Abstract

Vapor intrusion (VI) is the migration of subsurface vapors, including radon and volatile organic compounds (VOCs), from the subsurface to indoor air. The VI exposure pathway extends from the contaminant source, which can be impacted soil, non-aqueous phase liquid, or contaminated groundwater, to indoor air-exposure points. Therefore, contaminated matrices may include groundwater, soil, soil gas, and indoor air. VOC contaminants of concern typically include halogenated solvents such as trichloroethene, tetrachloroethene, and chloroform, as well as petroleum hydrocarbons, such as the aromatic VOCs benzene, toluene, and xylenes. Radon is a colorless radioactive gas that is released by radioactive decay of radionuclides in rock and soil that migrate into homes through VI in a similar fashion to VOCs. This project focused on the performance of permanent versus temporary sub-slab sampling ports for the determination of VI of halogenated VOCs and radon into an unoccupied house. VOC and radon concentrations measured simultaneously in soil gas using collocated temporary and permanent ports appeared to be independent of the type of port. The variability between collocated temporary and permanent ports was much less than the spatial variability between different locations within a single residential duplex. The agreement of the majority of VOC and radon concentrations, 0–36% relative percent difference, and 2–19% relative standard deviation respectively, of each sub-slab port (SSP) type was achieved even though the clay portion of the seal of the temporary ports was visibly desiccated and cracked. Post sampling leak test results suggested that the temporary SSP desiccation and cracking were not as detrimental to the port seal performance as would have been expected, this suggests that the Teflon tape portion of the seals served an important function. Post sampling leak tests are advisable (in addition to pre-sampling leak tests) when temporary ports are used to collect a time-integrated sample over a period of several hours. These results suggest that temporary sub-slab sampling ports can provide data equivalent to that collected from a permanent sub-slab sampling port. However, (1) only one type of seal material was tested in one location, (2) the seals were installed by experts with rigorous quality control, and; thus, (3) these results may not apply to all types of temporary seals and all building foundations.

Keywords: Sub-slab port, vapor intrusion, PCE, TCE, volatile organic compounds

Introduction

Vapor intrusion (VI) is the migration of subsurface vapors, including radon and volatile organic compounds (VOCs), from the subsurface to indoor air (USEPA, 2015a). VI has emerged as a priority VOC exposure pathway at many hazardous waste sites nationwide (USEPA, 2015a, NJDEP, 2012; AZDEQ, 2011; MDNR, 2013). VI occurs because of the pressure and concentration differentials between indoor air and soil gas. Indoor environments are often negatively pressurized with respect to outdoor air and soil gas, and this pressure difference allows soil gas with subsurface vapors to flow into indoor air through advection (USEPA, 2015a). In addition, concentration differentials may cause VOCs to migrate from areas of higher to lower concentrations through diffusion, which can lead to VI.

The VI exposure pathway extends from the contaminant source, which can be impacted soil, non-aqueous phase liquid or contaminated groundwater, to indoor air-exposure points. Contaminated matrices; therefore, may include groundwater, soil, soil gas, and indoor air. VOC contaminants of concern during VI typically include halogenated solvents such as trichloroethene (TCE), tetrachloroethene (PCE), and chloroform, and degradation products of TCE and PCE including dichloroethenes and vinyl chloride. Petroleum hydrocarbons, such as the aromatic VOCs benzene, toluene, and xylenes, can also be present as a result of VI. Radon is a colorless radioactive gas that is released by radioactive decay of radionuclides in rock and soil. Radon migrates into buildings through VI pathways in a similar fashion to VOCs. This project focused on the VI of halogenated VOCs, which are relatively recalcitrant to biodegradation in aerobic soils and groundwater, as well as radon, which has a radioactive half-life of about 3.8 days.

Experimental design

Study site

As part of a previously reported study (USEPA, 2012), sub-slab soil gas sampling ports were installed in the basement floor of the unoccupied and unfurnished test house at 422 East 28th St., Indianapolis, IN (Figure 1). The test house is an early twentieth-century duplex, dating from before 1915. Based on the mirrored floor plans of the two sides (Figure 2), it is likely that the house was always a duplex. Construction is wood frame on a brick foundation with a poured concrete basement floor. A subsequent ground-penetrating radar study suggested that the concrete slab ranged from 0.5 to 0.7 ft in thickness with an irregular undulating contact with the soil beneath (USEPA 2015b). The floor shows a moderate number of thin irregular cracks. The basement is a “look-out” basement where the basement walls extend above ground level to where the basement windows are above ground level.

