Abstract

Proteins are essential nutrients in the diet, with the recommended amount of daily protein consumption varying for people with different health status and activity level. Cookies could be an adequate carrier of proteins because of their great acceptability. The aim of this study was to analyse the effect of flour substitution with different types of protein (pea, potato, egg white and whey) in gluten-free cookies. Hydration properties, dough rheology, cookie characteristics (protein content, dimensions, texture) and sensory acceptability were studied. The hydration properties of mixtures with protein were lower than the control, with the exception of pea protein. As for results from rheological analysis, G′ and G″ values for pea and potato protein were similar to the control, while egg white and whey protein had lower values. Addition of egg white and whey protein respectively, produced harder and wider cookies. The addition of potato protein yielded cookies with darker edges, however, pea protein did not lead to any significant change in cookie parameters. Sensory evaluation showed that the addition of pea protein produced cookies with the same scores as the control sample, signifying that cookies with added pea protein had the best acceptability.

Keywords: Potato protein, Pea protein, Egg protein, Whey protein, Cookie quality

Introduction

Proteins, together with carbohydrates and lipids, are the basic macronutrients of the human diet. Exhaustive analysis led to the establishment of the protein Recommended Dietary Allowance (RDA) for both men and women of 0.80 g good quality protein/kg body weight/day. However, protein consumption should not exceed 35% of total energy intake (Institute of Medicine 2005). Other studies determined that older people (Nowson and O’Connell 2015) and athletes (Koopman and van Loon 2009) may need a higher protein intake. Also, there is convincing evidence that higher protein intake increases thermogenesis and satiety compared to lower protein intake (Halton and Hu 2004), thus high protein diets are recommended for weight loss.

Cookies could be an ideal carrier in which to incorporate protein because of their high acceptance and long shelf life. In general, the protein content of cookies is low and its influence on the final product quality is not clear. Some authors state that the quantity and quality of protein flours have an important role in dough rheology (Maache-Rezzoug et al. 1998). Conversely, other authors affirm that protein quantity is more important than protein quality, as a negative correlation between the quantity of gluten (protein contained in wheat flour)in flour and cookie diameter has been reported (Pareyt and Delcour 2008). However, these studies refer to the protein contained in wheat flour and not to the addition of other protein in gluten-free cookies. Studies about the addition of protein in cookies with gluten are varied and usually have focused on dairy protein (Conforti and Lupano 2004; Gani et al. 2015; Sarabhai and Prabhasankar 2015), soy protein (Singh and Mohamed 2007) or watermelon seed protein concentrates (Wani et al. 2015). Most of these studies do not exceed 15% of protein addition and some results are contradictory. Furthermore, due to the different formulations used in each study, the results cannot be compared. On the other hand, studies of protein enriched gluten-free cookies are limited. Of the few that exist, they have only included up to 20% of pea protein (Mancebo et al. 2016), 10% of whey-soy protein blend (Sarabhai et al. 2015) or 9% of canola protein isolate (Gerzhova et al. 2016). None compare different types of protein sources in this kind of cookie. Because of the limited available information about gluten-free cookies enriched with protein, efforts should be made to expand the knowledge about these products.

The aim of our study was to determine how the type (pea, potato, egg white and whey) and percentage of flour substitution (15–30%) with protein influences dough rheology, cookie characteristics and overall quality (dimensions and texture) of gluten-free cookies, along with its acceptability to consumers.

Materials and methods

Materials

Corn flour (8.41% moisture, 4.58% protein) was supplied by Molendum Ingredients S.L. (Zamora, Spain), Nutralys BF pea protein (78.13% protein) by Roquette (Leutrem, France), Solanic 300 potato protein (89.87% protein) by Avebe (Veendam, The Netherlands), egg white protein (84.83% protein) by Ovoprot (Wels, Austria), and Prolacta 200 whey protein (88.96% protein) by Lactalis Ingredients (Laval, France). Other ingredients were white sugar (AB Azucarera Iberica, Valladolid, Spain), 100% vegetable margarine (Argenta crema, Puratos, Barcelona, Spain), sodium bicarbonate (Manuel Riesgo S.A., Madrid, Spain) and local tap water.

Methods

Hydration properties of flour-protein blends

Water holding capacity (WHC) was evaluated following the standard method (AACC method 88-04 2012). Distilled water (10 ml) was added to 5 g of flour or flour-protein blend in a test tube and kept at room temperature to hydrate for 24 h. The excess water was removed and the hydrated solid was weighed. WHC values were expressed as grams of water per gram of solid. On the other hand, swelling volume (SV) was evaluated as the ratio of total volume of the swollen sample to the original dry weight. To measure water binding capacity (WBC), 5 g of sample was added to 25 g of distilled water and centrifuged at 2000×g for 10 min. WBC was expressed as grams of water retained per gram of solid (AACC method 56-30 2012). Flour and flour-protein blend hydration properties were analysed in duplicate.

