Abstract

The data sets in this article are related to a Placket Burman (PB) design of experiment (DOE) made on a wider range of uncertainties such as: reservoir, operational and reservoir architecture parameters that affect oil rim productivities. The design was based on a 2 level PB-DOE to create oil rim models which were developed into reservoir models using the Eclipse software and configured under the best depletion strategy of concurrent oil and gas production. Approximate solutions to the models was developed to forecast oil production using the least square method. The Monte-Carlo simulation approach was used in estimating 3 production forecasts for the oil rim reservoirs. This will help to create a probabilistic variety of forecasts that can further be used in making decisions.

Keywords: Reservoir Simulation, Design of Experiment, Placket Burman, Forecast, Exponential Decline, Monte-Carlo

Specification Table

| Subject area | Petroleum Engineering |

| More specific subject area | Reservoir simulation/forecasting |

| Type of data | Tables and Figures. |

| How data was acquired | Oil rim reservoir parameters from the Niger-Delta |

| Experimental features | 2 Level Placket Burman Design of Experiment |

| Data source location | Niger-Delta (Nigeria) |

Value of data

-

•

This data incorporates a wider range of parameters such as reservoir architecture (dip), operational parameters (horizontal well length, horizontal well completion with respect to fluid contacts and well bore diameter) and extra reservoir parameters (oil density, bottom hole pressure and gas oil ratio constraints) in describing the nature of oil recovery in oil rim reservoirs.

-

•

A response surface model can be developed from the given data to represent oil and gas recovery for all the models and a Pareto analysis can made to distinguish significant parameters that affect oil and gas recovery

-

•

The models generated from the data can be used to derive decline curve equations using the linear regression method of an Excel Program from which probability production forecasts can be estimated using Monte-Carlo.

-

•

The models generated from the data can also be classified based Pareto analysis ( large gas and large aquifer, small gas cap and small aquifer, large gas cap and small aquifer, large aquifer and small gas cap) and subjected to secondary and enhanced oil recovery schemes.

-

•

A 3 level design of experiment can be carried out on the outcomes of the Pareto analysis to scientifically reduce quantify (and reduce where possible) uncertainties thus making the outcome more effective.

1. Data

Parameters affecting oil rims have been highlighted by Ref. [1] and validated by Ref. [2] and these are actually not adequate as some key parameters are often omitted. This inevitable affects the usefulness of the response surface models and effectiveness of the Pareto analysis [3], [4]. Table 1 show the range of uncertainties under a 2 level PB DOE used in the study. Table 2 describes the 2 level spatial distribution of uncertainties while Table 3 shows the PB DOE with the reservoir uncertainties. Models in Table 3 can be converted to reservoir models by incorporating Grid properties, PVT (Pressure, Volume and Temperature properties) and Saturation properties using the Schlumberger Reservoir Simulation software (Eclipse)

Table 1.

Reservoir Uncertainties.

|

Parameter Range For The 15 uncertainties simulated |

|||||

|---|---|---|---|---|---|

| LOW | MID | HIGH | |||

| Parameters | Units | −1 | 0 | 1 | |

| 1 | Dip | degrees | 1° | 4 | 6 |

| 2 | Gas Wetness | stb/Mscf | 0.006 | 0.03 | 0.04 |

| 3 | Oil Column Height | feet | 20 | 40 | 70 |

| 4 | M-factor(gas cap size) | 0.7 | 3 | 6 | |

| 5 | Aquifer height to hydrocarbon thickness ratio(Aqfac) | 0.7 | 3 | 6 | |

| 6 | Horizontal permeability (Kx, Ky) | mD | 35 | 350 | 3500 |

| 7 | Kv/Kh | 0.001 | 0.01 | 0.1 | |

| 8 | Wellbore Diameter | feet | 0.35 | 0.45 | 0.55 |

| 9 | Oil Density | lb/cu. ft. | 37 | 42 | 47 |

| 10 | HGOC (Perforation with respect to the GOC) | feet | 0.25 | 0.45 | 0.6 |

| 11 | HWL (Horizontal well length) | feet | 1200 | 1500 | 1800 |

| 12 | Oil Rate | stb/day | 1200 | 2200 | 3500 |

| 13 | Krw (Rel. perm. to water) | 0.2 | 0.35 | 0.6 | |

| 14 | GOR control (*Rsi) | 2.5 | 5 | 7.5 | |

| 15 | BHP (Bottomhole Pressure) | psia | 1500 | 1800 | 2200 |

Table 2.

