Abstract

The feasibility of replacing wheat semolina by tiger nut flour (20 and 40%) and xanthan gum (1%) in order to obtain high fibre dry pappardelle with fair techno-functional, structural and sensory attributes, was assessed. The cooking properties, texture, colour and sensory acceptance of uncooked and cooked pasta were evaluated. The proximate chemical composition of the raw materials, and the microstructure of the dry pasta were also assessed. The results in this manuscript address the improved nutritional value in terms of its dietary fibre, mineral content, oleic and linoleic acids, and the positive effects on the textural characteristics and cooking behaviour achieved on dry tiger nut based pappardelle using 1% of xanthan gum as a structural agent. Micrographs revealed in fact that the gluten network was better formed when xanthan gum was used. Furthermore, the obtained results seem to support that consumers would prefer pappardelle with 40% tiger nut flour.

Keywords: Tiger nut pasta, Dietary fibre, Xanthan gum, Texture, Microstructure

Introduction

Nowadays, dietary patterns have changed and highly processed foods are increasing in availability. At the same time, as their eating patterns shift, people are consuming more energy-dense foods and less fruit, vegetables and dietary fibre (such as whole grains), that are key components of a healthy diet [1]. In fact, the daily fibre intake per capita is still today less than that recommended by the WHO (25 g/day, [2]. Therefore, its incorporation into pasta products -a staple cereal-based food that is widely consumed across the world with a certain frequency- could help to overcome this deficit whilst providing health benefits [3, 4]. Tigernut flour is a rich source of dietary fibre (8–15 g/100 g) [5], which has an important role in human health, specifically in the prevention, reduction, and treatment of some diseases such as colon cancer, cardiovascular diseases, diabetes, gastrointestinal disorders [6] and obesity [7]. This tuber is also rich in high-quality fatty acid profile oil, which is similar to olive and hazelnut oil, containing appreciable quantities of fatty acids such as myristic, oleic and linoleic acid [8]. It has also been found to be an excellent source of useful minerals and vitamins such as phosphorus, potassium, iron and calcium, as well as vitamins E and C [5]. Moreover, it has a moderate amount of proteins with higher essential amino acids than the protein standard proposed by the FAO/WHO (1985) [9]. In the last years, increasing demand for enriched pasta has resulted in the addition of ingredients to partially replace durum wheat semolina (DWS). This has included legume flours [10], barley flour [11] and even oregano leaves or carrot [12]. Other recent studies have been assessed the possibility of turning pasta into a functional food with health benefits by adding ingredients rich in dietary fibre, such as teff [13], kimchi by-product [14], bran [15, 16], brewer’s spent grains [17] or tomato by-product [18]. Considering the nutritional value of tiger nut flour, it may be a potential and interesting alternative to improve not only the fibre content of wheat formulations but also to provide a better nutritional quality. Pasta products made from durum wheat semolina are characterised by the viscoelastic protein network [19], responsible for the cohesive and elastic dough that leads to minimal cooking loss, no stickiness, and “al dente” texture of pasta. Tigernut flour could be incorporated up to 30% substitution level into fresh egg tagliatelle but obtained results revealed a need to strength the protein network and thus reducing cooking losses and increasing pasta firmness [20]. The literature reports that substances that swell in water—e.g. hydrocolloids- can be used to mimic the viscoelastic properties of gluten by improving its structural mouthfeel, acceptability and shelf life [21]. Its film-forming properties also act as a lubricant in batter and protect the other formulation ingredients from being damaged by mixing, particularly starch granules [22]. Non-starch polysaccharides -such as xanthan gum (XG) and locust bean gum (LBG)—have a significant effect on pasta’s viscoelastic properties and can be used to improve its elastic texture, as well as enhancing the firmness and mouthfeel of end products [23]. Xanthan gum has strong viscoelastic properties, adopting in aqueous solutions a double-stranded helix rigidly ordered conformation. It has been extensively used in the food industry because of its high solution viscosity at very low concentration, high stability in broad range of temperature, pH, ionic strength, and stability under shear [24]. Generally, the thermal stability of XG against hydrolysis is far better than other water-soluble polysaccharides or polymers, possibly because of the ordered helical structure of XG [25]. Furthermore, since it keeps low-shear viscosity even at high shear rates, it is easy to pour and mix with other materials [26]. It is used as a stabilizer and emulsifying agent at concentrations of 0.1–0.4% in different foodstuffs [27]. Previous trials (paper under publication) have demonstrated that the use of XG over 0.8% (DWS basis) may lead to better mechanical properties and cooking behaviour of fresh tiger nut pasta. [28] found positive correlations between XG content (1–7%, DWS basis) and tensile strength and texture properties of noodles. XG (0.2–0.4%, DWS basis) also improved the cooking properties and sensory acceptance, reducing the firmness and cooking loss, of dry spaghetti with deffated soy flour [27]. And [29] found an improvement in the network strength of proso millet pasta with xanthan gum (1–2%, DWS basis). To the authors’ knowledge, no research has been conducted on tiger nut dry pasta reinforced with xanthan gum. Therefore, this work aims to assess the impact of tiger nut incorporation −20 and 40% w/w, DWS basis- and xanthan gum as a structural agent (at 1% w/w, DWS basis) on the techno-functional and sensory properties of dry egg pappardelle. For this purpose, the cooking properties (water absorption index, swelling index, cooking loss) of the dry tiger nut pasta, and the mechanical properties (firmness, elasticity), the colour and the sensory attributes of the cooked pappardelle were evaluated. Proximate chemical composition of wheat semolina and tiger nut flour, and dry pasta microstructure observations were assessed as well.

