, and 4 from left to right [Figure 2]. Open tray impression copings were then attached to the implant analogs [Figure 3]. The impression copings were secured with 10-mm flat head guide pins on to the implants using a hex drive by applying a torque of 15 N. cm (Newton centimeters).

Figure 1.

Master model fabricated with heat cure acrylic

Figure 2.

Acrylic resin master model with implant analogs drilled in position which are sequentially numbered from left to right from 1 to 4

Figure 3.

Impression copings attached to analogs

For Group A – onto the open tray impression copings, dental floss was looped around tight on each of the copings and firmly secured. Autopolymerizing polymethyl methacrylate was mixed according to the manufacturer's instruction in a porcelain jar and subsequently adapted around on the dental floss and the open tray impression copings and allowed to set [Figure 4]. A custom metal impression tray on which windows has been prepared, coinciding with that of open tray impression copings were coated with vinyl polysiloxane (VPS) adhesive and allowed to dry for 15 min. Material was allowed to polymerize for 17 min. This splints then sectioned using a diamond disk in the center of each section so that a 0.2 mm standardized space was created between each of the splinted sections. The sectioned pieces were then reconnected just before the impression procedure with an incremental application autopolymerizing polymethyl methacrylate resin and attached to the splints. This technique of sectioning and bonding is to minimize polymerization shrinkage of the resin.

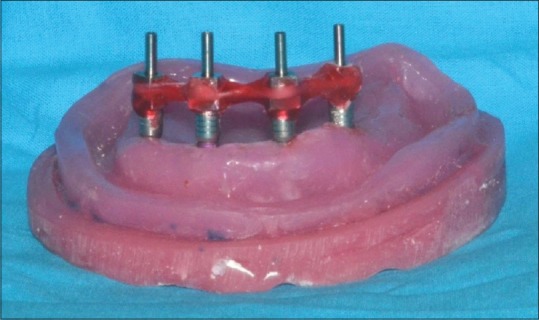

Figure 4.

Impression copings rigidly splinted with flowable composite

A two-layer wax spacer was adapted on the master model [Figure 5]. Tray adhesive was applied on the metal tray. The metal tray was customized to occupy the master model and windows were cut corresponding to the position of implant analogs. Soft putty consistency polyvinylsiloxane impression material was mixed and loaded onto the tray, and they were seated over the resin model with finger pressure. The wax spacer was removed and the impression tray was loaded with light body impression material and a wash impression was made. The stopper added on to the borders of master model ensured even distribution of impression material for all impression. Moreover, any excess material from the open tray windows was removed with a finger swipe to expose the guide pins. This position was maintained throughout the polymerization time. The guide pins were then loosened with a hex driver and the tray was separated from the definitive cast, with the impression copings along with guide pin remaining locked in the impression [Figure 6]. The implant analog was then connected to the hex at the bottom of the impression coping and the guide pins were tightened with the hex driver [Figure 7]. Five impressions were thus made for this group.

Figure 5.

Copings splinted with dental floss

Figure 6.

Impression copings rigidly splinted with acrylic resin after compensation procedures

Figure 7.

Impression copings rigidly splinted with pattern resin

For Group B – dental floss was looped around the impression coping in a similar manner, and splinting was done with pattern resin and the impression procedure was carried out and casts were obtained as previously described [Figure 8].

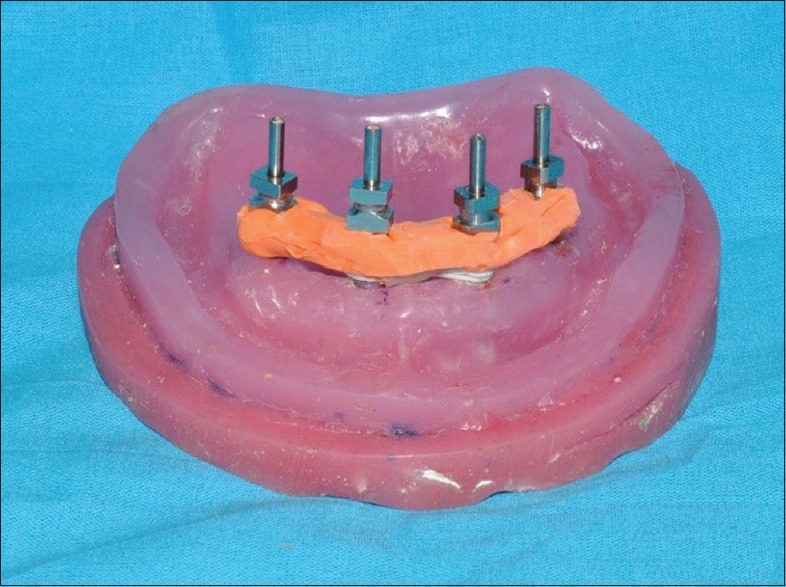

Figure 8.

