Abstract

To select a suitable drying process for using chestnut products in the food industry, this study investigated the effect of five drying methods, including natural drying, microwave drying (MD), hot air drying (HAD), freeze-vacuum drying (FVD) and microwave-vacuum drying (MVD) on the nutritional composition, flavor, and functional properties of dried chestnuts. The results indicated that the nutritional aspects and functional properties of chestnuts were enhanced by the freeze-drying process compared with the other four drying methods. The quality of the chestnuts dried using the MVD was second to the FVD. The hot-air dried products were quite similar to the naturally dried samples in terms of their functional component content and processability. In terms of the produce texture, the HAD was found to be the best. In total, 45 flavor components were identified in the samples, which comprised the following: 5 aldehydes, 4 alcohols, 4 esters, 8 terpenes, 16 hydrocarbons and, 8 others substances. The highest relative content of the ingredients in microwave-vacuum dried samples was pyrazine and 3-ethyl-2, 5-dimethyl. In the samples treated using the other four drying methods, benzyl alcohol was the ingredient with the highest concentration. Considering the fast drying rate, low energy consumption, and improved quality of chestnut products, MVD is the most suitable dehydration method for commercial production of Chinese chestnuts.

Keywords: Chinese chestnuts, Drying methods, Quality, Aroma components, Processing properties

Introduction

Chinese chestnuts (Castanea) are members of the Fagaceae family and occur naturally throughout the deciduous forests of Asia, Europe, and eastern North America (Lin et al. 2010). The genus includes an ecologically and economically important nut and timber producing trees, including the Chinese chestnut (Castanea mollissima), Japanese chestnut (Castanea crenata), European Chestnut (Castanea sativa), and American chestnut (Castanea dentata) (Barakat et al. 2009). Chestnuts represent one of the earliest domesticated tree crops and an important domestically marketed food worldwide that is characterized by low fat and protein content but high carbohydrate content (Thang et al. 2016). However, this fruit is an important source of essential fatty acids, primarily linoleic and linolenic acid, which play an important role in preventing cardiovascular diseases and in promoting cerebral and retinal development in infants (Krist et al. 2004).

Chinese chestnuts (Castanea Mollissima Blume) have a planted cultivation history in China that dates back to 3000 years, with production of 1,659,800 tons in 2013, which is 78.5% of the total production in the world (Lin et al. 2010; Xu et al. 2011). Chestnuts are seasonal fruits with high water content (50% on a wet basis) and are available for a short period of time due to the development of mildew, germination, and insect infection (Huang 2012). Drying is one the best methods of preservation for chestnuts as it can extend the shelf life of the fruit. Since chestnut is heat sensitive, the drying temperature has a great impact on its organoleptic and nutritional quality (Zheng 2001). The dried chestnuts can be further processed into a powder form and can be incorporated into various food formulations as a functional food additive with a distinct flavor. The powdered chestnut also has a potential for wider food implications such as drinks, bread, or some other health supplements.

Dehydration is one of the best preservation methods, which could extend the shelf life of the food and has been used for drying and preserving the fruit for several centuries. The traditional drying method is based on solar energy, but the products can be easily spoiled due to varying environmental conditions that can cause a major loss in product quality (Feng et al. 2012). New drying methods such as freeze drying, microwave drying (MD) and infrared radiation drying have been developed in recent years (Ratti 2001; Wang et al. 2014; Dutta et al. 2012). Microwave-vacuum drying (MVD) combines vacuum with microwave heating, which offers the advantages of high efficiency, low temperature, easy control, and high retention of the original flavor. This makes it suitable for heat sensitive and biological active ingredients (Li et al. 2011). At present, some studies have been conducted using MD of Chinese chestnuts and the quality of the resulting product has been assessed by some researchers. For example, the drying characteristics of Chinese chestnuts by microwave heating combined with hot air drying (HAD) were studied (Zhou et al. 2009). The major research on drying of Chinese chestnuts has focused on the aroma components of chestnut product. The flavor components of roasted chestnuts and boiled chestnuts were determined using the GC–MS analysis (Morini and Maga 1995). However, the effect of different drying methods on the quality and flavor components of Chinese chestnuts is not impeccably explained in comparative studies. To explore the suitable drying methods for further processing of Chinese chestnuts and their application in the food industry, the nutrients, flavor, and functional characteristics of the chestnuts were evaluated after the product was treated with ND, HAD, FVD, MD, MVD.

