Abstract

This study reports the colour changes using CIELAB measurements (L*a*b* color space) and their correlation with time, temperature, total soluble solids (TSS), and pH during the processing of Arenga pinnata (palm) sap into granulated sugar. As a function of time, the sap became darker, more red, and more yellow indicating a continuous decrease of L* values, and an increase in both a* and b* values. A constant decrease of L* and an increase of a* and b* were particularly observed when TSS of the sap was more than 33.5%. During the process, regression analysis showed that a linear pattern was indicated for total colour difference (ΔE*) with time, whereas a non linear relationship was shown for ΔE* with TSS, temperature and pH. Stirring the syrup changed the L*a*b* values while ΔE* showed a decrease throughout the process. This research will serve as a base for future developments for the manufacture and quality grading of A. pinnata (palm) sugar.

Keywords: Arenga pinnata (palm) sap, Palm sugar, CIELAB (L*a*b* colour space), Process parameters, Total colour difference (ΔE*), Regression analysis

Introduction

Colour of agri-food products is derived from natural pigments which vary in their physical and chemical properties (Maskan et al. 2002; Pathare et al. 2013). Many of those are sensitive to cultivar, oxidation, pH change, light, and temperature and time especially during processing. Changes in the structure of foods, including color modification, are produced during their manufacturing process (Maskan et al. 2002). In the food industry, colour change during the manufacture of a processed food is of vital interest since colour is among the primary considerations of consumers to make a decision of purchasing (Arabhosseini et al. 2011; Maskan et al. 2002).

Palm sugar, produced from Arenga pinnata (palm) sap, has been known as a local delicacy commonly consumed in Asia in cakes and desserts. Adding palm sugar in certain Asian foods is still a preference since palm sugar has a specific flavour profile that cannot be replaced by white sugar or other types of sweeteners. A. pinnata (palm) sugar contains total phenolic content and free radical scavenging activity (Choong et al. 2016; Victor and Orsat 2018). The sap was reported to have 87.20% water content, 11.28% sucrose, 0.20% protein, 0.02% fat, 0.24 mineral (Rumajar et al. 2008), 0.24% ash (Barlina et al. 2006), and 4.80% reducing sugar (Apriyantono et al. 2002). Some nutrients have also been identified in the sap such as K, P, Mg, Na, Ca, Fe, and Cu (Rumajar et al. 2008) in addition to polar side chain amino acids particularly asparagine and glutamine (Ho et al. 2007).

Processing A. pinnata (palm) sugar from the sap is achieved by thermal processing through boiling and it usually does not involve any purification process or use any chemical additive. Thermal processing is one of the most important methods of food preservation even though this preservation method can change the color and final appearance of the product. Whilst many studies have reported on the colour change in fruits, vegetables and their derivatives, only a few studies have been conducted on A. pinnata sap/sugar (Choong et al. 2016; Faridatul Ain et al. 2014; Ho et al. 2007, 2008). Therefore, this study was aimed at determining the colour changes using CIELAB (L*a*b* colour space) during the processing of A. pinnata sap into sugar. Colour change evolution in food product using CIELAB colour space has become very popular since this technique mimics well the human perception of this quality attribute (Quintas et al. 2007). In CIELAB colour space, L* indicates lightness, whereas a* and b* are the chromaticity coordinates and indicate colour directions with + a* is the red direction, − a* is the green direction, + b* is the yellow direction, and − b* is the blue direction. While L* presents 0 for black and 100 for white, the saturation of the colour increases as the a* and b* values increase (Minolta Co. 2007).

Colour is the main distinct parameter of the sugar produced from heating the sap. This study is believed to be the first article to employ L*a*b* colour space during the processing of A. pinnata (palm) sap into sugar. While other studies reported on solid palm sugar processing, this study works on processing granulated A. pinnata (palm) sugar, reports the connection between L*a*b* colour space and several process parameters of the sugar, and indicates relationship patterns between total colour difference (ΔE*) and these process parameters. The results of this study might be incorporated in the production lines of A. pinnata sugar industries, and could be used to develop a colour grading system for A. pinnata sugar and related palm sugar industries.

