Abstract

The objective was to determine the interactions between packaging type and degree of doneness on sensory traits of pork loins classified based on the newly proposed USDA quality grades. A total of 144 loins were selected from 2 groups of pigs (lean growth or meat quality production focus) to represent as much variation in visual color and marbling as possible. Selection was achieved with a VQG grading camera. The ventral surface of the loins was evaluated for loin quality traits at 1 d postmortem. At 2 d postmortem loins were sliced into 28-mm-thick chops. Chop within each loin was randomly assigned to either individual vacuum packages or to individual Styrofoam trays and overwrapped in polyvinyl chloride (PVC) oxygen permeable film. Overwrapped PVC packages were then placed in bulk packages and flushed with a gas mixture that contained approximately 0.4% carbon monoxide, 30% carbon dioxide, and 80% nitrogen. Vacuum-packaged chops were aged until 14 d postmortem. Chops packaged in PVC overwrap were aged until 9 d postmortem in the bulk packages, then placed on simulated retail display until 14 d postmortem. Chops from each packaging type were cooked to an internal temperature of either 63 °C or 71 °C for the evaluation of slice shear force (SSF) or for evaluation of tenderness, juiciness, and flavor by a trained panel. Data were analyzed as split-split plot design with production focus of the pigs, proposed USDA quality grade, packaging type, and degree of doneness as fixed effects. While there were main effect differences between production focuses, there were no interactions with production focus. There were also no 3-way (P ≥ 0.19) interactions and only one 2-way interaction among quality grade, packaging type, or degree of doneness. There were no differences in sensory tenderness (P = 0.30), juiciness (P = 0.49), flavor (P = 0.89), SSF (P = 0.13), or cook loss (P = 0.06) among USDA quality grades. There were no differences in sensory tenderness (P = 0.06), juiciness (P = 0.32), flavor (P = 0.74), SSF (P = 0.99), or cook loss (P = 0.12) between chops aged in vacuum packages or PVC packages. Chops cooked to 63 °C were 4.6% more tender (P < 0.0001), 10.1% juicier (P < 0.0001), and 2.9% less flavorful (P = 0.01) than chops cooked to 71 °C. These data suggest that cooking chops to 63 °C rather than 71 °C was a more effective way to improve tenderness and juiciness than selecting chops of a certain quality grade or altering packaging postmortem.

Keywords: degree of doneness, packaging, pork, quality grade, sensory

INTRODUCTION

Consumers routinely rate tenderness and juiciness as primary factors that influence eating experience (Moeller et al., 2010). Additionally, they use color and marbling as indicators for tenderness and juiciness when making purchasing decisions (Brewer et al., 2001). Because of this, the Agriculture Marketing Service has proposed a USDA pork loin grading system based on the visual color and marbling of the ventral surface of a boneless pork loin (USDA, 2017). One challenge with such a grading system is that grading decisions are based on evaluations on the ventral surface of the loin at 1 d postmortem, but consumers make purchasing decisions based on the cut surface of the loin after a period of postmortem aging. Fortunately, the initial color and marbling of the ventral surface of the loin is correlated with the cut surface of chops from that loin (Lowell et al., 2017). Additionally, Wilson et al. (2017) recently reported that the combination of increasing extractable lipid and a darker surface color increased instrumental tenderness of pork chops cooked to a medium-rare degree of doneness. So, it stands to reason that a USDA grading system has the potential to sort pork loins to provide a desired eating experience based on consumer expectations.

Nearly half (48.7%) of boneless pork chops produced in the United States are distributed to retail establishments as case-ready chops and the remainder (51.3%) as noncase-ready (Reicks et al., 2008). It is not known if this difference in packaging affects sensory traits of boneless pork chops. However, it is readily accepted that cooking pork chops to a medium-rare degree of doneness improves sensory tenderness and juiciness compared with cooking chops to a medium degree of doneness (Moeller et al., 2010). Thus, the objective was to determine the potential interactive effects of packaging type and degree of doneness on sensory traits of pork loins selected to represent the newly proposed USDA quality grades.

MATERIALS AND METHODS

Pigs were slaughtered under the supervision of the USDA Food Safety and Inspection Service at a federally inspected facility. Boneless loins were purchased from that facility and transported to the University of Illinois Meat Science Laboratory. Therefore, Institutional Animal Care and Use Committee approval was not obtained. All protocols for sensory evaluations were reviewed and approved by the University of Illinois Institutional Review Board (IRB #: 17485).