Materials and methods

Raw materials and characterisation

Commercial durum wheat semolina—abbreviated as DWS– (Harinas Villamayor, S.A., Huesca, Spain), tiger nut flour—abbreviated as TNF–(Tigernuts Traders S.L., Valencia, Spain) and xanthan gum—abbreviated as X—(E-415) (EPSA S.A., Torrente, Valencia, Spain) were used. Fresh eggs and mineral water were purchased in a local market. DWS and TNF were analysed for their moisture content, protein, fat and ash according to the American Association of Cereal Chemists´ approved methods [30] and for their total, soluble and insoluble fibre according to the Megazyme method K-TDFR (Megazyme Ltd., Ireland). Digestible carbohydrates were estimated by difference (100%—percentage of determined proximate chemical composition). For fatty acids determination, sample was subjected to transesterificantion with methanolic potassium hydroxide and n-heptane. The n-heptane extract was used to separate the fatty acid methyl esters using a Varian 3400 (Varian Associates, Walnut Creek, California, USA) gas chromatographer equipped with a Combi-Pal (CTC Analytics, Zwingen, Switzerland) autosampler and a flame ionization detector. The following fatty acids were determined: myristic acid (C14:0), palmitic acid (C16:0), margaric acid (C17:0), stearic acid (C18:0), arachidic acid (C20:0), behenic acid (C22:0), lignoceric acid (C24:0), palmitoleic acid (C16:1), margaroleic acid (C17:1), oleic acid (C18:1), gadoleic acid (C20:1), linoleic acid (C18:2), and linolenic acid (C18:3). Results for fatty acids content were expressed as percentage of the total fatty acid methyl esters present in the sample. Three replicates for each analysis were carried out.

Experimental design

Wheat semolina was replaced with TNF up to 40% (w/w) to obtain pasta with more than 6% (w/w) of fibre content (“high fibre”), according to the Nutritional Claims for Dietary Fiber Foods [31]. The fibre content was estimated considering the chemical composition of the raw materials (Table 2). The obtained values for tiger nut pasta ranged from 8.04 to 10.61 g/100 g pasta. The percentage of X was chosen taking into account the obtained results in previous trials with different hydrocolloids (and concentrations) and fresh tiger nut pasta (paper under publication). Six formulations (Table 1) were evaluated in total, considering three levels for wheat semolina replacement (0, 20 and 40% w/w, named henceforth as S, TNF20 and TNF40 respectively) and xanthan gum (0 and 1% w/w, this last one being noted with an X at the end of the code, that is, TNF20X, TNF40X and SX). Changes on the dry pasta characteristics (water content, water activity, textural characteristics, colour and sensory attributes), cooking properties (water absorption index –WAI–, swelling index –SI–, cooking loss –%CL–) and properties of the ready-to-eat product, that is, the cooked pasta (textural characteristics, colour and sensory attributes) were assessed. All the measurements were made in triplicate. In addition, the microstructure of the obtained dry pappardelle was observed.

Table 2.

Proximate chemical composition of durum wheat semolina (DWS) and tiger nut flour (TNF) (g/100 g)

| DWS | TNF | |

|---|---|---|

| Water | 13.67 (0.03) | 8.83 (0.05) |

| Protein | 13.2 (0.7) | 4.95 (0.07) |

| Fata | 0.90 (0.05) | 25.07 (0.02) |

| Miristic acid | 0.047 (0.013) | 0.094 (0.002) |

| Palmitic acid | 16.53 (0.04) | 13.870 (0.007) |

| Margaric acid | 0.075 (0.012) | 0.061 (0.002) |

| Stearic acid | 1.353 (0.004) | 5.977 (0.002) |

| Arachidic acid | 0.744 (0.004) | 0.167 (0.003) |

| Behenic acid | 0.123 (0.002) | 0.140 (0.002) |

| Lignoceric acid | 0.124 (0.004) | 0.247 (0.002) |

| Palmitoleic acid | 0.21 (0.02) | 0.329 (0.002) |

| Margaroleic acid | 0.078 (0.006) | 0.033 (0.002) |

| Oleic acid | 20.14 (0.04) | 66.984 (0.003) |

| Erucic acid | 0.099 (0.002) | – |

| Linoleic acid | 56.30 (0.04) | 11.162 (0.006) |

| Linolenic acid | 3.775 (0.002) | 0.152 (0.001) |

| Ash | 1.71 (0.07) | 2.05 (0.04) |

| Dietary fibre | ||

| Soluble | 4.75 (0.02) | 2.10 (0.03) |

| Insoluble | 5.25 (0.02) | 13.74 (0.03) |

| Total | 10.00 (0.02) | 15.85 (0.03) |

| DCb | 60.54 (0.02) | 43.25 (0.03) |

Mean values of three replicates (standard deviation)

aFatty acids content are expressed as percentage of the total fatty acid methyl esters

bDigestible carbohydrates calculated by difference

Table 1.

Experimental design: dry pasta formulations (percentage of sample mass)

| Sample | DWS (%) | TNF (%) | X (%) | E (%) | W (%) |

|---|---|---|---|---|---|

| S | 72 | – | – | 13 | 15 |

| SX | 71.28 | – | 0.72 | 13 | 15 |

| TNF20 | 57.6 | 14.4 | – | 13 | 15 |

| TNF20X | 56.88 | 14.4 | 0.72 | 13 | 15 |

| TNF40 | 43.2 | 28.8 | – | 13 | 15 |

| TNF40X | 42.48 | 28.8 | 0.72 | 13 | 15 |

DWS durum wheat semolina, TNF tiger nut flour, X xanthan gum

Pasta preparation

S formulation, used as control, was obtained by mixing durum wheat semolina (72% w/w), fresh egg (13% w/w) and water (15% w/w). For the other formulations, durum wheat semolina was replaced by TNF and X at different levels, as described in the previous section. All raw materials were mixed and kneaded in an electric cooking device (Thermomix TM-31, Vorwerk Spain M.S.L., S.C., Madrid). Dried (semolina/tiger nut flour/xanthan gum) and liquid (egg/water) components were separately mixed for 45 s. The resulting blends were then kneaded for 10 min. The resulting doughs were rested for 20 min inside a plastic bag in order to enable sample relaxation. Afterwards, the pappardelle were formed by using a domestic pasta making machine (Simplex SP150, Imperia, Italy) coupled with a specific motor (A2500, Imperia, Italy). Lamination was conducted to obtain pappardelle of 4.1 cm ± 0.03 mm width. Samples of 7 ± 0.03 cm length were then dried under controlled temperature 55 °C) and relative humidity (50%) conditions (until the pasta reached a water content of 10–12% (similar to that of dried commercial pasta). Drying was carried out in a convection drier (Mod. SCC 62, Rationel, Germany) for 1 h and 30 min. Once dried, the pappardelle were packed in vacuum bags and stored at room temperature until further analysis.