Materials and methods

Sample and reagents

A single batch (50 kg) of Chinese chestnut samples was provided by Shenli Co., Ltd. in the state of Kuan County, Hebei province, China in 2016. The original moisture content of the fresh kernels, without shells and pellicles, was 55.3 ± 0.4% w.b.

Anthrone was obtained from the Kermel Reagent Company (Tianjin, China). The Folin-Ciocalteu reagent was obtained from the Sbol Reagent Company (Beijing, China). Pyrogallic acid was obtained from the Guangfu Chemical Company (Tianjin, China). Potassium hydroxide, hydrochloric acid, potassium sulfate, and all other reagents were purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China).

Drying processes

The shells of Chinese chestnuts were removed using a huller (JG01, Xinyi Jinggong machinery equipment factory), after which all the chestnuts were cut into 5-mm flakes. These chestnut slits were divided into five batches. One sample batch was dried naturally in air at 15–20 °C for 4 d. Another batch was dried by HAD at 55 °C for 10 h. A third batch was dried in a vacuum freeze dryer (model NO. A 6/14) at a temperature of − 45 °C and a pressure of 0.01 kPa for 36 h (VFD-2000, Shanghai Bilon Co. Ltd., China). The fourth batch was dried for 15 min using a microwave dryer with microwave power of 420 W (G70F20CN3L-C2, Galanz Co., Ltd., China). The fifth batch was dried using the MVD method at a temperature of 35–45 °C and a pressure of − 0.06 MPa for 12 min (KL-2D-6KW, Kailing Microwave Co., Ltd., China).

Analysis of components

The starch content of the samples was determined by the anthrone colorimetry method (Guo and Peng 2007). The protein content of the samples was determined by the Kjeldahl method based on AOAC 925.40 (AOAC 2000). The samples were subjected to digestion in a digestion system sealed with a cork, and copper was used as a catalyst. The crude protein content of the samples was calculated using a nitrogen conversion factor of 5.30, which is specific for the chestnut fruit (Borges et al. 2008). The reducing sugar content was determined using the 3, 5-dititrobenzoic acid method (Qi et al. 2004). Vitamin C was determined according to AOAC 985.33 (AOAC 2000) based on the principle that it can be titrated with a colored oxidation-reduction indicator 2,6-dichloroindophenol (0.1% concentration), EDTA was added as chelating agent to remove Fe and Cu interference. The tannin content was determined by spectrophotometric method as explained in NY/T 1600-2008.

Processability evaluation

The color of Chinese chestnuts after the different drying processes was obtained using the base Hunter table color system by color-difference meter. The Hunter values indicated the color of the food via reflected and transmitted light, where “L” represents the lightness axis, “a” represents the red-green axis, and “b” represents the yellowness of yellow blue axis.

The textural characteristics of the dried samples were measured using texture profile analysis (TPA), which is similar to the method of Yangling and Mamat (Yang et al. 2014; Mamat et al. 2010) with the TAXT2i Texture Analyzer. The test was performed by supporting a dried sample with the parameters such as speed (60 mm/min); depth (30%); trigger force (2.5 N); force sensing element range (2500 N), and each sample was tested 10 times.

Rehydration: The rehydration ratio for the samples was determined using tap water at 70 °C for 10 min. The rehydration ratio was calculated using the following expression (Doymaz 2010):

RR rehydration ratio, Wr weight of rehydrated sample (grams), Wd weight of dried sample (grams).

Analysis of flavor compounds

Based on the protocol reported in previous studies (Rodríguez-Burruezo et al. 2010 and Krist et al. 2004), herein the volatiles were isolated from the samples using the head-space solid phase microextraction (HS-SPME) technique. The isolation was conducted using 2.0 g of sample, which was placed into a 15-mL flask and closed with cap. The flask was incubated for 60 min in a heated tray oven at 40 °C. An SPME fiber with three different coatings (50/30 μm DVB/CAR/PDMS) (Supelco, Bellefonte, PA, USA) was inserted for 10 min in the headspace of the vial for collecting the volatiles. After the sampling was done, the fiber was immediately inserted into a gas chromatograph coupled to a mass spectrometer (GC–MS).