Figure 1.

Front view of test house in Indianapolis, IN.

Figure 2.

Interiors of test buildings, showing soil gas points (SGP) and paired single-depth temporary and permanent sub-slab ports (SSP).

Sub-slab ports

Single-depth temporary and permanent sub-slab ports (SSPs) were constructed to test the equivalency of SSP systems side by side (Figure 3). Locations of the paired ports are shown in Figure 2, with each “SSP” indicating a paired temporary and permanent SSP. Each temporary single-depth, SSP was installed within 30 cm (12 inches [in]) of a single-depth, permanent port.

Figure 3.

Typical port construction before sampling; one temporary port shown at lower portion of figure and one permanent port shown in the upper portion of the figure.

Temporary sub-slab ports

Temporary single-depth sub-slab probes were constructed in accordance with the New Jersey VI Guidance (NJDEP, 2012). The ports were constructed with flexible tubing (Teflon), and were sealed with hydrated bentonite using the following method:

Mix bentonite in a container, starting with water, then add bentonite until no free water is present and the mixture has the consistency of gel or modeling clay. Apply the mixture to the top 2.5–5.0 centimeters (cm) (1–2 in) of the 0.64-cm (0.25-in) outer diameter (OD), 0.32-cm (0.125-in) inner diameter (ID) and approximately 61-cm (24-in) Teflon tubing [above the Teflon tape barrier required by the NJDEP (2012)] that is wrapped on the section of tubing that is twisted into the drill hole, and as needed at the surface to fill the remaining annular space and make a seal between the floor and the tubing.

For this application, granular bentonite with particle sizes, in the medium to fine sand range, were used for fast hydration and easy mixing (Benseal uniform granular Wyoming sodium bentonite). The other end of the Teflon tubing was sealed with a brass needle valve with 0.25-in compression fittings (Figure 3). During installation, the adherence of the hydrated bentonite to the slab material and to the tubing was qualitatively noted.

Permanent sub-slab ports

Using a rotary hammer drill with a 2.5-cm (1-in)-diameter by 25.4-cm (10-in)-long masonry bit, a hole was drilled to a depth of 3.5 cm (1–3/8 in), this was necessary to sink the SSP fitting below the surface of the basement floor. Next, using a 1.14-cm (3/8-in)-diameter by 25.4-cm (10-in)-long masonry bit, a 1.14-cm (3/8-in) hole was drilled from the bottom of the 2.5-cm (1-in) diameter through the slab into the subsurface material. An assembly of 0.64-cm (0.25-in) OD, 0.32-cm (0.125-in) ID, approximately 15.2-cm (6 in)-long piece of stainless steel tubing and a Swagelok™ fitting was grouted into the hole drilled into the slab using the following method:

Bentonite was mixed in a container, starting with water, then adding bentonite until no free water is present and the mixture had the consistency of gel or modeling clay. The mixture was applied to the top 2.5–5.0 cm (1–2 in) of stainless steel tubing (above the Teflon tape barrier required by the NJDEP (2012)) as it is twisted into the drill hole, and as needed at the surface to fill the remaining annular space and make a seal with the floor and tubing.

Leak checks

Leak checks were performed on each permanent and temporary port at the time of first use, utilizing the tracer gas/shroud method (CAEPA, 2015). Helium gas was used as the tracer. Leak checks were performed before sampling at each permanent port and before and after sampling at each temporary port. The temporary ports were leak checked approximately 2 hr after installation and were sampled approximately 3 hr after installation. During leak checking and sampling, a reasonable effort was made not to move the sample tubing at the ground surface, but changes to the integrity of the seal were documented as incidental movement of the tubing occurred and as the bentonite seal aged. Photographs of a typical seal as constructed and after sampling (24–48 hr) are provided in Figures 4 and 5 to show the effect of aging.

Figure 4.

Typical temporary port construction before sampling.

Figure 5.

Temporary Port 1 showing desiccation.

