Abstract

A total of 256 pigs (initially 55.9 ± 4.88 kg) were used in a 71-d study to determine the effects of increasing space allowance and pig removal on pig growth performance. Pens of pigs were blocked by body weight (BW) and allotted to 1 of 4 space allowance treatments, initially with 8 pigs per pen and 8 pens per treatment. First 2 treatments included pens with 0.91 m2 per pig or 0.63 m2 per pig for the entire study; two additional treatments initially provided 0.63 m2 per pig, but either a gate was adjusted on days 28, 45, and 62 or the heaviest pig in the pen was removed from the pen on days 28 and 45 to provide more space and keep pigs in accordance with their predicted minimum space requirement [(m2) = 0.0336 × (BW, kg)0.67]. From days 0 to 14 (56 to 69 kg), there was no effect of stocking density observed for average daily gain (ADG), average daily feed intake (ADFI), and gain:feed (G:F). From days 14 to 28 (69 to 83 kg), pigs provided 0.91 m2 had increased (P < 0.05) ADG and G:F compared with those allowed 0.63 m2. Pigs provided 0.91 m2 were marginally heavier (P = 0.081) on day 28 and had greater ADFI (P = 0.025) during days 28 to 45 than those provided 0.63 m2 or those that had the heaviest pig removed. From days 45 to 62 (98 to 116 kg), pigs provided 0.91 m2 were heavier (P < 0.01) than all others, wheras pigs provided 0.63 m2 had reduced ADFI compared with other treatments. From days 62 to 71 (116 to 124 kg), pigs provided 0.91 m2 and those with space adjustment treatments had greater (P < 0.05) ADG and ADFI than those provided 0.63 m2. Overall (56 to 124 kg), pigs provided 0.91 m2 had increased (P = 0.001) ADG compared with those allowed 0.63 m2 with pigs provided space adjustments intermediate. In summary, pigs with 0.91 m2 grew faster and consumed more feed than pigs restricted in space. As pigs reached the critical k value, gate adjustments and pig removals affected growth similarly. As pigs grew to the predicted space requirement and were subsequently allowed more space, performance was greater than those provided 0.63 m2 but less than those allowed 0.91 m2. It appears that the industry accepted critical k value, 0.0336, may not be adequate for optimal pig performance across multiple BW ranges.

Keywords: finishing pig, growth, k value, pig removal, space allowance

INTRODUCTION

Facility space is the second largest cost of pig production and efficient space usage is important for profitable pork production. A common allometric expression has been used to describe the relationship between floor space and pig body weight (BW). Gonyou et al. (2006) used the allometric expression A = k × BW0.67, where A is the area allowed per pig (m2), k is a coefficient, and BW is the pig weight (kg). This converts BW into a 2-dimensional concept, to describe floor space allowance in order to predict productivity. Ekkel et al. (2003) suggested that a minimum k value of 0.033 is needed for normal “social lying behavior” in finishing pigs. Gonyou et al. (2006) proposed a critical k value, 0.0336, and suggested that pig growth should not be decreased until their BW reaches the critical point where there is inadequate space to maintain maximal growth rate. However, recent studies (Flohr et al., 2016; Johnston et al., 2017; Thomas et al., 2017) demonstrated that growth reductions due to inadequate space may start to occur at k value above 0.0336.

Removing the heaviest pig(s) from the pen roughly 2 wk before marketing all the pigs in a pen is a common production practice that has been implemented by the commercial swine industry. Many studies have shown that the removal of the heaviest pig(s) before the entire pen is marketed results in an increased growth rate of remaining pigs in the pen (Woodworth et al., 2000; DeDecker et al., 2005; Flohr et al., 2016).

To the best of our knowledge, it is not known whether growth improvement upon lifting space restriction by removing the heaviest pig is due to changes in social dynamics or simply the increased space in the pen. Thus, the objective of our study was to validate the space allowance determined by using critical k value (0.0336) and compare the effects of increasing space allowance by pig removal or gate adjustment on finishing pig growth performance.