Impression copings rigidly splinted with bite registration material

For Group C – splinting was achieved with flowable composite. The impression procedure and casts were accomplished as previously described [Figure 9].

Figure 9.

Wax spacer adapted

For Group D – onto the impression copings, dental floss was looped around in a similar manner and the splinting was achieved with an addition silicone-based bite registration material (orange bite). The impression procedure was carried out as in the previous groups. Five impressions were thus made in a similar manner [Figure 10].

Figure 10.

Impression made with polyvinyl siloxane

An American Dental Association Type IV die stone was used in accordance with the manufacturer's instructions to pour the cast. The casts were retrieved from the impressions after 24 h. All the casts were stored at room temperature for a minimum of 24 h before measurements were made [Figure 11]. All clinical and laboratory procedures were performed by the same operator. A single examiner, blinded to the nature of the impression technique used, examined all definitive casts to evaluate the positional accuracy of the implant replicas using a coordinate measuring machine (CMM) [Figure 12].

Figure 11.

Analogs attached to the copings

Figure 12.

Definitive casts poured.jpg

RESULTS

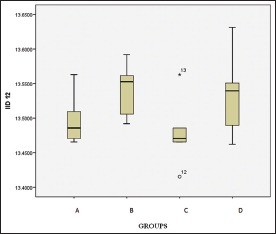

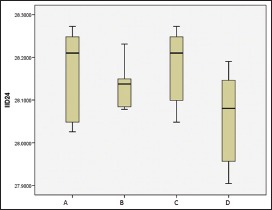

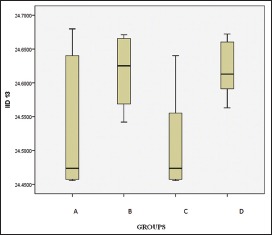

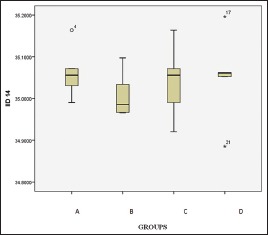

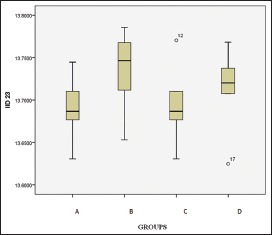

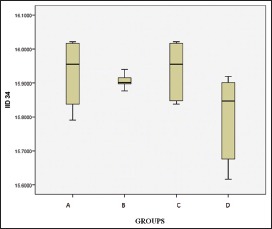

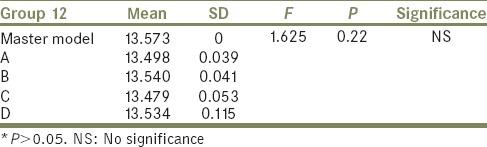

The present in vitro study was conducted to determine the positional accuracy of multiple implants using four different splinting materials. Comparative distance between the centroids of different implant analogs of the master model and all the samples in four different groups were obtained from CMM. Groups were categorized as Group A (splinted with autopolymerizing polymethyl methacrylate), Group B (splinted with pattern resin), Group C (splinted with flowable composite), Group D (splinted with bite registration paste), respectively, depending on the splinting materials used. Results were obtained in millimeters. Descriptive statistics was used to tabulate the data and were analyzed using computer software, Statistical Package for the Social Sciences (SPSS) version 22 (Armonk, NY: IBM Corp.). Data were expressed in its mean and standard deviation. One-way ANOVA was done to analyze the significant difference between the four implant analogs of each group with the master model [Graphs 1–6]. For all statistical evaluations, a probability value < 0.05 was considered statistically significant. The confidence interval was also calculated to assess the accuracy.

Graph 1.

