Abstract

This paper proposes a robustness analysis based on Multiple Criteria Decision Aiding (MCDA). The ensuing model was used to assess the implementation of green chemistry principles in the synthesis of silver nanoparticles. Its recommendations were also compared to an earlier developed model for the same purpose to investigate concordance between the models and potential decision support synergies. A three-phase procedure was adopted to achieve the research objectives. Firstly, an ordinal ranking of the evaluation criteria used to characterize the implementation of green chemistry principles was identified through relative ranking analysis. Secondly, a structured selection process for an MCDA classification method was conducted, which ensued in the identification of Stochastic Multi-Criteria Acceptability Analysis (SMAA). Lastly, the agreement of the classifications by the two MCDA models and the resulting synergistic role of decision recommendations were studied. This comparison showed that the results of the two models agree between 76% and 93% of the simulation set-ups and it confirmed that different MCDA models provide a more inclusive and transparent set of recommendations. This integrative research confirmed the beneficial complementary use of MCDA methods to aid responsible development of nanosynthesis, by accounting for multiple objectives and helping communication of complex information in a comprehensive and traceable format, suitable for stakeholders and/or decision-makers with diverse backgrounds.

Keywords: Multiple Criteria Decision Aiding, Robustness analysis, Green nanotechnology, Dominance-based Rough Set Approach, ELECTRE

Graphical abstract

1. Introduction

The comprehensive assessment of the implementation of green chemistry principles (GCP) during nanosynthesis processes is a complex decision-making problem, requiring the consideration of multiple evaluation parameters. The authors have recently proposed a model to provide a preliminary solution to this challenge (Cinelli et al., 2015) as well as a holistic set of criteria for the sustainability appraisal of nanoproducts (Cinelli et al., 2016). However, the credibility of sustainability-oriented assessments relies on the robustness of the results they provide to the Decision-Makers (DMs) (Sala et al., 2015). In order to achieve credible and sound decision support, the uncertainties inherent in these evaluations as well as the resulting modelling strategies need to be accounted for (Dias et al., 2012). This paper proposes a methodology that considers these requirements by employing a decision support method from the Multiple Criteria Decision Aiding (MCDA) research domain.

Nanomaterials can be produced via different techniques and the bio-inspired approaches are receiving surging interest from the scientific community for the possibility of implementing GCP (Gilbertson et al., 2015, Mata et al., 2015, Varma, 2014). The evaluation of how green synthesis processes are for nanomaterials is a challenging task, due to the limited information available on the specific operating conditions and the impacts associated with the employed materials (Feijoo et al., 2017, Meyer and Upadhyayula, 2014). Some studies have assessed the environmental impacts of nanomaterials synthesis with life cycle assessment (LCA), though the main limitation is that data are currently lacking or are of low quality to assess the implications of synthesis processes for nanomaterials with quantitative methods, especially those which are based on bio-inspired approaches (Pati et al., 2014, Pourzahedi and Eckelman, 2015). Nonetheless, qualitative and semi-quantitative information is available on the types of employed materials, operational conditions, equipment typologies and products’ performance. MCDA methods have been confirmed as excellent candidates to handle heterogeneous information and uncertainties and provide intelligible comprehensive evaluations of comparable materials, processes and technologies (Cinelli et al., 2014, Singh et al., 2012).

So far nanomaterials have been produced through the “bio-inspired” route with bacteria, fungi, plants, plants extracts, yeasts and algae and the literature is steadily growing in this domain (Stark et al., 2015, Varma, 2016, Virkutyte and Varma, 2013). However, limited research efforts were devoted to understand how “green” they are and assess the implementation of GCP in bio-inspired nanosynthesis processes in the form of a performance class (e.g. “green” nano) (Bergeson, 2013, Duan et al., 2015, Matus et al., 2011). Such research gap is an important limitation for practitioners who aim at complying with demands for green nanomaterials and associated synthesis processes, especially for those that do not yet allow quantitative assessments employing LCA, for example. This article contributes to this topic by developing an MCDA model that can support such type of evaluations and should not be seen as a tool in substitution for quantitative methods but rather as a decision aid instrument that can help chemists and engineers in reflecting on the implications of their choices during the development of new materials and products.

The challenge of assessing the “greenness” of nanosynthesis processes fits with the MCDA methodology, and the authors of this paper previously developed another MCDA model based on Dominance-based Rough Set Approach (DRSA) for the classification of synthesis processes of silver nanoparticles depending on the GCP implementation (Cinelli et al., 2015). The DRSA-based model is a notable contribution for the chemists’ and nanosynthesis’ communities because it shows how the MCDA process and one of its methods can be used through an intelligible approach for preferences elicitation, by posing limited burden on the DMs and obtaining condensed and intelligible representation of their knowledge in the form of decision rules. It can help screening “greenness” of new or existing processes by supplying quality classes on a five-level scale and justify the decision recommendation (i.e. classification) with easily intelligible “if condition, then decision” rules. However, the robustness of its recommendations must be verified in the form of its validity and stability according to a compatible set of modelling constraints (Bouyssou et al., 2006).

This paper presents a robustness analysis structured upon the MCDA process. The objective was achieved by exploiting a subset of criteria for the sustainability assessment of nanoproducts recently published (Cinelli et al., 2016) to develop an MCDA model, based on Stochastic Multi-Criteria Acceptability Analysis (SMAA), yielding uncertainty-characterized robust findings, which were compared with the classifications of the DRSA-based model.

This paper has two main objectives:

Describe the development and application of an MCDA model (ELECTRE-based (Figueira et al., 2005)) for the assessment of implementation of GCP in synthetic processes for silver nanoparticles;

Use its decision recommendations to evaluate the correspondence with the DRSA-based model described in (Cinelli et al., 2015) and study the potential decision support synergies.

The paper presents the methodology that was developed to conduct the robustness analysis (Section 2), and then describes its results with the main learning insights that MCDA empowers when supporting sustainability-oriented assessments (Section 3); tangible conclusions are summarized in Section 4.

2. Methodology

The decision-making challenge tackled in this case study is a classification problem. Considering that provision of decision recommendations in the form of a quality class is one of the main reasons why MCDA has been developed and excels (Cinelli et al., 2014, Roy and Słowiński, 2013), it was employed in this research project to advance a relevant classification model. This case study builds upon the decision-making problem described in the aforementioned previous study and the reader is referred to that article for details on its context (Cinelli et al., 2015).

The justification for the use of MCDA is supported by its capacities of effectively meeting three main challenges that hamper the assessment of the “greenness” of nanosynthesis processes, including (i) the need to account for performance criteria of different type (e.g. quantitative, qualitative, fuzzy) (Eason et al., 2011, Mata et al., 2015), (ii) high uncertainty in input dataset (Mata et al., 2015, Meyer and Upadhyayula, 2014, Pourzahedi et al., 2017), and (iii) limited capabilities of conventional tools to provide a comprehensive and easily interpretable evaluation of each process (Bates et al., 2015, Eason et al., 2011).

The model presented in this paper (i.e. ELECTRE-based model) provides classifications for a set of test synthesis processes as those considered in (Cinelli et al., 2015), which can be defined as robust following the definition proposed by Dias and Climaco (2000). Robustness analysis consists in assessing how robust conclusions are when a precise combination of the parameters (e.g. weights, thresholds) of the model is not imposed. This type of analysis leads to survey all the possible recommendations that are compatible with such modelling constraints. According to the grouping of robustness analysis forms proposed by Dias (2007), the one adopted in this case is the ex-post, because the research goal consists in assessing the stability of the recommendations according to a pre-defined set of compatible models. These models derive from the consideration of imprecise information, which can be lack of precise user’s preferences and values for the parameters on the input dataset.

