Abstract

Allicin is considered responsible for most of the pharmacological activity of crushed raw garlic cloves. However, when garlic supplements and garlic foods are consumed, allicin bioavailability or bioequivalence (ABB) has been unknown and in question because allicin formation from alliin and garlic alliinase usually occurs after consumption, under enzyme-inhibiting gastrointestinal conditions. The ABB from 13 garlic supplements and 9 garlic foods was determined by bioassay for 13 subjects by comparing the area under the 32-h concentration curve of breath allyl methyl sulfide (AMS), the main breath metabolite of allicin, to the area found after consuming a control (100% ABB) of known allicin content: homogenized raw garlic. For enteric tablets, ABB varied from 36–104%, but it was reduced to 22–57% when consumed with a high-protein meal, due to slower gastric emptying. Independent of meal type, non-enteric tablets gave high ABB (80–111%), while garlic powder capsules gave 26–109%. Kwai garlic powder tablets, which have been used in a large number of clinical trials, gave 80% ABB, validating it as representing raw garlic in those trials. ABB did not vary with alliinase activity, indicating that only a minimum level of activity is required. Enteric tablets (high-protein meal) disintegrated slower in women than men. The ABB of supplements was compared to that predicted in vitro by the dissolution test in the United States Pharmacopeia (USP); only partial agreement was found. Cooked or acidified garlic foods, which have no alliinase activity, gave higher ABB than expected: boiled (16%), roasted (30%), pickled (19%), and acid-minced (66%). Black garlic gave 5%. The mechanism for the higher than expected ABB for alliinase-inhibited garlic was explored; the results for an alliin-free/allicin-free extract indicate a partial role for the enhanced metabolism of γ-glutamyl S-allylcysteine and S-allylcysteine to AMS. In conclusion, these largely unexpected results (lower ABB for enteric tablets and higher ABB for all other products) provide guidelines for the qualities of garlic products to be used in future clinical trials and new standards for manufacturers of garlic powder supplements. They also give the consumer an awareness of how garlic foods might compare to the garlic powder supplements used to establish any allicin-related health benefit of garlic.

Keywords: allicin bioavailability, allicin metabolism, allyl methyl sulfide, alliin, S-allylcysteine, garlic supplements, cooked garlic, pickled garlic, black garlic, aged garlic extract

1. Introduction

Garlic supplements, mainly dried and pulverized whole clove supplements, have been used in a large number of controlled clinical trials since the mid-1980s, focusing primarily on serum cholesterol and blood pressure [1,2,3]. The effects on blood pressure have been moderately consistent for hypertensive subjects, while the effects on serum lipids have been inconsistent, even for persons with high baseline cholesterol levels [1,2,4,5,6]. Of the 23 qualifying trials on serum cholesterol with a garlic powder product, 43% found no effect [1]. Due to the inconsistencies, the trials have been the subject of several meta-analyses (nine on serum lipids and eight on blood pressure), with the overall conclusions being conservative [7]. Authors of the meta-analyses most frequently cite the high heterogeneity among the trials (high variation in dose, variable product types, identification of active compounds, standardization concerns, and unknown bioavailability) as the reason for caution in recommending garlic products for treatment of hypercholesterolemia and hypertension [1,4,5,7,8,9,10,11]. A recent review of the mostly in vitro antimicrobial effects of allicin concluded that determination of allicin bioavailability from various products is necessary before proper clinical studies can be conducted [12]. Hence, it is clear that attention needs to be given to the bioavailability and standardization of garlic’s active compounds under a variety of processing conditions, especially because of known or suspected potential issues with their formation, stability, metabolism, and detection in the body.

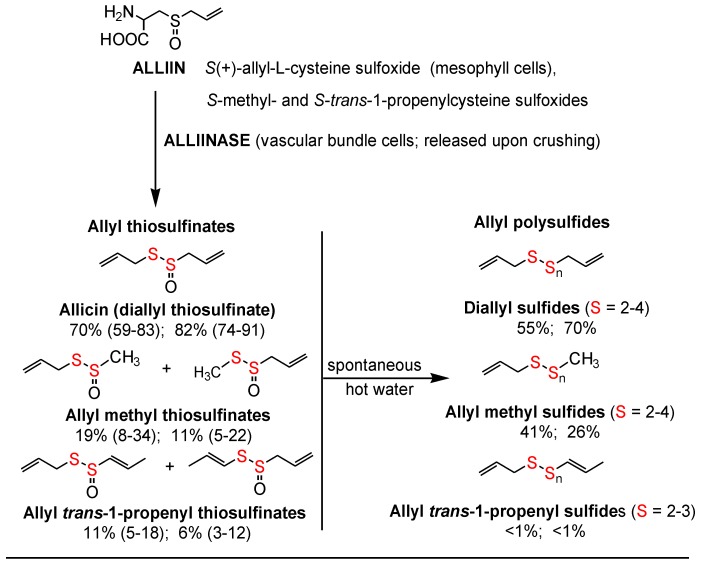

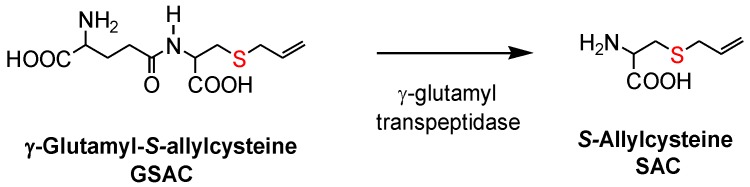

The allyl thiosulfinates, of which allicin (diallyl thiosulfinate) is the most abundant and most studied member (Figure 1), are enzymatic products of alliin, S(+)-allyl-l-cysteine sulfoxide, and alliinase. They are rapidly formed when raw garlic cloves undergo cell rupture (Figure 1) or when dried and pulverized cloves (garlic powder) become wet [13,14]. The allyl thiosulfinates have been shown to be responsible for most of the pharmacological activity of crushed raw garlic cloves. Beginning in 1944 it was shown that allicin is responsible for the antibacterial activity of garlic and that selective removal of allicin also removed all activity [15,16]. Considerable evidence suggests that the allyl thiosulfinates, or their spontaneous transformation compounds (allyl polysulfides), or their common metabolite (allyl methyl sulfide, AMS), Figure 1 and Figure 2, are responsible for most of the lipid-lowering, antioxidant, anti-atherosclerotic, and anticancer effects of whole garlic, as observed in animals and humans [13,17]. Both allicin and γ-glutamyl-S-allylcysteine (GSAC), as the source of S-allylcysteine (SAC) (Figure 1), appear to be responsible for the hypotensive effects of garlic [18]. Indeed, no other compound has yet been shown to have significant activity at levels present in a normal human dose (3–5 g) of crushed raw garlic. The majority of the clinical trials on the possible cardiovascular effects of garlic have used supplements that are standardized on alliin or allicin potential [1,2].

Figure 1.

Structures of the known significant S-allyl compounds derived from garlic, including transformation reactions. The compounds above the horizontal line comprise alliin and alliin-derived dithioallyl compounds (AADD).The first set of values for the allyl thiosulfinates represent the average, minimum, and maximum mol % of total allyl thiosulfinates found for 26 samples from six countries; the second set is the S-allyl mol % or percent of the alliin transformed to each thiosulfinates—allicin increased because it is has two S-allyl groups [19,20]. The values for the allyl polysulfides represent the average mol % and S-allyl mol % for five samples of steam-distilled garlic oil capsules; small amounts of penta- and hexasulfides (3%) are also present in these oils [21,22] (p. 100). Spontaneous formation of the allyl polysulfides from the thiosulfinates (rapid in hot water, slow in ambient water) results in loss of about 25% of the total S-allyl, due to the formation of SO2, propene, and allyl alcohol [23,24].

Figure 2.

Metabolism of allyl thiosulfinates and allyl polysulfides. R represents allyl, methyl, or trans-1-propenyl. When R is allyl (allicin or diallyl sulfides), two moles of allyl mercaptan and allyl methyl sulfide (AMS) are formed.

Due to the abundance of alliinase [25], complete formation of allicin takes place in 0.5 min (5 min for the allyl methyl thiosulfinates) when water is added to garlic powder [14]. However, their formation in the body after consumption of garlic powder supplements is questionable because alliinase is inactive at pH 3.5 or below [14,26], a pH range commonly found in the stomach, although a moderate to high-protein meal can briefly raise the pH to 4.4 or higher [27,28], a range in which alliinase is active. Hence, many brands of garlic supplements have been enteric-coated to prevent disintegration in the stomach, and the U.S. Pharmacopeia (USP) has established a monograph for estimating allicin formation and release from such products under simulated gastrointestinal dissolution conditions [29]. However, 21 of 24 enteric brands subjected to this dissolution allicin release test yielded less than 20% of their allicin potential (the maximum yield of allicin from alliin upon activation of alliinase; the USP monograph refers to it as “potential allicin”), due to low tablet alliinase activity and to slow tablet disintegration [30]. Similarly, dissolution allicin release from non-enteric Kwai (Lichtwer Pharma, Berlin) tablets, the most commonly used garlic supplement in cardiovascular clinical trials [1,2], has also been found to be problematic: 44% for tablets made before 1993 and only 15% for tablets made from 1994–1997 [31].

The surprisingly low allicin release found under these standardized in vitro conditions indicates either that allicin release in the body from most garlic supplements is very low or that the U.S.P. dissolution test is not accurate. This dilemma highlights the need to determine the allicin bioavailability in vivo from garlic products, but attempts to do so have been troublesome. Allicin has been shown to be metabolized rapidly (half-life <1 min) to allyl mercaptan (allyl thiol) when added to whole blood [32], but neither allicin nor its transformation compounds (Figure 1) nor allyl mercaptan were found in the blood, urine or stool after volunteers consumed a large amount (25 g) of chopped raw garlic [33] (p. 152). However, it has been known for some time that AMS is a component of human breath after consuming raw garlic and that its rate of appearance and decline in the breath indicated it to be a product of systemic metabolism [34,35,36]. Lawson and Wang [17] conducted studies on human breath AMS and showed that (a) the area under the 32-h breath AMS concentration curve (AUC) is linearly proportional to the amount of allicin consumed; (b) AMS is the main breath metabolite of allicin, accounting for at least 90% of the allicin consumed; (c) allyl mercaptan is a temporary intermediate in the formation of AMS from allicin; (d) allicin-derived diallyl disulfide and diallyl trisulfide are also metabolized mainly to AMS; and (e) AMS is an active metabolite, responsible for the ability of allicin to increase breath acetone levels. By the use of a sulfur-selective detector, the sensitivity of the method was improved for the consumption of small amounts of garlic [37]. Hence, a validated method for determining the bioavailability of allicin from any garlic product has been established.

