Summary

Stretchable, biocompatible devices can bridge electronics and biology. However, most stretchable conductors for such devices are toxic, costly, and regularly break/degrade after several large deformations. Here we show printable, highly stretchable, and biocompatible metal-polymer conductors by casting and peeling off polymers from patterned liquid metal particles, forming surface-embedded metal in polymeric hosts. Our printable conductors present good stretchability (2,316 S/cm at a strain of 500%) and repeatability (ΔR/R <3% after 10,000 cycles), which can satisfy most electrical applications in extreme deformations. This strategy not only overcomes large surface tension of liquid metal but also avoids the undesirable sintering of its particles by stress in deformations, such that stretchable conductors can form on various substrates with high resolution (15 μm), high throughput (∼2,000 samples/hour), and low cost (one-quarter price of silver). We use these conductors for stretchable circuits, motion sensors, wearable glove keyboards, and electroporation of live cells.

Subject Areas: Polymers, Alloys, Electronic Materials

Graphical Abstract

Highlights

-

•

A straightforward method for sintering liquid metal particles with high efficiency

-

•

Liquid metal can be patterned on different substrates with high resolution

-

•

Low-cost, high-throughput, stretchable printed conductors can be fabricated

-

•

Conductors are biocompatible and have potentials in implantable electronics

Polymers; Alloys; Electronic Materials

Introduction

Fusion of electronics with biology and medicine demands electronic devices that are supple, stretchable, and compatible with human tissues, such as the skin (Kim et al., 2011, Oh et al., 2016) and the brain (Kang et al., 2016, Liu et al., 2015), especially in the fields of health monitoring and disease treatment (Chortos et al., 2016, Sun et al., 2014, Jeong et al., 2015a). Flexible circuits are currently realized by depositing a thin layer of metal like copper and gold on flexible substrates such as polyimide. To further endow such flexible circuits with stretchability, wavy or serpentine structures are designed to counteract deformations (Lou et al., 2017, Kim et al., 2008). The stretchability of these strategies is limited (about 150%), and the fabrication processes of such structures are often complicated. Another approach is developing conductive materials that could bear large deformations such as carbon nanomaterials, silver inks, and liquid metals (LMs) (Kazem et al., 2017, Qi et al., 2015, Zheng et al., 2014, Matsuhisa et al., 2017, Tang et al., 2014). Most of these materials are hard to be patterned with microstructures in large scale. Among these materials, LMs, especially eutectic gallium indium alloy (EGaIn, melting point 15°C), stand out for their excellent performances of high conductivity and unequaled stretchability (Dickey, 2017). Besides, EGaIn is much less toxic (Lu et al., 2015) than other metals that may potentially be useful for these applications, such as mercury (also liquid at room temperature) or silver (its nanowires can withstand stretch). However, the huge surface tension (>400 mN/m) (Dickey, 2014) of LM impedes its direct patterning by using straightforward technologies such as stencil and ink-jet printing (Zheng et al., 2014, Wang et al., 2015), making its patterning limited to very few substrates that can be wetted by LMs. In addition, such strategies have high LM consumption (the thickness of the LM pattern is usually larger than 100 μm), which further limits their wider applications. Another common method, injecting the LM into microfluidic channels or hollow wires, can yield conductors with high stretchability (>1,000%). However, these methods cannot fabricate complex conductive patterns that require the microfluidic channels or hollow wires to be continuous from the beginning to end (Kubo et al., 2010, Zhu et al., 2013). By contrast, bottom-up approaches to fabricate LM into particles is a good way to minimize the surface tension. Some reported strategies usually deposit a layer of liquid metal particles (LMPs) (not conductive due to the oxide layer on the particles) on the surface of elastomers and use a marker to mechanically sinter LMPs (break the oxide layer to release the conductive LM) to obtain a desirable conductive pattern (Lin et al., 2015, Boley et al., 2015; Ren et al., 2016, Mohammed and Kramer, 2017). However, conductive patterns fabricated by these strategies cannot bear large deformations like stretching in practical applications, because stress in deformations will also sinter the LMPs in regions where conductive patterns are not desirable, causing short circuit in the electronics. Besides, using a marker to sinter the LMP to obtain electronics has low efficiency and low utilization of particles. These strategies using LMPs are not applicable to mass-manufacturing.