MATERIALS AND METHODS

General

The Kansas State University Institutional Animal Care and Use Committee approved the protocol used in this experiment. This study was conducted at the Kansas State University Swine Teaching and Research Center in Manhattan, KS. The research barn was an environmentally controlled solid-sided building with completely slatted flooring and deep pits for manure storage. Pens were 2.43 × 3.05 m, equipped with adjustable gates to allow different space allowances per pig and contained a 2-hole 71 × 25 cm (length × width) single-sided stainless steel dry self-feeder (Farmweld, Teutopolis, IL) and a cup waterer for ad libitum access to feed and water. Daily feed additions to each pen were accomplished through a robotic feeding system (FeedPro; Feedlogic Corp., Willmar, MN). All diets were manufactured at the Kansas State University O.H. Kruse Feed Mill, Manhattan, KS.

Live Animal Management

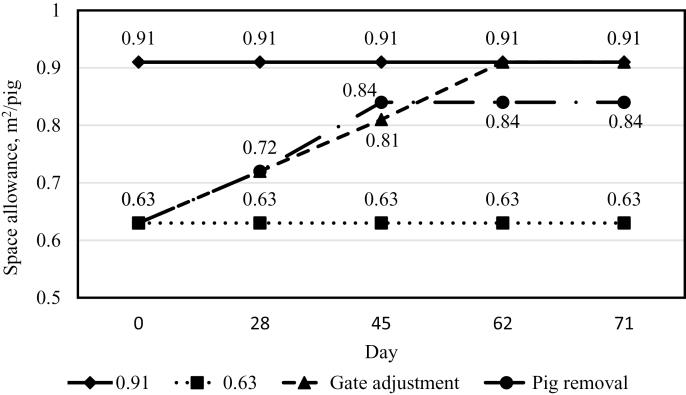

A total of 256 pigs (PIC 327 × 1050; Hendersonville, TN; initially 55.9 ± 4.88 kg) were used in a 71-d growth study. Pigs were initially placed into pens approximately 30 d prior to the start of the experiment with 7 or 8 pigs per pen (0.91 m2 per pig). On day 0, pigs were individually weighed and allotted to pens; pens of pigs were blocked by BW and allotted to 1 of 4 space allowance treatments, initially with 8 pigs per pen (4 barrows and 4 gilts) and 8 pens per treatment. First 2 treatments included pens with 0.91 m2 per pig or 0.63 m2 per pig for the entire study; two additional treatments initially provided 0.63 m2 per pig, but either a gate was adjusted on days 28, 45, and 62 providing 0.72, 0.81, and 0.91 m2, respectively, or the heaviest pig in the pen was removed on days 28 and 45 providing 0.72 and 0.84 m2, respectively (Table 1 and Figure 1). The space adjustments and pig removals were made to keep the pigs above their predicted minimum space requirement [(m2) = 0.0336 × (BW, kg)0.67], where 0.0336 is the k value. Throughout the experiment, 1 pig from the 0.91 m2 per pig treatment died (on day 27) and was removed from the pen; pen size was adjusted to maintain the correct space allowance per pig. Feeder and waterer space was maintained regardless of space adjustments. Pigs were fed a common corn-soybean meal-based diet offered in 3 phases (Table 2). Diets were formulated to meet or exceed the pigs’ nutrient requirement estimates (NRC, 2012) and the 3 phases were fed from approximately 56 to 83, 83 to 98, and 98 to 124 kg BW. Phase changes were made on days 28 and 45. Pens of pigs and feeders were weighed on days 0, 14, 28, 45, 62, and 71 to calculate average daily gain (ADG), average daily feed intake (ADFI), and gain:feed ratio (G:F).

Table 1.

