Abstract

The dataset in this article are related to the rheology of dispersions containing Gum Arabic coated Alumina Nanoparticles (GCNPs) and Gum Arabic (GA) polymer for Enhanced Oil Recovery (EOR) of Nigerian medium crude oil under varying temperatures. The data included the viscosity of the dispersion containing GCNPs compared to GA at different shear rates. In addition, data on the rheological properties (plastic viscosity, yield point, and apparent viscosity) of the dispersions under varying temperatures was also presented.

Keywords: Oil recovery, Temperature effect, Gum Arabic, Nanoparticles, Nigerian medium crude oil

Specifications Table

| Subject area | Petroleum Engineering |

| More specific subject area | Enhanced Oil Recovery/Tertiary Oil Recovery |

| Type of Data | Tables and Figures |

| How Data was Acquired | Rheological Study using the OFITE®Model 800 Viscometer |

| Data Format | Raw Data |

| Experimental Factors | Varying Temperatures |

| Experimental Features |

|

| Data Source Location | Department of Petroleum Engineering, Covenant University, Nigeria |

| Data Accessibility | Data is with the article |

Value of data

-

•

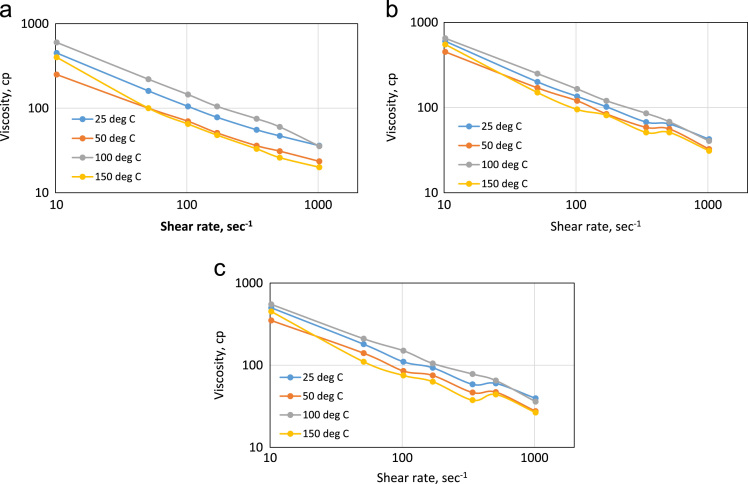

The data shows the relevance of polymer coated nanoparticles for the recovery of crude oil from conventional reservoirs under high-temperature conditions. The underlying mechanism in the thermal behavior of the GCNPs is required in explaining the trend in viscosity transition from 100 to 150 °C as captured in Fig. 1(a-c).

-

•

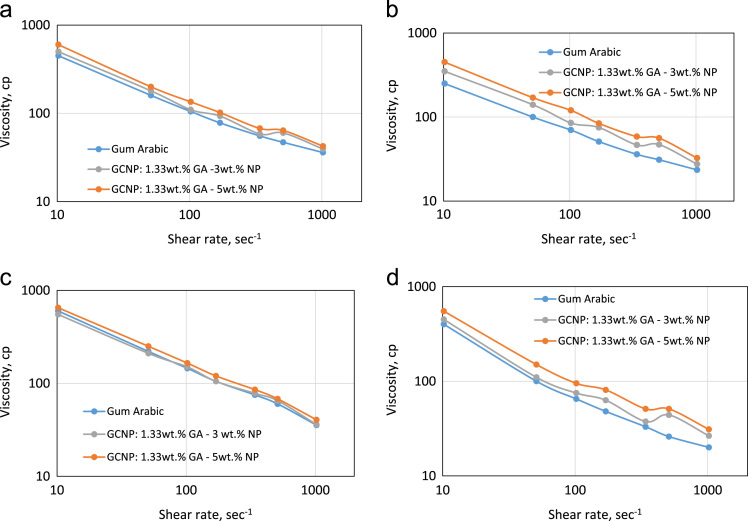

The data presented also shows that the quantity of nanoparticles in the GCNPs have a direct impact on the viscous property for the recovery of oil beyond the capacity of GA polymer flooding under high-temperature conditions (Table 2 and Fig. 2). This further indicates that a detailed characterization of the structural state and impact on nanoparticle content on the rheological performance of GCNPs is required.

-

•

The results obtained calls for a detailed study of the mechanisms at play with respect to the polymeric and surfactant property of Gum Arabic. Likewise, the performance of Gum Arabic should be evaluated and compared to that of known and standard polymers used in the industry.

Fig. 1.

Viscosity profile for (a) GA polymer solution (b) GCNPs (1.33 wt% GA-5 wt% Nanoparticles) (c) GCNPs (1.33 wt% GA-5wt% nanoparticles.

Table 2.

