Abstract

Tissue engineered vascular grafts (TEVGs) are beginning to achieve clinical success and hold promise as a source of grafting material when donor grafts are unsuitable or unavailable. Significant technological advances have generated small-diameter TEVGs that are mechanically stable and promote functional remodeling by regenerating host cells. However, developing a biocompatible blood-contacting surface remains a major challenge. The TEVG luminal surface must avoid negative inflammatory responses and thrombogenesis immediately upon implantation and promote endothelialization. The surface has therefore become a primary focus for research and development efforts. The current state of TEVGs is herein reviewed with an emphasis on the blood-contacting surface. General vascular physiology and developmental challenges and strategies are briefly described, followed by an overview of the materials currently employed in TEVGs. The use of biodegradable materials and stem cells requires careful control of graft composition, degradation behavior, and cell recruitment ability to ensure that a physiologically relevant vessel structure is ultimately achieved. The establishment of a stable monolayer of endothelial cells (ECs) and the quiescence of smooth muscle cells (SMCs) are critical to the maintenance of patency. Several strategies to modify blood-contacting surfaces to resist thrombosis and control cellular recruitment are reviewed, including coatings of biomimetic peptides and heparin.

Keywords: Vascular Engineering, Vascular Graft, Blood-Contacting Surface, Endothelialization, Surface Modification

1. INTRODUCTION

Cardiovascular disease (CVD) is currently the leading cause of death in the United States and the world. Approximately 800,000 CVD deaths occur annually in the US as reported in 2017 by the American Heart Association [1]. Additionally, the World Health Organization estimated that 17.5 million people died worldwide from cardiovascular related diseases in the year 2013, and this number is expected to grow to 23.6 million by 2030 [2]. CVD can cause stenosis or occlusion of blood vessels and is commonly associated with coronary artery disease, cerebrovascular disease, deep vein thrombosis, atherosclerosis, and other serious complications [3].

Treatment methods of CVD include lifestyle modification, pharmaceuticals, or surgery. For situations requiring surgery, autologous grafts are the current gold standard treatment method. However, although autologous grafts are preferred over synthetic grafts, acceptable donor sites are not always available. Synthetic grafts are a useful alternative for large diameter vessels but not ideal for small-diameter vessels (diameters less than 6 mm) due to poor patency rates. Tissue engineered vascular grafts (TEVGs) hold promise to overcome the limitations seen with synthetic grafts and serve as alternative replacement vessels for clinical applications. However, engineering materials to mimic the properties of native tissues is challenging due to the complex structure and composition. In order to develop a functional small-diameter vascular graft, it is essential to understand the blood-contacting surface and antithrombogenic mechanisms. The engineering strategies for TEVGs have been extensively reviewed by Pashneh-Tala et al. [3]. This review paper focuses on the blood-contracting surface of TEVGs.

1.1. Blood-Contacting Surface and Antithrombogenicity

The blood-contacting surface of a vessel’s lumen is covered with a confluent monolayer of endothelial cells (ECs). A healthy endothelium plays a critical role in hemostasis as it directly contacts and interacts with substances within circulating blood. The ECs are anchored to an underlying basement membrane, which consists of a thin mat of laminin, collagen, and assorted extracellular matrix (ECM) biomacromolecules. This matrix often contains basic fibroblast growth factor (bFGF) and transforming growth factor (TGF)-β1, which activates SMCs to synthesize elastin and other components of ECM [3, 4]. The morphology and function of ECs are critical for maintaining vascular health. Endothelial abnormalities are well known for their significant role in cardiovascular diseases, especially atherosclerosis [5, 6].

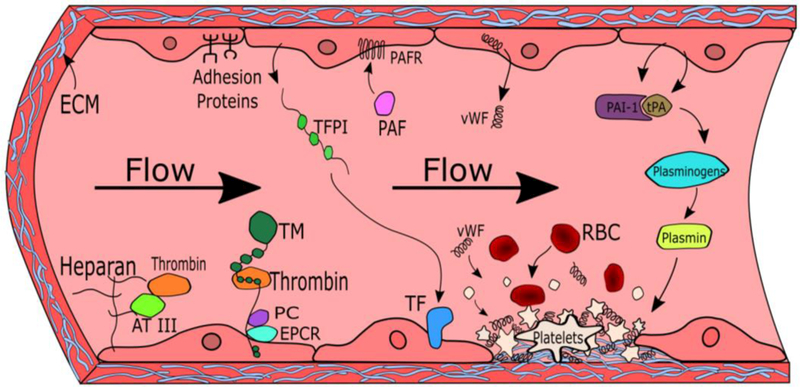

Hemostasis and thrombus formation are regulated by several interconnected systems and biological factors, including the coagulation and complement cascades, biomechanical forces, and circulating cells and blood borne molecules. ECs synthesize and control many key factors such as heparans, thrombomodulin, tissue plasminogen activator (tPA), plasminogen activator inhibitor-1 (PAI-1), adhesion proteins, and platelet activating factor (PAF) to regulate thrombus formation through interactions with secondary molecules. These EC-secreted molecules include thrombin, antithrombin III (AT III), protein C, endothelial protein coupled receptor (EPCR), platelet activating factor receptor (PAFR), plasmin, and plasminogen. Figure 1 depicts the ECs’ key role in regulating the antithrombogenic properties of blood vessels.

Figure 1. The role of endothelial cells (ECs) in the regulation of thrombogenesis.

Heparans, thrombomodulin, tissue plasminogen activator (tPA), plasminogen activator inhibitor-1 (PAI-1), adhesion proteins, and platelet activating factor (PAF) play key roles in regulating coagulation. These important factors interact with other molecules such as thrombin, antithrombin III (AT III), protein C, endothelial protein coupled receptor (EPCR), platelet activating factor receptor (PAFR), plasmin, and plasminogen to promote or prevent thrombus formation. Thrombi are formed when damaged endothelium expose extracellular matrix (ECM) proteins such as collagen, which then recruit platelets, von Willebrand factor (vWF), and red blood cells (RBCs).

1.1.1. Platelet adhesion, coagulation cascade and regulation of thrombus formation

The coagulation cascade is divided into an intrinsic and extrinsic pathway. The endothelium plays a central role in coagulation cascades due to its unique anti-thrombogenic, fibrinolytic, and anticoagulant properties. Because collagen and other ECM proteins are highly thrombogenic, trauma or disease that damages the endothelium and exposes underlying thrombogenic materials can trigger thrombosis. Platelets initiate the coagulation cascade by immediately binding to exposed ECM components such as collagen, fibronectin, laminin, and thrombospondin at the site of vascular damage. Binding to these molecules activates platelets, which release prothrombotic molecules, including adenosine diphosphate (ADP) and thromboxane, leading to further activation and aggregation of platelets [7, 8]. Platelet activation leads toward synthesis of additional adhesive molecules, which further increase the platelet adhesion rate. For example, the de novo expression of vascular cell adhesion molecule (VCAM-1), also known as CD106, facilitates the adhesion of leukocytes to ECs [6, 9]. von Willebrand factor (vWF) is another platelet adhesive protein that is synthesized by ECs and links platelets to collagen. vWF is present in all ECs but is not secreted unless activated by the coagulation cascade [7, 10]. CD31 (PECAM1), CD54, (ICAM-1), P-selectin, and E-selectin are cellular adhesion proteins present on ECs that can bind with platelets and leukocytes [6]. In order to stabilize the blood clot formed by platelet aggregation, components of the intrinsic pathway activate thrombin, which converts fibrinogen into fibrin polymers to facilitate thrombus cross-linking. The presence of a fibrin clot further increases platelet incorporation [11]. Avoiding activation of these adhesive proteins can reduce blood coagulation and thrombus formation after TEVG implantation.

Prothrombin, fibrinogen, tissue factor (TF), and kallikrein are key pro-coagulation factors. These thrombus-forming components are controlled by several anticoagulation factors, including tissue factor pathway inhibitor (TFPI), thrombomodulin, protein C, and tissue plasminogen activator. Thrombomodulin and EPCR stimulate protein C, which contributes to anticoagulation [6, 8, 10]. TF initiates the extrinsic pathway of the coagulation cascade and is released from damaged sub-endothelial tissues. TF is regulated by TFPI, which is a serine protease inhibitor secreted by healthy vascular ECs. Undamaged ECs also express thrombomodulin, an integral membrane protein that binds thrombin and stimulates the activation of protein C, another anticoagulant. In addition, it is crucial to disintegrate and clear the thrombus after damage is repaired in order to maintain homeostasis. Tissue plasminogen activator (tPA) promotes fibrinolysis by catalyzing the breakdown of plasminogen to plasmin and is inhibited by plasminogen activator inhibitor (PAI-1). tPA and PAI-1 are secreted by ECs to regulate fibrinolysis of thrombi [5, 6, 8–10].

The natural anticoagulation mechanism involves several factors that can be used or mimicked to improve patency of TEVGs. AT III and TFPI are upregulated by the presence of an intact endothelial layer, and they prevent activation of thrombus promoting factors in the coagulation cascade. Other anticoagulation factors present on ECs include heparans, thrombomodulin, and ADPase. ECs synthesize heparans (or heparin-like glycosaminoglycans), which bind to AT III and greatly decrease thrombogenesis by deactivating coagulation factors [5, 7, 12]. Several studies have demonstrated the anti-thrombogenic properties of heparin-coated vascular grafts [13].