Space allowance and k-value through the experiment

| Item | 0.91 m1 | 0.63 m1 | Gate adjustment1 | Pig removal2 |

|---|---|---|---|---|

| day 0 | ||||

| k-value3 | 0.0614 | 0.0425 | 0.0425 | 0.0425 |

| m2 per pig | 0.91 | 0.63 | 0.63 | 0.63 |

| day 28 | ||||

| k-value | ||||

| Before adjustment | 0.0471 | 0.0326 | 0.0326 | 0.0326 |

| After adjustment | — | — | 0.0373 | 0.0373 |

| m2 per pig | 0.91 | 0.63 | 0.72 | 0.72 |

| day 45 | ||||

| k-value | ||||

| Before adjustment | 0.0420 | 0.0291 | 0.0333 | 0.0333 |

| After adjustment | — | — | 0.0374 | 0.0388 |

| m2 per pig | 0.91 | 0.63 | 0.81 | 0.84 |

| day 62 | ||||

| k-value | ||||

| Before adjustment | 0.0377 | 0.0261 | 0.0335 | 0.0348 |

| After adjustment | — | — | 0.0377 | 0.0348 |

| m2 per pig | 0.91 | 0.63 | 0.91 | 0.84 |

| day 71 | ||||

| k-value | 0.0360 | 0.0249 | 0.0360 | 0.0332 |

| m2 per pig | 0.91 | 0.63 | 0.91 | 0.84 |

A total of 256 pigs (PIC 327 × 1050; Hendersonville, TN; initially 55.9 ± 0.43 kg) are used in a 71-d growth trial. Average body weights on days 0, 28, 45, 62, and 71 are 56, 83, 98, 116, and 124 kg, respectively.

1Increased space by gate adjustment.

2Increased space by pig removal.

3 k-value [(m2) = k × (BW, kg)0.67] calculated before and after a pig is removed or gates are adjusted.

Figure 1.

Space allowance of treatments through the experiment.

Table 2.

Diet composition (as-fed basis)

| Item | Phase1 | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| Ingredient, % | |||

| Corn | 71.48 | 78.42 | 82.85 |

| Soybean meal | 25.71 | 19.20 | 14.93 |

| Monocalcium P (21% P) | 0.55 | 0.33 | 0.30 |

| Limestone | 1.13 | 1.10 | 1.08 |

| Salt | 0.35 | 0.35 | 0.35 |

| L-Lys HCl | 0.31 | 0.25 | 0.22 |

| DL-Met | 0.06 | 0.02 | — |

| L-Thr | 0.09 | 0.05 | 0.05 |

| Trace mineral premix2 | 0.15 | 0.13 | 0.10 |

| Vitamin premix3 | 0.15 | 0.13 | 0.10 |

| Phytase4 | 0.02 | 0.02 | 0.02 |

| Total | 100 | 100 | 100 |

| Calculated analysis | |||

| Standardized ileal digestible (SID) amino acids, % | |||

| Lys | 1.05 | 0.85 | 0.72 |

| Ile:Lys | 62 | 64 | 66 |

| Met:Lys | 30 | 29 | 30 |

| Met & Cys:Lys | 55 | 56 | 59 |

| Thr:Lys | 61 | 61 | 64 |

| Trp:Lys | 18.0 | 18.0 | 18.0 |

| Val:Lys | 69 | 73 | 76 |

| Total Lys, % | 1.18 | 0.96 | 0.82 |

| Net energy, kcal/kg | 2,462 | 2,507 | 2,534 |

| SID Lys:net energy, g/Mcal | 4.26 | 3.39 | 2.84 |

| Crude protein, % | 18.5 | 15.9 | 14.2 |

| Ca, % | 0.62 | 0.55 | 0.52 |

| P, % | 0.49 | 0.41 | 0.39 |

| STTD P, %5 | 0.35 | 0.30 | 0.28 |

| Chemical analysi s, %6 | |||

| Dry matter | 88.32 | 87.25 | 87.41 |

| Crude protein | 18.5 | 15.4 | 14.8 |

1Phases 1, 2 and 3 are fed from approximately 56 to 83, 83 to 98, and 98 to 124 kg, respectively.

2Provided per kilogram of premix: 11 g Cu from copper sulfate, 0.2 g I from Ca iodate, 73 g Fe from ferrous sulfate, 22 g Mn from manganese sulfate, 0.2 g Se from sodium selenite, and 73 g Zn from zinc sulfate.

3Provided per kilogram of premix: 3,527,360 IU Vitamin A, 881,840 IU vitamin D3, 17,637 IU vitamin E, 15 mg vitamin B12, 3,307 mg riboflavin, 33,069 mg niacin, 11,023 mg pantothenic acid, and 1,764 mg menidione.

4HiPhos (DSM Inc, Parsippany, NJ) provided phytase units 3,174,624 (FTU)/kg of product and released 0.10% digestible P.