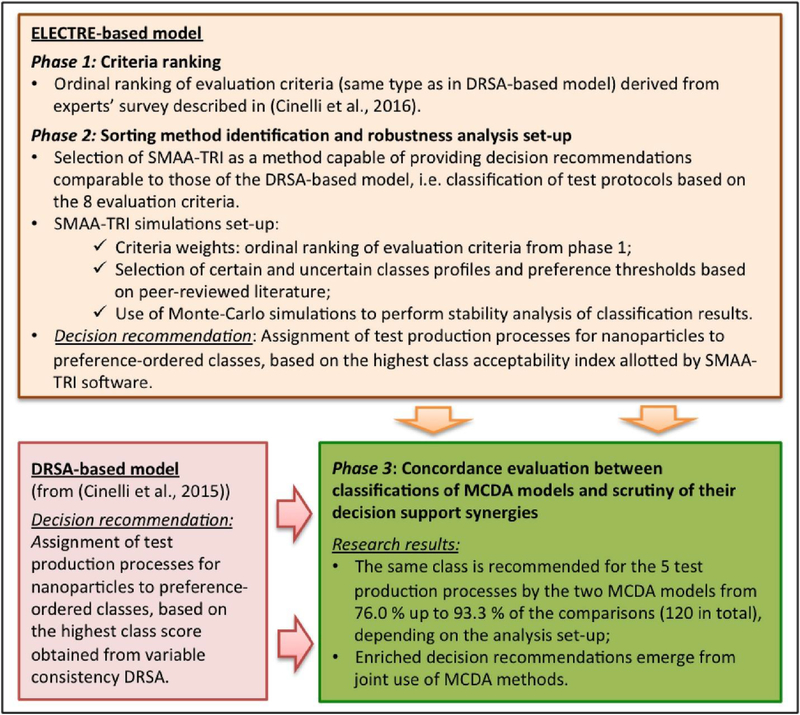

Fig. 1 summarizes the procedure proposed to develop the ELECTRE-based model and compare its results with the DRSA-based model. It incorporates the elaboration of the relative ranking of performance criteria from (Cinelli et al., 2016) (phase 1), the selection process for the suitable sorting method as well as the modelling used to obtain comparable classifications for the test protocols (phase 2), and the strategy used to assess the agreement between recommendations of the two models (phase 3).

Fig. 1.

Procedure of robustness analysis, summary of concordance between models recommendation and synergies of decision support.

2.1. Identification of alternatives and evaluation criteria

The alternatives used in this MCDA problem are “silver nanoparticle synthesis protocols based on bottom-up approaches that use reducing and capping agents to convert a silver salt to silver nanoparticles”. Eight evaluation criteria (gj) were selected and are shown in Table 1, together with the numerical coding of their scales and preference direction. They all have ordinal (i.e. qualitative) scales with the exception of criteria g5 and g6, which have a cardinal (i.e. quantitative) scale.

Table 1.

Criteria selected for evaluation of synthesis protocols, including coding and rationale for preference direction (the arrow ‘up’ means that the higher its rank on the list of possible values, the better it is, and the arrow ‘down’ says the opposite) (adapted from (Cinelli et al., 2015)).

| Criterion | Criterion values | Code | Preference order of the values |

|---|---|---|---|

| g1 = Reducing agent | Renewable – waste | 4 | ↑ |

| Renewable – primary | 3 | ||

| Biodegradable polymer | 2 | ||

| Synthetic | 1 | ||

| g2 = Capping agent | Not needed | 5 | ↑ |

| Renewable – waste | 4 | ||

| Renewable – primary | 3 | ||

| Biodegradable polymer | 2 | ||

| Synthetic | 1 | ||

| g3 = Solvent | Renewable – waste | 4 | ↑ |

| Renewable – primary | 3 | ||

| Biodegradable polymer | 2 | ||

| Synthetic | 1 | ||

| g4 = Local resources use | Yes | 1 | ↑ |

| No | 0 | ||

| g5 = Reaction time | In seconds | integer | ↓ |

| g6 = Reaction temperature | In Celsius | integer | ↓ |

| g7 = Equipment type | Static | 8 | ↑ |

| Stirring for at most 5 min | 7 | ||

| Stirring | 6 | ||

| Microwave – sealed vessel (≤300 W) | 5 | ||

| Microwave – sealed vessel (>300 W) | 4 | ||

| Microwave – open vessel | 3 | ||

| Conventional (oil bath, steam bath) | 2 | ||

| Not reported | 1 | ||

| g8 = Particles size range | 0 ≤ particle size ≤ 30 nm | 1 | ↓ |

| 0 ≤ particle size ≤ 60 nm | 2 | ||

| 30 < particle size ≤ 60 nm | 3 | ||

| 0 < particle size ≤ 100 nm | 4 | ||

| 60 < particle size ≤ 100 nm | 5 |

Table 2 shows the five synthesis protocols (t1–5) that were used as test dataset, which are the same as those employed in the DRSA-based model (Cinelli et al., 2015).

Table 2.

Test protocols used to show decision support capabilities of MCDA models (from (Cinelli et al., 2015)).

| Test protocol | g1 | g2 | g3 | g4 | g5 | g6 | g7 | g8 | Quality class (C1 < C2 < C3 < C4 < C5) |

|---|---|---|---|---|---|---|---|---|---|

| Reducing agent code | Capping agent code | Solvent code | Local resource use code | Reaction time (seconds) | Temperature (Celsius) | Equipment type code | Size range code | ||

| t1 | 3 | 5 | 3 | 0 | 55 | 42 | 5 | 1 | ? |

| t2 | 3 | 2 | 1 | 1 | 2500 | 85 | 2 | 2 | ? |

| t3 | 2 | 2 | 3 | 0 | 600 | 90 | 2 | 3 | ? |

| t4 | 3 | 3 | 3 | 0 | 70 | 65 | 5 | 1 | ? |

| t5 | 1 | 1 | 1 | 0 | 480 | 100 | 3 | 1 | ? |

2.2. Criteria weights

The first phase of the robustness analysis procedure (see Fig. 1) was inspired by the framework of sustainability evaluation criteria proposed in a recent paper in this journal, ranked according to their relative importance (Cinelli et al., 2016). A correspondence between a subset of such criteria and the evaluation criteria used in this case study could be derived, as shown in Table 3 and their ranking was used as preference information for ELECTRE-based model construction. Similar approaches emerged in comparable research contexts, where rankings of criteria based on experts’ survey were used as preference information to develop MCDA models (Akadiri and Olomolaiye, 2012, Tobiszewski and Orłowski, 2015).

Table 3.

Relative ranking of criteria (Cinelli et al., 2016) and correspondence with those employed in MCDA models.

| Criteria from experts' survey and relative ranking | Correspondent evaluation criteria in the MCDA models | |

|---|---|---|

| 1 | Functionality | Particle size range |

| 2 | Hazardous materials used or produced | Reducing agent/Capping agent/Solvent |

| 3 | Use of renewable resources | Reducing agent/Capping agent/Solvent |

| 4 | Energy efficiency | Equipment type |

| 5 | Energy consumption | Equipment type |

| 6 | Use of raw materials | Reducing agent/Capping agent/Solvent |

| 7 | Local resources use | Local resources use |

| 8 | Processing conditions | Reaction time |

| Reaction temperature | ||

Multiple correspondences between the criteria in the survey and the ELECTRE-based model indicate that various combinations of criteria priorities are possible (Table 3). As far as the MCDA models are concerned, the possible correspondence between criteria from the survey is that “Hazardous materials used or produced” (2nd rank), “Use of renewable resources” (3rd rank) and “Use of raw materials” (6th rank) can be represented by reducing agent (g1), capping agent (g2) and solvent (g3). “Energy efficiency” (4th rank) and “Energy consumption” (5th rank) are represented by the criterion equipment type (g7). Consequently, the 2nd, 3rd and 5th positions in the MCDA models (right column in Table 3) can be taken either by g1, g2 and g3, whereas the fourth position is always assigned to g7. These conditions lead to the following modelling constraints. Three criteria (i.e. g1, g2 and g3) can take their rank either in 2nd, 3rd or 5th position. There can be six permutations in place (three criteria * two positions to vary) and thus the overall set of possible rankings to consider is six. Such permutations are conducted for the five test protocols, which for each modelling set leads to 30 classifications. What is more, reaction time (g5) and reaction temperature (g6) can be allotted to rank 7th and 8th and vice-versa, which doubles the number of classifications to 60 (see also details in Section 2.3, “Accounting for uncertainty in the analysis”).