1.1.2. Inflammation and complement cascade activation

The complement cascade is an important system to terminate foreign cells. There are more than 20 types of plasma proteins involved in the complement system, which function as either binding proteins or catalysts in both the classical and alternative pathway [14]. Several components of the complement cascade are controlled by ECs. Complement factors, including C1s, C3, factor B, and the terminal complex components are secreted from ECs upon activation and initiate the cascade. Several other EC-secreted factors inhibit the complement cascade, including C1 inhibitor, factor H, and factor I. The complement inhibitors CD46, CD55, and CD59 are bound to the surface of ECs [6, 15].

Endothelial inflammation plays a key role in atherosclerosis and vascular occlusion. Endothelial inflammation is a complex response triggered by either an acute endothelial response or a phenotypic alteration, which can stimulate a prolonged reaction. Monocyte chemoattractant protein (MCP)-1, secreted by actively inflamed ECs, contributes to the inflammatory and immune response by recruiting monocytes (macrophages) to an injury site. Agonists (such as endotoxin, interleukin-1, and tumor necrosis factor (TNF)), oxidized lipoproteins, advanced glycation end products, and mechanical stimulation mediate endothelial activation and secretion of MCP-1. These factors regulate gene expression within ECs by activating the pleiotropic transcription factor, nuclear factor-κB. Prevention of endothelial activation can help prevent the accumulation of atherosclerotic plaque, which could otherwise lead to vascular occlusion [9, 16].

1.1.3. Influence of mechanical force on vascular tone maintenance

Pulsatile flow and mechanical stresses in the lumen of blood vessels also influence vascular patency. Blood flow produces shear stress on ECs and causes hyperpolarization of the cell membrane via potassium channels. This activation stimulates the release of nitric oxide (NO) by transcriptional upregulation of endothelial nitric oxide synthase (eNOS) and generates prostacyclin (PGI2), leading to vasodilation. The lipid molecule PGI2 acts as an antagonist to thromboxane A2, inhibits platelet aggregation, and promotes vasodilation [6, 17].

Relaxing factors are important for regulating vascular tone and contribute to the anti-thrombotic properties of the endothelium [5]. Endothelium-derived relaxing factor (EDRF) relaxes smooth muscle cells (SMCs) and inhibits thrombus formation. EDRF was identified as NO by Luis Ignarro and his colleagues, for which they won a Nobel Prize in 1998 [18]. PGI2 and NO inhibit platelet aggregation by stimulating increased levels of cAMP and cGMP. Endothelium-derived hyperpolarizing factor (EDHF) also contributes to vasodilation by hyperpolarization of the cell membrane through K+ channels, which causes the vascular smooth muscle layer to relax [5, 19]. In recent literature, NO release was found to decrease thrombus formation and improve vascular patency, demonstrating that eNOS and NO are important factors in regulating the anti-thrombogenic properties of ECs [20].

The endothelium acts as a mechanoreceptor, sensing changes in blood flow and pressure, which triggers the release of vasodilation or vasoconstriction signaling molecules to the vascular smooth muscle cells. To counter vasodilation, ECs produce endothelin-1 if activated by shear stress in the presence of thrombin or under hypoxic conditions, which stimulates SMCs to contract, leading to vasoconstriction [6, 21]. Studies investigating the effects of biomechanical stimulation on ECs have shown that laminar shear stress plays an important role in maintaining natural endothelial morphology. Cultured ECs under laminar shear stress upregulated transcription factors such as KLF-2 (Kruppel-like factor), KLF-4, and nuclear factor erythroid 2-related factor-2 (NRF-2). This biomechanical stimulation promotes an anti-thromobogenic phenotype and normal cell shape, alignment, and organization. It also promotes glycocalyx formation, a glycosaminoglycan-rich layer on the surface of ECs, which triggers the expression of eNOS and subsequent release of NO [9, 22]. In contrast, ECs under disturbed flow (ie non-directed, as found in branched or curved arteries) express the pleiotropic transcription factor nuclear factor-κB and mimic the abnormal phenotype of ECs found in patients with atherosclerotic cardiovascular disease [9, 23].

1.1.4. The influence of endothelial cell activation on thrombus formation

Activation of ECs can stimulate phenotypic changes that influence the anti-thrombogenic properties of blood vessels. ECs can be activated by vascular endothelial growth factor (VEGF), cellular adhesion, several cytokines, mechanical stimulation, or endotoxin. An understanding of endothelial activation and thrombotic endothelial diseases can help design TEVGs with improved anti-thrombogenic properties [5, 9].

Surgical implantation of a TEVG damages neighboring tissues and can disrupt endothelial continuity. It is particularly important to avoid surgical trauma induced intimal hyperplasia at the interface between the implant and native vasculature. This disease promoting tissue has mismatching mechanical properties and can protrude into the vascular lumen, which can disrupt laminar blood flow and predispose towards thrombus formation. Vascular trauma induces platelet adhesion, migration of pro-inflammatory cells especially monocytes/macrophages, and promotes excessive cellular proliferation and activation, which can result in atherosclerotic plaque development [5, 9, 24]. Activation of ECs or damage to the endothelial layer compromises the anti-thrombogenic properties of blood vessels. Therefore, maintaining a healthy and undamaged endothelial layer is the first and most important consideration to enhance the patency of cellularized TEVGs. Various strategies have been developed to address this issue that are reviewed in the present contribution. These strategies include novel in vitro anti-thrombogenic cell seeding, EC maturation by provision of physiological pulsatile flow, as well as promoting efficient in vitro and/or in situ endothelialization by modifying the blood-contacting surface via attachment of biomimetic peptides, antibodies and growth factors.

When developing vascular grafts for CVD patients, a broad range of disease characteristics that affect the confluence and functionality of the endothelium need to be considered. Symptoms of vascular dysfunction include generalized or localized vascular spasms, abnormal thrombosis, atherosclerosis, and restenosis [5]. Understanding mechanisms of endothelial dysfunction and treatment methods are critical in TEVG development to prevent coagulation and improve patency results.

2. BLOOD INTERFACE OF VASCULAR GRAFTS

Vascular graft implantation triggers protein absorption, complement activation, platelet adhesion and foreign reaction. Recapitulating a hemocompatible blood-contacting interface on vascular grafts is a major goal of bioengineering replacement vascular tissues. The character of the blood-material interface is determined by material properties, blood flow effects and the biological environment [25]. Material selection and understanding their affect on blood and blood borne cells is critical for TEVG engineering.

2.1. Naturally Derived Materials

A major benefit of naturally derived materials is that their chemical structure and biological effects are similar to their human counterparts. Most of the natural materials are biodegradable and can be remodeled and replaced by native cells and ECM. Consequently, grafts fabricated from naturally derived materials can be integrated and attain a close approximation to a native vessel [26].

2.1.1. Elastin

Elastin, composed of tropoelastin and fibrillin, is an important ECM constituent in vertebrate tissues that require elastic recoil [27]. As an essential constituent of blood vessels, it plays a vital role in vessel elasticity and SMC phenotype regulation [28]. Tropoelastin can be secreted by SMCs, ECs and fibroblasts. Elastin has become an important component for constructing TEVGs, as it exhibits anti-thrombogenic and anti-inflammatory properties in addition to imparting material properties of elasticity. Its degradation products, bioactive elastin-derived peptides (EDPs), retain the property of decreasing platelet aggregation and thrombosis [29]. Elastin directly isolated from vasculature was found to cause only minor platelet adhesion [30]. A study by Simionescu et al. obtained pure elastin from porcine aortas and tested its potential as a TEVG scaffold. In vitro results revealed reduced platelet adhesion and aggregation compared to collagen scaffolds derived from porcine aortas. The research demonstrated that elastin scaffolds promote EC proliferation, viability, and endothelial layer formation [31]. Another study applied purified porcine arterial elastin combined with fibrin-bonded layers from acellular small intestinal mucosa to improve the mechanical properties of elastin [32]. The researchers tested acute thrombogenicity of the construct using a porcine carotid artery interposition model. The elastin-containing construct remained patent significantly longer than commercially available PTFE. While thrombus in the elastin construct was restricted to the suture sites, thrombosis was elicited along the entire length of the PTFE graft. Incorporating elastin into TEVGs is therefore a promising approach to achieve a stable blood-contacting surface based on its antithrombogenic and natural properties.

2.1.2. Silk fibroin

Fibroin is the main component of silk fibers, composed of antiparallel beta sheets. Silk fibroin is a biodegradable and biocompatible scaffold material with high mechanical strength and a low degradation rate. It has been shown to be non-thrombogenic, as it avoided activation of platelets [33]. The anti-thrombotic property of fibroin was also observed by Enomoto et al, in a long term implantation of a vascular graft fabricated with silk fibroin thread by plaiting [34]. The fibroin graft maintained high patency after a one-year implantation. Implantation of grafts by Soffer that were fabricated into tubular silk fibroin scaffolds by electrospinning demonstrated sufficient structural integrity to allow handling and to maintain open conduits when hydrated [35]. The scaffolds possess a promising elastic modulus (average 2.45MPa) and ultimate tensile strength (average 2.42MPa) for potential use as vascular grafts, including the ability to withstand arterial pressures and to behave mechanically similar to native vessels. These systems also support EC and SMC proliferation [35, 36], suggesting their future potential in TEVG applications.