Placket–Burman design of experiment.

| PLACKETT-BURMAN DESIGN OF EXPERIMENT (DOE) FOR 15 FACTORS | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| The design is for 16 runs (the rows of dPB) manipulating 15 two-level factors (the last seven columns of dPB) | |||||||||||||||

| The number of runs is a fraction 16/((2^15))=0. 00,048,828,125 of the runs required by a full factorial design. | |||||||||||||||

| Run No. | Dip | OGR | Ho | m-Factor | Aqfac | Kx, Ky | Kv/Kh | Bore Diam. | OIL DENSITY | HGOC | HWL | Qo | Krw | GOR (*Rsi) | BHP (psia) |

| Model 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Model 2 | −1 | 1 | −1 | 1 | −1 | 1 | −1 | 1 | −1 | 1 | −1 | 1 | −1 | 1 | −1 |

| Model 3 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 |

| Model 4 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 |

| Model 5 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 |

| Model 6 | −1 | 1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | −1 | −1 | 1 | −1 | 1 |

| Model 7 | 1 | −1 | −1 | −1 | −1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | 1 |

| Model 8 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 |

| Model 9 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 |

| Model 10 | −1 | 1 | −1 | 1 | −1 | 1 | −1 | −1 | 1 | −1 | 1 | −1 | 1 | −1 | 1 |

| Model 11 | 1 | −1 | −1 | 1 | 1 | −1 | −1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 |

| Model 12 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 |

| Model 13 | 1 | 1 | 1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | 1 | 1 | 1 | 1 |

| Model 14 | −1 | 1 | −1 | −1 | 1 | −1 | 1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | −1 |

| Model 15 | 1 | −1 | −1 | −1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | 1 | 1 | −1 | −1 |

| Model 16 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | −1 | 1 | 1 | −1 | 1 | −1 | −1 | 1 |

| Model 17 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 |

| `Model 18 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

Table 3.

Placket–Burman design of experiment with reservoir uncertainties.

| PLACKETT-BURMAN DESIGN OF EXPERIMENT (DOE) FOR 15 FACTORS | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| The design is for 16 runs (the rows of dPB) manipulating 15 two-level factors (the last seven columns of dPB) | |||||||||||||||

| The number of runs is a fraction 16/((2^15))=0. 00,048,828,125 of the runs required by a full factorial design. | |||||||||||||||

| Run No. | Dip | OGR | Ho (ft.) | m-Factor | Aqfac | Kx, Ky | Kv/Kh | Bore Diam. (ft) | OIL DENSITY | HGOC (ft.) | HWL (ft.) | Qo | Krw | GOR (*Rsi) | BHP (psia0 |

| Model 1 | 6 | 0.04 | 70 | 6 | 6 | 3500 | 0.1 | 0.55 | 47 | 0.6 | 1800 | 3500 | 0.6 | 7.5 | 2200 |

| Model 2 | 1 | 0.04 | 20 | 6 | 0.7 | 3500 | 0.001 | 0.55 | 37 | 0.6 | 1200 | 3500 | 0.2 | 7.5 | 1500 |

| Model 3 | 6 | 0.006 | 20 | 6 | 6 | 35 | 0.001 | 0.55 | 47 | 0.25 | 1200 | 3500 | 0.6 | 2.5 | 1500 |

| Model 4 | 1 | 0.006 | 70 | 6 | 0.7 | 35 | 0.1 | 0.55 | 37 | 0.25 | 1800 | 3500 | 0.2 | 2.5 | 2200 |

| Model 5 | 6 | 0.04 | 70 | 0.7 | 0.7 | 35 | 0.001 | 0.55 | 47 | 0.6 | 1800 | 1200 | 0.2 | 2.5 | 1500 |

| Model 6 | 1 | 0.04 | 20 | 0.7 | 6 | 35 | 0.1 | 0.55 | 37 | 0.6 | 1200 | 1200 | 0.6 | 2.5 | 2200 |

| Model 7 | 6 | 0.006 | 20 | 0.7 | 0.7 | 3500 | 0.1 | 0.55 | 47 | 0.25 | 1200 | 1200 | 0.2 | 7.5 | 2200 |