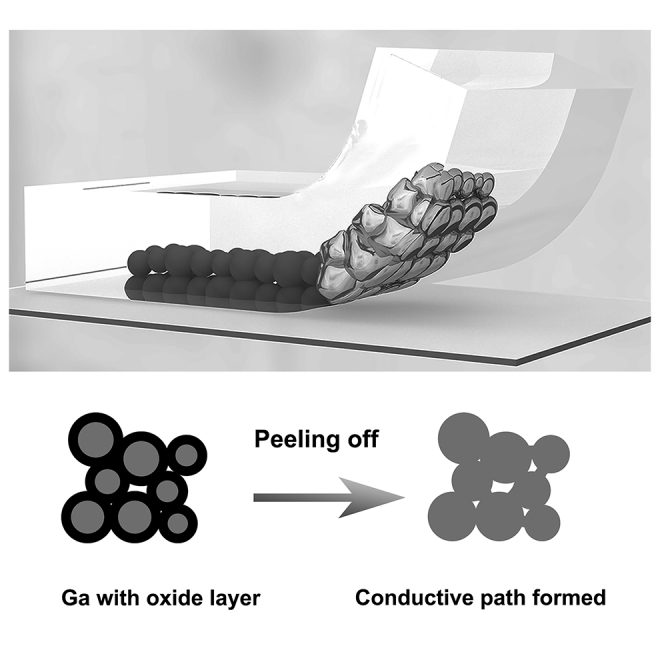

Here, we report printable and mass-manufacturable metal-polymer conductors (MPCs) by fabricating LM into LMPs (liquid core-oxide shell structure), and embedding the patterned LMPs on the surface of polymers by casting and peeling off steps, instead of using a marker or a nozzle, to result in microstructured, conductive path. The theoretical calculation indicates that the stress on the particles during stripping is much larger than the yield stress of gallium oxide, causing the release of the LM to form conductive paths. We used screen printing or microfluidic patterning strategy to pattern any 2D MPC pattern on various substrates in different thicknesses with high resolution (15 μm), high efficiency, and low cost. The printable MPC is highly conductive (8 × 103 S/cm), robust, and stretchable, which can keep conductivity as high as 2,316 S/cm at a strain of 500%. Because MPC patterns allow exposed LMs on the surface of polymer substrates (instead of completely buried within polymers), electronic components could be easily mounted. We used the printable MPC for highly stretchable circuits, motion sensors, wearable glove keyboards, and electroporation of live cells because of its biocompatibility. This potentially widely applicable approach will greatly increase the stretchability of electronic devices and sharply decrease the production cost of printed electronics, which will significantly promote the development of wearable or implantable electronic devices.

Results

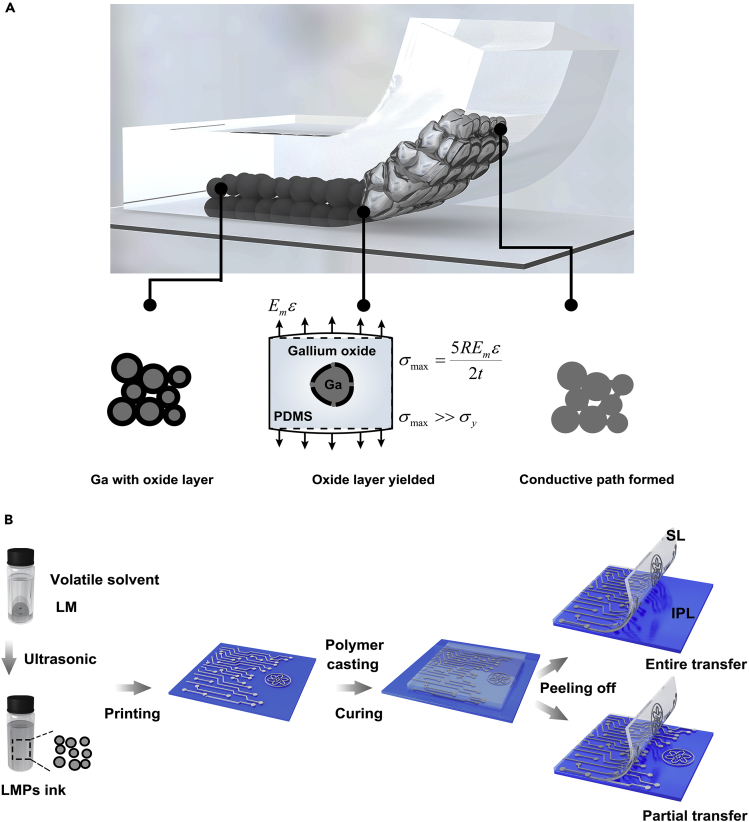

Fabrication of the MPC

To prove that the stress during stripping can effectively break the oxide layer of LMPs embedded in elastomers, we performed a theoretical calculation. We analyzed the stress of LMPs on the bending part (Figure 1A). The model can be simplified as a gallium particle embedded in a PDMS (polydimethylsiloxane) matrix. Through calculation, we concluded that the maximum Tresca's equivalent stress on the oxide layer of the particle is MPa (Em, ɛ, R, and t are the Young's modulus, strain at the bottom of the PDMS, the average radius of particles, and the thickness of gallium oxide, respectively), which is much larger than the yield stress of gallium oxide, σy = 200 MPa (details of calculation are shown in Figure S1, and mechanical calculation in Transparent Methods). It suggests that upon peeling off the PDMS from the LMP-patterned substrates, the oxide layer of the LM will yield and release the conductive core to form conductive paths.

Figure 1.

Conductive Mechanism and Fabrication of the MPC

(A) The oxide layer of LMPs will yield and form conductive paths after peeling off PDMS from the LMP-patterned substrate. σmax is the maximum Tresca's equivalent stress on the oxide layer of the particle, σy represents yield stress of gallium oxide, and Em,ɛ, R, and t are the Young's modulus, strain at the back end of the PDMS, the average radius of particles, and the thickness of gallium oxide, respectively.

(B) Fabricating microstructured MPC.

See also Figures S1 and S2, and Table S1.

Based on this mechanism, we developed an MPC micro-patterning strategy (Figure 1B). To prepare the LMP inks, we added LM (here we used EGaIn) into an organic, volatile solvent (n-decyl alcohol) and sonicated the mixture to convert EGaIn to LMP-based inks. The sonicated LMs tend to be particles with spherical shape, due to their large surface tension, thus the most straightforward way to pattern them would be to use 0D LMs rather than 1D wires or tubes. The diameters of the particles depend on the sonication time (Figure S2A). LMPs dispersed in solvent will not be sintered by stress. However, after the volatilization of the solvent, LMPs in ink become very sensitive to stress and any disturbance by the blade during printing will sinter the LMPs together. To increase the operation time for printing, we choose solvents with high boiling point instead of the commonly used ethanol. The n-decyl alcohol has higher boiling point (232.9°C) and more appropriate viscosity, allowing sufficient operation time for printing. We tested the viscosity and the contact angle of the LMP inks with different concentrations (Figures S2B and S2C). The LMP inks have contact angle in polyethylene terephthalate (PET) film smaller than 30° and viscosity around 20,000 cP. After printing of LMPs on the initial patterning layer (IPL) and evaporation of the solvent, the LMPs are stacked one atop another on the IPL (Figure 2A). At this point, the oxide layer of each particle inhibits electrical conductivity. We cast curable pre-polymers onto the stacked particles as the stripping layer (SL). Because our LMPs (about 5 μm in diameter) are in tight contact with each other and have larger density than polymers, the polymer cannot push neighboring LMPs apart. After curing the polymer and peeling it off, the tensile stress will break the oxide layer, forming pathways for electron transport; we can thus obtain microstructured MPC surface embedded on the IPL and/or SL (Figure 1A).