Cookie preparation

The cookies were elaborated using the following formulation (as g/100 g dough basis): flour (42.8), sugar (30.8), margarine (19.2), water (6.2) and sodium bicarbonate (0.9). All ingredients were used at the same proportions except for the flour which was substituted by different percentage of protein (15, 30 and 45%). The moisture of the flour-protein mixtures was adjusted to 15%. First, the margarine was heated in the microwave (1000 W) for 1 min. Thereafter, in the bowl of a Kitchen Aid 5KPM50 mixer (Kitchen Aid, Benton Harbor, Michigan, USA), the margarine and sugar were blended at speed 4 for 10 min (flat beater), scraping down every 60 s. When both margarine and water were perfectly creamed, the water was added and mixing was continued at speed 4 for 120 s. Finally, flour and sodium bicarbonate were added and mixed at speed 2 for 120 s, scraping down every 30 s. After mixing, the dough was kept at 24 °C for 30 min. The dough was laminated (6.00 mm gap) in pieces by a Salva L-500-J sheeter (Salva, Lezo, Spain). The laminated dough was cut with a circular cookie cutter (40 mm diameter). Cookies were baked for 14 min at 185 °C. Afterward, the cookies were kept at room temperature for 60 min and stored at 24 °C in plastic bags. All the cookies were prepared in duplicate batches.

Dough rheology

Rheological measurement was conducted using a controlled strain rheometer (Thermo Fisher Scientific, Schwerte, Germany) with constant temperature (25 °C) controlled by a water bath (Thermo Fisher Scientific, Schwerte, Germany). The rheometer was equipped with parallel-plate geometry (60 mm diameter). The dough pieces (3 mm height and 60 mm diameter) were compressed with 3 mm of gap. Following preparation, the dough was rested for 300 s before measuring. A strain sweep and frequency sweep were carried out at 25 °C. The strain sweep, with a constant frequency (1 Hz), was performed to identify the strain value included in the linear viscoelastic region. This value was used in a frequency sweep with a frequency range of 10–0.1 Hz to obtain the values of elastic modulus [G′ (Pa)] and viscous modulus [G″ (Pa)] based on frequency values [ω (Hz)].

Cookie characteristics

Following AACC method (AACC 2012), the protein content of cookies (46-30.01) was measured with a Leco TruSpec device (Leco, St. Joseph, MI, USA).

Cookie texture was measured by TA-XT2 texture analyser (Stable Microsystems, Surrey, United Kingdom) using the “three-point bending” test with the sounding line HDP/3 PB (test speed of 2.0 mm/s). Cookie hardness (N), or maximum force required to break the cookie, was obtained. Six cookies of each batch preparation were measured.

Diameter and thickness of cookies were measured in six pieces of each batch preparation with a caliper. The diameter of each cookie was measured twice and perpendicularly, to obtain the average diameter. The spread factor of cookies was calculated as the ratio between the average width and the thickness of the cookies.

Colour was measured using a Minolta CM-508i spectrophotometer (Minolta Co., Ltd, Japan) with the D65 standard illuminant and the 2° standard observer. Cookie colour measurements were made at the centre of the upper surface (crust) of six cookies from each batch preparation and the results were expressed in the CIE L*a*b* colour space.

Consumer test

Sensorial evaluation was conducted with 80 volunteers, who were habitual consumers of cookies between the ages of 18–64. Entire cookies were placed on white plastic plates coded with four-digit numbers and served in random order. The cookies were evaluated based on consumer acceptability of their appearance, odour, texture, taste and overall favourability. This evaluation was completed using a hedonic scale of 9 points, which ranged from “I like so much” to “I dislike so much”, respectively corresponding with the best (“9”) and worst (“1”) score.

Statistical analyses

The results obtained were studied by an analysis of variance (one-way ANOVA). Fisher’s least significant differences (LSD) test was used to differentiate between the medians, with signification level of 95% (p < 0.05). All statistical analyses were completed using Statgraphics Centurion XVI software (StatPoint Technologies Inc, Warrenton, EEUU).