Processing Facility Data Collection

Pigs used for this study were from 2 separate production focus programs (lean growth and meat quality) similar to those described by Arkfeld et al. (2016). Pigs were immobilized using carbon dioxide and terminated via exsanguination. Carcasses were blast-chilled for approximately 90 min and then held in an equilibration cooler until 1 d postmortem (~22 h). At 1 d postmortem, carcasses were fabricated into primal cuts and boneless loins were further cut into boneless strap-on (longissimus costarum) center cut pork loins (NAMP # 414, PSO 3; North American Meat Institute [NAMI], 2014). Loins were imaged using a VQG pork loin grading camera on the ventral side of the loin immediately after boning. The VQG camera was used to select loins with variation in color (max NPPC score = 5.0, min NPPC score = 1.5) and intramuscular fat content (max NPPC marbling score = 4.0, min NPPC marbling score = 1.0). A target of 18 loins was selected from each production focus for a total of 36 loins during each loin collection period. Loins were collected on 4 separate fabrication days throughout a 4-mo period for a total of 144 targeted loins. Loins were moved from the boning line to a table for early postmortem ventral evaluations. Ventral evaluations were conducted on the loin near the area of the 10th rib. Instrumental CIE lightness (L*), redness (a*), and yellowness (b*) were measured using a Konica Minolta CR-400 colorimeter (D65 light source, 10° observer, 8 mm aperture; Minolta Camera Company, Osaka, Japan) that was calibrated with a white tile prior to evaluations (CIE, 1978). Muscle pH was measured using a MPI pH-meter (Meat Probes Inc. pH-Meter, Topeka, KS) with a glass electrode probe that was calibrated prior to evaluations using pH 4 and pH 7 calibration buffers stored at 4 °C. A trained technician evaluated visual color and marbling, using National Pork Producers Council (NPPC, 1999) color and marbling standards and subjective firmness using National Pork Producers Council (NPPC, 1991) scale. Visual color was assigned using a 6-point scale (1 = pale, grayish-pink; 6 = dark, purplish-red); visual marbling was assigned using a 10-point scale (1 = 1% intramuscular fat; 10 = 10% intramuscular fat), and subjective firmness was assigned using a 5-point scale (1 = soft; 5 = firm). All evaluations were made in half score increments. Boneless loins were vacuum packaged and transported in coolers with ice packs approximately 520 km to the University of Illinois Meat Science Laboratory for aging and further evaluations.

A quality grade was assigned to each loin based on the proposed USDA quality grades where a Prime grade required a NPPC visual color score of 4 or 5 and a NPPC visual marbling score of 4 or greater. To be graded Choice, a lean color score of at least 3 and a visual marbling score of at least 2 were required. To be graded Select, a lean color score of at least 2 and a visual marbling score of at least 2 were required (USDA, 2017). Any loin that did not meet the requirements for Prime, Choice, or Select was categorized as Standard.

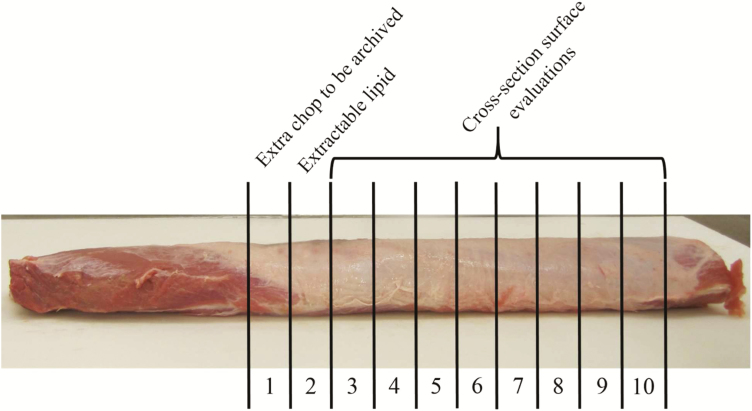

Upon arrival at the Meat Science Laboratory, loins were removed from their vacuum-sealed packaging at 2 d postmortem and sliced into 28-mm-thick chops using a PUMA slicer (TREIF USA Inc., Shelton, CT). Chops were selected starting from the anterior end of the loin where the first chop (chop #1) contained the posterior end of the spinalis dorsi (Fig. 1). Chop #1 was archived for potential additional needs. Chop #2 was used to quantify extractable lipid. Chops #3 to 10 were randomly assigned to either vacuum packaging or to be placed in a Styrofoam tray and overwrapped in polyvinyl chloride (PVC) oxygen permeable film. Within a packaging type, chops were randomly assigned to a cooking degree of doneness of either 63 °C (medium rare) or 71 °C (medium). These endpoint temperatures were chosen because in 2011 the USDA Food Safety and Inspection Service changes the recommended endpoint temperatures of whole cuts of pork from 160 °F (71 °C) to 145 °F (63 °C). This provided 4 combinations of packing type and degree of doneness with 2 chops designated for each of the 4 combinations from each loin. One of those chops was used for sensory evaluations and one of those chops was used for slice shear force (SSF) determination.

Figure 1.

Loins were sliced into 28-mm-thick chops. Chops were randomly assigned to instrumental and sensory evaluations. Chop 1 was archived for additional use at a later time. It was the most anterior chop used and contained the posterior portion of the spinalis dorsi. Chop 2 was used to determine extractable lipid content. Chops 3 to 10 were either packaged in individual vacuum-sealed packages or in PVC overwrapped trays packaged in gas-flushed bulk packages. A chop from each loin designated for each packaging type was cooked to either 63 °C or 71 °C. Chops from each of the 4 packaging types and degree of doneness combinations were evaluated for SSF or sensory tenderness, juiciness, and flavor.