5STTD = standardized total tract digestible.

6Six samples of each diet were collected, blended and subsampled, and analyzed (Ward Laboratories, Inc. Kearney, NE).

Statistical Analysis

Data were analyzed as a randomized complete block design with space allowance treatment as a fixed effect and BW block as a random effect using the MIXED procedure of SAS (SAS Institute, Inc., Cary, NC). Pen served as the experimental unit. Treatment means were separated using the PDIFFS option. Statistical significance was determined at P < 0.05 and P-values falling within P > 0.05 and P < 0.10 were considered marginally significant.

RESULTS

Growth Performance

From days 0 to 14 (56 to 69 kg), there was no effect of stocking density observed for ADG, ADFI, and G:F (Table 3) as anticipated. However, from days 14 to 28 (69 to 83 kg), pigs provided 0.91 m2 had increased (P < 0.05) ADG and G:F compared with those allowed 0.63 m2; ADFI of pigs from the 0.63 m2 treatment was decreased compared with those provided 0.91 m2, but was not different from that of pigs from the space adjustment treatments. These observations suggest space restriction started to influence growth rate between 69 and 83 kg BW.

Table 3.

Effects of increasing space allowance by removing a pig or gate adjustment on finishing pig body weight (BW), average daily gain (ADG), average daily feed intake (ADFI), and gain:feed (G:F)