Results and discussion

Hydration properties of flour-protein blends

As shown in Table 1, adding protein in flour mix had different effects on WHC related to type and quantity of protein. In the case of WBC, when pea protein was added, WBC increased, and the values of WBC were the lowest with whey protein. Egg white and potato blends presented similar values compared to the control, but with 30% potato protein the WBC was lower than control sample. Swelling volume (SV) of enriched blends did not present significant differences with respect to control, except for whey protein samples which presented lower values. As for WHC, the incorporation of pea protein produced an increase of this property in comparison with the control sample; that is, the greater the amount of protein added, the higher the WHC. These results are in accordance with those observed by Mancebo et al. (2016) when pea protein was added in rice flour blends. On the other hand, the addition of potato, egg white and whey proteins decreased WHC with both percentages, and significant differences between percentages were only observed for pea and whey. Some authors reported that protein structures and the presence of hydrophilic groups near the surface could produce changes in hydration properties (Sarabhai and Prabhasankar 2015). Einhorn-Stoll et al. (2012) determined that the reaction between a polymer and water molecules can be assisted by the presence of the amorphous particles with a great number of polar groups in the molecular structure of the polymer. The higher values of WHC in pea blends could be attributed to the presence of particles with wrinkled appearance and high amounts of polar amino acids, both of which are primary sites for water interaction (Chinma et al. 2013). Protein solubility is influenced by amino acid composition and sequence, molecular weight, conformation and content of polar and nonpolar groups in amino acids (Zayas 1997). Zhu et al. (2016) also stated that a negative correlation exists between the solubility of a nanoparticle and its polarity. Potato protein demonstrated very high solubility (Ralet and Guéguen 2000); therefore, its polarity, or number of polar groups, was lower and this also resulted in lower values of WHC. This effect was also observed in samples with egg white (Lili et al. 2015) and whey protein (Mulcahy et al. 2016) due to their high solubility.

Table 1.

Values obtained for hydration properties of flour-protein mixtures

| Sample | WHC | WBC | SV |

|---|---|---|---|

| Control | 1.72d | 2.32d | 2.39bc |

| Pea 15 | 1.93e | 2.40de | 2.40bc |

| Pea 30 | 2.12f | 2.48e | 2.79c |

| Potato 15 | 1.58c | 2.36d | 2.59bc |

| Potato 30 | 1.56c | 2.07c | 2.40bc |

| Egg white 15 | 1.56c | 1.97b | 2.19ab |

| Egg white 30 | 1.58c | 1.70a | 2.59bc |

| Whey 15 | 1.35b | 1.93b | 1.90a |

| Whey 30 | 0.56a | 1.63a | 1.90a |

| Standard error | 0.04 | 0.03 | 0.01 |

The numbers that appear in the sample name column indicate the percentage of flour substituted by protein

WHC water holding capacity; WBC water binding capacity; SV swelling volume

Values with the same letter in the same column do not present significant differences (p < 0.05)