Box plot showing comparison of inter implant distance 1 and 2, between four groups (A, B, C, and D).

Graph 6.

Box plot showing comparison of interimplant distance 2 and 4, between four groups (Group A, B, C and D)

Graph 2.

Box plot showing comparison of inter implant distance 1 and 3, between four groups (A, B, C and D)

Graph 3.

Box plot showing comparison of interimplant distance 1 and 4, between four groups (Group A, B, C and D).

Graph 4.

Box plot showing comparison of interimplant distance 2 and 3, between four groups (Group A, B, C and D)

Graph 5.

Box plot showing comparison of interimplant distance 3 and 4, between four groups (Group A, B, C and D)

DISCUSSION

Impression making and its pouring are critical steps in the process of producing a well-fitting and successful implant prosthesis. Judicious implant placement and its precise reproduction in an impression is essential to establish proper esthetics, occlusion, and preservation of peri-implant tissue health.[1] Splinting is a common practice of joining the transfer copings with a material. Splinting material should be selected based on their property to resist any dimensional changes. This[3,4] attempt to stabilize the copings against rotation during fixture or abutment analog fastening and also controlling the relationship between implants in a rigid fashion.[5,7,8] The choice of an impression material should be based on the consideration of several variables, such as the material accuracy, the amount of intraoral undercuts, the length of time before the impression is poured, and the experience of the clinician.[9,10] Some of the commonly used splinting materials include impression plaster, dental floss, pattern resin, autopolymerizing polymethyl methacrylate, addition silicone, or polyether-based bite registration material. Studies evaluating the relationship between the different type of splinting materials and its accuracy have yielded conflicting results.[11,12] Some authors have advocated the use of splinting, while others have concluded that splinting does not produce superior results especially acrylic is linked with some inevitable shrinkage. Similar amount of deviation values obtained with resin-splinted and bis-GMA-splinted impression copings in recent studies.[13] Lee[14] studied the effect of different splinting materials and found larger distortion among groups with bite registration paste and acrylic resin without compensation procedures. Many authors reported that the splinted technique was more accurate than the unsplinted technique.[15,16] Some authors, discussed potential problems associated with the splinting technique, such as distortion of the splint materials and fracture of the connection between the splint material and the impression copings.[17,18,19,21,22] Ibrahim and Ghuneim[20] found no significant differences when they compared composite resin and acrylic resin. Direct transfer impression technique ensures the high accuracy of transfer of implant positions from master cast to the laboratory cast compared to the indirect transfer impression technique.[21] It is reported that the shrinkage of the acrylic resin would create some errors during the transfer procedure. In recent years, the flowable composite has gained popularity and its use as a splinting material in lieu of the conventionally used materials has been attempted in this study. Taking all these factors into consideration, the study evaluated the accuracy of four different splinting materials and technique in multiple implant impressions.

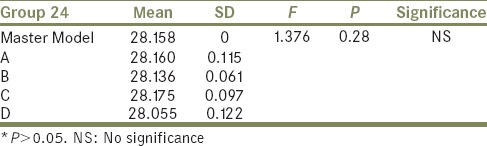

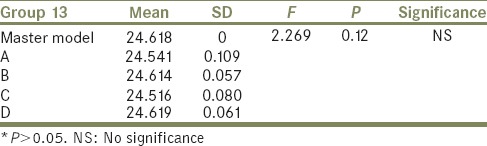

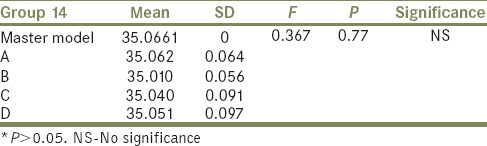

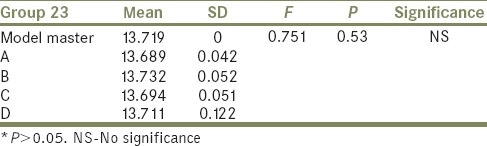

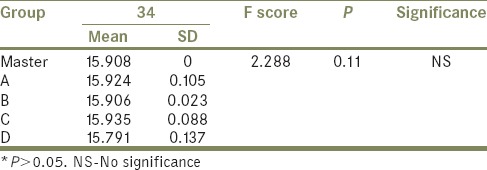

The result of the present study revealed that all splinting materials used in the study can be used for accurate reproduction of spatial relationship. One-way ANOVA was done to analyze the significant difference between the four implant analogs of each group with the master model. There was no significant difference between the centroids of implant analogs of master model and the mean of interimplant distance 1 and 2, 1 and 4, 3 and 4, and 2 and 4. The P values were 0.223, 0.120, 0.770, 0.537, 0.118, and 0.286, respectively [Tables 1–6]. These values were taken into consideration in measuring the accuracy of splinting techniques.