2.1.3. Collagen

Collagen is a main protein component of arteries and veins, made from amino acid-packed triple helices, providing mechanical support along the protein longitudinal axis. Although present in each layer of vasculature, larger bundles of collagen are concentrated in the vessel adventitia. TEVG scaffolds with high collagen content exhibit high mechanical strength, biocompatibility, degradability, and accessibility to native cells. The collagen fibrils contain integrin binding sites, which allow cells to attach and migrate [37]. However, at the same time, collagen can bind vWF and blood coagulation proteins, which promote platelet adhesion on the TEVG surface [38]. Similarly, activated platelets also express adhesion proteins including Gp1b, GpIIb-IIIa, CD40L, P-selectin, GPIbα46 and ICAM-2, which induce platelet aggregation and vessel wall invasion of activated leucocytes [39]. Therefore, when constructing TEVGs from collagen-containing matrices, antithromgenic materials or anticoagulation reagents should be incorporated into the scaffold, especially on the blood-contacting surface, to reduce the thrombogenic effects of collagen [40]. Huynh et al. developed an acellular collagen-based TEVG by depositing bovine type I collagen on the submucosa of swine small intestines, which is itself a highly collagenous material [41]. After treatment with an anti-thrombosis reagent and crosslinking, the graft was implanted into a rabbit model. Histological analysis identified SMCs infiltrating within the graft and an endothelial layer at 90 days. The grafts were responsive to various vasoactive agents, indicating successful functional remodeling.

2.1.4. Decellularized ECM

ECM is the collection of biomacromolecules secreted and organized by cells, which contains complex components including collagen, laminin, hyaluronic acid and fibronectin. The ECM provides an ideal environment for cells to proliferate and carry out their functions. It can mechanically support cells to form an integrated and functional tissue, as well as provide biomolecules to maintain cell motility and viability. Decellularized tubular tissues which contain a relatively organized ECM structure, such as human greater saphenous vein and intestine, have been investigated for use as vascular scaffolds [42]. Following decellularization processing, decellularized tissues have been found to maintain a high compositional similarity to native vasculature with respect to collagen and elastin content. Furthermore, the mechanical strength of decellularizeds scaffold, including suture retention and compliance, are comparable to native vasculature [43]. In vitro testing revealed that the decellularized human greater saphenous vein exhibits similar burst strength and suture-holding strength as fresh veins (fresh: 2480 ± 460 mm Hg, 185 ± 30 gm, decellularized: 2380 ± 620 mm Hg, 178 ± 66 gm). However, tissue engineering approaches that rely upon xenograft ECM must surmount pathogenic concerns, while allograft and homograft ECM is in limited supply. To solve this problem, one unique strategy developed tubular ECM by body foreign reaction over 3 weeks of subcutaneous implantation of polymer rods [44]. The tubular fibrocellular tissue capsule can be applied as a TEVG material. The graft can also be decellularized and repopulated with specialized cell types for improved performance as a TEVG. Widespread experience demonstrates that the ECM supports cell attachment, proliferation and infiltration, which permits their use as potential TEVG candidates [45]. Nevertheless, based on the complex composition of ECM, a bulk ECM implanted into the vascular system will promote thrombosis [46]. Antithrobogenic strategies need to be incorporated into these ECM constructs to improve the TEVG patency.

Besides decellularization of natural tissues, cell-derived ECM has been developed to circumvent pathogenic concerns associated with xenografts. [47, 48]. Our group has derived highly aligned ECM nanofibers by decellularizing aligned human dermal fibroblasts sheets. The nanofibers are around 80 nm in diameter, similar to the physiological size of collagen nanofibers [49]. Recently, we assembled a completely biological and anisotropic vascular graft by combining the aligned ECM nanofibrous sheet and hMSCs in a rotating wall bioreactor system [47]. The TEVG demonstrated increased tensile strength and anisotropy compared with its static culture counterpart. Dr. Tranquillo’s group has created a TEVG by growing ovine dermal fibroblasts in a sacrificial tubular fibrin gel mold and then decellularizing the resulting tubular cellular assembly. The 4 weeks implantation of this TEVG in sheep femoral arteries demonstrated graft patency and mechanical anisotropy along with extensive recellularization [50]. A similar approach was applied to create an “off-the-shelf” decellularized vascular graft, which was implanted into young lambs [51]. After 50 weeks, explanted grafts displayed physiological stiffness and complete lumen endothelialization without any signs of calcification, aneurysm or restenosis [51]. Most recently this group has developed decellularized arteriovenous grafts (AVGs) by seeding neonatal human dermal fibroblasts in the sacrificial fibrin mold [52]. These decellularized constructs were implanted into baboons and tested as hemodialysis access points. AVGs were extensively recellularized, showed an 83% and 60% patency rate at 3- and 5-months, respectively, without calcifications, loss of burst strength, or outflow stenosis [52]. Although significant progress has been achieved using this strategy, anticoagulation drugs were required for the entire duration of the study, and thus the study focused on long term graft function and biointegration without considering the blood contacting interface.

2.2. Synthetic Materials

Synthetic materials provide a reproducible, controllable and inexpensive source for TEVG engineering. Synthetic materials usually have higher mechanical strength than natural derived materials, which make them promising in blood pressure-bearing applications. One major obstacle of constructing TEVGs from synthetic materials is their lack of cell communication signals and integrin binding sites, which might hinder cell attachment and infiltration into the graft. Moreover, a broad mechanical compliance mismatch further undermines the long-term patency of these grafts. To improve the properties of synthetic materials, innovative modifications have been developed.

2.2.1. Non-biodegradable synthetic materials

Biostable polymers, such as polyethylene terephthalate (aka PET, Dacron) and expanded polytetrafluoroethylene (ePTFE), have been utilized as prosthetic large vascular grafts (ID > 6mm) [53]. When applied as large diameter vessels, the higher rate of blood flow and larger flow area together with the relatively inert property of PET and ePTFE decreases the possibility of TEVG occlusion. They also provide strong mechanical support to tolerate blood pressure and pulsatile blood flow [54]. However, when applied in small diameter vessels (ID < 6mm) that have a much lower blood flow rate, the vascular grafts tend to fail by occlusive thrombus. Moreover, biostable materials are prone to chronic foreign body responses that form fibrotic capsules around the graft. The mechanical mismatch between material and host tissue may also compromise vessel functionality, promoting cell hyperplasia near the graft-tissue interface. In order to improve the blood-contacting surface of non-biodegradable polymeric TEVGs, ECs have been seeded into the vascular lumen. Nevertheless, the generated endothelium fails to completely cover the neointima, which contributes to thrombus formation [55]. Thus, the biostable polymers require surface modification and bioactive molecular incorporation to improve EC confluence on the material surface [56].

2.2.2. Biodegradable synthetic materials

Linear aliphatic polyesters such as poly (caprolactone) (PCL), poly (lactic acid) (PLA), poly (glycolic acid) (PGA), and their copolymers poly (lactic acid-co-glycolic acid) (PLGA) are biodegradable and biocompatible polymers that have achieved approval from the US Food and Drug Administration (FDA) for clinical use [57]. The first preliminary study evaluating a PGA tube as a vascular graft was conducted in a rat model by Lauritzen in 1983 utilizing grafts with an internal diameter of 1mm, [58]. This initial experiment discovered that half the venous PGA grafts were completely replaced by regenerated vascular tissue with complete endothelium and developed sub endothelial layers over the duration of the study, suggesting that PGA tubes are promising constructs for vascular graft engineering. It should be noted that the failure mode for the other half of the PGA grafts was due to damage caused to the intima during surgery. PCL is a versatile biomaterial that has been extensively investigated. It degrades by the hydrolysis of ester linkages, and giant cells and macrophages can digest the fragments. Unlike PGA or PLA, the degradation of PCL is significantly slower (longer than 24 month), making it more compatible with the slow rate of tissue healing [59]. One study compared small-diameter PCL grafts with ePTFE grafts at 24 weeks in rats in terms of endothelial coverage, intima formation, and cell infiltration after implantation [60]. The authors found faster endothelialization and intima formation in the PCL grafts relative to ePTFE, with better cell infiltration and ECM deposition, indicating that PCL is a more appropriate candidate than ePTFE for TEVGs. Varied combinations of polyesters have been used to synthesize biodegradable materials with different mechanical properties and degradation rates. A PGA non-woven fabric sheet was combined with P(CL/LA) (50:50) by pouring P(CL/LA) solution onto the sheet followed by freeze-drying. Tubular grafts were constructed with the material to a diameter of 8 mm. The grafts were implanted in the inferior vena cava of canines for a long term performance test at low pressure [61]. The goal was to achieve a biodegradable scaffold that was capable of promoting regeneration through optimized mechanics and degradation time without the need for cell seeding. After two years of implantation the graft exhibited well-formed vasculature with high similarity to native vessels without observations of serious thrombus in the inner layer of the graft. However, due to the hydrolysis of the graft, the loss of mechanical strength at early stages of implantation resulted in stenosis. Reinforcement to increase mechanical strength and endothelialization of the graft is needed to improve the TEVG performance. Polydioxanone ((C4H6O3)n, PDO) is a biocompatible and biodegradable polymer that has been widely used as wound closure sutures. Similar to Dacron and ePTFE, PDO provides strong mechanical retention when applied as a TEVG scaffold [62]. Its degradation rate is lower than PLGA and PGA [63], but faster than PCL. Sell et al. co-spun PDO with elastin at a 1:1 ratio, using PDO as a backbone to provide mechanical support while elastin provided bioactive signals to prevent platelet adhesion [64]. The mechanical strength of the construct was similar to that of native vessels and the incorporation of elastin promoted cell infiltration. A similar study by Smith et al employed an electrospun PDO-elastin tube reinforced by crosslinking to withstand suturing. The burst strength of the tube was significantly elevated by the processing [65].