Dough rheology properties

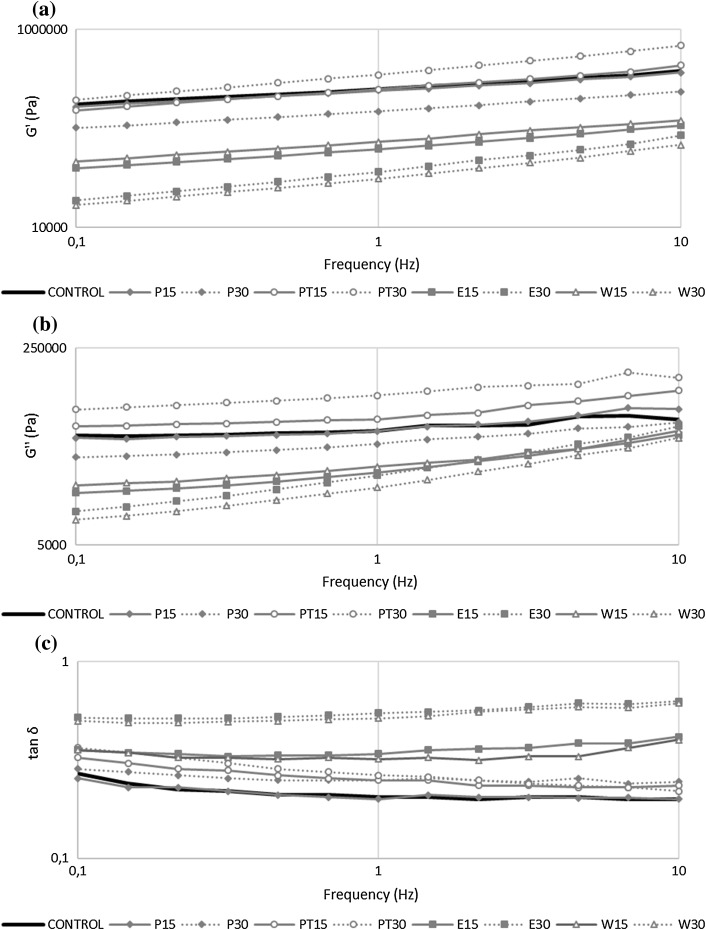

Small deformation oscillatory measurements provide better information in terms of material structure compared to large deformations in the empirical methods (Singh and Singh 2013). The dough rheological parameters (G′ and G″) obtained from oscillatory test are shown in Fig. 1a, b. Both G′ and G″ showed frequency dependence since both moduli demonstrated a rise with the increase in frequency. Over the frequency range (0.1–10 Hz) for all samples, the elastic moduli (G′) was higher than the viscous moduli (G″), which indicates that all doughs studied exhibited a solid elastic-like behaviour. These gluten-free doughs shared these characteristics with those with gluten since both frequency dependence and solid elastic behaviour also was observed in wheat doughs (Singh and Singh 2013; Katyal et al. 2018). The average G′, G″ and tan δ values at frequency 1 Hz for the control sample were 251.5, 50.95 and 0.20 kPa, respectively. For the vegetal proteins, the average G′, G″ and tan δ values at the same frequency ranged from ~ 151 to 354 kPa, ~ 38.5 to 101 kPa and ~ 0.21 to 0.28, respectively, while for the animal proteins ranged from ~ 31.8 to 74 kPa, ~ 16.4 to 24.6 kPa and ~ 0.34 to 0.55, respectively. Doughs with 30% potato protein presented higher G′ and G″ values than the control sample, and with 15% protein only G″ values increased. In the case of pea protein, the 15% substitution level did not modify G′ and G″ values, but a 30% substitution level reduced them. In blends with egg white and whey protein a significant reduction of these values was observed. This effect was more pronounced with higher level of protein substitution. Marco and Rosell (2008) found that introducing 5% of egg albumen and whey protein in rice flour blends led to a decrease in both moduli. Some authors have observed a positive correlation between hydration properties and dough rheology (Inglett et al. 2015; Mancebo et al. 2016). In our study, samples with lower G′ and G″ values also presented lower WBC values; thus, positive correlations between WBC-G′ (p < 0.01, r = 0.6574) and WBC-G″ (p < 0.05, r = 0.4747) were observed. Loss tangent (tan δ), which is calculated as the relation between viscous and elastic moduli, was also measured (Fig. 1c). Doughs with animal proteins presented higher tan δ values compared to the ones with vegetal proteins, so that presented a less elastic structure. In the case of animal proteins, doughs showed higher tan δ values at higher frequencies what suggested the increase in viscous characteristics with the increase in frequency. This also was observed by Tang and Liu (2017), who substituted wheat flour by whey protein (up to 30%) in cookies. However, samples with vegetal proteins presented lower tan δ values when the frequency was increased, which means the predominance of elastic character at higher frequencies.

Fig. 1.

Dynamic oscillatory properties of the doughs with different types and percentages of protein. a Elastic moduli (G′). b Viscous moduli (G″). c Loss tangent (tan δ). P pea protein; PT potato protein; E egg white protein; W whey protein

Cookie characteristics

Cookie properties are shown in Table 2. In general, incorporation of protein did not modify the width of cookies except for whey protein, which increased cookie width. The addition of protein also did not modify the thickness of most cookies. However, reduced thickness was observed in cookies with potato protein and increased thickness was seen in cookies with 30% whey protein. The explanation for this effect could be related to the rheology characteristics of cookies, as other authors have determined (Altındağ et al. 2015; Mancebo et al. 2015). In our study, cookie width was associated with G′ and G″, which showed negative correlations of r = − 0.55 and r = − 0.52, respectively, and a confidence of 95%. The width of cookies is related to their expansion during baking, so that a low consistency provides a higher dough expansion or relaxation (Hoseney and Rogers 1994; Mancebo et al. 2015). Thus, whey protein produced small G′ and G″ values causing doughs to be low in consistency. This was confirmed by the higher expansion of the pieces during baking and larger width of the final cookies obtained. On the other hand, cookie thickness also showed negative correlations of r = − 0.65 and r = − 0.69 with G′ and G″, respectively, and a confidence of 99%. This could be a result of the capacity to retain gas generated during baking as well as the emulsion formed. The hypothesis would be that potato protein produces a deficient emulsion, which leads to a loss in generated gas and, as a result, cookies with reduced thickness. This hypothesis is supported by Jackman and Yada (1988) and Ralet and Guéguen (2000), who reported poor emulsifying properties of potato proteins. Spread ratios, which are a relation of cookie width to its thickness, did not present significant differences between any of the cookies and the control, either because there were not differences in thickness and width, or because both parameters were compensated. Only with the addition of 15% whey protein was an increase observed, as this cookie presented a higher width that was not balanced with greater thickness. This also was observed by other authors, as Sarabhai et al. (2015) added 10% of whey protein in rice cookies and Sarabhai and Prabhasankar (2015) added the same percentage and type of protein in chestnut cookies. Both of them observed an increase of spread ratio in relation to a control sample.

Table 2.