Pasta cooking

Dried pappardelle was cooked in deionised water (300 ml/25 g). Optimal cooking time was previously determined on control sample according to the American Association of Cereal Chemists´ approved method 16–50 [30]. To avoid evaporation losses and maintain the 90% of the initial volume, the flask was covered and boiling water was added during cooking. Once 10 min elapsed (optimal cooking time), the pappardelle were removed from the flasks and the cooking process was immediately stopped with 50 ml of cold deionised water. Finally, the pappardelle were drained for 2 min and immediately analysed. Cooking trial was made in triplicate for each pasta formulation.

Cooking properties

The water absorption index –WAI– (g/g) was calculated from the mass gain (mo before and mc after cooking) and the increase in water content after cooking (Eq. 1). The water content in dry pasta (xwo) and cooked pasta (xwc) was determined according to the AACC 44-40 method [30].

| 1 |

Cooking loss –%CL– (g/100 g) is the amount of solid substance lost to cooking water and it was determined according to the AACC-approved method 16–50 [30].

The swelling index –SI– was expressed as the relative volume changes (cm3/cm3) between the uncooked and cooked pasta. The measurements of the pappardelle (thickness, width and length) were determined with a caliper (PCE-DCP 200 N, PCE Ibérica S.L., Albacete, Spain).

Water content and water activity of dry and cooked pasta

The water content (xw, g/g) of the dry and cooked pappardelle was determined by the AACC-approved gravimetric method 44–40 [30]. It was performed in triplicate for each sample. The AquaLab Series 4 TEV equipment (Decagon, CX-1, sensitivity 0.001) was used to measure the water activity (aw) of the dried and cooked pasta.

Mechanical properties of dry and cooked pappardelle

A TA.XT2 Texture Analyser (Stable Micro Systems, Godalming, Surrey, UK) was used to perform the AACC method 16–50 [30] at a rate of 0.17 mm/s until total sample deformation. Five replicates were made for each pasta formulation. The firmness of the uncooked (Fo) and cooked (Fc) pasta was obtained from the force-distance curves.

Colour

The colour of the pasta was determined in a spectrocolourimeter (Minolta CM-3600D) through the surface reflectance spectra between 400 and 700 nm (illuminant D65, 10° standard observer), using white background. From the reflectance spectra, CIEL*a*b* colour coordinates could be obtained: L* (lightness), a* (redness-greenness) and b* (yellowness-blueness). Each colour piece of data represents the mean of five replicates. Colour saturation (), hue angle (), and the total colour difference () [19] between TNF based formulations and wheat semolina (S) samples. In addition, the total colour difference (∆E) was calculated.

Field emission scanning electron microscope (FESEM)

FESEM was used in order to observe the effect of tiger nut flour and xanthan gum on pasta characteristics. For this purpose, microstructural analysis was carried out on the cross-section of dry pappardelle, using field emission scanning electron microscopy (FESEM) (ULTRA 55, Carl Zeiss AG, Oberkochen, Germany). The samples were fixed on copper stubs, platinum coated and observed using an accelerating voltage of 2 kV.

Sensory analysis

The cooked pappardelle samples used for sensory analysis were those containing xanthan gum (TNF20X and TNF40X), as they were the formulations with closer firmness to that of the control formulation (as discussed on the results’ section). The tasting was conducted in a laboratory of individual sensory booths, with 40 untrained tasters who assessed the intensity and acceptance of colour, homogeneity, softness, appearance, mouthfeel parameters (hardness, elasticity and tackiness), texture, comprehensive flavour and taste. Each taster received both formulations of cooked pappardelle at once, each coded with a three-digit number. A hedonic test with a 5 point scale (from 1 = low intensity attribute to 5 = high intensity attribute) was used. Tasters were informed before tasting that the products were rich in fibre.

Statistical analysis

Analysis of variance (ANOVA) was carried out by using Statgraphics Plus software version 5.1. (StatPoint Technologies, Inc., Warrenton, VA) in order to evaluate the effects of partial semolina replacement by tiger nut flour and xanthan gum on the measured parameters. The significance level was p = 0.05 in all cases.

Results and discussion

Proximate chemical composition of raw materials

The chemical composition of durum wheat semolina (DWS) and tiger nut flour (TNF) is summarised in Table 2. As expected, the total dietary fibre and fat contents of tiger nut flour are well above those of durum wheat semolina, while the amount of protein is significantly lower. Similar results have been reported by [32] for durum wheat semolina and [33] for tiger nut flour. It is important to mention once again that TNF is rich in unsaturated fatty acids, specially oleic and linoleic (Table 2). The amount of digestible carbohydrates is lower in tiger nut flour. Based on these results and taking into account the proportions used in each formulation, the chemical composition of the uncooked pasta was estimated (and considering the water evaporation that takes place during pasta drying). Increasing the amount of TNF improve the nutritional value of the dry egg pasta compared to the control wheat pasta, in terms of its dietary fibre (86.7% insoluble and 13.2% soluble) and mineral contents. And both 20 and 40% substitution levels lead to pasta with more than 6% w/w of fibre, which can be considered in the market as a “high fibre” product. The chemical composition of the cooked pasta is being investigated now as we are assessing and relating other aspects to the composition such as the in vitro digestibility and the glycemic index of fresh and dry pasta based on tiger nut flour. The results obtained up to now reveal that it is mainly amylose the component that is being leached during cooking (as it occurs on commercial pasta) as a result of starch gelatinization.