Overall, natural materials are more biocompatible since they are remodelable by host cells and their degradation products can be assimilated or metabolized and excreted by the body. However, using natural or naturally derived materials often requires complicated and time-consuming purification or isolation processes, and reproducibility may be challenged due to natural variations. The low mechanical strength of natural materials often necessitates additional processing for reinforcement. Synthetic materials are more reproducible and easily processed but require incorporation of bioactive molecules and careful design to obtain suitable degradation rates and mechanical strength. More importantly, a functional TEVG design must be antithrombotic. Incorporation of antithrombotic materials such as elastin and designing synthetic materials with non-thromobogenic surfaces provide new directions for engineering TEVGs.

2.3. Influence of Surface Roughness, Topography and Mechanical Properties on TEVG Hemocompatibility

In addition to considerations related to TEVG material selection, the architecture and topography of the blood-contacting surface are also important factors affecting thrombus formation. The aortic endothelium is rough at the submicron scale, with ridges and grooves that are generally aligned in the blood flow direction [66, 67]. These ridges have a ~500 nm width and ~100 nm height [66, 68]. These natural topographical features may provide increased cellular attachement as well as alignment in the direction of blood flow. In recent years, various studies have focused on elucidating the impact of biophysical stimulation on the behavior of platelets and ECs. These studies can help in designing appropariate blood-contacting surfaces for TEVGs that can provide better hemocompatibility.

Platelet adhesion and activation are significantly affected by material surface nano-topography gradients. A rough surface has been created by coating gold nano particles (36 nm and 56 nm of diameter) onto a smooth gold substrate, which was further coated with fibrinogen cell adhesion molecules [69]. Results showed that platelets were more adherent and readily activated on a smooth surface relative to a rough one. Others have also found that increased surface roughness at a micrometer level increases thrombogenicity, possibly due to the increased surface area available for platelet adhesion and activation [70]. Surfaces with roughness larger than a platelet dimension (~ 2 μm) have higher thrombogenic potential. Interestingly, roughness from a 36 nm nanoparticle coating does not affect platelet adhesion and activation, suggesting platelets may have a minimum roughness detection limit of ~36 nm for stimulating thrombogenic effects [71]. Variations in surface topography also affect platelet activity. In contrast to roughness, surface topography with structured ridges or grooves (50 nm - 2 μm) significantly reduce platelet adhesion area, as platelet attachment is generally restricted to the groove top. Thus, structured surfaces can be highly thrombo-resistant. Similarly, electrospun fibers having diameter less than 1 μm effectively avoid platelet adhesion and blood coagulation, while a significantly increased platelet adhesion has been observed on fibers with diameters of 2–3 μm [72]. Therefore, a well-designed TEVG surface with appropriate roughness and topography could significantly improve the hemocompatibility of the TEVG blood-contacting surface [69].

The native endothelial vascular basement membrane has nano to micro scale topographical features, which guide EC orientation [67]. These surface topographical features can be used to modulate EC behavior in order to enhance TEVG hemocompatibility. For example, a study conducted to explore rat aortic endothelial cell (RAEC) behavior on a patterned titanium surface having periodic arrays of grooves with width and pitch ranging from 750 nm to 100 μm demonstrated that a smaller feature size elicits enhanced cellular effects [73]. The patterned surface with a feature size less than 10 μm promoted increased cell density, elongation and proliferation compared to smooth or randomly pattered surfaces [73]. A similar study was conducted on patterns with ridge and groove sizes ranging from 200 nm to 2,000 nm and at a fixed 300 nm groove depth. Four different vascular cell types including human umbilical vein ECs, human dermal microvascular ECs, human aortic ECs and human saphenous vein ECs exhibited significantly increased cell orientation and alignment on aligned patterns ridges larger than 800 nm [74]. Moreover, all of the cell types excluding human aortic ECs showed a significantly increased rate of cell migration on aligned patterns having ridges larger than 1,200 nm [74].

The mechanical properties of the blood-contacting surface are also important regulators of platelet adhesion, spreading and activation [75–77]. A fibrinogen-immobilized polyacrylamide gel with varied stiffness (0.25 kPa - 100 kPa) revealed that stiffer surfaces (5 to 50 kPa) significantly enhance platelet adhesion and spreading through activation of integrin αIIbβ2, which binds fibrinogen [76]. They found that platelets respond to surface stiffness via Rac1 and actomyosin activity by secreting more alpha granules on stiffer substrates [76]. Another study with a collagen-conjugated polyacrylamide gel with varying stiffness from 0.25 kPa to 5 kPa confirmed this result, as the platelet spreading area increased (50–60 μm2) on gels stiffer than 5 kPa, compared to a spreading area of 30–40 of μm2 on softer gels with a stiffness between 0.25 to 2.5 kPa [75]. This study found that collagen mediated the stiffness effects by regulating extracellular Ca+2 levels and actomyosin pathways rather than through Rho-associated protein kinase pathways [75]. Although the influence of a TEVG’s blood-contacting surface topography and mechanical properties on platelet activation/adhesion is a relatively new research direction, this needs to be carefully considered for successful TEVG design.

3. STRATEGIES TO IMPROVE THE BLOOD INTERFACE OF VASCULAR GRAFTS

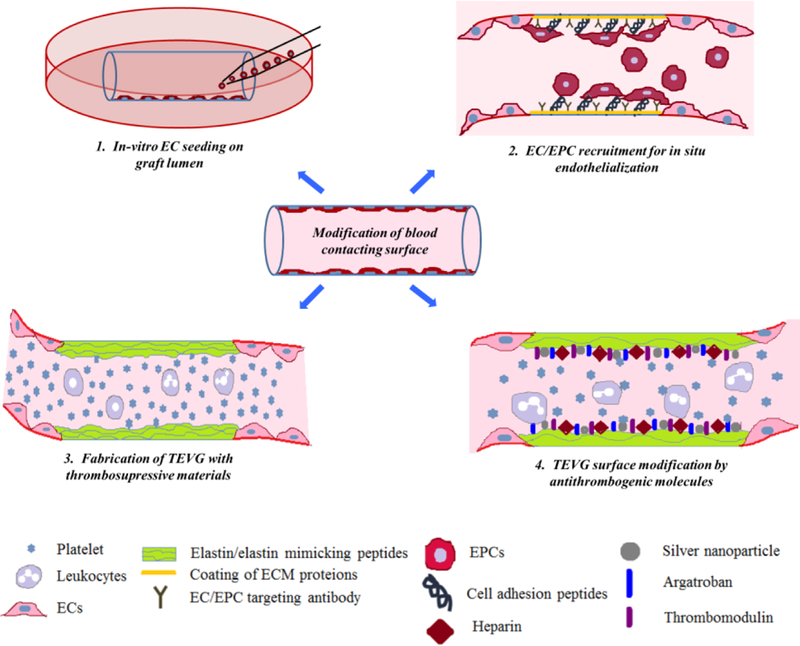

Whether off-the-shelf grafts made from biomaterials or cellular grafts fabricated by allogeneic or autologous cells, TEVGs all require a functional blood-contacting surface to reduce thrombogenicity and maintain patency. Different strategies, such as including anti-thrombotic cells in the graft lumen, stimulating in vivo endothelialization, utilizing thrombosis-resistant graft biomaterials, and chemical modification of the graft surface, have been employed to produce successful blood-contacting surfaces in TEVGs (Figure 2).

Figure 2. Modifying blood-contacting surface of TEVG.

(1). In vitro endothelial cell seeding on the graft lumen provides a biomimetic environment and prevents direct contact of blood with the graft surface. (2). In-situ endothelialization can be achieved by coating the graft lumen with ECM proteins, growth factors, EC/EPC specific cell binding peptides or antibodies. (3). Fabrication of TEVG with anti-thrombogenic natural or synthetic materials maintains graft patency by preventing platelet adhesion and activation. (4). Coating of various anti-thrombogenic molecules such as heparin, silver nano-particles, argatroban and thrombomodulin actively maintains graft patency by preventing platelet adhesion and activation.

3.1. Incorporating Anti-Thrombotic Luminal Cells to Improve TEBV Blood Interface

In most TEVGs, thrombosis occurs due to the lack of an EC layer or the failure to properly re-endothelialize after implantation. Pre-implant luminal cell seeding to provide a functional endothelium or anti-thrombotic cell layer would provide an effective blood-contacting surface. Seeding cells before implantation, if they are accepted by the host immune system, shortens the duration of TEVG regeneration post-implantation. An ideal cell source is one that is easy to obtain and expands quickly to large quantities in vitro, retains native function, and is non-immunogenic in the intended recipient.

