Abstract

Anthocyanins are widely distributed, glycosylated, water-soluble plant pigments, which give many fruits and flowers their red, purple or blue colouration. Their beneficial effects in a dietary context have encouraged increasing use of anthocyanins as natural colourants in the food and cosmetic industries. However, the limited availability and diversity of anthocyanins commercially have initiated searches for alternative sources of these natural colourants. In plants, high-level production of secondary metabolites, such as anthocyanins, can be achieved by engineering of regulatory genes as well as genes encoding biosynthetic enzymes. We have used tobacco lines which constitutively produce high levels of cyanidin 3-O-rutinoside, delphinidin 3-O-rutinoside or a novel anthocyanin, acylated cyanidin 3-O-(coumaroyl) rutinoside to generate cell suspension cultures. The cell lines are stable in their production rates and superior to conventional plant cell cultures. Scale-up of anthocyanin production in small scale fermenters has been demonstrated. The cell cultures have also proven to be a suitable system for production of 13C-labelled anthocyanins. Our method for anthocyanin production is transferable to other plant species, such as Arabidopsis thaliana, demonstrating the potential of this approach for making a wide range of highly-decorated anthocyanins. The tobacco cell cultures represent a customisable and sustainable alternative to conventional anthocyanin production platforms and have considerable potential for use in industrial and medical applications of anthocyanins.

Abbreviations: C3R, cyanidin 3-O-rutinoside; C3couR, cyanidin 3-O-(coumaroyl) rutinoside; C3ferR, cyanidin 3-O-(feruloyl) rutinoside; D3R, delphinidin 3-O-rutinoside; Pel3R, pelargonidin 3-O-rutinoside; Peo3R, peonidin 3-O-rutinoside; AmDel, Antirrhinum majus Delila; AmRos1, Antirrhinum majus Rosea1

Keywords: Anthocyanins, Natural colours, Plant cell culture, Blackcurrant

Graphical abstract

We have developed tobacco cell cultures as customisable and sustainable alternatives to conventional anthocyanin production platforms by engineering expression of regulatory genes together with expression of genes encoding side chain decorating enzymes.

Highlights

-

•

Tobacco cell cultures for customisable anthocyanin production have been developed.

-

•

Differentially decorated and 13C-labelled anthocyanins have been produced.

-

•

Anthocyanin yield has been shown to be stable, up to 30 mg per g dry weight.

-

•

Scale-up anthocyanin production in small scale fermenters and purification have been demonstrated.

-

•

The approach is transferrable to other species for production of highly decorated anthocyanins.

1. Introduction

Anthocyanins are a widely distributed group of water-soluble pigments that colour the fruit and flowers of many plants. More than 650 different anthocyanins have been identified, distinguished by methylation, hydroxylation, glycosylation and acylation with both aliphatic and aromatic groups (Andersen and Jordheim, 2010, Zhang et al., 2014). The colour of anthocyanins is influenced by the degree of aromatic acylation, pH, co-pigmentation with other phenolic compounds, metal complexation and can range from orange, through red, pink and purple to blue (Yoshida et al., 2009). Consumption of anthocyanin-rich food promotes health, supported by many recent studies of anthocyanin-rich fruits such as blood orange, blueberry, bilberry and cranberry (Li et al., 2017, Titta et al., 2010, Yousuf et al., 2016), anthocyanin-rich corn (Petroni et al., 2017, Toufektsian et al., 2008) and fruits engineered to be rich in anthocyanins (Butelli et al., 2008, Espley et al., 2014, Zhang et al., 2015). Based on the health-promoting effects of anthocyanins and concerns associated with synthetic food colourants, there is increasing interest in replacement of synthetic dyes by natural anthocyanin colours (Oplatowska-Stachowiak and Elliott, 2017).

The natural colours segment is one of the fastest growing markets of the food and cosmetic colourants industries, with a calculated global market volume for anthocyanins of $291.7 Million in 2014 and a forecast of $387.4 Million for 2021.3 Industrial production of anthocyanin pigments relies largely on extraction from whole plants, with the most common sources being waste grape skins from the wine industry, black carrots, red cabbage, sweet potato, and berries (Buchweitz, 2016, Downham and Collins, 2000, Rodriguez-Amaya, 2016). So far, no anthocyanin-based blue colourant is commercially available, and the only source for natural blue colours is phycocyanin from the blue algae, Spirulina (Arthrospira platensis, Sigurdson et al., 2017).

The composition of anthocyanins from natural sources varies quantitatively and qualitatively, with the region of origin and the growth season of the plant source (Scalzo et al., 2013, Timmers et al., 2017). Pigment formulations need continued, laborious quality control adjustments to guarantee that extracts have the same colour properties, over time. These restrictions have forced manufacturers to search for alternative sources of natural colourants, with the added attraction of the health-beneficial properties of anthocyanins.

Microbial cell factories have been promoted as anthocyanin production platforms, and allow application of well-established scale-up and bioprocessing technologies for large-scale production (Marienhagen and Bott, 2013). However, such micro-organisms, predominantly yeast and Escherichia coli (E. coli), require the expression of at least 11 transgenes to introduce the anthocyanin biosynthetic pathway to produce even the simplest anthocyanin, pelargonidin 3-O-glucoside, from phenylalanine (Fig. 1). The number of transgenes required increases with the degree of decoration of the target anthocyanins and could easily involve more than 20 transgenes for aromatically acylated anthocyanins with bluish colours. Furthermore, plant cytochrome P450 monooxygenases such as flavonoid 3′ and 3′,5′-hydroxylases (F3′H and F3′5′H), are bottlenecks in microbial production platforms because of inefficient cofactor pools and failures in protein folding and membrane insertion in prokaryotic hosts (Dudnik et al., 2016). Although progress has been made in engineering individual P450 monooxygenases to work efficiently in bacteria (Wei et al., 2018), this requires individual modifications of each P450 protein (Ajikumar et al., 2010) and has not yet been reported for F3′H and F3′5′H for the production of anthocyanins. In contrast to microbes, plant cells contain all the genetic information required to produce and store anthocyanins and, dependent on the species, are not limited to the synthesis of anthocyanin monoglucosides. Commercial use of plant cell cultures was considered early on, because they allow sustainable production in Good Manufacturing Practice (GMP) environments on industrial scales. However, industrial application of plant cell cultures for secondary metabolite production, including anthocyanins, is still rare, mostly as a result of the limited stability of cultures long-term, variable product yields and high costs.

Fig. 1.

Engineered anthocyanin production in Nicotiana tabacum. (a) Anthocyanin biosynthesis pathway. Co-expression of AmDel and AmRos1 induces the expression of structural genes (dotted lines) and leads to production of high amounts of cyanidin 3-O-rutinoside (C3R) and traces of pelargonidin 3-O-rutinoside (Pel3R) in N. tabacum. Expression of a Petunia x hybrida flavonoid-3′,5′-hydroxylase (PhF3′5′H) leads to hydroxylation of the anthocyanin backbone on the B-ring and production of delphinidin 3-O-rutinoside (D3R, blue box). Expression of an anthocyanin 3-O-rutinoside-4′′′-hydroxycinnamoyl transferase from Solanum lycopersicum (Sl3AT) leads to the production of aromatically acylated cyanidin 3-O-(6′′-O-coumaroyl) rutinoside (C3couR) and cyanidin 3-O-(6′′-O-feruloyl) rutinoside (C3ferR). (b) Structures of anthocyanins produced in tobacco cultures. Abbreviations: PAL, phenylalanine ammonia-lyase; C4H, cinnamate 4-hydroxylase; 4CL, 4-coumarate-CoA ligase; CHS, chalcone synthase; CHI, chalcone isomerase; F3′H, flavonoid 3′-hydroxylase; F3H, flavanone 3β-hydroxylase; DFR, dihydroflavonol 4-reductase; LDOX, leucoanthocyanidin dioxygenase; GT, glycosyltransferase; GST, glutathione S-transferase; MATE, multidrug and toxic compound extrusion transporter; ABC, ATP-binding cassette transporter.

Several strategies have been used to increase anthocyanin yields in plants, mostly through activation of the biosynthetic pathway by ectopic expression of regulatory genes. Anthocyanin biosynthesis is controlled primarily at the transcriptional level by a complex of R2R3MYB, bHLH and WD40 Repeat proteins (the MBW complex) that is well conserved across all angiosperms (Ramsay and Glover, 2005). In the present study, we describe the development of suspension cultures from tobacco plants constitutively expressing the MYB Rosea1 (AmRos1) and bHLH Delila (AmDel) transcription factors from Antirrhinum majus. These cultures produce exceptionally high levels of anthocyanins. In contrast to cultures generated from non-transgenic anthocyanin-rich tissues, anthocyanin production in these cultures can be maintained stably, independent of the differentiation status of the cells, thus overcoming the obstacle of instability observed in conventional plant cell cultures. To expand the spectrum of different anthocyanins that can be produced, we co-expressed additional transgenes that encode enzymes for further decoration of cyanidin 3-O-rutinoside (C3R), the basic anthocyanin produced by tobacco. Concepts for scale-up of cell production and anthocyanin purification to the gram scale have been developed, demonstrating the potential for commercial use in industrial anthocyanin production. We demonstrate that this metabolic engineering approach is applicable to other plant species allowing the production of highly-decorated anthocyanins, which could expand the range of anthocyanin colourants available commercially, especially those towards the blue end of the spectrum.

2. Materials and methods

2.1. Plant materials and generation of suspension cultures

The generation and genotyping of transgenic tobacco lines have been described in Kallam et al. (2017). All constructs were expressed stably in Nicotiana tabacum cv. Samsun under the control of a double CaMV 35S promoter in pBin19-derived T-DNAs (Luo et al., 2007). Cell cultures were generated as described in Mustafa et al. (2011) with modifications described in Supplementary Methods and the composition of all media is given in Supplementary Table 1. The Vitis vinifera L. cell culture (PC-1137) was obtained from the German Collection of Microorganisms and Cell Cultures (Leibniz Institute DSMZ Braunschweig, Germany) and was maintained in modified B5 medium according to the supplier's instructions (www.dsmz.de/fileadmin/downloads/PC/medium/B5VIT.pdf).