Chops packaged in overwrap packages were placed in a 13.7-cm2 tray (polystyrene Cascades Evok) on top of an absorbent pad (Ultra ZAP Soaker) and overwrapped in PVC film (O2 transmission = 23,250 mL·m2·d−1, 72 gauge; Resinite Packaging Films, Borden, Inc., North Andover, MA). Each chop was standardized by trimming subcutaneous fat and accessory muscles and then weighed. Packages of PVC overwrapped chops were placed in a 35.56 cm × 50.80 cm vacuum sealable bag with all chops from the same loin in 1 bulk modified atmosphere package (MAP) and gas-flushed with a 600 millibars of a gas mixture (0.2% to 0.4% carbon monoxide, 23% to 30% carbon dioxide, and 60% to 80% nitrogen). The bulk packages were boxed and aged in a cooler at 4 °C until 9 d postmortem. At 9 d postmortem, chops were removed from boxes and bulk packaging, and placed in simulated retail display under fluorescent lighting (General Electric 32 W, 122 cm fluorescent Kitchen/Bath bulb in an Utilitech 121 cm 2-light suspending fixture) in the overwrapped trays. Procedures for bulk MAP packaging and retail display followed the generally recognized as safe (GRAS) notice No. GRN 000083 MAP system for packaging fresh cuts of case-ready muscle meat (FDA, 2002). Chops designated for vacuum packaging were packaged in individual packages using an Ulma TF mini rollstock packaging machine (Ulma Packaging, Guipuzkoa, Spain). Chops were vacuum sealed between a high oxygen barrier thermal forming film thermally welded to a high oxygen barrier nonforming film.

At 12 d postmortem (3 d after simulated retail display), chops designated for SSF analysis were evaluated for instrumental CIE lightness, redness, and yellowness with the same equipment and procedures used to evaluate the ventral surface of the intact loin at 1 d postmortem. They were then removed from their overwrap packaging and vacuum sealed for shipment to the USDA Meat Animal Research Center. Additionally, at 12 d postmortem, chops designated from the vacuum-packing treatment for SSF analysis were also shipped to the USDA Meat Animal Research Center.

All remaining chops were assigned for sensory panel analysis and remained in their initial packaging (VAC or PVC) until 14 d postmortem. At 14 d postmortem, chops aged in PVC overwrap packaging taken out of the original overwrap packaging and repackaged in vacuum packages. All chops (PVC and vacuum packaged) were frozen until they were used for sensory evaluation.

Proximate Analyses

Chops for proximate analysis (designated chop #2 above and on Fig. 1) were trimmed of epimysium and other muscles and the remaining denuded longissimus chops were vacuum sealed in individual packages, boxed, and placed in a freezer at −20 °C. Chops were shipped in coolers with ice packs to the USDA Meat Animal Research Center for determination of moisture and extractable lipid. Chops were tempered and diced into cubes that were approximately 5 mm × 5 mm × 5 mm. Cubes were mixed and powdered with liquid nitrogen using a waring commercial blender and micro-mini (15–37 mL) blender cups. Powdered samples were maintained at −20 °C until weighed. Duplicate 1.5 g samples from each chop were weighed into preweighed filter bags (Ankom Technology XT4 Filter Bag). Filter bags were heat sealed (Ankom model HS), placed on a drying rack in a single layer and dried for 24 h at 102 °C with a drying oven (VWR 89511-414). The filter bags were placed into a weigh tin desiccator (Ankom X49) and cooled at room temperature for 15 min and then weighed. Ether-extractable lipid was removed with an Ankom XT15 system. Samples were dried for 15 min at 102 °C, returned to the weigh tin desiccator, cooled at room temperature for 15 min and then weighed. Moisture and fat percentage were calculated, agreement of duplicate samples was checked, and the average value was calculated for each loin.

Slice Shear Force

Chops for SSF determination were cooked on a belt grill (Magigrill model TBG-60; MagiKitch’n Inc., Quakertown, PA). Dwell time in the grill was modified to achieve a targeted internal temperature of either 63 °C or 71 °C. After the chops exited the belt grill, a needle thermocouple probe was inserted into the geometric center of the chop and post-cooking temperature rise was monitored with a handheld thermometer (Cole-Parmer, Vernon Hills, IL). The maximal temperature was recorded as the final cooked internal temperature. Immediately after cooking, a 1-cm-thick, 5-cm-long slice was removed from each chop parallel to the muscle fibers. The slice was acquired by first cutting across the width of the longissimus at a point approximately 2 cm from the lateral end of the muscle. Using a sample sizer, a cut was made across the longissimus parallel to the first cut at a distance 5 cm from the first cut. Using a knife that consisted of 2 parallel blades spaced 1 cm apart, 2 parallel cuts were simultaneously made through the length of the 5-cm-long steak portion at a 45° angle to the long axis of the longissimus and parallel with the muscle fibers. Each slice was sheared once with a flat, blunt-end blade using an electronic testing machine (model 4411; Instron Corp.).

Trained Sensory Panels

Sensory panel sessions consisted of 6 individuals that evaluated pork chop tenderness, juiciness, and pork flavor. Panelists were selected from a pool of trained students and faculty from the University of Illinois (Champaign-Urbana, IL). Panelists were trained to evaluate pork chops for tenderness, juiciness, and pork flavor. Pork tenderness was standardized by cooking 1 chop to an internal temperature of 60 °C and a second chop to 80 °C. Pork juiciness was standardized by cooking a nonenhanced chop and an enhanced chop both to an internal temperature of 68 °C. Pork flavor was standardized by cooking a pork chop and 80:20% lean:fat ground pork to an internal temperature of 71 °C. Previously, sensory tenderness scores from this group of trained panelists explained 57% (R2 = 0.57) of the variation in SSF instrumental tenderness (Wilson et al., 2017).