2.3. Sorting method selection and robustness analysis set-up

The decision recommendation provided by the DRSA-based model is a suggestion of classification of a protocol that results from inductive learning on the comprehensive evaluation of a set of reference protocols. This implies the evaluation of the robustness of its recommendation required a tool capable of providing a suitable result to which it could be compared (second phase of the robustness analysis procedure, Fig. 1). MCDA is ideal for aggregating information and providing a classification or ranking of the alternatives under evaluation (Cinelli et al., 2014, Domingues et al., 2015, Tervonen et al., 2009b), consequently the development of the new model was grounded on an MCDA method, with the following requirements driving its selection:

Need for enforcement of strong sustainability, so that limited compensation between criteria is guaranteed;

Independence of criteria weights from their evaluation scales. This is due to the nature of the importance of the criteria, which represent their relative importance and not the trade-offs between their measurement scales (details about weights typology is available in (Cinelli et al., 2014));

Decision recommendations (i.e. classes assignment) must be robust. The MCDA approach needs to investigate the possible changes in results by accounting for the uncertainty of input parameters, in this case weights and class profiles;

Most of the evaluation criteria (six out of the eight) are expressed on an ordinal scale, with two on a cardinal one. MCDA method, thus, has to be tailored for this typology.

An assessment of the MCDA methods available in the literature (drawing from the findings presented in (Cinelli et al., 2014, Ibáñez-Forés et al., 2014, Munda, 2016, Rowley et al., 2012) in relation to the requirements listed above lead to the identification of SMAA method (Tervonen et al., 2009a) as a relevant candidate to confront the research challenge. In this case, SMAA-TRI was selected as it is an MCDA classification method based on ELECTRE-TRI, with the added capability of using imprecise measurements values, thresholds, weights and class profiles, so that robust decision recommendations can be achieved through parameter stability analysis (Tervonen and Lahdelma, 2007).

The main differences this research introduces compared with previous studies dealing with evaluation of nanosynthesis processes based on sustainability metrics (Canis et al., 2010, Naidu et al., 2008), are that in this case:

The aim of the evaluation is to classify the processes rather than to rank them;

Real preference information is employed as data input;

The focus of the approach is on the synthesis of silver nanoparticles based on techniques which have been frequently labelled as green and more sustainable (Changseok et al., 2013, Dahl et al., 2007, Dubey et al., 2010, Hebbalalu et al., 2013, Karn, 2008, Karn and Wong, 2013, Kavitha et al., 2013, Kaviya et al., 2011, Kou et al., 2013, Luque, 2013, Matus et al., 2011, Patete et al., 2011, Pati et al., 2014, Senjen, 2009, Varma, 2014, Virkutyte and Varma, 2013).

For the sake of simplicity the multiple models developed for the RA based on SMAA-TRI will be termed “ELECTRE-based model.”

2.3.1. Class profiles and thresholds

The aim of the decision-aiding model is to classify synthesis protocols in preference-ordered classes, based on the implementation of the GCP and the technical performance, represented by the size range of the nanoparticles.

Five classes (C1 < C2 < C3 < C4 < C5) were devised by accounting for the nature of the data, as well as the arbitrariness that is inherent in the coding of the criteria values (Table 1):

C1 = GCP are completely overlooked;

C2 = limited implementation of GCP and/or satisfaction of quality requirements;

C3 = partial fulfilment of GCP and potentials for quality improvements;

C4 = performance standards are satisfied and many GCP are implemented;

C5 = the process is very good both from a green chemistry and technical perspective.

This set of classes was used to screen synthesis processes in terms of how “green” they are, by integrating the information conveyed by the eight evaluation criteria through the outranking method SMAA-TRI. C4 and C5 represent the processes with high potentials, where various GCP are implemented. On the other hand, processes assigned to C1 and C2 are those that require thorough considerations about the worthiness of such approaches and need improvement work to increase their “greenness”.

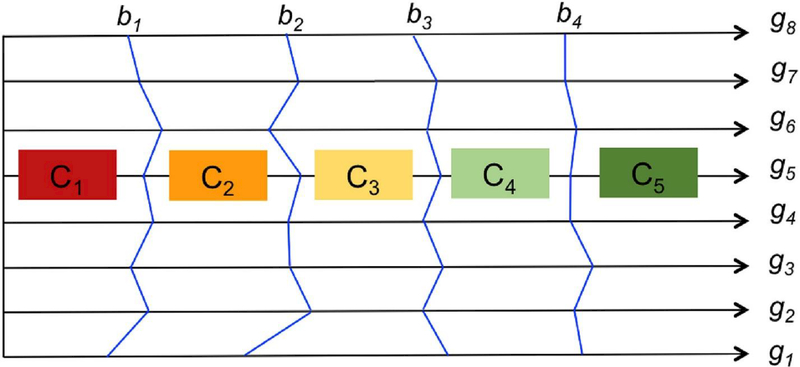

Every performance class C (C ε {1,2,3,4,5}) in SMAA-TRI is delimited by a profile bh(see Fig. 2), so that each of them has a certain discriminatory value for every criterion gj. bj is worse than bj+1 on all criteria.

Fig. 2.

Examples of class profiles (bh) for each criterion gj (Adapted from (Merad et al., 2004)).

The selection of the values of the profiles for the criteria was based on analysis of production strategies reported in the literature. Table 4 shows a summary of the selected profiles values and Appendix A in Electronic Supplementary Information (ESI) provides the scientific rationale on selection of such figures.

Table 4.

Class profiles, thresholds and preferences directions for criteria used in SMAA-TRI (*: the numbers within brackets indicate the code used for the value of each criterion).

| Class profiles | g1 | g2 | g3 | g4 | g5 | g6 | g7 | g8 | |

|---|---|---|---|---|---|---|---|---|---|

| Reducing agent code | Capping agent code | Solvent code | Local resource use code | Reaction time (seconds) | Temperature (Celsius) | Equipment type code | Size range code | ||

| Case A: Certain | b4 = C5 − C4 | Renewable – primary (3*) | Renewable – waste (4) | Renewable – primary (3) | Yes (1) | 50 | 30 | Stirring ≤ 5 min (7) | 0 ≤ particle size ≤ 30 nm (1) |

| b3 = C4 − C3 | Renewable – primary (3) | Renewable – primary (3) | Renewable – primary (3) | Yes (1) | 100 | 40 | Stirring (6) | 0 ≤ particle size ≤ 60 nm (2) | |

| b2 = C3 − C2 | Biodegradable polymer (2) | Renewable – primary (3) | Biodegradable polymer (2) | No (0) | 400 | 60 | Microwave – sealed vessel (>300 W) (4) | 30 < particle size ≤ 60 nm (3) | |

| b1 = C2 − C1 | Synthetic (1) | Biodegradable polymer (2) | Synthetic (1) | No (0) | 1500 | 95 | Conventional (2) | 0 < particle size ≤ 100 nm (4) | |