| Model 8 | 1 | 0.006 | 70 | 0.7 | 6 | 3500 | 0.001 | 0.55 | 37 | 0.25 | 1800 | 1200 | 0.6 | 7.5 | 1500 |

| Model 9 | 6 | 0.04 | 70 | 6 | 6 | 3500 | 0.1 | 0.35 | 37 | 0.25 | 1200 | 1200 | 0.2 | 2.5 | 1500 |

| Model 10 | 1 | 0.04 | 20 | 6 | 0.7 | 3500 | 0.001 | 0.35 | 47 | 0.25 | 1800 | 1200 | 0.6 | 2.5 | 2200 |

| Model 11 | 6 | 0.006 | 20 | 6 | 6 | 35 | 0.001 | 0.35 | 37 | 0.6 | 1800 | 1200 | 0.2 | 7.5 | 2200 |

| Model 12 | 1 | 0.006 | 70 | 6 | 0.7 | 35 | 0.1 | 0.35 | 47 | 0.6 | 1200 | 1200 | 0.6 | 7.5 | 1500 |

| Model 13 | 6 | 0.04 | 70 | 0.7 | 0.7 | 35 | 0.001 | 0.35 | 37 | 0.25 | 1200 | 3500 | 0.6 | 7.5 | 2200 |

| Model 14 | 1 | 0.04 | 20 | 0.7 | 6 | 35 | 0.1 | 0.35 | 47 | 0.25 | 1800 | 3500 | 0.2 | 7.5 | 1500 |

| Model 15 | 6 | 0.006 | 20 | 0.7 | 0.7 | 3500 | 0.1 | 0.35 | 37 | 0.6 | 1800 | 3500 | 0.6 | 2.5 | 1500 |

| Model 16 | 1 | 0.006 | 70 | 0.7 | 6 | 3500 | 0.001 | 0.35 | 47 | 0.6 | 1200 | 3500 | 0.2 | 2.5 | 2200 |

| Model 17 | 1 | 0.006 | 20 | 0.7 | 0.7 | 35 | 0.001 | 0.35 | 37 | 0.25 | 1200 | 1200 | 0.2 | 2.5 | 1500 |

| Model 18 | 4 | 0.03 | 40 | 3 | 3 | 350 | 0.01 | 0.45 | 42 | 0.45 | 1500 | 2200 | 0.35 | 5 | 1800 |