Table 1.

Between group comparison of positional accuracy of implant analogs 1 and 2 when compared with master model

Table 6.

Between group comparison of positional accuracy of implant analogs 2 and 4 when compared with master model

Table 2.

Between group comparison of positional accuracy of implant analogs 1 and 3 when compared with master model

Table 3.

Between group comparison of positional accuracy of implant analogs 1 and 4 when compared with master model

Table 4.

Between group comparison of positional accuracy of implant analogs 2 and 3 when compared with master model

Table 5.

Between group comparison of positional accuracy of implant analogs 3 and 4 when compared with master model

Considering the shrinkage of the material from literature, we have used the sectioned and rewelded material only for our group. VPS bite registration material could be a doubt as a splinting material because of its short working time, low flowability, and elastic property associated with the material although their dimensional stabilities are excellent. However, the result shows that these are also reliable as pattern resin as well as acrylic resin materials, as showed in previous literatures. These showed good dimensional stability as a splinting material. In this study, one standard impression material and technique was used as followed by various researchers who have conducted similar studies. It should be noted that discrepancies were evaluated in a horizontal plane between paired implants.

Under clinical conditions and in multiple implant restorations, these differences may be greater if the discrepancies are present in other spatial planes and if they occur in opposite dimensions.

Thus, such discrepancies may clinically result in a nonprecise fit of the metal supporting structure and potentiate the need for soldering procedures. Since variations in other spatial relationship are negligible when compared to horizontal axis, we have compared the horizontal movements occurred while impression making. Newer materials in this field should be tried and tested for accuracy. However, one of the positive outcomes of this study is that the newer materials such as flowable composite and bite registration paste for splinting implant impressions copings were attempted and was found to be a successful and accurate material similar to conventionally used materials. These could be recommended and tested as materials of choice. The natural tooth can move up to 100 μm within its periodontal ligament, thus compensating for a certain degree of misfit of a fixed partial denture, whereas an osseointegrated implant has extremely limited movement in the range of 10 μm.

This lack of implant flexure means that any tensile, compressive, and bending forces introduced into an implant-supported restoration due to malalignment will almost certainly remain as such. As distortion of an impression can occur in multiple axes such as X, Y, and Z, it is of utmost importance to analyze the distortion in three dimensions. Thus, detection of these spatial differences shows the dimensional inaccuracies of various materials which are used for splinting. The four groups which were tested in our study showed only little significant differences in between. Within the limitation of study, it is concluded that all materials used in the study such as pattern resin, bite registration paste, flowable composite, and acrylic rewelded.

The findings of the present study are in agreement with the majority of previous studies. Most of the literature showed controversial results in each case.[23] In our study, we compared very sensitive groups with acrylic resin with compensation procedures, pattern resin, flowable composites, and bite registration. Literatures regarding evaluation of positional accuracy of implants by splinting with these combinations were limited. The evaluation was done by CMM which is considered as the most accurate machine. During the comparison and evaluation of results, it was realized that all materials used for splinting implants were accurate and pattern resin and bite registration paste had more accurate values similar to master model, though it was statistically insignificant followed by bite registration paste. The results with flowable composite and acrylic resin were similar. Thus, it can be stated that the positional accuracy of implants when splinting with flowable composite as well as bite registration paste were in par with conventionally used pattern resin and acrylic resin. However, considering the chances of errors in other spatial relation, conclusions still need further validation. To come to a full understanding of the subject and the chances of errors in all spatial relations, there is a need for more comprehensive study using multiple parameters. The narrowest confidence interval was found for groups splinted with pattern resin and bite registration paste. More sample size and consideration of more parameters (three dimensional variations such as Y-, Z-axis along with X-axis, more sample sizes, and more in vivo studies) are required for exploring significant difference between groups. The analysis of results obtained from this in vitro study conclusively showed that the splinting of impression copings with flowable composite and bite registration paste showed similar results when compared to conventionally used materials and these could also be recommended as a material of choice. Within the limitation of the study, it was concluded that flowable composite and bite registration material can be recommended as splinting material of choice for multiple implant cases, as these exhibited similar results which is acceptable and accurate with other groups (pattern resin and acrylic resin) which are conventionally used. These materials are recommended due to its ease in manipulation, accuracy, and cost-effectiveness when compared to pattern resin. Hence, these are preferably more advisable in the clinical use.