3.1.1. Cell types

An ideal TEVG should have biomimetic components and structure. It should be able to withstand the natural mechanical forces from blood flow without rupture and should be functionally anti-thrombogenic, a property in which the vascular cells play a vital role. Including vascular cells in the design of TEVGs would help to reconstruct functional vascular tissue. Currently, ECs and SMCs are widely applied in TEVGs. Compared to traditional vascular cell types, stem cells expand the range of options when designing TEVGs, since the process to obtain vascular cells is invasive and the vitality and proliferative capability of adult cells are limited. Furthermore, the multi-differentiation capability of stem cells may decrease the number of required cell types involved in the whole procedure, which could shorten the time required to fabricate TEVGs. Table 1 provides examples of typical cell types that have been incorporated in TEVG fabrication to improve the TEVG-blood interface.

Table 1.

TEVG with Incorporated Cells

| ECs | Nondegradable scaffolds: Dacron [78,

79], Dacron-collagen [80], PTFE [81]; Degradable scaffolds: PCL [82], P(LLA/CL) [83], P(CS/CL) [84], collagen [85], decellularized vessels [86, 87], fibroblast cell sheets [88] |

Human vein [78], Human artery [79, 81, 86, 88], Canine artery [83, 84], Porcine artery [87] |

ECs | EC seeding significantly improved TEVG patency. Dynamic seeding increased endothelium confluence after implantation. |

ECs participated in re- endothelialization. Detached ECs circulated in peripheral blood. EC attachment depended upon EC source, seeding strategy and scaffold material. |

| ECFCs | Degradable scaffolds: decellularized vessels [89–91], decellularized small intestine submucosa [92],collagen [93] |

Sheep artery [89, 91], Canine artery [90, 93] |

ECFCs, ECFCs- derived ECs |

ECFCs promoted and directly integrated into the regenerating endothelium. Cell implantation improved TEVG patency. |

ECFCs differentiated into ECs and integrated into the reformed endothelium. ECFCs recruited circulating blood progenitor cells to promote re-endothelialization. |

| MSCs | Degradable scaffolds: P(CL/LA) [94], PLLA [95], PCL-gelatin [96], decellularized vessels [97, 98], PLGA- PU [99] |

Rat artery [95, 98], Ovine artery [97], Canine artery [99] |

MSCs, MSCs- derived ECs |

MSCs possess anti- thromobogenic properties, increasing TEVG patency. MSC-derived ECs involved in re-endothelialization. |

MSCs recruited endothelial lineage cells and stabilized EC colonization through paracrine factors. MSC-derived ECs directly participated in re- endothelialization. |

|

BM- MNCs |

Degradable scaffolds: P(CL/LA) [100- 102], decellularized vessels [103, 104], PGLA-P(CL/LA) [105] |

Canine artery [100], Lamb vein [101], Canine artery [103], Human vein [104, 105], Mice artery [102] |

BM-MNCs, BM-MNC derived ECs |

BM-MNCs enabled TEVG to regenerate SMCs and endothelium. BM-MNCs reduced platelet activation and inflammation, improving TEVG patency. |

BM-MNCs differentiated into endothelial lineage cells, lining the endothelium. The MSC sub- population within the BM-MNCs further stabilized the endothelium. |

Abbreviations: EC: endothelial cell; ECFC: endothelial colony forming cell; MSC: mesenchymal stem cell; BM-MNC: bone marrow mononuclear cell; PCL: poly(ɛ-caprolactone); CS: chitosan; PLLA: poly(L-lactide); PTFE: Polytetrafluoroethylene; PLGA: poly(lactic-glycolic acid); PU: polyurethane

3.1.1.1. Vascular cells

A monolayer of ECs line the vasculature, which plays a vital role in avoiding thrombus formation. The permeability of the vessel, fibrinolysis, and inflammation are also associated with a healthy EC layer that secretes an assortment of molecules to regulate the function of SMCs and blood borne cells. The expression level of these molecules is controlled by interactions between circulating blood, ECs and other vascular cells [6]. Early stage studies recognized the importance of ECs in the TEVG blood-contacting layer to avoid thrombosis post implantation. An endothelialized Dacron vascular graft was implanted in a patient for 9 months before requiring a resection, and upon explant the inner surface of the graft revealed an absence of thrombus due to the presence of a uniform endothelial layer similar to native vasculature [78]. Including ECs in the inner layer of TEVGs or applying growth factors to stimulate EC recruitment onto TEVGs contributes to the formation of a stable endothelium and reduces thrombosis after implantation. SMCs are distributed in the vascular media layer, sandwiched between layers of elastin. Although these cells do not directly contact the blood, they indirectly regulate the function of ECs through secretion, maturation, and organization of ECM [106], in addition to their mechanical role. SMC and EC interactions through paracrine factors influence vessel wall assembly and vessel maturation [107]. The presence of SMCs in EC culture decreases EC apoptosis and stimulates EC quiescence via Tie2 signaling, which increases vascular stability and EC survival [108]. Research by Neff et al. compared TEVG functionality in which ECs were seeded on the inner surface of decellularized porcine arteries either with or without SMCs on the outer layer [91]. The group with SMCs not only exhibited higher tensile strength and more rapid medial healing, but also displayed a greater EC physiologic response to receptor-mediated agonists compared with TEVGs seeded without SMCs. Unfortunately, although an engineered endothelial layer is the most straightforward and biomimetic analogue of the natural endothelium, ECs have limited proliferative and regenerative ability. Moreover, the sudden exposure to blood flow and physiological conditions could reduce the attachment of EC on TEVGs [109]. In order to improve endothelialization as well as reduce processing complexity, different cell sources and strategies have been explored.

3.1.1.2. Endothelial progenitor cells (EPCs)

Endothelial progenitor cells (EPCs) are defined as cells that can differentiate into ECs and contribute to new blood vessel formation [110]. By using cell culture technology, two phenotypes of EPCs have been produced: myeloid angiogenic cells (MACs) and endothelial colony forming cells (ECFCs). MACs do not have the ability to differentiate into ECs but can secrete paracrine factors to promote angiogenesis. ECFCs give rise to ECs and directly participate in vasculature formation [111]. ECFCs are positive for CD31, CD146, VEGFR-2, and vWF, but negative for CD45 and CD14, reflecting their normal morphology and function for EC differentiation [24]. ECFCs are recruited on-site where there is injured endothelium and differentiate into ECs to repair vascular damage. Compared to ECs, ECFCs have a higher proliferation ability and are therefore easier to expand in vitro [112], which provides an alternative source of ECs. ECFCs from dogs were isolated and expanded in vitro, and then prelined on a collagen mesh that was wrapped with segmented polyurethane. The graft exhibited high patency post implantation at 3 months, as 11 of 12 of the grafts were patent and covered confluently with cells expressing factor VIIIb-related antigen, indicating that the prelined ECFCs had formed into a functional vascular graft with a confluent EC layer [93]. ECFCs derived from sheep peripheral blood were seeded on decellularized porcine iliac vessels and then implanted in a sheep model [113]. The graft exhibited vascular function similar to native arteries, including contraction and relaxation responses. The results suggest that ECFCs could be used as an alternative source of ECs in TEVG biofabrication.

3.1.1.3. Mesenchymal stem cells (MSCs)

MSCs are a promising cell type for vascular engineering. They are widely available in the body and can be derived from various tissue sources, including adipose tissue, bone marrow, and umbilical vein blood. They can be easily expanded through at least 40 population doublings in vitro [114]. MSCs are immunoregulatory and non-autologous sources do not cause severe immune responses when implanted into foreign recipients [115]. More importantly, they are anti-thromobogenic because of heparan sulfate proteoglycan expression on their surface [95]. They can also recruit ECFCs and ECs on site [95], and be transdifferentiated into vascular cell types, including ECs and SMCs [116]. These properties make MSCs especially attractive as a cell source for TEVG engineering, as they could increase graft patency [117]. A completely biological TEVG was synthesized by MSC sheets by Zhao et al [118]. The TEVG integrated with native vasculature and formed an endothelial inner layer after 4 weeks implantation, which maintained the patency of the TEVG. Zhou et al developed a completely biological TEVG by combining MSC derived ECs and SMCs from transdifferentiation [119]. MSC derived SMCs were seeded on a PCL-gelatin mesh to help SMCs maintain a tubular shape and then the scaffold was sacrificed, leaving behind an SMC filled layer. MSC derived ECs were then seeded in the lumen under pulsatile stimulation. This method produced a TEVG with similar structure as native vessels and comparable mechanical properties including elastic modulus (12.7±1.19MPa), suture retention (1.62±0.1N) and burst pressure (1.72±0.14MPa) to the human saphenous vein. The study demonstrated that the multi-differentiation property of MSC makes it a viable cell source for TEVGs.