| Case B: Uncertain | b4 = C5 − C4 | 3.0–3.5 | 4.0–4.5 | 3.0–3.5 | 1 | 35–75 | 25–35 | 5–7 | 1 |

| b3 = C4 − C3 | 2.5–3.0 | 3.5–4.0 | 2.5–3.0 | 1 | 75–125 | 35–50 | 4–5 | 2 | |

| b2 = C3 − C2 | 2.0–2.5 | 3.0–3.5 | 2.0–2.5 | 0 | 125–675 | 50–80 | 3–4 | 3 | |

| b1 = C2 − C1 | 1.0–2.0 | 1.0–3.0 | 1.0–2.0 | 0 | 675–2250 | 80–115 | 2–3 | 4 | |

| Indifference threshold | 0 | 0 | 0 | 0 | 10 | 5 | 0 | 0 | |

| Preference threshold | 1 | 1 | 1 | 0 | 30 | 10 | 1 | 1 | |

| Criterion preference | ↑ | ↑ | ↑ | ↑ | ↓ | ↓ | ↑ | ↓ | |

Elaborate preferences can be accounted for by this MCDA method using two types of thresholds: indifference threshold qj and preference threshold pj. There are currently no guidelines to define such thresholds, however an elaboration of the research considerations reported by relevant authors in the published literature allowed them to be extracted (Table 4). Appendix A in ESI provides the scientific details for such values selection.

2.3.2. Classification of synthesis processes

SMAA-TRI operates with an outranking relation approach based on pairwise comparisons of alternatives, which means that the performance of each production process tm on each criterion gj is compared to profile bh to verify whether the synthesis protocol tm is “at least as good as” profile bh. In other words, it is checked if outranking relation tmS bh holds (Dias and Mousseau, 2003). This leads to the calculation of credibility index ρ for the outranking relations tmS bh (see Appendix B in ESI for details on the SMAA-TRI procedure).

ρ represents the credibility of outranking of each production protocol over the class profile. It is used to make a recommendation of the assignment of production protocols to classes.

SMAA-TRI operates a high number of simulations (i.e. 10,000), sampling at each run a set of weights (case I below) as well as class profiles (case II below) from a uniform probability distribution (Tervonen and Lahdelma, 2007). The final results are Class Acceptability Indices (CAI), which indicate the share of possible parameters (expressed as a percentage) that lead a protocol to be assigned to each class Ch(Tervonen and Lahdelma, 2007). CAI is an intelligible tool that conveys the stability of the input information, providing robust conclusions despite having incomplete information. The higher the score for a class, the higher the confidence for such class. The range of this index is between 0 and 1, with 0 indicating that the process will never be assigned to the specific class whereas 1 denoting that the process will be assigned to the target class with every combination of uncertain input values.

2.3.3. Weighting

SMAA-TRI uses weights as intrinsic measures of importance of each criterion so that the value of the weight is independent from the evaluation scale of each criterion (Figueira et al., 2005). There are various strategies that can be used to assign weight values to the criteria in outranking methods (Figueira et al., 2005) and the approach selected in this case benefits from part of the results described in Section 2.2, where the criteria priorities obtained from the survey questionnaire allow defining an ordinal ranking of such criteria, which can actually be used in SMAA-TRI. The novel contribution to the research area consists in the use of a method that does not depend on the opinions of two specific experts, uses parsimonious information about preferences (i.e. ordinal ranks) and supplies robust conclusions.

In order to account for an even broader uncertainty in weighting, SMAA-TRI was also run without any preference information on the weights (i.e. missing weights option). The results are summarized in Appendix H in ESI and do not deviate considerably from the ones presented and discussed in Section 3.

2.3.4. Accounting for uncertainty in the analysis

Two types of uncertainty had to be treated in the construction of the ELECTRE-based model: (i) selection of criteria weights; and (ii) definition of discriminatory profiles between the quality classes. Consequently, two modelling layouts were defined in this model to consider such uncertainties.

2.3.4.1. Case I: certain class profiles

The first modelling set-up with SMAA-TRI considered only the uncertainty in the weighting procedure. As described in Section 2.2, the weights of the criteria were based on an ordinal ranking, which did not impose a specific value for each of the weights. Furthermore, priorities of the criteria had to be varied as well, due to the multiple correspondences between them and those from the survey (see Table 3).

2.3.4.2. Case II: uncertain class profiles

The second set-up of the SMAA-TRI model included the previous type of uncertainty and also the one related to the values for the class profiles. This decision accounted for the fact that the profiles of the classes adopted for the discernment of quality of synthesis processes were selected from a range of possible values. Even though their appointment was based on the published literature as discussed above and in Appendix A in ESI, expert judgment was adopted to choose the individual discriminatory values (see Table 4 for the selected uncertain profiles values). This represents a second type of uncertainty that was considered in the model, together with the variability of the criteria weights, as in the previous case.

3. Results and discussion

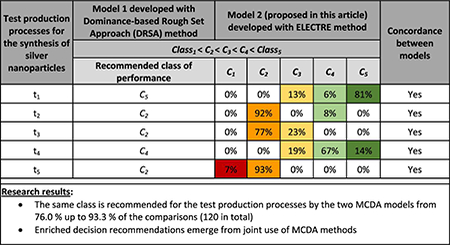

A robustness analysis of nanosynthesis test processes was conducted by means of SMAA-TRI through several simulations set-up settings, which included certain (i.e. case I) and uncertain (i.e. case II) class profiles with criteria in different importance ranks according to the combinations explained in Section 2.2.

The same five test protocols (see Table 2) used to show the applicability of DRSA-based model were employed to examine the decision support synergies with the ELECTRE-based model and also the decision recommendation (i.e. classification) agreement of the two models (third phase of the robustness analysis, Fig. 1). In addition, no veto threshold for any criteria was applied considering the lack of such type of information in the relevant literature, which means that only concordance indexes contributed to the calculation of the credibility indices. Such an approach is in line with a comparable case study application in the area of risk assessment of nanomaterials (Tervonen et al., 2009b). Lastly, the λ-cutting level range was [0.65;0.85], the recommended and sensible interval to be used for the ELECTRE-TRI method as it considers the cases for a simple (though strong, i.e. 65% of criteria weights) as well as above two-thirds criteria majority (Domingues et al., 2015, Tervonen et al., 2009b).

A summary of the RA outcomes is provided in Table 5, whereas the detailed results are reported in Appendices C–F in ESI. In each case, six different combinations of the materials type criteria were tested with SMAA-TRI, which leads to a total of 30 agreement comparisons between the two models. Moreover, a distinction between certain (case I) and uncertain profiles (case II) was applied. In Appendices C and D, reaction time (g5) was kept as the second-to-last (7th rank) and reaction temperature (g6) was the last one (8th rank) whereas the setting was the opposite (7th rank for reaction temperature and 8th rank for reaction time) in Appendices E and F. The overall modelling sets amount to four as the models were run with certain and uncertain profiles, combined with reaction time in 7th rank and reaction temperature in 8th rank and vice-versa. This led to a 120 comparisons on the whole.

Table 5.