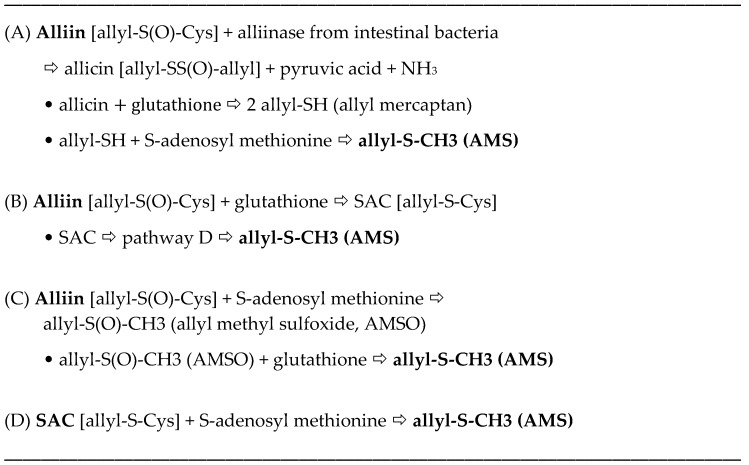

The term “allicin bioavailability” is being used to represent the sum of three processes: enzymatic (garlic alliinase) formation of allyl thiosulfinates (mainly allicin) from alliin, usually in the gastrointestinal tract, followed by their absorption and metabolism to a quantifiable metabolite, AMS. Allicin absorption is known to be highly efficient [38,39], although partial metabolism to the rapidly absorbed intermediate, allyl mercaptan, may occur during absorption [17]. The term “allicin bioequivalence” refers to the metabolic formation of the allicin metabolite, AMS, from any S-allyl compound, without the assistance of garlic alliinase, including allyl polysulfides, alliin and possibly other S-allyl compounds, such as GSAC and SAC; the term is being used in particular for products in which garlic alliinase is inactive. Together, the terms are referred to as allicin bioavailability or bioequivalence (ABB).

Although garlic supplements have been used in a large number of clinical trials, garlic is most commonly consumed as a food, usually as a cooked food and often as a commercial product suspended in an acid, such as whole cloves (pickled garlic) or small pieces (minced garlic), but no known clinical trials have been conducted with cooked or acidified garlic foods. However, the general public often wants to know if the results of clinical trials with supplements apply to garlic as a food, especially cooked garlic. In the U.S., cooked garlic is commonly prepared by boiling (soups) or roasting [40,41]. Because cooking or suspending garlic in acid fully inactivates alliinase [14,26], any allicin-related health benefits found with garlic supplements will probably be negligible in such foods. However, this logic assumes that the body itself—in the absence of active garlic alliinase—does not have the ability to metabolize alliin to allicin or allicin metabolites. Now that a method exists for determining the ABB of any garlic product, the validity of this assumption can be tested for alliinase-inhibited garlic foods.

The primary objective of this study has been to determine the problematic and hitherto unknown bioavailability of allicin from a variety of commonly consumed garlic supplements and garlic foods, in order to provide clinical trial researchers, manufacturers, and consumers with an improved knowledge basis when considering the possible health benefits of garlic products. The study has answered the following questions:

Can allicin bioavailability from garlic powder supplements be as high as that from crushed raw garlic?

Is the allicin bioavailability of the main garlic powder supplement (Kwai) used in clinical trials significantly less than that of raw garlic?

Is the allicin bioavailability of enteric garlic supplements greater than that of non-enteric ones?

Does the protein content of the meal being consumed with the supplement influence the allicin bioavailability?

How much supplement alliinase activity is necessary to achieve high allicin bioavailability?

What standards are recommended for the quality, content, and allicin bioavailability of garlic supplements being used in clinical trials?

Is the in vitro USP. dissolution allicin release test accurate for estimating allicin bioavailability from garlic supplements?

Do cooked garlic or acidified commercial garlic products have significant allicin bioequivalence? If so, how much of these foods would one need to consume to obtain the same ABB as raw garlic or a garlic powder supplement used in clinical trials?

Do garlic compounds other than alliin-derived compounds have significant allicin bioequivalence?

2. Materials and Methods

2.1. Standards

l(+)- and l(±)-S-allylcysteine sulfoxides (natural and racemic alliin), S-allylcysteine, diallyl disulfide, and diallyl trisulfide (each ≥98%) were purchased from LKT Laboratories, Inc. (St. Paul, MN, USA). Allyl methyl sulfide and diallyl sulfide (each 99%) were purchased from Sigma-Aldrich (St. Louis, MO, USA). γ-Glutamyl-S-allylcysteine (99%) was purchased from U.S. Pharmacopeia (Rockville, MD, USA). Allicin (98%) was prepared by oxidation of diallyl disulfide with hydrogen peroxide, followed by purification, as previously described [30]. Its concentration was validated with a second allicin standard prepared from alliin and crude alliinase [29]. Allyl methyl thiosulfinates, allyl-1-propenyl thiosulfinates, diallyl tetrasulfide, allyl methyl disulfide, allyl methyl trisulfide, and allyl methyl tetrasulfide were identified and quantified based on their relative retention times and relative extinction coefficients, compared to allicin and diallyl trisulfide, as previously described [19,21].

2.2. Control

The control for 100% ABB was prepared by homogenization of 500 g of peeled raw garlic cloves (California Late variety, Garlic World, Gilroy, CA, USA; 39.5% dry weight), after addition of water at 0.60 mL/g, in an Osterizer blender at the highest speed for 2 min. This allowed alliinase to transform all of the alliin to known amounts of allicin and other allyl thiosulfinates. The homogenate was divided into 50-mL jars and stored at −80 °C, under which condition the allyl thiosulfinates have been shown to be stable for at least 24 months [37]. Prior to consumption, the homogenate was thawed overnight at 4 °C, at which temperature the allyl thiosulfinates have been shown to be stable for at least 3 days [30]. After thawing, the homogenate was further macerated with a high speed Polytron homogenizer (Brinkmann, Kinematica AG, Luzern, Switzerland) with a 12-mm generator for 1 min at speed 6 of 10. This made it possible for the viscous homogenate to pass through the modified tip (drilled to 3 mm, inside diameter) of a 10-mL disposable syringe. At the time of consumption, a specific weight of the homogenate was transferred by syringe into the bottom of one or more size 0 hypromellose (hydroxypropyl methylcellulose) capsules (vegetarian capsules). The bottom of the size 0 capsule rested inside the bottom of a size 00 capsule to prevent aqueous allicin from coming in contact with the throat. The capsule was then closed with the top of a size 00 capsule. Under these conditions, the outer capsule remained firm and tasteless for 6 min. The standard control was 1.4 g of garlic homogenate, which was made from 0.88 g of raw garlic (0.35 g dry wt).

2.3. Supplements

All garlic supplements used in the study were purchased in 2009 at local stores or from online distributors and stored at ambient temperature. Only C1 was purchased directly from the manufacturer. All were tested by May 2011, within their claimed expiration dates (typically 2 years from the manufacture date, except 3 years for N1 and N4), with two intended exceptions (E6 and N4). Table 1 identifies the garlic supplements used in the study and includes the claims for garlic powder content (sometimes called garlic extract content or garlic dry weight), the actual tablet or capsule weights (average of at least 10 units), standardization claims, if any, and the recommended dose. All labels stated that the products should be consumed with a meal, except for N3. Table 2 gives the complete list of other ingredients for the supplements, with indications for the likely enteric coating agents when not specifically stated. The 13 supplements contained 51 different ingredients other than garlic powder.

Table 1.

Garlic supplements: identification and claims for garlic powder content and standardization. 1

| ID | Brand Name and Lot Number | Manufacturer | Garlic Powder Claim per Tablet or Capsule (g) | Weight of Tablet or Capsule 2 (g) | Standardization Claims (per Tablet or Capsule) | Daily Dose 3 |

|---|---|---|---|---|---|---|

| Enteric coated tablets (all claim to be enteric coated) | ||||||

| E1 | Garlicin (584401) | Nature’s Way Products, Inc., Springville, UT, USA | 0.35 | 0.66 | 3.2 mg allicin | 1 × 2 |

| E2 | Garlique (09A301) | Chattem, Inc., Chattanooga, TN, USA | (0.40) 4 | 0.67 | ≥5.0 mg allicin | 1 × 1 |

| E3 | Garlinase Fresh (95178189) | Enzymatic Therapy, Inc., Green Bay, WI, USA | 0.32 | 0.48 | 11 mg alliin, 5.0 mg allicin | 1 × 1 |

| E4 | Garlic-Gold (8097) | Olympian Labs, Inc., Scottsdale, AZ, USA | 0.60 | 0.99 | 15.6 mg alliin, 7.2 mg allicin | 1 × 1 |

| E5 | Sundown Naturals Odor-Free Garlic (239029-09) | Sundown, Inc., Boca Raton, FL, USA | 0.40 | 0.74 | none | 1 × 2–3 |

| E6 | NOW Pure-Gar Garlic (104872) | NOW Foods, Glendale Heights, IL, USA (manufactured 1999) | 0.60 | 0.90 | 5.0 mg allicin | 1 × 1 |

| Normal (non-enteric) tablets | ||||||

| N1 | Kwai forte 300 mg 5 (02051450) | Klosterfrau, Cologne, Germany | 0.30 | 0.75 | 3.9 mg alliin, 1.8 mg allicin | 1 × 3 |

| N2 | Odor Free Garlic (197348-04) | Nature’s Bounty, Inc., Bohemia, NY, USA | 0.10 | 0.26 | “contains allicin” | 1 × 3–6 |

| N3 | Natural Brand Odorless Garlic 1000 (2522EJ1818) | General Nutrition Corp., Pittsburgh, PA, USA | 1.00 | 1.80 | none | 1 × 1–2 |

| N4 | Kwai 5 (92021901) | Lichtwer Pharma, GmbH, Berlin, Germany (manufactured 1992) | 0.10 | 0.27 | 1.3 mg alliin, 0.6 mg allicin | 2 × 3 |

| Capsules | ||||||

| C1 | Garlic (00839138) | Nature’s Sunshine Products, Inc., Spanish Fork, UT, USA | 0.55 fine 6 |

0.67 | none | 1 × 2 |

| C2 | Deodorized Garlic 500 (2040348) | Vitamin Shoppe, Inc., North Bergen, NJ, USA (Pure-Gar garlic powder) | 0.50 fine 6 |

0.69 | none | 1–3 3 |

| C3 | GarliPure 500 mg (2037406) | Natrol, Inc., Chatsworth, CA, USA (Pure-Gar garlic powder) | 0.50 coarse 6 |