Materials and methods

The sap used in all experiments was tapped from A. pinnata (palm) trees and was obtained from farmers in Tomohon, Indonesia. The initial pH and TSS of the sap were 6.388 and 14.9 (% w/w) with L*a*b* values of 54.9, − 1.7, 10.5, respectively. Four liters of the sap were boiled in an open pan. Ten ml of the sample was collected at each specified time interval throughout the heating process. The heating of the sap was terminated at a temperature of 127 °C, and stirred continuously until it formed granulated sugar. During processing the granulated sugar samples were taken at three phases: before the liquid was stirred (phase 1), during the stirring process (phase 2), and at the end when granulated sugar was finally produced (phase 3).

Measurements

Temperature

The temperature was measured using a digital stainless steel probe thermometer (BG 363, Blue Gizmo, Acez).

Total soluble solids (TSS)

TSS (% w/w) was measured using an Atago Pocket Refractometer (PAL-3, Atago, Japan) (0–93% Brix).

pH

The sample was diluted ten fold, and measured using a pH meter (WTW Sentix 81, pH 3110, Weilheim 2008, Germany). Calibration was accomplished employing pH 7.0 and 4.0 buffer solutions.

Colour

Colour was measured using a Konica Minolta Color Reader CR 10 (Konica Minolta Optics, Inc., Japan). The colour changes measurement was recorded in L*a*b* colour space with L* representing the lightness of colour (0 = black, 100 = white), + a* is red while − a* is green, and + b* is yellow whereas − b* is blue.

Total colour difference (ΔE*) is expressed using the following equation:

, and represented the reading at time zero.

Statistical analysis

All samples used in the measurements of pH, TSS and colour space (L*a*b*) were taken in triplicate. All the statistical analysis was done using JMP 10 software program (SAS Institute Inc.).