The GC–MS analysis was performed using an Agilent 7890A gas chromatograph coupled to a 5975C mass spectrometer equipped with a HP-5MS capillary column (5% phenylmethylpolysiloxane, 30 m, 0.25 µm i.d., 0.1 Lm film thickness; J&W Scientific, Folsom, CA, USA). Using the same program reported above, the carrier gas (helium), the flow rate (1.0 mL/min), and the initial temperature of the column (40 °C) was held for 3 min and then increased at the rate of 3 °C min−1 up to a temperature of 150 °C. From this point, the temperature was increased at the rate of 9 °C min−1 up to a temperature of 230 °C and held for 5 min. The injector port and transfer line temperature was 250 °C in the splitless mode.

The mass spectrometer was operated in electron-impact (EI) mode. The scan range and the acquisition mass range was 10–300 and 35–500 amu, respectively. The ion-source temperature was 230 °C. The entire mass spectra were acquired in EI mode with an ionization voltage of 70 eV. The volatile compounds were identified by comparing their retention index and mass spectra with those of a commercial spectra database (NIST 2.0) and an internal library of the laboratory.

Data analysis

Statistical analysis and experimental results were expressed as the mean ± standard deviation. The experimental data was analyzed using the statistical package for social scientists (SPSS; version 18.0). The significant difference from the respective controls for each experiment was tested using the Tukey’s LSD test. A P < 0.05 was considered as statistically significant.

Results and discussion

The nutritional components

The nutritional composition of the dried Chinese chestnuts using different drying methods is presented in Table 1. Complex (starch) and simple (sugars) carbohydrates are a major energy source and have a specific influence on the sweetness of chestnuts, which is a processing and palatability characteristic. Starch comprised the bulk of total carbohydrates in the dried samples with the content ranging from 40.8% (HAD) to 44.75% (FVD) for the five drying methods used. The results show that the FVD produced a higher level of starch, reducing sugar, vitamin C, and tannin compared with other four drying methods. The chestnut nutrient components for the MVD method were second to the FVD method. The MVD method had less effect on the quality of chestnut owing to its short time consumption. The starch, reducing sugar, and Vitamin C content for the naturally dried samples were higher than the hot-air dried samples. The components in the product were sharply reduced by the HAD method. This was attributed to the high temperature and long processing, which may be the main reasons for component loss.

Table 1.

The effect of drying methods on nutritional components of the Chinese chestnuts

| Drying methods | Starch | Reducing sugar | Protein | Vitamin C | Tannin |

|---|---|---|---|---|---|

| ND | 41.52 ± 0.24b | 13.84 ± 0.011c | 7.48 ± 0.52b | 63.81 ± 0.43b | 1.88 ± 0.006c |

| HAD | 40.8 ± 0.013c | 13.76 ± 0.04c | 7.62 ± 0.018a | 59.74 ± 0.43c | 1.93 ± 0.013c |

| FVD | 44.75 ± 0.43a | 14.67 ± 0.07a | 7.66 ± 0.024a | 69.72 ± 0.4a | 2.89 ± 0.08a |

| MD | 42.58 ± 0.39b | 14.13 ± 0.06b | 7.65 ± 0.012a | 68.43 ± 0.41a | 1.961 ± 0.009c |

| MVD | 43.53 ± 0.28a | 14.4 ± 0.074a | 7.67 ± 0.028a | 68.2 ± 0.22a | 2.40 ± 0.023b |

a, b, c, and d in the same column indicate significant mean difference by Tukey’s LSD test at P = 0.05