0.68 | 5.0 mg alliin, 0.75 mg allicin 7 | 2 × 2 |

1 All supplements were manufactured in the U.S., except N1 and N4. 2 Average weight of at least 10 tablets or capsules (including shell). 3 Daily dose recommended on the product label. The first number is the number tablets or capsules recommended per meal; the second number is the number of times per day this amount is to be consumed. For example, 1 × 2–3 means to take 1 tablet two or three times per day. Product C2 simply stated to take 1–3 capsules per day. 4 For E2, no claim was made for the amount of garlic powder; it is estimated to be 0.40 g garlic powder per tablet, based on an average of 60% of tablet weight. 5 Kwai or Kwai Sapec or Kwai forte was originally made by Lichtwer Pharma, GmbH, Berlin, using 300 mg of LI 111 garlic powder that was standardized to contain 1.3% alliin and to yield 0.6% allicin. The tablets were used in numerous cardiovascular clinical trials from 1986 to 2005. In 2007, Lichtwer Pharma was sold to Klosterfrau Healthcare Group, Cologne, Germany, which has sold the same tablets under the names of Kwai forte 300 mg (apo-discounter.de) and Kwai Heartcare Garlic 300 mg (standardized allicin yield of 0.6% or 1.8 mg per tablet), with minor changes in the excipients. Kwai has also been sold in smaller tablets (100 mg garlic powder, product N4). 6 Sieving results. C1 contained fine, almost white particles: 91% smaller than 125 μm, 3% larger than 250 μm. C2 contained fine, almost white, and some darker particles: 85% smaller than 125 μm, 0.8% larger than 250 μm. C3 contained coarse, light brown and medium brown particles: 6% smaller than 125 μm, 79% larger than 250 μm. When C3 was purchased again (lot 2065372), seven years later (2016), the powder was much finer and appeared identical to product C2. 7 The claimed ratio of alliin to allicin is unusually high, 6.7. The normally claimed weight ratio of alliin to allicin is 2.2, representing a mole ratio of 2.0. However, the actual alliin to allicin weight ratio for garlic cloves and powders is about 2.5 because about 20% of the alliin forms other allyl thiosulfinates [19,20].

Table 2.

Other ingredients in the garlic supplements, including possible enteric-coating agents: complete list, in the same order as on the label claims.

| Supplement | Other Ingredients |

|---|---|

| Enteric coated | |

| E1 1 | cellulose, aqueous coating solution, modified cellulose gum, stearic acid 2, silica |

| E2 | silicified microcrystalline cellulose, croscarmellose sodium, methacrylic acid, hypromellose, magnesium stearate, stearic acid 2, magnesium silicate, titanium dioxide, mineral oil, triacetin 2, polyethylene glycol 2, microcrystalline cellulose, glycerol monostearate, triethyl citrate 2, sodium lauryl sulfate |

| E3 | cellulose, modified cellulose, modified cellulose gum, silica, titanium dioxide, calcium stearate, fractionated coconut oil, sodium alginate 2, vegetable glycerin, stearic acid 2 |

| E4 | enteric coating 2 (Eudagrit L30D-55, triethyl citrate, methylcellulose), microcrystalline cellulose, dicalcium phosphate, ascorbyl palmitate, modified cellulose, silica, stearic acid 2, corn starch |

| E5 | calcium phosphate, cellulose, calcium carbonate, croscarmellose, cellulose coating 2, titanium dioxide, calcium silicate, food glaze, magnesium stearate, sodium alginate 2 |

| E6 1 | calcium phosphate, cellulose, magnesium stearate, stearic acid 2, silica, enteric coating |

| Normal (non-enteric) tablets | |

| N1 | lactose, cellulose, silica, magnesium stearate, castor oil, polyethylene glycol, hypromellose, sucrose, magnesium silicate, gelatin, povidone K25, carnauba wax, bleached wax, quinoline yellow E104, indigo carmine 132 |

| N2 | cellulose, dicalcium phosphate, titanium dioxide, silica, magnesium silicate, calcium carbonate, magnesium stearate, natural flavor |

| N3 | calcium carbonate, cellulose, titanium dioxide, acetoglycerides |

| N4 | lactose, cellulose, silica, magnesium stearate, sucrose, magnesium silicate, calcium carbonate, gum arabic, shellac, glucose, castor oil, bees wax |

| Capsules | |

| C1 | gelatin, water |

| C2 | gelatin, water, magnesium stearate, silicon dioxide |

| C3 | gelatin, water, magnesium stearate |

1 Products E1 and E6 do not list a main enteric coating agent. Later labels for product E1 (© 2013–© 2016) omitted the phrase “aqueous coating solution” and included sodium alginate, a common enteric coating agent; however, the newer tablets have a different appearance (less shine) than those used in this study, indicating a change in the coating formulation. 2 Known enteric coating agents. Stearic acid has additional purposes in tablet formulation. Only product E4 specifically stated which ingredients were used for the enteric coating.

2.4. Commercially Prepared Garlic Foods

Three common (purchased at grocery stores) and one less common (black garlic, purchased online) commercially prepared garlic foods were tested for ABB. The manufacturing procedures for all the products inactivates alliinase. Spicy Pickled Garlic (referred to as pickled garlic), manufactured by G.L. Mezzetta, Inc. (Napa Valley, CA, USA) consisted of whole raw cloves suspended in a medium of water, vinegar, crushed chili, and sodium bisulfite; cloves constituted 65% of the total volume. The pH of a 1:10 aqueous extract of the cloves was 4.3; the pH of the undiluted medium was also 4.3. Minced Garlic (referred to as acid-minced garlic), manufactured by Spice World, Inc. (Orlando, FL, USA) consisted of finely minced raw cloves mixed with a minimal amount of water (almost no standing liquid) and phosphoric acid; the pH of a 1:10 aqueous extract was 3.6. Chopped Garlic (referred to as oil-chopped garlic), manufactured by Christopher Ranch (Gilroy, CA, USA), consisted of finely chopped raw garlic mixed with soybean oil, olive oil (almost no standing liquid) and citric acid; the pH of a 1:10 aqueous extract was 4.3. The manufacturer’s web site calls it Chopped Garlic in Oil. Black garlic, manufactured in South Korea and distributed by Black Garlic, Inc. (Hayward, CA, USA), consisted of peeled whole cloves that were black (no additives).

2.5. Kitchen-Prepared Garlic Foods (Cooked and Raw Diced)

Roasted. Garlic (California Early variety, Garlic World, Gilroy, CA, USA) was roasted at two different temperatures commonly used for cooking (actual air temperature): 160 °C for 30 min and 215 °C for 60 min. Three garlic bulbs were placed on a rack inside a pre-heated Nesco 6 L electric roaster oven (Walmart). Wire probes from a calibrated Fluke 52II digital thermometer (Fluke Corp., Everett, WA, USA) were used to measure the temperature (recorded every 5–10 min) of the air inside the oven and the temperature inside the cloves of two different bulbs. The average temperature inside the cloves, after the first 10 min, was 92 °C for the 160 °C preparation and 101 °C for the 215 °C preparation. Roasting caused 5% and 25% loss of total weight, respectively. After cooling, the cloves were peeled and the soft contents thoroughly mashed and mixed. All of the contents of the 160 °C cloves were soft, but about half of the weight of the 215 °C cloves was hard and unusable. Roasting decreased the moisture content of the cloves from 63% to 58% and 55%, respectively.

Boiled. Unpeeled garlic cloves (California Early variety, Garlic World, Gilroy, CA, USA) were boiled for 4 min or for 45 min, by adding 24 cloves (80 g for 4 min or 110 g for 45 min) from six bulbs to 1.5 L of boiling water. The water resumed boiling about 15 s after the cloves were added. After boiling, the cloves were cooled, peeled, and thoroughly mashed and mixed. Preliminary studies showed that the temperature inside the cloves reached 95 °C (boiling point 96 °C) by 4 min if the clove weights were under 5 g or by 6 min if the clove weights were 5.5 to 7 g. It was also shown that alliinase activity was completely inhibited in 2 min for cloves weighing under 5 g. Hence, for the 4 min preparation, only cloves weighing 1.2 to 5.0 g were used, while cloves for the 45 min preparation weighed 1.2 to 9 g. The total weight of the cloves boiled for 4 min did not change, while the weight of the cloves boiled for 45 min increased by 5%. To reduce variation, cloves from each of the six bulbs were split into the two groups used for boiling.

Diced (cubed) raw. Raw garlic cloves (California Early variety, Garlic World, Gilroy, CA, USA) were peeled, then placed on a plastic grid of 3-mm lines, and cut with a razor blade into cubes measuring approximately 3 mm on each side (40 cubes per gram). This size is similar to that of commercial minced garlic. Two cloves from each of the same bulbs used for the boiling preparations were used. The cloves were carefully peeled and cut in order to minimize allicin formation.

2.6. Special Garlic Extracts

Protein-free, high-alliin garlic extract (PFHA). A garlic extract was prepared in which 97% of the soluble protein was removed, without loss of alliin. Garlic cloves (California Early variety, Garlic World, Gilroy, CA, USA) were peeled (100 g), boiled for 15 min in 1.5 L water (giving 14 mL water/g clove after evaporation loss), transferred to an Osterizer blender, homogenized at the highest speed for 1 min, filtered through cheesecloth, centrifuged at 1300× g for 20 min, subjected to 11 cycles of freezing at −22 °C and thawing, and finally centrifuged at 16,000× g. The soluble protein content decreased from 12.5 mg/g clove (before boiling) to 0.80 mg/g clove (before freeze-thawing) to 0.42 mg/g clove. The final clear extract contained 0.034 mg protein/mL.

Alliin-free, high-GSAC extract (AFHG). A garlic extract void of alliin and alliin-derived compounds was prepared to examine the effects of GSAC on breath AMS. Cloves (85 g), from the same 2-kg batch of bulbs that were used to prepare PFHA, were peeled, homogenized (2 min) in an Osterizer blender after addition of water at 14 mL/g (converted all of the alliin to allyl thiosulfinates), filtered through cheesecloth, boiled for 100 min, (causing all of the allyl thiosulfinates and resultant allyl sulfides to evaporate), and centrifuged at 1300× g for 20 min. Additional water was added as needed during boiling to make up for most of the evaporation loss. The soluble protein content decreased from 12.5 mg/g clove (before homogenization) to 2.4 mg/g clove (81% loss of protein). The final clear extract contained 0.25 mg protein/mL.

Alliin-free, high-SAC extract (AFHS). Product AFHG was treated with γ-glutamyl transpeptidase to convert 95% of the GSAC to SAC to learn if the two compounds have equal effects on breath AMS. A portion of AFHG (200 mL) was adjusted to pH 8.5 with 0.1 N NaOH, followed by the addition of 100 units of equine kidney γ-glutamyl transpeptidase (9.1 units/mg) (Sigma-Aldrich) and incubation at 37 °C for 3.5 h.

2.7. Participants

A total of 13 self-described healthy persons (6 female, 7 male) were recruited for the study in May–June 2009, all of whom continued throughout the 22 months of the study. Persons who had an intestinal disease, used tobacco, or frequently consumed alcohol, were excluded from the study.