Class recommendation agreement (in % and ratio) between the MCDA models, based on class with highest CAI. (+/− = higher or lower SMAA-TRI classes compared to DRSA-based model).

| Criteria ranking | Appendix | Case I: Certain class profiles | Appendix | Case II: Uncertain class profiles case |

|---|---|---|---|---|

| 7th rank for reaction time (g5) and 8th rank for reaction temperature (g6) | C | 93.3% (28/30 protocols) | D | 86.0% (26/30 protocols) |

| +1 class in 2 cases: protocol t3 | −1 class in 4 cases: protocol t5 | |||

| 7th rank for reaction temperature (g6) and 8th rank for reaction time (g5) | E | 86.0% (26/30 protocols) | F | 76.0% (23/30 protocols) |

| +1 class in 2 cases: protocol t3 +1 class in 2 cases: protocol t4 |

−1 class in 4 cases: protocol t5 2 cases of same index for two classes: protocol t5 1 case of same index for two classes: protocol t4 |

The overall correspondence was just under 86%, a satisfactory value for such a different application of MCDA (Dimitras et al., 1999, Słowiński et al., 1997). In all the comparisons it can be seen that there is a high to very high correspondence between decision recommendations of the two MCDA models, with values up to 93.3% (i.e., the same class recommended for 28 out of 30 protocols). The lowest agreement (76.0%) is reached in the case of uncertain class profiles with reaction temperature in 7th rank and reaction time in 8th rank, still an acceptable concordance level in this case as well (Dimitras et al., 1999, Słowiński et al., 1997).

Most of the disagreement between the models (14 out of 17 discordance cases) involves protocols t3 and t5. As far as t3 is concerned, the reason is that the protocol employs a renewable primary material as a solvent, which is considered as good from a green chemistry perspective. When the solvent is placed at a high position in the ordinal ranking, its relative weight increases, which overall determines a higher assignment to class 3 (medium) rather than 2 (low) as DRSA does. In the case of t5, the reason is that the process uses a synthetic capping agent, the worst condition from the green chemistry perspective. In fact, a synthetic material should be the least preferred choice and the capping agent can be eliminated if a multifunctional reducing agent is used. For this reason, C5 (very low) receives a lot of CAI share from SMAA-TRI, especially when the capping agent has a high ordinal rank and thus it has a higher weight.

The comprehensibility of the justifications “behind” the decision recommendation is an important feature of MCDA models as it can increase their transparency to non-experts in MCDA who are interested in understanding why an alternative receives a certain evaluation while others do not. More specifically, transparency is essential to avoid the model being perceived as a “black box” (Słowiński et al., 2009). Furthermore, the combined use of MCDA methods working with different methodological foundations can enhance the credibility of the recommendations; these detailed considerations are elaborated in the remaining of this section.

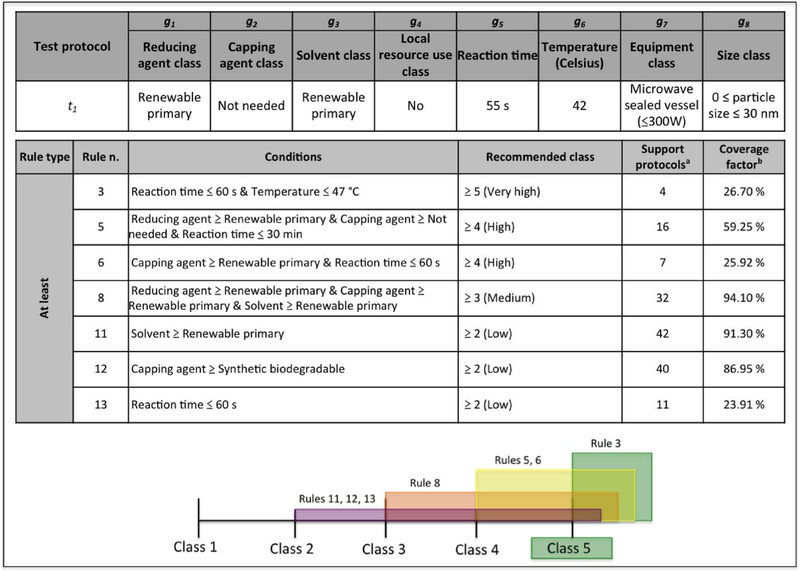

In the case of t1, the DRSA-based model provides a recommendation that is supported by the decision rules 3, 5, 6, 8, 11, 12, 13 (see Scheme 1 for explanation of rules). These rules point out important characteristics of green chemistry protocols, including the possibility of producing nanoparticles within short timeframes and under milder temperatures (rule 3, 13) in combination with the use of a renewable capping agent or the adoption of multifunctional renewable materials that eliminate the need for a capping agent in the process (rule 5, 6). This is coupled with the possibility of using benign solvents such as water (rule 8, 11). These set-ups lead to fulfilment of several GCP, including reduction in hazardousness of chemical synthesis, prevention of waste and reduction of derivatives, use of safer solvents and inherently safer chemistry (e.g. closed vessels and low power). The decision recommendations provided by the DRSA-based model can be easily traced back to the protocols that applied these principles and that form the basis of the decision rules.

Scheme 1.

Performance of test protocol t1, matching rules from DRSA-based model and recommendation of performance class based on standard classification scheme (a = number of protocols that support the rule; b = percentage of protocols that satisfy the conditions of the rule and are assigned to the class or union of classes) (adapted from (Cinelli et al., 2015)).

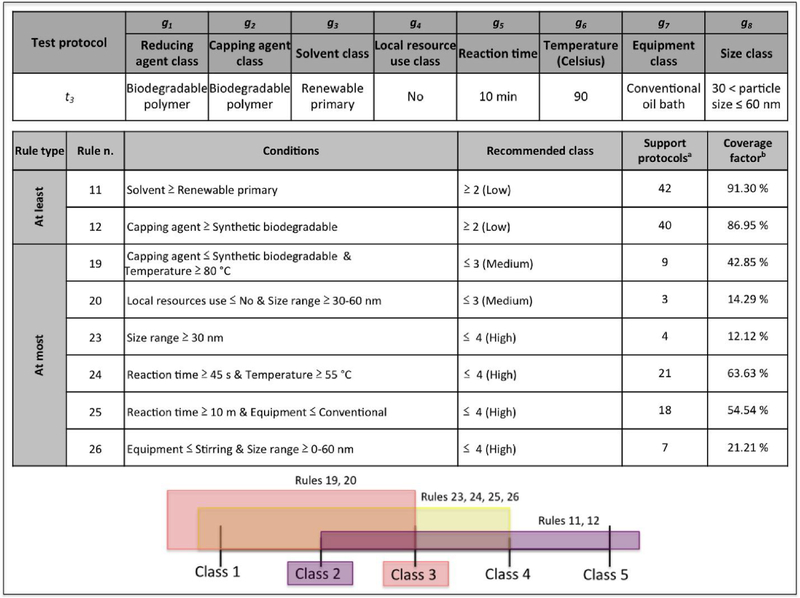

The example for t3 leads to other considerations as the matching rules are 11, 12, 19, 20, 23, 24, 25, 26 (see Scheme 2 for explanation of rules). The learning process in this case is more elaborate as there are both types of rules involved, “at least” and “at most.” As far as the “at least” rules are concerned (i.e. 11, 12), the DRSA-based model indicates a potentially at least low performance based on the use of a renewable primary material as a solvent and a bio-polymer as a capping agent instead of synthetic chemicals. On the other hand, the other types of rules (i.e. at most) are indicative of several concerns. Firstly, the use of a rather high temperature (80 °C) and the selection of a capping agent at most bio-polymer (rule 19) in addition to the use of non-local resources as well as producing lower quality particles (between 30 and 60 nm size) (rule 20) suggest a maximum assignment to medium class. This is complemented by the use of a conventional heating technique that requires rather long reaction times (10 min in this case) (rule 25), not desirable when looking at the process from the green chemistry perspective (Gilbertson et al., 2015). The intersection of the rules following the standard DRSA procedure would suggest a low or medium class as a decision recommendation, whereas the more elaborate approach provides the low class as an assignment.

Scheme 2.