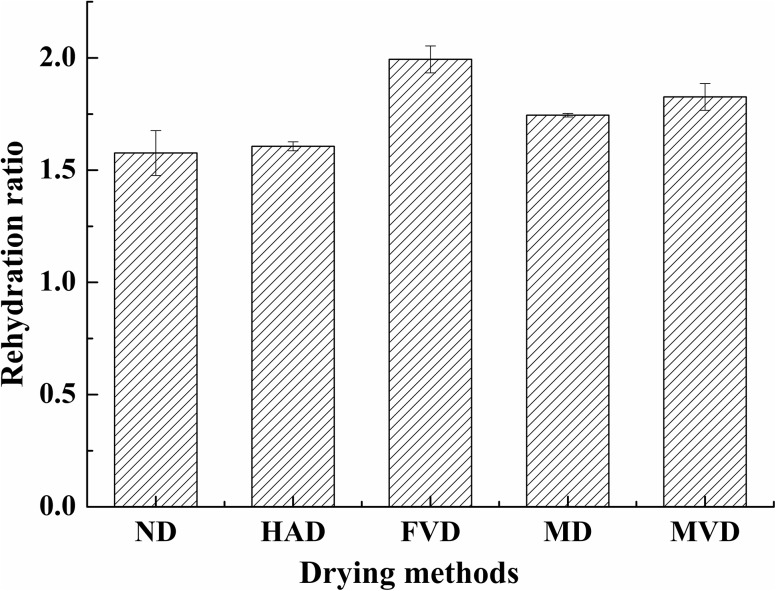

Effect of drying methods on rehydration properties of Chinese chestnuts

The rehydration of dried chestnuts depends on the structural changes in the material during drying, which causes shrinkage and structural collapse (Kaymak-Ertekin 2002). The quality of the dried product is a basic consideration in the selection of an adequate method for dehydrating the product. The rehydration properties of the chestnuts previously dried using different drying methods are presented in Fig. 1. The results show that the FVD method produced a higher rehydration ratio, whereas the ND had the lowest. It may have been that the chestnut dried by FVD method had a porous texture, which resulted in the highest rehydration ratio. The rehydration ratios were similar for the other four drying methods.

Fig. 1.

The effect of drying methods on rehydration capacity of the Chinese chestnuts

Effect of drying methods on the color of the Chinese chestnuts

The color of a product is usually the first quality parameter that consumers evaluate and is critical to the consumer’s acceptance of the product. Recently, image analysis has been used as a promising approach to objectively assess the quality of dried products. It is known that during drying, non-enzymic browning reactions (mainly the Maillard reaction) occur, which can be promoted by heat treatment. The color of the chestnuts was monitored and measured by the L*, a*, and b* CIELab coordinates. As shown in Table 2, the freeze-vacuum dried sample had the highest L* value and b* values compared to the products resulting from the other drying methods. However, the a* values exhibited opposite behavior. There was a significant difference between FVD and the other four methods. This may be cause of the thermal degradation, i.e., enzymatic browning, caramelization, and ascorbic-acid browning that resulted from the high temperature imposed during the drying process.

Table 2.

Color of Chinese chestnuts resulting from various drying methods

| Drying methods | L* | a* | b* |

|---|---|---|---|

| ND | 85.43 ± 0.26b | 0.76 ± 0.04b | 21.34 ± 0.05b |

| HAD | 85.21 ± 0.16b | 0.95 ± 0.07ab | 20.40 ± 0.13c |

| FVD | 89.29 ± 0.24a | − 0.13 ± 0.04d | 23.55 ± 0.44a |

| MD | 83.34 ± 0.13d | 1.08 ± 0.12a | 21.10 ± 0.09b |

| MVD | 84.63 ± 0.17c | 0.10 ± 0.036c | 18.78 ± 0.23d |

a, b, c, and d in the same column indicate significant mean difference by Tukey’s LSD test at P = 0.05

Effect of drying methods on the textural properties of Chinese chestnuts

We obtained textural parameters for the dried Chinese chestnuts using TPA. The textural properties of the Chinese chestnut resulting from various drying method are shown in Table 3. The hardness of the chestnut was determined by the magnitude of the yield force caused by fruit deformation under pressure. Statistical analysis showed a significant difference in hardness between chestnuts dried by HAD and those dried by the other methods. The order of the hardness (from high to low) of the chestnuts resulting from different drying methods was: HAD > FVD > MD > ND > MVD. The results of the chewiness and gumminess of the various dried chestnuts were similar to their hardness. The adhesiveness and cohesiveness of the chestnuts were better when dried using FVD and HAD methods. The springiness of the dried fruit was determined based on the degree of structural recovery following compression deformation. The springiness of chestnuts dried by MD was found to be the best.

Table 3.