The participant age range was 26–62 year (averages: total 35, men 34, women 36), with a body mass index (BMI) range of 22–35 kg/m2 (averages: total 26, men 28, women 25). The study was a series of bioassays; hence, it was not blind, nor was there a placebo or randomization Participants were always informed which garlic product they were consuming prior to consumption. Twenty-three types of garlic products were used in 43 tests, with usually 7–13 participants per test. A single set of bioavailability tests required two days to conduct; they were usually conducted two times per week and included 3–4 participants per set. Participants usually participated in two tests per month and were paid for each test. A record of all interactions with the subjects during a test, along with any report of side effects, was maintained on set consumption records. All bioavailability tests with garlic products and garlic extracts, along with the consent form and research protocol, were approved by the Western Institutional Review Board, Olympia, Washington, USA, on 18 March 2009 (study number 1105434).

2.8. Standard Breakfast Meals and Garlic Product Consumption

All garlic supplements, the homogenized raw garlic (control), and the extracts, were consumed with either a standardized low-protein meal (LP) or a standardized high-protein meal (HP). The LP meal consisted of two slices of toasted white bread, 19 g of butter, 30 g of jam, a banana, and 200 mL of water; it contained 5.5 g of protein and 17 g of fat. The HP meal consisted of a whole wheat tuna sandwich and 200 mL of whole milk, including two slices of bread, 54 g of pressed canned albacore solid white tuna, and 34 g of garlic-free light mayonnaise; it contained 31 g of protein and 19 g of fat. The meals were isocaloric (460 kcal). The gastric pH is lowest before a meal (av 1.9) and quickly rises (av 14 min), depending upon the meal protein content, to a maximum pH of 4.4–6.7 after starting a meal [28,42]. Hence, the supplements were consumed immediately before the LP meal, to allow exposure to approximately the lowest gastric pH attainable when they are consumed with a meal—or immediately after the HP meal, to allow exposure to a substantially higher gastric pH. The control, in capsules, was always consumed immediately after the LP or HP meals to reduce the chance of stomach disturbance. For the control, gastric pH was not a concern, as alliinase had been activated before consumption. Garlic foods (cooked garlic, etc.) and their control were consumed inside the LP meal, with the garlic placed between the two slices of buttered bread and the jam omitted. The special extracts (clear aqueous liquids) were consumed with the LP meal.

2.9. Diet Restrictions

It was essential to prevent dietary interference with the bioavailability test by restricting the consumption of garlic and onions for two days before each test and for the 1.5 days of each test. The restrictions were as follows: two days before a test, only modest amounts of garlic; one day before the test and during the test, no foods containing garlic or onion, with some exceptions. Some prepared foods listing garlic were found to contain too little garlic to cause breath AMS production: Kraft Miracle Whip, Pace Chunky Salsa, and Doritos Cool Ranch Chips. A small amount of cooked onion caused no interference. Prepared foods, such as ketchup, mustard, salad dressing, tomato sauce, and chips, which listed onion as a spice, but not garlic, caused no interference. Participants were discouraged from eating restaurant food unless they were sure garlic and onion were absent from their choices.

On the day of each test, participants were asked to not eat or drink until arriving at the facility, except, if necessary, up to 150 mL water one hour before arrival. After consuming the standard breakfast meal and garlic product, participants were asked to not eat or drink again until two hours later. However, if they felt discomfort during the two hours, small amounts of non-protein food were permitted. Participants were occasionally asked if they had adhered to these restrictions.

Compliance with the diet restrictions was determined by the absence of AMS and the presence of no more than a modest amount of onion sulfides in a breath sample taken immediately before the test product was consumed. Non-compliance after the test began was monitored by a sudden increase in breath AMS concentration at 2–3 h after consumption of the subsequent meals consumed during the test. If non-compliance was determined, participants were asked to stop the test and repeat it at a later date.

2.10. Breath Sampling Procedure

Participants breathed into 1.2-L Tedlar® gas sampling bags (Grace Davison Discovery Sciences, Waukegan, IL, USA), fitted with a septum port, a barbed nickel-plated twist-valve, and a 4-cm length of Tygon® tubing, as a mouthpiece, attached to the valve. They were instructed to exhale a normal breath, starting at the top of the breath (avoiding the natural tendency to first take a deep breath), into the bag, then to empty the bag by flattening it, followed by exhaling a second breath until the bag was at least mostly full and closing the valve. After the flattening, the mouthpiece was placed against the tongue or lip to prevent air from entering the bag until the participant was ready to exhale the second breath. The speed at which one breathes into the bag was found to have no influence on the breath AMS concentration. Participants recorded their name and breath time on each bag.

Whole breath, rather than alveolar breath, was used throughout the study. Although alveolar breath has been shown to contain 18% higher AMS than whole breath [17], the procedure for sampling alveolar breath was considered too difficult for participants to use away from the laboratory, where most of the 17 breaths per test needed to be collected. Because all tests were conducted in the same manner and because only relative amounts are important, using whole breath was considered sufficient.

2.11. Breath Bag Quality

The average rate of disappearance of AMS from the Tedlar® bags was 0.4%/h (range 0.05–1.05%/h). The disappearance rate for each bag was determined over a 48-h period and only the better bags (<0.50% loss/h) were used for the breaths that needed to be stored overnight before analysis. Except for the overnight breaths, breaths were usually analyzed within 4–6 h after sampling. Following these guidelines, losses were considered insignificant and not corrected. Moisture accumulation in the bags was found to have no effect on the AMS concentration.

2.12. Test Protocol

After an overnight fast, participants came to the facility, breathed into a bag and then consumed the standardized breakfast meal and the garlic product. After consuming the garlic product, participants left the facility with several empty bags and provided breath samples every hour for the next eight hours, then every two hours, except during sleep, until breath AMS was undetectable (typically 24–30 h), but not longer than 32 h. Participants returned to the facility to deliver breath samples and obtain more bags at about noon and 5 pm of the first day and at about 8 am and 2 pm of the second day.

2.13. Breath Analysis for Allyl Methyl Sulfide (AMS)

Breath samples (5 mL) were injected directly (manually with a 5-mL gas-tight syringe fitted with a 0.63 mm side-port needle), one time, into a gas chromatograph (Agilent 6890) fitted with a model 5380 sulfur-selective pulsed flame photometric detector (PFPD, OI Analytical, College Station, TX, USA), PFPD zero-output setting of 10, and a 30 m × 0.32 mm × 4 μm SPB-1 Sulfur (bonded polydimethylpolysiloxane) capillary column (Sigma-Aldrich #24158). Helium was the carrier gas (1.6 mL/min, constant flow). The column temperature was programmed from 45 °C (0.2 min) to 200 °C (1.2 min) at 50°/min, with a hold time of 2 min, giving a retention time of about 4.0 min, a run time of 5 min, and a re-injection time of 11 min. The injection port contained a straight 4 mm borosilicate liner (Agilent #19251-60540) and was operated at 175 °C in the splitless mode, with a purge flow of 45 mL/min for 0.8 min. The detector was operated at 250 °C, with the following flow rates: hydrogen 9.5 mL/min, air 18.5 mL/min, helium (make-up) 5.5 mL/min. Due to injection of an overload volume of 5 mL and a rapid temperature gradient, the baseline did not become stable until 2.9–3.0 min after each injection. Because inserting the column into the detector requires disassembly of the detector and several hours of equilibration time, a 40-cm piece of the column (extension) was attached to the detector, with the other end attached to an Agilent Ultimate Union (G3182-61580). The remainder of the column was then attached to the extension at the union. This allowed for quick removal and replacement of the column for other uses of the gas chromatograph. The PFPD peak area is the square root of the detector response to sulfur. This detector gave about 20 times greater sensitivity (detection limit, 40 area units or 3 ng/L or 1 ppb at s/n = 2) than the FID (flame ionization detector) detector used in prior allicin bioavailability studies [17], which made it possible to measure the AUC after consuming small amounts of garlic products. AMS is normally absent from human breath [43].

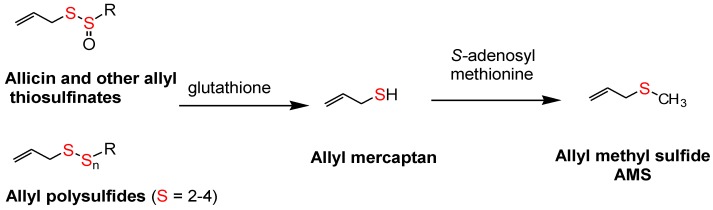

2.14. AMS Standard Curve

The stock allyl methyl sulfide vapor standard (266 ng/L) was prepared by adding 13.0 μL of a solution of 88 μg allyl methyl sulfide/mL in methanol to duplicate 4.3-L glass jugs with lids fitted with septum ports. The concentration in the jugs reached stability by 2–3 h and remained stable for 24–30 h. Dilutions of this standard gave a curvilinear linear response down to 6 ng/L. Dilutions were prepared by adding various volumes of the stock (0.25–3 mL) and air (4.75–2 mL) to a 5-mL syringe and injecting the 5-mL. For volumes less than 1 mL, the stock was added to the 5-mL syringe using a 1-mL syringe. An air-blank was injected daily. When eight standard curves, created over a 14-month period (see examples in Figure 3), were applied to a single set of breath data, the resultant AUC was found to vary by only 5% (RSD, relative standard deviation), indicating the stability of the PFPD detector response.

Figure 3.

Examples of standard curves for AMS standards, 13–106 ng/L, over the course of 14 months.

2.15. AMS Concentration Curve (AUC)

The AUC was measured in ng-h/L by determining the AMS concentration of each breath, based on AMS peak areas and interpolated concentration values (Spline Lowess regression) from the standard curve, followed by determining the AUC over 32 h. All of the calculations were determined using GraphPad Prism 5.0 (San Diego, CA, USA) software.

2.16. Allicin Bioavailability or Bioequivalence

The ABB for each product was based on response factors (RF, RF2, RF3) and calculated as relative response factors (RRF, RRF2, RRF3). RF is the ratio of AUC to the μmol of alliin and alliin-derived dithioallyl compounds (AADD, see Figure 1) consumed. RF2 is the ratio of AUC to the μmol of total known S-allyl compounds (TKSA) consumed; TKSA is AADD plus GSAC and SAC (G/SAC). RF2 was especially useful when AADD was very low and G/SAC were dominant. RF3 is the ratio of AUC to the weight (g) of product consumed; it was used mainly for “aged” garlic products, such as black garlic, in which most of the alliin has been converted to unidentified S-allyl compounds. The relative response factors were calculated as 100% times the response factors for the products divided by the response factors for the standard control. When products contained alliinase activity (the supplements and diced raw garlic), allicin bioavailability was determined based on AADD. When the alliinase of garlic products had been inhibited (cooked, acidified), allicin bioequivalence was determined based either on AADD or TKSA. The minimum AUC that could be accurately determined was 15 ng-h/L, when there was a relatively sharp decline in AMS after Tmax was reached (typical when the product had active alliinase, such as with the control and N1). It was about 45 ng-h/L when there was a gradual decline after the Tmax (typical when alliinase was absent, such as with PHFA, AFHG, and alliin). When the product contained active alliinase, ABB as low as 0.7–11% could be determined when the AADD consumed was 320–20 μmol, respectively. When the product did not contain active alliinase, ABB as low as 2–32% could be determined when the AADD consumed was 320–20 μmol.

