Abstract

Technical lignins are bulk feedstocks. They are generated as byproducts from pulping or cellulosic ethanol production. Since lignin undergoes significant structural changes in the chemical and physical treatments, all technical lignins are unique in terms of chemical structure, molecular weight, polydispersity, and impurity profile.

Kraft lignin is potentially the largest source of technical lignin as new isolation technologies have been implemented on industrial scale in recent years. Lignosulfonate has been an integral product in sulfite pulping biorefinery. It has a well-established market in construction industry. Organosolv-like lignin production is increasing as cellulosic ethanol has been promoted as the substitute of fossil fuel. It may have unique applications because it has low molecule weight and is free from sulfur. Technical lignin application is expected to expand as the characteristics are improved with fractionation or chemical modification.

The application of technical lignin has been focusing on developing products equivalent to those made by petroleum chemicals. The recent development in technical lignin supply should increase its market share as additives in polyurethanes and as the substitute of phenol-formaldehyde adhesives. Quality improvement of technical lignin may also encourage the study of lignin as an alternative feedstock for carbon fiber. In addition, technical lignin depolymerization has been extensively explored to provide renewable aromatic chemicals. Starting from controlled pyrolysis and thermal liquefaction as the baseline technologies, many different chemical depolymerization have been invented with a wide range of underlying chemical principles.

Keywords: Lignocellulose, lignin, Kraft Process, lignosulfonate, biorefinery

Introduction

Lignin is the largest repository of renewable aromatic chemicals on earth. It makes up 20–35% of the biomass. Therefore, lignin valorization is expected to play an essential role in the bio-based economy. There has been a rapid increase in the number of publications to isolate, modify, and expand the use of lignin in recent years. To evaluate the potential of emerging technologies, it is desirable to have a knowledge framework with which stakeholders can characterize the supply of technical lignin, identify the critical issues in lignin transformation processes, benchmark new options with equivalent technologies, and project impacts of an innovation.

Over the history, technical lignin is a byproduct from pulping industry. Also, lignin from the upcoming cellulosic ethanol industry is becoming significant. Both chemical and physical treatments cause changes in lignin in terms of structure, molecular weight distribution and dispersity. The impurity profile is influenced not only by the process, but also by the isolation method. The quality of technical lignin sums up all its experience from feedstock to production isolation. Therefore, it is important to understand the pathway from which a lignin product is generated. The quality of lignin is critical for applications in polymeric form, particularly when as-received lignin is needed for applications with low profit margin. There is also a vigorous effort to depolymerize lignin for monomers as platform chemicals. The quality of lignin feedstock is also important as it influences the yield of depolymerization.

Contextual information of technical lignin production is highly valuable. The production scale and location reflect the local biomass supply and established market. The history of technology development demonstrates how new technologies have been adopted to address the most critical issues in the highly integrated processes. The product portfolio evolution exemplifies the approaches to maximize the value of a biorefinery. All the information would help to identify realistic opportunities to improve efficiency with new technologies, minimize capital investment, identify cross-sector collaborators for new product development, and build flexible and adaptive product portfolio.

These topics are organized by underlying chemical principles with highlights on the efficiency and sustainability. We hope this review will serve as a subject reference in a broad knowledge framework for cross functional collaboration to prioritize research or product development.

Main components of lignocellulosic biomass

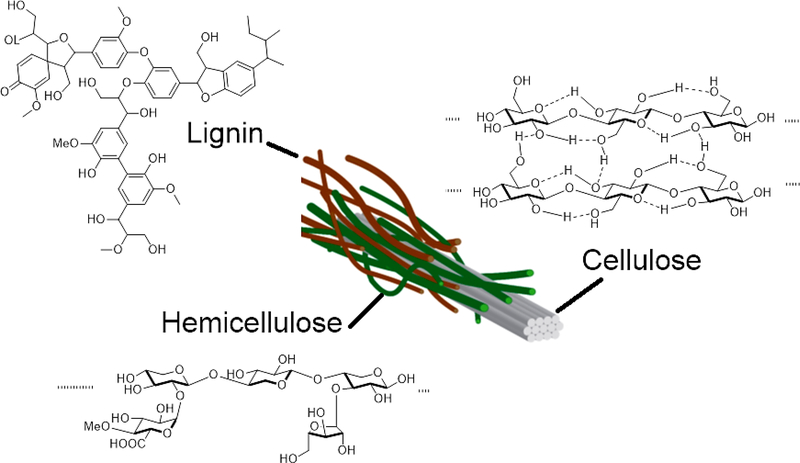

Lignocellulosic biomass is the most abundant terrestrial plant material. From energy point of view, biomass is the most condensed form of energy from sunlight on earth surface. Therefore, it is the ultimate renewable source of energy. Biomass is a composite material that is built as plants grow. The property of biomass is unique to the plant and influenced by growth condition. It is made up with three main polymeric components; including cellulose, hemicellulose, and lignin.1 Its physical character can be fine-tuned by changing the composition and organization of the three components. The components are different in chemical structure and physical property. They play complimentary roles in building biomass (Figure 1).

Figure 1.

The organization of three components in lignocellulosic biomass

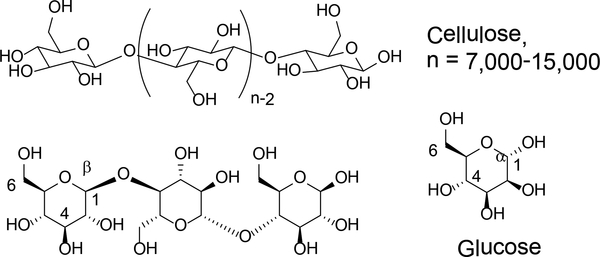

Cellulose (Figure 2) is the main component in plant cell wall. It is a linear homopolymer consisting of 7000 – 15000 units of β-(1–4) linked D-glucose. The highly regular structure allows cellulose to form crystalline region through hydrogen bonds within and between molecules. Cellulose is highly stable as it has crystalline lattice energy at 20 kcal mole−1 of glucose.2 It is insoluble in water or nearly all traditional solvents. The crystalline structure also renders resistance to enzymatic or chemical hydrolysis.

Figure 2.

Chemical composition and structure of cellulose

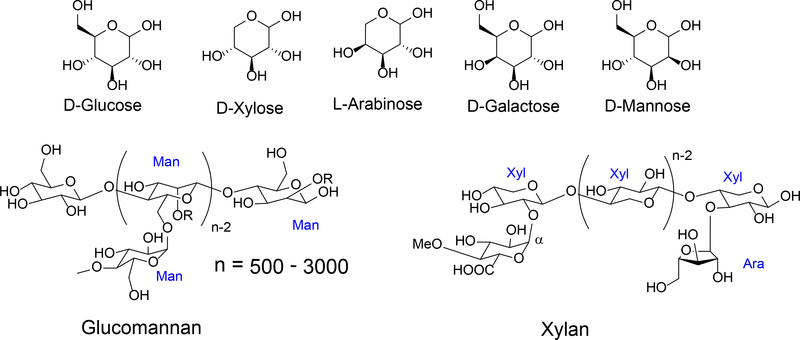

Hemicellulose (Figure 3) is a two-dimensional copolymer with lower degree of polymerization (n = 500–3000). It is comprised of different hexoses and pentoses, including D-Glu, D-Gal, D-Man, D-Xyl, and L-Ara. The hydroxyl groups on the branches may also form acetate or glucuronides. Hemicellulose is structurally irregular with several different regional motifs. It is soluble in water and easier to hydrolyze.

Figure 3.

Chemical composition and structure of hemi-cellulose

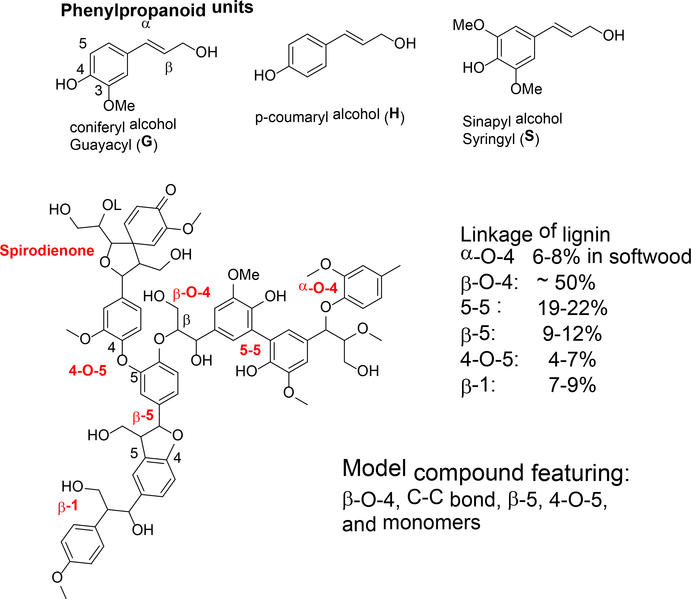

Lignin contributes to the strength of plant cell wall by gluing cellulose and hemicellulose together. It is a three-dimensional heterogeneous copolymer of three phenylpropanoid monomers, including coniferyl alcohol (G), coumaryl alcohol (H), and sinapyl alcohol (S). Each monomer has several polymerization sites, allowing many different linkages between the monomers (Figure 4). The content of lignin depends on the species of a plant. For example, softwood is comprised of 45–50% of cellulose, 25–35% of hemicellulose, and 25–35% of lignin. Monomer composition of the lignin is also dependent on the plant species.3

Figure 4.

Monomers and linkages in lignin

For structure determination, lignin needs to be separated from the other two components. Native lignin structure is difficult to determine as it is changed in harsh chemical and physical treatment. As the result, much of lignin chemistry is derived from the study on model compounds. With isolated lignin, the structure is characterized in terms of aromatic units (GHS), interunit linkages, functional groups (aliphatic alcohols, aromatic alcohols, and carboxylic acids), side chains, and molar mass distribution.4

Kraft process is potentially the largest source of lignin feedstock

Lignin for chemical recovery in Kraft pulping process

Wood pulp industry provides cellulose fiber for paper and paper board commodity. In a survey by The Food and Agriculture Organization of the United Nations, the total capacity of dry wood pulp in the US has been 53,830 – 54,280 million tons between years 2014 – 2019.5 As the side stream, lignin has been generated at approximately 25% of the scale, but most is burned for energy. The survey also shows that 87% of the product is produced by chemical pulping, which involves thermal chemical digestion of woody feedstock.