The textural profile analysis of chestnuts

| Drying methods | Hardness/N | Adhesiveness/N mm | Cohesiveness | Springiness/mm | Gumminess/N | Chewiness/mJ |

|---|---|---|---|---|---|---|

| ND | 591.15 ± 5.84b | 0.044 ± 0.007c | 0.591 ± 0.016ab | 0.81 ± 0.07a | 343.85 ± 8.45b | 289.27 ± 3.54b |

| HAD | 790.55 ± 11.10a | 0.09 ± 0.001ab | 0.619 ± 0.018a | 0.66 ± 0.02b | 551.80 ± 9.88a | 512.43 ± 5.70a |

| FVD | 623.90 ± 4.32b | 0.11 ± 0.001a | 0.536 ± 0.09b | 0.77 ± 0.02ab | 331.80 ± 6.22b | 242.36 ± 5.83b |

| MD | 521.10 ± 2.12b | 0.082 ± 0.003b | 0.53 ± 0.09b | 0.89 ± 0.01a | 256.45 ± 0.77bc | 251.36 ± 9.90b |

| MVD | 262.20 ± 7.75c | 0.047 ± 0.004c | 0.544 ± 0.014b | 0.84 ± 0.03a | 161.75 ± 7.68c | 119.06 ± 5.28c |

a, b, c, and d in the same column indicate significant mean difference by Tukey’s LSD test at P = 0.05

Analysis of the flavor compounds

The volatile flavor compounds of dried Chinese chestnuts as a result of the five different drying methods were determined by capillary gas-chromatography with a mass selective detector. A total of 45 flavor compounds were identified and the results are presented in Table 4. These compounds comprised 5 aldehydes, 4 alcohols, 4 esters, 8 terpenes, 16 hydrocarbons, and 8 others substances. We obtained 28 substances from the Chinese chestnuts dried by freeze drying, 27 substances from MD, 23 substances from HAD, 21 substances from MVD, and only 13 substances from ND. The 3-ethyl-2, 5-dimethyl pyrazine in the chestnuts dried using MVD method was the most abundant volatile compounds and constituted approximately 21.933% of the total compounds. Benzyl alcohol was the most abundant aroma compounds in the chestnuts dried using the other four drying methods, and the respective benzyl alcohol content obtained using the four drying methods was 36.622, 36.117, 44.069, 27.029%. The volatiles were possibly affected by temperature making the flavor unstable, oxidation and decomposition occurred during the drying process. The aroma compounds such as benzaldehyde, pyrazine, 2, 5-dimethyl- were identified in roasted Italian chestnuts, whereas decanal, hexanedioic acid, and dimethyl ester have been found in roasted and boiled Chinese chestnuts (Krist et al. 2004).

Table 4.

Aroma compounds and relative contents of Chinese chestnuts dried using different drying methods

| Peak | Compound name | Relative content /% | ||||

|---|---|---|---|---|---|---|

| ND | HAD | FVD | MVD | MD | ||

| Aldehydes | ||||||

| 2 | Benzaldehyde | 15.889 | 17.476 | 18.750 | – | 17.576 |

| 5 | Benzeneacetaldehyde | – | – | – | 6.089 | – |

| 7 | 2-Octenal, (E)- | – | 2.644 | 1.072 | – | 1.416 |

| 9 | Nonanal | 7.426 | 7.086 | 4.979 | 8.453 | 4.749 |

| 15 | Decanal | – | 0.890 | 0.606 | 2.234 | 0.848 |

| Alcohols | ||||||

| 4 | Benzyl Alcohol | 36.622 | 36.117 | 44.069 | – | 27.029 |

| 12 | 3-Cyclohexene-1-methanol, ππ-trimethyl- | – | 1.056 | – | – | – |

| 13 | 5-Caranol, (1S, 3R, 5S, 6R)-(-)- | – | – | 0.560 | – | 0.809 |

| 27 | (-)-Isolongifolol, acetate | – | – | 0.430 | – | – |

| Esters | ||||||

| 16 | Hexanedioic acid, dimethyl ester | – | – | 1.599 | – | 0.493 |

| 31 | Acetic acid, chloro-, hexadecyl ester | – | – | – | 2.732 | – |

| 37 | Tributyl phosphate | 14.065 | – | 7.711 | – | 5.406 |

| 45 | Dibutyl phthalate | – | – | 0.435 | – | 0.496 |

| Terpenes | ||||||

| 20 | Bicyclo[4.4.1]undeca-1,3,5,7,9-pentaene | – | 1.070 | 0.375 | – | 2.147 |

| 26 | 1H-Benzocycloheptene, 2,4a,5,6,7,8,9,9a-octahydro-3,5,5-trimethyl-9-methylene-, | – | – | – | – | 0.575 |