Results and discussion

Colour changes during the heating process of Arenga pinnata (palm) sap

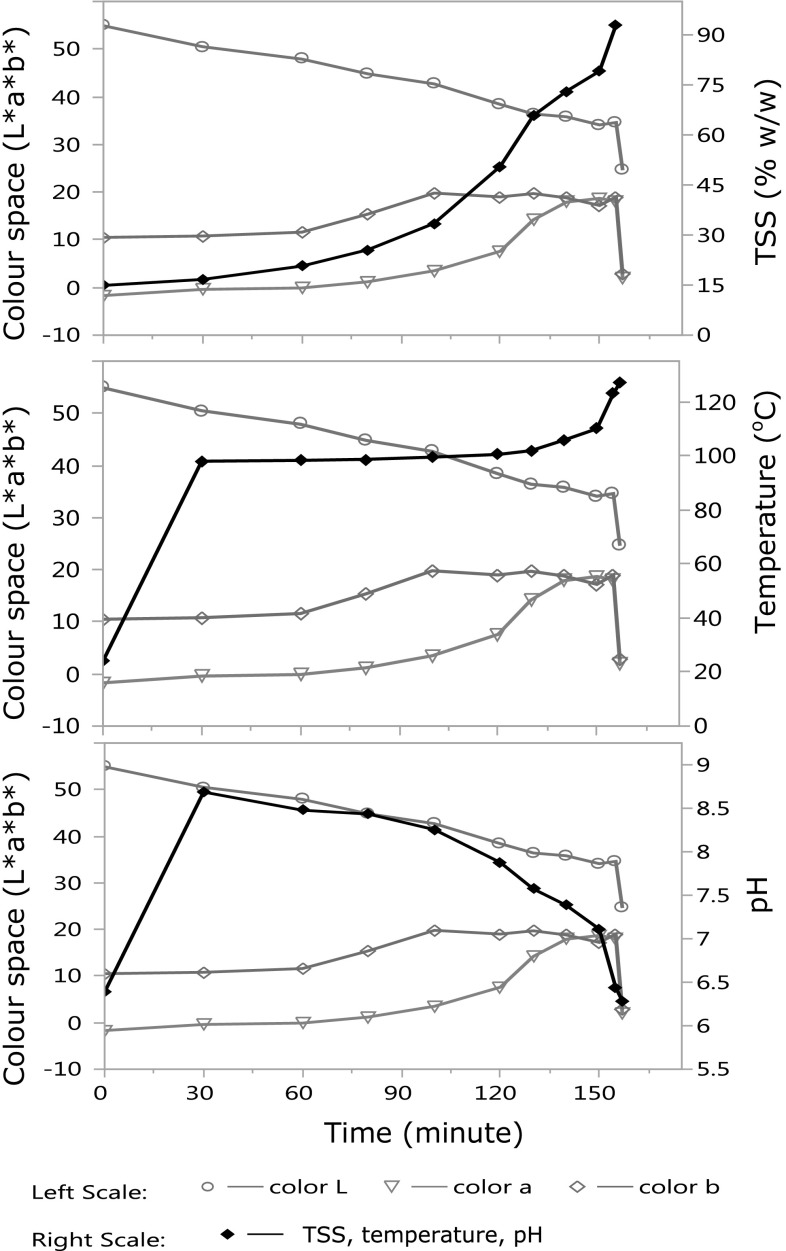

The changes of some parameters i.e., time, temperature, TSS, pH, and L*a*b* colour space values were recorded during the evaporation of A. pinnata sap into sugar (Fig. 1). The temperature of the sap increased rapidly in the first 30 min to reach the sap’s boiling point, before it rose slowly to 105.8 °C, followed by a sharp increase to the final temperature of 127 °C. TSS of the sap, on the other hand, showed a very small rise of less than 2% in the first 30 min, before it increased continuously and reached about 93%. Figure 1 illustrates the increase of pH from the initial pH of 6.388, reaching a peak of 8.686, before it decreased to 6.285 at the end of the boiling process.

Fig. 1.

Changes in L*a*b* colour space, temperature, TSS, and pH during the sap evaporation process

In contrast to earlier findings, these results have not been previously described in any palm juice processing studies (Ben Thabet et al. 2009; Ho et al. 2008; Rao et al. 2009). The differences may be explained by the fact that previous studies reported on the heating process of sap into solid sugar with TSS of less than 88%, whereas the present study resulted both solid and granulated sugar with TSS greater than 93%.

Colour-time

As a function of time, the sap became darker, more red, and more yellow from beginning indicated by a continuous decrease of L* values, and an increase both in a* and b* values. Trends of decreasing L* and both increasing a* and b* observed in the current study are consistent with those of Rao et al. (2009) and Maskan et al. (2002). The onset of non-enzymatic browning, especially because of the ascorbic acid degradation might favour the decrease of L* (Mercali et al. 2014).

Colour-temperature

Figure 1 implies that a* and b* of the boiling sap were not affected by temperature in the beginning of the process. L* decreased and both a* and b* increased as temperature increased to 123 °C, in agreement with Rao’s findings (Rao et al. 2009), but these results differed from Quintas et al. (2007). This might be the difference in the composition and purity of the raw material used. An increase of a* as affected by a process temperature was demonstrated for grape leather (Maskan et al. 2002), whereas b* was reported to be sensitive to the change of temperature during heating of pineapple puree (Chutintrasri and Noomhorm 2007).

Colour-TSS

L* changed gradually before it considerable decreased when the TSS reached greater than 93%. Both a* and b* did not change significantly in the beginning until the sap was about 20.7% in TSS. A continuous increase was shown by a* and by b* at TSS of 79.1%, before demonstrating a sharp decline.