Anthocyanin production from a mutated version of the Delila protein (AmDel*) in combination with AmRos1, discovered originally by screening stably-transformed plants carrying 35S:Del and 35S:Ros1 in the same T-DNA for high anthocyanin production without impact on plant growth, was investigated using transient assays in N. benthamiana (Northern Territory ecotype (NT), Bally et al., 2015). Infiltration of leaves with A. tumefaciens carrying the binary vector for expression of just AmRos1 induced anthocyanin biosynthesis 4 days after infiltration (Supplementary Fig. 1). Infiltration of two A. tumefaciens strains expressing AmRos1 and AmDel, resulted in about three-fold higher levels of anthocyanin production. Infiltration with A. tumefaciens strains carrying vectors for expression of AmRos1 and the truncated version of Delila (AmDelΔ) that is encoded by AmDel* showed enhanced anthocyanin production compared to AmRos1 alone, but not as great as with unmutated AmDel with AmRos1. These results suggested that the stable high level production of anthocyanins produced by 35S:AmRos1: 35S:AmDel* results from the N-terminus of the Del protein stabilizing the R2R3Myb protein in its interactions in the MBW complex. Similar reports have been made for deletions of the R/B-proteins in corn in their control of anthocyanin biosynthesis (Goff et al., 1992). We used plants stably transformed with 35S:AmRos1: 35S:AmDel* to generate cell cultures for scale-up production of anthocyanins in bioreactors. For the generation of Arabidopsis thaliana cultures, Columbia-0 wildtype and f3′h/tt7-7 plants (Appelhagen et al., 2014) were transformed with the vector carrying 35S:AmRos1: 35S:AmDel* through floral dipping. Callus was initiated as described for tobacco and was selected from strongly pigmented upper shoots of young plants. Explants with emerging callus were transferred from induction plates to modified B5 medium (Supplementary Table 1). Darkly pigmented callus was selected until the culture became stable for anthocyanin production. Fruits that were used for anthocyanin quantifications were purchased in a local grocery store.

2.2. Anthocyanin labelling with 13C-sucrose

Cell cultures of the AmDel/AmRos1 line were grown in small scale (20 mL total volume) using 3% (w/v) of unlabelled sucrose in the control treatments and 0.5% (w/v) fully labelled 13C-sucrose (Sigma-Aldrich, Germany, product number 605417) plus 2.5% unlabelled sucrose for anthocyanin labelling experiments. Cells were harvested and freeze dried after 10 days of cultivation at 23 °C. The experiment has been performed twice.

2.3. Cultivation of suspension cultures in plant cell bioreactors

Tobacco cells were grown on petri dishes and inoculated in a small amount of nutrient medium (LS supplemented with 1 mg L−1 2.4-D and 100 mg L−1 kanamycin). The medium was replaced every seven days, after 3–4 weeks, the suspension cultures were moved to 100 mL culture volume in 1 L Erlenmeyer flasks. For bioreactor cultivation, the LS or tobacco growth medium (Supplementary Table 1), with 1 mgL−1 2,4-D and 100 mgL−1 kanamycin was added to the bioreactors prior to sterilization by autoclaving at 121 °C for 15 min. After cooling, the bioreactors were connected to the controller for approximately 24 h prior to inoculation, to stabilize pH and to control and calibrate the flow of O2. Upon inoculation, each bioreactor was moved to a flow hood to maintain sterility. Prior to inoculation, the nutrient medium was removed from the Erlenmeyer flasks and the cells were diluted to a concentration of 30 g FW 100 mL−1 medium. This suspension was transferred to the bioreactors for a final concentration of 30 g cells L−1 medium, or 3% FW in a final volume of 1 L medium. Samples (10 mL) were collected from each reactor every other day, while maintaining constant stirring, to monitor growth rates. The weight of each 10 mL sample was measured, the growth medium was drained and the weight of the remaining cells was measured. The growth rate was calculated from the weight of cells, divided by total weight of the 10 mL sample. The corresponding growth rate per L was then calculated. Nutrient medium was replaced after seven days, and the final harvest was made after 14 days. The samples from each reactor were freeze dried for shipment. All cultures were maintained in the dark.

2.4. Anthocyanin extraction, spectrophotometric quantification and LC-UV/MS and LC-MS/MS analysis

Anthocyanins were extracted twice with 500 µL of 80% methanol/10 mg freeze-dried sample, acidified with either 2% formic acid or 1% HCl. The combined extract (1000 µL) was cleared by centrifugation prior to further use. Quantification of total anthocyanin content was performed following the pH differential method described by Giusti and Wrolstad (2001). Total anthocyanin content was calculated based on reference curves for cyanidin 3-O-glucoside and cyanidin 3-O-rutinoside in the range from 0.001 mg mL−1 to 0.05 mg mL−1, respectively. For LC-UV/MS analysis, 100 µL of the extract were mixed with 25 µL of solvent A (water + 0.5% formic acid) and incubated for one hour at 4 °C prior to injection to allow the formation of any potential precipitates. After centrifugation, 5 µL of the supernatant were injected per sample. Anthocyanins were analysed by LC-UV/MS as described in Oertel et al. (2017). Details for LC-UV/MS and MS/MS fragmentation analyses are provided in Supplementary Methods. LC-UV/MS data were analysed by means of Bruker Compass DataAnalysis version 4.1 software. The annotation of compounds was based on comparison of the measured retention times and molecular ion masses with reference standards and fragmentation patterns as obtained from LC-MS/MS experiments. Quantification was based on reference curves for the standard compounds C3G and C3R from integrated peak areas of extracted ion chromatograms.

2.5. Preparative isolation of anthocyanins from tobacco suspension cultures

Freeze dried cell suspension culture material was ground finely and anthocyanins were extracted sequentially with 80% methanol, 2% formic acid (FA) to a final ratio of 100 mL solvent g−1 cell dry weight (DW). After degreasing with heptane and filtering through nylon filters down to 0.2 µm, individual anthocyanins were isolated by sequential chromatographic separation as described in Supplementary Methods. The resulting fractions, showing absorption at 515 nm, were analysed by LC-UV/MS. The volume and the content of organic solvent in the final pure fraction were reduced under vacuum using a rotary evaporator. This fraction was frozen and lyophilised. The dry anthocyanin powder was covered with argon and stored at − 20 °C until further use.

3. Results

3.1. Suspension cultures of AmDel/AmRos1 tobacco plants are a stable source for production of C3R

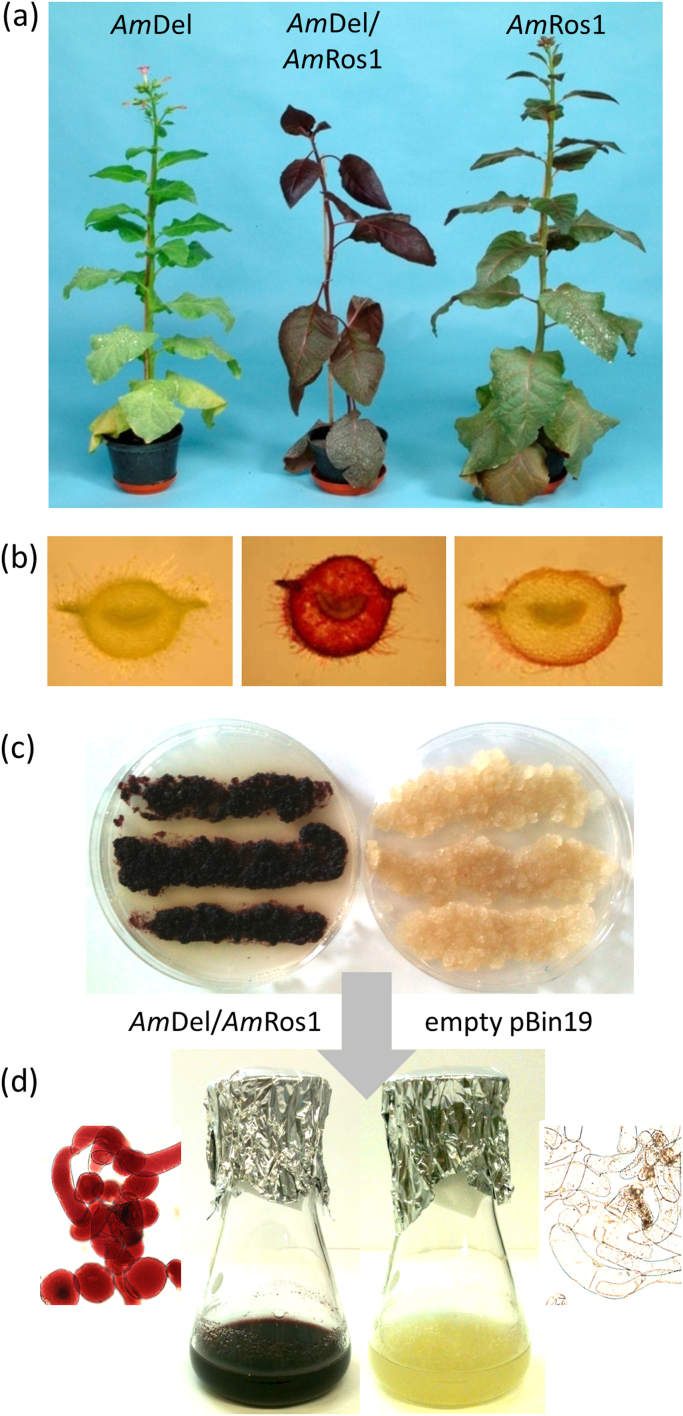

The structural genes of the anthocyanin biosynthetic pathway are usually controlled as a single regulon by MYB-bHLH-WD40 (MBW) transcription factor complexes. Altering the expression of components of the MBW complex has proven to be a powerful tool to manipulate anthocyanin accumulation. We reconstructed anthocyanin biosynthesis in Nicotiana tabacum cv. Samsun plants by constitutive co-expression of the AmRos1 and AmDel transcription factors from Antirrhinum majus (Kallam et al., 2017), Fig. 2a, b). Explants of these lines were dedifferentiated to develop in vitro cultures of friable calli, without losing the strength of anthocyanin production (Fig. 2c). Cultures were kept in the dark to prevent the biogenesis of chloroplasts and to maintain the biosynthesis of anthocyanins. Friable calli were subsequently used to establish cell suspensions in liquid MS medium (Fig. 2d), which were grown aerobically and heterotrophically in simple shake flasks with sucrose as carbon source, as described for the BY2 cell line from Nicotiana tabacum cv. Bright Yellow 2 (Nagata et al., 1992). Suspensions grew as single cells or as small clusters, which allowed optimal supply of nutrients and oxygen. Anthocyanin accumulation in N. tabacum wildtype plants is restricted to flower petals, which produce cyanidin 3-O-rutinoside almost exclusively (Luo et al., 2007). Extracts of suspension cultures generated from AmDel/AmRos1 plants were analysed by LC-MS and showed accumulation of up to 30 mg C3R g−1 DW (Fig. 3d). The oldest AmDel/AmRos1 culture has been maintained for more than 10 years without substantial reduction in anthocyanin production, demonstrating its stability, long-term, without aging or silencing of the transgenes.

Fig. 2.