| 29 | Cedrene | – | – | – | 1.298 | – |

| 30 | Caryophyllene | 3.822 | 3.980 | 1.955 | 4.053 | 2.895 |

| 33 | (-)-γ-Cadinene | – | 1.259 | 0.824 | – | 2.791 |

| 35 | α-Selinene | – | 1.867 | 1.355 | – | – |

| 38 | d-Cadinene | – | 3.527 | – | – | 2.810 |

| 39 | πGuaiene | – | – | 1.821 | – | – |

| Hydrocarbons | ||||||

| 10 | Azulene | – | – | – | – | 1.380 |

| 11 | Naphthalene | – | 1.266 | 0.741 | 2.696 | – |

| 14 | Dodecane | – | 2.641 | 1.720 | 8.439 | 3.623 |

| 17 | Hexadecane | – | – | – | – | 0.845 |

| 18 | Heptadecane,2,6,10,14-tetramethyl- | – | – | – | 2.322 | – |

| 19 | Dodecane, 2,6,11-trimethyl- | 1.392 | 1.057 | 0.501 | – | – |

| 21 | Naphthalene, 1-methyl- | – | – | 0.676 | 4.505 | 2.147 |

| 22 | Tridecane, 3-methyl- | 1.716 | 1.415 | – | – | – |

| 23 | Tetradecane, 4-methyl- | – | – | 0.643 | 3.694 | 1.054 |

| 25 | Tetradecane | 7.418 | 6.383 | 2.798 | 12.665 | 4.990 |

| 32 | Tetradecane, 2,6,10-trimethyl- | 0.948 | 0.626 | 0.821 | 2.203 | 1.787 |

| 34 | 1,1,4a-Trimethyl-5,6-dimethylenedecahydronaphthalene | – | – | – | 2.024 | – |

| 40 | Pentadecane, 3-methyl-3 | 2.079 | 1.523 | 0.646 | 2.179 | 1.067 |

| 41 | Hexadecane | – | 1.285 | – | 1.565 | – |

| 42 | Tetradecane, 2,6,10-trimethyl- | 1.498 | 0.893 | 0.384 | – | 1.681 |

| 44 | 1,1’-Biphenyl, 3,4diethyl- | – | 1.087 | – | – | 1.564 |

| Others | ||||||

| 1 | Pyrazine, 2,5-dimethyl- | – | – | – | 1.996 | – |

| 3 | Pyrazine, 2-ethyl-6-methyl- | – | – | – | 4.734 | – |

| 6 | Benzene,[(2-propenyloxy)methyl]- | – | 3.693 | – | – | 2.491 |

| 8 | Pyrazine,3-ethyl-2,5-dimethyl- | 5.110 | – | 3.163 | 21.933 | 7.321 |

| 24 | 3-Trifluoroacetoxytetradecane | 0.794 | 1.160 | 0.528 | 2.710 | 0.919 |

| 28 | 1H-Isoindole, 3-methoxy-4,7-dimethyl- | – | – | 0.578 | – | – |

| 36 | Butylated Hydroxytoluene | – | – | – | 1.476 | – |

| 43 | Cedrane, 8-propoxy- | – | – | 0.308 | – | – |

Table 5 presents a comparison of the relative contents of different categories of volatile components that resulted from the five types of drying methods used for Chinese chestnuts. The volatiles mainly comprised alcohols among the four samples (ND, HAD, FVD, MD), and the relative content was 36.622, 37.173, 45.059, 27.838%, respectively. Hydrocarbons were the most abundant aroma component in chestnuts dried using the MVD methods and constituted 42.292% of the total aroma components. The heating process catalyzes the reaction between amino acids and sugars via the Maillard reaction, which is responsible for the development of product color, and volatile heterocyclic compounds. Interestingly, only one pyrazine derivate (2,5-dimethylpyrazine) was detected in microwave-vacuum dried chestnuts, whereas numerous pyrazines have been identified from the other drying methods. This is in agreement with previous studies by Morini and Maga, which focused on the volatile compounds in roasted and boiled Chinese chestnuts (Morini and Maga 1995). The terpenes exhibit a soft aroma of flowers, fruits and are sweet because of the presence of caryophyllene, (-)-γ-cadinene, and α-selinene. The chemical properties of aldehydes are generally more active and the odor threshold is very low, which has an important influence on the overall flavor characteristics of chestnuts. Benzaldehyde exhibits pleasant nutty aroma, whereas nonanal exhibits the smell of fish. Esters usually present a fruity taste despite the fact that the relative content of these compounds is low in Chinese chestnuts; however, the odor threshold of esters is also low, which gives them important sensory characteristics.