The change in TSS is the most obvious transformation observed during the heating of A. pinnata sap. A trend of decreasing L* and increasing a* and b* from the beginning of the heating process determined in this study corroborates the finding by Rao et al. (2009). However, an immediate decline identified nearly at the end of heating process of A. pinnata sap was not shown on other palm sweeteners processing such as processing of palmyra-palm and date-palm juices. The decline of a* and b* change on A. pinnata sap is possible as a result of more 93% TSS.

Colour-pH

The pH increased from 6.388 to 8.686 associated with the decrease in L*, and the increased values of both a* and b*. Then, the pH values decreased continuously throughout the heating process and reached a pH of 6.285. After the sap reached a peak pH, L* and pH values decreased gradually whereas both a* and b* increased.

No obvious changes in a* and b*, and only a slight increase in L* was observed with the increase in pH from the beginning until it reached a peak. This suggests that a* and b* were not affected by pH changes in the beginning. The change of pH detected in the present work might explain the occurrence of Maillard reactions during A. pinnata sugar processing, a similar condition occurred during the heating process of grape juice (Maskan et al. 2002) and date palm (Phoenix dactylifera) syrup (Ben Thabet et al. 2009).

Total colour difference (ΔE*) and the process parameters

A single numerical value for describing colour change expressed as total colour difference (ΔE*) has become one of the best parameter since it combines all colour parameters L*a*b* (Chutintrasri and Noomhorm 2007; Rattanathanalerk et al. 2005). The ΔE* values presented here are derived from L*a*b* values recorded during the evaporation process of A. pinnata sap. To obtain ΔE* values, the initial sample’s colour value was used as a reference colour. Table 1 provides the best models obtained by the regression analysis of ΔE* and each parameter viz. time, TSS, temperature and pH. Overall, the regression analysis shows that the correlation between ΔE* and the processing parameters was mostly identified as having non linear relationship rather than linear relationship.

Table 1.

Regression models identified for relationship between total colour difference (ΔE*) and time, TSS, temperature and pH

| Parameter | Prediction model | R2 |

|---|---|---|

| ΔE* − time | Linear: | 0.9717 |

| ΔE* − TSS | Exponential: | 0.9899 |

| ΔE* − temperature | Gompertz: | 0.9946 |

| ΔE* − pH (past boiling point) | Gompertz: | 0.9862 |

Time

A strong positive correlation between ΔE* and time was identified during the heating of A. pinnata sap, and it was shown by high value of R2. These results are consistent with those of other studies reporting significant change in colour during heating process (Chutintrasri and Noomhorm 2007; Rattanathanalerk et al. 2005).

TSS

The correlation between ΔE* and TSS determined was an exponential decay model in increasing form or limited growth as it showed the negative growth rate (c = − 0.0329). The result obtained through the regression analysis is in agreement with colour changes observed during the evaporation of maple sap (Koelling et al. 1996).

Temperature

The regression analysis shows a non linear Gompertz model for correlation between ΔE* and temperature with R2 of 0.9946. This result supports the idea of the significant effect of temperature on ΔE* when using high temperatures from 80 to 98 °C (Chutintrasri and Noomhorm 2007; Rattanathanalerk et al. 2005). Higher temperature accelerated the chemical reactions and colour changes may be a result of more than one reaction which may not occur simultaneously at one temperature (Rattanathanalerk et al. 2005).

pH

The Gompertz model implies a decrease in the correlation between ΔE* and pH after the boiling point. A correlation between ΔE* and pH could only be expressed after the pH of the sap reached a peak at boiling temperature. The results suggest that the correlation between ΔE* and pH could only be identified during that particular period of boiling process. This result complies with earlier observations made during maple syrup processing (Koelling et al. 1996) showing a continuous decrease of pH after it reached a peak associated with an increase on colour formation.