2.17. Dissolution Allicin Release

The formation and release of allicin from garlic tablets and capsules under simulated gastrointestinal conditions was determined according to the USP-NF (U.S. Pharmacopeia-National Formulary) dissolution method for delayed-release garlic tablets [29]. Using a model VK 700 dissolution apparatus (Agilent/Varian, Palo Alto, CA, USA) equilibrated at 37 °C, 2–6 tablets or capsules (enough to provide 20–30 mg alliin) were placed into each of two covered 1-L round bottom glass vessels containing 750 mL of 0.1 N HCl and paddle-stirred at 100 rpm for 2 h, after which 250 mL of 0.2 M Na3PO4 was added and the pH slightly adjusted, if necessary, giving 1000 mL at pH 6.80 ± 0.05. After stirring the buffered medium for 60 min, 1 mL was added to 0.05 mL of 210 mM (final 10 mM) carboxymethoxylamine (CMA) (Sigma-Aldrich) alliinase inhibitor, followed by high-performance liquid chromatography (HPLC) analysis of allicin. For tablets that had not completely disintegrated in 60 min of buffer, an additional 1 mL aliquot was taken upon complete tablet disintegration. Capsules were loosely wrapped with three winds of plastic-covered wire to keep them from floating. The time to achieve complete disintegration was determined by observation during the dissolution test. The percent dissolution allicin release (DAR) was calculated as the amount of allicin released during the dissolution tests divided by the amount of allicin released when pulverized tablets or capsule contents were incubated 30 min in water to allow complete allicin formation (allicin potential).

2.18. Analysis of Garlic Products

Garlic supplements (tablets and capsule contents) were mortar ground, extracted with 20 mM CMA alliinase inhibitor (50–100 mL/g) for analysis of alliin, GSAC, and SAC, or extracted with 70% acetonitrile (ACN)/30% 40 mM CMA (10 mL/g) for analysis of allyl sulfides. For water activation of alliinase to generate the allyl thiosulfinates, ground tablets or the contents of capsules were mixed with water at 50 mL/g, rotated rapidly for 10 min, centrifuged for 5 min at 1000× g, followed by addition of one volume of ACN (precipitates protein), centrifuged for 3 min at 16,000× g, and kept at 4 °C or lower until analyzed [37]. Commercial garlic foods were extracted with a Polytron homogenizer at speed 6 for 15 s, in the presence of either 20 mM CMA (10 mL/g) for analysis of alliin, GSAC, and SAC or in the presence of 75% ACN/25% water (10 mL/g) for analysis of allyl thiosulfinates and allyl sulfides. The control (raw garlic homogenate) was extracted with 20 mM CMA (20 mL/g) for analysis of alliin, GSAC, and SAC, or with 50% ACN (10 mL/g) for analysis of allyl thiosulfinates, or with 70% ACN (10 mL/g) for analysis of allyl sulfides. Diced raw garlic was extracted with a Polytron homogenizer (speed 6, 15 s) in the presence of 20 mM CMA (25 mL/g) for analysis of alliin, GSAC, SAC, and, after addition of 1 volume of ACN, for analysis of allyl thiosulfinates and allyl sulfides. Roasted or boiled garlic were extracted with a Polytron homogenizer (speed 6, 15 s) in the presence of water (25 mL/g) for analysis of alliin, GSAC, and SAC, or in the presence of 75% ACN (10 mL/g) for analysis of allyl thiosulfinates and allyl sulfides.

Alliin, GSAC, and SAC were analyzed by ion-pair HPLC (250 mm × 4.6 mm, Agilent/Varian Microsorb-MV 100-5 C18 250 mm × 4.6 mm column) at 208 nm by modification of the method of Arnault et al. [44]. Solvent A consisted of 20 mM sodium heptanesulfonate (ion-pair agent) (Sigma-Aldrich) and 20 mM sodium phosphate monobasic, pH adjusted to 2.1 with concentrated phosphoric acid. Solvent B was ACN. The column was heated at 38 °C with a flow rate of 1.0 mL/min. Gradient: from 0% B to 15% B in 5 min, then to 22% B by 15 min and hold until 17 min, then back to 0% B by 18 min and hold until 24 min. Typical retention times: l(−)-alliin 8.5 min, l(+)-alliin 8.8 min, isoalliin 9.1 min, γ-glutamyl-S-methylcysteine 11.0 min, S-allylcysteine 13.7 min, γ-glutamyl-S-allylcysteine 15.9 min, γ-glutamyl-S-cis-1-propenylcysteine 17.3 min, γ-glutamyl-S-trans-1-propenylcysteine 17.5 min, γ-glutamylphenylalanine 18.5 min. The allyl sulfides and allyl thiosulfinates (when their abundance was small) were analyzed, using the same column, isocratically with 70% ACN/30% water at 210 nm, as previously described [21] (1991 sulfides pub). When the allyl thiosulfinates were abundant, such as with the control, or when the dissolution allicin release and USP potential allicin (allicin potential) were determined, they were analyzed isocratically with 45% ACN/55% water at 240 nm, as previously described [37].

2.19. Alliinase Assay

Alliinase activity, as μg allicin produced min−1 g−1 garlic powder (dry garlic matter), was determined as previously described [30]. Briefly, the capsule contents or mortar-pulverized tablets, without sieving, were added to water at a concentration of 1 g garlic powder content to 800 mL water, followed by immediate and vigorous shaking for 7–8 s and removal of 1 mL aliquots at 15, 30, 60, and 120 s to 0.05 mL of 210 mM CMA to stop the reaction. After analysis of allicin, the alliinase activity was determined from the time point giving the highest rate of allicin production. If the activity was found to be less than 500, it was redetermined at 200 mL/g garlic powder. The garlic powder content for tablets and capsules was based on label claims.

2.20. Protein Assay

The protein content of extracts PFHA and AFHG were assayed according to the procedure of Bradford [45], using Brilliant Blue G (Sigma-Aldrich) in methanol as the binding dye and bovine serum albumin (Sigma-Aldrich) as the protein standard (standard curve 10–100 μg/mL).

2.21. Peptide Hydrolysis

To reveal any possible peptide-bound alliin or SAC, both AFHG extract and roasted garlic prepared at 160 °C (homogenized with 10 mL water/g) were incubated while stirring at pH 8.5 at 37 °C for one hour with a large excess of either protease from Bacillus licheniformis (9.6 units/mg, Sigma-Aldrich) or alkaline protease from Bacillus subtilis (400 PC units/mg, Bio-Cat, Inc., Troy, VA, USA), followed by one hour of incubation with porcine kidney γ-glutamyl transpeptidase (3.4 units/mg, Sigma-Aldrich). Aliquots were centrifuged at 16,000× g and directly assayed for alliin, SAC, and GSAC as described in Section 2.18.

2.22. Statistical Analysis

Statistical analyses were conducted using Microsoft Excel Analysis ToolPak software (Redmond, WA, USA). Student’s t-Test (paired two sample for means; two-tail) was used to determine differences between groups. In a few cases, the two-sample t-Test was used when n was small (≤4). p-Values < 0.05 were considered to be significant. Data are presented as means ± standard deviation (SD).

3. Results

3.1. AMS Peak Resolution and Interference from Onion Sulfides

AMS (retention time 4.0 min) was well-resolved from other volatile sulfur compounds derived from garlic: allyl mercaptan (3.3 min), diallyl sulfide (4.9 min), and diallyl disulfide (6.9 min), although none of these compounds were detected when the breath was sampled at ≥0.5 h after garlic product consumption. AMS was almost baseline separated from XMS (4.2 min), the only volatile sulfur compound detected after consuming 5 g cooked onion. Upon consuming raw onion, only two peaks were found: XMS and YMS (4.1 min). AMS was not well-separated from YMS; hence, it was important to restrict study participants from eating raw onion. Consumption of small amounts of cooked onion did not cause interference. No sulfur compounds were detected in the breath unless garlic or onion had been consumed.

The identities of XMS and YMS were not confirmed by gas chromatography–mass spectrometry (GC–MS); however, XMS is probably trans-1-propenyl methyl sulfide, which is often found in human breath [43], and YMS co-eluted with pure n-propyl methyl sulfide (Alfa Aesar, Tewksbury, MA, USA). For cooked onion, these sulfides would be metabolites of isoalliin (S-trans-1-propenylcysteine sulfoxide), the main sulfur compound found in onion, and propiin (S-n-propylcysteine sulfoxide), which is only 3–10% as abundant [46,47]. For raw onion, they would be the metabolites of the respective 1-propenyl and propyl thiosulfinates. In contrast to the much greater abundance of isoalliin than propiin in whole raw onion, consumption of raw onion resulted in 6-fold more YMS than XMS. This probably occurred because, after the action of alliinase and lachrymatory factor synthetase upon crushing raw onion, isoalliin is mainly (80–90%) transformed to highly volatile lachrymatory factor (propanethial S-oxide, CH3CH2CH=S-O) and only a small amount (5–10%) to 1-propenyl thiosulfinates, while propiin is transformed only to propyl thiosulfinates [24,46,47]. It is also possible that 1-propenyl thiosulfinates are metabolized to the methyl sulfides less efficiently than are the propyl thiosulfinates. A small amount of XMS was often seen after consuming garlic products, probably due to the presence of a small amount isoalliin in garlic and the subsequent 1-propenyl thiosulfinates found in crushed raw garlic [19,48].