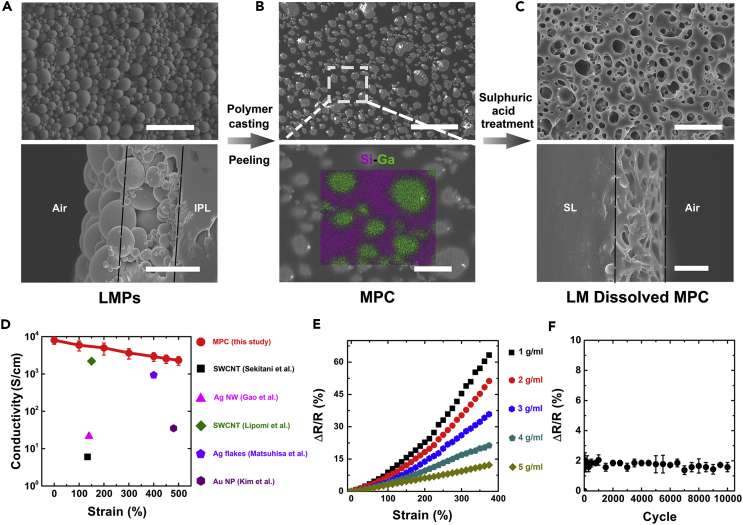

Figure 2.

Characterization of the MPC

(A) Scanning electron microscopy of LMPs: top, top view; bottom, cross-sectional view. Scale bar, top, 30 μm; bottom, 10 μm. Black dashed line: region of stacked LMPs.

(B) The scanning electron microscopic and elemental analyses of the surface of the MPC. LM islands (green: Ga) in the sea of polymer (purple: Si). Scale bar, top, 30 μm; bottom, 5 μm.

(C) The MPC after dissolving the LM. Top, surface appearance, scale bar, 20 μm; bottom, cross-sectional appearance, scale bar, 10 μm. Dashed line: thickness of the MPC.

(D) Conductivity dependence on tensile strain of printed MPC and comparison with reported printed conductors.

(E) The change of resistance with different strain using MPC patterns printed by inks with different concentrations.

(F) ΔR/R changes with a strain of 50% for 10,000 cycles. Data in (D) and (F) are expressed as mean ± SD.

See also Figures S3 and S4.

Characterization of the MPC

We characterized the structure of the MPC. MPC is composed of interlinked LM and infiltrated, porous polymeric host (Figure 1). The surface of MPC presented an “islands-in-the-sea” appearance, as LM islands are dispersed in the sea of polymers when using a variety of curable polymers with a broad range of hardness/elasticity (modulus from 30 kPa to 5 GPa) as the SL (Figures 2B and S3A). To confirm that the metallic phase within the MPC is interlinked, we exposed the MPC to a sulfuric acid solution, which will dissolve the LM but not the polymer, to see if the LM within the MPC can dissolve completely. The continuous hollow space left in the cross section of MPC after sulfuric acid treatment suggests that the LM must have formed a continuous phase within the MPC; if the LM did not form a continuous phase, we would not expect the sulfuric acid to dissolve the LM in the middle of the MPC (Figure 2C). The continuous LM inside the MPC ensures unparalleled conductivity, while the LM islands on the surface promise stable contact with external devices. Unlike the LM surfaces, the MPC will not stick to the operator's finger upon gentle touch. Also, after connecting other devices with our MPC interconnects, we can use another layer of polymer to completely encase the MPC to avoid damage by sharp objects. MPCs cast by different polymers have similar conductivities (about 8 × 103 S/cm, Figure S2D). In comparison, without the stripping step, an MPC of similar size appears as an insulator. Both morphological and electrical analyses indicate that MPC has a continuous phase of conductive material embedded within the polymeric host.

We evaluated the electro-mechanical properties of the MPC cast by elastic polymer Ecoflex 0030 (a commercial silicone softer than PDMS). This MPC has a high initial conductivity (8 × 103 S/cm) and an excellent stretchability, retaining a conductivity of 2,316 S/cm at a strain of 500%, which is comparable to those of stretchable, printed conductors under similar strains reported so far (Figure 2D) (Matsuhisa et al., 2017, Kim et al., 2013, Sekitani et al., 2009, Gao et al., 2014, Lipomi et al., 2011). We did not push the limit of stretchability further because an extension of 500% can itself satisfy the requirements of all our applications. To verify the performance of the MPC connected to a device, we used EGaIn as solder to weld a 100-Ω resistor to the MPC interconnects screen printed by different concentrations of LMP inks. The change of resistance of the MPC can be precisely tuned by inks with different concentrations of LMPs (Figure 2E). To test the repeatability of stretch, we repeatedly exerted tensile strain to an MPC strip (2.5 g/mL) cast by PDMS for 10,000 cycles (Figure 2F), the resistance kept essentially the same: ΔR/R <3% after 10,000 cycles. After the peeling off of the polymers, most of the particles are broken, forming a stable conductive structure; we thus do not see any change in resistance after the strain cycle. We characterized the MPC after 10,000 stretch cycles: several LM droplets with diameters of hundreds of micrometers will be squeezed out from several LM “islands” on the surface of MPC (Figure S4). However, the squeezed LMs cause no problem with regard to the electrical performance of the MPC (Figure 2F). The leakage of the LM can be prevented by encapsulating another layer of polymer on the surface of MPC.