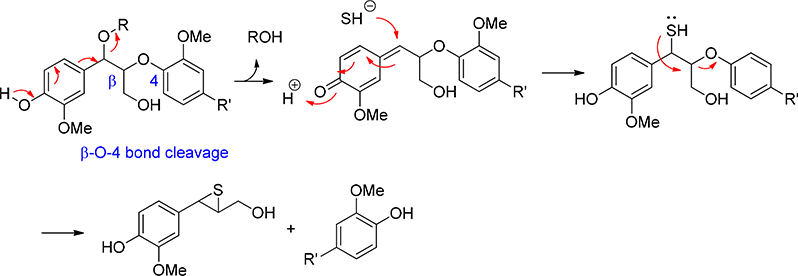

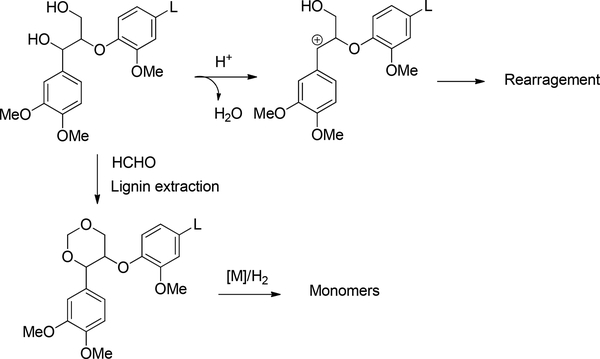

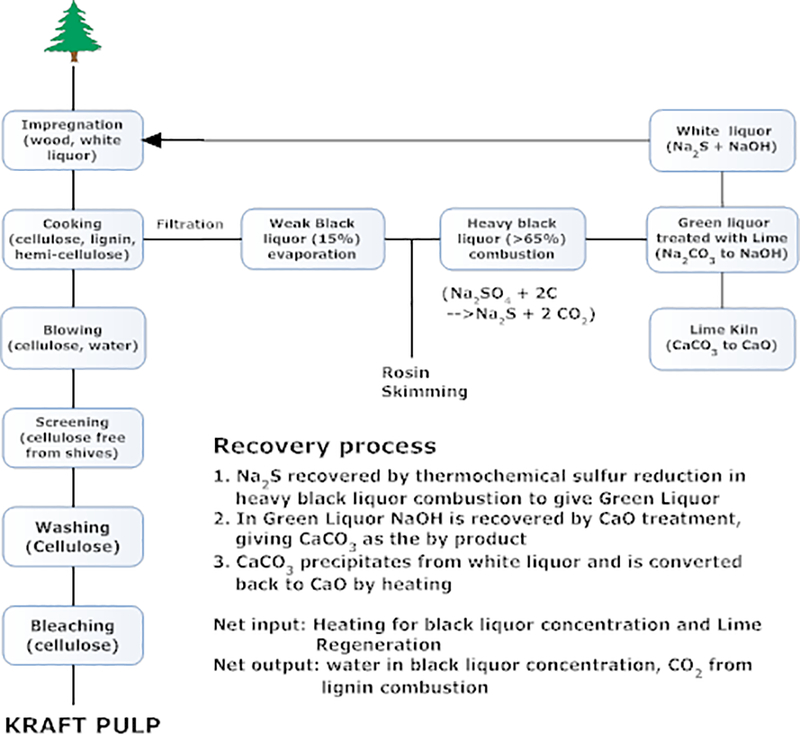

The Kraft process (Figure 5) is the primary pulping process.6 The chemicals to digest lignocellulose is a mixture of Na2S and NaOH (White Liquor). At high temperature (150–180 ͦC), ether bonds in lignin are broken through an episulfide intermediate (Figure 6). Cellulose is separated by filtration, leaving lignin and hemicellulose in the liquid phase (Black Liquor). The most important feature for Kraft process is the recovery of all chemicals for pulping. Sulfur and sodium are both completely recycled through the recovery process (Figure 5). To prepare for the recycling, the Weak Black Liquor is concentrated to give Heavy Black Liquor. Heavy Black Liquor is then combusted to reduce sulfate to sulfide by a thermochemical reduction with lignin. Combusted lignin gives carbonate as the byproduct in Green Liquor. In the next step, lime (CaO) is added to Green Liquor. It reacts with sodium carbonate to give sodium hydroxide and calcium carbonate precipitate. White Liquor is regenerated by removing CaCO3 from the liquid. The CaCO3 is transformed back to lime by heating in a kiln. In Kraft process sodium, sulfur and calcium are essentially catalytic as they are recycled through the recovery process. The theoretical byproducts are water and carbon dioxide.

Figure 5.

Kraft process involves chemical recovery

Figure 6.

Lignin ether cleavage in Kraft Process (α-O-ether and β-O-4 cleavage)

Energy is also produced in the chemical recovery. In theory, only a fraction of the lignin in Black Liquor is needed for sulfate reduction and energy production. Therefore, it is feasible to remove a portion of lignin form the Black Liquor by rebalancing the chemical and energy allocation in Kraft process.6

Weak Black Liquor is concentrated by evaporation to give Thick Black Liquor to sustain the combustion for chemical recovery. The Thick Black Liquor is sprayed into the boiler and burned to give a smelt of Na2S and Na2CO3. In addition to the chemical products, this step also involves steam generation as the energy product. This step is usually the scale limiting step in Kraft process because recovery boiler is the most expensive unit in Kraft pulping equipment.

The efficiency of the boiler depends on the chemical composition and physical properties of the incoming black liquor. The Heavy Black Liquor contains > 65% of lignin and about 30% of the dissolved salts. The heating value of the black liquor is from the oxidation of the organics, while the boiling point rise is dictated by the inorganics. The smelt product is used to produce green liquor; therefore, a Na/S balance needs to be maintained by adding salts or sulfuric acid before the recovery. Importantly, the non-processing elements (such as potassium, chloride, calcium, aluminum, silicon, and iron) may cause incrustation on the heat exchange surface in boiler and reduce its efficiency. Both thermal and chemical properties need be re-evaluated in the scenario of lignin removal from black liquor.

The composition of black liquor was plant dependent. The lignin contents, average lignin molar masses, and non-processing elements, were quite different among black liquors from eucalyptus, pine, and bamboo.7 However, the heating values were found to be similar among them. The rheological properties were also different among the black liquors.

The technologies to isolate lignin from Kraft Black liquor

Indulin is the technical lignin byproduct from the Kraft black liquor of linerboard pulp. It was marketed by West Virginia Pulp and Paper Company (Now Mead-Westvaco) in 1950’s, with applications in asphalt emulsifiers, or for rubber reinforcement, etc.8, 9 For a long time, this was the only technical lignin from Kraft process. In the last two decades, efforts have been made to improve economic and environmental performance of Kraft pulp mills. Since most Kraft pulp mills were limited by chemical recovery, this step became the target for debottlenecking the mill. Lignin removal would allow higher throughput by reducing heat value in black liquor. Therefore, the pulping scale can be increased without investing on a larger recovery boiler. In addition to improving the efficiency of pulping, the lignin removal can generate technical lignin product for additional revenue.10–12 Kraft lignin can be used either as a biofuel or as a chemical feedstock for value added applications.

In 1989, Uloth and Wearing reported that acid precipitation was more economical than ultrafiltration for Kraft lignin isolation, because its capital and operational costs were lower. Plus, acid precipitation also gave better lignin product.13, 14 Black liquor oxidation was proposed to address the issue of odor hazard. At 15% lignin removal, the heating value and combustibility of the black liquor still met the need for chemical recovery.

Acid precipitation involves protonation of the phenols in lignin. As the pH reaches the pKa range of the phenolic groups, lignin molecules undergo conformation change and start to flocculate.15 In addition to pH, temperature and ionic strength also influence lignin solubility. The molecular weight distribution in precipitated lignin is related to the yield.16 Both molecular weight and the ratio of phenol to aromatic unit contribute to lignin solubility.16, 17

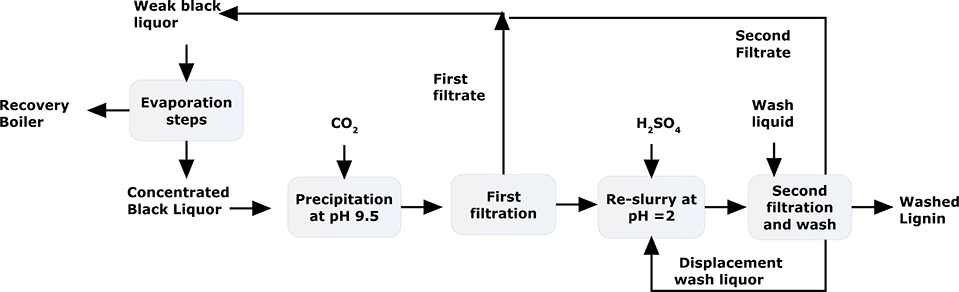

Starting from 1997, Inventia (Formerly STFI-Packforsk, Sweden) and Chalmers Technical University jointly developed a lignin extraction process based on acid precipitation.11 The development focused on maximizing efficiency in lignin isolation and salt removal. As the result LignoBoost was invented in 2002 (Figure 7).18, 19 This process began with adjusting the pH of the black liquor to around 9.5 with carbon dioxide. After aging to flocculate, lignin was isolated by the first filtration. In the next step, the recovered lignin was re-slurried to equilibrate at pH 2. In the last step, the lignin was isolated by filtration, and the liquid from the re-slurry step was displaced by washing with diluted sulfuric acid. In this process, the filtrations were highly efficient. Salts were efficiently removed at low pH; therefore the ash content was low in the product.20 Later, flocculation was further improved by adding lignin germ particles.21

Figure 7.

LignoBoost Process to isolate Kraft lignin

Lignin removal reduced the heat value and changed the physical properties of black liquor. At a constant ratio of air to mass unit of black liquor, the removal of lignin caused reduction of heat transfer rate in recovery boiler, therefore making room for more input in terms of dry solid load or heat load.22 Integrating LignoBoost process into Kraft pulp mill involved re-balancing material and energy.23 To maintain the balance of Na/S, the later streams were sent back to black liquor or for re-slurry. The sodium sulfate in Electro Static Precipitator Dust was also sent back to make up for salt loss.24

Debottlenecking the mill decreased the operational cost. The isolated Kraft lignin was used as a fuel in lime kiln, in which the sulfur in lignin was captured by the calcium. The lignin was also used for other combustion applications with certain benefits. For example, the sulfur in the Kraft lignin (1–3%) was expected to reduce the corrosion caused by KCl when combusted with biomass.23, 25

The LignoBoost process was first scaled up to 8000 tons year−1 in Nordic Paper Bäckhammer (Sweden) for demonstration in 2007. In 2013, Domtar Plymouth Mill in North Carolina (USA) installed the process to produce lignin at about 27,300 tons year−1, and the product was marketed as Bio-Choice Lignin. Comparing with Indulin, Bio-Choice Lignin had higher phenol hydroxyl, catechol, and enol ether; and lower methoxy and β-O-4 contents.26 In 2015, Stora Enso installed the second LignoBoost at Sunila Mill (Finland) to produce LignoBoost lignin at 50,000 tons year−1.