3.2. Example Breath AMS Concentration Curves

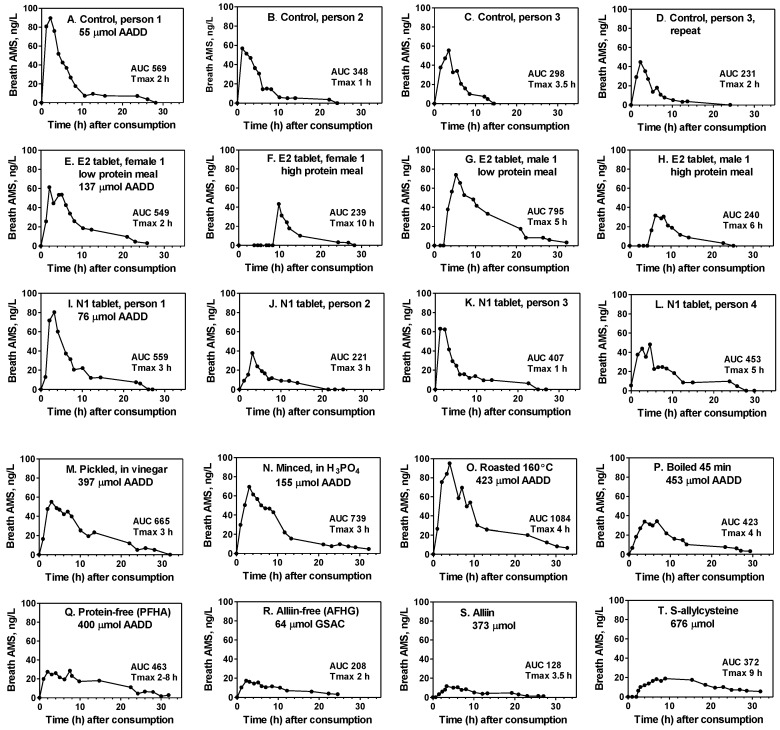

Typical breath AMS concentration curves for several of the products consumed in the study are illustrated in Figure 4. They depict hourly fluctuations, the Tmax (time to achieve maximum breath concentration), the AUC relative to the amount consumed (AADD), and delays in AMS production (F, G, H, T). They also demonstrate the variation between persons for the standard control (A–C) and N1 tablets (I–L), the variation between duplicate tests by the same person (C and D), and the effect of a high meal protein content on reduced AUC and delayed AMS production when enteric-coated tablets are consumed (E–H). The substantial production of breath AMS, even when active garlic alliinase is not present, is shown for both acid-processed and cooked garlic foods (M–P) as well as for extracts and pure S-allyl compounds (Q–T).

Figure 4.

Typical concentration curves for breath AMS, after consumption of various garlic products. (A–D), 1.4 g of raw garlic homogenate (0.88 g raw garlic) consumed in capsules with low-protein meal (the standard control). (E–H), enteric-coated tablets, brand E2 (2 tablets), consumed with low or high-protein meals by a female or male. (I–L), normal tablets, brand N1 (3 tablets), consumed with low-protein meal (not the same persons as A–D). (M–P), garlic foods consumed with low-protein meals (four different persons): M = 12 g pickled garlic; N = 7 g acid-minced garlic; O = 6.1 g roasted garlic (160 °C for 30 min); P = 5.5 g boiled garlic (45 min). (Q–T), garlic extracts and pure compounds: Q = protein-free high alliin extract (PFHA); R = alliin-free high GSAC extract (AFHG); S = pure l(+)-alliin; T = pure S-allylcysteine. S and T were consumed by the same person. Q and R were consumed by another person, but very similar curves were found when Q and R were consumed by the person who consumed S and T.

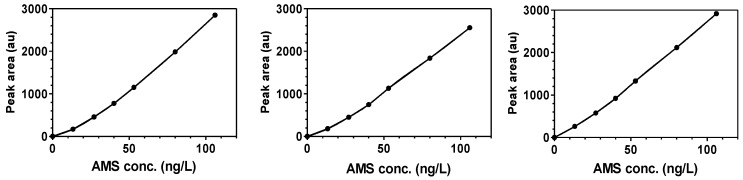

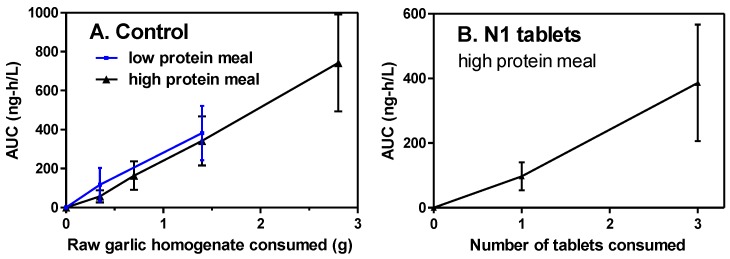

3.3. Dose Response

The response of the breath AMS-AUC to consumption of 0.35, 0.70, 1.4, and 2.8 g of the raw homogenate control (0.22–1.76 g raw garlic) under high-protein meal conditions was determined for all 13 participants (Figure 5). The allicin content of the control was 0.87–6.94 mg per dose and was fully present before consumption. The response was dose-dependent (r2 = 0.9989) and gave high linearity through 0.35 g. Under low-protein meal conditions, only two doses were used, 0.35 and 1.4 g, which closely paralleled the result with the high-protein meal. A dose of 1.4 g with the low-protein meal was chosen as the standard control condition. N1 tablets, where allicin was absent until made in the body, were tested at two doses with a high-protein meal. The response was dose-dependent (r2 = 0.9975) and moderately linear.

Figure 5.

Dose response of the breath AMS concentration curve (AUC) after consumption of A, the control (raw garlic homogenate) or B, N1 tablets, with high- or low-protein meals. Values are means ± standard deviation (SD) (n = 13).

3.4. Experimental Variation

The experimental variation is summarized in Table 3. The variation (RSD) in the AMS peak area between triplicate injections of the same breath was 3.4% (n = 12), with no significant difference (p > 0.4) between breaths containing a high AMS concentration (88 ng/L, peak area 2110 au), a moderate concentration (42 ng/L, peak area 860 au), or a low concentration (10 ng/L, peak area 180 au). The variation between triplicate breaths taken 1 min apart was a little greater, 5.6%, as determined for four persons, and also includes the variation between replicate injections of the same breath. The average variation in the AUC between all 13 persons consuming the same product was 42 ± 7.5% (range 32–63%) for 21 tests with garlic supplements and the control. However, this variation decreased to 32 ± 9.9%, a significant (p < 0.001) 24% decrease, by comparing the AUC for a product to the control AUC value found for each person, the relative response (AUC/AUCcontrol). The variation was independent of meal type and supplement type.

Table 3.

Summary of the experimental variation.

| Source of Variation | Variation (RSD, %) | Measurement |

|---|---|---|

| Between triplicate injections of the same breath | 3.4 (n = 12 sets) | Peak area |

| Between triplicate breaths taken 1 min apart | 5.6 (n = 4 sets) | Peak area |

| Between 13 persons consuming the same product | 42 (n = 21 sets) 32 (n = 21 sets) |

AUC AUCproduct/AUCcontrol |

| Between duplicate consumptions of a garlic product by the same person (within person) | 17 (n = 39 sets) | AUC |

| Between duplicate sets of tests with 13 persons (between test sets) | 4.7 (n = 3 sets) | Average AUC |

RSD: relative standard deviation; AUC: area under the 32-h breath AMS concentration curve.

The variation in the AUC for duplicate consumption of a garlic product by the same person was determined three times for all 13 participants, which revealed an overall average within-person variation of 16.9%. When 1.4 g of the raw homogenate control was consumed with a low-protein meal, the variation was 14.4 ± 11.5%. When 1.4 g of the raw homogenate control was consumed with a high-protein meal, the variation was 17.4 ± 15.4%. When three N1 tablets were consumed with a high-protein meal, the duplicate variation was 18.7 ± 14.0%. The variation in the average AUC for duplicate sets of tests with the same product, same dose, and same meal type for the 13 persons was 4.7%. Duplicate test sets were conducted three times: 1.4 g of control with the low-protein meal (1.2% RSD), 1.4 g of control with the high-protein meal (3.9% RSD), and three N1 tablets with the high-protein meal (9.0% RSD).

3.5. Composition

The TKSA content of the garlic products consumed in the study is described in Table 4. Alliin was absent from the homogenized raw garlic used as the control because it had been converted to allicin and other allyl thiosulfinates during homogenization; however, the original alliin content of the cloves—calculated from the allyl thiosulfinates produced—was 154 μmol/g dry wt (60.9 μmol/g fr wt) or 27.3 mg/g dry wt (10.8 mg/g fr wt), which values are close to the average values reported for 46 samples: 156 ± 33 μmol/g dry wt (54.7 μmol/g fr wt) or 27.7 ± 5.8 mg/g dry wt (9.7 ± 2.0 mg/g fr wt) [49,50,51]. Among the garlic supplements and foods, alliin was usually the most abundant S-allyl compound, typically accounting for 65 to 85% of the total, but it was lower, 30–40%, for products E5, N2, and oil-chopped garlic, while being undetectable in black garlic. The alliin concentration in the garlic powders used in the supplements varied 7.5-fold (6.5–49; 21.0 ± 12.2 mg/g) (Table 4, second set of alliin values). This range is substantially broader than the 2-fold range consistently found for garlic bulbs among sets of 13, 9, and 24 cultivars [49,50,51]; this indicates variable loss of alliin upon manufacture of garlic powders and validates the need for the allicin potential or alliin standardization label claims found for most brands (Table 1).

Table 4.

Composition of the garlic products: S-allyl 1 compounds, as μmol of S-allyl per dose consumed.

| Code or Name | Dose | Alliin 2 | Allyl Thiosulfinates 3 | Allyl Polysulfides 4 | GSAC | SAC | AADD 5 | TKSA 6 |

|---|---|---|---|---|---|---|---|---|

| Control, raw homogenate | 1.4 g 7 | nd, <0.2 | 53.3 3 | 1.4 4 | 10.7 | 0.13 | 54.7 | 65.5 |