Cooking properties

Cooking loss is one of the important parameters in assessing the pasta overall quality. Soluble parts of starch and other soluble components leach into the water during cooking, hence cooking loss can be associated with the level of accessibility that water molecules have to reach starch granules. Incorporation of tiger nut flour-with less protein and more fat and fibre-into pasta formulation results in the development of a weaker gluten network, where swelled starch granules are poorly captured and are thus more easily leached into the cooking water. In fact, the obtained results revealed that the substitution of durum wheat semolina by 40% of TNF leads to the highest cooking losses (> 8 g/100 g for TNF40) (Table 3). Pasta with cooking loss below 6 g/100 g is regarded as being of good quality, between 6–8 g/100 g of fair quality and over 10 g/100 g of poor quality [34]. Similar results were obtained when using millet flour [32], mango peel powder [35] or wheat bran [36]. However, when using a 20% substitution level of TNF, cooking losses are similar to those obtained for durum wheat semolina pasta (below to 6 g/100 g). Thus, a sufficiently continuous and less soluble structure seems to be formed in this case. Incorporation of xanthan gum (X) in the formulations significantly reduced the cooking loss (p < 0.05) (Table 3). Durum wheat pasta values decreased from 4.8(0.9) to 2.2(0.9) g/100 g when using X at 1%. For tiger nut based products, a lower decrease could be reached (23.4 and 25.4% for 20 and 40% replacement levels, respectively). As reported by [37], this soluble fibre can form a network around the starch granules, trapping them in place during cooking and restricting excessive swelling and the diffusion of amylose. From the obtained results, it seems that a higher concentration of this hydrocolloid may be recommendable when incorporating a 40% of TNF.

Table 3.

Cooking properties (WAI: water absorption index; SI: swelling index) and firmness of uncooked (Fo) and cooked (Fc) pasta samples

| Sample | WAI (g/g) | SI (cm3/cm3) | %CL (g/100 g) | Fo (N) | Fc (N) |

|---|---|---|---|---|---|

| S | 1.193 (0.012)d | 0.48 (0.02)ab | 4.8 (0.9)c | 160 (6)b | 7.0 (0.5)b |

| SX | 1.049 (0.014)f | 0.49 (0.04)bc | 2.2 (0.9)d | 233 (7)a | 10.9 (0.5)a |

| TNF20 | 1.28 (0.02)b | 0.52 (0.03)a | 5.3 (0.7)c | 88 (8)e | 5.1 (0.4)e |

| TNF20X | 1.24 (0.02)c | 0.45 (0.02)bc | 4.1 (0.3)cd | 148 (4)c | 6.6 (0.3)c |

| TNF40 | 1.380 (0.004)a | 0.40 (0.02)cd | 10.2 (0.7)a | 95 (4)e | 4.3 (0.4)f |

| TNF40X | 1.09 (0.02)e | 0.36 (0.06)d | 7.6 (0.6)b | 115 (2)d | 5.8 (0.3)d |

Mean values of at least three replicates (standard deviation)

S semolina pasta, TNF20 and TNF40 tiger nut pasta (20 and 40% replacement levels, respectively), TNF20X and TNF40X tiger nut pasta with 1% xanthan gum. Means with different letters in the same column indicate significant differences (p < 0.05)

The moisture achieved in the dry pasta is within the range 10-12% (w/w), while the aw value is between 0.6 and 0.8 (similar values in commercial pasta). WAI is a parameter that provides information about the water absorption capacity of pasta during its cooking. As it can be observed in Table 3, the higher the presence of TNF, the higher the WAI. This could be due to the large amount of fibre in this flour (Table 2), a fibre with a high water holding capacity due to the high proportion of hemicellulose and lignin [38]. In addition, [20] report that the higher the level of tiger nut incorporation, the lower the mean particle diameter D[4,3] and the higher the Span value (measurement of the width of the size distribution); a smaller particle size leads to a larger surface area available for water absorption. Also, changes in the gluten network by the interference of the fibre present in the TNF would promote water absorption and facilitate granule swelling and rupture [16], thus increasing amylose leaching [32]. These results are in accordance with the overall higher cooking loss values observed in tiger nut based pappardelle. In addition, incorporation of xanthan gum at 1% significantly reduced (p < 0.05) the WAI values compared to the corresponding sample without hydrocolloids. As explained before, this soluble fibre can form a network around the starch granules restricting excessive swelling, therefore helping WAI values to come closer to those obtained for durum wheat semolina samples (S). The swelling index didn’t reveal differences due to the incorporation of TNF or X.

Mechanical properties of dry and cooked pappardelle

The determination of textural parameters in pasta after cooking is very important from the point of view of consumer acceptability. Good quality pasta must have a high firmness and elasticity level, which is known commonly as being “al dente” [39]. The effect of TNF and X on the mechanical properties of dried and cooked pappardelle can be observed on Table 3. Statistical analysis indicated that the firmness of both uncooked and cooked pappardelle was significantly affected by TNF addition (p < 0.05). Generally, firmness values of TNF-based pasta were lower than those of the control samples. Similar results were obtained for pasta incorporating carrot pomace [32] and brown rice [34]. This trend is in accordance with the higher cooking loss and the higher water absorption index (Table 3) observed when tiger nut flour was incorporated. Before cooking, the higher presence of fibre with high affinity for water in TNF [25] probably hinders water availability for gluten network development through hydrogen bonds and thus a weaker structure is formed. During cooking, the disruption or development of a weaker protein matrix -mainly as a result of a higher fibre presence-, together with prevalent starch swelling and a discrete protein coagulation (less protein content), seem to be responsible for the development of a non-continuous and sticky structure [40].

Moreover, the dry pasta with incorporation of xanthan gum ended up having significantly (p < 0.05) higher firmness and this attribute was maintained after cooking. This indicates that a better structure -with a continuous protein matrix entrapping starch granules- could be obtained, as it can absorb water and gelatinise without major loss occurring during cooking (Table 3). The formulations with closer firmness to that of the control formulation (S) -which represents commercialised dry pasta- were those with tiger nut flour and xanthan gum. Thus, the negative effects on pasta texture -as a result of TNF incorporation- could be reduced with the incorporation of xanthan gum at 1% (w/w).