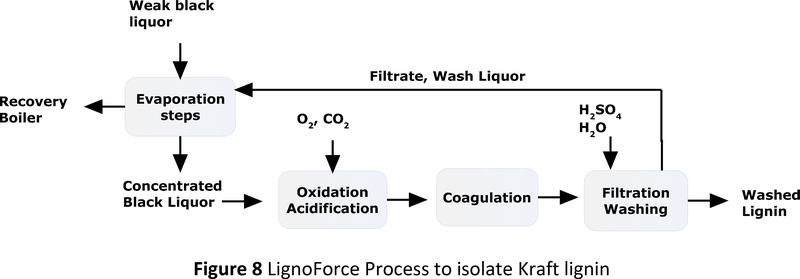

When mill capacity is not limited, lignin isolation has to be justified by high value applications and low isolation cost. FPinnovations, a Canadian non-profit organization surveyed the cost and benefit of isolating lignin from Kraft process.27 Initial evaluation showed that the operating cost of lignin isolation was mainly from the CO2 for acidification. Hazard from sulfur compounds was also a significant concern.28 In Kraft black liquor, totally reduced sulfur (TRS) compounds include hydrogen sulfide, methyl mercaptan, dimethyl sulfide, and dimethyl disulfides. They produce unpleasant odor and are poorly soluble in water. For non-fuel applications, the isolated lignin ought to be free from the malodorous hazard. Although most of the TRS compounds could be removed by repeated wash, they were much easier to remove by oxidation. Based on this observation, the FPinnovations group invented LignoForce process through collaboration with NORAM (Figure 8).29

Figure 8.

LignoForce Process to isolate Kraft lignin

The LignoForce process30 started with sparging oxygen to a black liquor containing 30–40% of solid. The oxidation was carried out at 75 °C until the sulfide concentration was reduced a specific level. The solution was then acidified by CO2 to pH around 10. The lignin slurry was coagulated at 65–70 °C and the lignin particle was isolated with filtration. In the final step, the lignin cake was washed with diluted sulfuric acid. Only one filtration was needed to produce high quality lignin. In this process, the TRS compounds were transformed into more acidic species such as sulfate, sulfonate, or sulfone,28 hence reduced the need for CO2 to adjust pH in lignin precipitation. Lignin formed larger particle in the coagulation step, therefore the filtration was faster. Hazard from TRS compounds was removed from the process and lignin product. This process was demonstrated with feedstocks from hardwood, softwood and eucalyptus. In 2015, West Fraser built a lignin plant based on LignoForce technology in Hinton pulp mill in Alberta, Canada.31 The scale was 30 tons per day, with removal rate at 0.15 ton of lignin per ton of pulp. The integration also involved rebalancing energy, water, steam, chemicals and Na/S ratio.10, 31 Since the mill operated below its maximum capacity, the lignin product was expected to be used in specialty chemical applications such as replacing phenol in phenol formaldehyde resin.31, 32

Process intensification is a less explored, but highly desirable technology for lignin isolation from black liquor. In 1950’s, West Virginia Pulp & Paper Co. patented a coagulating technology involving turbulent mixing in a tubular reactor of black liquor that had been acidified with stack gas. The fusion of lignin particles was better managed in a continuous process.33 In 2010, Finnish company UPM-Kymmene Co. disclosed a method by integrating acidification with pressurized CO2 and turbulent mixing in one tubular reactor plus a rapid pressure release at the exit.34 In the continuous process, lignin precipitation was much faster, therefore black liquor residence time was less than 300s.

In a different approach, the Sequential Liquid-lignin Recovery and Purification (SLRP™) technology employs reactive extraction to facilitate lignin isolation based on the fact that a lignin-rich liquid phase is formed from black liquor upon carbonation.35 After phase-split separation, lignin is precipitated from the raffinate by acidification with sulfuric acid. The reactive extraction was continuous. The H2S was efficiently recovered in the White Liquor, and CO2 consumption was reduced by 30%. This process has been tested on pilot scale with black liquors from different wood feedstocks.

Currently, only press filter has been used for solid lignin separation and wash. Belt filter was tested in LignoForce process, but the solid content was only 34% in product, indicating much lower efficiency for water removal.32

Lignosulfonate is an integral member in the product portfolio from sulfite pulping biorefinery

Sulfite pulping processes and spent sulfite liquor

Sulfite process was the predominant pulping process from late 19th century to early 20th century. The process employs sulfite or bisulfite to digest biomass. It is characterized by the flexibility to operate over a wide pH range. Depending on the pH, the base for pulping is a cation from Ca2+, Mg2+, Na+ and NH4+. Calcium can only be used in acid bisulfite pulping, as it will precipitate when pH is ≥ 3. Magnesium is used in the processes when pH ≤ 5. At higher pH, only ammonium and sodium are feasible. Different degrees of delignification can be achieved by fine tuning the cooking liquor, the ratio of chemicals to biomass, and physical conditions. The pulping can also be carried out in multiple stages with different cooking liquors.36 Major types of sulfite pulping include Acid Sulfite Process (pH 1–2), Neutral Sulfite Process (Neutral Sulfite Semi Chemical, NSSC, pH 5–7), and Alkaline Sulfite Process (pH 9–13.5).

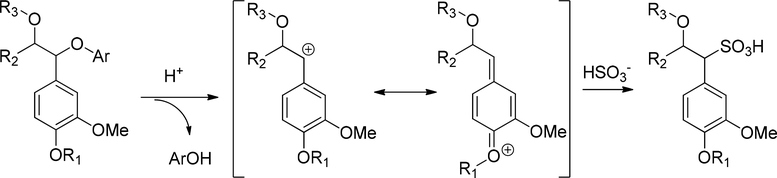

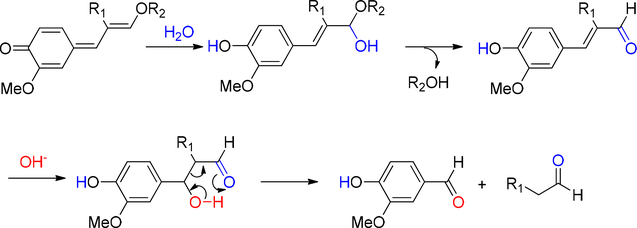

In Acidic Sulfite process with softwood, the main reaction involves the formation of an α-C cation from the α-O-4 ether, followed by a sulfonation (Figure 9). Unlike the lignin depolymerization in Kraft process, the lignin is solubilized through sulfonate formation. For carbohydrate, hemi-cellulose is degraded under acidic condition to give corresponding mono-, oligo saccharides, acetic acid, and other derivatives. As the pH increases, both reactions are slower, and the intensity of pulping is decreased.36

Figure 9.

Lignin sulfonation in acidic sulfite process with softwood feedstock

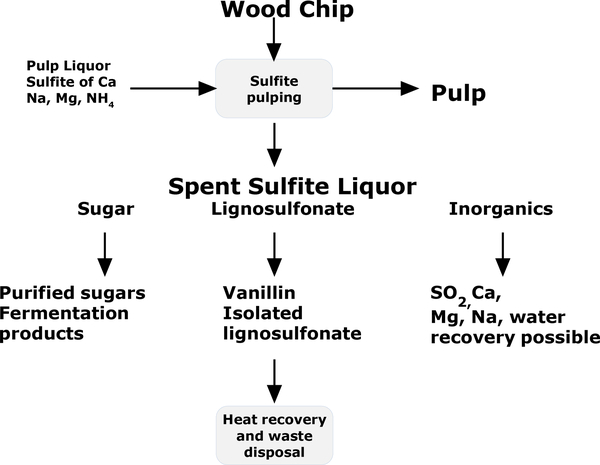

The spent sulfite liquor (SSL) is largely composed of lignosulfonate, acetic acid, sugars from hemicellulose, inorganics, and small quantities of derivatives from sugar dehydration. Based on the oven dried ton of pulp (ODT), the organic is in the range of 595 – 1224 kg/ODT. Lignin is in the range of 410–892 kg/ODT, representing 64–76% of the organics. Sugar is in the range of 129 – 288 kg/ODT, accounting for 17–25% of the organics. The chemical oxygen demand (COD) of SSL is typically 120–220 g/L.37 In sulfite mill, many products are extracted from the organics in the SSL to improve the economic performance and reduce the burden of waste disposal.

Biorefinery based on sulfite process

When the concept “biorefinery” emerged in the 1990’s,38 sulfite pulping had already advanced to a platform with a multiproduct-portfolio. It offers important experience in maximizing value of a biomass waste with integrated processes. The flexibility of sulfite process allows it to generate many types of pulp, with potential products from both sugar and lignosulfonate in SSL (Figure 10).

Figure 10.

Principles to build a biorefinery based sulfite process

Hardwood gives xylose, while softwood gives mannose and glucose as the main products.39 Higher temperature and longer cooking time increase the amount of dissolved sugars as well as the byproducts from them.40 The analysis of Borregaard (Sarpsborg, Norway) samples showed that the property of lignosulfonates was also dependent on biomass feedstock. Hardwood lignosulfonate had a weighted average molecular weight (Mw with UV detection) of 7.2–11 kDa with polydispersity values of 3.0–5.3 (with MALLS detection), while the softwood lignosulfonate had Mw of 35–57 kDa with polydispersity values of 8.2–12.3. The degrees of sulfonation were similar between hardwood and softwood, but were inversely correlated to the molecular weight. The Mw and degree of sulfonation were both reduced in the oxidation to generate vanillin.41

Lignosulfonate is highly soluble in a wide pH range. Before 1970’s Howard process was the most practical technology to separate lignosulfonate from SSL.42 In this process, lime suspension was added to the SSL. Both lignosulfonate and sulfite were precipitated by forming calcium salts. The calcium lignosulfonate formed a low density colloidal phase as a mixture with air, while the crystalline calcium sulfite settled as solid sediment. They were separated by the difference in density. The isolated calcium lignosulfonate was low in ash and free from carbohydrates. The isolated calcium lignosulfonate was used in tanning. It was also a flexible feedstock, as it could be converted to other salts by exchanging the cation with the corresponding carbonate.43

The calcium lignosulfonate was used in the preparation of vanillin.44 In a process invented in Marathon Paper Mills Company (Wisconsin, US), calcium lignosulfonate was converted to the sodium salt through an exchange reaction. After calcium sulfate precipitate was removed, the sodium lignosulfonate was oxidized to generate vanillin under basic condition and high steam pressure. The reaction mixture was acidified with sulfurous acid, converting vanillin to the bisulfite adduct and precipitating the remaining lignosulfonate. After the remaining lignosulfonate precipitate was removed by filtration, vanillin was regenerated by decomposing the bisulfite adduct and isolated by extraction. Since softwood lignin is rich in guaiacyl unit, it is more suitable for lignin production.

An alternative strategy started from converting sugar to a product separable from lignosulfonate. In 1903, It was found ethanol could be made by fermenting the hexoses in SSL.45 In 1938, Borregaard started to produce ethanol from SSL. The ethanol fermentation step was later integrated with the production of vanillin. The SSL from softwood was fermented to produce ethanol. After ethanol removal, the lignosulfonate in the stillage liquor was used for vanillin production. In 1945, a plant was built in Thorod mill (Ontario, Canada) to produce 227 tons of lignin vanillin per year with this technology.46

The ethanol process is more suitable for softwood SSL because most of the sugars are hexoses. Since most mills used both hardwood and softwood in pulping, this option was not practical. In 1940’s, Candida utilis (torula yeast) was selected to produce single cell protein from SSL because it used both hexose and pentose. Rhinelander Paper Company (Wisconsin, US) employed a fermentation-first process to produce torula yeast from SSL.47 Prior to fermentation, inorganic sulfite was removed with lime treatment or stripping. Nitrogen, potassium, and phosphorus were also added to the SSL for medium preparation. In fermentation, yeast was produced in 50% yield from the fermentable materials. The yeast was isolated and sold as a food or animal feed additive. The lignosulfonate-rich liquor was evaporated to 50% thick and the lignosulfonate was sold as Toranil. It was further processed to a dry powder and sold as Toranil B. An important development of single cell protein from SSL was the commercial production with Pekilo process in Finland.48 In 1973, Jämsä River Mill (Jämsäkoski, Finland) built a single cell protein facility with SSL as the carbohydrate feed. The fast-growing fungus Paescilomyces varioti was produced for animal feed at the scale of 10,000 tons per year.

Membrane technology in biorefinery based on sulfite process

As mature equipment became available in early 1970’s, membrane technology was introduced into pulping industry.49 In 1972, Green Bay Packaging Inc. (WI, USA) used reverse osmosis to treat effluent, resulting in a nearly closed water system.50 The feed was a neutral sulfite hardwood pulping waste with 4–6% dissolved solids. The equipment employed cellulose acetate membrane with a total area of 446 m2 to treat waste water at the rate of 340.6 L min−1. The new system reduced the biological oxygen demand (BOD) of the effluent from 9072 kg day−1 to 454 kg day−1. Later reverse osmosis was used in US, Sweden, and Japan for the treatment of bleaching effluents with polysulfone membrane in larger scales. In 1981, two Japanese companies built membrane separation for effluent treatment. Taio Paper Co. treated 3600 m3 day−1 effluent with 1480 m2 membrane, and Sanyo Kokusaku treated 2500 m3 day effluent with 672 m2 membrane.51 The membrane technology improved the efficiency of waste treatment,52 and the concentrate was incinerated for energy recovery.53

Concentration and fractionation are basic needs to manipulate SSL. There has been an expanding effort to address these needs with membrane technologies including ultrafiltration, nanofiltration, diafiltration, reverse osmosis, and electrolysis.51, 54, 55

A survey demonstrated that sugar and lignosulfonate were separable with a polyethersulfone membrane (UP010 from Microdyn-Nadia) with a molecular weight cut-off (MWCO) at 10 kDa.56 Ideally, all lignosulfonate is rejected by the membrane while all sugar passes through at practical flux. In practice, this was carried out by two or three consecutive filtrations with decreasing MWCO, 57 thereby most lignosulfonate was rejected in retentate while most sugar stayed in permeate.

Membrane technology offered the most effective lignin fractionation processes by combining ultrafiltration (UF) and diafiltration (DF).58 The process involved concentrating SSL to a conversion ratio of 0.75–0.8 with ultrafiltration, followed by small molecule removal with diafiltration until a specific purity of lignin was reached. With molecular weight cut-off at 10 kDa in diafiltration, the process gave a lignosulfonate solution with 25% total solid content. The yield of lignosulfonate was 68%, and the purity was 93%. The capacity of the UF-DF process was dependent on the content of SSL. When the stream was from Pekilo process, the capacity of lignosulfonate fractionation increased by 50% as most sugars had been consumed in the fermentation.59

In late 1970s, several Scandinavian mills and Reed Paper (Quebec, Canada) integrated membrane technology to concentrate SSL,59 thereby to reduce the energy cost and improve product quality. With hyperfiltration (Reverse Osmosis), the SSL could be concentrated from 11 to 22% total solid with a flux of 40L m−2 h−1.52 The technology reduced energy cost by about 50% from that for water reduction by evaporation.59

Lignosulfonate has been used as a dispersant for concrete, but the function was impaired by the presence of impurities such as carbohydrates, inorganic salts, and resins. In addition, the high molecular weight lignosulfonate did not contribute to the dispersant capacity. Therefore, ultrafiltration was used to remove the impurities as well as high molecular weight lignosulfonates.60 The process involved two consecutive ultrafiltration steps with MWCO = 60 kDa at the first step and MWCO = 5 kDa at the second. Ceramic membranes were used so that the both steps could be carried out at 95 °C. High molecular weight lignosulfonate was rejected along with the resins in the retentate of the first filtration. The low molecular weight impurities, such as salts and sugars, were removed in the permeate of the second filtration. The resulting lignosulfonate fraction shortened the settlement time in concrete making and gave a product with lower air content.

For vanillin production, Borregaard 61 employed membrane fractionation to separate lignosulfonate with molecular weight in the range of 6 – 65 kDa. In a batch reaction with copper sulfate as the catalyst, this fraction offered 14.9% vanillin yield on a lignin base. For fraction with molecular weight < 6 kDa and the one with molecular weight > 65kDa, the yields were 9.8% and 9%, respectively. The fractionation step not only improved the yield and throughput of vanillin production, it also reduced the consumption of other reactants. The cost of equipment maintenance was also lower because scaling and crusting incidents were reduced or eliminated.

For sugar conversion in SSL, the liquor needs to be prepared to improve fermentation efficiency because microbial growth is inhibited by such chemicals as acetic acid, furfural, hydroxymethylfurfural, and phenolics.62, 63 These chemicals were typically removed by over-liming and evaporation of SSL. Alternatively, fermentation was carried out with sugars isolated from SSL by membrane technology.56, 57. The latter is more attractive as the separation can be installed before chemical transformation, so that product development can be more flexible from either lignosulfonate or sugar. The process efficiency is also improved because the two streams can be handled in parallel.

Succinic acid could be produced from xylose and hexoses by fermentation with Actinobacillus succinogenes and Basfia succinociproducens.64 To prepare for the fermentation, lignosulfonate was removed from a hardwood SSL with either ultrafiltration or nanofiltration. Nanofiltration was the best pretreatment for the fermentation with Basfia succinociproducens. Comparing to non-treated stream, nanofiltration increased final product concentration by 3 folds and product yield (g of succinic acid/g of consumed sugar) by 29%. By product formation was reduced by 43%. With nanofiltration, 95.6% of the lignosulfonate was rejected in the retentate. The benefit of nanofiltration was also demonstrated in fermentation with immobilized microorganisms for succinic acid production.65

In biorefinery design, sugar fraction from SSL can be converted to many products such as xylitol, ethanol, polyhydroxyalkanoates.66–70 They are the most flexible candidates for biorefinery design, therefore critical for maximizing the profitability of lignosulfonate value chain.71

Many methods have been developed to extract lignosulfonate from SSL.72 A recent method featuring selective adsorption of lignosulfonate with XAD-7 exemplified many desirable features for analytical extraction. 73 The method recovered lignosulfonate quantitatively with a simple protocol. The product had only < 1% of carbohydrate. The method was quick, robust, reproducible, and easy to scale up to prepare grams of material. Size exclusion chromatography (SEC) is the most commonly used method to fractionate lignin.74 Sodium lignosulfonate (4.8–14.2 kDa) was fractionated in 0.5 M NaOH with Toyopearl HW-55.74 With a combination of Sephacryl-100 (2 – 20kDa) and Sephadex LH20 (2–6 kDa), lignosulfonate could be purified to fractions with polydispersity between 1.76 and 1.07.75 Ultrafiltration has been compared with amine extraction76 and ethanol precipitation77 to fractionate lignosulfonate. Ultrafiltration gave products with polydispersity between 1.3–2.4,76 or 1.25–1.98.77 Both were much lower than the values by amine extraction or ethanol precipitation.

Membrane separation is highly flexible for SSL fractionation because the selectivity can be adjusted by the choice of membrane and operational conditions.54, 55, 78 It also has the important advantage of straightforward scale up from analytical fractionation to process technology. When combined with lignin characterization, membrane technology will be a very effective tool for product development.79

Organosolv pulping generates sulfur-free lignin byproduct

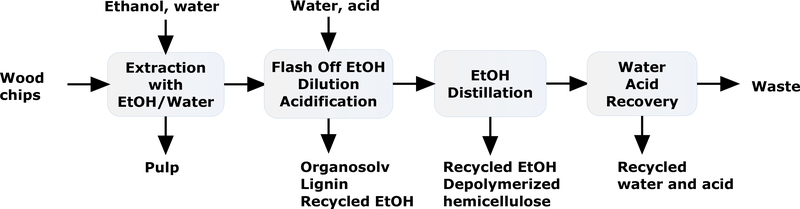

Organosolv pretreatment of lignocellulose involves a biomass extraction in a mixture of solvent and water under high pressure.80 The most common solvent is ethanol. In the treatment, lignin is fragmented and dissolved in organic solvent, and hemicellulose is depolymerized into soluble saccharides, leaving cellulose as the insoluble ingredients. Since all solvent is recycled, the environmental impact is small. Smaller mills are economically feasible with Organosolv process because there is no capital investment on chemical recovery boiler and kiln.

In 1989, Repap Enterprise Inc. built a commercial scale mill based on Alcell process in New Castle, New Brunswick, Canada.81 The process used recovered EtOH/water mixture from later steps as the solvent for the prior steps to minimize the amount of ethanol (Figure 11).82 The pulp from the process was easy to bleach and exhibited similar properties to those in Kraft pulp. Lignin was an important by product. In an example (Figure 11),83 the process started from cooking the wood chips in ethanol and water (60:40) mixture under pressure at 190–200 °C for 30 – 90 min. After the treatment, ethanol content was reduced to 12–21% by flash distillation and cellulose was separated. To the black liquor, water and strong acid were added to precipitate lignin. After settling, lignin was isolated by centrifugal filtration, leaving digested hemicellulose and small lignin fragments in the liquid. In the next step, ethanol was stripped from the liquid phase, leaving saccharides from digested hemicellulose in the remaining syrup. Xylose could be recovered from the syrup as a product. In a recent development, lignin was precipitated by a fed-batch precipitation, in which ethanol was removed continuously from the incoming liquor stream.84 The precipitation was optimized based on the solubility profile of the lignin. Overall, spent liquor was reduced by 50% since no water dilution was needed, and filterability was improved by particle size optimization.

Figure 11.

Alcell process based on organosolv pulping

Alcell lignin had low molecular weight (Mw < 900) with low polydispersity, no sulfur, and low ash content.85 Comparing to Kraft lignin and Lignosulfoante, Alcell lignin was more hydrophobic, and had lower glass transition temperature (90–100 °C). After lignin isolation, the xylose was converted to furfural and easily isolated as a fraction in the distillation for solvent recovery. Since lignin was not combusted for energy, all energy was from external source.81

The main mechanism of lignin depolymerization of the original Alcell process involves α-O-4 ether cleavage, while other reactions are involved when additional chemicals are added to increase the severity.86 The lignin also undergoes condensation. In the absence of sulfide, delignification was slower in Alcell process. Indeed, the original Alcell process could only remove less than 60% lignin from softwood.87 In pulping of softwood or mixed hardwood, sulfite, bisulfite, and caustic could be added to improve the efficiency.88

For hardwood pulping with Alcell process, ethanol was more efficient than dioxane and diglyme in delignification.89 The molecular weight distributions of degraded lignin were similar under different digestion conditions. About 60–80% of the lignin had a Mn of 900, which was precipitated in the dilution step. The rest were low molecular lignins remaining in the mixture with depolymerized hemicellulose. From the inception of Alcell process to 2005, 3500 tons of Alcell lignin was sold as the technical lignin.90

Characterizations showed that Alcell lignin had about 2% moisture, and purity > 96%. The main impurities include 0.2% carbohydrates, < 0.1% ash.79, 91–93 Depending on the analytical methods, the Mn was from 600 to approximately 1000, with polydispersity values between 2.4–6.3.91, 93 Alcell lignin had softening points around 138–147 °C. The heating value was 26, 700 J/g. 91 Organosolv lignins are sulfur- and ash- free, therefore they are more suitable for catalytic transformation into value-added material or chemicals.93

Cellulosic ethanol industry is an emerging source of lignin

The background of lignocellulosic ethanol for transportation fuel

Ethanol was used as an oxygenate to replace tetraethyl lead to boost octane value of transportation fuel. Although ethanol has lower energy value, it offers important benefits such as higher combustion efficiency at shorter combustion duration. Gasoline blended with ethanol generates lower emission of carbon monoxide, hydrocarbons, and NOx etc. Gasoline with < 10% ethanol can be used in most modern vehicles and are available in many nations worldwide.94 Methyl tetrabutyl ether was another oxygenate for transportation fuel, but it caused significant environmental issues as a persistent pollutant in water and air.95 Comparing to methyl tetrabutyl ether, ethanol is a safer oxygenate as it is readily biodegradable. As such, ethanol has a stable basic role in transportation fuel market.

In the first oil crisis in 1973, ethanol was evaluated as a primary fuel source when energy security became a legitimate concern. In 1975, Brazil established the National Program of Alcohol (PróAlcool) with ethanol from the sugarcane sucrose for transportation.94 In less than 10 years, sugarcane ethanol established a significant role in transportation fuel.96 From 1976 to 2004, the total amount of ethanol used in transportation was equivalent to 1440 million barrels of gasoline. In 2004, 29.4% of Brazilian energy consumption was from Biomass.97 In 2008, 25 billion liters of ethanol was produced, of which 2.8 billion liters were exported to the US and 2.36 million liters were exported to other nations.96

Since 2000s, replacing fossil fuel with renewable fuel became a global effort as the impact of Greenhouse Gas on climate change was widely recognized. In the US, the first-generation bioethanol is made by fermentation of the glucose from corn starch. This is only a solution in transition because fuel and food are competing for the feedstock. Since cellulose in biomass is the largest source of low cost feedstock, cellulosic ethanol became a highly desirable candidate for transportation fuel.1, 98, 99 Waste biomass is the low-cost byproducts of agriculture and forestry; including wheat straw, rice straw, sugarcane bagasse, and corn stover. The global yield of waste biomass was estimated between 10 and 50 billion tons per year.100 They are ideal feedstocks for ethanol production because they are generated as crop byproduct and must be disposed.

Unlike fossil fuel, biomass is widely distributed on earth surface. Therefore, collecting and shipping costs in supply chain are the limiting factors for feedstock inventory management. The feed stock of a biorefinery can only be collected in a limited area. It is usually packaged and shipped to the biorefinery directly. However, the supply chain can be more resilient by installing an optimized network of biomass depots.101

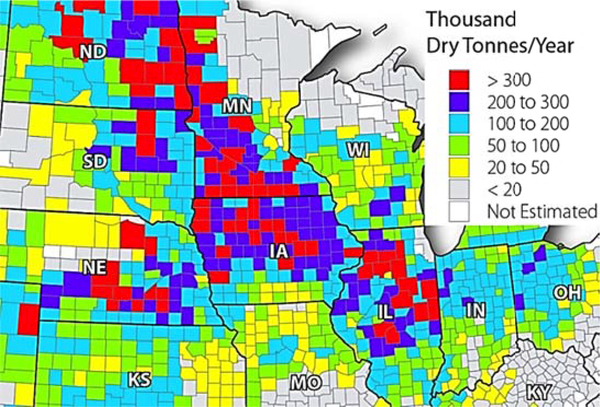

Lignocellulose waste is abundant in many parts of the US. The National Renewable Laboratory (NREL) characterized the available biomass in the United States by county.102 Web-based tools were put online for users to search and study for general understanding or specific applications. A quick search showed that crop residue is most abundant in the Midwest (Figure 12), where corn, soybeans and wheat are the predominant crops.

Figure 12.

The crop residue available for value-added applications in Midwest (Assuming 35% of the total residue could be collected)102

In the past two decades, US legislation passed a series of laws to support the R&D or scale up in biomass based technologies and subsidize biofuel. The use of biofuel (mainly ethanol) in transportation increased as the result of enforcing National Renewable Fuel Standard rule (RSF, and RSF2) set forth by The Energy Policy Act of 2005, and Energy Independence and Security Act of 2007.103 In the US, National Renewable Energy Laboratory (NREL) has been the leading institution to develop renewable fuel through either fermentation or syngas route. In 2013 the cellulosic ethanol cost by fermentation was reduced to $2.15 per gallon.99

In 2006, Canadian Federal Government initiated a 5% ethanol mix (E5) mandate as guided by the federal environmental policy to reduce greenhouse gas. Tax exemption was applied to E5 gasoline. Different provinces applied additional incentives to promote ethanol use in gasoline mix. To meet this need, fuel ethanol has been produced from starch of corn and wheat.98 For long term supply, bioethanol was expected to be produced from lignocellulose biomass from agriculture residue, forest and mill residues, disturbance wood, and energy crops. Together, the total supply was estimated to be 24–86.7 million dry tons year−1. The ethanol from biomass would meet 6.4 −61.1% of national gasoline need in 2006. The progress of R&D in government and academia in Canada was summarized in two recent reviews. 104, 105

In Europe, lignocellulosic ethanol for transportation was governed by a more complex legal framework.106 For European Union (EU) nations, the Fuel Quality Directive requires its member to reduce greenhouse intensity by 6% in 2020, while the Renewable Energy Directive requires that ≥ 10% of transportation fuel should be from renewable sources by 2020. Each nation in EU needs to provide energy targets and an action plan. The lignocellulose feedstock potential was evaluated with Geographical Information System modeling for 27 nations in Europe, Switzerland, Norway, and Ukraine. In total, 42.7 million hectares of land was available for feedstock production. Within a nation, the government could mandate the use of biofuel or provide tax exemptions on carbon dioxide emission or road use. A 2017 study with the Norwegian case found that the viability of biofuel companies was directly dependent on policy support.107 Another study focused on cellulosic ethanol producers showed that even though mandate for bioethanol created a national market, fuel companies could import the ethanol, or outsource the technology to places where cost of production was lower.108 Basically, all the producers needed to have stable customers to stay in business. Building a cellulosic ethanol industry is highly risky as ethanol is a commodity product with low profit margin. Cellulosic ethanol faces severe competition in the global market while the support for developing biorefinery industry is national.

The unit operations in a lignocellulosic ethanol process

The lignocellulosic ethanol process involves eight essential operation units as shown in Table 1. 104, 105, 109 A certain percentage of biomass is gathered, packaged in the field, and delivered to the biorefinery. The quality of the feedstock needs to be managed by standardized protocols. Agriculture residue could have high non-processing impurities. Indeed, Italian plant Crescentino needed to moving away from wheat straw due to high impurities.108 The quality of the incoming biomass is stabilized in the next step involving cleaning and size reduction. Size-reduced biomass is treated under severe conditions to de-assembly lignocellulose for cellulose hydrolysis. The saccharification of cellulose and hemicellulose is generally carried out by enzyme digestion. The efficiency of enzyme catalysis is dependent on the substrates and impurity profile. In fermentation, hexose and pentose are converted to ethanol. The ethanol product is distilled and dehydrated for transportation fuel application. The lignin has been a spectator species and can be separated from the stream before fermentation or after ethanol separation. Currently, the isolated lignin is burnt for energy recovery. The remaining waste is treated with anaerobic fermentation to generate methane as well as reduce organics in the waste.

Table 1.