Patterning of the MPC

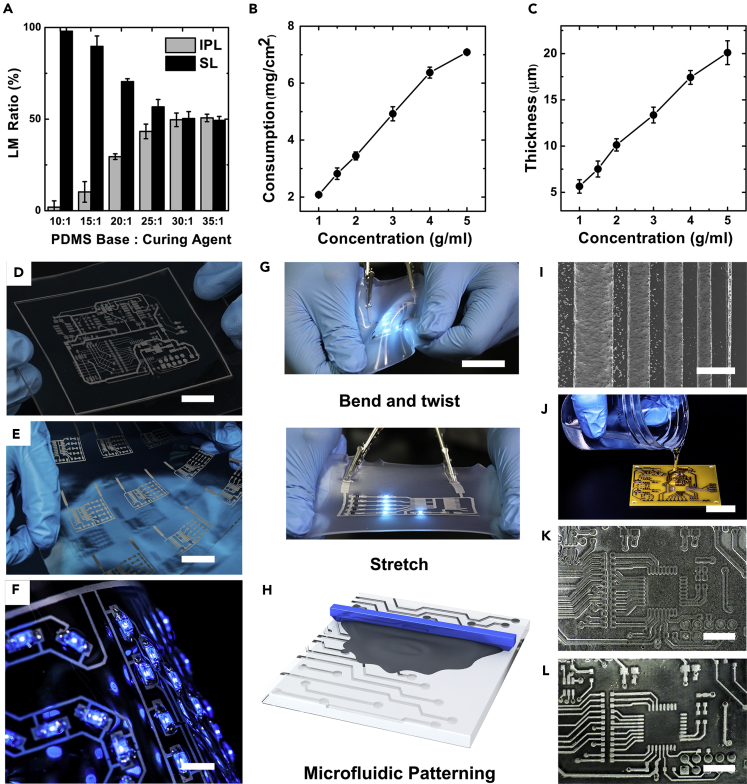

To show that the MPC allows patterning of microstructured conductor on non-cured materials such as PET, glass, and paper using these substrates as the IPL, we try to decrease the amount of LM transferred onto the SL, since we have already achieved MPC patterning on different SLs such as PLGA [poly (DL-lactide-co-glycolide)] and PCL [poly (caprolactone)] by casting different polymers (Figure S6 top). Entire transfer (Figure S5A) or partial transfer (Figure S5B) mainly depends on the affinity between the IPL and the SL. Compared with the polymer, the structure of MPC (a porous structure of polymer with LM filled in the porous) is fragile and can be torn apart in the Z direction (Figure S5B bottom), such that part of the MPC becomes attached to the IPL if the affinity between the IPL and the polymer in the SL is large enough. Since increasing the base-to-curing-agent ratio for PDMS can increase its stickiness, we used PDMS with different proportion of curing agent as the SL (PET as the IPL) to control the transfer amount of LM. When this ratio exceeds 30:1, IPL can retain the maximum amount of LM (50%) (Figure 3A), such that complete 2D patterns formed on both IPL and SL. To keep the feature resolution intact on SL, we need to decrease the affinity between the IPL and SL. To keep the feature resolution intact on IPL, we need to increase such affinity. The surface in partial transfer reflects the inner structure of the MPC, which presents a continuous metallic phase (Figure S3B). This strategy allows further broadening of the types of substrates on which we can pattern flexible microstructured conductors. For instance, when using non-curable materials (Figure S6 bottom) as the IPL, they can keep the MPC patterns by using sticky PDMS as the SL. Some of these substrates have features such as flexibility, biocompatibility, and biodegradability.

Figure 3.

Micro-patterning of the MPC

(A) Transfer amount of LM versus different concentration of curing agent in PDMS.

(B) The consumption of LM versus the concentration of LMP inks.

(C) The thickness of the LMP patterns versus the concentration of LMP inks.

(D) A mutilayered circuit by stacking MPC patterned on pieces of PDMS.

(E) Large-scale production of circuit arrays by screen printing.

(F) An LED array.

(G) An LED circuit deformed by bending, twisting, and stretching.

(H) A schematic to demonstrate the microfluidic patterning method.

(I) MPC-filled ultrafine channels.

(J–L) Process of the microfluidic patterning using a PBC board as a convex mold. (J) PDMS casting, (K) PDMS replica, (L) MPC-filled microfluidic channels as a stretchable circuit. Scale bars: (D) 15 mm, (E) 3 cm, (F, K, and L) 5 mm, (G and J) 2 cm, and (I) 200 μm. Data in (A), (B), and (C) are expressed as mean ± SD.

See also Figures S5–S7, and Video S1.

To test whether alloys other than EGaIn can be fabricated to MPC, we used LM with higher melting point. We sonicated an alloy that melts at 47°C (Sn 8.30, Pb 22.60, Bi 44.70, Cd 5.30, In 19.10) into LMPs and utilize partial transfer to fabricate the MPC on PET. At room temperature, the LM within the MPC is in solid state. The MPC possesses excellent flexibility; after bending for 1,000 cycles, the conductivity remains the same (Figure S7A). MPC can thus be a general approach for making flexible conductors by combining LM with a variety of polymers, as long as the melting pointing of the metal alloy is within the working range of polymers.