Generation of tobacco suspension cultures. (a) Stably transformed tobacco plants expressing AmDel or AmRos1 and both transcription factors together. Only AmDel/AmRos1 lines showed strong anthocyanin accumulation throughout the plant. (b) Petiole sections of the same plants. AmDel/AmRos1 plants produce anthocyanins in all tissues, whereas in AmRos1 the pigmentation is limited to the epidermis and is completely absent in AmDel plants. (c) Dedifferentiated callus from leaf tissue. (d) Suspension cultures from dedifferentiated callus cells in MS medium and microscopic images of cells of suspension cultures.

Fig. 3.

Tobacco suspension cultures. (a) Shake flasks after 7 days of cultivation. (b) Microscopic images of the same suspension cultures. Scale bar 100 µm. (c) Freeze dried powder from suspension cultures. (d) Total anthocyanin amount in different suspension culture batches that have been collected over a period of six months. Error bars show standard deviation of 10 samples. (e) Total anthocyanin content in various fruits, quantified under the same conditions (n = 3).

3.2. Tobacco suspension cultures can produce variously decorated anthocyanins

Aiming to produce different anthocyanins with increasing complexity, we additionally expressed a gene encoding flavonoid 3′,5′-hydroxylase from Petunia x hybrida (PhF3′5′H) or a gene encoding an anthocyanin 3-O-rutinoside-4′′′-hydroxycinnamoyl transferase from Solanum lycopersicum (Sl3AT) in AmDel/AmRos1 tobacco lines (Kallam et al., 2017). Material from these lines was used to generate cell cultures as described for the AmDel/AmRos1 lines. All cultures were dark red due to the production of high amounts of anthocyanins, in contrast to a yellowish culture that had been generated from plants carrying the empty pBin19 T-DNA (Fig. 3a-c). In comparison, a conventional cell suspension culture, generated from wildtype grape skins, appeared pale red (Fig. 3a-c, right panel). Cells of the AmDel/AmRos1 line were red due to their production of C3R, while cells expressing AmDel/AmRos1 and PhF3′5′H were purple due to the production of D3R in addition to C3R. Cultures expressing the tomato anthocyanin 3-acyltransferase produced insoluble anthocyanin precipitates, known as anthocyanic vacuolar inclusions (AVIs, Kallam et al., 2017). In contrast to our anthocyanin tobacco cultures, the conventional grape culture contained sub-populations of cells, which produced no or only very small amounts of anthocyanins, when grown under the same conditions in the dark (Fig. 3b, right panel).

To establish whether the production of anthocyanins was stable over time, we quantified the total anthocyanin content in various batches of tobacco cultures that were grown over a period of six months and compared these to the conventional grape culture (Fig. 3d). All tobacco cultures produced between 4 and 5 times more anthocyanins in total than the grape culture, and had better stability. White cells in the grape culture became more dominant with increasing passages, which made it occasionally necessary to set up new liquid cultures from plate-grown callus, to allow better selection of cells that produced high amounts of anthocyanins. The engineered tobacco cultures, however, were always inoculated with cells from the last batch, and produced between 20 and 25 mg C3R equivalents g−1 DW. Compared to the amounts of anthocyanins found in plant tissues, the amount produced in the engineered tobacco cultures was exceptionally high, even when compared to anthocyanin-rich berries like blueberries and blackberries (Fig. 3e).

We analysed the anthocyanin composition in the different tobacco lines and evaluated the relative abundance of different anthocyanins based on the integrated peak areas from extracted ion chromatograms, and identified anthocyanins based on their PDA absorbance and mass fragmentation patterns (Fig. 4, Supplementary Fig. 2, 3 and 4). Anthocyanin extracts of AmDel/AmRos1 lines contained almost exclusively C3R, with very minor amounts of cyanidin 3-O-glucoside (C3G), pelargonidin 3-O-rutinoside (Pel3R) and peonidin 3-O-rutinoside (Peo3R). Similar profiles were observed for lines expressing AmDel/AmRos1 and PhF3′5′h, except for the additional production of delphinidin 3-O-rutinoside (D3R) which made up at least 30% of the total anthocyanins (Fig. 4, middle panel). About half of the anthocyanins in AmDel/AmRos1/Sl3AT extracts were aromatically acylated with coumaroyl- or feruloyl-moieties, with cyanidin 3-O-(coumaroyl) rutinoside (C3couR) and cyanidin 3-O-(feruloyl) rutinoside (C3ferR) being the most abundant acylated anthocyanins. Additionally, small amounts of pelargonidin 3-O-(coumaroyl) rutinoside (Pel3couR) and cyanidin 3-O-(coumaroyl) glucoside (C3couG) were detected (Fig. 4, lower panel). In addition to anthocyanins, we analysed the accumulation of different phenylpropanoids at 280 nm (Supplementary Fig. 5). The most abundant secondary phenylpropanoid compound in all lines was caffeoylquinic acid (CQA), with similar levels between the lines. Interestingly, the pBin19 cell culture without the transcription factors produced only minor amounts of CQA, indicating that AmDel/AmRos1 enhances the biosynthesis of chlorogenic acid as well as anthocyanins. As expected, no anthocyanins were detected in cell culture material carrying the T-DNA from a pBin19 empty vector (Supplementary Fig. 5c). Finally, we analysed changes in the anthocyanin and phenylpropanoid composition over time in different batches of the engineered tobacco cultures by LC-MS, without finding major differences (Supplementary Fig. 6). Thus, the production of anthocyanins was stable in the engineered cultures, both quantitatively and qualitatively.

Fig. 4.

Phytochemical characterisation of anthocyanins produced in tobacco cultures. (a) Representative UV-chromatograms at 515 nm for lines expressing AmDel/AmRos1, AmDel/AmRos1/PhF3′5′H and AmDel/AmRos1/Sl3AT. (b) Relative amount of anthocyanins, shown as percentage of total anthocyanins calculated from integrated peak areas of respective extracted ion chromatograms. Error bars show standard deviation of 2, 9 and 5 batches. Peak annotation is given in Supplementary Fig. 3.

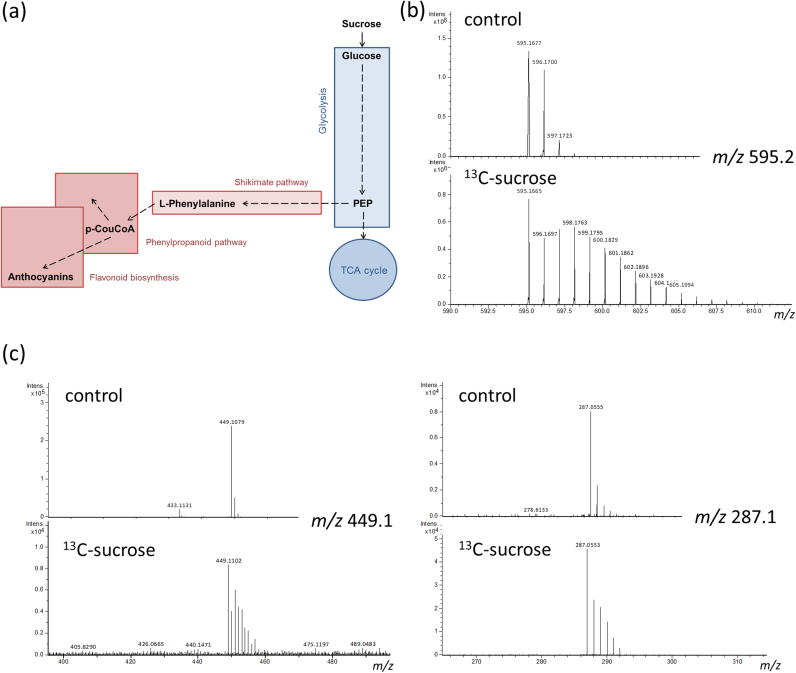

3.3. Production of 13C labelled anthocyanins

Regioselective 13C-labelling of anthocyanins can be obtained either by chemical synthesis or by production in plant cells using 13C-labelled precursors, such as phenylalanine or sucrose (Fig. 5a). Cultures of the AmDel/AmRos1 line were grown with 13C-sucrose. Growth was slightly reduced during cultivation with 13C-sucrose, but cultures produced similar amounts of C3R to unlabelled cultures. We extracted the sum of mass spectra across the chromatographic peak for C3R (monoisotopic mass m/z 595.2) at a retention time of 3.8 min to evaluate the carbon status of both samples (control and 13C-sucrose). The mass spectra were compared for their isotopic patterns of C3R (Fig. 5b). Under control conditions six isotopic variants of C3R were detected (Supplementary Table 2, top) although the second and the third isotopic versions accounted for 82% and 16% of the monoisotopic peak, respectively. Higher isotopic variants accounted for only minor percentages (2% for isotope 4, and > 1% for isotope 5 and 6). When one sixth of the sucrose in the medium was replaced by 13C-sucrose, the pattern showed a greater number of higher isotopic variants; we were able to detect at least 20 isotopic variants (Supplementary Table 2, bottom). The second and the third isotopic versions accounted for 63% and 71% of the monoisotopic peak, respectively. The fourth isotope accounted for 74% of the monoisotopic peak representing the highest amount of incorporated 13C with three atoms per C3R molecule. We concluded that there had been incorporation of three 13C molecules in about 70% of the C3R produced. This correlated to the biosynthesis of the anthocyanin backbone from phosphoenolpyruvate (PEP) units (C3-units) leading to an additive effect on the abundance of the fourth isotopic variant of C3R during cultivation with medium containing 13C-sucrose. The isotopes 5–11 had intensities between 11% and 64% relative to the monoisotopic peak. Higher isotopic variants were present at percentages below 10%. Incorporation of the 13C atoms into the anthocyanin backbone was confirmed by MS fragmentation analysis (Fig. 5c), where the change in isotopic pattern was observed for the C3G fragment ion (m/z 449.1) and the cyanidin fragment ion (m/z 287.1).

Fig. 5.

Regioselective 13C labelling of anthocyanins. (a) Schematic representation of anthocyanin biosynthesis highlighting major precursors and intermediates. (b) Mass spectrum of C3R showing the isotope pattern under control conditions with unlabelled sucrose (top) and after feeding of 13C-sucrose (bottom). The evaluation of the carbon status is given in Supplementary Table 2. (c) Mass spectra of C3G (left) and cyanidin (right) after MS fragmentation of the C3R precursor ion showing the isotope pattern under control conditions (top) and after 13C-sucrose treatment (bottom).