The unit operations in lignocellulosic ethanol production and challenges

| Step | Operation Unit | Objectives |

|---|---|---|

| 1 | Feed handling | Efficient biomass gathering Packaging and densification for transportation Efficient delivery to biorefinery Steady inventory maintenance |

| 2 | Cleaning, size reduction | Removal of non-processing impurities. Pelletization, comminution, decreasing the size of lignocellulose waste to improve pretreatment |

| 3 | Pretreatment | Disruption of plant cells Separating hemicellulos and lignin from cellulose Decreasing cellulose crystallinity Minimizing fermentation inhibitor formation. |

| 4 | Saccharification | Hydrolyzing cellulose and hemicellulose into monomers for fermentation Maximizing fermentable sugar generation |

| 5 | Fermentation | Hexose and pentose fermentation to produce ethanol |

| 6 | Ethanol separation | Distillation and dehydration for fuel application |

| 7 | Lignin isolation | Separation for use in energy recovery or further upgrade |

| 8 | Waste treatment | Bio-digestion for methane generation |

Pretreatment is the most critical step in cellulosic ethanol production because a compromise needs to be reached to maximize the efficiency while minimize the impurity generation. Several pretreatment methods are available based on different mechanisms.105 The most popular method is acid hydrolysis in which hemicellulose is depolymerized and ether bonds in lignin are efficiently cleaved. Other approaches emphasize delignification. Lignin is redistributed and depolymerized when heated. This process can be facilitated by including organic solvents in Organosolv, ammonia in Ammonia Fiber Expansion, or ionic liquid solvation.110 However, the recalcitrance of lignocellulosic biomass is a multi-scale issue.111 Chemical treatment alone is not adequate to overcome recalcitrance at nano and meso scales. Intensified physical factors have been added to overcome recalcitrance at higher scales, leading to the increase in porosity and specific area for enzyme digestion. Microwave causes multiscale changes in lignocellulosic biomass by delivering energy directly into the biomass and causing molecule friction. It has been used with chemical pretreatment to enhance biomass degradation, but its application on industrial scale is limited by the concern of energy efficiency.112 A more practical physical treatment is steam explosion.113 The process involves building up energy in biomass with pressurized vapor, followed by a quick pressure release to generate shear force to disrupt cell walls. The severity of steam explosion is mainly dependent on temperature and retention time. The technology has been used on industrial scale, and can be combined with chemical pretreatments.

Woody biomass has higher density, therefore needs to be milled into workable particles before pretreatment. The energy cost of mechanic size reduction can be as high as 42% of that from the ethanol obtainable from woody biomass.114 Sulfide dioxide steam explosion has been applied for woody biomass pretreatment, but pressurized sulfur dioxide is corrosive and toxic. This issue was addressed by changing the order of treatments in SPORL (sulfite pretreatment to overcome recalcitrance of lignocellulose).115 The wood chip was cooked with 8–10% bisulfite and 1.8–3.7% sulfuric acid at 180 °C for 30 min. The cooked chip was then milled for enzyme digestion in the next step. As the result of the mild treatment, the cellulose hydrolysis yield was > 90% and the formation of byproducts was reduced by 53 – 73%. Ethanol from woody biomass became attractive with SPORL because energy consumption in milling was reduced by > 90%. This process was successfully tested with spruce and red pine for ethanol production.115, 116

In saccharification, cellulose and hemicellulose are generally hydrolyzed with enzyme cocktails. A suite of enzymes is needed to break different bonds in carbohydrates. Statistical analysis were applied to understand the need for digestion of different carbohydrates and optimize the ratio of enzymes in the cocktail.117 The saccharification can be consolidated with ethanol fermentation with engineered microorganisms.118 Microorganism selection and metabolic engineering have been used to integrate other desirable features such as robustness for fermentation, low energy demand in cooling, better tolerance of ethanol, etc.119 Metabolic engineering has also been used to enable xylose fermentation, improve electron flux to ethanol, and block the formation of byproducts. 119, 120 Membrane separation has also been integrated with fermentation. In pervaporation-coupled fermentation, ethanol was selectively separated in situ as a gaseous permeate. The product removal increased ethanol production by removing solvent inhibition and improving microorganism activity.121 In a continuous and closed-circulation fermentation with Saccharomyces cerevisiae, integrating pervaporation increased time and space productivity for ethanol when ethanol was recovered with separation factors of 8.8 and 9.5 in two repeats.122 The membrane does not need to be in direct contact with the broth. When vapor permeation was used instead of pervaporation with fermentation, the rate of ethanol production was further increased by 15%.123

Cellulosic ethanol industry is potentially the largest source of industrial lignin. The lignin products from the processes without using sulfite are expected to be sulfur-free, a desirable feature found in Organosolv lignin.

Organosolv ethanol biorefinery with corn stover as the feedstock

Corn stover is the most abundant agricultural residue in the US, with a yield of 64 million tons in 2012. Up to 30% of corn stover can be removed without affecting soil quality. The greenhouse gas emission of using ethanol from corn stover would be 70% lower than that of using US gasoline.124

Corn stover features high content of xylose. The potential yield of ethanol from corn stover was estimated to be 493 L (equivalent to 130.2 gallon) per dry ton. Pentose fermentation contributed 39% of the estimated ethanol due to high content of xylan.125 In an evaluation to compare technology options,126 dilute acid pretreatment was the cheapest one for corn stover. Enzyme for saccharification and feedstock were the main contributors to the operating cost. There was an energy surplus for the scenario involving burning lignin, and the capital cost contributions from combustor, boiler and turbo-generator were high.

The progress of cellulosic ethanol production in the US has been below expectation. According to a 2016 survey, there were five commercial scale biorefineries in the US in operation. They all used fermentation technology to convert lignocellulose into ethanol.127 In total the output of ethanol was 0.73 million gallons in 2014, 2.2 million gallons in 2015, and 3.3 million gallons in 2016. The productivity of lignin byproduct can be estimated with the following two assumptions:128

Biomass conversion efficiency: 70 gal ethanol per ton of biomass

Lignin in Biomass: 25% by weight

Based on the assumption, it takes 14.3 kg of lignocellulose biomass to produce one gallon of ethanol. The amount of lignin byproduct is 3.57 kg. In 2016, the theoretical amount of lignin from biorefinery is 11.8×103 tons. All the lignin was combusted for energy.

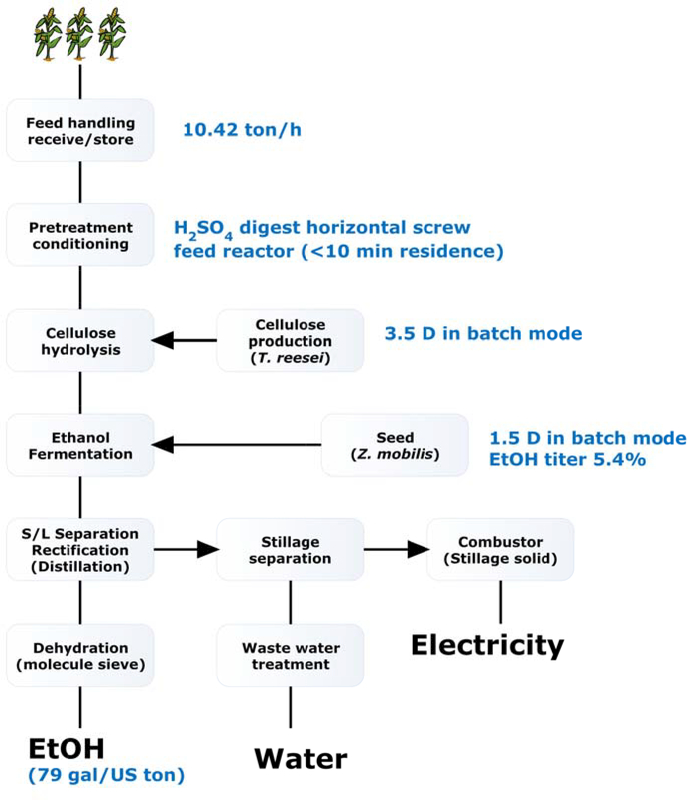

In 2011, NREL published a technoeconomic analysis for ethanol production from corn stover.129 The reported case was highly representative as it adopted the latest design with validated key technologies. The scale was set at 7.73×105 US tons year−1 of biomass. Corn stover was the most practical option as it was the most stable lignocellulose waste in the US Corn Belt. The lignin content in corn stover is low. According to the sampling study, the lignin content was between 11.2–17.8% (n = 508). The study used lignin content at 15.76% in the modeling. Correspondingly, the lignin byproduct was less than those from other feedstocks.

The process design integrated several critical innovations as outlined in Table 2. The most significant change involved direct cellulose digestion and sugar fermentation in a heterogeneous mixture. Lignin was removed after ethanol recovery (Figure 13). This design eliminated lignin separation step prior to digestion and fermentation. Another change was co-fermentation of xylose with glucose by an engineered bacteria Zymomonas mobilis strain 8b. With this process, the yield of ethanol was 79.0 gal/dry US ton corn stover. The Minimum Selling Price (MESP) of EtOH was $2.15/gal, equivalent to $3.27/gal gasoline.

Table 2.

Critical feature in the NREL bioethanol process

| Critical feature | Details |

|---|---|

| Pretreatment Intensification | Milled corn stover was treated with H2SO4 in a flow reactor for pretreatment to break down lignocellulose. No organic solvent was used in the pretreatment. In the second step, the oligomer of xylose was completely hydrolyzed. |

| Lignocellulose digestion stream telescoping | The pH was adjusted with NH4OH, which was the nitrogen source in fermentation. Subsequent steps (cellulose hydrolysis and fermentation) was not influenced by the presence of lignin. |

| Cellulose hydrolysis | Efficient enzyme cocktail was prepared by fermentation of Trichoderma reesei. These enzymes include endoglucanases, exoglucanases, β-glucosidase, hemicellulase, and accessory enzymes such as ferulic acid esterase |

| Co-fermentation | Genetically engineered Zymomonas mobilis strain 8b could ferment glucose and xylose to give ethanol. There were improvements in ethanol tolerance, and ability to ferment minor hemicellulose sugars (e.g., arabinose, galactose, and mannose). |

Figure 13.

A lignocellulose ethanol process with corn stover as the feedstock

In the process, the isolated lignin (Stillage solid, Figure 13) was combusted to generate electricity. For each gallon of Ethanol, 5.8 kWh electricity was generated. Only 3.9 kWh was needed for plant use. The rest (1.8 kWh, or 31%) of the electricity was sent back to the grid.

The process of corn stover to ethanol is put to test in Project Liberty

In Late 2000’s POET initiated “Project Liberty” in collaboration with DSM (Netherland) to build a corn stover-to-ethanol process with the key steps involving acid-hydrolysis, saccharification, and fermentation. The site was selected at Emmetsburg, Iowa. It is co-located with a corn starch ethanol facility so that all the equipment after cellulosic ethanol fermentation could be shared.130 Standard protocol was developed to collect 770 bone-dry ton corn stover per day, representing 25% of the above ground plant from the farms in 35 mile radius.131 Non-processable impurities were minimized in the standardized baling procedure. In the plant, the corn stover underwent three stages of size reductions to prepare for acidic pretreatment as well as further impurity removal.132 In the last stage, the feedstock was a slurry of particles with sizes < 0.5 inch and free from dirt, sand, rocks, tramp metals, glass, etc. The biomass was treated with 1–1.6% H2SO4 at 120–150 ͦC to depolymerize xylan while leaving lignin with cellulose in the solid phase.133 The acidic liquid was separated from the solid and reused in the next batch of pretreatment. The cellulose in the solid was converted to glucose in a continuous saccharification at 50 °C.134 The fermentation was carried out with yeast to convert hexoses to ethanol. After fermentation, lignin was separated, dried and pelleted.135 The waste stream was treated in anaerobic digestion for methane generation. Currently, all the lignin was combusted for energy.