Performance of test protocol t3, matching rules from DRSA-based model and recommendation of performance class based on standard classification scheme (a = number of protocols that support the rule; b = percentage of protocols that satisfy the conditions of the rule and are assigned to the class or union of classes) (adapted from (Cinelli et al., 2015)).

These assessment examples show that, from a decision aiding perspective, the recommendation provided by the DRSA-based model is traceable and supported by previous knowledge base that in this case was extracted from the two experts that collaborated during the case study. These rules are a summary of the characteristics of synthesis processes that have already been developed in reality and can thus be used as comparative measures when developing brand new processes or while assessing existing ones.

The ELECTRE-based model provides a different and complementary perspective on each process by accounting for the performance on each criterion and aggregating the information following the procedure presented in Section 2.3 and Appendix B. This means that the decision aiding support is focused on the evaluation of the performance of each protocol for every criterion in respect to a performance profile for each class. Table 6, Table 7 illustrate the scoring on the evaluation criteria for the first (t1) and third (t3) test protocols with respect to every class profile, together with the assigned CAI for each quality class. Process t1 performs well in relation to the class profiles, which explains the high percentage for the very high CAI (i.e. 81%), though there is not a specific indication/explanation about the combined effect of the criteria on the decision recommendation (Table 6). Similarly, when considering process t3 it is evident that the protocol does not perform well on the green chemistry criteria, which explains the reason behind the recommendation mostly for a low performance class (Table 7). In this case, the developer of a new process could consider the improvement on the worst criteria (e.g. capping agent g2, processing conditions g5, g6and equipment g7), however he/she would not be provided with a recommendation on how the process could be improved by taking exemplary real case processes as indicative guidelines, which is what the DRSA-based model does through the supporting protocols for the rules.

Table 6.

Performance of t1 with respect to the class profiles of ELECTRE-based model and resulting share of CAI (case for reducing agent (g1) > capping agent (g2) > solvent (g3)).

| Class profiles | g1 | g2 | g3 | g4 | g5 | g6 | g7 | g8 | CAI | |

|---|---|---|---|---|---|---|---|---|---|---|

| Reducing agent | Capping agent | Solvent | Local resource use | Reaction time (seconds) | Tempera ture (Celsius) | Equipment type | Size range | |||

| Case A: Certain | Class very high (5) | t1 | t1 | t1 | t1 | t1 | 81% | |||

| b4 = Very high - high | Renewable – primary | Renewable – waste | Renewable – primary | Yes | 50 | 30 | Stirrings ≤ 5 minutes | 0 ≤ particle size ≤ 30 nm | ||

| Class high (4) | t1 | 6% | ||||||||

| b3 = High - medium | Renewable – primary | Renewable – primary | Renewable – primary | Yes | 100 | 40 | Stirring | 0 ≤ particle size ≤ 60 nm | ||

| Class medium (3) | t1 | t1 | 13% | |||||||

| b2 = Medium - low | Biodegradeble polymer | Renewable – primary | Biodegradable polymer | No | 400 | 60 | Microwave – sealed vessel (> 300 W) | 30 < particle size ≤ 60 nm | ||

| Class low (2) | ||||||||||

| b1 = Low - very low | Synthetic | Biodegradable polymer | Synthetic | No | 1500 | 95 | Conventional | 0 < particle size ≤ 100 nm | ||

| Class low (1) | ||||||||||

Table 7.

Performance of t3 with respect to the class profiles of ELECTRE-based model and resulting share of CAI (case for reducing agent (g1) > capping agent (g2) > solvent (g3)).

| Class profiles | g1 | g2 | g3 | g4 | g5 | g6 | g7 | g8 | CAI | |

|---|---|---|---|---|---|---|---|---|---|---|

| Reducing agent | Capping agent | Solvent | Local resource use | Reaction time (seconds) | Tempera ture (Celsius) | Equipment type | Size range | |||

| Case A: Certain | Class very high (5) | t3 | ||||||||

| b4 = Very high - high | Renewable – primary | Renewable – waste | Renewable – primary | Yes | 50 | 30 | Stirrings ≤ 5 minutes | 0 ≤ particle size ≤ 30 nm | ||

| Class high (4) | ||||||||||

| b3 = High - medium | Renewable – primary | Renewable – primary | Renewable – primary | Yes | 100 | 40 | Stirring | 0 ≤ particle size ≤ 60 nm | ||

| Class medium (3) | t3 | t3 | t3 | 23% | ||||||

| b2 = Medium - low | Biodegradeble polymer | Renewable – primary | Biodegradable polymer | No | 400 | 60 | Microwave – sealed vessel (> 300 W) | 30 < particle size ≤ 60 nm | ||

| Class low (2) | t3 | t3 | t3 | t3 | 77% | |||||

| b1 = Low - very low | Synthetic | Biodegradable polymer | Synthetic | No | 1500 | 95 | Conventional | 0 < particle size ≤ 100 nm | ||

| Class low (1) | ||||||||||

One key advantage of SMAA-TRI is the possibility of obtaining results that do not depend on a specific weights vector elicited from some DM. The method empower the analysts to use different rankings of the criteria weights based on the survey involving many experts, resulting in conclusions which are more acceptable, since they are not contingent on the opinion of a specific person or a small group.

This research has shown the benefit of MCDA methods to foster traceable and robust decision support. They enable integration of evaluation criteria of production processes for a typology of nanomaterials in the form of a comprehensive preference-oriented class, enhancing the understandability of the performance of each of them. However, it needs to be mentioned that these models are not substitutes for quantitative assessment tools that can cover the whole life cycle impact of nanomaterials. They are rather powerful instruments that could include the results of such tools in the form of criteria to allow a comprehensive understanding of the environmental as well as sustainability impacts of nanomaterials.

It is also worthy highlighting that the use of different MCDA methods for the same case study has the added benefit of providing multiple facets of the potentials of decision support tools. Within this perspective, the authors have recently proposed a MCDA methodology to study this dataset and classify the nanoparticle synthesis protocols using a value function approach, interestingly supplying the same pattern of recommendations as the DRSA-based and ELECTRE-based models (Kadziński et al., 2016).

4. Conclusions

There is currently a vital need for decision support models in the area of nanosynthesis to improve the understanding of the comprehensive implications that it can have on the environment, the economy and the society as well. MCDA processes and methods have received growing interest from the scientific community because of their capabilities to develop such models and clearly condense the results in the form of a ranking, classification or performance score.

In this paper, the contribution and impact that MCDA methods can have in the synthesis of silver nanoparticles has been shown through (i) the development of an ELECTRE-based model providing uncertainty-characterized performance classes of synthesis processes for silver nanoparticles and (ii) the concordance assessment as well as evaluation of decision support synergies of its recommendations with those of a comparable model based on the DRSA approach (Cinelli et al., 2015).

The research objectives were achieved through a three-phase procedure that integrated part of the results from an experts’ survey with another MCDA method. Firstly, an ordinal ranking of the evaluation parameters was derived from the relative priorities of a comprehensive framework of sustainability evaluation criteria for nanoproducts presented in another paper recently (Cinelli et al., 2016). Secondly, a suitable method capable of providing a decision recommendation comparable with the one of the DRSA-based model was identified. This was the SMAA-TRI, an MCDA method specifically tailored to supply uncertainty-characterized classifications. The integration of criteria rankings and SMAA-TRI method led to another model, called ELECTRE-based model to derive probabilistically characterized quality classes for the same test protocols with which the DRSA-based model was trialled with. A key strength of this model, from a decision support perspective, is the possibility of not imposing specific weights vectors on the criteria and the capacity of providing robust conclusions.