| Item | 0.91 m2 | 0.63 m2 | Gate adjustment1 | Pig removal2 | SEM | P < |

|---|---|---|---|---|---|---|

| days 0 to 14 | ||||||

| days 0 BW, kg | 55.9 | 56.0 | 55.9 | 55.6 | 0.15 | 0.361 |

| ADG, kg | 0.94 | 0.94 | 0.96 | 0.96 | 0.015 | 0.495 |

| ADFI, kg | 2.19 | 2.15 | 2.19 | 2.19 | 0.044 | 0.894 |

| G:F | 0.429 | 0.439 | 0.440 | 0.442 | 0.008 | 0.657 |

| days 14 to 28 | ||||||

| days 14 BW, kg | 69.1 | 69.2 | 69.4 | 69.1 | 0.26 | 0.835 |

| ADG, kg | 1.05a | 0.94b | 0.95b | 0.98b | 0.020 | 0.002 |

| ADFI, kg | 2.59a | 2.41b | 2.50ab | 2.54a | 0.041 | 0.041 |

| G:F | 0.407a | 0.388b | 0.379b | 0.386b | 0.0067 | 0.021 |

| days 28 to 45 | ||||||

| days 28 BW, kg | 84.0x | 82.3y | 82.6y | 82.8y | 0.47 | 0.081 |

| ADG, kg | 0.98 | 0.88 | 0.92 | 0.93 | 0.028 | 0.143 |

| ADFI, kg | 2.87a | 2.69b | 2.79ab | 2.68b | 0.046 | 0.025 |

| G:F | 0.339 | 0.327 | 0.330 | 0.349 | 0.0086 | 0.266 |

| days 45 to 62 | ||||||

| days 45 BW, kg | 100.6a | 97.3b | 98.2b | 97.4b | 0.49 | 0.001 |

| ADG, kg | 1.06 | 1.01 | 1.08 | 1.05 | 0.022 | 0.260 |

| ADFI, kg | 3.20a | 2.90b | 3.16a | 3.12a | 0.046 | 0.001 |

| G:F | 0.331 | 0.350 | 0.341 | 0.337 | 0.0066 | 0.259 |

| days 62 to 71 | ||||||

| days 62 BW, kg | 118.6a | 114.6c | 116.5b | 114.0c | 0.63 | 0.001 |

| ADG, kg | 0.97a | 0.80b | 0.93a | 0.94a | 0.035 | 0.008 |

| ADFI, kg | 2.92a | 2.67b | 2.98a | 2.93a | 0.046 | 0.001 |

| G:F | 0.331 | 0.298 | 0.314 | 0.320 | 0.0113 | 0.233 |

| days 0 to 71 | ||||||

| days 71 BW, kg | 127.3a | 121.7c | 124.9b | 122.5c | 0.73 | 0.001 |

| ADG, kg | 1.00a | 0.93c | 0.97b | 0.98b | 0.009 | 0.001 |

| ADFI, kg | 2.76a | 2.58c | 2.73ab | 2.66b | 0.029 | 0.001 |

| G:F | 0.363 | 0.356 | 0.356 | 0.361 | 0.0038 | 0.476 |

A total of 256 pigs (PIC 327 × 1050; Hendersonville, TN; initially 55.9 ± 0.43 kg) are used in a 71-d growth study with 4 barrows and 4 gilts per pen and 8 pens per treatment. Means within a row with different superscripts differ: abcP < 0.05; xyzP < 0.10.

1Gate adjustment = increasing space allowance by gate adjustment; initially 0.63 m2/pig with gates adjusted as pigs reached the k value to be non-limiting: 0.72 m2 at 83 kg (day 28), 0.81 m2 at 98 kg (day 45), and 0.91 m2 at 116 kg (day 62).

2Pig removal = increasing space allowance by removing heaviest pigs; initially 0.63 m2 per pig with a pig removed as the k-value is reached to be non-limiting: 1 pig at 83 kg (day 28) and at 98 kg (day 45).

On day 28, floor space was increased to 0.72 m2 per pig for pens on the space adjustment treatments by either adjusting the gate or removing the heaviest pig, which maintained the space allowance of these pigs above the critical k value coefficient (0.0336). From days 28 to 45 (83 to 98 kg), pigs provided 0.63 m2 or increased space allowance by pig removal had decreased (P = 0.025) ADFI compared with pigs provided 0.91 m2, with pigs from pens where the gate was adjusted intermediate. There was no evidence for any differences in ADG or G:F among treatments during days 28 to 45.

On day 45, floor space was further increased by adjusting the gate or removing the heaviest pig to 0.81 m2 or 0.84 m2 per pig, respectively, for the increased space allowance treatments. This adjustment kept those above the critical k value coefficient (0.0336). From days 45 to 62 (98 to 116 kg), ADFI was decreased (P = 0.001) for pigs provided 0.63 m2 compared with all other treatments. During this period, increasing space allowance by either adjusting the gate or removing the heaviest pig resulted in similar performance as pigs allowed 0.91 m2.

On day 62 (116 kg), because the critical k value was reached sooner for pigs in the gate adjustment treatment than for the pig removal treatment (based on the actual m2), gates were adjusted to maintain the desired k value; however, no space adjustment was performed for pig removal treatment. On day 62, pigs provided 0.91 m2 were heavier (P = 0.001) than those provided 0.63 m2 or those had the heaviest pig removed, with pigs from the gate adjustment treatment intermediate. From days 62 to 71 (116 to 124 kg), ADG decreased (P = 0.008) when pigs were allowed 0.63 m2 compared with all other treatments, which is likely due to the decreased (P = 0.001) ADFI as G:F was not affected.

For the overall study (66 to 124 kg), pigs provided 0.91 m2 had increased (P = 0.001) ADG compared with those allowed 0.63 m2 with pigs from pens provided increased space intermediate. Pigs provided 0.91 m2 had increased (P = 0.001) ADFI compared with pigs allowed 0.63 m2 and those where a pig was removed; however, pigs from pens where the gate was adjusted had intermediate ADFI.

DISCUSSION

In this study, space allowance was set so as not to limit pig ADG (0.91 m2 per pig), or to be limiting (0.63 m2 per pig) throughout most of the study. Two additional treatments were initially nonlimiting (0.63 m2 per pig at 56 kg BW), but as the pigs grew, either the gate was adjusted or the heaviest pig was removed to keep the remaining pigs in the pen above the predicted space requirement. Therefore, these 2 treatments should have provided adequate space allowance so that ADG should be similar to those offered 0.91 m2 per pig. The space allowances were predicted using the equation developed by Gonyou et al. (2006): (m2) = 0.0336 × (BW, kg)0.67.