The plant capacity was designed to produce 25 million gallons of cellulosic ethanol each year. The realization of this objective is strongly dependent on the implementation of renewable fuel standard (RFS) in the US.131 Since the inception of RFS in 2005, corn ethanol industry expanded significantly. In the period of 2006 and 2014, the consumption of corn rose from 2.1 billion bushels to 5.2 billion bushels, representing an increase from 17.6 to 43.7% of total domestic corn supply.103 Clearly, the successful industrialization of corn stover-to-ethanol process will change the paradigm in corn industry.

The BALI-process is a practical extension of sulfite pulping technology

Borregaard has been producing ethanol by fermenting the hexoses in the SSL stream of sulfite pulping since 1938.136 When transportation ethanol market emerged, a cellulose to ethanol process (BALI, or Borregaard Advanced Lignin Process) was developed in 2000’s based on the delignification with sulfite process.137 The BALI process is the most straightforward approach to convert cellulose to ethanol. It started with cooking the biomass with sulfite to solubilize lignin. Cellulose and a portion of hemicellulose were isolated from the SSL as a pulp. The pulp was enzymatically digested and fermented to give ethanol. Hexoses were converted to ethanol with Saccharomyces cerevisiae in the initial version. Bagasse was extensively tested as the feedstock because it did not require other treatments than sulfite cooking. Sulfite cooking was tested in a wide range of conditions to adjust the extent of delignification and hemicellulose removal. Based on pulp hydrolysis test, the best was weak alkaline sulfite cook, involving treating bagasse with 6% Na2CO3 and 16% Na2SO3 with liquid to solid ratio of 6 to 1 at 160 °C for 180 min. The small amount of lignin remained with cellulose pulp did not inhibit enzymes for saccharification. The glucose yield of the resulting pulp was almost 100%.137 The enzymes for saccharification was expected to be recyclable. Practical cellulose pulp could be generated from several other feedstocks including straw, willow, and spruce with BALI pretreatment.136 Co-fermentation of pentose was planned in the future versions of BALI. The BALI process was put on test at one-ton dry matter day−1 scale in 2012.45 As of the July of 2016, Borregaard were working on the scale up of BALI process after 800 tons of biomass had been successfully processed.138

Application of lignin in polymeric form

For application in polymeric form, a technical lignin needs to be specified by its plant source and process condition. It is also important to characterize the lignin in terms of purity, and chemical and physical properties.79 The heterogeneity in technical lignin mixture is multiscale: the lignin content and impurity profile are process dependent, the lignin may have different molecular weight and polydispersity, and the functional groups are different.139 Despite the fact that feedstock contributes to lignin property, technical lignins are classified based on the chemical processes they are from.140 They include Kraft lignin, Soda Lignin, Lignosulfonate, Organosolve Lignin, Hydrolysis Lignin, and Ionic Liquid Lignin. Only the first four have been commercialized and extensively studied for applications.141 Minimizing the impact of heterogeneity is a critical issue to address for functional specification.

The applications of lignosulfonate

With an annual production of 1.8 million tons per year, lignosulfonate accounts for 90% technical lignin in the world market.142 Four main functions of lignosulfonate have been explored for industrial application. These functions include adhesive properties for a binder, plastic properties for a dispersant, surface stabilizing properties for an emulsifier, and chelation properties for a sequestrant. Major applications of lignosulfonate are limited to those in civil engineering, where multiple functions are employed and specifications are not stringent (Table 3).6, 142

Table 3.

Lignosulfonate application in civil engineering infrastructure

| Application | Key function |

|---|---|

| Soil stabilization | Maintain soil moisture, increase soil particle cohesion, increase cohesive strength, cementing, increase soil density, reduce optimum moisture content, improve oil shear strength and plasticity, water proofing |

| Dust control on unpaved roads | Cement soil, improve surface strength, reduce road surface fines, reduce surface erosion caused by rainfall and temperature change, improve road stability |

| Asphalt stabilization | Decrease asphalt oxidation aging |

| Cement additives | Concrete admixture to reduce the need for water in cement pouring, prevent cavity formation |

Lignosulfonate has also been used for other minor applications, such as component of coal briquettes, components of linoleum paste, dispersant for dyes and pigments, dispersant in oil drilling mud, metal sequestrant for water treatment for boilers and cooling systems, flocculants, metal absorbents, etc.142

The application of lignin as phenol substitute in phenol formaldehyde resin

There have been efforts to find applications for Kraft lignin and Organosolv lignin since Indulin and Alcell lignin became available. While both are insoluble in water under acidic condition, they are very different in structures and composition.93 Alcell lignin had a lignin content of 96.2%, and impurities including 0.2% of carbohydrates and < 0.1% of ash. The aromatic units in Alcell was composed of 50% of S, 37% of G, and 11% of H. The total ethers (β-O-4, β−5, and β-β) was 8.9 per 100 aromatic units, the highest among all technical lignins. Alcell lignin had Mw of 2580 g mol−1 with polydispersity of 4.3. Indulin had a lignin content of 92.2%, and impurities including 1.4% of carbohydrates, 2.6% of Ash, and 1.7% of sulfur. The aromatic units in Indulin was 97% of G and 3% of H. The total ether was 7.4 per 100 aromatic units. Indulin had Mw of 4290 g mol−1 with polydispersity of 8.1. Apparently, Alcell lignin was purer in composition, underwent less structural change in the process, was smaller in size, and was more homogeneous. Organosolv lignins from feedstocks other than mixed hardwood were similar in composition, molecular weight, and polydispersity.

Phenol formaldehyde (PF) resin is a potential application for technical lignin. In PF resin formation, formaldehyde reacts with phenol at ortho or para position to give methylol groups, which can crosslink to other phenols via methylene bridges (Figure 14).143 The largest application of PF resins is wood adhesive in the fabrication of plywood, particle board, waferboard, and fiberboard. It is also used in molding compounds, abrasives, coatings, etc. The aromatic moieties in lignin may react with formaldehyde to form the resin that resembles PF polymer. However, the reactivity of the aromatic units in lignin is low and only a part of reactive sites is accessible. It was reported that the amount of formaldehyde that could be incorporated in each mol aromatic unit was 1.6 moles for Alcell lignin, 1.6–2.1 moles for sulfite lignin, and 0.1–0.5 moles for Kraft lignin.91 Initial evaluation showed that Alcell lignin could replace 30% of the PF resin in waferboard,91 and ultra-filtered Kraft lignin could replace 20% of the PF resin in particle board.144 Alcell lignin was also used in the PF resin for automotive brake pad on commercial scale. The inclusion of 10 – 20% of the lignin stabilized the friction coefficient to temperature change and improved the wear behavior.145

Figure 14.

Formation of resole resin from phenol and formaldehyde

Many methods have been explored to improve the reactivity of lignin to substitute phenols in PF resin preparation.146 Demethylation would create additional phenols in G and S moieties, resulting in aromatics with more active sites for formaldehyde. Methylolation (hydroxymethylation) would generate additional sites for ring-joining reaction in curing. These reactions were mostly tested for Kraft lignin activation.

Plywood manufacture uses resole-type PF adhesive (Figure 14). The adhesive is used as a glue to bind veneers. Filler can be added to the adhesive in glue formulation. In the final stage, the plywood is hot pressed at 140 – 150 °C to cure the glue by finalizing the crosslinking in PF polymer.143 Replacing phenol with lignin caused changes both in adhesive synthesis and in the curing.147 When a portion of phenol was replaced with lignin, the polymerization was faster to form the adhesive, but higher temperature was needed for curing. The lignin impregnated glue was tested in plywood manufacture. It was found 20% of the PF resin could be substituted with pine Kraft lignin without changing the mechanical properties of the plywood samples. The corn stover lignin from POET cellulosic ethanol process was also evaluated for the PF application.148 The POET lignin was purified by dissolution and acid precipitation. The ash content was reduced and structure was changed as indicated by FTIR analysis. The purified lignin had a Mw of 1176 g mol−1 with a polydispersity of 2.1. The adhesive prepared by 100% lignin-based resin had higher viscosity, and required higher temperature for curing. The mechanical properties of the plywood made by 100% lignin resin were similar to those of the plywood made by PF resin.

The application of lignin as polyol substitute in polyurethane synthesis

The available OH group in technical lignin can now be conveniently quantified by 31P NMR after phosphitylation. These groups include the aliphatic alcohols, phenols in different aromatic units, and carboxylic acids. Alcell lignin was found to have 1.10–1.04 mmol g−1 aliphatic OH and 3.30–3.61 mmol/g of total phenols.93, 149 Indulin was found to have 1.79–2.34 mmol/g of aliphatic OH and 2.23 – 3.87 mmol g−1 of total phenols.79, 93, 149 The polyol feature of lignin enabled its direct use as a macromonomers for polyurethane synthesis.149

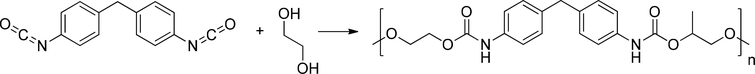

Polyurethane is formed by the polymerization of diisocyanates with polyols to give urethane polymers via carbamate links (Figure 15). Diol extender may be added to form spacers between neighboring poly isocyanates. Polyurethane polymers are easy to prepare and are remarkably flexible for material design. They can form flexible foam, rigid foam, and CASE (coating, adhesives, sealants, and elastomers) polyurethanes.150

Figure 15.

Polyurethane formation from the condensation of 4,4’-methylenebis-(phenylisocyanate) (MDI) with ethylene glycol

Lignin has been used mostly to synthesize rigid polyurethane foams.145, 151 Rigid polyurethane foams are structural material with low thermal conductivity and high strength-to-weight ratio. They are mostly used for insulation in construction and transportation. Replacing a portion of polyol with Kraft lignin could improve the mechanical property of rigid polyurethane foams.152 However, the use of non-modified technical lignin is limited to less than 30% replacement. Higher percentage replacement resulted in brittle polyurethane foam. It was postulated that the reaction mixture could be heterogeneous because the high molecule weight fraction of Kraft lignin was insoluble. The insoluble lignin would form particles and generate mechanically weak points in polyurethane.

Oxypropylation is an important strategy to convert lignin into liquid polyol monomers. This transformation was applied to modify both Organosolv lignin and Kraft lignin.153 The lignin polyol product had moderate increase in hydroxyl groups through the reaction with propylene oxide. The viscosity of lignin polyol increased rapidly as the content of lignin increased from 10 to 40%. The reaction of Kraft lignin with propylene oxide in 1:4 ratio under basic condition caused favorable changes for urethane synthesis.154 Kraft lignin was depolymerized under the reaction condition. The Mw and polydispersity were both reduced in the transformation. All the phenols were converted to phenoxy ether 2-ols. The hydroxyl index (mg KOH/g), a measure of total hydroxyl group, was increased by 23%. The lignin polyol was more reactive than Kraft lignin in condensation with toluene-2.4-diisocyanate and could be used as the only polyol in polyurethane synthesis. The rigid polyurethane product with lignin polyol had better mechanical properties than the commercial counterpart.