The last research stage entailed comparing the decision recommendations from the two models to assess their concordance and discuss the decision support synergies of these decision support tools. This was achieved by comparing the classification for five test protocols from the model based on DRSA with those derived by the one based on ELECTRE, adopting different criteria weights and discriminatory class profiles to account for input data variability. Out of 120 classifications comparisons, the overall correspondence reached a remarkable level of just under 86%, whereas it varied between 76.0% and 93.3% depending on the settings of the analysis.

This multidisciplinary research confirmed the beneficial complementary use of MCDA methods to aid criteria aggregation in a traceable and understandable format. DRSA method enriches the decision support by means of decision rules which substantiate the classification with previously stored knowledge in the form of simple “if … then …” connectors, whereas SMAA-TRI employs parsimonious information on preferences to lead to robust conclusions according to traceable modelling constraints. These potentials can be particularly useful in research domains characterized by conflicting criteria, such as LCA, life cycle costing (LCC) and social LCA (SLCA), where alternatives excel on some indicators while underperform on others, and for this reason multiple objectives must be addressed to reach a decision recommendation as transparent as possible.

Supplementary Material

Acknowledgements

The authors would like to express their gratitude to Dr. Miłosz Kadziński and Dr. Tommi Tervonen for their constructive feedback provided during the preparation of this article. The work of Marco Cinelli was supported by the Institute of Advanced Study from the University of Warwick under the Early Career Fellowship scheme in award number IAS/ECF/250452/15. Marco Cinelli, Stuart R. Coles and Kerry Kirwan gratefully acknowledge the funding from the UK Engineering and Physical Sciences Research Council, WMG Department of the University of Warwick (UK) (grant number EP/K503204/1), the “CL4W”, Cleaning Land for Wealth, project (grant number EP/K026216/1) and the Innovative Manufacturing Global Research Priority at the University of Warwick (UK).

Abbreviations

- CAI

Class Acceptability Indices

- DMs

Decision-Makers

- ESI

Electronic Supplementary Information

- GCP

Green Chemistry Principles

- LCA

Life Cycle Assessment

- LCC

Life Cycle Costing

- RA

Robustness Analysis

- SLCA

Social Life Cycle Assessment

- SMAA

Stochastic Multi-Criteria Acceptability Analysis

Footnotes

Disclaimer

The views expressed in this article are those of the authors and do not necessarily represent the views or policies of the U.S. Environmental Protection Agency. Any mention of trade names or commercial products does not constitute endorsement or recommendation for use.

References

- Akadiri PO, Olomolaiye PO, 2012. Development of sustainable assessment criteria for building materials selection. Eng. Constr. Archit. Manag 19, 666–687. [Google Scholar]

- Bates ME, Larkin S, Keisler JM, Linkov I, 2015. How decision analysis can further nanoinformatics. Beilstein J. Nanotechnol 6, 1594–1600. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bergeson LL, 2013. Sustainable nanomaterials: emerging governance Systems. ACS Sustain. Chem. Eng 1, 724–730. [Google Scholar]

- Bouyssou D, Marchant T, Pirlot M, Tsouki’as A, Vincke P, 2006. Problem Formulation and Structuring: the Decision Aiding Process, Evaluation and Decision Models with Multiple Criteria: Stepping Stones for the Analyst. Springer US, Boston, MA, pp. 19–65. [Google Scholar]

- Canis L, Linkov I, Seager TP, 2010. Application of stochastic multiattribute analysis to assessment of single walled carbon nanotube synthesis processes. Environ. Sci. Technol 44, 8704–8711. [DOI] [PubMed] [Google Scholar]

- Changseok H, Joel A, Suresh CP, Rachel F, Polycarpos F, Byrne JA, Patrick SMD, Hyeok C, Wenjun J, Kevin OS, Dionysios DD, 2013. Green Nanotechnology: Development of Nanomaterials for Environmental and Energy Applications, Sustainable Nanotechnology and the Environment: Advances and Achievements. American Chemical Society, pp. 201–229. [Google Scholar]

- Cinelli M, Coles SR, Kirwan K, 2014. Analysis of the potentials of multi criteria decision analysis methods to conduct sustainability assessment. Ecol. Indic 46, 138–148. [Google Scholar]

- Cinelli M, Coles SR, Nadagouda MN, Błaszczyn’ski J, Słowin’ski R, Varma RS, Kirwan K, 2015. A green chemistry-based classification model for the synthesis of silver nanoparticles. Green Chem 17, 2825–2839. [Google Scholar]

- Cinelli M, Coles SR, Sadik O, Karn B, Kirwan K, 2016. A framework of criteria for the sustainability assessment of nanoproducts. J. Clean. Prod 126, 277–287. [Google Scholar]

- Dahl JA, Maddux BLS, Hutchison JE, 2007. Toward greener nanosynthesis. Chem. Rev. 107, 2228–2269. [DOI] [PubMed] [Google Scholar]

- Dias LC, 2007. A note on the role of robustness analysis in decision-aiding processes In: Roy B, Aloulou MA, Kalaï R (Eds.), Rubustness in OR-DA. LAM- SADE, Paris, pp. 53–70. [Google Scholar]

- Dias LC, Antunes CH, Insua DR, 2012. Dealing with uncertainty in Decision Support Systems: recent trends 2000–2011. Intell. Decis. Technol 6, 245–264. [Google Scholar]

- Dias LC, Climaco JN, 2000. Additive aggregation with variable interdependent parameters: the VIP analysis software. J. Oper. Res. Soc 51, 1070–1082. [Google Scholar]

- Dias LC, Mousseau V, 2003. IRIS: a DSS for multiple criteria sorting problems. J. Multi Criteria Decis. Anal 12, 285–298. [Google Scholar]

- Dimitras AI, Słowin’ski R, Susmaga R, Zopounidis C, 1999. Business failure prediction using rough sets. Eur. J. Oper. Res 114, 263–280. [Google Scholar]

- Domingues AR, Marques P, Garcia R, Freire F, Dias LC, 2015. Applying multi- criteria decision analysis to the life-cycle assessment of vehicles. J. Clean. Prod 107, 749–759. [Google Scholar]

- Duan H, Wang D, Li Y, 2015. Green chemistry for nanoparticle synthesis. Chem. Soc. Rev 44, 5778–5792. [DOI] [PubMed] [Google Scholar]

- Dubey SP, Lahtinen M, Sillanpa€€a M, 2010. Green synthesis and characterizations of silver and gold nanoparticles using leaf extract of Rosa rugosa. Colloids Surf. A Physicochem. Eng. Aspects 364, 3 4–41. [Google Scholar]

- Eason T, Meyer DE, Curran MA, Upadhyayula V, 2011. Guidance to Facilitate Decisions for Sustainable Nanotechnology. EPA/600/R-11/107. U.S. Environ- mental Protection Agency; https://cfpub.epa.gov/si/si_public_record_report.cfm?dirEntryId238589 (Accessed 22 September 2016). [Google Scholar]

- Feijoo S, Gonzalez-García S, Moldes-Diz Y, Vazquez-Vazquez C, Feijoo G, Moreira MT, 2017. Comparative life cycle assessment of different synthesis routes of magnetic nanoparticles. J. Clean. Prod 143, 528–538. [Google Scholar]

- Figueira J, Mousseau V, Roy B, 2005. ELECTRE methods In: Figueira J, Greco S, Ehrgott M (Eds.), Multi Criteria Decision Analysis: State of the Art Surveys. Springer, New York, pp. 133–162. [Google Scholar]

- Gilbertson LM, Zimmerman JB, Plata DL, Hutchison JE, Anastas PT, 2015. Designing nanomaterials to maximize performance and minimize undesirable implications guided by the Principles of Green Chemistry. Chem. Soc. Rev 44, 5758–5777. [DOI] [PubMed] [Google Scholar]