2. Experimental design, materials and methods

2.1. Formulation of approximate model

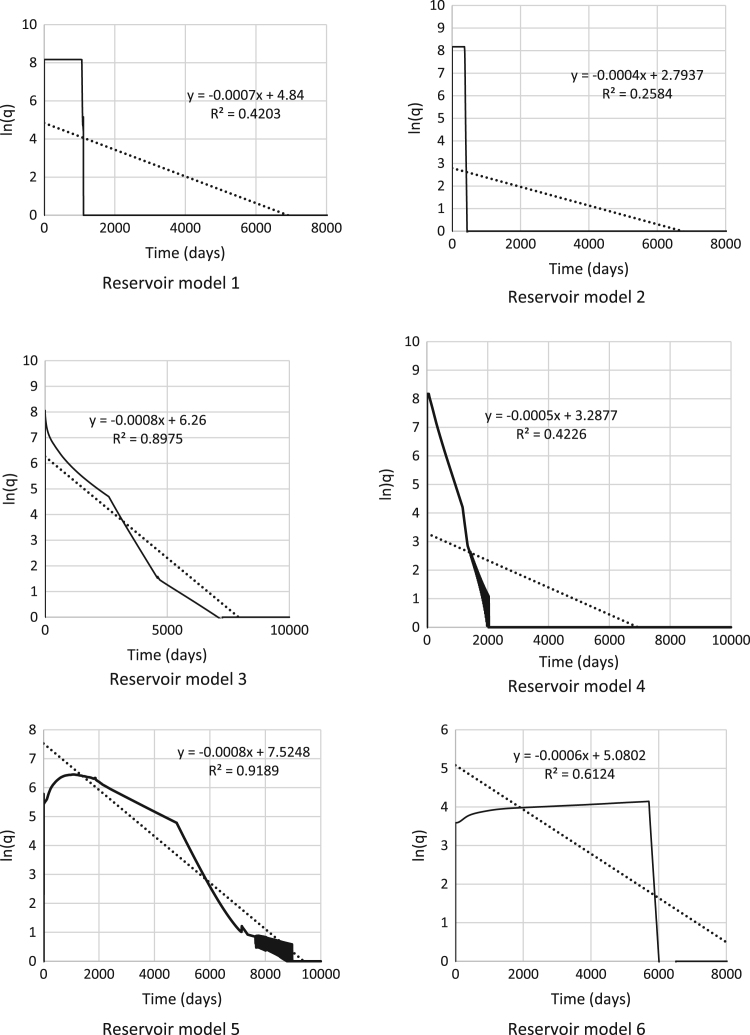

Fig. 1 shows the R2 values and profile equations to the production profiles for some of the models were used to develop decline curve based models. Table 4 shows the original fluids in place, fluids produced and recovery factors under a concurrent oil and gas production. These models are a special form of response surface models using the least square method. The initial stages of production were considered in the proxy equation and further generalized to obtain 3 production forecast models using the exponential decline curve model defined by Ref. [5] in Eq. (1).

| (1) |

Fig. 1.

R2 values and production profile equations.

Table 4.

Oil and gas production profile.

|

Cumulative oil production |

Cumulative gas production |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model no | CUMM. PROD. (stb) | OIIP (Mstb) | RF (%) | OCIP (Mstb) | NFA | GIIP (Mscf) | CUMM. PROD. (Mscf) | RF (%) | GCIP (Mscf) | NFA |

| model 1 | 3780,909 | 26,905 | 14 | 23,124 | 1095 | 589,284 | 277,540 | 47.1 | 311,744 | 1055 |

| Model 2 | 1313,602 | 8471 | 16 | 7157 | 376 | 286,844 | 198,933 | 62.9 | 87,911 | 376 |

| Model 3 | 1222,449 | 55,616 | 22 | 4339 | 3995 | 315,410 | 203,742 | 64.6 | 111,668 | 3960 |

| Model 4 | 299,295 | 28,071 | 1 | 27,773 | 1609 | 330,684 | 50,000 | 15.1 | 280,684 | 1410 |

| Model 5 | 1,859,613 | 16,267 | 11 | 14,408 | 6204 | 96,761 | 63,316 | 65.4 | 33,445 | 6000 |

| Model 6 | 316,218 | 4690 | 7 | 4374 | 6000 | 62,184 | 28,892 | 46.5 | 33,292 | 6000 |

| Model 7 | 914,593 | 5750 | 16 | 4836 | 740 | 412,231 | 152,432 | 37.0 | 259,799 | 740 |

| Model 8 | 1,208,603 | 23,521 | 5 | 22,312 | 1000 | 42,015 | 22,561 | 53.7 | 19,454 | 1128 |

| Model 9 | 10,750,810 | 60,981 | 18 | 50,230 | 8672 | 1,009,138 | 620,356 | 61.5 | 388,782 | 8660 |

| Model 10 | 1,284,098 | 4542 | 28 | 3258 | 1069 | 122,448 | 49,020 | 40.0 | 73,428 | 1069 |

| Model 11 | 387,335 | 4161 | 9 | 3773 | 7990 | 135,949 | 64,556 | 47.5 | 71,393 | 8000 |

| Model 12 | 1,971,314 | 25,498 | 8 | 23,527 | 4000 | 612,799 | 445,696 | 62.5 | 167,103 | 4000 |

| Model 13 | 1,154,199 | 17,063 | 7 | 15,909 | 5793 | 97,566 | 37,710 | 38.7 | 59,856 | 6000 |

| Model 14 | 248,143 | 2878 | 9 | 2630 | 270 | 20,356 | 12,944 | 63.6 | 7412 | 542 |

| Model 15 | 191,164 | 2728 | 7 | 2549 | 70.5 | 65,116 | 31,860 | 48.9 | 33,256 | 70.5 |

| Model 16 | 1,499,402 | 33,279 | 7 | 21,631 | 470 | 68,235 | 27,672 | 40.6 | 40,563 | 470 |

| Model 17 | 88,231 | 3495 | 3 | 3406 | 3000 | 20,049 | 12,999 | 64.8 | 7050 | 3000 |

| Model 18 | 457,304 | 11,989 | 4 | 11,532 | 1000 | 132,143 | 50,000 | 37.8 | 82,143 | 10,000 |

*Where OOIP is oil initially in place, OCIP is oil currently in place, GIIP is gas initially in place, GCIP is gas currently in place and NFA means no further action.