Depolymerization of lignin involves ether fragmentation, thus creating more hydroxyl groups for polyurethane synthesis. Treating a softwood lignin with HBr generated 28% more hydroxyl groups as the result of demethylation and ether cleavage.155 The polyurethane prepared with HBr-treated lignin had dramatic improvement in mechanical strength. Depolymerization based on other mechanisms were also explored with the objective to minimize the molecular weight while creating more hydroxyl groups.151 A lignin from lignocellulosic ethanol process was depolymerized by hydrothermal liquefaction, giving a product with Mw around 1000 g mol−1 and hydroxyl index of 442 mg KOH g−1 in 70% yield. The liquefied lignin was soluble in acetone and tetrahydrofuran. It could replace 50% of sucrose polyols in polyurethane preparation.156

The use of lignin in carbon fiber synthesis

For more than 50 years, there has been persistent R&D to develop carbon fiber with lignin as the feedstock.139 Kayacarbon, a lignin based carbon fiber was commercialized by Nippon Kayaku Company in the 1960s and 1970s. This product was removed from the market in the 1970s because better carbon fibers based on different precursors became available.157

Currently carbon fiber is manufactured with polyacrylonitrile (PAN) as the starting material.158 It is a copolymer made by condensation of acrylonitrile, methyl methacrylate, and itaconic acid. It has a molecular weight of 70,000 – 260,000 g mol−1 with a polydispersity of 1.5 – 3.5. The fiber precursor is made from PAN by wet spinning. The fibers are finished and wound into tow before heat treatment. In the next step, the precursor fiber is oxidized at 200–300 ͦC. The side chains and the backbone undergo cyclization and dehydrogenation to form heteroaromatic structures. This reaction prepares the fibers for carbonization at higher temperature because the stabilized fibers are more heat resistant. In carbonization, the temperature is ramped up to approximately 2000 ͦC. Almost all oxygen, hydrogen, and nitrogen atoms are rejected as HCN, H2O, O2, H2, CO, NH3, and CH4. The resulting carbon fiber is composed of > 98% of graphenated carbon in highly ordered turbostratic structure. The carbon fibers from PAN have tensile strengths of up to 7 GPa and moduli up to 900 GPa. However, PAN based carbon fiber is expensive; therefore it is used only in high-end applications.

Lignin based carbon fiber became an attractive objective as the need for low cost carbon fiber emerges for making major products such as automobile and wind turbines.158 Other than low cost and renewability, lignin is expected to offer additional benefits including high carbon yield and elimination of toxic substances involved in carbon fiber preparation with PAN.

The preparation of carbon fiber from lignin also follows the three-step protocol involving spinning, thermostabilization, and carbonization.139 The most common methods to prepare precursor from lignin are melt-spinning and solvent-assisted spinning. The spinning temperature is dependent on the type of lignin and other components in the blend. According to Oak Ridge National Laboratory, the lignin feedstock has to be highly purified, with ash content < 0.1%, low in sulfur, and free from particulate matter. The spinning should not generate additional impurities through side reactions such as charring. Several strategies have been explored to improve the spinnability. These strategies include lignin fractionation,159 blending with a plasticizer such as polyethylene oxide,160 or partial acetylation.161 However, improving spinnability by these strategies may decrease the lignin softening temperature (Ts) and reduce the thermal resistance of the fiber precursor.158 In the thermostabilization step, the temperature is increased to the range of 200 – 300 ͦC to promote a series of reactions such as rearranging the ether bonds to C-C bonds through radical coupling, dehydration, elimination of CO or CO2, additional crosslinking, etc. Ultimately, the fiber precursor is converted from a thermoplastic to a thermoset in thermostabilization. The cross section of the fiber is expected to become homogeneous in this step. However, impractical slow heating rate was required to minimize fiber fusion in oxidative thermostabilization of lignin precursor,.162 Applying UV reduced the heating time from 40 h to 4 h by promoting crosslinking.163 Embedding desirable reactions in thermostabilization was also explored. One example involved converting a portion of the phenols in softwood lignin to the propargyl ethers. The resulting structure underwent cyclization to give benzopyrans, which created new courses of polymerization in thermostabilization.164 Finally, the stabilized fiber is carbonated at temperatures above 1000 ͦC to eliminate all elements other than carbon. The heating needs to be optimized to minimize defection while facilitating the formation of graphitic structure. The best lignin carbon fiber only reached tensile strength of 1.07 GPa and Modulus 82.7 GPa.157 Analysis showed that the lignin carbon fiber did not have ordered turbostratic structure,158 most likely due to the fact that the lignin-based precursor was poorly oriented. Overcoming heterogeneity remains to be a critical challenge to use lignin in carbon fiber manufacture.

There is much more to explore for lignin applications in polymeric forms. Many options for lignin functionalization have been explored.165, 166 The purified lignin can be functionalized through electrophilic aromatic substitution (Lederer-Manasse reaction with formaldehyde, Kolbe-Schmitt reaction), urethane reaction via hydroxyl groups (with isocyanate), esterification (with ε-caprolactone, maleic anhydride, and succinic anhydride) of the hydroxyl groups, demethylation of the methoxy group to create additional phenols, and radical polymerization, etc. Olefin and epoxy groups can also be introduced via some of these reactions for further derivatization. Although technical lignin is cheap, its derivatives can be expensive due to low efficiency in functionalizing lignin and product isolation. As such, the derivatization process development, and product specification are both critical for product development.

Expanding the use of lignin through depolymerization

Preparing monomeric chemicals from lignin is potentially profitable. The basic cost for technical lignin was €110/ton, while the corresponding phenol monomer price was roughly €1220/ton. The large profit margin has been a main driver for research into lignin depolymerization. In addition, lignin depolymerization is strategically important for sustainable development, as the phenol products may be used as the drop-in replacement for those from petroleum-based BTX (€876/ton in 2010) stream.141

Controlled pyrolysis and hydrothermal liquefaction as the baseline examples

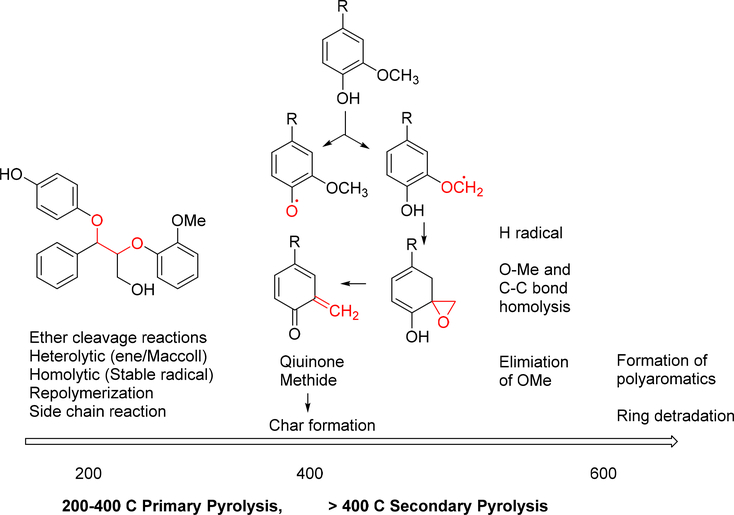

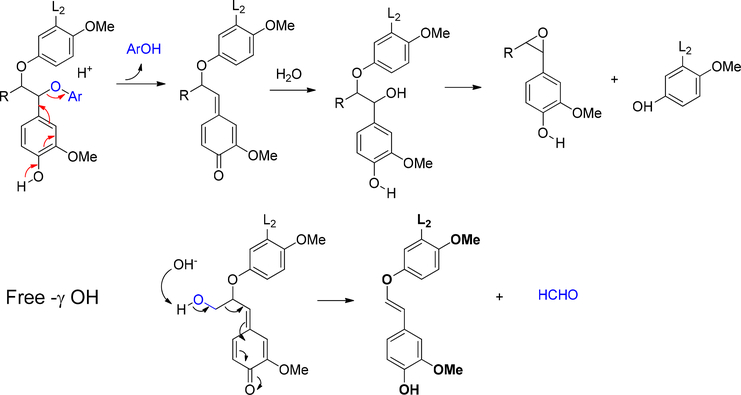

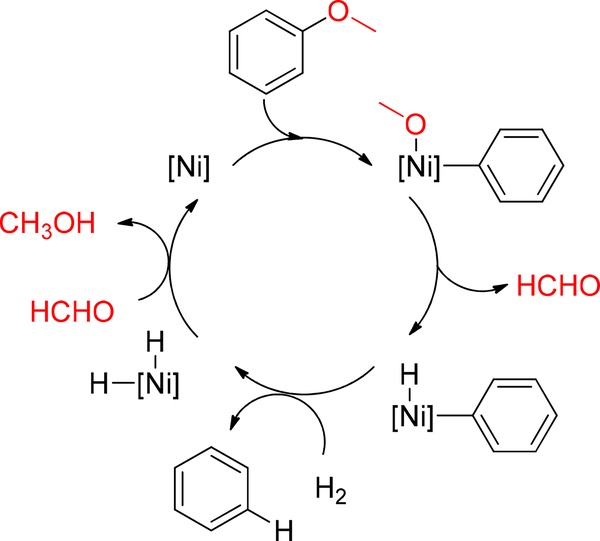

Through combustion, lignin was completely transformed into CO2 and H2O at the temperature between 800–1200 °C. This was the last option to treat the residue. Lignin was degraded into monomers by controlled heating under special reaction conditions. Pyrolysis involved heating in the absence of oxygen. It was a valuable tool to study bond cleavage of lignin as the temperature rose. The degradation of lignin by pyrolysis was divided into two stages (Figure 16). Between 200 – 400 °C, most of the reactions involved heterolytic ether (mainly α-O-4, β-O-4) cleavage. In this temperature range, homolytic cleavage of ether only happened when the radical product was stabilized by aromatic substitution pattern. When temperature rose to > 400 °C, radical reaction mechanism predominated in the degradation and caused extensive rearrangement. Significantly, the C-C bonds were broken and monomers started to form. However, the severe reaction condition also promoted rearrangement and re-polymerization. There was also char formation through some of the intermediates. In practice, tar or coke formation was the main issue in thermal process development.167

Figure 16.

Intermediates and reactions involved in lignin pyrolysis