CONCLUSIONS

The positional accuracy of multiple implants splinted with different materials was analyzed in the present study. A total of 20 samples with four different groups were analyzed in the study. Five casts were obtained from each group. The groups were divided as Group A, B, C, and D, which were autopolymerizing acrylic resin, pattern resin, flowable composite, bite registration paste, respectively. Within the limitation of this study, the following conclusions were drawn.

Splinting of open tray impression copings with materials of all four groups showed minimal variation in positions of multiple implants

The readings were very close to the reference model and within the clinical limits. No statistically significant difference were revealed between different groups such as flowable composite, bite registration paste, pattern resin, and acrylic resin which was sectioned and rewelded

Mean values of group with 95% confidence interval showed minimum deviation for pattern resin group and bite registration paste group when compared to master model while measuring interimplant distances

Groups with flowable composite and acrylic resin showed similar results although no statistical significance was derived

Thus, it is observed that the splinting materials showed the same amount of variation from the reference model, and these splinting materials were statistically similar to each other and fell in same homogenous subsets.

This study concluded that flowable composite and bite registration material can also be recommended as splinting material of choice for multiple implant cases, as these exhibited similar results which is acceptable and accurate with other groups (pattern resin and acrylic resin) which are conventionally used. These materials are recommended due to its ease in manipulation, accuracy, and cost-effectiveness when compared to pattern resin. Hence, these are preferably more advisable in the clinical use. Considering the chances of errors in other spatial relation, conclusions still need further validation. To come to a full understanding of the subject and the chances of errors in all spatial relations, there is a need for more comprehensive study with various materials of clinical use which are readily available, and using multiple parameters and more sample sizes.

Financial support and sponsorship

Supported by a grant from indian council of medical research(ICMR), human resource development, government of india

Conflicts of interest

There are no conflicts of interest.

REFERENCES

- 1.Carr AB. Comparison of impression techniques for a two-implant 15-degree divergent model. Int J Oral Maxillofac Implants. 1992;7:468–75. [PubMed] [Google Scholar]

- 2.Burawi G, Houston F, Byrne D, Claffey N. A comparison of the dimensional accuracy of the splinted and unsplinted impression techniques for the bone-lock implant system. J Prosthet Dent. 1997;77:68–75. doi: 10.1016/s0022-3913(97)70209-9. [DOI] [PubMed] [Google Scholar]

- 3.Wee AG. Comparison of impression materials for direct multi-implant impressions. J Prosthet Dent. 2000;83:323–31. doi: 10.1016/s0022-3913(00)70136-3. [DOI] [PubMed] [Google Scholar]

- 4.Vigolo P, Majzoub Z, Cordioli G. In vitro comparison of master cast accuracy for single-tooth implant replacement. J Prosthet Dent. 2000;83:562–6. doi: 10.1016/s0022-3913(00)70015-1. [DOI] [PubMed] [Google Scholar]

- 5.Herbst D, Nel JC, Driessen CH, Becker PJ. Evaluation of impression accuracy for osseointegrated implant supported superstructures. J Prosthet Dent. 2000;83:555–61. doi: 10.1016/s0022-3913(00)70014-x. [DOI] [PubMed] [Google Scholar]

- 6.Akça K, Cehreli MC. Accuracy of 2 impression techniques for ITI implants. Int J Oral Maxillofac Implants. 2004;19:517–23. [PubMed] [Google Scholar]

- 7.Michalakis KX, Kalpidis CD, Kang K, Hirayama H. A simple impression technique for dental implants placed in close proximity or adverse angulations. J Prosthet Dent. 2005;94:293–5. doi: 10.1016/j.prosdent.2005.05.027. [DOI] [PubMed] [Google Scholar]