Colour of dry and cooked pappardelle

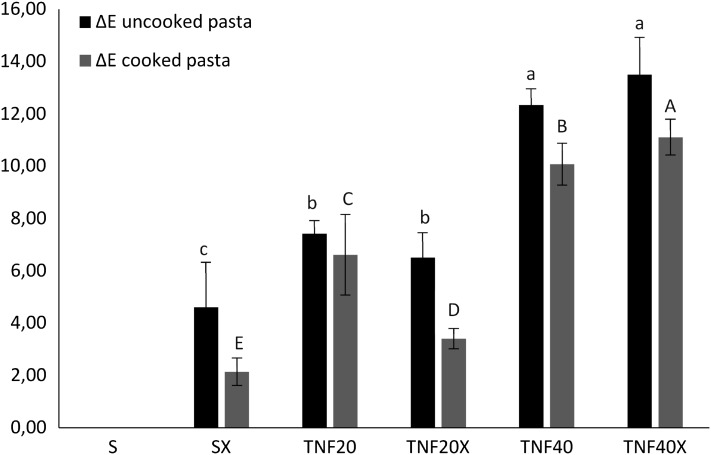

Traditional pasta has a light yellowish colour due to the egg and the carotene contained in hard grain semolina. As expected, the control samples in uncooked and cooked pasta -both with and without xanthan gum- showed higher values of lightness (L*) (p < 0.05) (Table 4). As the content of TNF in the formulations increased, the pappardelle became darker (lower L*) and browner (increase in the a* coordinate and decrease in both the b* coordinate and the hue angle h*ab), both before and after cooking due to the characteristic brown colour of tiger nut flour. Figure 1 shows the total colour difference (ΔE) between the formulations and the control sample (S) in dried and cooked pasta. Both TNF and X incorporation increased the colour difference, showing that the final product colour was affected by the colour characteristics of the raw materials included in the formulation. These colour variations were more evident in the dry samples, because once the pasta was cooked the colour difference –compared to the control formulation- decreased slightly [41]. The total colour differences between the tiger nut and wheat samples are high enough to be visible to the naked eye [42], as confirmed by the sensory evaluation. Nevertheless, this colour variation in the pappardelle samples is not penalised normally punished by consumers, as they generally associate pasta rich in dietary fibre with a darker colour.

Table 4.

Colour parameters of uncooked and cooked pasta

| Sample | L*o | a*o | b*o | C*o | h*o | L*c | a*c | b*c | C*c | h*c |

|---|---|---|---|---|---|---|---|---|---|---|

| S | 77.1 (0.3)a | 2.8 (0.2)d | 30.5 (0.4)a | 30.6 (0.4)a | 84.8 (0.2)a | 72.4 (0.4)a | −1.816 (0.105)e | 21.5 (0.6)a | 21.6 (0.6)a | 94.8 (0.4)a |

| SX | 76.9 (0.3)a | 2.9 (0.2)d | 28.3 (0.9)b | 28.4 (0.9)b | 84.1 (0.2)b | 70.5 (0.7)b | −1.3 (0.2)d | 21.4 (0.8)a | 21.4 (0.8)a | 93.4 (0.7)b |

| TNF20 | 70.7 (0.6)b | 4.0 (0.2)c | 26.7 (0.5)c | 27.0 (0.5)c | 81.7 (0.2)c | 67.3 (0.9)c | 0.3 (0.3)c | 18.1 (0.3)b | 18.7 (1.2)b | 89.2 (0.9)c |

| TNF20X | 71.1 (0.9)b | 4.0 (0.3)c | 28.3 (0.5)b | 28.6 (0.5)b | 82.0 (0.6)c | 69.9 (0.4)b | 0.5 (0.2)c | 21.2 (0.5)a | 21.2 (0.5)a | 88.8 (0.5)c |

| TNF40 | 67.4 (0.7)b | 4.5 (0.2)b | 23.1 (0.3)d | 23.5 (0.3)d | 78.9 (0.5)d | 63.6 (0.8)d | 1.4 (0.2)b | 17.5 (0.4)c | 17.6 (0.4)c | 85.5 (0.7)d |

| TNF40X | 64.5 (1.4)b | 5.4 (0.3)a | 26.4 (0.7)c | 27.0 (0.7)c | 78.5 (0.6)d | 62.4 (0.7)e | 2.2 (0.2)a | 18.2 (0.2)b | 18.4 (0.2)b | 83.2 (0.7)e |

Mean values of five replicates (standard deviation)

Means with different letters in the same column indicate significant differences (p < 0.05)

S semolina pasta, TNF20 and TNF40 tiger nut pasta (20 and 40% replacement levels, respectively), TNF20X and TNF40X tiger nut pasta with 1% xanthan gum. Subscript o indicate parameters for uncooked pasta and subscript c for cooked pasta

Fig. 1.

Total colour difference (∆E) between the formulations and the control sample (S) for uncooked and cooked samples (means of five replicates). Different letters between bars indicate significant differences (p < 0.05). S: semolina pasta, TNF20 and TNF40: tiger nut pasta (20 and 40% replacement levels, respectively), TNF20X and TNF40X: tiger nut pasta with 1% xanthan gum