Colour changes during the formation of granulated sugar

Granulated sugar was produced by boiling the sap up to 127 °C with a TSS greater than 93%, then stirring it continuously until the granulation was formed. L* values had a slight increase at the beginning from 24.6 to 29.0, before increase sharply to 42.6 as the granulated sugar was produced. Likewise, both values of a* and b* also showed an increase in the beginning to the second phase from 1.9 to 6.7 and 2.8 to 7.3 for a* and b*, respectively. Then, b* increased significantly to 13.5, while a* indicated a minor increase to 7.4 at the end of the stirring.

The results showed that a* had less significant change than b*, and L* changed the most among these colour space values. The overall colour value, ΔE* showed a decrease from the beginning to the end of the stirring process. These results suggest that stirring the syrup changed L*a*b*, and there was an improvement in colour as it became lighter (L* increased), more red (a* increased), and more yellow (b* increased) throughout the stirring process. There are similarities between the colour changes expressed by a* and b* in this study and other reports where b* was found to give more adequate information on the colour change of maple sugar (Aider et al. 2007a, b). The present study suggests that b* value might be considered as a stronger indicator of colour changes in the production of A. pinnata sugar when comparing with L* and a* values.

Conclusion

The present study was designed to examine the colour changes occurring during boiling of A. pinnata (palm) sap and during its processing into solid and granulated sugars. This study has shown that L*a*b* colour space values changed during the evaporation of the sap associated with the evolution of the process as a function of time, temperature, TSS and pH. Regression analysis indicated both linear and non linear relationships between ΔE* and the processing parameters. It was also shown that L*a*b* changed during the formation of granulated sugar with b* might be used as a stronger colour change indicator. The current findings can be used to develop targeted interventions on process and colour development aimed at producing both A. pinnata (palm) solid and granulated sugars of high market quality.

Acknowledgements

This research was supported by the Ministry of Research, Technology and Higher Education of the Republic of Indonesia (previously the Ministry of Education and Culture of the Republic of Indonesia) through providing financial assistance to the first author. The authors are grateful to Mr. Nico Tatontos and Ms. Praycillia Karundeng for their help during the experiments and to the farmers in Tomohon who have provided the sap.

Contributor Information

Inneke Victor, Phone: +62 85242679630, Email: inneke.victor@mail.mcgil.ca, Email: innekevictor@yahoo.com.au.

Valérie Orsat, Email: valerie.orsat@mcgill.ca.

References

- Aider M, de Halleux D, Belkacemi K. Production of granulated sugar from maple syrup with high content of inverted sugar. J Food Eng. 2007;80(3):791–797. doi: 10.1016/j.jfoodeng.2006.07.008. [DOI] [Google Scholar]

- Aider M, de Halleux D, Belkacemi K, Brunet S. Contribution to the improvement of maple sugar production. J Food Eng. 2007;80(3):798–804. doi: 10.1016/j.jfoodeng.2006.04.066. [DOI] [Google Scholar]

- Apriyantono A, Aristyani A, Lidya Y, Budiyanto S, Soekarto T. Rate of browning reaction during preparation of coconut and palm sugar. Maillard React Food Chem Med Sci Update Postgenomic Era. 2002;1245:275–278. [Google Scholar]

- Arabhosseini A, Padhye S, Huisman W, Boxtel A, Müller J. Effect of drying on the color of tarragon (Artemisia dracunculus L.) leaves. Food Bioprocess Technol. 2011;4(7):1281–1287. doi: 10.1007/s11947-009-0305-9. [DOI] [Google Scholar]

- Barlina R, Karouw S, Pasang P. Pengaruh Sabut Kelapa Terhadap Kualitas Nira Aren dan Palm Wine. Jurnal Littri. 2006;12(4):166–171. [Google Scholar]

- Ben Thabet I, Besbes S, Masmoudi M, Attia H, Deroanne C, Blecker C. Compositional, physical, antioxidant and sensory characteristics of novel syrup from date palm (Phoenix dactylifera L.) Food Sci Technol Int. 2009;15(6):583–590. doi: 10.1177/1082013209353079. [DOI] [Google Scholar]