- 8.Fueki K, Kimoto K, Ogawa T, Garrett NR. Effect of implant-supported or retained dentures on masticatory performance: A systematic review. J Prosthet Dent. 2007;98:470–7. doi: 10.1016/S0022-3913(07)60147-4. [DOI] [PubMed] [Google Scholar]

- 9.Cabral LM, Guedes CG. Comparative analysis of 4 impression techniques for implants. Implant Dent. 2007;16:187–94. doi: 10.1097/ID.0b013e3180587b3f. [DOI] [PubMed] [Google Scholar]

- 10.Walker MP, Ries D, Borello B. Implant cast accuracy as a function of impression techniques and impression material viscosity. Int J Oral Maxillofac Implants. 2008;23:669–74. [PubMed] [Google Scholar]

- 11.Faria AC, Rodrigues RC, Macedo AP, Mattos Mda G, Ribeiro RF. Accuracy of stone casts obtained by different impression materials. Braz Oral Res. 2008;22:293–8. doi: 10.1590/s1806-83242008000400002. [DOI] [PubMed] [Google Scholar]

- 12.Lee H, So JS, Hochstedler JL, Ercoli C. The accuracy of implant impressions: A systematic review. J Prosthet Dent. 2008;100:285–91. doi: 10.1016/S0022-3913(08)60208-5. [DOI] [PubMed] [Google Scholar]

- 13.Wenz HJ, Hertrampf K. Accuracy of impressions and casts using different implant impression techniques in a multi-implant system with an internal hex connection. Int J Oral Maxillofac Implants. 2008;23:39–47. [PubMed] [Google Scholar]

- 14.Lee HJ, Lim YJ, Kim CW, Choi JH, Kim MJ. Accuracy of a proposed implant impression technique using abutments and metal framework. J Adv Prosthodont. 2010;2:25–31. doi: 10.4047/jap.2010.2.1.25. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Sorrentino R, Gherlone EF, Calesini G, Zarone F. Effect of implant angulation, connection length, and impression material on the dimensional accuracy of implant impressions: An in vitro comparative study. Clin Implant Dent Relat Res. 2010;12(Suppl 1):e63–76. doi: 10.1111/j.1708-8208.2009.00167.x. [DOI] [PubMed] [Google Scholar]

- 16.Hariharan R, Shankar C, Rajan M, Baig MR, Azhagarasan NS. Evaluation of accuracy of multiple dental implant impressions using various splinting materials. Int J Oral Maxillofac Implants. 2010;25:38–44. [PubMed] [Google Scholar]

- 17.Prithviraj DR, Malesh L, Pooja G, Shruthi DP. Accuracy of the implant impression obtained from different impression materials and techniques: Review. J Clin Exp Dent. 2011;3:106–11. [Google Scholar]

- 18.Lee SJ, Cho SB. Accuracy of five implant impression technique: Effect of splinting materials and methods. J Adv Prosthodont. 2011;3:177–85. doi: 10.4047/jap.2011.3.4.177. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Ma J, Rubenstein JE. Complete arch implant impression technique. J Prosthet Dent. 2012;107:405–10. doi: 10.1016/S0022-3913(12)60100-0. [DOI] [PubMed] [Google Scholar]

- 20.Ibrahim TO, Ghuneim WA. Composite resin versus two different splinting techniques on evaluation of impression accuracy for dental implants. Life Sci J. 2013;10:12. [Google Scholar]

- 21.Balamurugan T, Manimaran P. Evaluation of accuracy of direct transfer snapon impression coping closed tray impression technique and direct transfer open tray impression technique: An in vitro study. J Indian Prosthodont Soc. 2013;13:226–32. doi: 10.1007/s13191-012-0141-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Geramipanah F, Sahebi M, Davari M, Hajimahmoudi M, Rakhshan V. Effects of impression levels and trays on the accuracy of impressions taken from angulated implants. Clin Oral Implants Res. 2015;26:1098–105. doi: 10.1111/clr.12410. [DOI] [PubMed] [Google Scholar]

- 23.Selvaraj S, Dorairaj J, Mohan J, Simon P. Comparison of implant cast accuracy of multiple implant impression technique with different splinting materials: An in vitro study. J Indian Prosthodont Soc. 2016;16:167–75. doi: 10.4103/0972-4052.167937. [DOI] [PMC free article] [PubMed] [Google Scholar]