3.1.1.4. Induced pluripotent stem cells (iPSCs)

iPSCs are pluripotent stem cells that are derived by reprogramming adult cells [120]. iPSCs can avoid the ethical issues involved in the use of embryonic stem cells (ESCs) while retaining the pluripotent ability to differentiate into all cell types. In use, iPSCs are always induced to differentiate into specific lineages before seeding since their pluripotent property might otherwise produce a teratoma. iPSCs provide a novel source for obtaining vascular cells. The SMCs derived from iPSCs have been shown to maintain phenotype stability and perform better than vascular derived SMCs in terms of SMC specific proteins and gene expression [121]. Since iPSCs can be induced into an EC type with phenotypic plasticity [122, 123], their use as blood contacting cells in a TEVG may reduce platelet activation and thrombogenesis post implantation. Studies utilizing iPSC-derived ECs in engineering vasculature in 3D tissues [122, 124] demonstrated the pro-angiogenic capability of the ECs. Research by Nakayama et al. engineered a bilayered vascular graft by incorporating iPSC-derived SMCs and ECs into aligned fibrillary collagen. The aligned EC layer significantly reduced the inflammatory response of monocytes as compared to randomly-oriented ECs [125]. The study demonstrated the feasibility of applying iPSC derived ECs in building TEVGs. The iPSCs provide a promising cell source for engineering TEVGs, overcoming the limitations of ESCs while possessing pluripotent differentiation capability.

3.1.1.5. Bone marrow mononuclear cells (BM-MNCs)

BM-MNCs include EPCs, ECs, MSCs, immune-related cells and hematopoietic stem cells. By combining their features, BM-MNCs may provide an anti-thrombogenic property when incorporated into TEVGs. Harvesting BM-MNCs from bone marrow is also less invasive than collecting vascular cells from blood vessels [126]. The BM-MNCs can be differentiated into ECs and SMCs, prior to seeding them in a scaffold [127], or seeded while undifferentiated [128]. In a study by Cho et al, BM-MNCs were differentiated to SMC and EC phenotypes and seeded on decellularized canine carotid arteries [129]. The resulting TEVGs were evaluated in a canine model. They found a significantly improved patency of the BM-MNC graft compared with unseeded groups after 8 weeks. The structure of the TEVG was similar to native tissue and the BM-MN derived ECs and SMCs were detected in the construct, demonstrating the long-term self-renewal capacity of the BM-MNCs. Fukunishi et al combined BM-MNCs with a nanofibrous scaffold employed as an infrarenal inferior vena cava graft. The patency of the conduits with BM-MNCs was significantly increased (from 1/10 to 9/10) relative to the non-seeded group after a six month implantation [130]. Histological results depicted concentric laminated SMCs and a confluent EC layer, demonstrating the differentiation ability of BM-MNCs and their applicability in TEVGs. A clinical study was also conducted employing BM-MNCs in vascular tissue engineering. BM-MNCs were seeded on a polymer tube composed of PLA and PCL and reinforced by PGLA [131]. The conduits were implanted into patients with a median age of 5.5 years. In a follow-up with a median duration of 16.7 months post operation there were no complications due to thrombosis or obstruction. The maximum follow-up time of 32 months demonstrated the long-term feasibility of TEVGs constructed from BM-MNCs with an effective blood-contacting luminal surface.

The establishment of an EC lining or a complete layer of non-EC anti-thrombotic cells on the lumen of vascular grafts offers the most effective method to avoid thrombus formation and maintain patency after implantation. The cell seeding strategy is as important as the cell type selection to ensure a confluent and functional blood-contacting surface in the TEVG lumen.

3.1.2. Strategies for preventing immune rejection

Vascular grafts seeded with autologous ECs normally do not evoke host immune responses. However, obtaining autologous cells requires a biopsy, which might be distressing for patients. Moreover, this approach suffers from various limitations including a long culture period for host cell expansion and decreased cellular health depending upon the patient’s age and disease status. Allogenic ECs are readily available from donors but increase the risk of immune rejection. In addition to humeral responses, host T cells can detect allogenic antigens by allorestricted (direct) recognition and/or self-restricted (indirect) recognition, which might result in massive cell death and graft rejection [132]. Monoclonal antibody treatment is an efficient way to modulate host immune responses. Antibodies targeted to immune cell receptors can block chronic graft rejection. Treatment with an anti VCAM-1 monoclonal antibody after allogenic vascular graft implantation resulted in prolonged graft survival [133]. This treatment reduced macrophage and T cell infiltration at the implant site. Moreover, infiltrated T cells appeared to be quiescent after antibody treatment [133]. Very late antigen-4 (VLA-4) can bind with VCAM-1 and induce a costimulatory immune reaction. Monoclonal antibody treatment against VLA-4 and VCAM-1 prevents active graft rejection and provides immosupression to cardiac allografts [134]. In another study, a rat anti-CD2 monoclonal antibody was tested in a pre-clinical model of pig-to-baboon xenograft transplantation [135]. This treatment prevented direct cytotoxicity of baboon immune cells toward pig aortic ECs by depleting all peripheral CD2 positive cells [135]. A similar study was performed to determine the influence of an anti-CD4 monoclonal antibody and gallium nitrate for murine cardiac allograft acceptance. During this treatment, immune processes similar to the acute graft rejection were observed. Moreover, transplanted allografts did not undergo long-term tissue remodeling [136].

Although current immunosuppression regimens are adequate for preventing acute allograft rejection, these treatments pose a risk of malignancy, infection, hypertension, diabetes and hypercholesterolemia [137]. Interestingly, ECFC express all EC markers but are negative for CD14, CD115 and CD45 [138], which might reduce the risk of immune rejection. ECFCs can be cultured in endothelial differentiation medium to induce their differentiated into ECs. In order to compare immunogenicity of allogenic ECFC derived ECs with allogenic aortic ECs (not differentiated from ECFC), J. Ladhoff, et al., seeded both of these cell types into an acellular aortic graft, which was implanted into an allogeneic mismatch rat model [139]. Their results indicated that ECFC derived ECs moderately upregulate MHC-II and are protected against allogenic humoral as well as cytotoxic T cell mediated immune responses. In addition, allogenic ECFC derived ECs showed excellent endothelialization and very mild inflammatory responses without any signs of graft rejection compared to allogenic aortic ECs [139]. Besides ECFCs, MSCs can also be used to modulate host immune responses. Allogenic MSCs can alter the cytokine secretion profile of major immune cells, including dendritic cells (DCs), natural killer (NK) cells and effector T cells [140]. It has been shown that allogenic hMSCs can reduce secretion of TNF-α, Interferon-γ and increase secretion of IL-4, IL-10 from DCs, T helper cells and macrophages [140]. These immune-modulatory properties of MSCs make them an appropriate candidate for development of vascular grafts. Another study demonstrated that IL-1β activated macrophages can induce MSC differentiation into α-actin positive SMC like cells, which can provide contractility to vascular grafts [141]. Most recently, a novel approach was developed to reduce immunogenicity of ECs by silencing the human leukocyte antigen class I (HLA I) using lentiviral vector mediated RNA interfearence (RNAi), which could silence HLA-I expression up to 67 percent [142]. Importantly, HLA I silenced ECs were positive for CD31 and vascular endothelial (VE)-cadherin, which are critical for successful tight junction formation. In addition, HLA I silenced ECs were able to synthesize vWF and NO [142]. This approach can possibly reduce immunogenicity of autologous and allogenic ECs for successful TEVG construction. It is crucial to design efficient approaches to modulate host immune responses in order to prevent TEVG rejection. These approaches might include (but are not limited to) the use of autologous cell types, systemic immune suppression treatment, inclusion of immunosuppressive antibodies into graft design and use of immunomodulatory stem cells for allogenic cellular TEVGs.

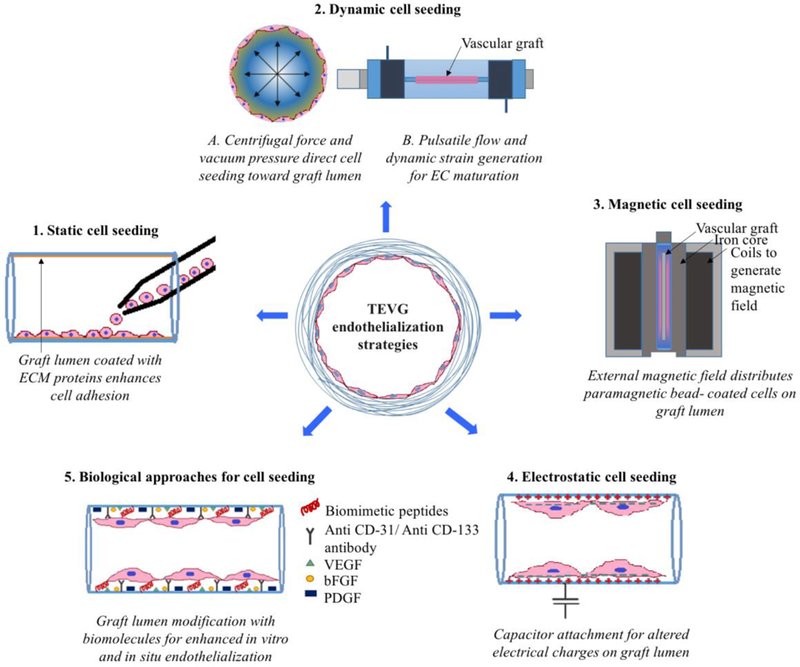

3.1.2. Cell seeding strategies

Various strategies have been developed for cell seeding in small diameter vascular grafts. In vitro cell seeding techniques include static/gravitational cell seeding, dynamic cell seeding, magnetic cell seeding and electrostatic cell seeding [143]. These techniques are briefly summarized in Figure 3.