3.4. Scale-up in bioreactors

The degree of scale-up required to make a production system economically viable depends on the value of the product. The value of pure anthocyanins in today's market is at least $120 mg−1, where they are commercially available, meaning that exploring factors that might limit scale-up production to, at least, the 1–10 L level was necessary. The lines carrying 35S:AmDel and 35S:AmRos1 were derived by crossing lines homozygous for the individual transgenes, and produced very high levels of anthocyanins but were relatively slow growing, even in shake flasks. To identify lines more suitable for scale-up production of anthocyanins, we selected one primary transformant with a T-DNA insertion from a vector carrying both 35S:AmDel and 35S:AmRos1, which produced somewhat lower levels of anthocyanin which did not inhibit growth of the plants (Fig. 6a). We investigated why this line supported better plant growth, albeit with lower levels of anthocyanin production compared to the AmDel/AmRos1 plants produced from crosses. Molecular analysis showed that this line carried a 4 bp insertion in the sequence encoding AmDel, such that a truncated Delila protein was produced, explaining the lower level of anthocyanin production in this line. Callus from these plants initially produced sub-populations of pale or uncoloured cells, but continuous selection of dark calli allowed us to establish a suspension culture that stably produced about 20 mg C3R mg−1 DW in shake flasks. Despite lower anthocyanin production, this line (named AmDel*/AmRos1) was characterised by fast cell growth and higher net total anthocyanin yields (Fig. 6b, c), consistent with our observation that the production of higher amounts of anthocyanins was associated with limited cell growth, as also reported for strawberry and other plant cell cultures (Deroles, 2009, Nakamura et al., 1998).

Fig. 6.

Scale-up in bioreactors. (a) Dark red leaves of an AmDel*/AmRos1 tobacco plant next to green leaves of a wildtype plant (left panel) and a suspension culture generated from AmDel*/AmRos1 leaves (right panel). (b) Cells harvested from 50 mL suspension cultures after 7 days of growth with the same amount of starting material. (c) Total amount of anthocyanins produced in 50 mL AmDel*/AmRos1 and AmDel/AmRos1 suspension cultures. Error bar shows standard deviation of anthocyanin yield for 3 batches with each construct. (d) Array of stir tank bioreactors and control units. The outer vessels allow water circulation for temperature control and were wrapped in aluminium foil to prevent light exposure. (e) Growth curves of AmDel*/AmRos1 suspensions from four different bioreactor runs, grown in LS medium at 23° after inoculation with 3% packed cell volume. Biomass is shown as average FW ± standard deviation.

We used six small industrial scale bioreactors (2 L, Fig. 6d) specially designed for the cultivation of plant cells (Hvoslef-Eide et al., 2005, Lyngved et al., 2008). Particular problems associated with culturing of plant cells in commercial fermenters include shear-forces and cell growth on the stirring unit and sensors, which were minimised in our customised fermenters. Enrichment of the culture medium with sterile oxygen was achieved through thin-walled (0.2 mm) silicone tubes, in free-hanging loops, which allowed oxygen to pass through, but not the normal contaminants of laboratory air, which prevented infections while ensuring an optimal concentration of oxygen for the rapid proliferation of plant cells (Heyerdahl et al., 1995). We transferred the growth of AmDel*/AmRos1 line from shake flasks to these bioreactors. Several inoculation levels (2%, 3%, and 5%) were tested in LS medium, defining an optimal concentration of 3% starting material for this cell line. Optimum growth rates were obtained at 23 °C. We cultivated cells in parallel in four bioreactors and monitored growth over 14 days (Fig. 6e). Phytochemical characterisation did not show any differences in the anthocyanin composition when compared to flask-grown cultures. With tobacco growth medium with lowered 2,4-D concentration, the total amount produced in the bioreactors was up to 90 mg C3G equivalents L−1 culture medium or 180 mg per bioreactor run. At today's prices we estimate this to have a value of > $20,000.

3.5. Purification of anthocyanins from plant cell cultures to analytical standard grade

We developed a purification pipeline to isolate pure anthocyanins from the tobacco cultures. The overall purification strategy is shown in Fig. 7a together with results from the purification of D3R from AmDel/AmRos1/PhF3′5′H cultures. When using solvents containing hydrochloric acid (HCl) we observed rapid hydrolysis of conjugated sugars and browning due to degradation of anthocyanins. Therefore, we used methanol acidified with formic acid for extraction. Extracts generated this way were stable in colour, total anthocyanin amounts and composition for a period of several weeks when stored at 4 °C. To remove soluble lipophilic compounds from the crude extracts, a two-phase separation by the non-polar solvent, n-heptane was included. Micro-particles were removed by filtration through nylon membranes giving a clear polar extract with a comparable chromatographic profile (Fig. 7b, upper panel) to those obtained from the simple cell extracts. Consequently, we used column chromatography separation on C18-derivatized silica matrices because this offered the possibility of gradient elution and automation of UV-monitoring and fraction collection. Column separation removed the main non-anthocyanin phenylpropanoids, primarily CQA, and generated fractions containing anthocyanins, even the minor ones. For final preparative liquid chromatography purification, a C6 bonded phenyl ligand (Phenyl-Hexyl) based matrix was used because it gave unique selectivity for aromatic and moderately polar analytes through pi-pi interactions. As a result, highly pure anthocyanin preparations were obtained (Fig. 7b, lower panel) with UV-chromatogram-based purities of 95–98% and mass spectrometry based purities of 70–78%. The identities of the purified anthocyanins were confirmed by MS fragment analysis (Fig. 7c). The combination of these methods gave recovery rates of about 90%.

Fig. 7.

Anthocyanin purification from tobacco cell suspension cultures. (a) Purification scheme. (b) Representative UV-chromatograms at 515 nm and 280 nm for defatted extract and pure isolate fractions from purification of D3R. (C) Purity check by mass spectrometry analysis. MS spectra of solvent and pure isolate fractions are shown together with the MS fragmentation spectrum for confirming the identity of the isolated D3R. Abbreviations: delphinidin (D); glucoside (Glc); rutinoside (R); delphinidin 3-O-rutinoside (D3R); methanol (MeOH); acetonitrile (AcN).

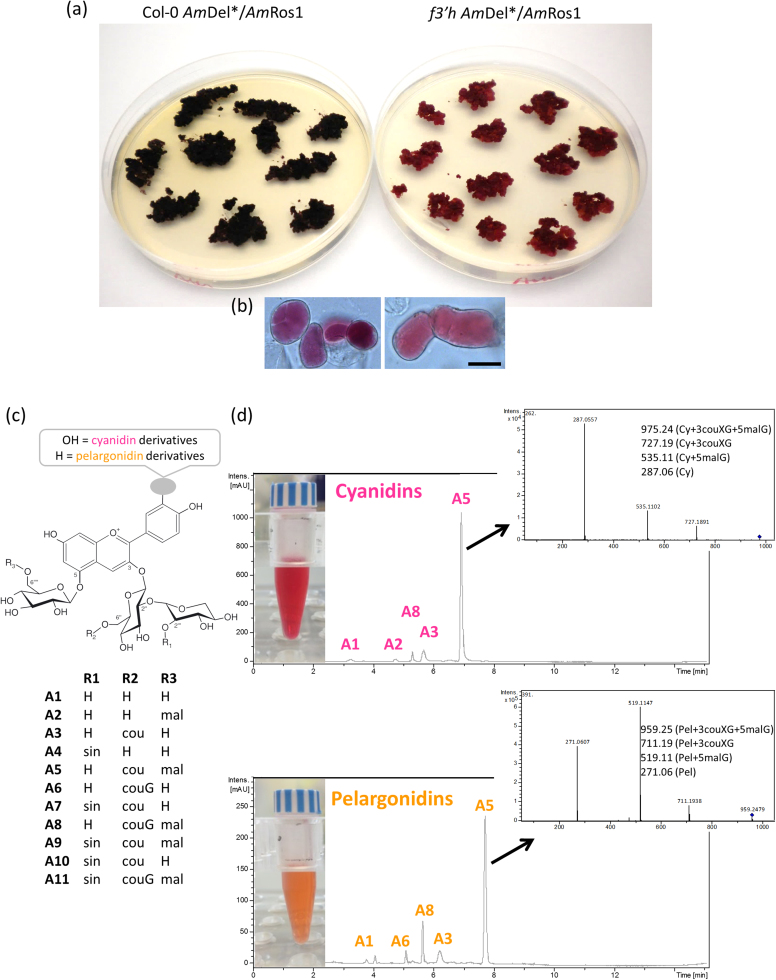

3.6. Engineered cell cultures of different species can produce anthocyanins with multiple decorations

There is considerable commercial interest in developing strong blue anthocyanin preparations and to improve the stability of anthocyanins such that they can be used industrially as reliable, natural colourants. The amounts and types of anthocyanins that we have been able to generate from tobacco cell cultures are currently dominated by anthocyanins with red to purple colours (Fig. 3, Fig. 9). To establish whether our engineering strategy could be transferred to plants which produce more highly decorated anthocyanins, especially those that give rise to bluer colours, we generated cell cultures from Arabidopsis thaliana, aiming at the production of anthocyanins with multiple acyl-groups (Fig. 8). Callus cultures were generated from Col-0 and f3′h plants, both expressing the AmDel*/AmRos1 transcription factors. Arabidopsis f3′h mutants can produce only pelargonidin-derived anthocyanins, due to the lack of 3′-hydroxylation of the anthocyanin B-ring (Appelhagen et al., 2014, Fig. 1). Cells of the Col-0 culture appeared dark purple due to the accumulation of acylated cyanidin derivatives while cells of the f3′h culture had a more coral colour due to accumulation of acylated pelargonidin derivatives (Fig. 8a, b). A11, the most abundant and most highly modified anthocyanin in Arabidopsis, is decorated with four glycosyl and three acyl-groups (cyanidin 3-O-[2′′-O-(2′′′-O-(sinapoyl) xylosyl) 6′′-O-(p-O-(glucosyl)-p-coumaroyl) glucoside] 5-O-[6′′′′-O-(malonyl) glucoside], Bloor and Abrahams, 2002). The other anthocyanins, A1-A10, represent less decorated precursors of A11. Analysis of the anthocyanins produced by the Arabidopsis cultures showed cyanidin 3-O-[2′′-O-(xylosyl)−6"-O-(p-coumaroyl) glucoside] 5-O-[6′′′′-O-(malonyl) glucoside] to be the major anthocyanin in Col-0 lines (m/z 975.24) and pelargonidin 3-O-[2′′-O-(xylosyl)−6′′-O-(p-coumaroyl) glucoside] 5-O-[6′′′′-O-(malonyl) glucoside] to be the major anthocyanin in the f3′h lines (m/z 959.25, Fig. 8d). Both anthocyanins lack the sinapoyl and glucosyl moieties attached to the glucose on the C3 position and correspond to the A5 type anthocyanin found in wildtype Arabidopsis Col-0 (Fig. 8c).

Fig. 9.