We can pattern the MPC into any complex 2D geometry using handwriting (Figure S7B), screen printing, or microfluidic patterning (Figure 3H). To achieve rapid fabrication of patterns, we used screen printing to make a batch of nine integrated circuits, each circuit controlling an array of light-emitting diode (LED) (Figure 3E). Each circuit is highly supple and can undergo repeated bending, twisting, and stretching without compromising the function of any of its components (Figure 3G and Video S1). We achieved such circuit array within 10 s, which suggested that an estimated number of 2,000 circuits can be obtained within 1 hour when taking the casting and peeling off process into account. Comparing with direct ink-jet printing of LM, which requires LM 60 mg/cm2 (the patterns are usually 100 μm in thickness) (Wang et al., 2015), the MPC fabricated by screen printing is unprecedented in minimizing the amount of metal, only several milligrams per square centimeter (depending on the concentration of inks, Figure 3B). The LMPs on the mesh can be easily washed by ethanol. After the printing, we usually wash the mesh using ethanol and collect such washed LMPs. After centrifugation, LMPs can be recycled. The thickness of the MPC can be controlled by the concentration of the LMP inks (Figure 3C). We achieved MPC patterns on an ultrathin membrane (30 μm) (Figure S7D). We successfully achieved multi-layered circuits by stacking MPC patterned on pieces of PDMS (Figure 3D). This approach may allow us to ultimately make stretchable displays (Figures 3F and S7C).

We used microfluidic patterning method to obtain ultra-fine interconnects. Briefly, we used a blade to scrap the LMP inks into the microfluidic channels (Figure 3H). When scraping the LMP ink, the LMPs will not be broken by blades because they are in a solution form (dispersed in solvent and cannot be sintered). After evaporation of the solvents, we used sticky PDMS as the SL to retain half of the MPC in the microfluidic channels. We achieved a minimum trace width of 15 μm on PDMS (Figure 3I) using this method (the discrete ink residues by the wide lines caused by the surface tension of the solvents may be improved by increasing the concentration of the LMP inks or by adding some surfactants). Microfluidic patterning method is also suitable for converting a Printed circuit board (PCB) into flexible and stretchable circuit. Using a PCB as a convex mold (Figure 3J), we can replicate a concave microfluidic network, which allows the filling of LMP inks (Figures 3K and 3L). Our MPC patterning strategies perfectly meet the requirements of the industrial standard PCB, where the minimum trace width is ∼70 μm. Compared with conventional patterning strategies of LM, the patterning of the MPC could be much more flexible, economic, and extremely high in yield.

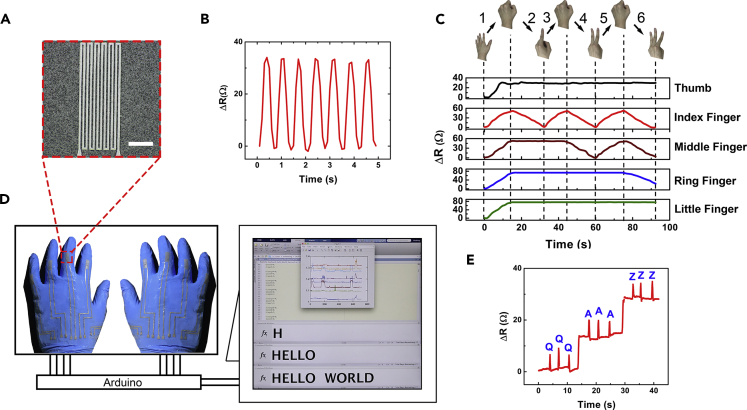

MPC Sensors and Wearable Glove Keyboards

We fabricated strain sensors for motion capture using the MPC patterns (entire transfer, and PDMS as the SL) (Figure 4A). We attached these sensors onto the knuckles of a glove, and monitored the motion of the fingers in real time (Video S2). The detected signals have good repeatability when we bent and straightened the finger with high frequency (Figure 4B). When slowly and evenly bending and straightening different fingers, the signals showed a good linear relationship with time, which demonstrated that our sensors have high motion resolution to reflect different degrees of bending of fingers (Figure 4C).

Figure 4.

Fully Printed MPC Strain Sensors for Motion Monitoring and a Wearable Glove Keyboard

(A) Photograph of the strain sensor. Scale bar, 2 mm.

(B) Electrical signals from finger bending and straightening with high frequency.

(C) Motion monitoring of five fingers with slow bending and straightening: 1. making a fist; 2. straightening index finger; 3. bending index finger; 4. straightening two fingers; 5. bending two fingers; 6. straightening three fingers.

(D) Using a wearable glove keyboard to input the phrase “HELLO WORLD.”

(E) An example showing left little finger typing the letters Q, A, and Z.

Based on the high repeatability of the MPC (Figure 2F), we developed a wearable QWERTY keyboard on a pair of gloves using an array of sensors. Wearable keyboards can dramatically improve the productivity of work; this improvement can accelerate the process of converting ideas to texts. We use MPC sensors to convert mechanical signals into electrical ones and use Arduino and MATLAB to process electrical signals, which mainly comprise peak recognition, cliff recognition, and the elimination of the interference peak caused by neighboring fingers when typing. Our keyboard suits the traditional typing style where each finger is responsible for typing three letters. For example, the left little finger is responsible for the input of Q, A, and Z (Figure 4E). The three levels of resistance signals represent three different bending degrees of the finger, whereas the peaks represent the tapping movements. We typed the phrase “HELLO WORLD” using this wearable glove keyboard (Figures 4D and S8). The robustness of the MPC under stretch ensures that a real device as complex as the keyboard can function properly. Since each sensor has to accurately differentiate between at least six modes of stretch, the entire device with 10 sensors will have to accommodate 60 parameters repetitively. MPC can thus be instrumental in developing a series of wearable devices.