- Hebbalalu D, Lalley J, Nadagouda MN, Varma RS, 2013. Greener techniques for the synthesis of silver nanoparticles using plant extracts, enzymes, bacteria, Biodegradable polymers, and microwaves. ACS Sustain. Chem. Eng 1, 703–712. [Google Scholar]

- Ibanez-Fores V, Bovea MD, Perez-Belis V, 2014. A holistic review of applied methodologies for assessing and selecting the optimal technological alternative from a sustainability perspective. J. Clean. Prod 70, 259–281. [Google Scholar]

- Kadzin’ski M, Cinelli M, Ciomek K, Coles SR, Nadagouda MN, Varma RS, Kirwan K, 2016. Co-constructive development of a green chemistry-based model for the performance assessment of nanoparticles synthesis. Eur. J. Oper. Res 10.1016/j.ejor.2016.10.019. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Karn B, 2008. The road to green nanotechnology. J. Ind. Ecol. 12, 263–266. [Google Scholar]

- Karn B, Wong SS, 2013. Ten Years of Green Nanotechnology. In: Sustainable Nanotechnology and the Environment: Advances and Achievements. American Chemical Society, pp. 1–10. [Google Scholar]

- Kavitha KS, Syed B, Rakshith D, Kavitha HU, Yashwantha RHC, Harini BP, Satish S, 2013. Plants as green source towards synthesis of nanoparticles. Int. Res. J. Biol. Sci 2, 66–76. [Google Scholar]

- Kaviya S, Santhanalakshmi J, Viswanathan B, Muthumary J, Srinivasan K, 2011. Biosynthesis of silver nanoparticles using citrus sinensis peel extract and its antibacterial activity. Spectroch. Acta Part A Mol. Biomol. Spectrosc 79, 594–598. [DOI] [PubMed] [Google Scholar]

- Kou J, Bennett-Stamper C, Varma RS, 2013. Green synthesis of noble nanometals (Au, Pt, Pd) using glycerol under microwave irradiation conditions. ACS Sustain. Chem. Eng 1, 810–816. [Google Scholar]

- Luque R, 2013. Sustainable nanomaterials: a greener future avenue? Mater. Sci. Nanotechnol 1, 1–2. [Google Scholar]

- Mata MT, Martins AA, Costa AVC, Sikdar KS, 2015. Nanotechnology and sustainability - current status and future challenges In: Vaseashta A (Ed.), Life Cycle Analysis of Nanoparticles. Risk, Assessment, and Sustainability. DEStech Publications, pp. 271–306. [Google Scholar]

- Matus KJM, Hutchinson JE, Peoples R, Rung S, Tanguay R, 2011. Green Nanotechnology Challenges and Opportunities. American Chemical Society. [Google Scholar]

- Merad M, Verdel T, Roy B, Kouniali S, 2004. Use of multi-criteria decision-aids for risk zoning and management of large area subjected to mining-induced hazards. Tunn. Undergr. Space Technol 19, 125–138. [Google Scholar]

- Meyer DE, Upadhyayula VKK, 2014. The use of life cycle tools to support decision making for sustainable nanotechnologies. Clean. Techn Environ. Policy 16, 757–772. [Google Scholar]

- Munda G, 2016. Multiple criteria decision analysis and sustainable development In: Greco S, Ehrgott M, Figueira RJ (Eds.), Multiple Criteria Decision Analysis: State of the Art Surveys. Springer New York, New York, NY, pp. 1235–1267. [Google Scholar]

- Naidu S, Sawhney R, Li X, 2008. A methodology for evaluation and selection of nanoparticle manufacturing processes based on sustainability metrics. Environ. Sci. Technol 42, 6697–6702. [DOI] [PubMed] [Google Scholar]

- Patete JM, Peng X, Koenigsmann C, Xu Y, Karn B, Wong SS, 2011. Viable methodologies for the synthesis of high-quality nanostructures. Green Chem. 13, 482–519. [Google Scholar]

- Pati P, Sean M, Vikeseland P, 2014. Life cycle assessment of “green” nanoparticle synthesis methods. Environ. Eng. Sci 31, 410–420. [Google Scholar]

- Pourzahedi L, Eckelman MJ, 2015. Comparative life cycle assessment of silver nanoparticle synthesis routes. Environ. Sci. Nano 2, 361–369. [Google Scholar]

- Pourzahedi L, Zhai P, Isaacs JA, Eckelman MJ, 2017. Life cycle energy benefits of carbon nanotubes for electromagnetic interference (EMI) shielding applications. J. Clean. Prod 142 (Part 4), 1971–1978. [Google Scholar]

- Rowley HV, Peters GM, Lundie S, Moore SJ, 2012. Aggregating sustainability indicators: beyond the weighted sum. J. Environ. Manag 111, 24–33. [DOI] [PubMed] [Google Scholar]

- Roy B, Słowinski R, 2013. Questions guiding the choice of a multicriteria decision aiding method. EURO J. Decis. Process 1, 69–97. [Google Scholar]

- Sala S, Ciuffo B, Nijkamp P, 2015. A systemic framework for sustainability assessment. Ecol. Econ 119, 314–325. [Google Scholar]

- Senjen R, 2009. Challenges and Opportunities to Green Nanotechnologies, Nano- technologies in the 21st Century. European Environmental Bureau. http://www.bef.lt/fileadmin/Publications/2009-NanoBrochureNo1-WEB_Eng.pdf (Accessed 13 March 2016). [Google Scholar]

- Singh RK, Murty HR, Gupta SK, Dikshit AK, 2012. An overview of sustainability assessment methodologies. Ecol. Indic 15, 281–299. [Google Scholar]

- Słowin’ski R, Greco S, Matarazzo B, 2009. Rough sets in decision making In: Meyers AR (Ed.), Encyclopedia of Complexity and Systems Science. Springer New York, New York, NY, pp. 7753–7787. [Google Scholar]

- Słowin’ski R, Zopounidis C, Dimitras AI, 1997. Prediction of company acquisition in Greece by means of the rough set approach. Eur. J. Oper. Res 100, 1–15. [Google Scholar]

- Stark WJ, Stoessel PR, Wohlleben W, Hafner A, 2015. Industrial applications of nanoparticles. Chem. Soc. Rev 44, 5793–5805. [DOI] [PubMed] [Google Scholar]

- Tervonen T, Figueira JR, Lahdelma R, Dias JA, Salminen P, 2009a. A stochastic method for robustness analysis in sorting problems. Eur. J. Oper. Res 192, 236–242. [Google Scholar]

- Tervonen T, Lahdelma R, 2007. Implementing stochastic multicriteria accept- ability analysis. Eur. J. Oper. Res 178, 500–513. [Google Scholar]

- Tervonen T, Linkov I, Figueirs JR, Steevens J, Chappel M, Merad M, 2009b. Risk-based classification system of nanomaterials. J. Nanoparticle Res 11, 757–766. [Google Scholar]

- Tobiszewski M, Orłowski A, 2015. Multicriteria decision analysis in ranking of analytical procedures for aldrin determination in water. J. Chromatogr. A 1387, 116–122. [DOI] [PubMed] [Google Scholar]

- Varma RS, 2014. Journey on greener pathways: from the use of alternate energy inputs and benign reaction media to sustainable applications of nano-catalysts in synthesis and environmental remediation. Green Chem. 16, 2027–2041. [Google Scholar]

- Varma RS, 2016. Greener and sustainable trends in synthesis of organics and nanomaterials. ACS Sustain. Chem. Eng 4, 5866–5878. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Virkutyte J, Varma RS, 2013. Green Synthesis of Nanomaterials: Environmental Aspects, Sustainable Nanotechnology and the Environment: Advances and Achievements. American Chemical Society, pp. 1 1–39. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.