Sample collection and analysis

One round of paired samples (10 samples total) was collected from each of the five temporary/permanent pairs, for VOCs and radon by the following methods:

Sub-slab sampling using summa type canisters for VOCs

Sub-slab soil gas samples were collected in evacuated, 6-L Summa-type polished canisters. For sub-slab air sample collection, a brass or stainless national pipe thread taper to Swagelok union fitting was used to connect vapor probes to a “T” fitting made of a Teflon flexible line and an in-line valve (Figure 3). A portable vacuum pump was used to purge a volume of 100 mL from the vapor probes and sampling lines, which is greater than five line volumes. The line volume or total internal volume of the Teflon sampling lines, brass tee and valves, and the stainless steel vapor probe at the permanent port locations is approximately 7 mL. At the temporary probe locations, the total internal volume of the Teflon sampling lines, and brass tee and valves is approximately 6 mL. Immediately after the probe was purged, the in-line valve on the pump end of the “T” fitting was closed and the Summa canister valve was opened to collect a grab sample at a maximum rate of 0.1–0.2 L/min. The Summa canisters are equipped with an adjustable critical orifice with back pressure regulator that is calibrated at the laboratory for a target fill time of 24 hr. The start, ending, and duration of sampling times are reported in Table 1. The collection of all temporary probe samples were initiated within 7 min of their permanent probe counterpart at each location. The sampling was ceased when canister pressure decreased to within 2–7 in of mercury (Hg). Two samples, temporary port 3 and permanent port SSP 1 were observed to have pressures above 7 in Hg after 24 hr and sampling was continued for a final fill time of 45–48 hr. One ambient background sample was also collected in the basement for comparison with the soil gas samples. The collected samples were then shipped to a National Environmental Laboratory Accreditation Program-certified commercial analytical laboratory for analysis by USEPA Method TO-15 (USEPA, 1999). Samples from SSP 5 and ambient background samples had a final vacuum of 0 in. Hg but were observed to have some small vacuum with a more sensitive vacuum gauge upon receipt in the lab (Table 1).

Table 1.

Summa canister sampling dates, times and vacuums.

| Port # | Can # | Flow controller # | Initial vacuum recorded in field (in. Hg) | Final vacuum recorded in field (in. Hg) | Final vacuum measured at lab (in. Hg) | Start date | Start time | End date | End time | Sampling duration (hh:mn) |

|---|---|---|---|---|---|---|---|---|---|---|

| Ambient | 4338 | 6010 | 28 | 0 | 0.8 | 11/30/2010 | 19:57 | 12/1/2010 | 19:02 | 23:55 |

| SSP 1 | 35245 | 40145 | 30 | 3 | 3.0 | 11/30/2010 | 19:27 | 12/2/2010 | 16:34 | 21:07 |

| SSP 1 Temp | 12669 | 40324 | 29.5 | 2 | 2.5 | 11/30/2010 | 19:27 | 12/1/2010 | 19:27 | 24:00 |

| SSP 2 | 31442 | 40522 | 30 | 1.5 | 1.5 | 11/30/2010 | 19:15 | 12/1/2010 | 18:40 | 23:25 |

| SSP 2 Temp | 5738 | 40658 | 30 | 2.5 | 2.5 | 11/30/2010 | 19:15 | 12/1/2010 | 19:32 | 24:17 |

| SSP 3 | 5766 | 40259 | 29 | 2.5 | 2.5 | 11/30/2010 | 19:34 | 12/1/2010 | 18:58 | 23:32 |

| SSP 3 Temp | 14008 | 40487 | 28.5 | 2 | 1.0 | 11/30/2010 | 19:43 | 12/2/2010 | 16:30 | 48:02 |

| SSP 4 | 13345 | 40701 | 30 | 5.5 | 5.0 | 11/30/2010 | 19:48 | 12/1/2010 | 21:27 | 25:39 |

| SSP 4 DUP | 12940 | 40060 | 30 | 3.5 | 3.5 | 11/30/2010 | 19:48 | 12/1/2010 | 18:48 | 23:00 |

| SSP 4 Temp | 12687 | 40281 | 30 | 3 | 3.5 | 11/30/2010 | 19:48 | 12/1/2010 | 19:59 | 24:11 |

| SSP 4 Temp DUP | 4181 | 40085 | 30 | 1.5 | 2.0 | 11/30/2010 | 19:48 | 12/1/2010 | 18:48 | 23:00 |

| SSP 5 | 5619 | 40376 | 29 | 0 | 1.2 | 11/30/2010 | 19:09 | 12/1/2010 | 18:53 | 23:44 |

| SSP 5 Temp | 12011 | 40597 | 29 | 1.5 | 1.5 | 11/30/2010 | 19:23 | 12/1/2010 | 19:23 | 24:00 |

Radon sample collection

Radon concentrations were measured with a portable AlphaGUARD Professional Radon Monitor (Genitron Instruments GMBH, Frankfurt Germany). Operations were based on USEPA guidelines for using continuous radon monitors (USEPA, 1992). For sample collection and analysis, 0.64 cm (0.25 in) OD, 0.32 cm (0.13 in) ID Tygon™ tubing was used to connect the input port of the AlphaGUARD to a SSP. Tygon™ tubing was used for collection of radon samples because it is more flexible than Teflon tubing. Another section of 0.64 cm (0.25 in) Tygon™ tubing was connected from the outlet port of the AlphaGUARD to the inlet port of a SKC Universal XR pump (SKC Inc., Eighty Four, PA) to provide a sample flow of 1 L/min through the AlphaGUARD. A purge line was connected to the outlet port of SKC pump that was exhausted to the outside through a basement window. Before sampling of the SSP s was initiated, an ambient background radon concentration measurement was taken outdoors and approximately 6 m (20 ft) away from the duplex. Then, the SSP to be sampled was purged with the SKC pump (five SSP line volumes, 100 mL total volume). Finally, the pump was connected to the AlphaGUARD to acquire a full 10-min sample. The Radon data downloaded from the AlphaGUARD were in units of Becquerel (Bq)/m3, therefore, these data were transfered into a spreadsheet and converted to picocurie (pCi)/L. The time lag between the sampling of a location’s permanent and temporary port ranged from 20 to 170 min.

Results and discussion

Seal integrity

All of the port seals passed the leak test criteria of the detection of less than five percent of tracer compound concentration when initially installed. However, the leak check integrity of the temporary ports declined with time (Table 2). All of the bentonite seals had visible desiccation cracks several days after installation (Figure 5). This cracking was beginning to be visible at the end of the 24-hr sampling period as well. It is suspected that given the visible cracks in the bentonite, the ability of the seals to pass the post sampling leak test is primarily attributable to the careful use of Teflon tape around the tube as part of the sealing process, as required by the NJDEP (2005). It was also noted that the effectiveness of the seal was not expected to be solely dependent on the construction methods for the seal. From first principles, it was expected that the seal effectiveness would also be dependent on:

Table 2.

Leak test results for temporary probes (expressed as percentage of detected helium concentration in port of the measured helium concentration in the Shroud).

| Location | Leak (% He) | |

|---|---|---|

| 11/30/2010 (before sampling) | 12/06/2010 (after sampling) | |

| Temporary SSP 1 | 0.070 | 0.365 |

| Temporary SSP 2 | 0.126 | 0.288 |

| Temporary SSP 3 | 0.003a | 0.174 |

| Temporary SSP 4 | 0.003a | 0.636 |

| Temporary SSP 5 | 0.003a | 0.850 |

Non-detects reported at detection limit.

Acceptance criteria, >5%.

The degree to which the field staff can hold the tube immobile during the attachment of sampling equipment and sampling.

The humidity of the air around the clay portion of the seal, as humidity affects the rate of desiccation.

The permeability contrast between the probe-seal (all parts combined) and the immediate subsurface soils.

VOC sampling results

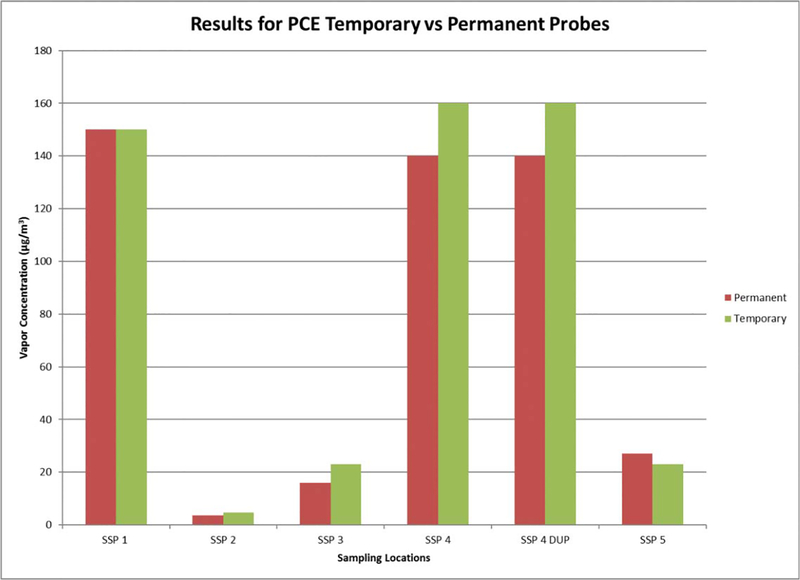

The VOCs detected in soil gas at concentrations markedly different from the ambient background sample were chloroform and PCE (Table 3, Figures 6–8). Concentrations for chloroform, PCE, and TCE in the five paired permanent and temporary sampling ports (excluding the duplicate samples) were within 32, 36, and 4% relative percent difference (RPD), respectively (Table 4). At one location, SSP-4, a duplicate sample was collected and the RPD in concentrations for chloroform were 8% for the permanent probe and 5% for the temporary probe. The RPD in concentration for PCE in either the permanent or temporary probes in the duplicate sample was zero. The paired data show considerable spatial variability under the basement slab (subbasement) throughout the duplex (more than one order of magnitude), demonstrating the utility of collecting multiple samples in even relatively small structures. The highest concentrations appear in the central and southern portions of the 422 East 28th St. side of the duplex (Figure 2). In reviewing the data presented in Tables 3 and 4, it appears that the concentrations from the temporary probes may be slightly higher than the permanent probes, but with this limited amount of data, no conclusion can be drawn about the statistical significance of the difference. If only the data from the temporary ports were used, or the data from only the permanent ports were used; it is highly likely that a practitioner would have reached the same site management decision.

Table 3.

VOC sample results.

| Location | Chloroform (μg/m3) | Flag | Tetrachloroethene (μg/m3) | Flag | Trichloroethene (μg/m3) | Flag |

|---|---|---|---|---|---|---|

| Ambient | 3.2 | U | 4.4 | U | 3.5 | U |

| SSP-1 Perm | 66 | 150 | 7 | |||

| SSP-1 Temp | 69 | 150 | 7.3 | |||

| SSP-2 Perm | 3.4 | U | 3.7 | J | 3.8 | U |

| SSP-2 Temp | 3.6 | U | 4.8 | J | 3.9 | U |

| SSP-3 Perm | 4.2 | 16 | 3.9 | U | ||

| SSP-3 Temp | 4.8 | 23 | 3.7 | U | ||

| SSP-4 Perm | 13 | 140 | 4.3 | U | ||

| SSP-4 Perm DUP | 12 | 140 | 4.1 | U | ||

| SSP-4 Temp | 18 | 160 | 4.1 | U | ||

| SSP-4 Temp DUP | 19 | 160 | 1.2 | J | ||

| SSP-5 Perm | 0.55 | J | 27 | 3.5 | U | |

| SSP-5 Temp | 3.4 | U | 23 | 3.8 | U |

U – Compound not detected, concentration reported at reporting limit.

J – Compound concentration is reported as estimated because concentration reported concentration was between the lowest calibration standard concentration and the MDL.

Figure 6.

Results for PCE, temporary versus permanent probes.

Figure 8.

Results for TCE, temporary versus permanent probes (ND – non-detect).

Table 4.

Relative percent difference (RPD) of temporary and permanent probe results.

| Location | Chloroform | Tetrachloroethene | Trichloroethene |

|---|---|---|---|

| SSP-1 | 4 | 0 | 4 |

| SSP-2 | NA | NA | NA |

| SSP-3 | 13 | 36 | NA |

| SSP-4 | 32 | 13 | NA |

| SSP-4 DUP | 45 | 13 | NA |

| SSP-5 | NA | 16 | NA |

NA – not applicable

Radon results

As shown in Table 5, there was relatively good agreement (RPD < 20%) between short-term field radon measurements in soil gas, made after the VOC sampling, in both the temporary and permanent ports, except in SSP3. The radon concentration in temporary port SSP3 was substantially higher than in the permanent port at that location. Variability between short-term field radon measurements in soil gas made before and after the VOC sampling was also greatest in location SSP3. This may suggest that port SSP3 is located at an area with a sharp gradient in radon concentrations over a very small area of 30 cm.

Table 5.

Radon data comparing temporary and permanent probes.

| Location | Radon (pCi/L) 11/30/10 before VOC sampling Permanent Port | Sample collection time on 12/6/2010 | Radon (pCi/L) 12/6/2010 after VOC sampling | RPD | ||

|---|---|---|---|---|---|---|

| Temporary Port | Permanent Port | Temporary Port | Permanent Port | |||

| SSP 1 | 1068 | 16:13 | 18:13 | 735 | 719 | 2 |

| SSP 2 | 1203 | 18:43 | 15:53 | 1108 | 1338 | 19 |

| SSP 3 | 219 | 14:13 | 14:33 | 1151 | 543 | 72 |

| SSP 4 | 1865 | 17:43 | 16:33 | 1659 | 1708 | 3 |

| SSP 5 | 1089 | 11:33 | 12:13 | 1214 | 1089 | 11 |

Study limitations

There were several limitations of this study:

This study was performed at only one site.

The temporary ports installed in this study were under the direct field supervision of a highly experienced staff member who had installed numerous ports over several years. No attempt was made to evaluate the variability in seal quality of ports installed by workers with varying levels of experience.

This study did not examine whether the repetitive sampling over many months, which is a primary purpose of permanent sample port installation, would have yielded a different result than the one-time use of either permanent or temporary ports. Results of sampling the permanent ports used here over a year have been published (USEPA, 2012) and show considerable seasonal variability.

This study evaluated only one sealing material, bentonite clay. The NJDEP (2005) allows a number of different materials such as “modeling clay, beeswax or other non-volatile emitting and non-shrinking materials” to be used with Teflon tape “to create a snug fit when the tubing is twisted into the hole.” The NY state guidance (2006) includes a somewhat different list of permissible seal materials “the implant should be sealed to the surface with non-VOC-containing and non-shrinking products for temporary installations (e.g., permagum grout, melted beeswax, putty, etc.) or cement for permanent installations.” We are not aware of any studies that have compared the seal quality that can be achieved with these different materials to one another.

The term “modeling clay” used in the NJDEP (2005) to describe an acceptable seal material is commonly used for a very broad range of product formulations used for a common artistic and educational purpose. The term can be used for at least four different types of materials: (1) products composed primarily of natural, mined clay minerals; (2) products produced by combining oils, waxes, and clay minerals; (3) products made entirely of organic polymers; and (4) products made into a dough of flour, cornstarch, oil, water, and cream of tartar1. The organic polymer clays include those primarily composed of polyvinylchloride for example2. These have been reported to potentially contain residual vinyl chloride (Woodard, 2000).

Conclusions

Under the conditions studied here, VOC and radon concentrations, measured simultaneously in soil gas using collocated temporary and permanent ports, appeared to be independent of the type of port. The variability between collocated temporary and permanent ports was much less than the spatial variability between different locations within the same residential duplex. The agreement of concentrations was achieved even though the clay portion of the seal of the temporary ports were visibly desiccated and cracked. Post sampling leak test results suggested that this desiccation and cracking was not as detrimental to port seal performance as would have been expected, suggesting that the Teflon tape portion of the seals served an important function. Post sampling leak tests are advisable (in addition to pre-sampling leak tests) when temporary ports are used to collect a time-integrated sample over a period of several hours.

These results suggest that temporary sub-slab sampling ports which have equilibrated for a minimum of 2 hr can provide data equivalent to that collected from a permanent sub-slab sampling port at the same time. However, it is cautioned that: (1) only one type of seal material was tested in one location; (2) the seals were installed by experts with rigorous quality control, and; thus, (3) these results may not apply to all types of temporary seals and all building foundations.

Figure 7.

Results for chloroform, temporary versus permanent probes (ND – non-detect).

Acknowledgments

The authors would like to thank the following for their valuable input to the project: Leigh Riley Evens, Jackie Nytes, and Nate Lichti, Mapleton-Fall Creek Development Corporation for loan of the house used for this work; Dale Greenwell USEPA NRMRL and Ron Mosley (retired), radon expertise and equipment support; Gregory Budd, USEPA Radiation and Indoor Environments National Laboratory, radon QC sample analysis and instrument support; Ausha Scott, Air Toxics Ltd., analytical support; Alan Williams and Jade Morgan, USEPA NERL, TO-17 analytical support; Rebecca Forbort and Valerie Kull, ARCADIS, Shu-yi Lin, RTI, data management and analysis support; Scott Forsberg, Harvard School of Public Health, air exchange rate measurement support.

Footnotes

Notice

The United States Environmental Protection Agency through its Office of Research and Development funded, managed and collaborated in the research described here under contract EP-C-11–036 to RTI International. It has been subjected to Agency review and approved for publication. Mention of trade names or commercial products does not constitute endorsement or recommendation for use.

Two websites accessed December 20, 2016 http://en.wikipedia.org/wiki/Modelling_clay http://www.wisegeek.com/what-are-the-different-types-of-modeling-clay.htm

References

- Arizona Department of Environmental Quality (AZDEQ). 2011. Soil Vapor Sampling Guidance. July 10, 2008 (Revised May 19, 2011). http://www.azdeq.gov/environ/waste/download/svsg.pdf

- California Environmental Protection Agency (CAEPA), Department of Toxic Substances Control (DTSC). 2015. Advisory Active Soil Gas Investigations. https://www.dtsc.ca.gov/SiteCleanup/upload/VI_ActiveSoilGasAdvisory_FINAL.pdf, July.

- Missouri Department of Natural Resources (MDNR). 2013. Missouri Risk-Based Corrective Action Process for Petroleum Storage Tanks. Appendix C, Evaluation of the Vapor Intrusion Pathway. http://dnr.mo.gov/env/hwp/docs/tanks-final-guidance2013.pdf, October.

- New York State Department of Health (NYDOH). 2006, Guidance for Evaluating Soil Vapor Intrusion in the State of New York. New York State Department of Health, Bureau of Environmental Exposure Investigation, Troy, New York, October. [Google Scholar]

- New Jersey Department of Environmental Protection (NJDEP). 2005. Draft Vapor Intrusion Guidance, June 2005.

- New Jersey Department of Environmental Protection (NJDEP). 2012. Draft Vapor Intrusion Guidance.

- United States Environmental Protection Agency (USEPA). 1992. Indoor Radon and Radon Decay Product Measurement, Device Protocols. EPA 402-R-92–004, Office of Radiation Programs, Washington, DC, July (revised). [Google Scholar]

- United States Environmental Protection Agency (USEPA). 1999. Compendium of Methods for the Determination of Toxic Organic Compounds in Ambient Air Second Edition Compendium Method TO-15 Determination Of Volatile Organic Compounds (VOCs) In Air Collected In Specially-Prepared Canisters And Analyzed By Gas Chromatography Mass Spectrometry (GC/MS) EPA/625/R-96/010b. At http://www.epa.gov/ttnamti1/files/ambient/airtox/to-15r.pdf

- United States Environmental Protection Agency (USEPA). 2012. Project Report, Fluctuation of Indoor Radon and VOC Concentrations Due to Seasonal Variations, Office of Research and Development, National Exposure Research Laboratory, Las Vegas, NV, EPA/600/R-12/673. [Google Scholar]

- United States Environmental Protection Agency (USEPA). 2015a. Office of Solid Waste and Emergency Response Technical Guide For Assessing And Mitigating The Vapor Intrusion Pathway From Sub-surface Vapor Sources To Indoor Air, U.S. EPA, Office of Solid Waste and Emergency Response, Washington, DC: https://www.epa.gov/sites/production/files/2015-09/documents/oswer-vapor-intrusion-technical-guide-final.pdf [Google Scholar]

- United States Environmental Protection Agency (USEPA). 2015b. Assessment of Mitigation Systems on Vapor Intrusion: Sub-slab Depressurization of a Indianapolis Duplex, EPA/600/R-14/397, Office of Research and Development, National Exposure Research Laboratory, Las Vegas, NV, January. [Google Scholar]

- Woodard S 2000. Hazard Risk Assessment from the Use of Polymer Clays, Division of Occupational and Environmental Medicine, Duke University Medical Center; Durham, NC 27710; http://www.polymerclaycentral.com/cyclopedia/polymerclay_safety.htm, May 2000.