MPC for Live-Cell Electroporation

To explore the biocompatibility and biodegradability of the MPC, we fabricated the MPC cast by PDMS to culture human umbilical vascular epithelial cells (HUVECs) and human aortic fibroblasts (HAFs). After a 7-day incubation in the cell culture medium, the cells showed good viability (Figure S9), which demonstrated that MPC is safe to cells. We found that the surface of MPC is slightly degraded (Figures 5B and 5C) without compromising its conductivity (Figure S10A), whereas the control group exposed to cell culture medium alone showed no degradation (Figure S10B). We speculate that the metabolic wastes from cells, such as CO2, reduced the pH around the MPC to partially dissolve the LM. This experiment indicates that neither the MPC itself nor its dissolvable components (such as gallium ion and indium ion) are toxic to mammalian cells.

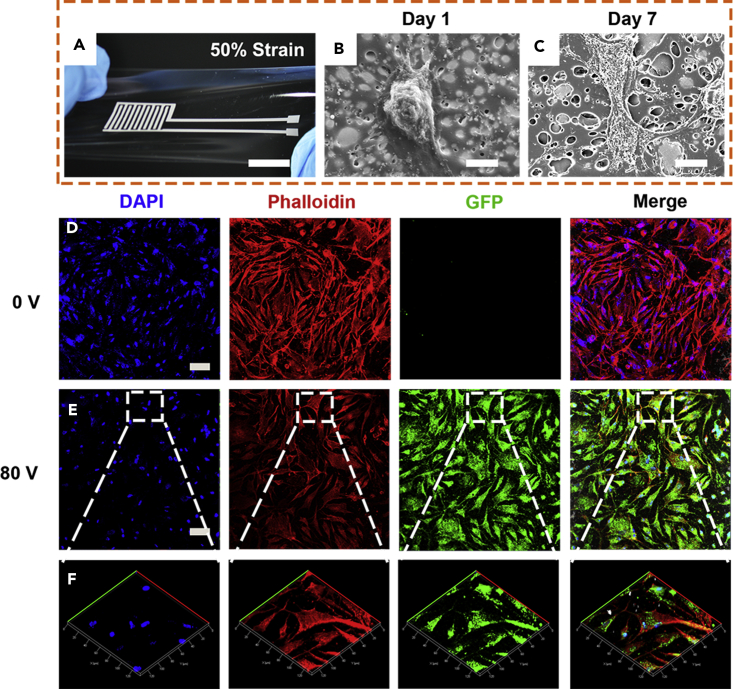

Figure 5.

Cell Culture and Electroporation Using MPC Electrode

(A–E) (A) Photograph showing the MPC electrode under stretch, scale bar, 8 mm. Scanning electron microscopic characterization of HUVEC on the surface of MPC on (B) day 1 and (C) day 7, scale bar, 10 μm. Fluorescent cytoskeleton staining of fibroblasts on the MPC (D) without and (E) with electroporation. Scale bar, 50 μm.

(F) 3D reconstruction of fibroblasts on the MPC treated by electroporation.

See also Figures S9–S11.

To further explore the biomedical potential of MPC, we designed comb-like MPC electrodes and performed electroporation to introduce exogenous genes into live cells. The controlled introduction of exogenous materials into live cells using stretchable devices is a potentially useful, but a poorly explored area. To verify the excellent stretchability of MPC electrodes, we exerted tensile cycle for 100 times to the MPC electrode (Figure 5A) before electroporation, using gold electrodes of the same geometry as a control. The gold electrodes lost their conductivity owing to the formation of cracks after the first tensile cycle (Figure S10C). After adhesion of HAFs on the MPC electrodes, we delivered DNA plasmid encoding GFP into HAF by electroporation. We stimulated cells with a voltage of 80 V five times by exerting a square wave. After a 24-hr incubation, the HAFs on the electrodes (Figures 5E and 5F) and between the electrodes (Figure S11) successfully realized GFP expression, with 95% of cells showing green fluorescence, whereas there was no green fluorescence in the control group (Figure 5D). Thus MPC can function as completely biocompatible, biofunctional, and stretchable electronics.

Discussion

In this work, we reported a straightforward MPC patterning strategy. Through the printing, casting, and peeling off steps, we could easily achieve any 2D pattern of MPC on most substrates in different thickness with high resolution, high efficiency, and low cost, which cannot be achieved by reported strategies in LM, because in these studies, the performances of LM are constrained by limited substrates (Zheng et al., 2014) (few substrates can be wetted by LM), poor resolution (Jeong et al., 2015a, Jeong et al., 2015b) (limited by surface tension and the stencil), inability to achieve arbitrary patterns (Kubo et al., 2010, Zhu et al., 2013) (for example, injecting LM into microfluidic channels or hollow wires), high LM consumption caused by low efficiency and utilizations (Wang et al., 2015, Lin et al., 2015; Boley et al., 2015, Ren et al., 2016, Mohammed and Kramer, 2017, Jeong et al., 2015b) (most of the LMs are wasted on stencils or not as the conductive part), or undesirable sintering of the LMPs (Mohammed and Kramer, 2017) (stress caused by deformation can sinter the LMPs in regions where conductive patterns are not desirable). Because MPC patterns allow exposed LMs on the surface of solid substrates (instead of completely buried within polymers), electronic components could be easily mounted. Compared with stretchable silver ink (Matsuhisa et al., 2017), our MPCs have not only better performances but also low cost, because the price of gallium is about one-quarter of that of silver (silver: ∼ US $530 per kilogram, gallium: ∼ US $150 per kilogram, indium: ∼ US $180 per kilogram, 2018) (as conductors, gallium and indium in high purity are not necessary), not to mention the expensive processing of the microstructured silver. Our MPC patterning method meets the minimum trace width requirements of the commercial PCB, and its low cost and high yields will make broad applications of the LM-based electronic devices possible.