FEM observations of dry pappardelle

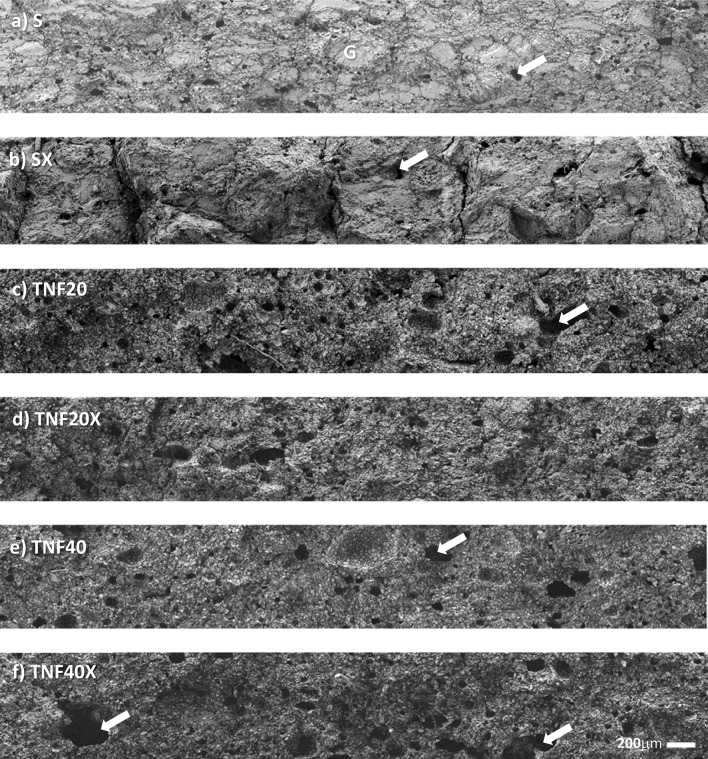

Figure 2 shows the microstructure of all the formulations of dried pappardelle pasta. The micrographs show a sequence of cross-section images of the pasta. In this figure, we can observe differences in the structure of the protein matrix and porosity of the samples. The control formulation [S, Fig. 2(a)] was characterised by a uniform structure with few and small voids, caused by water removal during drying. The pasta with added tiger nut flour [TNF20 and TNF40, Fig. 2(c), (e), respectively] was characterised by a structure with medium to big sized voids, probably due to the weaker gluten network. This porous profile supports the analyzed texture of the pasta, as pappardelle with added TNF had less firmness (Table 3). The profile of the pasta showed that with the incorporation of xanthan gum [Fig. 2(d), (f)], a smaller amount of voids appeared, and the gluten network was well hydrated, smooth and better formed; this is in accordance with the observed higher firmness of the pasta with this hydrocolloid (Table 3). As observed, pasta with xanthan gum and without TNF shows a good gluten network development [Fig. 2(b)], enabling the embedment of starch granules, thus producing less loss during cooking (Table 3). [43] observed as well that adding xanthan gum, especially at 1% concentration, to non-extruded sorghum-wheat composite doughs, formed a uniform and compact structure with the starch granules close to each other.

Fig. 2.

Scanning electron micrographs obtained of cross sections of uncooked pasta samples (100x) at different tiger nut flour (0, 20 and 40%) and xanthan gum (0 and 1%) substitution levels. S: semolina pasta, TNF20 and TNF40: tiger nut pasta without xanthan gum, TNF20X and TNF40X: tiger nut pasta with 1% xanthan gum. G: gluten network. Arrows show voids

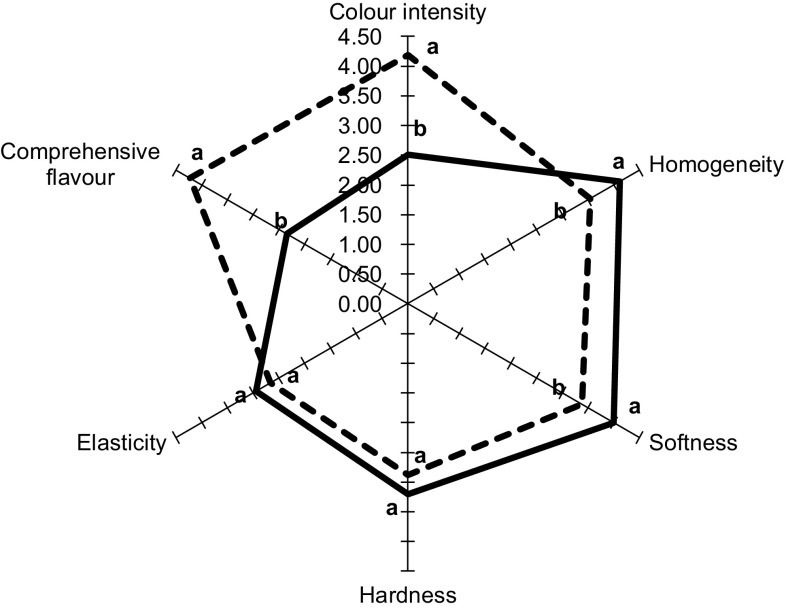

Sensory analysis of cooked pappardelle

The health benefits and nutritional added value derived from tiger nut flour incorporation into pappardelle has to be compatible with consumer satisfaction with the end product. The sensory trails for cooked pappardelle with two levels of TNF are summarised in Fig. 3. Attributes such as elasticity, hardness, softness and homogeneity were lower when TNF was added at a 40% replacement level. These results are in agreement with the values obtained in the analysis of the texture of the cooked pasta, where the firmness (Table 3) of the samples with higher TNF content were lower. The decrease in softness and homogeneity (40TNF sample) can be linked to the greater fibre content in the pappardelle. In fact, the results suggest that the addition of TNF -in higher amounts- to pappardelle modifies the visual aspect (colour intensity) and the comprehensive flavour—obtaining a higher score- due to the higher TNF content -and therefore fibre—in sample TNF40X. Tasters may perceive from the colour and the flavour that this formulation is closer to a whole food, with more fibre and therefore more health benefits. Finally, it is important to point out that both formulations (TNF20X and TNF40X) obtained moderate to good results in colour, appearance, texture and flavour, obtaining from 2.5 (colour intensity, TNF20X) to 4.7 (comprehensive flavour, TNF40X) points over 5. This indicates that tasters would easily consume any of them, regardless of the amount of TNF added, but highlighting the fact that pappardelle with 40% TNF was chosen as the preferred one.

Fig. 3.

Sensory parameters of TNF20X (solid line) and TNF40X (dashed line). TNF20X and TNF40X: tiger nut pasta with 1% xanthan gum (20 and 40% replacement level, respectively)

Acknowledgements

This work was supported by the Conselleria de Empresa, Universidad y Ciencia (Spain) throughout the project AICO/2016/056. Authors are thankful to Harinas Villamayor S.A. for providing raw materials for conducting this study.