Viscosity values for GA and GCNPs at given temperatures of 25, 50, 100 and 150 °C.

| Shear rate (1/s) | GA | GCNP: 1.33–3 wt% | GCNP: 1.33 wt%- 5 wt% |

|---|---|---|---|

| Rheology @ 25 °C | |||

| 1021.38 | 36 | 42.5 | 39.5 |

| 510.69 | 47 | 64 | 60 |

| 340.46 | 55.5 | 67.5 | 58.5 |

| 170.23 | 78 | 102 | 93 |

| 102.138 | 105 | 135 | 110 |

| 51.069 | 160 | 200 | 180 |

| 10.2138 | 450 | 600 | 500 |

| Rheology @ 50 °C | |||

| 1021.38 | 23.5 | 32.5 | 27.5 |

| 510.69 | 31 | 56 | 47 |

| 340.46 | 36 | 58.5 | 46.5 |

| 170.23 | 51 | 84 | 75 |

| 102.138 | 70 | 120 | 85 |

| 51.069 | 100 | 170 | 140 |

| 10.2138 | 250 | 450 | 350 |

| Rheology @ 100 °C | |||

| 1021.38 | 35.5 | 40.5 | 36 |

| 510.69 | 60 | 68 | 65 |

| 340.46 | 75 | 85.5 | 78 |

| 170.23 | 105 | 120 | 105 |

| 102.138 | 145 | 165 | 150 |

| 51.069 | 220 | 250 | 210 |

| 10.2138 | 600 | 650 | 550 |

| Rheology @ 150 °C | |||

| 1021.38 | 20 | 31 | 26.5 |

| 510.69 | 26 | 51 | 44 |

| 340.46 | 33 | 51 | 37.5 |

| 170.23 | 48 | 81 | 63 |

| 102.138 | 65 | 95 | 75 |

| 51.069 | 100 | 150 | 110 |

| 10.2138 | 400 | 550 | 450 |

Fig. 2.

Viscosity profile (a) 25 °C (b) 50 °C (c) 100 °C and (d) 150 °C.

1. Data

Nanoparticles are reported in [1], [2], [3] to improve oil recovery but its instability paved the way for stable polymer-coated nanoparticles [4], [5]. The dataset presented in this paper provides an experimental investigation on temperature effect on the rheology of Gum Arabic (GA) polymer and Gum Arabic Coated Nanoparticle (GCNPs) for Enhanced Recovery of Nigerian Medium Crude Oil. Gum Arabic is a naturally occurring polymer that is abundant in Nigeria and Sudan. Table 1 shows the dataset on the rheological properties of Gum Arabic Polymer, GCNPs (1.33 wt% GA - 5 wt% NP, GCNPs) and GCNPs (1.33 wt% GA - 3 wt% NP, GCNPs) at varying temperatures and shear rates. Table 2 shows the viscosity data values for GA and GCNPs at given temperatures of 25, 50, 100 and 150 °C. Whereas Fig. 1 displays graphically, Viscosity profile for (a) GA polymer solution (b) GCNPs (1.33 wt% GA-5wt% Nanoparticles) (c) GCNPs (1.33 wt% GA-5wt% Nanoparticles). Fig. 2 displays the viscosity profile of GA polymer and GCNPs at 25, 50, 100 and 150 °C.

Table 1.

Rheology of Gum Arabic Polymer, GCNPs (1.33 wt% GA - 5 wt% NP, GCNPs) and GCNPs (1.33 wt% GA - 3 wt% NP, GCNPs).