Chops were assigned to sensory sessions using an incomplete randomized block schedule of chops for each sensory panel, generated using the OPTEX procedure in SAS (SAS Inst. Inc., Cary, NC). Each sensory panel session included all 4 chops (PVC/63 °C, PVC/71 °C, vacuum packaged/63 °C, vacuum packaged/71 °C) from 2 loins. Each session included a set of chops from pigs from the meat quality focus and a set of chops from pigs from the lean growth focus.

Panelists evaluated samples in a breadbox-style booth with red overhead lights to mask color differences. Tenderness, juiciness, and flavor were measured on a 15-cm continuous scale anchored at 0, 7.5, and 15 cm where 0 = extremely tough, extremely dry, or no pork flavor and 15 = extremely tender, extremely juicy, or very intense pork flavor. Chops were removed from −20 °C and placed in a 4 °C cooler 24 h prior to cooking to allow for proper thawing. Chops were removed from their individual packages and weighed prior to cooking. Chops were cooked to either medium-rare degree of doneness (63 °C internal temperature) or medium degree of doneness (71 °C internal temperature) following National Pork Board cooking guidelines and served to panelists while still warm. Chops were cooked on a Farberware Open Hearth grill (model 455N, Walter Kidde, Bronx, NY) with a copper-constantan thermocouple (Type T, Omega Engineering, Stamford, CT) inserted into the geometric center of each chop to accurately monitor internal cooking temperature on a digital thermometer (model 92000-00, Barnat Co., Barrington, IL). Chops were initially cooked to an initial internal temperature of either 31 °C (medium-rare) or 36 °C (medium) and then flipped and cooked to the final temperature. Once chops were cooked to their assigned final internal temperature, they were immediately removed, weighed, and placed in plastic serving cups to keep the chops warm until serving. Chops were then cut using a 1 cm × 1 cm sample sizer. Panelists were given 3 random cubes per sample. Each testing day consisted of no more than 2 sessions with 8 samples per session. Sessions were held at least 1 h apart to reduce sensory fatigue. The study consisted of 576 samples in 72 sessions on 36 different days. Panelists were recalibrated at the midpoint of the 72 sessions. Results from all panelists were averaged and the averages were used for calculation of least squares means.

Statistical Analyses

Sensory and SSF data were analyzed with the MIXED procedure of SAS as split-split plot design. Individual loin served as the experimental unit and the fixed effects in the model were production focus of the pigs, proposed USDA quality grade, packaging type, and degree of doneness and all possible interactions. Sensory session served as the blocking factor and was coded as a random variable. The whole plot factor of production focus and quality grade was tested with the 3-way interaction of session, focus, and quality grade. The split plot was packaging type (vacuum packaging or PVC overwrap) and was tested with the 4-way interaction of session, quality grade, focus, and packaging type. The split-split plot was degree of doneness (63 °C or 71 °C) and was tested with the 5-way interaction of session, quality grade, focus, packaging type, and degree of doneness. There were no interactions among production focus and the other treatments of interest. Therefore, production focus interactive data were pooled among production focus for evaluation of the other treatments of interest. Least squares means were separated with the Probably of Difference (PDIFF) option of SAS in the Mixed procedure. Effects of USDA quality grade, packaging type, degree of doneness and all possible interactions were considered significantly different at P < 0.05.

RESULTS

Early Postmortem Ventral Surface Loin Quality

There were no interactions (P ≥ 0.15) between production focus and proposed USDA quality grade for any early postmortem ventral loin quality trait (Supplementary Tables S1–S4).

Loins from lean production focused pigs (5.40 kg) were 7.1% heavier (P < 0.01) than loins from quality focused pigs (5.03 kg, Table 1). There were no differences in ventral pH (P = 0.20) of loins between the lean and quality production focuses. Loins from lean focused pigs were instrumentally 1.43 L* units darker (P = 0.01), 0.47 a* units less red (P = 0.05), and 0.41 b* units less yellow (P = 0.04) than loins from quality focused pigs. Visual color did not differ (P = 0.55) between production focuses. Loins from quality focused pigs (2.51%) had 0.39 percentage units greater (P = 0.04) extractable lipid compared with loins from lean focused (2.12%) pigs but visual marbling scores did not differ (P = 0.39) between production focuses (Table 1). Subjective firmness scores did not differ between loins from the lean and quality production focuses.

Table 1.