References

- 1.WHO. Salt reduction. Fact sheet, World Health Organization (2016).

- 2.Romo C, Mize K, Warfel K. Addition of hi-maize, natural dietary fiber, to a commercial cake mix. J Am Diet Assoc. 2008;108:76–77. doi: 10.1016/j.jada.2008.06.205. [DOI] [Google Scholar]

- 3.Aravind N, Sissons M, Fellows CM. Effect of soluble fibre (guar gum and carboxymethylcellulose) addition on technological, sensory and structural properties of durum wheat spaghetti. Food Chem. 2012;131(3):893–900. doi: 10.1016/j.foodchem.2011.09.073. [DOI] [Google Scholar]

- 4.Yokoyama WH, Hudson CA, Knuckles BE, Chiu MCM, Sayre RN, Turnlund JR, Schneeman BO. Effect of barley beta-glucan in durum wheat pasta on human glycemic response. Cereal Chem. 1997;74(3):293–296. doi: 10.1094/CCHEM.1997.74.3.293. [DOI] [Google Scholar]

- 5.Sánchez-Zapata E, Fernández-López J, Pérez-Alvarez JA. Tiger Nut (Cyperus esculentus) Commercialization: Health aspects, composition, properties, and food applications. Compr Rev Food Sci Food Saf. 2012;11(4):366–377. doi: 10.1111/j.1541-4337.2012.00190.x. [DOI] [Google Scholar]

- 6.Kaczmarczyk MM, Miller MJ, Freund GG. The health benefits of dietary fiber: beyond the usual suspects of type 2 diabetes mellitus, cardiovascular disease and colon cancer. Metab. 2012;61(8):1058–1066. doi: 10.1016/j.metabol.2012.01.017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Buttriss JL, Stokes CS. Dietary fibre and health: an overview. Nutr Bull. 2008;33(3):186–200. doi: 10.1111/j.1467-3010.2008.00705.x. [DOI] [Google Scholar]

- 8.Demirkesen I, Sumnu G, Sahin S. Quality of Gluten-Free Bread Formulations Baked in Different Ovens. Food Bioprocess Tech. 2013;6(3):746–753. doi: 10.1007/s11947-011-0712-6. [DOI] [Google Scholar]

- 9.Ade-Omowaye BIO, Akinwande BA, Bolarinwa IF, Adebiyi AO. Evaluation of tigernut (Cyperus esculentus) wheat composite flour and bread. Afr. J. Food Sci. 2008;2:87–91. [Google Scholar]

- 10.Fares C, Menga V. Effects of toasting on the carbohydrate profile and antioxidant properties of chickpea (Cicer arietinum L.) flour added to durum wheat pasta. Food Chem. 2012;131(4):1140–1148. doi: 10.1016/j.foodchem.2011.09.080. [DOI] [Google Scholar]

- 11.Verardo V, Gomez-Caravaca AM, Messia MC, Marconi E, Caboni MF. Development of functional spaghetti enriched in bioactive compounds using barley coarse fraction obtained by air classification. J. Agric. Food Chem. 2011;59(17):9127–9134. doi: 10.1021/jf202804v. [DOI] [PubMed] [Google Scholar]

- 12.Boroski M, de Aguiar AC, Boeing JS, Rotta EM, Wibby CL, Bonafé EG, de Souza NE, Visentainer JV. Enhancement of pasta antioxidant activity with oregano and carrot leaf. Food Chem. 2011;125(2):696–700. doi: 10.1016/j.foodchem.2010.09.068. [DOI] [Google Scholar]

- 13.Giuberti A, Fiorentini L, Fortunati P, Masoero F. In vitro starch digestibility and quality attributes of gluten free ‘tagliatelle’ prepared with teff flour and increasing levels of a new developed bean cultivar. Starch-Stärke. 2016;68(3–4):374–378. doi: 10.1002/star.201500007. [DOI] [Google Scholar]

- 14.Kim BR, Kim S, Bae GS, Chang MB, Moon B. Quality characteristics of common wheat fresh noodle with insoluble dietary fiber from kimchi by-product. LWT–Food. Sci Technol. 2017;85:240–245. [Google Scholar]

- 15.la Gatta B, Rutigliano M, Padalino L, Conte A, del Nobile MA, Di Luccia A. The role of hydration on the cooking quality of bran-enriched pasta. LWT–Food. Sci Technol. 2017;84:489–496. [Google Scholar]

- 16.Kaur G, Sharma S, Nagi HPS, Dar BN. Functional properties of pasta enriched with variable cereal brans. J Food Sci Tech Mys. 2012;49(4):467–474. doi: 10.1007/s13197-011-0294-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Cappa C, Alamprese C. Brewer’s spent grain valorization in fiber-enriched fresh egg pasta production: Modelling and optimization study. LWT–Food. Sci Technol. 2017;82:464–470. [Google Scholar]

- 18.Padalino L, Conte A, Lecce L, Likyova D, Sicari V, Pellicano TM. Functional Pasta with Tomato By-product as a Source of Antioxidant Compounds and Dietary Fibre. Czech J Food Sci. 2017;35(1):48–56. doi: 10.17221/171/2016-CJFS. [DOI] [Google Scholar]

- 19.Mariotti M, Iametti S, Cappa C, Rasmussen P, Lucisano M. Characterisation of gluten-free pasta through conventional and innovative methods: Evaluation of the uncooked products. J Cereal Sci. 2011;53(3):319–327. doi: 10.1016/j.jcs.2011.02.001. [DOI] [Google Scholar]

- 20.Albors A, Raigon MD, García-Martínez MD, Martín-Esparza ME. Assessment of techno-functional and sensory attributes of tiger nut fresh egg tagliatelle. LWT–Food. Sci Technol. 2016;74:183–190. [Google Scholar]