| Shear rate (1/s) |

Temperature °C |

|||

|---|---|---|---|---|

| 25 |

50 |

100 |

150 |

|

| Viscosity (cp) | ||||

| Rheology of Gum Arabic Polymer | ||||

| 1021.38 | 36 | 23.5 | 35.5 | 20 |

| 510.69 | 47 | 31 | 60 | 26 |

| 340.46 | 55.5 | 36 | 75 | 33 |

| 170.23 | 78 | 51 | 105 | 48 |

| 102.138 | 105 | 70 | 145 | 65 |

| 51.069 | 160 | 100 | 220 | 100 |

| 10.2138 | 450 | 250 | 600 | 400 |

| Plastic Viscosity (cp) | 25 | 16 | 11 | 14 |

| Yield Point (lb/100 ft2) | 22 | 15 | 49 | 12 |

| Apparent Viscosity (cp) | 36 | 23.5 | 35.5 | 20 |

| Rheology of (1.33 wt% GA - 5 wt% NP, GCNPs) | ||||

| 1021.38 | 42.5 | 32.5 | 40.5 | 31 |

| 510.69 | 64 | 56 | 68 | 51 |

| 340.46 | 67.5 | 58.5 | 85.5 | 51 |

| 170.23 | 102 | 84 | 120 | 81 |

| 102.138 | 135 | 120 | 165 | 95 |

| 51.069 | 200 | 170 | 250 | 150 |

| 10.2138 | 600 | 450 | 650 | 550 |

| Plastic Viscosity (cp) | 21 | 9 | 13 | 11 |

| Yield Point (lb/100 ft2) | 43 | 47 | 55 | 40 |

| Apparent Viscosity (cp) | 42.5 | 32.5 | 40.5 | 31 |

| Rheology of (1.33 wt% GA - 3 wt% NP, GCNPs) | ||||

| 1021.38 | 39.5 | 27.5 | 36 | 26.5 |

| 510.69 | 60 | 47 | 65 | 44 |

| 340.46 | 58.5 | 46.5 | 78 | 37.5 |

| 170.23 | 93 | 75 | 105 | 63 |

| 102.138 | 110 | 85 | 150 | 75 |

| 51.069 | 180 | 140 | 210 | 110 |

| 10.2138 | 500 | 350 | 550 | 450 |

| Plastic Viscosity (cp) | 19 | 8 | 7 | 9 |

| Yield Point (lb/100 ft2) | 41 | 39 | 58 | 35 |

| Apparent Viscosity (cp) | 39.5 | 27.5 | 36 | 26.5 |

2. Experimental design, materials and methods

2.1. Preparation of Gum Arabic Coated Nanoparticles (GCNPs)

The nanoparticle in use was Al2O3 (30–60 nm, purity greater than 99%; manufactured by Sigma Aldrich and purchased from Equilab Solutions in Nigeria.). 50 g of Al2O3 was dispersed in 1 l of deionized water to make nano-fluid suspensions, making a 5 wt% mixture. It was further diluted to 3 wt% in order to completely carry out further experiments. The Gum Arabic (a polymer; purchased locally in Nigeria) was mixed with the prepared nanofluids at a concentration of 1.33 wt. %. Finally, the concentration of GCNPs prepared are 1.33 wt% Gum Arabic – 3.0 wt% Al2O3 Nanoparticles –GCNPs and 1.33 wt% Gum Arabic – 5.0 wt% Al2O3 Nanoparticles – GCNPs.

2.2. Rheological analysis of Gum Arabic (GA) and Gum Arabic Coated Nanoparticles (GCNPs)

The OFITE Model 800 (8-Speed) Viscometer was used to obtain dial readings, θ, at various RPM (Revolution per Minute) values (3, 6, 30, 60, 100, 200, 300, and 600). Based on the API specification 13A, the Eqs. (1), (2), (3) was used in estimating the rheological properties of the prepared drilling mud.

| (1) |

| (2) |

| (3) |

θ600 and θ300 are the dial readings at 600 and 300 RPM respectively. The viscosity values were calculated using the relationship in Eq. (4) as specified in the OFITE operational manual (1cp is equivalent to ).

| (4) |

is the viscosity in cp, K is the machine constant of the Rotor – Bob combination (R1B1) = 300, F is the spring factor = 1 for the R1B1 combination.

Acknowledgment

The authors would like to thank the management of Covenant University for providing the needed facilities to carry out this research.

Footnotes

Transparency document associated with this article can be found in the online version at https://doi.org/10.1016/j.dib.2018.06.075.

Contributor Information

Oyinkepreye D. Orodu, Email: oyinkepreye.orodu@covenantuniversity.edu.ng.

Richard O. Afolabi, Email: richard.afolabi@covenantuniversity.edu.ng.

Transparency document. Supplementary material

Transparency document

References

- 1.M.V. Bennetzen, K. Mogensen, Novel applications of nanoparticles for future enhanced oil recovery, in: Proceedings of International Petroleum Technology Conference, Kuala Lumpur, 2014, pp. 1–14.

- 2.Roustaei A., Barzagadeh H. Experimental investigation of SiO2 nanoparticles on enhanced oil recovery of carbonate reservoirs. J. Pet. Explor. Prod. Technol. 2014;5:27–33. [Google Scholar]

- 3.A. Roustaei, J. Moghadasi, H. Bagherzadeh, A. Shahrabadi, An experimental investigation of polysilicon nanoparticles׳ recovery efficiencies through changes in interfacial tension and wettability alteration, in: Proceedings of SPE International Oilfield Nanotechnology Conference and Exhibition, Noordwijk, Netherlands, 2012, pp. 1–7.

- 4.ShamsiJazeyi H., Miller C.A., Wong M.S., Tour J.M., Verduzco R. Polymer-coated nanoparticles for enhanced oil recovery. J. Appl. Polym. Sci. 2014;131:1–13. [Google Scholar]

- 5.Afolabi R.O., Orodu O.D., Efevobkhan V.E. Properties and application of Nigerian bentonite clay deposits for drilling mud formulation: recent advances and future prospects. Appl. Clay Sci. 2017;143:39–49. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Transparency document