Lean quality estimates of the ventral surface boneless pork loins from pigs selected for lean growth or meat quality traits and categorized based on proposed USDA grade standards of pork carcasses

| Item | Production focus | SEM | USDA quality gradea | SEM | P-values | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lean | Quality | Standard | Select | Choice | Production focus | USDA quality grade | Focus × quality grade | |||

| Loins, n | 78 | 73 | 38 | 13 | 92 | |||||

| Loin weight, kg | 5.40 | 5.03 | 1.07 | 5.40b | 5.19ab | 5.07a | 1.08 | < 0.01 | 0.01 | 0.44 |

| Ventral pH | 5.69 | 5.72 | 0.05 | 5.72ab | 5.65a | 5.75b | 0.06 | 0.20 | 0.02 | 0.95 |

| Lightnessb, L* | 43.80 | 45.23 | 0.51 | 44.20b | 46.14c | 43.21a | 0.80 | 0.01 | <0.01 | 0.41 |

| Rednessb, a* | 7.36 | 7.83 | 0.20 | 7.16a | 7.83b | 7.79b | 0.32 | 0.05 | 0.01 | 0.62 |

| Yellownessb, b* | 0.46 | 0.87 | 0.20 | 0.41 | 0.95 | 0.64 | 0.29 | 0.04 | 0.15 | 0.15 |

| Colorc | 3.08 | 3.16 | 0.15 | 3.27b | 2.49a | 3.60c | 0.20 | 0.55 | <0.0001 | 0.69 |

| Extractable lipid, % | 2.12 | 2.51 | 0.23 | 1.61a | 2.77b | 2.56b | 0.30 | 0.04 | <0.0001 | 0.78 |

| Marblingc | 1.95 | 2.03 | 0.07 | 1.28a | 2.27b | 2.42b | 0.11 | 0.39 | <0.0001 | 0.73 |

| Firmnessc | 2.62 | 2.76 | 0.28 | 2.46a | 2.66ab | 2.95b | 0.32 | 0.34 | <0.01 | 0.63 |

aUSDA quality grades are based on the newly proposed grade standards for pork carcasses where: Choice = NPPC color score of 3 and a NPPC marbling score ≥ 2, Select = NPPC color score of 2 and a NPPC marbling score ≥ 2, Standard either has a NPPC color and a NPPC marbling score ≥ 2, Select = NPPC color score of 2 and a NPPC marbling score ≥ 2, Standard either has a NPPC color score < 2 or a NPPC marbling score < 2.

bL* = measure of lightness (greater value indicates a lighter color), a* = measure of redness (greater value indicates a redder color), and b* = measure of yellowness (greater value indicates a more yellow color).

cNPPC color (1 = pale pink to 6 = dark purplish red), NPPC marbling (1 = 1% intramuscular lipid to 10 = ≥10% intramuscular lipid), and NPPC firmness (1 = very soft to 5 = very firm) were based on NPPC (1991, 1999) standards.

A total of 144 loins were used in the data analyses. Of those, 38 graded Standard (did not meet the minimum requirements for Select), 13 Select, and 92 Choice (Table 1). Only one loin met the proposed criteria for Prime and therefore, was excluded from the analyses. Instrumental L* values for loins categorized as USDA Select (46.14) were greater (P < 0.05) than loins categorized as USDA Choice (43.21) or Standard (44.20). Additionally, loins categorized as Standard were lighter (P < 0.05) than loins categorized as Choice (Table 1). In terms of a*, loins categorized as Choice (7.79) and Select (7.83) were redder (P < 0.05) than loins categorized as Standard (7.16). When visually evaluated for NPPC color scores, loins categorized as Choice (3.60) were darker (P < 0.05) than either Select (2.49) or Standard (3.27). Loins categorized as Standard were darker (P < 0.05) than loins categorized as Select. Neither extractable lipid nor visual marbling differed (P > 0.05) between loins categorized as Select (2.77%, NPPC 2.56) or Choice (2.27%, NPPC 2.42), but both Select and Choice loins had more extractable lipid and visual marbling than Standard loins (Table 1). Subjective firmness scores did not differ (P > 0.05) between Standard and Select loins, but Standard loins were less firm than Choice loins (Table 1). Subjective firmness scores did not differ (P > 0.05) between Select and Choice loins.

Effects of Proposed USDA Quality Grade on Eating Experience

There were no 3-way interactions (P ≥ 0.19) among proposed UDSA quality grade, packaging type, and degree of doneness for any sensory or instrumental characteristics (Supplementary Table S1). The only 2-way interaction for any parameter was sensory tenderness between proposed USDA quality grade and packaging type for tenderness. Sensory tenderness scores of chops from loins categorized as Standard and aged in vacuum packages (8.81) were less (P < 0.05) tender than Standard chops aged in PVC packages (9.14) or chops categorized as Select and aged in vacuum packages (9.23) or chops categorized as Choice and aged in PVC packages (9.46). The 0.33-unit difference in sensory tenderness between Standard chops packaged in vacuum packages and Standard chops packaged in PVC packages was 3.7%. At the same time a 3.6% difference was observed between the same 2 parameters for SSF. A magnitude of that difference, although detected by highly trained sensory panelists, may not be detectable by consumers.

There were no differences in sensory tenderness (P = 0.30), juiciness (P = 0.49), or flavor (P = 0.89) among proposed USDA quality grades (Table 2). There were no differences in SSF (P = 0.13) or cook loss (P = 0.06) among proposed USDA quality grades.

Table 2.