- 21.Lazaridou A, Duta D, Papageorgiou M, Belc N, Biliaderis CG. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J Food Eng. 2007;79(3):1033–1047. doi: 10.1016/j.jfoodeng.2006.03.032. [DOI] [Google Scholar]

- 22.Alamprese C, Casiraghi E, Rossi M. Modeling of fresh egg pasta characteristics for egg content and albumen to yolk ratio. J Food Eng. 2009;93:302–307. doi: 10.1016/j.jfoodeng.2009.01.025. [DOI] [Google Scholar]

- 23.Larrosa V, Lorenzo G, Zaritzky N, Califano A. Optimization of rheological properties of gluten-free pasta dough using mixture design. J Cereal Sci. 2013;57(3):520–526. doi: 10.1016/j.jcs.2013.03.003. [DOI] [Google Scholar]

- 24.Petri DFS. Xanthan gum: A versatile biopolymer for biomedical and technological applications. J Appl Polym Sci. 2015;132(23):1–13. doi: 10.1002/app.42035. [DOI] [Google Scholar]

- 25.Kumar A, Rao KM, Hana SS. Application of xanthan gum as polysaccharide in tissue engineering: A Review. Carbohyd Polym. 2018;180:128–144. doi: 10.1016/j.carbpol.2017.10.009. [DOI] [PubMed] [Google Scholar]

- 26.Kohajdová Z, Karovicová J. Application of Hydrocolloids as Baking Improvers. Review. Chem Pap. 2009;63(1):26–38. [Google Scholar]

- 27.Ansari A, Kalbasi-Ashtari A, Gerami A. Effects of Defatted Soy Flour, Xanthan Gum, and Processing Temperatures on Quality Criteria of Spaghetti. J. Agr. Sci. Tech. 2013;15:265–278. [Google Scholar]

- 28.Cai J, Chiang JH, Tau MYP, Saur LK, Xu Y, Ngan-Loong MN. Physicochemical properties of hydrothermally treated glutinous rice flour and xanthan gum mixture and its applications in gluten-free noodles. J Food Eng. 2016;186:1–9. doi: 10.1016/j.jfoodeng.2016.03.033. [DOI] [Google Scholar]

- 29.Romero HM, Santra D, Rose D, Zhang Y. Dough rheological properties and texture of gluten-free pasta based on proso millet flour. J Cereal Sci. 2017;74:238–243. doi: 10.1016/j.jcs.2017.02.014. [DOI] [Google Scholar]

- 30.AACC. Approved methods of the AACC. 10th ed. American Association of Cereal Chemists, St. Paul, MN, USA (2005)

- 31.Official Journal of the European Union (2006). L 404/9e25.

- 32.Gull A, Prasad K, Kumar P. Effect of millet flours and carrot pomace oncooking qualities, color and texture of developed pasta. LWT–Food. Sci Technol. 2015;63(1):470–474. [Google Scholar]

- 33.Aguilar N, Albanell E, Miñaro B, Guamis B, Capellas M. Effect of tigernut-derived products in gluten-free batter and bread. Food Sci Technol Int. 2014;21(5):323–331. doi: 10.1177/1082013214535615. [DOI] [PubMed] [Google Scholar]

- 34.Da Silva EMM, Ascheri JLR. Ascheri DPR. Quality assessment of gluten-free pasta prepared with a brown rice and corn meal blend via thermoplastic extrusion. LWT–Food. Sci Technol. 2016;68:698–706. [Google Scholar]

- 35.Ajila CM, Aalami M, Leelavathi K, Prasada Rao UJS. Mango peel powder: A potential source of antioxidant and dietary fiber in macaroni preparations. Innovative Food Sci Emerg Technol. 2010;11(1):219–224. doi: 10.1016/j.ifset.2009.10.004. [DOI] [Google Scholar]

- 36.Sozer N, Dalgıç AC, Kaya A. Thermal, textural and cooking properties of spaghetti enriched with resistant starch. J Food Eng. 2007;81(2):476–484. doi: 10.1016/j.jfoodeng.2006.11.026. [DOI] [Google Scholar]

- 37.Brennan CS, Tudorica CM. Fresh pasta quality as affected by enrichment of nonstarch polysaccharides. J Food Sci. 2007;72(9):659–665. doi: 10.1111/j.1750-3841.2007.00541.x. [DOI] [PubMed] [Google Scholar]

- 38.Sánchez-Zapata E, Fuentes-Zaragoza E, Fernández-López J, Sendra E, Sayas E, Navarro C, Pérez-Álvarez JA. Preparation of Dietary Fiber Powder from Tiger Nut (Cyperus esculentus) Milk (“Horchata”) Byproducts and Its Physicochemical Properties. J Agric Food Chem. 2009;57(17):7719–7725. doi: 10.1021/jf901687r. [DOI] [PubMed] [Google Scholar]

- 39.Pomeranz Y. Modern cereal science and technology. New York, USA (1987)

- 40.Maningat CC, Seib P, Bassi SD, Woo KS, Lasater GD. Wheat starch:production, properties, modification and uses. pp. 441–510. In: Starch: Chemistry and Technology, 3rd ed., J. BeMiller & R. Whistler (eds.). Elsevier Inc., London, UK (2009)

- 41.Gallegos-Infante JA, Rocha-Guzman NE, Gonzalez-Laredo RF, Ochoa-Martinez LA, Corzo N, Bello-Perez LA, Peralta-Alvarez LE. Quality of spaghetti pasta containing Mexican common bean flour (Phaseolus vulgaris L.) Food Chem. 2010;119(4):1544–1549. doi: 10.1016/j.foodchem.2009.09.040. [DOI] [Google Scholar]

- 42.Francis FJ, Clydesdale FM. The measurement of meat color. Food Colorimetry: Theory and Application. The AVI Publishing Company, Westsport, CT; 1975. [Google Scholar]

- 43.Jafari M, Koocheki A, Milani E. Functional effects of xanthan gum on quality attributes and microstructure of extruded sorghum-wheat composite dough and bread. LWT–Food. Sci Technol. 2018;89:551–558. [Google Scholar]