Application of anthocyanins from plant cell cultures as food colourants. (a) Colours of anthocyanin extracts (200 µM C3R equivalents) from AmDel*/AmRos1 Arabidopsis cultures in 25 mM KCL pH1 and McIlvaine's citrate-phosphate buffer at various pH, as indicated, in comparison to extracts of AmDel*/AmRos1 tobacco cultures and a conventional grape culture. (b) Cupcakes decorated with icing sugar, supplemented with anthocyanins from Arabidopsis AmDel*/AmRos1 cell cultures. Preparations with acylated cyanidins had purple to dark blue colours at neutral and slightly alkaline pH (cupcakes on the left-hand side) and aubergine hues at acidic pH (lower cupcake on the right-hand side). Icing with extracts containing acylated pelargonidins had orange to red colours at acidic pH (cupcakes on the right-hand side).

Fig. 8.

Anthocyanins from Arabidopsis cell cultures. (a) Callus cultures generated from Col-0 (left) and f3′h plants (right), both expressing AmDel*/AmRos1. (b) Microscopic images of cells from the same cultures. Scale bar 25 µm. (c) Anthocyanin structures detected in A. thaliana. (d) UV chromatograms at 515 nm and MS fragmentation pattern of extracts from cultures carrying the AmDel*/AmRos1 construct in Col-0 (upper panel) and in the f3′h background (lower panel). The major compounds are cyanidin 3-O-[2′′-O-(xylosyl)−6′′-O-(p-coumaroyl) glucoside] 5-O-malonylglucoside (m/z 975.24) and pelargonidin cyanidin 3-O-[2′′-O-(xylosyl)−6′′-O-(p-coumaroyl) glucoside] 5-O-malonylglucoside (m/z 959.25).

The colour of anthocyanins at higher pH is of particular interest because many food and cosmetic applications involve environments of pH 6–8. The colours of the anthocyanins from Arabidopsis were compared at various pH to anthocyanins extracted from a conventional grape culture and a C3R tobacco culture (Fig. 9a). The anthocyanin extracts from Arabidopsis were purple to blue at neutral and slightly alkaline pH, whereas both the tobacco anthocyanin and those from the grape culture, had a brown grey hue, which quickly faded away. To demonstrate that these anthocyanins can also exhibit blue colours in food applications, we prepared cupcakes with icing that had been supplemented with freeze-dried powder preparations of our Arabidopsis cultures (Fig. 9b). By changing the pH with citrate-phosphate buffer, we generated purple colours and different shades of blue at neutral and slightly alkaline pH with the acylated Arabidopsis cyanidins, and orange to red colours at acidic pH with the acylated cyanidins and pelargonidins, respectively.

4. Discussion

4.1. Anthocyanin production in AmDel/AmRos1 cell cultures

Currently, the main commercial sources of anthocyanins are crude extracts from fruits or waste products from the beverage industries. These are not standardised with respect to the particular anthocyanins they contain, nor the amounts of each anthocyanin in the extract. The production in AmDel/AmRos1 cell cultures in contrast allowed us to control the type of anthocyanin produced and increased yields substantially (Fig. 3d). Our tobacco cultures produced C3R after activating the anthocyanin biosynthetic pathway with the AmDel/AmRos1 transcription factors and D3R or C3couR after expression of PhF′5′H and Sl3AT, respectively (Fig. 4). C3R and D3R are the major anthocyanins in blackcurrant and other berry juices (Nielsen et al., 2003). The anthocyanin composition in extracts of these cultures is simple, with just one or two major anthocyanins, which allows easy purification of pure compounds (Fig. 4, Fig. 7). The cultures produced the same anthocyanins as the corresponding tobacco plants (Kallam et al., 2017), with the exception of small quantities of Peo3R (less than 4% of the total anthocyanins), presumably through the activity of endogenous methyltransferases (Nakamura et al., 1998, Zhou et al., 2012).

The number of commercially available pure anthocyanins is very small and limited to mono- and diglycosides of cyanidin, delphinidin, peonidin and petunidin, while acylated anthocyanins are almost entirely unavailable. The repertoire of anthocyanins produced in AmDel/AmRos1 cell cultures can be expanded, as demonstrated by the production of D3R and C3couR. The co-expression of different glycosyl- and acyltransferases can be used as a molecular toolkit to produce variously decorated custom-made anthocyanins (Kallam et al., 2017). Acylated anthocyanins are of particular interest, due to their increased stability and for aromatic acylation, their colour properties. Aromatic acylation causes a bathochromic shift such that the absorption maximum of the anthocyanin is shifted towards red and the pigment appears bluer (Luo et al., 2007). Some of the most intense blues in flowers (such as those in morning glory and delphinium) are conferred by highly acylated anthocyanins (Yoshida et al., 2009). We extended our approach by expressing AmDel*/AmRos1 in Arabidopsis, which already carries the genetic information to produce tri-acylated anthocyanins. The decoration-pattern of Arabidopsis anthocyanins depends on the growth conditions and stimuli that were used to induce anthocyanin biosynthesis (Kovinich et al., 2014). The most decorated and usually most abundant anthocyanidin in Arabidopsis wildtype leaves is the coumaroylated, sinapoylated and malonylated cyanidin A11 (Bloor and Abrahams, 2002). The Col-0 and f3′h AmDel*/AmRos1 cultures of Arabidopsis produced predominantly A5-type anthocyanins without the sinapoyl- and second glucosyl-groups on the anthocyanins (Fig. 8). Similar anthocyanin profiles have been described for cultured cells and roots of the Arabidopsis pap1-D mutant (Tohge et al., 2005, Zhou et al., 2012), that ectopically produces anthocyanins as a result of insertion of a T-DNA for activation tagging close to the PAP1 (MYB75) gene. Anthocyanin acyltransferases belong to two different families. BAHD acyltransferases localise to the cytoplasm and use acyl-coenzyme A thioesters as acyl-donors, while serine carboxypeptidase-like (SCPL) acyltransferases are vacuolar enzymes that utilise acyl-sugars as substrates (Sasaki et al., 2014). The Arabidopsis anthocyanin 3-O-glucoside coumaroyltransferase and anthocyanin 5-O-glucoside malonyltransferase are BAHD acyltransferases required for the synthesis of A5 (Luo et al., 2007), while the anthocyanin 3-O-glucoside-2″-O-xyloside: sinapoyltransferase (SCLP10) belongs to the SCLP family (Fraser et al., 2007). A lack of sinapoylated anthocyanins has also been reported after loss of SCLP10 activity and for ugt84a2 mutants, suggesting that UGT84A2 is crucial for the supply of 1-O-sinapoyl glucose for the biosynthesis of A11 (Yonekura‐Sakakibara et al., 2012). Similarly, the supply of sinapoyl glucose may limit the production of sinapoylated anthocyanins in our AmDel*/AmRos1 cultures or the expression of SCLP10 may not be activated by the transcription factors. When compared to A11, the final glycosylation of the coumarate moiety is also absent in A5, which, like sinapoylation, is catalysed by a vacuolar enzyme, the acyl-glucose dependent glycosyltransferase BGLU10 (Miyahara et al., 2013). In contrast to the SCLP catalysed steps, both cultures, Col-0 and f3′h, produced A8-type anthocyanins, possibly due to some BGLU10 activity. However, we cannot rule out that the expression of the vacuolar acyl- and glycosyltransferases is not under control of AmDel*/AmRos1. Induction of these genes might require a full-length bHLH or different regulators. Interestingly, overexpression of PAP1 preferentially increased accumulation of A5 (208-fold induction compared to controls) relative to A11 (29.31-fold) suggesting that even the endogenous MBW complex does not activate the SCLP10 and BGLU10 as strongly as other genes in the anthocyanin biosynthetic pathway (Tohge et al., 2005). The expression of the anthocyanin BAHD acyltransferases and UDP-sugar dependent glycosyltransferases (UGTs) is controlled by the MBW complex, as already demonstrated in tomato (Butelli et al., 2008, Tohge et al., 2015, Zhang et al., 2014) and by the induced production of A5 in our Arabidopsis cell cultures (Fig. 8). The production of anthocyanins through expression of AmDel*/AmRos1 and without further engineering of vacuolar glycosyl- and acyltransferases might be limited to anthocyanins with decorations added by BAHD acyltransferases and UGTs.

Blue anthocyanins are industrially important, due to the lack of natural blue colourants and the desire to replace synthetic food dyes with natural pigments (Sigurdson et al., 2017). The best targets for stable blue colours are aromatically acylated anthocyanins. The acylated A5 cyanidin from the Col-0 Arabidopsis culture showed improved stability of blue colours at neutral to slightly alkaline pH, whereas the non- or monoacylated cyanidin and peonidin glycosides from the tobacco and grape cultures had almost no colour at these pH values and gave browning upon oxidation (Fig. 9). The Arabidopsis A5 cyanidin confirms the idea that acylated anthocyanins could provide a blue pigment suitable as a replacement for synthetic blue dyes.

4.2. Production of 13C-labelled anthocyanins in AmDel/AmRos1 cell cultures

Despite the high demand of labelled anthocyanins for bioavailability and tracer studies in humans, regioselective 13C-labelling of anthocyanins has been shown only rarely. Production of 13C-labelled anthocyanins by Vitis vinifera cell suspension cultures was demonstrated decades ago (Krisa et al., 1999), but the system never went into commercial use. Recent studies on the pharmacokinetics of anthocyanins and their metabolites in humans (Czank et al., 2013, Ferrars et al., 2014) relied on chemical synthesis of the isotopically labelled anthocyanin, C3G (Zhang et al., 2011). We have shown the suitability of our cell cultures for the 13C-labelling of anthocyanins. The observed reduction in cell growth upon addition of 13C-sucrose may be overcome by application of the 13C-labelled precursor after exponential growth of the cells has started, as shown for 13C-phenylalanine application in Vitis vinifera cell suspension cultures (Krisa et al., 1999). Full labelling of the anthocyanin backbone would require several rounds of media exchange until the cellular pool of 13C-sucrose has reached equilibrium. To date, a maximum 13C enrichment of 65% for anthocyanins from Vitis vinifera cell suspension cultures (Krisa et al., 1999) and of nearly 100% for chemically synthesised 13C5-C3G (Zhang et al., 2011) have been reported. Against this background, our cell cultures present a valuable system for the production of defined isotopically labelled anthocyanins which can be used for bioavailability and degradation studies in humans.

4.3. Plant cell cultures versus microbial production platforms

Flavonoids such as anthocyanins are made specifically by plants and microbes such as yeast and E. coli require extensive engineering to produce anthocyanins. The main hurdles are the cytochrome P450 monooxygenases F3′H and F3′5′H, which have low activity in prokaryotic hosts. When anthocyanins are synthesised from coumaroyl-CoA and malonyl-CoA in bacterial hosts, production is limited to pelargonidin derivatives with just one hydroxyl group on the B-ring, due to the low activity of the F3′H and F3′5′H cytochrome P450 proteins. Circumvention of these limiting steps has been achieved by feeding precursors to produce cyanidin- and delphinidin-derived anthocyanins. Progress has been made in engineering anthocyanin production in E. coli by feeding of eriodictyol or catechin and their conversion to cyanidin 3-O-glucoside (Chouhan et al., 2017). Production titers in the mg L−1 range have been obtained after improving substrate uptake, increasing the intracellular availability of UDP-glucose, inhibition of the UDP-glucose degradation pathway and construction of artificial enzyme clusters to avoid fast degradation of anthocyanidin aglycones (Leonard et al., 2008, Lim et al., 2015, Yan et al., 2008). Plant cell cultures, in contrast, can produce relatively large amounts of anthocyanins from just sugar, without precursor-feeding or extensive engineering of enzymes to improve metabolic flux, and without the production of non-specific side-products. More recently an E. coli polyculture strategy has been developed to synthesise pelargonidin 3-O-glucoside (Pel3G) from p-coumaric and caffeic acids derived from different sugars (Jones et al., 2017). Although encouraging, these protocols have not been demonstrated as effective under scale-up conditions where competition between different microbial components of the communities might limit production of anthocyanins. Similar approaches have been taken for anthocyanin production in Saccharomyces cerevisiae, without substantial success in high level production of anthocyanins (Krivoruchko and Nielsen, 2015).

The three pillars of efficient production platforms are product titers, total yield, and production rate. About 25–30 mg per g DW of AmDel/AmRos1 cultures consists of anthocyanins, which makes their yield superior to other production platforms that synthesise anthocyanins from sugars. De novo synthesis in E. coli polycultures has led to the production of up to 10 mg Pel3G L−1 (Jones et al., 2017), in comparison to 90 mg C3R L−1 in our plant cell bioreactor experiments, which is at least nine times higher yields. However, plant cells grow more slowly than E. coli and, consequently, must have higher yields to match the production rates of microbial systems. Preliminary experiments with improved growth medium indicated that yield in our tobacco cultures can be increased substantially under current scale-up conditions, making the plant cell production platforms comparable to microbial ones. Microbial systems might be suitable platforms for the production of simple pelargonidin glycosides or, with precursor-feeding, for cyanidin and delphinidin glycosides, but the main strength of plant cell cultures is their ability to produce rare anthocyanins with highly decorated side-chains that are currently unavailable, commercially. The activation of the whole anthocyanin pathway simply by expressing the AmDel/AmRos1 transcription factors allows rapid development of new cell lines, particularly when existing cell cultures can be transformed directly, and offers flexibility in the production of different anthocyanins, with properties widely diverged from those of simple anthocyanin glycosides

4.4. Are the AmDel/AmRos1 cultures superior to non-transformed, non-GM cultures?

Commercial use of plant cell cultures for the production of high-value secondary metabolites, such as terpenoids, flavonoids and alkaloids has been considered for many decades (Ananga et al., 2013, Davies and Deroles, 2014, Nosov, 2012, Ochoa-Villarreal et al., 2016, Roberts, 2007, Seitz and Hinderer, 1988, Wilson and Roberts, 2012). Cell cultures for the production of anthocyanins have been developed from black carrot (Gläßgen et al., 1992), grape skins (Ananga et al., 2013, Fig. 3), sweet potato (Konczak-Islam et al., 2003, Nozue et al., 1987) and other plants (Deroles, 2009), but no cell culture system has yet made it to bulk production on industrial-scales. Plant cells cultures are typically heterogeneous in their cell composition, as a result of selection during callus formation and de-differentiation, which can cause variation in growth rates and product yields (Ochoa-Villarreal et al., 2016). Culturing cambial meristematic cells, the stem cells that form vascular tissues, is a promising alternative to dedifferentiated cells, with better growth rates, aggregate sizes and overall consistency (Lee et al., 2010, Ochoa-Villarreal et al., 2016). However, it is unlikely that anthocyanin biosynthesis can be induced in these cells without genetic manipulation because anthocyanin biosynthesis does not normally occur in cambial or vascular tissues. The major limitation in conventional cell cultures is that anthocyanins, similar to most natural compounds, accumulate in specialised differentiated cells, but fast and continuous growth of suspension cultures requires undifferentiated cells. Dedifferentiation is usually associated with loss of anthocyanin production (Deroles, 2009). Conventional cell cultures from wildtype grapes produced anthocyanins mainly in small cell aggregates that underwent some level of differentiation (clearly recognisable by their regular spherical shape, Fig. 3b), while the fast-growing undifferentiated fraction of cells lost their ability to produce anthocyanins (Ananga et al., 2013, Fig. 3). Cells that do not produce anthocyanins usually have shorter doubling times and consequently become dominant over time and cause instability of these cultures. The conflict between growth rate and anthocyanin production requires the maintenance of a differentiation state that is an effective balance between the two extremes (Deroles, 2009). Plant materials must be continuously selected and cryobanks used to source materials for the growth of production batches. This is expensive and the resulting production costs are often too high to match sales-prices, particularly in the natural colourants market. In contrast to anthocyanins, some active pharmaceutical ingredients with limited availability and very high value have been produced economically in cell cultures such as the diterpenoid chemotherapeutic agents, Paclitaxel and Docetaxel, both produced in cell cultures of Taxus brevifolia (Howat et al., 2014).

The expression of the AmDel/AmRos1 transcription factors activates anthocyanin biosynthesis independent of the cell type and leads to anthocyanin accumulation in all cells (Fig. 3b). The total yields are higher than in conventional cultures. The continuous anthocyanin accumulation in AmDel/AmRos1 cultures simplifies and reduces the time that is required to develop novel cell cultures, because selection of anthocyanin-producing cells with the right differentiation state is unnecessary. Silencing of the transgenes can be prevented by selection with kanamycin, which, as a positive side effect, also prevents microbial contamination. The constitutive expression of AmDel/AmRos1 avoids aging of the cell cultures and confers long-term stability. We found that most of our AmDel/AmRos1 lines produced exceptionally high amounts of C3R, but grew slowly when compared to the pBin19 control or BY2 cell line, depending on the amounts of anthocyanins produced. This is consistent with previous observations that anthocyanin production affects cell growth reciprocally (Deroles, 2009). Efficient production systems require a good balance between anthocyanin production and cell growth to maximise yields. Using the truncated Delila protein in the AmDel*/AmRos1 lines, we found a simple way to reduce anthocyanin production to increase biomass production (Fig. 6a-c), in multiple plant hosts.

Production costs are crucial for commercialisation of plant cell cultures, particularly for colourants and pigments with lower market values than fine chemicals or pharmaceuticals. The easy and rapid development and the very high yields together with the stability of our cell cultures offer the potential to reduce the costs of anthocyanin production substantially. The system is flexible and can be set up in a relatively short time for different species, as demonstrated for the diacylated anthocyanins from Arabidopsis cultures (Fig. 8). Since anthocyanins with multiple aromatic acyl-groups are promising targets to replace synthetic blue food colourants, production in cell cultures of GRAS (Generally Regarded As Save) species, such as tomato and potato, could be of particular interest. This approach could also minimise the inclusion of unwanted by-products such as allergens and toxins in coloring food additives and potentially allows the use of crude extracts of cell cultures as colourants without the need for extensive and costly purification.

While the beneficial attributes of these cultures of necessity involve genetic modification, this is equally true of all microbial production systems. Regulatory approval for food colourant applications would involve cell cultures from GRAS species and demonstration that the effects of the individual transformation events are safe for human consumption.

5. Conclusion

Anthocyanin production is stable in AmDel/AmRos1 cultures. They have higher yields than conventional cultures which can reduce production costs substantially. The expression of AmDel/AmRos1 can be extended to other species, which already carry the genetic information to produce exotic anthocyanins, such as variously acylated anthocyanins. Cell cultures, also in bioreactors, offer an easy tool to expand the potential range of commercially available anthocyanins, on different scales, either as high-value fine chemicals or for the bulk production of colourants as well as for the customised production of labelled anthocyanins which are required for human stable-isotope tracer and bioavailability studies.

Acknowledgements

This research was funded by the ERA-IB ANTHOPLUS project (031A336A0), the BBSRC- OpenPlant Synthetic Biology Research grant BB/L014130/1, the Institute Strategic Programs ‘Understanding and Exploiting Plant and Microbial Secondary Metabolism’ (BB/J004596/1) and ‘Molecules from Nature’ (BB/P012523/1) from the Biotechnological and Biological Scientific Research Council (BBSRC) and an Institute Development Grant from the John Innes Centre. The authors thank Helen Ghirardello, Lionel Hill, Hilary Ford and Elena Barthel for their excellent assistance, as well as Andrew Davis and Phil Robinson for their photographic service and JIC Bioimaging Platform for the use of microscopes. We thank Professor Peter Waterhouse, QUT, Brisbane for the seeds of N. benthamiana (Northern Territory) and confirm that we have used them for research purposes only.

Acknowledgments

Competing interests

CM declares being a co-author of a patent (US 9,580,725 B2; Feb. 28, 2017) granted in the USA governing the use of AmDel and AmRos1 to induce anthocyanin biosynthesis in Solanaceous plants. The other authors have no competing interests to declare which could arise from pertinent commercial or other relationships.

Author contributions

IA, AM, HPM, AKHE, SM and CM contributed to conception and design of this study and participated in drafting and revising the manuscript. IA, and JR cultivated the plants, generated transgenic lines and cell cultures. AKWV, MW and AKHE performed the bioreactor scale-up. AM and AO undertook the metabolite profiling and AM undertook the preparative isolation of anthocyanins. IA, AM and CM wrote the manuscript. All authors read and approved the manuscript.

Footnotes

Supplementary data associated with this article can be found in the online version at doi:10.1016/j.ymben.2018.06.004.

Contributor Information

Ingo Appelhagen, Email: ingo.appelhagen@jic.ac.uk.

Anders Keim Wulff-Vester, Email: anders.wulff-vester@nmbu.no.

Micael Wendell, Email: Micael.Wendell@vkm.no.

Anne-Kathrine Hvoslef-Eide, Email: trine.hvoslef-eide@nmbu.no.

Julia Russell, Email: julia.russell@jic.ac.uk.

Anne Oertel, Email: oertel@ipk-gatersleben.de.

Stefan Martens, Email: stefan.martens@fmach.it.

Hans-Peter Mock, Email: mock@ipk-gatersleben.de.

Cathie Martin, Email: cathie.martin@jic.ac.uk.

Andrea Matros, Email: andrea.matros@adelaide.edu.au.

Appendix A. Supplementary material

Supplementary material

References

- Ajikumar P.K., Xiao W.H., Tyo K.E., Wang Y., Simeon F., Leonard E., Mucha O., Phon T.H., Pfeifer B., Stephanopoulos G. Isoprenoid pathway optimization for Taxol precursor overproduction in Escherichia coli. Science. 2010;330:70–74. doi: 10.1126/science.1191652. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ananga A., Phills B., Ochieng J., Georgiev V., Tsolova V. Production of anthocyanins in grape cell cultures: a potential source of raw material for pharmaceutical, food, and cosmetic industries. In: Sladonja B., editor. The Mediterranean Genetic Code - Grapevine and Olive. InTech Open Access Publisher; 2013. p. 41. [Google Scholar]

- Andersen Ø.M., Jordheim M. Anthocyanins. In: Andersen Ø.M., Jordheim M., editors. Encyclopedia of Life Sciences. eLS. John Wiley & Sons, Ltd; Chichester: 2010. p. 12. [Google Scholar]

- Appelhagen I., Thiedig K., Nordholt N., Schmidt N., Huep G., Sagasser M., Weisshaar B. Update on transparent testa mutants from Arabidopsis thaliana: characterisation of new alleles from an isogenic collection. Planta. 2014;240:955–970. doi: 10.1007/s00425-014-2088-0. [DOI] [PubMed] [Google Scholar]

- Bally J., Nakasugi K., Jia F., Jung H., Ho S.Y., Wong M., Paul C.M., Naim F., Wood C.C., Crowhurst R.N., Hellens R.P., Dale J.L., Waterhouse P.M. The extremophile Nicotiana benthamiana has traded viral defence for early vigour. Nat. Plants. 2015;1:15165. doi: 10.1038/nplants.2015.165. [DOI] [PubMed] [Google Scholar]

- Bloor S.J., Abrahams S. The structure of the major anthocyanin in Arabidopsis thaliana. Phytochemistry. 2002;59:343–346. doi: 10.1016/s0031-9422(01)00460-5. [DOI] [PubMed] [Google Scholar]

- Buchweitz M. Natural solutions for blue colors in food. In: Carle R., Schweiggert R., editors. Handbook on Natural Pigments in Food and Beverages. Elsevier; 2016. pp. 355–384. [Google Scholar]

- Butelli E., Titta L., Giorgio M., Mock H.P., Matros A., Peterek S., Schijlen E.G.W.M., Hall R.D., Bovy A.G., Luo J., Martin C. Enrichment of tomato fruit with health-promoting anthocyanins by expression of select transcription factors. Nat. Biotechnol. 2008;26:1301–1308. doi: 10.1038/nbt.1506. [DOI] [PubMed] [Google Scholar]

- Chouhan S., Sharma K., Zha J., Guleria S., Koffas M.A.G. Recent advances in the recombinant biosynthesis of polyphenols. Front. Microbiol. 2017;8:2259. doi: 10.3389/fmicb.2017.02259. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Czank C., Cassidy A., Zhang Q., Morrison D.J., Preston T., Kroon P.A., Botting N.P., Kay C.D. Human metabolism and elimination of the anthocyanin, cyanidin-3-glucoside: a 13C-tracer study. Am. Clin. Nutr. 2013;97:995–1003. doi: 10.3945/ajcn.112.049247. [DOI] [PubMed] [Google Scholar]

- Davies K.M., Deroles S.C. Prospects for the use of plant cell cultures in food biotechnology. Curr. Opin. Biotechnol. 2014;26:133–140. doi: 10.1016/j.copbio.2013.12.010. [DOI] [PubMed] [Google Scholar]

- Deroles S. Anthocyanin biosynthesis in plant cell cultures: a potential source of natural colourants. In: Gould K., Davies K.M., Winefield C., editors. Anthocyanins: Biosynthesis, Functions, and Applications. Springer; New York, New York, NY: 2009. pp. 108–167. [Google Scholar]

- Downham A., Collins P. Colouring our foods in the last and next millennium. Int. J. Food Sci. Technol. 2000;35:5–22. [Google Scholar]

- Dudnik A., Almeida A.F., Andrade R., Avila B., Bañados P., Barbay D., Bassard J.-E., Benkoulouche M., Bott M., Braga A. BacHBerry: bacterial hosts for production of bioactive phenolics from bERRY fruits. Phytochem. Rev. 2016:1–36. [Google Scholar]

- Espley R.V., Butts C.A., Laing W.A., Martell S., Smith H., McGhie T.K., Zhang J., Paturi G., Hedderley D., Bovy A. Dietary flavonoids from modified apple reduce inflammation markers and modulate gut microbiota in mice. J. Nutr. 2014;144:146–154. doi: 10.3945/jn.113.182659. [DOI] [PubMed] [Google Scholar]

- Ferrars R., Czank C., Zhang Q., Botting N., Kroon P., Cassidy A., Kay C. The pharmacokinetics of anthocyanins and their metabolites in humans. Br. J. Pharmacol. 2014;171:3268–3282. doi: 10.1111/bph.12676. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fraser C.M., Thompson M.G., Shirley A.M., Ralph J., Schoenherr J.A., Sinlapadech T., Hall M.C., Chapple C. Related Arabidopsis serine carboxypeptidase-like sinapoylglucose acyltransferases display distinct but overlapping substrate specificities. Plant Physiol. 2007;144:1986–1999. doi: 10.1104/pp.107.098970. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Giusti M.M., Wrolstad R.E. Characterization and measurement of anthocyanins by UV‐visible spectroscopy. Curr. Protoc. Food Anal. Chem. 2001 [Google Scholar]

- Gläßgen W.E., Wray V., Strack D., Metzger J.W., Seitz H.U. Anthocyanins from cell suspension cultures of Daucus carota. Phytochemistry. 1992;31:1593–1601. doi: 10.1016/0031-9422(92)83113-d. [DOI] [PubMed] [Google Scholar]

- Goff S.A., Cone K.C., Chandler V.L. Functional analysis of the transcriptional activator encoded by the maize B gene: evidence for a direct functional interaction between two classes of regulatory proteins. Genes Dev. 1992;6:864–875. doi: 10.1101/gad.6.5.864. [DOI] [PubMed] [Google Scholar]

- Heyerdahl P.H., Olsen O.A.S., Hvoslef-Eide A.K. Engineering aspects of plant propagation in bioreactors. In: Aitken-Christie J., Kozai T., Smith M.A.L., editors. Automation and Environmental Control in Plant Tissue Culture. Springer; 1995. pp. 87–123. [Google Scholar]

- Howat S., Park B., Oh I.S., Jin Y.-W., Lee E.-K., Loake G.J. Paclitaxel: biosynthesis, production and future prospects. New Biotechnol. 2014;31:242–245. doi: 10.1016/j.nbt.2014.02.010. [DOI] [PubMed] [Google Scholar]

- Hvoslef-Eide A.K., Olsen O.A.S., Lyngved R., Munster C., Heyerdahl P.H. Bioreactor design for propagation of somatic embryos. Plant Cell, Tissue Organ Cult. 2005;81:265–276. [Google Scholar]

- Jones J.A., Vernacchio V.R., Collins S.M., Shirke A.N., Xiu Y., Englaender J.A., Cress B.F., McCutcheon C.C., Linhardt R.J., Gross R.A., Koffas M.A.G. Complete Biosynthesis of Anthocyanins Using E. coli Polycultures. MBio. 2017;8:e00621–00617. doi: 10.1128/mBio.00621-17. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kallam K., Appelhagen I., Luo J., Albert N., Zhang H., Deroles S., Hill L., Findlay K., Andersen Ø.M., Davies K. Aromatic decoration determines the formation of anthocyanic vacuolar inclusions. Curr. Biol. 2017;27:945–957. doi: 10.1016/j.cub.2017.02.027. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Konczak-Islam I., Okuno S., Yoshimoto M., Yamakawa O. Composition of phenolics and anthocyanins in a sweet potato cell suspension culture. Biochem. Eng. J. 2003;14:155–161. [Google Scholar]

- Kovinich N., Kayanja G., Chanoca A., Riedl K., Otegui M.S., Grotewold E. Not all anthocyanins are born equal: distinct patterns induced by stress in Arabidopsis. Planta. 2014;240:931–940. doi: 10.1007/s00425-014-2079-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Krisa S., Téguo P.W., Decendit A., Deffieux G., Vercauteren J., Mérillon J.-M. Production of 13C-labelled anthocyanins by Vitis vinifera cell suspension cultures. Phytochemistry. 1999;51:651–656. doi: 10.1016/s0031-9422(99)00068-0. [DOI] [PubMed] [Google Scholar]

- Krivoruchko A., Nielsen J. Production of natural products through metabolic engineering of Saccharomyces cerevisiae. Curr. Opin. Biotechnol. 2015;35:7–15. doi: 10.1016/j.copbio.2014.12.004. [DOI] [PubMed] [Google Scholar]

- Lee E.K., Jin Y.W., Park J.H., Yoo Y.M., Hong S.M., Amir R., Yan Z., Kwon E., Elfick A., Tomlinson S., Halbritter F., Waibel T., Yun B.W., Loake G.J. Cultured cambial meristematic cells as a source of plant natural products. Nat. Biotechnol. 2010;28:1213–1217. doi: 10.1038/nbt.1693. [DOI] [PubMed] [Google Scholar]

- Leonard E., Yan Y., Fowler Z.L., Li Z., Lim C.G., Lim K.H., Koffas M.A. Strain improvement of recombinant Escherichia coli for efficient production of plant flavonoids. Mol. Pharm. 2008;5:257–265. doi: 10.1021/mp7001472. [DOI] [PubMed] [Google Scholar]

- Li D., Wang P., Luo Y., Zhao M., Chen F. Health benefits of anthocyanins and molecular mechanisms: update from recent decade. Crit. Rev. Food Sci. Nutr. 2017;57:1729–1741. doi: 10.1080/10408398.2015.1030064. [DOI] [PubMed] [Google Scholar]

- Lim C.G., Wong L., Bhan N., Dvora H., Xu P., Venkiteswaran S., Koffas M.A. Development of a recombinant escherichia coli strain for overproduction of the plant pigment anthocyanin. Appl. Environ. Microbiol. 2015;81:6276–6284. doi: 10.1128/AEM.01448-15. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Luo J., Nishiyama Y., Fuell C., Taguchi G., Elliott K., Hill L., Tanaka Y., Kitayama M., Yamazaki M., Bailey P., Parr A., Michael A.J., Saito K., Martin C. Convergent evolution in the BAHD family of acyl transferases: identification and characterization of anthocyanin acyl transferases from Arabidopsis thaliana. Plant J. 2007;50:678–695. doi: 10.1111/j.1365-313X.2007.03079.x. [DOI] [PubMed] [Google Scholar]