Table 5.

Number and relative content of different categories volatile components present in Chinese chestnuts

| ND | HAD | FVD | MVD | MD | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Classification | Quantity | Relative content/% | Quantity | Relative content /% | Quantity | Relative content/% | Quantity | Relative content/% | Quantity | Relative content/% |

| Aldehydes | 2 | 23.315 | 4 | 28.096 | 4 | 25.407 | 3 | 16.776 | 4 | 24.589 |

| Alcohols | 1 | 36.622 | 2 | 37.173 | 3 | 45.059 | 0 | 0 | 2 | 27.838 |

| Esters | 1 | 14.065 | 0 | 0 | 3 | 9.745 | 1 | 2.732 | 3 | 6.395 |

| Terpenes | 1 | 3.822 | 5 | 11.703 | 3 | 6.33 | 2 | 5.351 | 5 | 11.218 |

| Hydrocarbons | 6 | 15.051 | 13 | 18.176 | 11 | 8.93 | 10 | 42.292 | 12 | 20.138 |

| Others | 2 | 5.904 | 2 | 4.853 | 4 | 4.577 | 5 | 32.849 | 3 | 10.731 |

Conclusion

The results demonstrated that the type of drying method used of this study had significant effect on the quality of the Chinese chestnuts, and the freeze-vacuum dried products were superior to those dried by the other four drying methods. In terms of nutrient components, the starch, protein, sugar, Vitamin C, and tannin were the highest contents observed in the chestnuts dried using FVD method, and MVD method was second preferred method. Significant differences between the natural ventilating dried chestnuts and the hot air dried chestnuts were not observed in terms of component contents and processing properties of the chestnuts. The texture parameters such as hardness, chewiness, and gumminess were the highest in hot air dried product and freeze-vacuum dried product; MD and ND produced the lowest values for these parameters, whereas MD alone produced better springiness in the product than the other four drying methods. A total of 45 flavor compounds were identified with 28 substances present in the Chinese chestnut dried by FVD, 27 substances resulted from MD, 23 substances from HAD, 21 substances from MVD, and only 13 substances from ND. In conclusion, the quality of Chinese chestnuts dried using MVD was right behind that of using FVD, whereas FVD was long time and energy consumption and was not suitable for industrial production. In addition, MVD exhibited a fast drying rate and low energy consumption, which makes it suitable for commercialization of Chinese chestnut drying process. This study provided an in-depth understanding of the nutritional components, flavor processing properties of chestnut flour produced using five drying processes, which will be helpful for selection of ingredients and their application in food industries.

Acknowledgements

Financial support from the Key Scientific and Technological Project of Henan province (No. 152102210386) and the Outstanding Youth Fund of Henan Province (No. 184100510010) is gratefully acknowledged.

References

- AOAC . Official methods of analysis. 16. Washington: Association of Official Analytical Chemists; 2000. [Google Scholar]

- Barakat A, DiLoreto DS, Zhang Y, Smith C, Baier K, Powell WA, Wheeler N, Sederoff R, Carlson JE. Comparison of the transcriptomes of American chestnut (Castanea dentata) and Chinese chestnut (Castanea mollissima) in response to the chestnut blight infection. BMC Plant Biol. 2009;9(1):51. doi: 10.1186/1471-2229-9-51. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Borges O, Gonçalves B, Carvalho JLSD, Correia P, Silva AP. Nutritional quality of chestnut (Castanea sativa, Mill.) cultivars from Portugal. Food Chem. 2008;106(3):976–984. doi: 10.1016/j.foodchem.2007.07.011. [DOI] [Google Scholar]

- Doymaz Dİ. Effect of citric acid and blanching pretreatments on drying and rehydration of Amasya red apples. Food Bioprod Process. 2010;88(2–3):124–132. doi: 10.1016/j.fbp.2009.09.003. [DOI] [Google Scholar]