| Garlic supplements | ||||||||

| Enteric tablets | ||||||||

| E1 | 2 tab | 132 (33) 2 | nd, <0.1 | 0.4 | 33.2 | 6.0 | 132 | 171 |

| E2 | 2 tab | 134 (30) | nd, <0.1 | 2.4 | 12.9 | 5.3 | 137 | 155 |

| E3 | 3 tab | 264 (49) | nd, <0.1 | 13.5 4 | 29.3 | 16.4 | 278 | 323 |

| E4 | 2 tab | 174 (26) | nd, <0.1 | 5.8 | 63.6 | 10.6 | 180 | 254 |

| E5 | 3 tab | 44 (6.5) | nd, <0.1 | 7.3 | 62.7 | 6.8 | 52 | 121 |

| E6 | 2 tab | 106 (16) | nd, <0.1 | 3.9 | 41.0 | 5.8 | 110 | 157 |

| Normal tablets | ||||||||

| N1 | 3 tab | 72 (14) | nd, <0.1 | 3.8 | 48.5 | 4.1 | 75.8 | 128 |

| N2 | 9 tab | 40 (7.9) 2 | nd, <0.1 | 5.6 | 52.9 | 4.3 | 45.2 | 102 |

| N3 | 1 tab | 155 (28) | nd, <0.1 | 0.5 | 44.7 | 7.7 | 155 | 207 |

| N4 | 9 tab | 57 (11) | nd, <0.1 | 2.4 | 47.4 | 6.4 | 58.8 | 113 |

| Capsules | ||||||||

| C1 | 1 cap | 73 (24) | nd, <0.1 | 0.2 | 28.4 | 5.1 | 73.0 | 106 |

| C2 | 3 cap | 167 (20) | nd, <0.1 | 2.5 | 97.7 | 14.1 | 169 | 281 |

| C3 | 4 cap | 98 (8.7) | nd, <0.1 | 1.9 | 77.5 | 26.1 | 99.5 | 203 |

| Commercial garlic foods | ||||||||

| Pickled 8 | 12 g | 388 | nd, <0.2 | 9.0 | 32.6 | 25.7 | 397 | 455 |

| Acid-minced | 7 g | 134 | nd, <0.2 | 21 4 | 81.9 | 14.5 | 155 | 251 |

| Oil-chopped | 2.5 g | 36 | nd, <0.2 | 36 4 | 31.5 | 10.8 | 71.5 | 114 |

| Black garlic | 10.2 g | nd, <2 | nd, <0.2 | 0.8 | 5.9 | 40.1 | 0.8 | 46.8 |

| Kitchen-prepared garlic foods | ||||||||

| Roasted 160 °C | 6.1 g | 400 | 4.0 | 19.6 4 | 92.7 | 5.4 | 423 | 521 |

| Roasted 215 °C | 5.5 g | 400 | 0.4 | 7.9 | 82.0 | 8.6 | 409 | 499 |

| Boiled 4 min | 7.6 g | 451 | 2.6 | 1.7 | 97.3 | 6.2 | 455 | 558 |

| Boiled 45 min | 5.5 g | 450 | 0.2 | 2.2 | 86.4 | 0.9 | 452 | 540 |

| Raw, diced | 1.5 g | 110 | 2.1 | nd, <0.2 | 24.5 | 3.2 | 112 | 140 |

| Special extracts 9 | ||||||||

| PFHA | 68 mL | 399 | nd, <0.1 | 0.05 | 68.7 | 2.7 | 399 | 470 |

| AFHG | 57 mL | nd, <0.4 | nd, <0.1 | nd, <0.03 | 63.6 | 7.0 | nd, <0.5 | 70.6 |

| AFHS | 57 mL | nd, <0.4 | nd, <0.1 | nd, <0.03 | 3.4 | 67.2 | nd, <0.5 | 70.6 |

| AFHG + SAC | 57 mL | nd, <0.4 | nd, <0.1 | nd, <0.03 | 63.6 | 148 | nd, <0.5 | 212 |

1 Allicin and the diallyl polysulfides have two S-allyl groups per molecule; allyl methyl thiosulfinates, allyl methyl polysulfides, alliin, γ-glutamyl-S-allylcysteine (GSAC) and S-allylcysteine (SAC) have one S-allyl. 2 For alliin, a second set of values is included (in parentheses) for the supplements: mg alliin per gram garlic powder content claimed (Table 1); for product N2 the garlic powder content was not stated, but it was estimated (Table 1). 3 Allyl thiosulfinates = sum of allicin, allyl methyl thiosulfinates, and allyl-trans-1-propenyl thiosulfinates. Distribution for the control product, as mol % of S-allyl (allicin has two per molecule) and as mol % of compounds = allicin 80.3% and 67.1%, allyl methyl thiosulfinates 17.0% and 28.3%, and allyl-trans-1-propenyl thiosulfinates 2.7% and 4.6%. 4 Allyl polysulfides = sum of diallyl di-, tri- and tetrasulfides (DAS2, DAS3, DAS4) and allyl methyl di-, tri-, and tetrasulfides (AMS2, AMS3, AMS4). Diallyl sulfide (DAS) was typically <3% of the total allyl sulfides, and AMS was undetectable. Distribution for the control and the more abundant samples, as S-allyl mol %: control, DAS2 72%, DAS3 25%, AMS3 3%; E3, DAS2 22%, DAS3 38%, DAS4 22%, AMS2 3%, AMS3 10%, AMS4 5%; Acid-minced, DAS2 7%, DAS3 69%, DAS4 18%, AMS2 < 1%, AMS3 4%, AMS4 2%; Oil-chopped, DAS2 28%, DAS3 51%, DAS4 8%, AMS2 1%, AMS3 10%, AMS4 2%, ajoene 0.3%; Roasted 160 °C, DAS2 16%, DAS3 70%, DAS4 8%, AMS2 < 1%, AMS3 6%, AMS4 1%. 5 AADD = alliin and alliin-derived dithioallyl compounds (alliin, allyl thiosulfinates, allyl polysulfides), expressed as μmol S-allyl per dose consumed. 6 TKSA = total known S-allyl compounds (AADD + GSAC + SAC), expressed as μmol S-allyl per dose consumed. 7 Control: 1.4 g of homogenate obtained from 0.88 g raw garlic (0.35 g dry wt). 8 The liquid in which the pickled garlic was immersed (35% of the container contents), although not normally consumed, contained substantial amounts of alliin (43% of the container contents), GSAC (43%), and SAC (41%), as the result of diffusion. 9 PFHA = protein-free, high alliin extract. AFHG = alliin-free, high GSAC extract. AFHS = alliin-free, high SAC extract.

Alliin consists of both the l(+)-isomer and the l(−)-isomer. The l(−)-isomer, which tends to increase with age, constituted <6% of the alliin for most of the products, the exceptions being E4 (8%), E5 (14%), E6 (24%), N1 (8%), N2 (10%), N4 (19%), C2 (9%), C3 (15%), pickled (11%), acid-minced (18%), and oil-chopped (24%). Second in abundance was GSAC, which accounted for 8–35% of the total S-allyl, with E5 and N2 being exceptionally high (57–58%). SAC accounted for 2–6% of the total, except 13% for C3 and 86% for black garlic. Of the total SAC (GSAC + SAC), SAC typically accounted for 1–15%, exceptions being E3 (36%), pickled garlic (44%), and black garlic (87%).

As intended, alliin, allyl thiosulfinates and allyl polysulfides were absent from the AFHG and AFHS extracts, and treatment of AFHG with γ-glutamyl transpeptidase to produce AFHS converted 95% of the GSAC to SAC. Allicin and other allyl thiosulfinates were absent from all supplements because alliinase had not been activated. Upon activation in water (Section 2.18), the following average yields and ranges were found (n = 13, not shown in Table 4): (a) as mg/g garlic powder (powder weight claims are in Table 1)—allicin 7.8 ± 4.8 (2.4–16.8), allyl methyl thiosulfinates 1.7 ± 1.1 (0.5–4.6), allyl trans-1-propenyl thiosulfinates 0.3 ± 0.4 (0.01–1.4); (b) as mg/tablet or capsule—allicin 3.6 ± 2.9 (0.3–10.8), allyl methyl thiosulfinates 0.8 ± 0.6 (0.05–2.1), allyl trans-1-propenyl thiosulfinates 0.2 ± 0.2 (0.002–0.6). The allyl thiosulfinates were absent from homogenized commercial garlic foods because alliinase had been inhibited by the processing acids (vinegar, phosphoric acid, citric acid). They were abundant in the homogenized control, where allicin accounted for 80.3 S-allyl mol % or 70.3 wt % of the allyl thiosulfinates, and they were slightly present in the roasted, boiled, and diced raw garlic preparations. Dicing cloves into 3 mm cubes caused only about 3% of the alliin to be transformed to thiosulfinates, while homogenization in water caused complete transformation.

The allyl polysulfides, which are metabolized to AMS to the same extent as allicin [17], were significant (>5% of the AADD) only in E5 (14%), acid-minced garlic (14%), and oil-chopped garlic (51%). Oil-chopped garlic uniquely contained cyclic vinyldithiins, 2-vinyl-4H-1,3-dithiin and 3-vinyl-4H-1,2-dithiin (5.4 μmol/2.5 g), which are not metabolized to AMS, and a small amount of ajoene (0.1 μmol/2.5 g), which is metabolized to AMS [17]. Of these products, the diallyl sulfides comprised 82–94% of the total allyl sulfides, with diallyl trisulfide always dominant, as detailed in the footnotes of Table 4. AMS itself was not found in any product except in oil-chopped garlic (0.7% of the AADD).

3.6. Control: Allicin Bioavailability or Bioequivalence

The response factor (RF) for 1.4 g of the control was used for determining the ABB of all other products. Hence, it was important to establish its variation between duplicate tests, its variation with respect to meal types, its variation with the mode of consumption, and its variation over the duration of the study. The results for the individual duplicate tests and their averages for consumption with the high-protein or low-protein meals are shown in Table 5. The variation in the AUC and RF between duplicate tests was low for both the high-protein meal (RSD 3.9%) and the low-protein meal (RSD 1.2%). Compared to the low-protein meal, consuming the control with a high-protein meal significantly decreased (p = 0.023) the RF by 18% (7.37 vs. 6.25), delayed the Tmax by 0.7 h and decreased the Cmax by 25%. Apparently, some of the allicin binds to or reacts with the milk protein or tuna protein or other components in the high-protein meal without forming a reaction product that can be transformed to AMS. The RF was not significantly different between men and women for either the low-protein tests (p = 0.56) or the high-protein tests (p = 0.78).

Table 5.

Breath AMS after consumption of the control (raw garlic homogenate) at the standard dose. 1,2

| Test | Meal Protein | Mode | n | Tmax (h) | Cmax (ng/L) | % Cmax at 1 h 3 | AUC 4 (ng-h/L) | RF (AUC/AADD) |

|---|---|---|---|---|---|---|---|---|

| 1a | high | capsules | 13 | 3.1 ± 1.0 | 54 ± 20 | 31 ± 28 | 351 ± 143 | 6.41 ± 2.62 |

| 1b | high | capsules | 13 | 3.5 ± 1.1 | 47 ± 13 | 25 ± 16 | 332 ± 108 | 6.08 ± 1.97 |

| 1 av | high | capsules | 13 | 3.3 ± 0.95 a | 51 ± 15 c | 28 ± 18 t | 342 ± 119 a | 6.25 ± 2.17 a |

| 2a | low | capsules | 13 | 2.5 ± 0.6 | 69 ± 21 | 34 ± 21 | 399 ± 142 | 7.30 ± 2.60 |

| 2b | low | capsules | 13 | 2.6 ± 0.6 | 69 ± 29 | 49 ± 26 | 406 ± 162 | 7.43 ± 2.97 |

| 2 av | low | capsules | 13 | 2.6 ± 0.45 a | 68 ± 22 c | 41 ± 20 t | 403 ± 144 a | 7.37 ± 2.64 a |

| 2c 2 | low | capsules | 13 | 2.7 ± 0.8 | 51 ± 15 | 44 ± 24 | 342 ± 113 | 6.25 ± 2.07 |

| 2 final 5 | low | capsules | 13 | 2.6 ± 0.46 c | 63 ± 19 n | 42 ± 17 c | 383 ± 131 n | 6.99 ± 2.39 n,6 |

| 3 7 | low | sandwich | 13 | 1.4 ± 0.8 c | 60 ± 20 n | 88 ± 13 c | 400 ± 157 n | 7.31 ± 2.87 n |

1 Standard dose: 1.4 g homogenate from 0.88 g raw garlic (0.35 g dry wt); AADD = 54.7 μmol S-allyl. 2 Tests 1a to 2b (four tests) were conducted over a two month period. Tests 2a and 2b were conducted the same month. Test 2c was conducted nine months after tests 2a and 2b. Test 3 was conducted one month after test 2c. Values are mean ± SD (standard deviation). Statistical comparisons (share same letter) were made between (1) capsules consumed with high or low-protein meals (1 av vs. 2 av) and (2) consumption in capsules or sandwich for the low-protein meal (2 final vs. test 3). Designations for significance: n = not significant (p > 0.05); t = trend (p = 0.05–0.1), a = p < 0.05, c = p < 0.001. 3 The % Cmax at 1 h value provides an evaluation of Tmin; the true Tmin is often not known because the first breath sampled after consuming the product was usually taken at 1 h. 4 AUC = area under the 32 h concentration curve for breath AMS. 5 The standard control: average for all three tests conducted with the low-protein meal in capsules (2a, 2b, 2c). 6 The individual average response factor values (RF) for all 13 participants were, from low to high: 2.49, 4.37, 4.80, 4.93, 5.12, 7.31, 7.82, 7.97, 8.10, 8.72, 9.42, 9.90, 9.92 (av 6.99). 7 In test 3, the garlic homogenate was placed directly inside the bread and butter sandwich, immediately before consumption, rather than inside capsules.