We can combine the benefits of both metals and polymers. We may use functional polymers such as shape memory polymers, self-healing polymers, and biodegradable polymers to cast the LMPs to form thousands of new functional MPCs in desirable temperature.

Our MPC also paves a brand new avenue for the implantable electronic devices. Based on the excellent stretchability and biocompatibility of our MPC, stretchable patches can be designed for highly active organs, such as the heart and joints. For example, in a myocardial infarction model, we intend to fabricate a biodegradable cardiac patch patterned by MPC electrodes to enhance the conductivity of myocardial cells and monitor the electrophysiological signals simultaneously.

The ease of fabrication and high level of biocompatibility will make MPC useful for wearable electronics, implantable devices, soft robotics, future fabrics, virtual/augmented reality, flexible display, artificial organs, brain-computer interface, and wherever biocompatible, soft electronics is necessary.

Methods

All methods can be found in the accompanying Transparent Methods supplemental file.

Acknowledgments

We thank Zewen Wei and Deyao Zhao for their great help in electroporation. We thank the Ministry of Science and Technology of China (2013YQ190467), Chinese Academy of Sciences (XDA09030305), and the National Natural Science Foundation of China (81361140345, 51373043, and 21535001) for financial support.

Author Contributions

X.J. conceived and supervised this project. L.T. designed, fabricated, and characterized materials and devices with the help of L.M., and S.Y., L.T., S.C., and Z.H. carried out cell experiments. L.Z. and X.S. performed the calculation and simulation of the MPC. H.M. coded the virtual keyboard. L.T., S.C., and X.J. wrote the manuscript. All authors discussed the results and commented on the manuscript.

Declaration of Interests

The authors declare that they have no competing interests.

Published: June 14, 2018

Footnotes

Supplemental Information includes Transparent Methods, 11 figures, 1 table, and 2 videos and can be found with this article online at https://doi.org/10.1016/j.isci.2018.05.013.

Supplemental Information

The LED circuits interconnected by MPC can undergo repeated bending, twisting, and stretching.

We attached MPC sensors onto the knuckles of a glove, and the motion of the fingers can be monitored in real time.

References

- Boley J.W., White E.L., Kramer R.K. Mechanically sintered gallium-indium nanoparticles. Adv. Mater. 2015;27:2355–2360. doi: 10.1002/adma.201404790. [DOI] [PubMed] [Google Scholar]

- Chortos A., Liu J., Bao Z. Pursuing prosthetic electronic skin. Nat. Mater. 2016;15:937–950. doi: 10.1038/nmat4671. [DOI] [PubMed] [Google Scholar]

- Dickey M.D. Emerging applications of liquid metals featuring surface oxides. ACS Appl. Mater. Interaces. 2014;6:18369–18379. doi: 10.1021/am5043017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dickey M.D. Stretchable and soft electronics using liquid metals. Adv. Mater. 2017;29 doi: 10.1002/adma.201606425. 1606425. [DOI] [PubMed] [Google Scholar]

- Gao H.L., Xu L., Long F., Pan Z., Du Y.X., Lu Y., Ge J., Yu S.H. Macroscopic free-standing hierarchical 3D architectures assembled from silver nanowires by ice templating. Angew. Chem. Int. Ed. 2014;53:4561–4566. doi: 10.1002/anie.201400457. [DOI] [PubMed] [Google Scholar]

- Jeong J.W., McCall J.G., Shin G., Zhang Y., Al-Hasani R., Kim M., Li S., Sim J.Y., Jang K.I., Shi Y. Wireless optofluidic systems for programmable in vivo pharmacology and optogenetics. Cell. 2015;162:662–674. doi: 10.1016/j.cell.2015.06.058. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jeong S.H., Hjort K., Wu Z. Tape transfer atomization patterning of liquid alloys for microfluidic stretchable wireless power transfer. Sci. Rep. 2015;5:8419. doi: 10.1038/srep08419. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kang S., Murphy R.K.J., Hwang S., Lee S.M., Harburg D.V., Krueger N.A., Shin J., Gamble P., Cheng H., Yu S. Bioresorbable silicon electronic sensors for the brain. Nature. 2016;530:71–76. doi: 10.1038/nature16492. [DOI] [PubMed] [Google Scholar]

- Kazem N., Hellebrekers T., Majidi C. Soft multifunctional composites and emulsions with liquid metals. Adv. Mater. 2017;29:1–14. doi: 10.1002/adma.201605985. [DOI] [PubMed] [Google Scholar]

- Kim D.H., Song J., Choi W.M., Kim H.S., Kim R.H., Liu Z., Huang Y.Y., Hwang K.C., Zhang Y., Rogers J.A. Materials and noncoplanar mesh designs for integrated circuits with linear elastic responses to extreme mechanical deformations. Proc. Natl. Acad. Sci. USA. 2008;105:18675–18680. doi: 10.1073/pnas.0807476105. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim D.H., Lu N., Ma R., Kim Y.S., Kim R.H., Wang S., Wu J., Won S.M., Tao H., Islam A. Epidermal electronics. Science. 2011;333:838–843. doi: 10.1126/science.1206157. [DOI] [PubMed] [Google Scholar]