Effects of proposed USDA quality grade on trained sensory and instrumental tenderness values of boneless pork loin chops

| Item | USDA quality gradea | SEM | P-value | ||

|---|---|---|---|---|---|

| Standard | Select | Choice | |||

| Chops, n | 152 | 52 | 368 | ||

| Tendernessb | 8.97 | 9.09 | 9.24 | 0.25 | 0.30 |

| Juicinessb | 8.52 | 8.40 | 8.61 | 0.19 | 0.49 |

| Flavorb | 2.08 | 2.10 | 2.07 | 0.05 | 0.89 |

| SSFc, kg | 11.05 | 10.12 | 10.90 | 0.43 | 0.13 |

| Cook loss, % | 12.36 | 12.05 | 11.92 | 0.27 | 0.06 |

aUSDA quality grades are based on the newly proposed grade standards for pork carcasses where: Choice = NPPC color score of 3 and a NPPC marbling score ≥ 2, Select = NPPC color score of 2 and a NPPC marbling score ≥ 2, Standard either has a NPPC color score < 2 or a NPPC marbling score < 2.

bEvaluated on a 15-point scale, where 0 = extremely tough, dry, or not flavorful and 15 = extremely tender, juicy, or flavorful.

cSlice shear force; cooked to a final internal temperature of 63 °C or 71 °C and sheared at internal temperature of approximately 22 °C.

Effects of Packaging Type on Eating Experience

There were no differences in sensory tenderness (P = 0.06), juiciness (P = 0.32), or flavor (P = 0.74) between chops aged in vacuum packages or PVC packages (Table 3). There were no differences in SSF (P = 0.99) or cook loss (P = 0.12) between chops aged in vacuum packages or PVC packages.

Table 3.

Effects of packaging type on trained sensory and instrumental tenderness values of boneless pork loin chops

| Item | Packaging type | SEM | P-value | |

|---|---|---|---|---|

| Vacuum | PVCa | |||

| Chops, n | 286 | 286 | ||

| Tendernessb | 9.02 | 9.18 | 0.11 | 0.06 |

| Juicinessb | 8.47 | 8.55 | 0.10 | 0.32 |

| Flavorb | 2.08 | 2.09 | 0.03 | 0.74 |

| SSFc, kg | 10.69 | 10.69 | 0.32 | 0.99 |

| Cook loss, % | 12.49 | 11.74 | 0.18 | 0.12 |

aPVC = polyvinyl chloride film. Chops were placed in a polystyrene tray and wrapped in PVC film. Chops were placed in a gas-flushed bag and flushed to 600 millibars of a gas mixture (0.2% to 0.4% carbon monoxide, 23% to 30% carbon dioxide, and 60% to 80% nitrogen).

bEvaluated on a 15-point scale, where 0 = extremely tough, dry, or not flavorful and 15 = extremely tender, juicy, or flavorful.

cSlice shear force; cooked to a final internal temperature of 63 °C or 71 °C and sheared at an internal temperature of approximately 22 °C.

Effects of Degree of Doneness on Eating Experience

Chops cooked to a medium-rare (9.31) degree of doneness were rated 4.6% more tender (P < 0.0001) than chops cooked to a medium (8.89) degree of doneness (Table 4). Instrumentally, chops cooked to a medium-rare (10.30 kg) degree of doneness were 7.3% more tender (P = 0.01) than chops cooked to a medium (11.08 kg) degree of doneness. Chops cooked to a medium-rare (8.94) degree of doneness were rated 10.1% juicier (P < 0.0001) than chops cooked to a medium (8.08) degree of doneness. Chops cooked to a medium-rare (2.05) degree of doneness were rated 2.9% less flavorful (P = 0.01) than chops cooked to a medium (2.11) degree of doneness. Chops cooked to a medium-rare (11.29%) degree of doneness had 1.64 percentage units less (P < 0.0001) cook loss than chops cooked to a medium (12.93%) degree of doneness.

Table 4.

Effects of internal degree of doneness on trained sensory and instrumental tenderness values of boneless pork loin chops

| Item | Degree of doneness | SEM | P-value | |

|---|---|---|---|---|

| 63 °C | 71 °C | |||

| Chops, n | 286 | 286 | ||

| Tendernessa | 9.31 | 8.89 | 0.11 | <0.0001 |

| Juicinessa | 8.94 | 8.08 | 0.10 | <0.0001 |

| Flavora | 2.05 | 2.11 | 0.03 | 0.01 |

| SSF, kg | 10.30 | 11.08 | 0.32 | 0.01 |

| Cook loss, % | 11.29 | 12.93 | 0.18 | <0.0001 |

aEvaluated on a 15-point scale, where 0 = extremely tough, dry, or not flavorful and 15 = extremely tender, juicy, or flavorful.

DISCUSSION

It is likely that color and marbling were chosen as the traits to develop the newly proposed USDA pork quality system because these are traits usually associated with consumer purchasing decisions and eating experience (Brewer et al., 2001). Choosing these traits is logical based on previously reported pork quality research concerning color and the historical precedence the beef industry has set using marbling as part of the beef quality grades. Additionally, nearly 53% of consumers chose darker colored pork chops compared with lighter colored pork chops during a consumer preference study (Norman et al., 2003).