With the linear regression method of an Excel program, the calculations of the continuous decline rate constant, R-squared value of the straight line fitting, the production rate,∗, when the straight line is extrapolated to time zero were estimated.

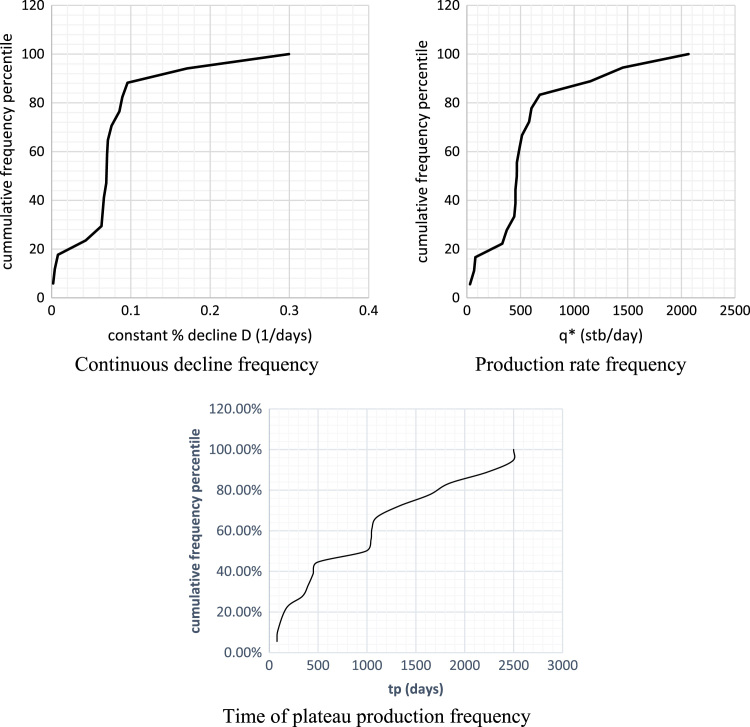

The time of plateau production, initial production rates q⁎ and continuous decline rate constants used in analyzing the decline plots are shown in Table 5, Table 6, Table 7 while Fig. 2 presents the plot.

Table 5.

Time of plateau production cumulative frequency.

| tp (days) | % Cumm. F | F | Cumm. F |

|---|---|---|---|

| 80 | 5.56 | 1 | 1 |

| 90 | 11.11 | 1 | 2 |

| 180 | 22.22 | 2 | 4 |

| 340 | 27.78 | 1 | 5 |

| 400 | 33.33 | 1 | 6 |

| 450 | 38.89 | 1 | 7 |

| 490 | 44.44 | 1 | 8 |

| 990 | 50.00 | 1 | 9 |

| 1041 | 55.56 | 1 | 10 |

| 1051 | 61.11 | 1 | 11 |

| 1100 | 66.67 | 1 | 12 |

| 1330 | 72.22 | 1 | 13 |

| 1640 | 77.78 | 1 | 14 |

| 1840 | 83.33 | 1 | 15 |

| 2230 | 88.89 | 1 | 16 |

| 2490 | 94.44 | 1 | 17 |

| 2500 | 100.00 | 1 | 18 |

Table 6.

Production rate cumulative frequency.

| Q* (stb/day) | % Cumm. F | F | Cumm. F |

|---|---|---|---|

| 28.623 | 5.5555556 | 1 | 1 |

| 67.235 | 11.111111 | 1 | 2 |

| 78.901 | 16.666667 | 1 | 3 |

| 329.9 | 22.222222 | 1 | 4 |

| 371.22 | 27.777778 | 1 | 5 |

| 441.89 | 33.333333 | 1 | 6 |

| 452.55 | 38.888889 | 1 | 7 |

| 452.55 | 44.444444 | 1 | 8 |

| 465.72 | 50 | 1 | 9 |

| 466.49 | 55.555556 | 1 | 10 |

| 489.01 | 61.111111 | 1 | 11 |

| 513.26 | 66.666667 | 1 | 12 |

| 579.86 | 72.222222 | 1 | 13 |

| 602.09 | 77.777778 | 1 | 14 |

| 679.33 | 83.333333 | 1 | 15 |

| 1152 | 88.888889 | 1 | 16 |

| 1453.8 | 94.444444 | 1 | 17 |

| 2066.7 | 100 | 1 | 18 |

Table 7.