Quality parameters of protein enriched cookies: dimensions, texture, colour and protein content

| Sample | Thickness (mm) | Width (mm) | Spread ratio | Hardness (N) | L* | a* | b* | Protein content (%) |

|---|---|---|---|---|---|---|---|---|

| Control | 9.61b | 46.08a | 4.81ab | 36.73a | 74.96b | 4.31a | 23.26a | 3.39a |

| P15 | 8.93b | 44.09a | 4.73a | 40.31a | 74.85b | 5.91ab | 24.02a | 8.34b |

| P30 | 8.93b | 42.76a | 4.79ab | 36.28a | 70.80ab | 9.28bc | 24.77a | 13.30e |

| PT15 | 7.99a | 43.38a | 5.43abc | 32.61a | 73.84b | 6.74ab | 25.19a | 9.58d |

| PT30 | 7.81a | 43.08a | 5.52bc | 40.13a | 67.37ab | 10.51cd | 24.45a | 15.7h |

| E15 | 9.20b | 45.17a | 4.92ab | 64.94b | 73.70b | 7.73abc | 26.91a | 9.08c |

| E30 | 9.22b | 45.42a | 4.93ab | 57.86b | 70.85ab | 9.44bcd | 26.92a | 14.34f |

| W15 | 9.09b | 52.73b | 5.81c | 35.54a | 64.54a | 11.26cd | 24.01a | 9.19c |

| W30 | 10.88c | 52.79b | 4.87ab | 43.20a | 64.38a | 12.97d | 25.82a | 14.97g |

| Standard error | 0.28 | 1.69 | 0.24 | 3.95 | 2.51 | 1.14 | 1.22 | 0.05 |

The numbers that appear in the sample name column indicate the percentage of flour substituted by protein

P pea protein; PT potato protein; E egg white protein; W whey protein

Values with the same letter in the same column do not present significant differences (p < 0.05)

Regarding hardness, cookies with pea, potato and whey protein did not present significant differences with respect to the control sample. However, other authors showed different and contradictory results. Mancebo et al. (2015) observed a decrease in hardness with addition of pea protein. Conforti and Lupano (2004) and Sarabhai et al. (2015) also reported a decrease in hardness, in this case with whey protein. On the other hand, Gani et al. (2015) and Sarabhai and Prabhasankar (2015) obtained harder cookies with addition of whey protein. This may be due to protein-starch interactions formed with the different kinds of flour used in the studies. This explanation is stems from Hoseney and Rogers (1994), who reported that the interaction between protein and starch by hydrogen bonding affects cookie hardness. Among enriched cookies, only those which contained egg white protein stood out due to their unusually higher hardness values. Nozawa et al. (2016) and Ziobro et al. (2016) also observed that the samples with albumin revealed higher hardness values than control. Egg white is a globular protein that experiences a loss of tertiary structure upon heating, and hence an irreversible loss of solubility occurs, which can lead to thermal coagulation (Gossett et al. 1984). This coagulation was produced as a result of a two-step process: a first step of denaturation and a second step of aggregation (Campbell et al. 2003). The formed aggregates could have resulted in a compact structure and high texture values.

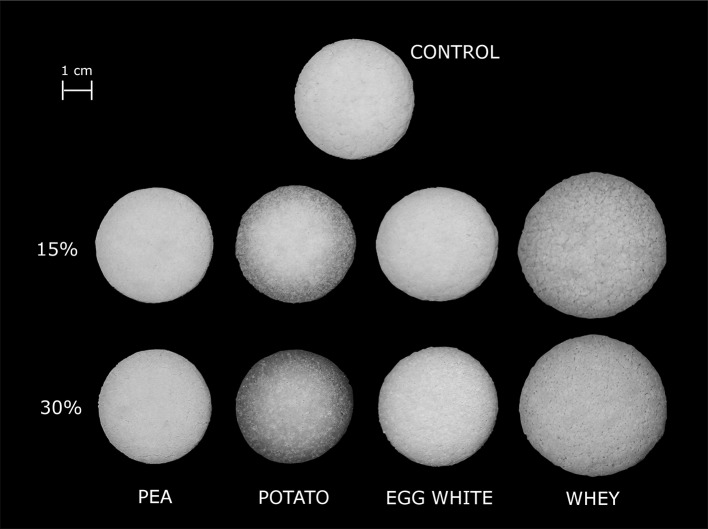

Regarding colour values (Table 2), cookies with whey protein presented darker colour (lower values of L*). Some authors also observed that the addition of whey protein decreases luminance values (Conforti and Lupano 2004; Sarabhai and Prabhasankar 2015). Changes in cookie colour were produced due to Maillard reactions that occurred between reducing sugars and the amino side-chain of lysine. In the non-enzymatic browning, lysine has an important role because its ε-amino groups are a source of free amino groups that react with the carbonyl groups of reducing sugars (Tamnak et al. 2016). In whey protein, lysine content is high and, since lysine is mainly responsible for Maillard reactions, a dark colour was observed in cookies containing whey protein. Although potato protein cookies seemed darker in Fig. 2, this observation was not demonstrated in the results from the colour test because it only measured colour of the central surface of cookies and the dark colour was on the edge. In all cases, a* and b* values were positive, thus cookies appeared more yellow and red. For b* values, none of the samples presented significant differences with respect to the control sample. There was a trend of increasing a* values with increasing protein content, but cookies with 15% pea, potato and with egg protein did not present significant differences.

Fig. 2.

Images of cookies with different types and percentages of protein

Considering the protein content of cookies, protein isolates with greater purity produced cookies with higher protein content. Protein level in cookies increased with increasing percentage of protein added. Samples with 30% protein added resulted in cookies with a protein content close to 15%.

Consumer acceptability

The results of sensorial evaluation of cookie are shown in Table 3. Cookies with egg white protein were not included in the consumer test because they presented excessively high values in texture analysis, as depicted in Table 2, and their rupture in the mouth would be very difficult for tasters. Among the rest of cookies, those with potato protein obtained the worst scores due to mouthfeel (texture and taste) and because they presented strange flavours. This type of protein also obtained the lowest score in appearance and this could be explained because the edge of cookies was slightly burnt, as shown in Fig. 2. Whey protein cookies were rated very good for appearance but, as with pea protein, they were not rated well for taste. The parameter “taste” achieved the worst values in all sample with protein and this caused a reduction of overall acceptability. Gani et al. (2015), adding up to 15% whey protein in wheat cookies, also observed a reduction of taste scores. This may be explained due to taste that protein imparts on cookies, either from the protein itself or from Maillard reactions. Maillard reactions produce a few bitter compounds with off-tastes that many people do not find favourable. As reported through an analysis of bitter compounds in whole wheat bread, Maillard reactions are responsible for the generation of these compounds and they can negatively influence product acceptability and consumption (Bakke and Vickers 2007; Jiang and Peterson 2013). One potential solution for this problem would be to add flavouring to the cookies to mask the off-flavour. Pea protein cookies presented similar scores in comparison to the control sample, although their taste score was lower. Both cookies obtained the highest values of overall acceptability and they were the most preferred samples. However, although pea protein cookies obtained the best acceptability score among enriched ones, some consumers could also keep in mind the digestibility of proteins on choosing. In this way, as dairy proteins have higher digestibility than vegetal proteins (Tome 2012), whey protein cookies could be a better option than pea protein cookies because there were not significant differences in acceptability between them.

Table 3.

Results from consumer test of protein enriched cookies with 30% pea, potato and whey protein

| Sample | Appearance | Odour | Texture | Taste | Overall acceptability |

|---|---|---|---|---|---|

| Control | 6.56b | 6.00b | 6.13b | 6.58c | 6.43c |

| P30 | 6.94bc | 6.01b | 6.35b | 5.79b | 6.21bc |

| PT30 | 4.51a | 5.08a | 3.96a | 3.35a | 3.97a |

| W30 | 7.13c | 6.04b | 5.87b | 5.24b | 5.83b |

| Standard error | 0.18 | 0.16 | 0.19 | 0.23 | 0.17 |

P pea protein; PT potato protein; W whey protein

Values with the same letter in the same column do not present significant differences (p < 0.05)

Conclusion

According to the results, it is possible to achieve protein enriched cookies with 30% flour substitution without negatively changing dough and cookie properties or modifying their acceptability. However, the choice of the correct protein is essential, as certain types of protein with suboptimal characteristics cause alterations in dough and cookie properties as well as a reduction in their acceptability. Among the proteins studied, pea protein was the type which presented the fewest differences compared to the control cookie, while egg white and potato protein produced cookies with the poorest quality.

Acknowledgements

The authors acknowledge the financial support of the Spanish Ministry of Economy and Competitiveness (Project AGL2014-52928-C2) and the European Regional Development Fund (FEDER). The authors are also grateful to Molendum Ingredients, Roquette Laisa, Alifarma and Lactalis Ingredients for supplying the raw materials. They also would like to thank Paula Martínez for her assistance whilst carrying out product analyses.

References

- AACC International . Approved methods of the American Association of Cereal Chemists International. Methods: 46-30.01 (protein content), 56-30 (WBC), 88-04 (WHC) 11. St Paul: American Association of Cereal Chemists; 2012. [Google Scholar]

- Altındağ G, Certel M, Erem F, Konak Üİ. Quality characteristics of gluten-free cookies made of buckwheat, corn, and rice flour with/without transglutaminase. Food Sci Technol Int. 2015;21:213–220. doi: 10.1177/1082013214525428. [DOI] [PubMed] [Google Scholar]

- Bakke A, Vickers Z. Consumer liking of refined and whole wheat breads. J Food Sci. 2007;72:473–480. doi: 10.1111/j.1750-3841.2007.00440.x. [DOI] [PubMed] [Google Scholar]

- Campbell L, Raikos V, Euston SR. Modification of functional properties of egg-white proteins. Nahrung Food. 2003;47:369–376. doi: 10.1002/food.200390084. [DOI] [PubMed] [Google Scholar]

- Chinma CE, Ariahu CC, Abu JO. Chemical composition, functional and pasting properties of cassava starch and soy protein concentrate blends. J Food Sci Technol. 2013;50:1179–1185. doi: 10.1007/s13197-011-0451-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Conforti PA, Lupano CE. Functional properties of biscuits with whey protein concentrate and honey. Int J Food Sci Technol. 2004;39:745–753. doi: 10.1111/j.1365-2621.2004.00838.x. [DOI] [Google Scholar]

- Einhorn-Stoll U, Kastner H, Senge B. Comparison of molecular parameters; material properties and gelling behaviour of commercial citrus pectins. In: Williams PA, Phillips GO, editors. Gums and stabilisers for the food industry 16. Cambridge (UK): Royal Society of Chemistry; 2012. pp. 199–206. [Google Scholar]

- Gani A, Broadway AA, Ahmad M, Ashwar BA, Wani AA, Wani SM, Masoodi FA, Khatkar BS. Effect of whey and casein protein hydrolysates on rheological, textural and sensory properties of cookies. J Food Sci Technol. 2015;52:5718–5726. doi: 10.1007/s13197-014-1649-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gerzhova A, Mondor M, Benall M, Aider M. Incorporation of canola proteins extracted by electroactived solutions in gluten-free biscuit formulation of rice-buckwheat flour blend: assessment of quality characteristics and textural properties of the product. Int J Food Sci Technol. 2016;51:814–827. doi: 10.1111/ijfs.13034. [DOI] [Google Scholar]

- Gossett PW, Rizvi SSH, Baker RC. Quantitative analysis of gelation in egg protein systems. Food Technol. 1984;38:67–96. [Google Scholar]

- Halton TL, Hu FB. The effects of high protein diets on thermogenesis, satiety and weight loss: a critical review. J Am Coll Nutr. 2004;23:373–385. doi: 10.1080/07315724.2004.10719381. [DOI] [PubMed] [Google Scholar]

- Hoseney RC, Rogers DE. Mechanism of sugar functionality in cookies. In: Faridi H, editor. The science of cookie and cracker production. New York: Chapman & Hall; 1994. pp. 203–225. [Google Scholar]

- Inglett GE, Chen D, Liu SX. Physical properties of gluten-free sugar cookies made from amaranth–oat composites. LWT Food Sci Technol. 2015;63:214–220. doi: 10.1016/j.lwt.2015.03.056. [DOI] [Google Scholar]

- Institute of Medicine . Dietary reference intakes for energy, carbohydrate, fiber, fat, fatty acids, cholesterol, protein, and amino acids (macronutrients) Washington: The National Academies Press; 2005. [Google Scholar]

- Jackman RL, Yada RY. Functional properties of whey-potato protein composite blends in a model system. J Food Sci. 1988;53:1427–1432. doi: 10.1111/j.1365-2621.1988.tb09292.x. [DOI] [Google Scholar]

- Jiang D, Peterson DG. Identification of bitter compounds in whole wheat bread. Food Chem. 2013;141:1345–1353. doi: 10.1016/j.foodchem.2013.03.021. [DOI] [PubMed] [Google Scholar]

- Katyal M, Virdi AS, Singh N, Kaur A, Rana JC, Kumari J. Diversity in protein profiling, pasting, empirical and dynamic dough rheological properties of meal from different durum wheat accessions. J Food Sci Technol. 2018;55:1256–1269. doi: 10.1007/s13197-018-3036-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Koopman R, van Loon LJC. Aging, exercise, and muscle protein metabolism. J Appl Physiol. 2009;10:2040–2048. doi: 10.1152/japplphysiol.91551.2008. [DOI] [PubMed] [Google Scholar]

- Lili L, Huan W, Guangyue R, Xu D, Dan L, Guangjun Y. Effects of freeze-drying and spray drying processes on functional properties of phosphorylation of egg white protein. Int J Agric Biol Eng. 2015;8:116–123. [Google Scholar]

- Maache-Rezzoug Z, Bouvier JM, Allaf K, Patras C. Effect of principal ingredients on rheological behaviour of biscuit dough and on quality of biscuits. J Food Eng. 1998;35:23–42. doi: 10.1016/S0260-8774(98)00017-X. [DOI] [Google Scholar]

- Mancebo CM, Picón J, Gómez M. Effect of flour properties on the quality characteristics of gluten free sugar-snap cookies. LWT Food Sci Technol. 2015;64:264–269. doi: 10.1016/j.lwt.2015.05.057. [DOI] [Google Scholar]

- Mancebo CM, Rodríguez P, Gómez M. Assessing rice flour-starch-protein mixtures to produce gluten free sugar-snap cookies. LWT Food Sci Technol. 2016;67:127–132. doi: 10.1016/j.lwt.2015.11.045. [DOI] [Google Scholar]

- Marco C, Rosell CM. Effect of different protein isolates and transglutaminase on rice flour properties. J Food Eng. 2008;84:132–139. doi: 10.1016/j.jfoodeng.2007.05.003. [DOI] [Google Scholar]

- Mulcahy EM, Park CW, Drake M, Mulvihill DM, O’Mahony JA. Improvement of the functional properties of whey protein hydrolysate by conjugation with maltodextrin. Int Dairy J. 2016;60:47–54. doi: 10.1016/j.idairyj.2016.02.049. [DOI] [Google Scholar]

- Nowson C, O’Connell S. Protein requirements and recommendations for older people: a review. Nutrients. 2015;7:6874–6899. doi: 10.3390/nu7085311. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nozawa M, Ito S, Arai E. Effect of ovalbumin on the quality of gluten-free rice flour bread made with soymilk. LWT Food Sci Technol. 2016;66:598–605. doi: 10.1016/j.lwt.2015.11.010. [DOI] [Google Scholar]

- Pareyt B, Delcour JA. The role of wheat flour constituents, sugar, and fat in low moisture cereal based products: a review on sugar-snap cookies. Crit Rev Food Sci Nutr. 2008;48:824–839. doi: 10.1080/10408390701719223. [DOI] [PubMed] [Google Scholar]

- Ralet MC, Guéguen J. Fractionation of potato proteins: solubility, thermal coagulation and emulsifying properties. LWT Food Sci Technol. 2000;33:380–387. doi: 10.1006/fstl.2000.0672. [DOI] [Google Scholar]

- Sarabhai S, Prabhasankar P. Influence of whey protein concentrate and potato starch on rheological properties and baking performance of Indian water chestnut flour based gluten free cookie dough. LWT Food Sci Technol. 2015;63:1301–1308. doi: 10.1016/j.lwt.2015.03.111. [DOI] [Google Scholar]

- Sarabhai S, Indrani D, Vijaykrishnaraj M, Milind Kuman VA, Prabhasankar P. Effect of protein concentrates, emulsifiers on textural and sensory characteristics of gluten free cookies and its immunochemical validation. J Food Sci Technol. 2015;52:3763–3772. doi: 10.1007/s13197-014-1432-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Singh M, Mohamed A. Influence of gluten-soy protein blends on the quality of reduced carbohydrates cookies. LWT Food Sci Technol. 2007;40:353–360. doi: 10.1016/j.lwt.2005.09.013. [DOI] [Google Scholar]

- Singh S, Singh N. Relationship of polymeric proteins and empirical dough rheology with dynamic rheology of dough and gluten from different wheat varieties. Food Hydrocoll. 2013;33:342–348. doi: 10.1016/j.foodhyd.2013.04.007. [DOI] [Google Scholar]

- Tamnak S, Mirhosseini H, Tan CP, Ghazali HM, Muhammad K. Physicochemical properties, rheological behaviour and morphology of pectin-pea protein isolate mixtures and conjugates in aqueous system and oil in water emulsion. Food Hydrocoll. 2016;56:405–416. doi: 10.1016/j.foodhyd.2015.12.033. [DOI] [Google Scholar]

- Tang X, Liu J. A comparative study of partial replacement of wheat flour with whey and soy protein on rheological properties of dough and cookie quality. J Food Qual. 2017 [Google Scholar]

- Tome D. Criteria and markers for protein quality assessment—a review. Br J Nutr. 2012;108:222–229. doi: 10.1017/S0007114512002565. [DOI] [PubMed] [Google Scholar]

- Wani AA, Sogi DS, Singh P, Khatkar BS. Influence of watermelon seed protein concentrates on dough handling, textural and sensory properties of cookies. J Food Sci Technol. 2015;52:2139–2147. doi: 10.1007/s13197-013-1224-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zayas JF. Functionality of proteins in food. Berlin: Springer; 1997. [Google Scholar]

- Zhu J, Ou X, Su J, Li J. The impacts of surface polarity on the solubility of nanoparticle. J Chem Phys. 2016;145:044504. doi: 10.1063/1.4959805. [DOI] [PubMed] [Google Scholar]

- Ziobro R, Juszczak L, Witczak M, Korus J. Non-gluten proteins as structure forming agents in gluten free bread. J Food Sci Technol. 2016;53:571–580. doi: 10.1007/s13197-015-2043-5. [DOI] [PMC free article] [PubMed] [Google Scholar]