Increasing ultimate loin pH is correlated in darker visual color (Huff-Lonergan et al., 2002; Boler et al., 2010). Therefore, it was our hypothesis that chops categorized as Choice would, by definition of the program, be darker in color and therefore have a greater ultimate pH than loins categorized as Select. Likewise Choice loins would be darker in color and therefore have a greater ultimate pH than standard. However, because the proposed grading system also includes visual marbling, it is possible for loins to qualify for a superior grade based on color but ultimately be categorized as a lesser grade due to a lack of marbling. That was the scenario in the current experiment where loins categorized as standard were visually and instrumentally darker than Select loins due to some of the loins in the standard grade being dark enough to qualify for a Choice grade, but did not have enough marbling to qualify for Choice or Select. This complicated the effects of pH, but upon closer examination proved to be quite logical. The ultimate pH of chops rated as standard was intermediate and not statistically different from Select and Choice chops. Chops rated as Choice had a greater ultimate pH than chops rated as Select. Still, based on the results of Wilson et al. (2017) and Wright et al. (2005) an attempt to develop a grading system based on color and marbling has merit. Wright et al. (2005) reported an increase in sensory scores of pork chops rated as high quality (NPPC color score of 4.01 and marbling score of 4.12) compared with chops rated as average quality (NPPC color score of 3.51 and marbling score of 2.40) or low quality (NPPC color score of 2.97 and marbling score of 1.42). Further, Wilson et al. (2017) reported a decrease in SSF in high quality chops compared with medium quality chops and from medium quality chops compared with low quality chops using a similar categorization scheme as describe by Wright et al. (2005). It should be noted that in both of the previous reports as color became darker, marbling also increased. This is in contrast to the current experiment where chops grading Select and those grading Choice had similar amounts of marbling. This highlights a complication with the proposed pork quality grades as thresholds for both color and marbling must be met to grade Choice. Therefore, it is possible to have Select loins that are equal to or even exceed Choice loins in terms of marbling but did not have a dark enough color to qualify as Choice. As opposed to beef quality grades where color is only used as a marker for maturity, using both color and marbling in the pork quality grading system can be expected to produce results similar to those in the current study.

In addition to color, ultimate pH is also correlated with traits associated with water holding capacity such as purge and cook loss (Huff-Lonergan et al., 2002; Boler et al., 2010). These traits are often associated with tenderness, and increasing ultimate pH from 5.50 through greater than 5.95 increased sensory tenderness scores by over 12% (Lonergan et al., 2007). Packaging chops in modified atmosphere packaging containing low carbon monoxide and high carbon dioxide induces greater package purge loss during aging compared with packaging chops in a vacuum package (Krause et al., 2003). It was anticipated that chops rated as Choice would have a greater ultimate pH, and therefore, greater water holding capacity. Therefore, these Choice chops might better withstand packaging in a MAP bulk package followed by PVC overwrap packages. It was hypothesized that the improved water holding capacity of Choice chops would be able to overcome the negative effects of the carbon monoxide on water holding capacity. If this were the case, an improvement in sensory tenderness and juiciness would be expected in Choice chops packaged in PVC when compared with Select or Standard chops packaged in PVC. This was not the case however, and no interactions between proposed USDA quality grade and packaging type were detected for any sensory traits. Therefore, current data suggest that designating 1 grade of pork to 1 particular packaging type over another is not warranted.

Historically, as endpoint cooking temperature (degree of doneness) increases, consumers rate pork chops as less tender and less juicy (Rincker et al., 2008; Moeller et al., 2010). Both decreases in tenderness and juiciness attributed to the loss of free water and some fat during cooking. Similar to previous reports, cooking chops to a medium-rare degree of doneness resulted in greater sensory tenderness and juiciness scores when compared with chops cooked to a medium degree of doneness. It was also hypothesized that this improvement in sensory ratings of tenderness and juiciness from a reduced endpoint temperature would help overcome anticipated issues with these traits from lesser quality grades or PVC packaging. As such, interactions between degree of doneness and packaging type or with quality grade were anticipated. However, this was not the case. Packaging had no impact on sensory traits regardless if chops were cooked to medium-rare or a medium degree of doneness. Furthermore, the positive effects of cooking chops to a lesser degree of doneness were similar in Standard, Select, and Choice chops. Therefore, in this set of pork chops, degree of doneness had a greater impact on eating experience than either USDA quality grade or packaging type.

CONCLUSIONS

In the conditions of the current experiment, it can be concluded that there were not any differences in sensory traits among the chops categorized based on the proposed USDA quality grading system or packaging type. Cooking chops to 63 °C rather than 71 °C was a more effective way to improve eating experience than the newly proposed USDA quality grades or differing packaging types.

SUPPLEMENTARY DATA

Supplementary data are available at Journal of Animal Science online.

ACKNOWLEDGMENTS

Funding, wholly or in part, was provided by The National Pork Board . Mention of trade names, proprietary products, or specified equipment does not constitute a guarantee or warranty by the USDA and does not imply approval to the exclusion of other products that may be suitable. The USDA is an equal opportunity provider and employer.