Gonyou et al. (2006) proposed a predicted optimal threshold that when the k value [k = m2/(BW, kg)0.67] drops below 0.0336, ADG and ADFI will be decreased, which is supported by the study herein. More recently, 2 studies (Flohr et al., 2016; Thomas et al., 2017) have applied these equations in both commercial and research environments and found reductions in performance due to inadequate space allowance at lighter BWs than predicted previously. Johnston et al. (2017) also observed that floor space allowance predicted by Gonyou et al. (2006) might be underestimated for heavy weight market pigs. In the study herein, we used a limited number of pigs per pen (7 or 8) relative to what is frequent observed in commercial production (25 to 30 pigs per pen). This is certainly a factor to consider in applying our results to commercial production. However, in a meta-analysis involving over 30 studies to develop prediction equations evaluating floor space allowances on pig growth, Flohr et al. (2018) observed that group size was not a significant predictor of ADG, ADFI, or G:F using multivariate models. Certainly, more research is needed to evaluate the possible interactions of space allowance and the number of pigs per pen.

Over the last 2 decades, several studies have observed an increase in growth rate following the removal of heavy weight pig(s) from a group (Woodworth et al., 2000; DeDecker et al., 2005; Jacela et al., 2009). These authors reported that removal of heavy weight pigs resulted in the remaining pigs having increased ADG compared with those from intact pens (Woodworth et al., 2000; DeDecker et al., 2005; Jacela et al., 2009). Similar results were observed in our study where removing a pig from the pen increased the growth rate of pigs compared with pigs stocked at 0.63 m2. Interestingly, in our study, it appears that the remaining pigs in pens that had the heaviest pig(s) removed over time did not maintain similar performance to those stocked at 0.91 m2. It is possible that removal of the heaviest, and likely the most dominant, pig(s) from a pen might have induced changes in social dynamics of the remaining pigs and negatively affected their growth performance. Our results also indicate that the pigs remaining in pens that had the heaviest pigs removed over time had similar ADG and ADFI compared with those from pens with gate adjustment. It is also worthy to note that the space allowance treatments tested in the present study appear to have minimal impact on G:F, indicating that the improvement in growth performance in response to greater space allowance was primarily driven by increased ADFI.

Recently, Flohr et al. (2016) evaluated the effects of initial stocking density and marketing removal strategies on the growth of pigs remaining in the pen until market. One of the study’s objectives was to determine whether pigs maintained above the critical k coefficient perform like those that are unrestricted throughout finishing. During the first growth period of their study, pigs provided 0.91 m2 (unrestricted) had greater ADG and ADFI than those provided 0.65 m2, regardless of removal strategy, with G:F unchanged. Based on the predicted reduction in ADG by Gonyou et al. (2006), Flohr et al (2016) should have observed a 1.4% reduction in ADG; however, their observed reduction in growth was 3.4%. This suggests the predicted ADG outcome was underestimated by Gonyou et al. (2006). According to the critical k value of 0.0336, no differences in ADG or ADFI should have been observed until pigs reached approximately 83 kg when the pen started to become crowded. A possible explanation might be that the response to space is curvilinear as the pig approaches the actual k value, whereas Gonyou et al. (2006) described the response in growth as a broken-line response.

In our study, there was a 10% reduction in ADG from 69 to 83 kg BW when comparing the 0.63 vs. 0.91 m2 treatments, which was greater than the magnitude of reduction observed by Flohr et al. (2016). Thomas et al. (2017) evaluated the effects of floor space allowance on finishing pigs in a study by adjusting gates and reported similar findings to ours. Together, these studies suggest that growth rate restriction could occur at k value above 0.0336. This finding is not surprising given the fact that the model proposed by Gonyou et al. (2016) was generated more than 12 yr ago when genetics, especially the maintenance requirement, of pigs are different from modern pigs.

In conclusion, pigs provided 0.91 m2 grew faster and consumed more feed than pigs provided 0.63 m2. It also appeared that either removing the heaviest pig(s) or adjusting the gating as pigs reached the critical k value affected pig performance similarly. We had speculated that when removing a pig(s) from a pen, the change in social dynamics of the remaining pigs might have negatively affected ADG. However, our study indicates the performance benefit from removing the heaviest pig(s) from the pen is primarily from the increased space allowance alone. Increasing space allowance by removing pig(s) or gate adjustment increased ADG compared with pigs provided 0.63 m2 for the entire experiment. However, neither strategy allowed pigs to maintain ADG like space-unrestricted pigs provided 0.91 m2 throughout the study. This indicates that the industry accepted critical k value, 0.0336, may not be adequate for optimal pig performance across multiple BW ranges.