- Choong CC, Anzian A, Che Wan Sapawi CWNS, Meor Hussin AS. Characterization of sugar from Arenga pinnata and Saccharum officinarum. Int Food Res J. 2016;23(4):1642–1652. [Google Scholar]

- Chutintrasri B, Noomhorm A. Color degradation kinetics of pineapple puree during thermal processing. LWT Food Sci Technol. 2007;40(2):300–306. doi: 10.1016/j.lwt.2005.11.003. [DOI] [Google Scholar]

- Faridatul Ain MR, Yusof YA, Chin NL, Mohd Dom Z. Storage study of Arenga pinnata juice. Agric Agric Sci Procedia. 2014;2:218–223. doi: 10.1016/j.aaspro.2014.11.031. [DOI] [Google Scholar]

- Ho CW, Aida WMW, Maskat MY, Osman H. Changes in volatile compounds of palm sap (Arenga pinnata) during the heating process for production of palm sugar. Food Chem. 2007;102(4):1156–1162. doi: 10.1016/j.foodchem.2006.07.004. [DOI] [Google Scholar]

- Ho CW, Aida WMW, Maskat MY, Osman H. Effect of thermal processing of palm sap on the physico-chemical composition of traditional palm sugar. Pak J Biol Sci PJBS. 2008;11(7):989–995. doi: 10.3923/pjbs.2008.989.995. [DOI] [PubMed] [Google Scholar]

- Koelling MR, Heiligmann RB, Scardena DE. North American maple syrup producers manual. Columbus: Ohio State University; 1996. [Google Scholar]

- Maskan A, Kaya S, Maskan M. Effect of concentration and drying processes on color change of grape juice and leather (pestil) J Food Eng. 2002;54(1):75–80. doi: 10.1016/S0260-8774(01)00187-X. [DOI] [Google Scholar]

- Mercali GD, Schwartz S, Marczak LDF, Tessaro IC, Sastry S. Ascorbic acid degradation and color changes in acerola pulp during ohmic heating: effect of electric field frequency. J Food Eng. 2014;123:1–7. doi: 10.1016/j.jfoodeng.2013.09.011. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Minolta Co., L . Precise color communication. 1. Japan: Konica Minolta Sensing; 2007. [Google Scholar]

- Pathare P, Opara U, Al-Said F-J. Colour measurement and analysis in fresh and processed foods: a review. Food Bioprocess Technol. 2013;6(1):36–60. doi: 10.1007/s11947-012-0867-9. [DOI] [Google Scholar]

- Quintas MAC, Brandao TRS, Silva CLM. Modelling colour changes during the caramelisation reaction. J Food Eng. 2007;83(4):483–491. doi: 10.1016/j.jfoodeng.2007.03.036. [DOI] [Google Scholar]

- Rao PVKJ, Das M, Das SK. Changes in physical and thermo-physical properties of sugarcane, palmyra-palm and date-palm juices at different concentration of sugar. J Food Eng. 2009;90(4):559–566. doi: 10.1016/j.jfoodeng.2008.07.024. [DOI] [Google Scholar]

- Rattanathanalerk M, Chiewchan N, Srichumpoung W. Effect of thermal processing on the quality loss of pineapple juice. J Food Eng. 2005;66(2):259–265. doi: 10.1016/j.jfoodeng.2004.03.016. [DOI] [Google Scholar]

- Rumajar H, Pajow H, Walangitan AJV, Syarif SR, Rosmaeni A, Maliatja J, Pangau H. Teknologi pembuatan gula kristal. Manado: Departemen Perindustrian, Balai Penelitian dan Pengembangan Industri; 2008. [Google Scholar]

- Victor I, Orsat V. Characterization of Arenga pinnata (palm) sugar. Sugar Tech. 2018;20(1):105–109. doi: 10.1007/s12355-017-0537-3. [DOI] [PMC free article] [PubMed] [Google Scholar]