LITERATURE CITED

- Arkfeld E. K., K. B., Wilson M. F., Overholt B. N., Harsh J. E., Lowell E. K., Hogan B. J., Klehm B. M., Bohrer D. A., Mohrhauser D. A., King et al. 2016. Pork loin quality is not indicative of fresh belly or fresh and cured ham quality. J. Anim. Sci. 94:5155–5167. doi:10.2527/jas.2016-0886 [DOI] [PubMed] [Google Scholar]

- Boler D. D., Dilger A. C., Bidner B. S., Carr S. N., Eggert J. M., Day J. W., Ellis M., McKeith F. K., and Killefer J.. 2010. Ultimate pH explains variation in pork quality traits. J. Muscle Foods 21: 119–130. doi:10.1111/j.1745-4573.2009.00171.x [Google Scholar]

- Brewer M. S., L. G. Zhu, and McKeith F. K.. 2001. Marbling effects on quality characteristics of pork loin chops: consumer purchase intent, visual and sensory characteristics. Meat Sci. 59:153–163. doi:10.1016/S0309-1740(01)00065-1 [DOI] [PubMed] [Google Scholar]

- CIE 1978. Recommendations on uniform color spaces, color difference equations. Psychometric Color Terms. Commission Internationale de l’Eclairage, Paris. Supplement 2 of CIE Publication 15 (E-1.3.1) 1971. P. 8–12. [Google Scholar]

- FDA (Food and Drug Administration U.S.) 2002. GRAS Notice No. GRN 000083.

- Huff-Lonergan E., T. J. Baas M. Malek J. C. Dekkers K. Prusa, and Rothschild M. F.. 2002. Correlations among selected pork quality traits. J. Anim. Sci. 80:617–627. doi:10.2527/2005.8392058x [DOI] [PubMed] [Google Scholar]

- Krause T. R., Sebranek J. G., Rust R. E., and Honeyman M. S.. 2003. Use of carbon monoxide packaging for improving the shelf life of pork. J. Food Sci. 68: 2596–2603. doi:10.1111/j.1365–2621.2003.tb07067.x [Google Scholar]

- Lonergan S. M., K. J. Stalder E. Huff-Lonergan T. J. Knight R. N. Goodwin K. J. Prusa, and Beitz D. C.. 2007. Influence of lipid content on pork sensory quality within pH classification. J. Anim. Sci. 85:1074–1079. doi:10.2527/jas.2006-413 [DOI] [PubMed] [Google Scholar]

- Lowell J. E., Overholt M. F., Harsh B. N., Stahl C. A., Dilger A. C., and Boler D. D.. 2017. Relationships among early postmortem loin quality and aged loin and pork chop quality characteristics between barrows and gilts. Transl. Anim. Sci. 1:607–619. doi:10.2527/tas2017.0074 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Moeller S. J., R. K. Miller K. K. Edwards H. N. Zerby K. E. Logan T. L. Aldredge C. A. Stahl M. Boggess, and Box-Steffensmeier J. M.. 2010. Consumer perceptions of pork eating quality as affected by pork quality attributes and end-point cooked temperature. Meat Sci. 84:14–22. doi:10.1016/j.meatsci.2009.06.023 [DOI] [PubMed] [Google Scholar]

- Norman J. L., E. P. Berg H. Heymann, and Lorenzen C. L.. 2003. Pork loin color relative to sensory and instrumental tenderness and consumer acceptance. Meat Sci. 65:927–933. doi:10.1016/S0309-1740(02)00310-8 [DOI] [PubMed] [Google Scholar]

- National Pork Producers Council (NPPC).. 1991. Procedures to evaluate market hogs. 3rd ed. NPPC, Des Moines, IA. [Google Scholar]

- National Pork Producers Council (NPPC).. 1999. Official color and marbling standards. NPPC, Des Moines, IA. [Google Scholar]

- North American Meat Institute (NAMI) 2014. NAMP meat buyer’s guide. 8th rev. ed. North American Meat Association, Washington, DC. [Google Scholar]

- Reicks A. L., Brooks J. C., Kelly J. M., Kuecker W. G., Boillot K., Irion R., and Miller M. F.. 2008. National Meat Case Study 2004:product labeling information, branding, and packaging trends. J. Anim. Sci. 86: 3593–3599. doi:10.2527/jas.2007-0680 [DOI] [PubMed] [Google Scholar]

- Rincker P. J., Killefer J., Ellis M., Brewer M. S., and McKeith F. K.. 2008. Intramuscular fat content has little influence on the eating quality of fresh pork loin chops. J. Anim. Sci. 86:730–737. doi:10.2527/jas.2007-0490 [DOI] [PubMed] [Google Scholar]

- USDA 2017. U.S. grade standards: pork carcasses https://www.regulations.gov/document?D=AMS_FRDOC_0001-1640 (Accessed 15 December 2017).

- Wilson K. B., M. F. Overholt C. M. Shull C. Schwab A. C. Dilger, and Boler D. D.. 2017. The effects of instrumental color and extractable lipid content on sensory characteristics of pork loin chops cooked to a medium-rare degree of doneness. J. Anim. Sci. 95:2052–2060. doi:10.2527/jas.2016.1313 [DOI] [PubMed] [Google Scholar]

- Wright L. I., J. A., Scanga K. E., Belk T. E., Engle J. D., Tatum R. C., Person D. R., McKenna D. B., Griffin F. K., McKeith J. W., Savell et al. 2005. Benchmarking value in the pork supply chain: characterization of US pork in the retail marketplace. Meat Sci. 71:451–463. doi:10.1016/j.meatsci.2005.04.024 [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.