- Dutta B, Raghavan GSV, Dev SRS, Liplap P, Murugesan R, Anekella K, Kaushal T. A comparative study on the effects of microwave and high electric field pretreatments on drying kinetics and quality of mushrooms. Dry Technol. 2012;30(8):891–897. doi: 10.1080/07373937.2012.678957. [DOI] [Google Scholar]

- Feng AG, Li GX, Li CY. Research progress of food drying technology. Farm Mach. 2012;18:90–93. [Google Scholar]

- Guo DS, Peng XL. Comparative study on antrone chromametry and enzymatic hydrolysisfor assay starch method. J Hunan Univ (Nat Sci Edit) 2007;19(3):34–36. [Google Scholar]

- Huang LP. Storage of chestnut at the normal temperature difficulties and countermeasures. Shanxi For Sci Technol. 2012;4:120–122. [Google Scholar]

- Kaymak-Ertekin F. Drying and rehydrating kinetics of green and red peppers. J Food Sci. 2002;67(1):168–175. doi: 10.1111/j.1365-2621.2002.tb11378.x. [DOI] [Google Scholar]

- Krist S, Unterweger H, Bandion F, Buchbauer G. Volatile compound analysis of SPME headspace and extract samples from roasted Italian chestnuts (Castanes mollissima) using GC-MS. Eur Food Res Technol. 2004;219(5):470–473. doi: 10.1007/s00217-004-0983-5. [DOI] [Google Scholar]

- Li H, Yuan F, Lin HT, Lin YF, Chen YH, Wang SQ. Research advances of microwave vacuum drying technology for dried food processing. Packag Food Mach. 2011;29(1):46–50. [Google Scholar]

- Lin SS, Zhu MY, Zhang JW. Research status and prospects of Chinese chestnut. Acad Aeriodical Farm Prod Process. 2010;12:74–76. [Google Scholar]

- Mamat H, Abu Hardan MO, Hill SE. Physicochemical properties of commercial semi-sweet biscuit. Food Chem. 2010;121(4):1029–1038. doi: 10.1016/j.foodchem.2010.01.043. [DOI] [Google Scholar]

- Morini G, Maga JA. Volatile compounds in roasted and boiled Chinese chestnut (Castanes mollissima) Lebensm Wiss u Technol. 1995;28:638–640. doi: 10.1016/0023-6438(95)90014-4. [DOI] [Google Scholar]

- Qi XJ, Gou JX, Han XJ, Yan B. Study on measuring reducing sugar by DNS reagent. J Cellul Sci Technol. 2004;12(3):17–19. [Google Scholar]

- Ratti C. Hot air and freeze-drying of high-value foods: a review. J Food Eng. 2001;49(4):311–319. doi: 10.1016/S0260-8774(00)00228-4. [DOI] [Google Scholar]

- Rodríguez-Burruezo A, Kollmannsberger H, González-Mas MC, Nitz S, Nuez F. HS-SPME comparative analysis of genotypic diversity in volatile fraction and aroma contributing compounds of Capsicum fruits from the annuum–chinense–frutescens complex. J Agric Food Chem. 2010;58(7):4388–4400. doi: 10.1021/jf903931t. [DOI] [PubMed] [Google Scholar]

- Thang NT, Do TV, Sato T, Binh NT, Kozan O, Cam NV. Yield and nutrient content of chestnut (Castanopsis piriformis) in catural central highlands forests, Vietnam. Small Scale For. 2016;15(2):229–239. doi: 10.1007/s11842-015-9319-5. [DOI] [Google Scholar]

- Wang HC, Zhang M, Adhikari B. Drying of shiitake mushroom by combining freeze-drying and mid-infrared radiation. Food Bioprod Process. 2014;94:507–517. doi: 10.1016/j.fbp.2014.07.008. [DOI] [Google Scholar]

- Xu TC, Wang WL, Liu J. Development trends and progress of chestnut products in China. Food Nutr China. 2011;17(8):17–19. [Google Scholar]

- Yang L, Xiao L, Wang Q. Study on texture properties of apple flesh by using texture profile analysis. J Fruit Sci. 2014;31(5):977–985. [Google Scholar]

- Zheng CX. Chestnuts drying character and chestnut dryer. J Chin Cereals Oils Assoc. 2001;16(5):55–58. [Google Scholar]

- Zhou J, Kong XL, Gao N. Effects of combination of microwave and hot-air drying on characteristics of chestnuts. Packag Food Mach. 2009;2:11–13. [Google Scholar]