ACKNOWLEDGMENTS

We would also like to express appreciation to Mark Nelson and Duane Baughman for technical assistance.

Footnotes

Contribution no. 17-341-J from the Kansas Agricultural Experiment Station, Manhattan, KS 66506-0210

Appreciation is expressed to Kansas State University Swine Teaching and Research Center and the O.H. Kruse Feed Mill, Manhattan, KS for use of research facilities and feed mill.

LITERATURE CITED

- DeDecker J. M., Ellis M., Wolter B. F., Corrigan B. P., Curtis S. E., Parr E. N., and Webel D. M.. 2005. Effects of proportion of pigs removed from a group and subsequent floor space on growth performance of finishing pigs. J. Anim. Sci. 83:449–454. doi:10.2527/2005.832449x [DOI] [PubMed] [Google Scholar]

- Ekkel E. D., Spoolder H. A. M., Hulsegge I., and Hopster H.. 2003. Lying characteristics as determinants for space requirements in pigs. Appl. Anim. Behav. Sci. 80:19–30. doi:10.1016/S0168-1591(02)00154-5 [Google Scholar]

- Flohr J. R., Dritz S. S., Tokach M. D., Woodworth J. C., DeRouchey J. M., and Goodband R. D.. 2018. Development of equations to predict the influence of floor space on average daily gain, average daily feed intake and gain: feed ratio of finishing pigs. Animal. 12:1022–1029. doi:10.1017/S1751731117002440 [DOI] [PubMed] [Google Scholar]

- Flohr J. R., Tokach M. D., DeRouchey J. M., Woodworth J. C., Goodband R. D., and Dritz S. S.. 2016. Evaluating the removal of pigs from a group and subsequent floor space allowance on the growth performance of heavy-weight finishing pigs. J. Anim. Sci. 94:4388–4400. doi:10.2527/jas2016-0407 [DOI] [PubMed] [Google Scholar]

- Gonyou H. W., Brumm M. C., Bush E., Deen J., Edwards S. A., Fangman T., McGlone J. J., Meunier-Salaun M., Morrison R. B., Spoolder H., et al. 2006. Application of broken-line analysis to assess floor space requirements of nursery and grower-finisher pigs expressed on an allometric basis. J. Anim. Sci. 84:229–235. doi:10.2527/2006.841229x [DOI] [PubMed] [Google Scholar]

- Jacela J. Y., Dritz S. S., Tokach M. D., DeRouchey J. M., Goodband R. D., and Nelssen J. L.. 2009. Economic impact of removing pigs before marketing on the remaining pig’s growth performance. Kansas Swine Ind. Day Rep. Prog. No. 1020. Kansas State University Agricultural Experiment Station, Manhattan, KS: p. 262–269. Available from: http://hdl.handle.net/2097/2122 [Google Scholar]

- Johnston L. J., Rozeboom D. W., Goodband R. D., Moeller S. J., Shannon M. C., and Schieck S. J.. 2017. Effect of floor space allowances on growth performance of finishing pigs marketed at 138 kilograms. J. Anim. Sci. 95:4917–4925. doi:10.2527/jas2017.1870 [DOI] [PMC free article] [PubMed] [Google Scholar]

- NRC 2012. Nutrient requirements of swine. 11th rev. ed Natl. Acad. Press, Washington, DC. [Google Scholar]

- Thomas L. L., Goodband R. D., Woodworth J. C., Tokach M. D., DeRouchey J. M., and Dritz S. S.. 2017. Effects of space allocation on finishing pig growth performance and carcass characteristics. Transl. Anim. Sci. 1: 351–357. doi:10.2527/tas2017.0042 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Woodworth J. C., Dritz S. S., Tokach M. D., Goodband R. D., and Nelssen J. L.. 2000. Examination of the interactive effects of stocking density and marketing strategies in a commercial production environment. J. Anim. Sci. 78(Suppl. 2): 56. (Abstr.) [Google Scholar]