- Lyngved R., Snipen L., Iversen T.-H., Hvoslef-Eide A. Influence of potential growth factors on the production of proembryogenic masses of Cyclamen persicum Mill. in bioreactors. Sci. Hortic. 2008;118:53–59. [Google Scholar]

- Marienhagen J., Bott M. Metabolic engineering of microorganisms for the synthesis of plant natural products. J. Biotechnol. 2013;163:166–178. doi: 10.1016/j.jbiotec.2012.06.001. [DOI] [PubMed] [Google Scholar]

- Miyahara T., Sakiyama R., Ozeki Y., Sasaki N. Acyl-glucose-dependent glucosyltransferase catalyzes the final step of anthocyanin formation in Arabidopsis. J. Plant Physiol. 2013;170:619–624. doi: 10.1016/j.jplph.2012.12.001. [DOI] [PubMed] [Google Scholar]

- Mustafa N.R., De Winter W., Van Iren F., Verpoorte R. Initiation, growth and cryopreservation of plant cell suspension cultures. Nat. Protoc. 2011;6:715. doi: 10.1038/nprot.2010.144. [DOI] [PubMed] [Google Scholar]

- Nagata T., Nemoto Y., Hasezawa S. Tobacco BY-2 cell line as the “HeLa” cell in the cell biology of higher plants. Int. Rev. Cytol. 1992;132:1–30. [Google Scholar]

- Nakamura M., Seki M., Furusaki S. Enhanced anthocyanin methylation by growth limitation in strawberry suspension culture. Enzyme Microb. Technol. 1998;22:404–408. [Google Scholar]

- Nielsen I.L.F., Haren G.R., Magnussen E.L., Dragsted L.O., Rasmussen S.E. Quantification of anthocyanins in commercial black currant juices by simple high-performance liquid chromatography. Investigation of their pH stability and antioxidative potency. J. Agric. Food Chem. 2003;51:5861–5866. doi: 10.1021/jf034004+. [DOI] [PubMed] [Google Scholar]

- Nosov A. Application of cell technologies for production of plant-derived bioactive substances of plant origin. Appl. Biochem. Microbiol. 2012;48:609–624. [Google Scholar]

- Nozue M., Kawai J., Yoshitama K. Selection of a high anthocyanin-producing cell line of sweet potato cell cultures and identification of pigments. J. Plant Physiol. 1987;129:81–88. [Google Scholar]

- Ochoa-Villarreal M., Howat S., Hong S., Jang M.O., Jin Y.-W., Lee E.-K., Loake G.J. Plant cell culture strategies for the production of natural products. BMB Rep. 2016;49:149–158. doi: 10.5483/BMBRep.2016.49.3.264. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Oertel A., Matros A., Hartmann A., Arapitsas P., Dehmer K.J., Martens S., Mock H.-P. Metabolite profiling of red and blue potatoes revealed cultivar and tissue specific patterns for anthocyanins and other polyphenols. Planta. 2017;246:281–297. doi: 10.1007/s00425-017-2718-4. [DOI] [PubMed] [Google Scholar]

- Oplatowska-Stachowiak M., Elliott C.T. Food colors: existing and emerging food safety concerns. Crit. Rev. Food Sci. Nutr. 2017;57:524–548. doi: 10.1080/10408398.2014.889652. [DOI] [PubMed] [Google Scholar]

- Petroni K., Trinei M., Fornari M., Calvenzani V., Marinelli A., Micheli L., Pilu R., Matros A., Mock H.-P., Tonelli C. Dietary cyanidin 3-glucoside from purple corn ameliorates doxorubicin-induced cardiotoxicity in mice. Nutr., Metab. Cardiovasc. Dis. 2017;27:462–469. doi: 10.1016/j.numecd.2017.02.002. [DOI] [PubMed] [Google Scholar]

- Ramsay N.A., Glover B.J. MYB–bHLH–WD40 protein complex and the evolution of cellular diversity. Trends Plant Sci. 2005;10:63–70. doi: 10.1016/j.tplants.2004.12.011. [DOI] [PubMed] [Google Scholar]

- Roberts S.C. Production and engineering of terpenoids in plant cell culture. Nat. Chem. Biol. 2007;3:387–395. doi: 10.1038/nchembio.2007.8. [DOI] [PubMed] [Google Scholar]

- Rodriguez-Amaya D.B. Natural food pigments and colorants. Curr. Opin. Food Sci. 2016;7:20–26. [Google Scholar]

- Sasaki N., Nishizaki Y., Ozeki Y., Miyahara T. The role of acyl-glucose in anthocyanin modifications. Molecules. 2014;19:18747–18766. doi: 10.3390/molecules191118747. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Scalzo J., Stevenson D., Hedderley D. Blueberry estimated harvest from seven new cultivars: fruit and anthocyanins. Food Chem. 2013;139:44–50. doi: 10.1016/j.foodchem.2013.01.091. [DOI] [PubMed] [Google Scholar]

- Seitz H.U., Hinderer W. Phytochemicals in plant cell cultures; Anthocyanins. In: Constabel F., Vasil I.K., editors. Vol. 5. Academic Press; San Diego: 1988. pp. 49–76. (Cell Culture and Somatic Cell Genetics of Plants). [Google Scholar]

- Sigurdson G.T., Tang P., Giusti M.M. Natural colorants: food colorants from natural sources. Annu. Rev. Food Sci. Technol. 2017;8:261–280. doi: 10.1146/annurev-food-030216-025923. [DOI] [PubMed] [Google Scholar]

- Timmers M.A., Grace M.H., Yousef G.G., Lila M.A. Inter-and intra-seasonal changes in anthocyanin accumulation and global metabolite profiling of six blueberry genotypes. J. Food Compos. Anal. 2017 [Google Scholar]

- Titta L., Trinei M., Stendardo M., Berniakovich I., Petroni K., Tonelli C., Riso P., Porrini M., Minucci S., Pelicci P. Blood orange juice inhibits fat accumulation in mice. Int. J. Obes. 2010;34:578–588. doi: 10.1038/ijo.2009.266. [DOI] [PubMed] [Google Scholar]

- Tohge T., Nishiyama Y., Hirai M.Y., Yano M., Nakajima J. i., Awazuhara M., Inoue E., Takahashi H., Goodenowe D.B., Kitayama M. Functional genomics by integrated analysis of metabolome and transcriptome of Arabidopsis plants over‐expressing an MYB transcription factor. Plant J. 2005;42:218–235. doi: 10.1111/j.1365-313X.2005.02371.x. [DOI] [PubMed] [Google Scholar]

- Tohge T., Zhang Y., Peterek S., Matros A., Rallapalli G., Tandrón Y.A., Butelli E., Kallam K., Hertkorn N., Mock H.P. Ectopic expression of snapdragon transcription factors facilitates the identification of genes encoding enzymes of anthocyanin decoration in tomato. Plant J. 2015;83:686–704. doi: 10.1111/tpj.12920. [DOI] [PubMed] [Google Scholar]

- Toufektsian M.C., Lorgeril M., Nagy N., Salen P., Donati M.B., Giordano L., Mock H.P., Peterek S., Matros A., Petroni K., Pilu R., Rotilio D., Tonelli C., de Leiris J., Boucher F., Martin C. Chronic dietary intake of plant-derived anthocyanins protects the rat heart against ischemia-reperfusion injury. J. Nutr. 2008;138:747–752. doi: 10.1093/jn/138.4.747. [DOI] [PubMed] [Google Scholar]

- Wei Y., Ang E.L., Zhao H. Recent developments in the application of P450-based biocatalysts. Curr. Opin. Chem. Biol. 2018;43:1–7. doi: 10.1016/j.cbpa.2017.08.006. [DOI] [PubMed] [Google Scholar]

- Wilson S.A., Roberts S.C. Recent advances towards development and commercialization of plant cell culture processes for the synthesis of biomolecules. Plant Biotechnol. J. 2012;10:249–268. doi: 10.1111/j.1467-7652.2011.00664.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yan Y., Li Z., Koffas M.A. High-yield anthocyanin biosynthesis in engineered Escherichia coli. Biotechnol. Bioeng. 2008;100:126–140. doi: 10.1002/bit.21721. [DOI] [PubMed] [Google Scholar]

- Yonekura‐Sakakibara K., Fukushima A., Nakabayashi R., Hanada K., Matsuda F., Sugawara S., Inoue E., Kuromori T., Ito T., Shinozaki K. Two glycosyltransferases involved in anthocyanin modification delineated by transcriptome independent component analysis in Arabidopsis thaliana. Plant J. 2012;69:154–167. doi: 10.1111/j.1365-313X.2011.04779.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yoshida K., Mori M., Kondo T. Blue flower color development by anthocyanins: from chemical structure to cell physiology. Nat. Product. Rep. 2009;26:884–915. doi: 10.1039/b800165k. [DOI] [PubMed] [Google Scholar]

- Yousuf B., Gul K., Wani A.A., Singh P. Health benefits of anthocyanins and their encapsulation for potential use in food systems: a review. Crit. Rev. Food Sci. Nutr. 2016;56:2223–2230. doi: 10.1080/10408398.2013.805316. [DOI] [PubMed] [Google Scholar]

- Zhang Q., Botting N.P., Kay C. A gram scale synthesis of a multi-13C-labelled anthocyanin,[6, 8, 10, 3′, 5′−13C 5] cyanidin-3-glucoside, for use in oral tracer studies in humans. Chem. Commun. 2011;47:10596–10598. doi: 10.1039/c1cc14323a. [DOI] [PubMed] [Google Scholar]

- Zhang Y., Butelli E., Alseekh S., Tohge T., Rallapalli G., Luo J., Kawar P.G., Hill L., Santino A., Fernie A.R., Martin C. Multi-level engineering facilitates the production of phenylpropanoid compounds in tomato. Nat. Commun. 2015;6:8635. doi: 10.1038/ncomms9635. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang Y., Butelli E., Martin C. Engineering anthocyanin biosynthesis in plants. Curr. Opin. Plant Biol. 2014;19:81–90. doi: 10.1016/j.pbi.2014.05.011. [DOI] [PubMed] [Google Scholar]

- Zhou L.-L., Shi M.-Z., Xie D.-Y. Regulation of anthocyanin biosynthesis by nitrogen in TTG1–GL3/TT8–PAP1-programmed red cells of Arabidopsis thaliana. Planta. 2012;236:825–837. doi: 10.1007/s00425-012-1674-2. [DOI] [PubMed] [Google Scholar]

Associated Data