Figure 3: Cell-seeding strategies for TEVG Endothelialization.

(1). Static cell seeding: ECs/ EPCs can be directly seeded on the vascular graft lumen. A graft lumen can be coated with individual or combinations of various ECM proteins for enhanced cell attachment and retention [144, 145]. (2). Dynamic cell seeding: (A) Vacuum pressure and centrifugal force applied toward graft lumen increases cell seeding efficiency and reduces cell culture period [146, 147]. (B) Bioreactors can provide a physiological pulsatile flow environment, which can be used to promote a mature, non-activated EC phenotype [148–150]. (3). Magnetic cell seeding: An external magnetic field can efficiently guide and regulate seeding of paramagnetic/superparamagnetic particle coated EC/EPCs on a graft lumen [151–153]. (4). Electrostatic cell seeding: attachment of e-PTFE graft with capacitor generates temporary positive charge on graft lumen. Cell surface is usually negatively charged; thus, this temporary positive charge on graft lumen can be used for successful adhesion of ECs/EPCs [154]. (5). Biological approaches for cell seeding: A graft lumen can be coated with biomimetic cell adhesion peptides [155–164], specific antibodies to capture ECs/EPCs [165–168] and various growth factors to promote in vitro/in situ migration and maturation of ECs/EPCs during cell culture and/or after implantation [169–173].

3.1.2.1. Static cell seeding

Static or gravitational cell seeding is the simplest technique, in which cells are seeded directly on the lumen of vascular scaffolds. Static cell seeding usually requires coating the graft lumen with cell adhesion molecules, such as ECM proteins. The cell adhesion molecule fibronectin has been used to coat small-caliber PTFE and Dacron vascular grafts in order to promote EC attachment and growth [145]. Similarly, other ECM proteins such as collagen, gelatin, fibrin and laminin, alone or in various combinations, promotes in vitro EC adhesion and proliferation on the lumen of PTFE and Dacron grafts [144]. However, static cell seeding is associated with several notable problems including non-uniform seeding, poor seeding efficiency, longer culture periods (typically 5 to 9 days), and the risk of contamination [145, 174]. In addition, coating the lumen with adhesion molecules increases the risk of platelet adhesion [175]. If the EC layer is damaged during implantation, the underlying thrombogenic adhesion molecules can promote serious complications including graft occlusion. Thus, with cellularized grafts, it is crucial to protect the surface with a confluent layer of anti-thrombotic cells.

3.1.2.2. Dynamic cell seeding

Dynamic cell seeding uses centrifugal force, vacuum pressure, and fluid sheer stress to enhance seeding efficiency. Graft porosity plays a crucial role for successful cell seeding under dynamic conditions, especially in vacuum seeding [147]. However, synthetic grafts such as PTFE and Dacron need to be pre-clotted after cell seeding in order to close pores present in the constructs. There are several challenges associated with pre-clotting procedures, as review by Burkel, W.E. [176]. For example, the pre-clotted surface is rough and can promote platelet adhesion or activation, which eventually leads to the induction of neointimal hyperplasia. Thus, patients are required to take systemic heparin treatments to prevent platelet activation after implantation [177].

Tissue engineered scaffolds can be used to mitigate these problems. It is possible to create vascular scaffolds with desired pore size and mechanical properties similar to native arteries [178]. Tissue-engineering approaches eliminate the need for pre-clotting the scaffolds with a patient’s blood. Park, I.S., et al., used a dynamic perfusion reactor for seeding cells into elastic scaffolds to form small diameter vascular grafts [146]. They seeded a collagen-SMC mixture into poly (L-lactide-co-ϵ-caprolactone) (PLCL) scaffolds under vacuum and cultured the constructs under dynamic strain in a perfusion bioreactor to promote ECM synthesis and uniform SMC distribution. ECs were seeded on the lumen of the graft under the same dynamic culture conditions to complete the TEVG. The engineered grafts showed a confluent EC layer on the lumen along with secreted elastin content similar to native arteries. [146]. Various types of bioreactors are being used to generate negative pressure for enhanced cell seeding along with dynamic fluid flow for uniform cell distribution and matrix deposition.

With advances in bioreactor design and technology, various physiological conditions can be generated during cell culture. For example, physiological pulse dynamics can be mimicked using perfusion bioreactors to improve endothelialization in small diameter TEVGs. Decellularized umbilical vein scaffolds promote efficient cell seeding and development of uniform EC monolayers on the graft lumen under axial rotation [150]. Moreover, use of perfusion circuits (flow-ramping paradigm) to generate physiological fluid sheer stress and pressure of 1.45 pascals (Pa) with pulse frequencies at 80 pulses/min significantly improves expression of a non-activated EC phenotype, which inhibits the induction of neointimal hyperplasia [150].

The physiological pulsatile flow generated by a perfusion bioreactor creates temporal and spatial variations in shear stress experienced at the graft lumen, which directly affects the function and phenotype of luminally seeded ECs. ECs respond to differences in fluid flow conditions, including laminar, sinusoidal, and physiological pulsatile flow. These different flow conditions affect EC morphology, retention rate, alignment, and apoptosis [148]. Among these various flow conditions, physiological pulsatile fluid flow with a pulse frequency of 1.25 Hz and a time-average pressure of 100 mmHg produces excellent cell retention with unidirectional EC alignment and actin bundles oriented in the same direction. In addition, physiological pulsatile fluid flow significantly reduces the rate of apoptosis compared to laminar flow and sinusoidal flow conditions [148]. Novel advances in pulsatile perfusion bioreactors are being made by optimizing culture conditions for continuous maintenance of O2 and CO2 concentrations along with constant delivery of nutrients and removal of waste products [149]. This approach eliminates the conventional need to replace culture medium.

3.1.2.3. Magnetic cell seeding

One of the major obstacles in the development of TEVGs is long cell culture periods and the maintenance of complicated dynamic physiological conditions for proper cell seeding into vascular scaffolds. A novel strategy for faster and more efficient seeding of vascular cells involves the use of magnetic beads to label desired cells and application of an external magnetic field to regulate cellular distribution. Carboxydextran coated superparamagnetic nanoparticles (Resovist®, Schering, Berlin, Germany) with a diameter of 50nm can be used to label human umbilical vein endothelial cells (HUVECs), which is a typical and widely used EC model [151]. Concentrations of superparamagnetic nanoparticles of 10–200 μg/ml do not affect cellular viability or eNOS expression. An external magnetic field can be used to seed labeled HUVECs on the lumen of a PTFE graft. In addition, cell seeding can be observed non-invasively using magnetic resonance imaging (MRI). This method produces a complete and homogeneous monolayer of HUVECs on the graft lumen. However, long-term cell retention and potential side effects from the beads needs to be evaluated to validate the usefulness of this technology.

Internalization of magnetic nanoparticles may negatively affect cellular physiology and function. Thus, non-invasive cell coating with magnetic beads may provide a better solution. Superparamagnetic polymer particles known as Dynabeads® (DynaBiotec, Oslo, Norway), have been used to coat the cell surface. Similarly, an external magnetic field is used to uniformly seed cells on graft lumens. However, the concentration of beads on a single cell surface must be optimized. Tiwari, A., et al., used CD31 coated Dynabeads to attach them on the surface of HUVECs (4, 10 and 50 beads per cell) and seeded these cells on the lumen of PTFE TEVGs using an external magnetic field [153]. Their results indicate that a higher number of beads per cell produced detrimental effects on cell proliferation and metabolism over time. Although this is an effective method for cell seeding, the internalization of the nanoparticles and their side effects were not discussed.

In addition to distributing cells on synthetic grafts, such as PTFE and Dacron, Dynabeads can be used to cover tissue-engineered scaffolds with different vascular cell types. For example, Perea, H., et al., labeled SMCs and HUVECs with CD44 and CD31 coated Dynabeads, respectively [152]. They seeded SMCs into the lumen of a collagen membrane under a magnetic field for 40 minutes, followed by HUVEC seeding for another 20 minutes under an external magnetic force of 2 pN on each magnetic bead, with 90% seeding efficiency. Magnetic cell seeding can create uniform and monolayer cell coatings on the lumen of both synthetic and natural scaffolds, accurately and within short culture times. However, the long-term cell retention, phenotypic changes, and other side effects after in vivo implantation need to be addressed.

3.1.2.4. Electrostatic cell seeding

The material properties of vascular grafts also play a crucial role in successful endothelialization processing. For example, synthetic grafts such as e-PTFE are highly negatively charged [179]. The surfaces of ECs and platelets are also negatively charged [180]. Thus, ECs must overcome the repulsive force present between the material and cell interface for successful cell attachment. To overcome this challenge, various research groups have evaluated the effects of a range of ECM protein coatings on the graft lumen for successful cell adhesion [144, 163]. However, these coatings create a risk of platelet adhesion and activation if the EC layer becomes damaged during or after implantation.