- Kim Y., Zhu J., Yeom B., Di Prima M., Su X., Kim J.G., Yoo S.J., Uher C., Kotov N.A. Stretchable nanoparticle conductors with self-organized conductive pathways. Nature. 2013;500:59–63. doi: 10.1038/nature12401. [DOI] [PubMed] [Google Scholar]

- Kubo M., Li X., Kim C., Hashimoto M., Wiley B.J., Ham D., Whitesides G.M. Stretchable microfluidic radiofrequency antennas. Adv. Mater. 2010;22:2749–2752. doi: 10.1002/adma.200904201. [DOI] [PubMed] [Google Scholar]

- Lin Y., Cooper C., Wang M., Adams J.J., Genzer J., Dickey M.D. Handwritten, soft circuit boards and antennas using liquid metal nanoparticles. Small. 2015;11:6397–6403. doi: 10.1002/smll.201502692. [DOI] [PubMed] [Google Scholar]

- Lipomi D.J., Vosgueritchian M., Tee B.C.K., Hellstrom S.L., Lee J.A., Fox C.H., Bao Z. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat. Nanotechnol. 2011;6:788–792. doi: 10.1038/nnano.2011.184. [DOI] [PubMed] [Google Scholar]

- Liu J., Fu T.M., Cheng Z., Hong G., Zhou T., Jin L., Duvvuri M., Jiang Z., Kruskal P., Xie C. Syringe-injectable electronics. Nat. Nanotechnol. 2015;10:629–636. doi: 10.1038/nnano.2015.115. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lou Z., Chen S., Wang L., Shi R., Li L., Jiang K., Chen D., Shen G. Ultrasensitive and ultra flexible E-skins with dual functionalities for wearable electronics. Nano Energy. 2017;38:28–35. [Google Scholar]

- Lu Y., Hu Q., Lin Y., Pacardo D.B., Wang C., Sun W., Ligler F.S., Dickey M.D., Gu Z. Transformable liquid-metal nanomedicine. Nat. Commun. 2015;6:10066. doi: 10.1038/ncomms10066. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Matsuhisa N., Inoue D., Zalar P., Jin H., Matsuba Y., Itoh A., Yokota T., Hashizume D., Someya T. Printable elastic conductors by in situ formation of silver nanoparticles from silver flakes. Nat. Mater. 2017;5:1–8. doi: 10.1038/nmat4904. [DOI] [PubMed] [Google Scholar]

- Mohammed M.G., Kramer R. All-printed flexible and stretchable electronics. Adv. Mater. 2017;29 doi: 10.1002/adma.201604965. 1604965. [DOI] [PubMed] [Google Scholar]

- Oh J.Y., Rondeau-gagné S., Chiu Y., Chortos A., Lissel F., Wang G.N., Schroeder B.C., Kurosawa T., Lopez J., Katsumata T. Intrinsically stretchable and healable semiconducting polymer for organic transistors. Nature. 2016;539:411–415. doi: 10.1038/nature20102. [DOI] [PubMed] [Google Scholar]

- Qi D., Liu Z., Liu Y., Leow W.R., Zhu B., Yang H., Yu J., Wang W., Wang H., Yin S. Suspended wavy graphene microribbons for highly stretchable microsupercapacitors. Adv. Mater. 2015;27:5559–5566. doi: 10.1002/adma.201502549. [DOI] [PubMed] [Google Scholar]

- Ren L., Zhuang J., Casillas G., Feng H., Liu Y., Xu X., Liu Y., Chen J., Du Y., Jiang L. Nanodroplets for stretchable superconducting circuits. Adv. Funct. Mater. 2016;26:8111–8118. [Google Scholar]

- Sekitani T., Nakajima H., Maeda H., Fukushima T., Aida T., Hata K., Someya T. Stretchable active-matrix organic light-emitting diode display using printable elastic conductors. Nat. Mater. 2009;8:494–499. doi: 10.1038/nmat2459. [DOI] [PubMed] [Google Scholar]

- Sun J., Xianyu Y., Jiang X. Point-of-care biochemical assays using gold Nanoparticle-implemented Microfluidics. Chem. Soc. Rev. 2014;43:6239–6253. doi: 10.1039/c4cs00125g. [DOI] [PubMed] [Google Scholar]

- Tang Y., Gong S., Chen Y., Yap L.W., Cheng W. Manufacturable conducting rubber ambers and stretchable conductors from copper nanowire aerogel monoliths. ACS Nano. 2014;8:5707–5714. doi: 10.1021/nn502702a. [DOI] [PubMed] [Google Scholar]

- Wang Q., Yu Y., Yang J., Liu J. Fast fabrication of flexible functional circuits based on liquid metal dual-trans printing. Adv. Mater. 2015;27:7109–7116. doi: 10.1002/adma.201502200. [DOI] [PubMed] [Google Scholar]

- Zheng Y., He Z.Z., Yang J., Liu J. Personal electronics printing via tapping mode composite liquid metal ink delivery and adhesion mechanism. Sci. Rep. 2014;4:4588. doi: 10.1038/srep04588. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhu S., So J.H., Mays R., Desai S., Barnes W.R., Pourdeyhimi B., Dickey M.D. Ultrastretchable fibers with metallic conductivity using a liquid metal alloy core. Adv. Funct. Mater. 2013;23:2308–2314. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

The LED circuits interconnected by MPC can undergo repeated bending, twisting, and stretching.

We attached MPC sensors onto the knuckles of a glove, and the motion of the fingers can be monitored in real time.