The control was also consumed in the same two modes in which the various garlic products were consumed. Similar to the consumption of supplements, it was consumed in capsules, giving the gastrointestinal tract initial contact with allicin and other garlic compounds. Garlic foods were consumed inside a low-protein sandwich, giving the mouth initial contact with the garlic compounds; hence, the control was also consumed inside the same sandwich. The RF for the control consumed inside the sandwich (Table 5, test 3) was not found to be significantly different (p = 0.48) than consumption in capsules (7.31 vs. 6.99). As expected, consumption in a bread sandwich significantly decreased the Tmax from 2.6 h to 1.4 h and doubled the breath AMS concentration at 1 h after consumption (% of Cmax at 1 h, an evaluation of Tmin).

It was critical to the validity of the bioavailability control to consume it under conditions that allowed for maximum allicin availability (maximum RF). Based on the factors presented in Table 5, the standard control RF used was the value found upon consumption of the control in capsules with the low-protein meal (test 2). Tests 2a and 2b were conducted just prior to the tests with the supplements. Because of the long duration needed to conduct most of the supplement tests, 10 months, an additional standard control test (test 2c) was conducted 9 months after the initial tests. The average RF for all three standard tests (test 2, final = 6.99 ± 2.39) was used for determining ABB for all the garlic products, regardless of the type of meal with which they were consumed.

3.7. Garlic Supplements: Allicin Bioavailability

3.7.1. Dose Basis

The dose used for the supplement bioavailability tests was not based on manufacturer recommendations (Table 1), which varied from 1–6 units per day (garlic powder range of 0.3 to 2.0 g, average 1.0) or from 1–3 units per meal (garlic powder range of 0.1–1.5 g, average 0.6 g). Rather, it was based on the amount needed to give an AUC value within or near the tested linear range that was found for the control (100–750 ng-h/L, Figure 5a), as determined from a preliminary test for each product with a person who gave a typical response. It was also desired to consume at least two units to obtain a better average response. In one case, N3, only 1 tablet was consumed because of its very large size (1.8 g) and high AUC. If there was low alliinase activity, a higher dose was used. Typically, the dose consumed was 1–2 times the recommended daily dose or 2–3 times the recommended dose per meal.

3.7.2. Enteric-Coated Tablets

Under low-protein meal conditions, allicin bioavailability from brands E1, E4, and E5 was not significantly different from that of the 100% bioavailability control, but the bioavailability for brands E2 and E3 was significantly lower, especially for E3 (Table 6). Four of the five brands gave medium to high allicin bioavailability (>65%), while E3 gave moderate bioavailability (35–65%). Even brand E6, which was 12 years old, also gave moderate bioavailability. The delay in tablet disintegration and allicin formation caused by the enteric coatings is indicated by both the Tmax and the Tmin (the first measured time for AMS to appear in the breath), relative to the garlic homogenate control that contained allicin before consumption. However, because the first breath was not sampled until one hour after consumption, the true Tmin is not known for any garlic product with a Tmin of less than 1 h. The true Tmin for the control was determined for one person by taking breath samples every 6–8 min for the first hour and was found to be 26 min if consumed immediately after the low-protein meal or 15 min if consumed immediately before the same meal. As learned from the % of Cmax at 1 h, which was 35–50% among products with a designated Tmin of less than about 1 h, it is apparent that the true Tmin for these products is indeed less than 1 h. The Tmin for the low-protein meal was delayed, relative to the control, by about 1.5–2.0 h for brands E1 and E2, with similar delays for the Tmax. However, for brands E3, E4, and E5, the Tmin and Tmax were not significantly different from the control, indicating that the coatings of these products did not delay tablet disintegration in vivo, even though that was their intended purpose.

Table 6.

Allicin bioavailability for garlic supplements, based on breath AMS-AUC. 1

| Product | Dose and AADD 2 | Meal Protein | n | Alliinase Activity 3 | Tmin 4 (h) | Tmax (h) | % Cmaxat 1 h | AUC (ng-h/L) | RF (AUC/AADD) | Allicin Bioavailability, RRF 5 (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| Control 2 | 1.4; 54.7 | low | 13 | -- 3 | <1.1 ± 0.2 | 2.6 ± 0.5 | 42 ± 17 | 383 ± 131 | 7.0 ± 2.4 5 | 100 ± 34 |

| 1.4; 54.7 | high | 13 | -- | 1.4 ± 0.3 b | 3.3 ± 0.95 a | 28 ± 18 a | -- | -- | -- | |

| Enteric tablets | ||||||||||

| E1 | 2; 132 | low | 12 | 12,650 | 2.6 ± 1.7 a | 4.7 ± 2.1 b | 20 ± 35 a | 802 ± 342 | 6.1 ± 2.6 n | 91 ± 28 n |

| 2; 132 | high | 13 | 9.1 ± 6.5 bb | 10.3 ± 6.5 ba | <1 ct | 496 ± 178 | 3.8 ± 1.4 cb | 57 ± 17 bb | ||

| E2 | 2; 137 | low | 8 | 2360 | 2.2 ± 1.4 a | 4.1 ± 1.9 t | 27 ± 39 n | 782 ± 471 | 5.4 ± 3.1 a | 69 ± 29 a |

| 2; 137 | high | 13 | 6.1 ± 2.4 cc | 7.1 ± 3.1 ca | <1 ct | 324 ± 205 | 2.7 ± 1.6 ct | 33 ± 16 ca | ||

| E3 | 3; 278 | low | 4 | 1950 | <1.0 ± 0.1 n | 2.6 ± 1.7 n | 50 ± 34 n | 720 ± 235 | 2.7 ± 0.7 a | 36 ± 12 a |

| 3; 278 | high | 7 | 2.6 ± 0.8 ab | 4.9 ± 2.0 tn | 11 ± 29 nn | 432 ± 192 | 1.6 ± 0.7 ca | 22 ± 7 ba | ||

| E4 | 2; 180 | low | 7 | 13,500 | <1.0 ± 0.1 n | 3.3 ± 1.2 n | 38 ± 26 n | 826 ± 473 | 4.6 ± 2.6 n | 71 ± 33 n |

| E5 | 3; 51.7 | low | 7 | 520 | <1.4 ± 0.5 n | 3.6 ± 1.4 n | 35 ± 30 n | 407 ± 156 | 7.9 ± 3.0 n | 104 ± 31 n |

| E6 6 | 2; 106 | low | 3 | 550 | 4.6 ± 0.5 a | 6.3 ± 0.6 a | 0.8 ± 1.9 c | 496 ± 160 | 4.7 ± 1.5 a | 52 ± 12 b |

| Normal tablets | ||||||||||

| N1 | 3; 75.8 | low | 13 | 6520 | <1.3 ± 0.3 t | 3.0 ± 1.0 n | 47 ± 29 n | 400 ± 137 | 5.3 ± 1.8 b | 80 ± 26 n |

| 3; 75.8 | high | 13 | 1.6 ± 0.5 nn | 3.9 ± 1.1 aa | 12 ± 13 ab | 385 ± 169 | 5.1 ± 2.2 cn | 73 ± 17 an | ||

| 3; 75.8 | high-w 7 | 13 | 1.5 ± 0.4 nn | 3.9 ± 1.4 nn | 27 ± 32 nt | 457 ± 230 | 6.0 ± 3.0 nn | 85 ± 33 nn | ||

| N2 | 9; 41.5 | low | 13 | 360 | <1.2 ± 0.3 n | 2.1 ± 0.6 b | 66 ± 27 a | 294 ± 135 | 6.5 ± 3.0 n | 93 ± 32 n |

| 9; 41.5 | high | 13 | <1.3 ± 0.5 nn | 3.5 ± 0.9 nc | 18 ± 14 tc | 263 ± 128 | 5.8 ± 2.8 an | 82 ± 30 nn | ||

| N3 | 1; 155 | low | 4 | 10,700 | <0.9 ± 0.1 n | 2.2 ± 0.5 n | 47 ± 19 n | 1247 ± 357 | 8.0 ± 2.3 n | 111 ± 38 n |

| N4 6 | 9; 58.8 | low | 4 | 1160 | 1.6 ± 0.6 t | 3.9 ± 0.6 a | 8 ± 12 a | 345 ± 168 | 5.9 ± 2.9 n | 76 ± 31 n |

| Capsules | ||||||||||

| C1 | 1; 73 | low | 13 | 10,800 | <1.0 ± 0.3 n | 2.3 ± 0.7 t | 51 ± 24 n | 267 ± 96 | 3.7 ± 1.3 c | 54 ± 14 b |

| 1; 73 | high | 12 | <1.2 ± 0.4 nn | 3.6 ± 0.6 ac | 22 ± 14 nb | 281 ± 132 | 3.9 ± 1.8 cn | 53 ± 13 cn | ||

| C2 | 3; 169 | low | 13 | 210 | 1.5 ± 0.5 a | 3.6 ± 1.2 a | 19 ± 24 b | 290 ± 119 | 1.7 ± 0.7 c | 26 ± 11 c |

| 3; 169 | high | 13 | 2.2 ± 0.7 ba | 4.8 ± 2.0 aa | 2 ± 6 ca | 314 ± 123 | 1.9 ± 0.7 cn | 27 ± 8 cn | ||

| C3 | 4; 99.5 | high | 13 | 250 | <1.3 ± 0.8 n | 3.8 ± 1.0 t | 6 ± 4 b | 733 ± 245 | 7.4 ± 2.5 n | 109 ± 24 n |