Electrostatic cell seeding temporarily alters the electrical charge of the graft lumen to enhance cell attachment. For example, e-PTFE is dielectric. When the graft is attached to a capacitor, negatively charged nuclei (electrons) of dielectric (graft) material are attracted toward the surface of the capacitor, temporarily imposing a positively charged lumen surface [154]. This temporary positive charge facilitates EC attachment. It is important to remember that the graft is made up of insulating material, so there is no electric current passing from graft to capacitor. When the graft is removed from the capacitor, the negative charge returns to the e-PTFE surface. After implantation, this negatively charged surface prevents platelet adhesion and contributes to graft patency if the EC layer becomes damaged.

In summary, small diameter vascular grafts are especially vulnerable to occlusion. They must be engineered with favorable surface properties to avoid thrombogenesis [181]. Endothelialization and chemical stability have been shown to be the most important factors controlling the thrombosis property [182]. As ECs form the interface between blood and tissues, the presence of a confluent EC monolayer in a vascular graft can inhibit the bioactive substances responsible for SMC migration and proliferation and their production of ECM, and thus improve thromboresistance and reduce intimal hyperplasia. However, innovative approaches are needed to improve the limited capacity of ECs to re-endothelialize. In the absence of a confluent endothelium, surface treatments have the potential to improve thrombosis resistance of small diameter grafts [183]. For instance, elastic laminae and modified elastin coatings, or heparin conjugates can control platelet distribution and decrease the degree of platelet activation [184].

3.2. Biological Approaches for Enhancing Cell Recruitment and Retention on TEVGs

Various biological approaches are being developed for successful in vitro and/or in situ recruitment of EPCs and ECs. These include attachment of EPC/EC specific adhesion peptides, growth factors, and EPC/EC capturing antibodies for enhanced endothelialization of the graft lumen. This section will explore the advantages and limitations associated with various biological cell adhesion approaches that have been developed for TEVGs.

3.2.1. Biomimetic peptides

Coating TEVGs with the Arg–Gly–Asp (RGD) peptide is an effective approach to promote EC adhesion and migration [185]. Several research groups have used variants of RGD peptides to enhance endothelialization, including Gly–Arg–Gly–Asp–Ser–Pro (GRGDSP) [162], RGD combined with the Pro-His-Ser-Arg-Asn (PHSRN) peptide (a fibronectin associated binding sequence), and RGD combined with the Tyr-Ile-Gly-Ser-Arg (YIGSR) peptide (part of the laminin β1 chain) [156]. However, coating the graft lumen with chemically synthesized low molecular weight RGD peptides has some limitations. For instance, instead of increasing EC adhesion, the RGD peptide can detach from the graft substrate after becoming attached to a cell’s surface via integrin receptors. In order to increase the molecular weight of RGD peptides and their retention capability on the graft lumen, a novel recombinant RGD-containing fusion protein was created by connecting the cellulose-binding domain (CBD) to RGD peptides. This fusion protein was coated on an inner gelatin layer of polyurethane grafts [158] and significantly increased EC retention and reduced platelet adhesion/activation .

Other biomimetic substances, such as the mussel inspired adhesive polydopamine, are being investigated to determine their potential for enhancing endothelialization. A study conducted by Lee et al., found that a polydopamine coating in combination with RGD and YIGSR on decellularized vein matrix promotes EPC differentiation into ECs with enhanced focal adhesions [161]. However, platelet adhesion/activation was not investigated in this study. In order to promote in situ recruitment of EPCs and ECs, a microporous PCL graft coated with fusion proteins containing the mussel adhesive protein (MAP) and RGD peptide was evaluated over four weeks in the rabbit carotid artery [159]. Results showed that the MAP-RGD promoted in situ EPC/EC recruitment with a 66% patency rate. For unknown reasons, the graft endothelialized prior to implantation was less effective at maintaining patency than the graft that was endothelialized in situ [159].

Various studies suggest that stromal cell–derived factor-1α (SDF-1α) plays a major role in the transportation of hematopoietic stem cells from bone marrow to the peripheral blood. It also promotes EPC recruitment into ischemic microenvironments and regulates neoangiogenesis [155, 163]. Thus, SDF-1α can be used to promote TEVG endothelialization. Nanofibrous vascular scaffolds prepared from a PLLA and PCL polymer blend, with the luminal surface coated with heparin and SDF-1α, reduces platelet adhesion and activation. Moreover, the combination of heparin and SDF-1α improved long-term graft patency as well as in situ recruitment of EPCs and smooth muscle progenitor cells (SMPCs). The SMPCs differentiated into SMCs, which significantly improved the elastic modulus of the grafts [164].

Currently, peptides/proteins that bind selectively to ECs or EPCs are being developed to allow highly specific cell recruitment for endothelialization with minimal risk of platelet adhesion and activation side-effects. The basement membrane that separates ECs and SMCs in arteries contains a high collagen type IV content. Trimeric peptides found with high redundancy in human collagen type IV were screened using peptide array based cell adhesion effects [186]. By comparing results between EC and SMC adhesion using cysteine-alanine-glycine (CAG) peptides, it was found that CAG has a high affinity for ECs with minimal cross-reactivity for SMCs [160]. Small caliber PCL grafts containing the CAG peptide sequence, incorporated by blending the CAG peptide with the polymer during electrospinning, experience a significantly increased endothelialization and eNOS expression after implantation compared to grafts without the CAG peptide. [160]. Hao, D., et al., studied the cell recruitment potential for the LXW7 ligand, which specifically binds to the αvβ3 integrin present on the EC/EPC surface. LXW7 is a disulfide cyclic octa-peptide with unnatural amino acids flanking both sides of the main functional motif. Due to the presence of unnatural amino acids, it is more resistant to proteolysis in vivo compared to linear and natural amino acid containing peptides. [157]. They found that the LXW7 ligand exhibits very strong binding affinity toward ECs/EPCs and weaker binding to platelets compared to the conventional GRGD ligand for αvβ3 integrin. Moreover, it promotes cellular proliferation, possibly due to activation of VEGFR2 and the MAPK pathway [157]. These EPC/EC specific proteins/peptide sequences can significantly improve the rate of endothelialization in vitro and/or after graft implantation.

3.2.2. Growth factors

VEGF and bFGF are known regulators of angiogenesis, vascular growth, and blood vessel maturation. VEGF in particular is a potent mitogen and chemoattractant for ECs [187]. Thus, it is a good promoter for TEVG endothelialization [188]. Decellularized carotid arteries can be coated with VEGF and heparin [173]. This modified graft can sustainably release VEGF up to 20 days and promotes complete endothelialization within 6 months of implantation. Moreover, they showed significantly reduced neointimal hyperplasia and increased patency compared to unmodified grafts following in vivo implantation [173]. In addition to decellularized scaffolds, nanofiberous scaffolds coated with VEGF and heparin exhibited anticoagulation properties and enhanced EPC growth in vitro [169].

PDGF plays a critical role in the recruitment of pericytes and smooth muscle cells, which stabilizes blood vessels [172]. Multilayer electrospun nanofibrous scaffolds with an inner layer of poly(ethylene glycol)-b-poly(Llactide-co-ε-caprolactone) (PELCL) along with gelatin and VEGF, a middle layer containing poly(L-lactide-co-glycolide) (PLGA) along with gelatin and PDGF and an outer layer containing poly(ε-caprolactone) (PCL) enhances recruitment of vascular ECs and SMCs. Release of VEGF and PDGF increases endothelialization and inhibits SMC hyperproliferation, with enhanced patency over 8 weeks [170]. The crosslinking process to conjugate various growth factors depends on the type of scaffold (i.e. synthetic grafts, decellularized scaffolds, and electrospun scaffolds), and details can be found in articles cited for each graft type.

In addition to growth factor coatings, plasmids encoding genes of specific growth factors can be incorporated into the graft lumen. Lahtinen, M., et al., developed this novel approach for vascular graft endothelialization via incorporation of plasmids encoding the human VEGF165 and FGF-2 genes into the lumen of ePTFE and pre-clotted polyester grafts [171]. They found that the VEGF165 plasmid improves graft endothelialization while combined FGF-2 and VEGF165 plasmids reduce graft endothelialization. They also found that VEGF165 plasmid incorporation into pre-clotted polyester grafts increases endothelialization and patency relative to ePTFE grafts [171].

3.2.3. Antibody coating

Antibodies can specifically target and recruit ECs / EPCs on the graft lumen by engaging with specific surface antigens or receptors. For example, several studies have reported that coating cardiovascular stents with anti-CD34 antibodies enhances in situ recruitment, adhesion, and proliferation of ECs and circulating EPCs [189]. Similarly, ePTFE graft lumens can be coated with anti-CD34 antibodies using peptide linkages for faster endothelialization and enhanced patency [168]. After 28 days of implantation into pig models, 85% of the graft surface was covered with an EC layer compared to 32% EC coverage in non-coated grafts. However, despite a promising endothelialization, anti-CD34 antibody coated grafts evoke an excessive intimal hyperplasia at the anastomoses [168]. Similarly, another study showed that anti-CD34-coating significantly increases platelet adhesion along with protein adsorption, compared to non-coated grafts [167].