Cumulative frequency constant decline D (1/days).

| Constant % decline D (1/days) | % Cumm. F | F | Cumm. F |

|---|---|---|---|

| 0.002 | 5.88235294 | 1 | 1 |

| 0.004 | 11.7647059 | 1 | 2 |

| 0.008 | 17.6470588 | 1 | 3 |

| 0.043 | 23.5294118 | 1 | 4 |

| 0.063 | 29.4117647 | 1 | 5 |

| 0.066 | 41.1764706 | 2 | 7 |

| 0.069 | 47.0588235 | 1 | 8 |

| 0.07 | 58.8235294 | 2 | 10 |

| 0.071 | 64.7058824 | 1 | 11 |

| 0.076 | 70.5882353 | 1 | 12 |

| 0.086 | 76.4705882 | 1 | 13 |

| 0.089 | 82.3529412 | 1 | 14 |

| 0.096 | 88.2352941 | 1 | 15 |

| 0.171 | 94.1176471 | 1 | 16 |

| 0.299 | 100 | 1 | 17 |

Fig. 2.

Cumulative frequency plots.

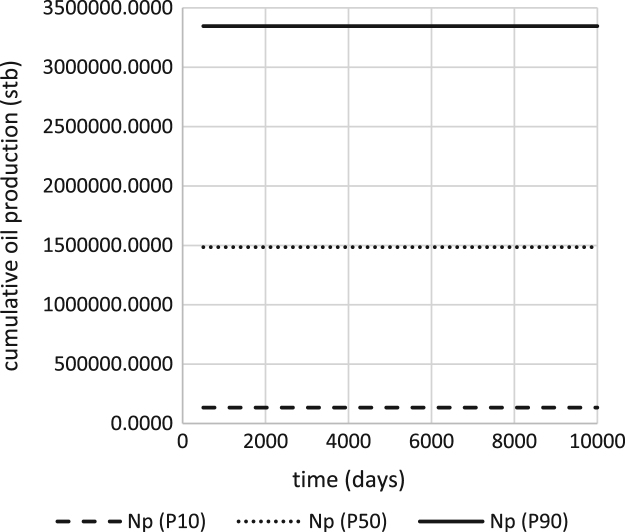

The values of the selected models are shown in Table 8 and were used to generate the probabilistic range of production forecast (Fig. 3) at 1500 stb/day.

Table 8.

Probability Distribution of the Input Variables of the Proxy Equation.

| Percentile | q* (stb/day) | D (1/Days) | tp (days) |

|---|---|---|---|

| P10 | 1.94075 | 0.003 | 89 |

| P50 | 465.72 | 0.073 | 990 |

| P90 | 1352.248 | 0.0961 | 2231 |

Fig. 3.

Probabilistic Production Forecast for oil rate of 1800 stb/d.

Acknowledgement

The author would like to thank the management of Covenant University for creating an enabling environment that supports research.

Footnotes

Supplementary data associated with this article can be found in the online version at https://doi.org/10.1016/j.dib.2018.06.115.

Transparency document. Supplementary material

Supplementary material

.

References

- 1.Ibukun S. University of Ibadan; ibadan: 2011. Evaluation of oil rim reservoir development: a case study. [Google Scholar]

- 2.D. Vo, S. Waryan, A. Dharmawan, R. Ssilo, R. Wicaksana, Lookback on Performance of 50 Horizontal Wells Targeting Thin Oil Columns, Mahakam Delta, East Kalimantan, in SPE 64385, Brisbane, 2000.

- 3.O. Olamigoke, A. Peacock, First-pass screening of reservoirs with large gas caps for oil rim development, in: SPE, 33rd Annual Technical Conference and Exhibition Paper 128603 Proceedings of the SPE, 33rd Annual Technical Conference and Exhibition Paper 128603, Abuja, 2012.

- 4.C. Kabir, M. Agamini, R. Holguin, Production strategy for thin oil columns in saturated reservoirs, in: SPE Annual technical Conference Proceedings of the SPE Annual Technical Conference, Abuja, 2004.

- 5.Arps J. Analysis of Decline Curves. Transactions of the American Institute of Mining, Metallurgical and Petroleum Engineers. 1945;160:228–247. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary material