Abstract

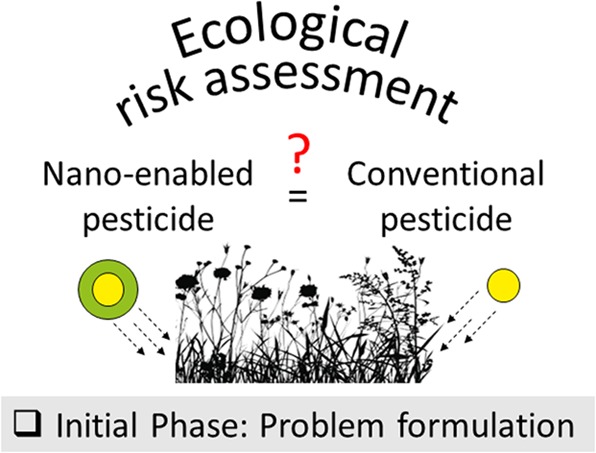

Plant protection products containing nanomaterials that alter the functionality or risk profile of active ingredients (nano-enabled pesticides) promise many benefits over conventional pesticide products. These benefits may include improved formulation characteristics, easier application, better targeting of pest species, increased efficacy, lower application rates, and enhanced environmental safety. After many years of research and development, nano-enabled pesticides are starting to make their way into the market. The introduction of this technology raises a number of issues for regulators, including how does the ecological risk assessment of nano-enabled pesticide products differ from that of conventional plant protection products? In this paper, a group drawn from regulatory agencies, academia, research, and the agrochemicals industry offers a perspective on relevant considerations pertaining to the problem formulation phase of the ecological risk assessment of nano-enabled pesticides.

Keywords: nanopesticides, agrochemicals, nanotechnology, problem formulation, risk assessment

Introduction

Nanotechnology is being harnessed to develop new pharmaceutical drugs (nanomedicines)1 as well as agrochemical products (nanofertilizers and nanopesticides).2−5 These new medicines and agrochemicals exploit the properties of materials with dimensions on the nanoscale (the size range of approximately 1–100 nm), which can display very different or additional physical, chemical, and biological properties compared to the properties of the bulk materials. The application of nanotechnology in agriculture presents significant, new opportunities for developing more effective fertilizers and pesticides that may also have reduced impacts on the environment.

There are a variety of possible ways in which nanotechnology may be used to produce new pesticide products. There are inert ingredients used in conventional formulations of pesticides that exist in a nanoscale form, and these nanoscale inert ingredients have been incorporated into a range of crop protection products. Examples include nanoscale titania as an ultraviolet (UV) blocker and whitener, nanoscale silica or clays as a rheology modifier, and many nanoscale polymers used as surfactants. There are also microemulsion-type solvent-based pesticides on the market that may be considered nano-enabled because many contain oil droplets with significant populations of <100 nm. In most cases, these products have a long history of safe use.

There is growing interest in more deliberate applications of nanotechnology in the development of new plant protection products.6 Dendrimer technology is being applied to a number of active ingredients (a.i.) to develop nano-enabled pesticides with enhanced efficacy, and some products are in an advanced stage of development.7 Some products using nanopolymers as carriers for targeted delivery of pesticides and for application with fertilizers have already been registered for use. These include soil-applied AZteroid fungicide (azoxystrobin), soil-applied Bifender insecticide (bifenthrin), and plant-applied Fenstro insecticide (azoxystrobin + bifenthrin).8 It is expected that an increasing number of nano-enabled pesticide products will be submitted to regulatory agencies for registration over the next 5 years.

For the purposes of this perspective, a nano-enabled pesticide means a product in which a nanomaterial has been used to enhance the functionality and utility and/or alter the risk profile of a conventional a.i.

Risk Assessment Frameworks for Nano-enabled Pesticides

Ecological risk assessment of pesticide a.i. and formulated products is a highly developed process, which forms an integral part of pesticide regulatory frameworks.8−10 The issues associated with assessing the ecological risks of nanomaterials within the conventional risk-assessment paradigm used for chemicals and chemical products have been explored by the Organisation for Economic Co-operation and Development (OECD) Working Party on Manufactured Nanomaterials.11,12 This work concluded that the existing risk-assessment paradigm used for chemicals can be adapted to the risk assessment of nanomaterials.

Problem formulation is a key initial phase in the ecological risk assessment of chemicals. This phase of assessment is intended to define the nature of the problem to be addressed by risk assessment and to develop a plan or strategy by which the risks can be subsequently characterized.13 The consistent and structured application of problem formulation principles to the risk assessment of nano-enabled pesticide products will be essential in formulating sound recommendations to risk managers and decision makers in regulatory agencies. It will also help identify the most relevant assessment information, including hazard and exposure data, and available risk reduction measures at an early stage in the risk assessment process. These are acknowledged to be key factors influencing the conduct of effective risk assessments.14

In this perspective, we describe an approach to problem formulation using a case study involving a hypothetical nano-enabled pesticide product. The approach taken is intended to demonstrate how a practical assessment strategy would be developed using principles adapted from the ecological risk assessment of conventional pesticide products. As part of this strategy, an initial planning phase was conducted, in which representatives from key stakeholders, including regulators, research scientists, and agrochemical scientists, collaborated to identify key issues that should be considered before the problem formulation phase began. The key elements of this stage in the process are presented in the form of the following questions:

What is the agronomic context for the use of the nano-enabled pesticide formulation?

What is the nature and purpose of the nanomaterial in the formulation?

What are the ecological protection priorities that need to be considered in the risk assessment of the nano-enabled pesticide formulation?

Following the collection of relevant information from the stakeholder group, the problem formulation phase was undertaken focusing on another set of key questions:

How does the environmental behavior of the nano-enabled pesticide differ from conventional formulations of the same a.i.?

How does the nanomaterial release the a.i. in the environment?

What information is necessary to characterize the novel properties of the nano-enabled pesticide formulation?

What risk reduction measures can be used to manage any environmental risks that are considered possible from the intended use of the nano-enabled pesticide product?

Pendimethalin in Nano-Sized Hydrogels: A Case Study

Background Information and Agronomic Context

Pendimethalin [CAS Registry Number 40487-42-1; benzeneamine, N-(1-ethylpropyl)-3,4-dimethyl-2,6-dinitro-, or N-(1-ethylpropyl)-2,6-dinitro-3,4-xylidene] is a dinitroaniline herbicide that is absorbed through the roots and shoots. It is used to control annual grasses and broadleaf weeds and is applied as a pre- or post-emergence spray.15 Conventional formulations of pendimethalin include aqueous capsule suspensions, granules, emulsifiable concentrates, and liquid formulations, all of which will include surfactants and other ingredients necessary for proper function of the formulation. Dry (granular) formulations will also typically use an inorganic carrier that is impregnated with the a.i.

Pendimethalin is a lipophilic neutral organic chemical [log octanol/water partition coefficient (Kow) = 5.2] that is slightly soluble in water (0.33 mg/L at 20 °C) and slightly volatile (0.0013 Pa at 25 °C). Henry’s law constant for the chemical (0.087 Pa m3 mol–1) indicates that it is moderately volatile from water and moist soil. The chemical adsorbs strongly to soil [soil organic carbon/water partitioning coefficient (Koc) = 6500–43 863 L/kg], and pendimethalin is generally considered immobile in soil. Pendimethalin is slightly degradable in aerobic soil, and the reported half-life is in the range of 3–4 months.15

Pendimethalin has high acute toxicity to aquatic life, including fish, invertebrates, algae, and aquatic plants. The chemical has moderate to high chronic toxicity to aquatic life and is a bioaccumulation hazard in aquatic organisms based on the measured bioconcentration factor in fish (BCF = 5100). The chemical has low to moderate toxicity to non-target terrestrial organisms.16

Description of the Nano-enabled Pesticide Formulation and Intended Use

A realistic nano-enabled formulation was chosen to allow this “thought experiment” to describe the process of problem formulation. This formulation is a simplified version of the technology developed by Vive Crop Protection. The hypothetical pendimethalin herbicide product considered in this case study is a suspension concentrate (SC) formulation containing 20% by weight of a.i. and 5% by weight of lightly cross-linked polyacrylate polymer particles, which function as a nanoscale carrier for the a.i. Polyacrylates are a broad class of polymers; for this thought experiment, polyacrylates that are water-dispersible hydrogels with both hydrophilic and hydrophobic monomers are considered. Formulations with 20% a.i. and 5% by weight polymer particles have been described previously (U.S. Patent 8,741,808). The specific chemistry of the hydrogel necessary to increase soil mobility does not significantly impact the problem formulation provided in a later section. Therefore, for simplicity in this thought experiment as well as to protect confidential information of Vive Crop Protection, a generic polyacrylate hydrogel was chosen as a model. The average size of the polyacrylate nanocarriers is in the range of 5–20 nm.

The polyacrylate nanocarriers are hydrogels, which are a class of materials that have been investigated for delivery of many different poorly soluble bioactive pharmaceuticals as well as agrochemical molecules.17,18 A hydrogel is able to absorb large amounts of water or other fluids17 and swell (as a result of cross-links formed during synthesis), as opposed to dissolving in an aqueous environment. The purpose of the polyacrylate hydrogel in this SC formulation is to assist with dispersion of the a.i. in aqueous media (such as water in spray tanks) and with a.i. mobility in soil.18

Pendimethalin is loaded into the matrix of the hydrogel nanocarrier to form a composite structure (the complex). This complex is a labile structure and is able to release the a.i. in soil for uptake by plants. The overall properties of the complex are determined by the hydrogel composition, method and degree of cross-linking, a.i. loading, and nature of the environment in which the complex is deployed (dry, liquid, pH, etc.).18,19 The formation of this complex has the net effect that the properties of the external portion of the nanocarrier dominate the interaction with the environment for as long as the a.i. remains within the matrix of the hydrogel particles. For the purposes of this perspective, we are considering a complex where the hydrogel assists pendimethalin to penetrate into soil, thereby increasing the amount of a.i. that reaches sub-surface weeds.

This product will be applied as a pre-emergence herbicide at a maximum application rate of 4 kg of a.i./ha. The product is intended to penetrate through surface residue into the soil without manual incorporation. It requires moderate rainfall or irrigation to be active against target species. In moderate to heavy rains or irrigation, the applied a.i. is expected to penetrate between 2.5 and 10 cm below the soil surface, with <1% of applied a.i. penetrating below 10 cm. This effect has been observed with a modified version of the polyacrylate hydrogels described in this paper (personal communication, Vive Crop Protection, Canada). Formulation benefits are similar to existing techniques for increasing soil penetration, such as soil conditioners or penetration aid surfactants.

For the purposes of this case study, it is assumed that the product will be applied by ground spraying using technology that minimizes off-site movement of the pesticide through spray drift.

Ecological Protection Priorities

The nano-enabled pendimethalin SC product considered here is intended to be applied to a wide variety of agricultural crops for the control of annual grasses and weeds by ground spray application at a rate of nearly 4 kg of a.i./ha. Similar to conventional pendimethalin herbicide products, there is a potential risk to aquatic environments from the off-site movement of the a.i. in the nano-enabled pesticide product because pendimethalin is highly toxic to aquatic life and bioconcentrates in fish. The ecological risk assessment of the nano-enabled product will, therefore, need to establish that the proposed use pattern and application rate will not result in levels of pendimethalin in aquatic ecosystems in excess of the locally applicable water quality guideline values for this a.i.

Problem Formulation

Pendimethalin is highly toxic to aquatic organisms and is also a bioaccumulation hazard in aquatic ecosystems. The off-site movement of this a.i. from its application as a pre-emergence herbicide, which results in contamination of aquatic ecosystems, may cause adverse effects on the natural environment. The ecological risk assessment of the intended uses of the nano-enabled pendimethalin SC product will, therefore, need to establish whether aquatic ecosystems will be adversely impacted by the a.i. or any of the excipients in the product, including the polyacrylate nanocarrier.

Comparative Evaluation of the Nano-enabled Pendimethalin Formulation and Conventional Formulations

One key difference between traditional surfactants (used in conventional formulations) and the use of nanoscale hydrogel carriers is the durability of the complex in diverse environments. Surfactant systems are sensitive to exposure conditions, such as surface interactions, pH, and concentration, which may mean that the a.i.–surfactant complex is only stable over a relatively narrow range of operating conditions. The inclusion of cross-links in a hydrogel enables the nanocarrier complex to maintain its tertiary structure and retain its integrity under a wider range of conditions.20

Similar to previous studies,21 the nanocarrier complex envisioned here would facilitate the dispersion of this poorly water-soluble herbicide in water without the use of organic solvents and would also reduce the volatilization of the a.i. after application. These two formulation characteristics have the potential to increase the amount of a.i. available for weed control and reduce the amount of a.i. lost off-site through atmospheric transport processes. The complex would also enable the a.i. to penetrate the subsoil surface without the need for physical incorporation, such as tilling.

The nanocarrier is designed to enhance the soil penetration of pendimethalin. Consequently, the potential key differences between this formulation and a conventional formulation may include penetration of pendimethalin into the subsoil water column, reduced biological and chemical degradation of the a.i., leading to increased persistence, and a reduction in off-site migration of the a.i. through volatilization and other processes, such as surface runoff.

Fate of the Nano-enabled Pesticide Formulation in Soil

The fate and behavior of nano-enabled pesticides in the environment are likely to be dependent upon the functional characteristics of the carrier and the durability of the a.i.–carrier complex. Both characteristics should be considered in problem formulation of nano-enabled pesticides because the spatial and temporal nature of exposure to non-target organisms could change significantly when compared to conventional pesticide formulations.

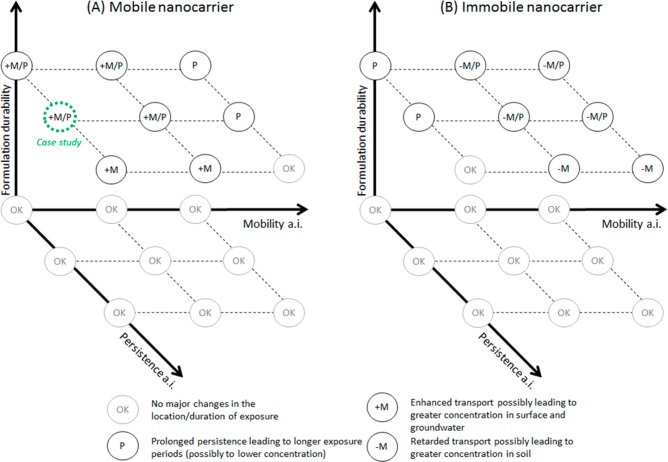

Durability is a measure of how long a pesticide–nanocarrier complex maintains its integrity after application in the field.22 The durability of pesticide–nanocarrier complexes can be categorized into three broad classes, as shown in Figure 1.

Figure 1.

Durability of nano-enabled pesticide with a core–shell structure. When a nano-enabled pesticide comprised of a carrier/encapsulation material (represented in green) and an a.i. (represented in yellow) is applied in the field, environmental durability can vary widely. This variation is depicted for rapid release, slow release, and no release of the a.i. from the complex. A, scenario when the a.i. is released rapidly (e.g., within hours after application); B, slower release (over several days) of a.i.; and C, a.i. is not released (e.g., over several weeks) from the nanocarrier.

Durability is likely to be dependent upon the exposure conditions. For example, a nano-enabled pesticide may release the a.i. at different rates in soil depending upon factors such as soil moisture or soil pH. These will be important considerations for the risk assessment.

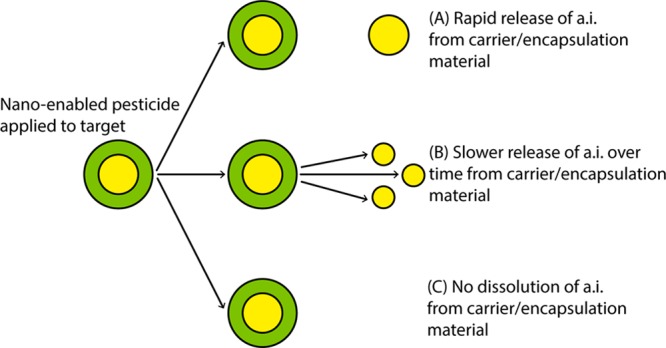

A conceptual model that can help identify the altered scenario of the pesticide fate (mobility and persistence) relative to the pure a.i., depending upon the properties of the nanocarrier and pesticide a.i. in the new formulation, has been presented in Figure 2. The figure provides an overview of the different combinations of nanocarrier and a.i. properties that are most relevant for environmental exposure assessment of the a.i. (here, it is assumed that the exhausted nanocarrier is of low hazard, an assumption that may need to be verified in some cases).

Figure 2.

Possible association between nanocarriers [either (A) mobile or (B) immobile in the environment] and pesticide a.i. (exhibiting various degrees of mobility and persistence in the environment). The durability of the complex is key to determining the extent to which the exposure profile is modified.

The most sensitive fate descriptors are expected to be (i) the mobility of the nanocarrier (panels A and B of Figure 2), (ii) the mobility and persistence of the a.i. (x and z axes in Figure 2), and (iii) the rate at which the a.i. is released from the nanocarrier (y axis in Figure 2).4,23 Distinguishing different combinations of nanocarrier and a.i. properties allows for situations to be identified where the impact on the fate is likely to be minimal (“OK” flag in Figure 2) and where particular attention to changes in the mobility (“M” flag in Figure 2) and/or persistence (“P” flag in Figure 2) of the a.i. is required.

In cases where the release rate of the a.i. from the carrier is very fast compared to the time scale of the environmental processes of interest (e.g., complete release occurs upon dilution in the mixing tank or upon application in the field), no changes in the behavior of the nano-enabled a.i. formulation are to be expected in comparison to that of the pure a.i. Therefore, an exposure assessment solely based on data derived with the pure a.i. should be adequate (indicated with the “OK” flag in Figure 2).

Conversely, when the nanocarriers and a.i. remain associated for a significant time, effects of the formulation on the fate of the a.i. are to be expected in almost all cases. For instance, for an a.i. that is not excessively persistent, association with a nanocarrier may increase the persistence of the a.i. (“P” flag in Figure 2) because the availability of the a.i. for degradation processes is likely to be reduced until it is released from the nanocarrier. The impact of the formulation on the transport of an a.i. in this case depends upon the mobility of the nanocarriers relative to that of the a.i. Mobile carriers are likely to increase the mobility of a relatively immobile a.i. (“+M” flag in Figure 2A), while relatively immobile nanocarriers will decrease the mobility of a relatively mobile a.i. (“–M” flag in Figure 2B), which could lead to greater exposure concentrations in the surface soil compartment for longer periods.

In the case study being considered here, the hydrogel is a mobile nanocarrier (personal communication, Vive Crop Protection). Therefore, Figure 2A will be the relevant scheme for this formulation. The formulation is designed such that the a.i. remains encapsulated in the mobile nanocarrier long enough to facilitate its entry into soil. The formulation is, therefore, considered to be at least moderately durable, and the upper plane in Figure 2 is relevant. Pendimethalin is inherently a relatively immobile and moderately persistent herbicide, as discussed above. Hence, the ultimate locus for the product will be at the low mobility end of the x axis and at the moderate persistence location on the z axis, as shown in Figure 2A. Hence, according to this conceptual scheme, +M/P is the most relevant flag, suggesting possible increased mobility and persistence of nano-enabled pendimethalin relative to the pure a.i.

However, as stated above, pendimethalin has a half-life in aerobic soil in the range of 3–4 months. The durability of the a.i.–nanocarrier complex is assumed to be on the time scale of days in this case, and the apparent increase in persistence of pendimethalin is, therefore, not expected to be consequential. In other cases, where the durability of the a.i.–nanocarrier complex is comparable or greater than the persistence of the a.i., the overall persistence of an a.i. could be significantly enhanced because the nanocarrier facilitates penetration of the a.i. into the deeper subsoil, where lower microbial activity is expected.

Key End Points

An extensive set of aquatic toxicity data is available for pendimethalin that could be used to characterize the ecological risks to aquatic ecosystems, where the magnitude and frequency of exposure to the a.i. can be quantified. Similarly, the environmental fate and behavior of this a.i. in conventional herbicide products are well-studied, and the available data are sufficient to allow models for environmental exposure to be developed. However, the conceptual model for the nano-enabled formulation of pendimethalin has identified some potentially significant modifications in the fate and behavior of the a.i. The significance of these particular properties of the nano-enabled formulation will need to be considered during the risk analysis and risk characterization stage of the assessment.

The two most significant environmental fate characteristics identified for the nano-enabled formulation through the conceptual model are the depth of penetration of the a.i.–nanocarrier complex through the soil column and the rate of release of the a.i. from the carrier. The depth of penetration is expected to be unique to this particular formulation, because it is a functional characteristic that has been engineered by selection of the particular polyacrylate nanoparticles used as a carrier. Because the behavior of the a.i.–polyacrylate complex is dominated by the properties of the nanocarrier, it may be possible to use surrogate information on the general soil penetration behavior of polyacrylate nanoparticles with similar size distributions, chemical structure, and surface characteristics. However, where no reference data are available or where the properties of the complex differ substantially from the nanocarrier alone, a specific evaluation of the soil penetration depth for the complex may be required.

The rate of release of the a.i. from the complex has also been identified as a key environmental fate characteristic of the formulation and needs to be considered during the risk analysis phase. If the rate of release of the a.i. from the carrier is slow compared to major transport processes, such as leaching or transport in surface water runoff, then the aquatic environment may be exposed to pendimethalin in ways that are not well represented by available ecotoxicity data. In an exposure scenario involving the release of a mobile and moderately durable a.i.–carrier complex into aquatic ecosystems, aquatic life may be exposed to the a.i. for a longer period at lower concentrations, resulting from the slow release of the a.i. from the carrier. Conversely, if the rate of release of the a.i. from the complex is fast compared to these transport processes, the environmental fate and effects of the a.i. may be indistinguishable from conventional formulations. It is for this reason that an early and reliable measure of the durability of the nanocarrier complex under environmentally relevant conditions would be considered a priority.

Risk Reduction and Risk Management Options

The focus of the risk assessment can be shaped by considering the available risk reduction measures and their effectiveness in the problem formulation stage of the assessment.12 For the purposes of this assessment, it is assumed that good agricultural practices will limit off-site movement of the pesticide following application. In addition, because the nano-enabled product will only be applied by ground spraying using spray-drift reduction technology, there is a reduced potential for direct exposure of the aquatic environment to the a.i.–nanocarrier complex. This reduces both the need to consider the risks posed to the aquatic environment through slow release of the a.i. from the nanocarrier over an extended time frame and the likelihood that additional aquatic ecotoxicity data will be required to determine the specific toxicity of the a.i.–nanocarrier complex. Conversely, if the typical application pattern were to be broadened to include aerial application of the nano-enabled formulation, then the scope of the assessment would need to include factors such as the spray-drift distances of the nano-enabled formulation and the effectiveness of no-spray buffer zones to mitigate impacts on aquatic ecosystems.

Analysis Plan

The hypothetical nano-enabled pendimethalin SC product considered in this case study does potentially pose risks to the aquatic environment where off-site movement of the a.i. and/or the a.i.–nanocarrier complex occurs. A conceptual model for the fate and behavior of the a.i.–nanocarrier complex in soil has identified some potential for the a.i. to have increased persistence in soil relative to conventional formulations of pendimethalin. The model also shows a potential for increased depth of penetration of the a.i. through the soil horizon because of transport of the more mobile polyacrylate nanoparticle carriers. There is, therefore, an increased potential for pendimethalin to reach groundwater compared to conventional formulations.

A key priority for the risk analysis phase of the assessment is to establish the durability of the a.i.–nanocarrier complex in soil. An understanding of this characteristic will allow for further decisions to be made regarding both exposure assessment and hazard evaluation. The initial analysis of the ecological risks of the product will, therefore, focus on evaluating any available data on the durability of the a.i.–nanocarrier complex in soil. Where such data are lacking and no useful reference data can be identified, it may be necessary to recommend targeted evaluation of the durability of the complex in soil. Once this key property has been evaluated, the problem formulation may need to be revised. For example, if the complex is determined to be not durable on the time scale of applicable off-site transport processes, then the risk analysis may be abbreviated because the risks of the nano-enabled product would not be considered significantly different from conventional formulations of pendimethalin. Conversely, if this initial evaluation demonstrates that the a.i.–nanocarrier complex is moderately durable in soil and the complex is significantly mobile in soil and water, then the risk analysis phase may need to consider the need for specific environmental fate and effects data on the nano-enabled formulation.

Problem Formulation Is an Iterative Process

Problem formulation provides an important opportunity to properly define the scope of a risk assessment and to integrate the needs of the risk managers and decision makers, who ultimately decide how and when chemicals or chemical products can be safely introduced to the marketplace. The approach outlined above is based around a series of general questions that guide the process. The crucial step is to determine what information is necessary to characterize the novel properties of the nano-enabled pesticide formulation. The use of nanomaterials in formulations (such as nanocarriers) can significantly alter the fate of the a.i. in soil, and we describe a simple framework to help risk assessors determine how the formulation is likely to affect mobility and persistence of the a.i. based on the known persistence and mobility of the a.i. and the durability of the nano-enabled pesticide.

The problem formulation is guided by the nature of the product being assessed and associated application scenario. The problem formulation presented here for the nano-enabled pendimethalin SC herbicide product shows only the first iteration of the process. An important feature of the problem formulation phase of risk assessment is iteration.13 For conventional chemicals and chemical products, the iterative cycle may be abbreviated because there is a wealth of relevant experience that can be used when formulating the initial risk assessment hypothesis. The major factors influencing the environmental fate and effects of most major classes of chemicals are well-understood, and the most important factors influencing ecological risks have been established over decades of practice. However, for unconventional chemicals and/or novel exposure scenarios, there is often a need to revise the initial risk assessment hypotheses developed during the problem formulation phase and to revise the risk analysis plan accordingly. This iterative approach is also likely to be important in regulatory assessment of nano-enabled pesticides because there are as of yet few registered nano-enabled agrochemical products.

Acknowledgments

The authors acknowledge Dr. David Brittain (Department of the Environment and Energy, Australia) for assistance with modeling of various scenarios for release of pesticides from nanocarriers and for a critical review of the manuscript. The authors are also thankful to the three anonymous reviewers for their constructive comments on the manuscript.

Glossary

Abbreviations Used

- a.i.

active ingredient

- BCF

bioconcentration factor

- IUPAC

International Union of Pure and Applied Chemistry

- Koc

soil organic carbon/water partitioning coefficient

- Kow

octanol/water partition coefficient

- OECD

Organisation for Economic Co-operation and Development

- UV

ultraviolet

- SC

suspension concentrate

The study was partially supported by the Division of Chemistry and Environment of the International Union of Pure and Applied Chemistry (IUPAC) through a project on nano-enabled pesticides (2016-016-2-600), and the contributions from the project team are gratefully acknowledged. Dr. Melanie Kah was supported by the Austrian Science Fund (FWFV408-N28).

Disclaimer: The views and opinions expressed in this publication are those of the authors and do not necessarily reflect those of the Australian Government or the Minister for the Environment. While reasonable efforts have been made to ensure that the contents of this publication are factually correct, the Commonwealth does not accept responsibility for the accuracy or completeness of the contents and shall not be liable for any loss or damage that may be occasioned directly or indirectly through the use of or reliance on the contents of this publication.

The authors declare no competing financial interest.

References

- McCarthy C. A.; Ahern R. J.; Dontireddy R.; Ryan K. B.; Crean A. M. Mesoporous silica formulation strategies for drug dissolution enhancement: A review. Expert Opin. Drug Delivery 2016, 13, 93–108. 10.1517/17425247.2016.1100165. [DOI] [PubMed] [Google Scholar]

- Liu F.; Wen L. X.; Li Z. Z.; Yu W.; Sun H. Y.; Chen J. F. Porous hollow silica nanoparticles as controlled delivery system for water-soluble pesticide. Mater. Res. Bull. 2006, 41, 2268–2275. 10.1016/j.materresbull.2006.04.014. [DOI] [Google Scholar]

- Gogos A.; Knauer K.; Bucheli T. D. Nanomaterials in plant protection and fertilization: Current state, foreseen applications, and research priorities. J. Agric. Food Chem. 2012, 60, 9781–9792. 10.1021/jf302154y. [DOI] [PubMed] [Google Scholar]

- Kah M.; Hofmann T. Nanopesticide research: Current trends and future priorities. Environ. Int. 2014, 63, 224–235. 10.1016/j.envint.2013.11.015. [DOI] [PubMed] [Google Scholar]

- Mitter N.; Worrall E. A.; Robinson K. E.; Li P.; Jain R. G.; Taochy C.; Fletcher S. J.; Carroll B. J.; Lu G. Q.; Xu Z. P. Clay nanosheets for topical delivery of RNAi for sustained protection against plant viruses. Nat. Plants 2017, 3, 16207. 10.1038/nplants.2016.207. [DOI] [PubMed] [Google Scholar]

- Australian Pesticides and Veterinary Medicines Authority (APVMA). Nanotechnologies for Pesticides and Veterinary Medicines: Regulatory Considerations. Final Report; APVMA: Canberra, Australian Capital Territory, Australia, 2015; https://apvma.gov.au/sites/default/files/publication/15626-nanotechnologies-pesticides-veterinary-medicines_regulatory-considerations_july2015.pdf (accessed March 29, 2017). [Google Scholar]

- Starpharma Holdings Limited. Corporate Overview; Starpharma Holdings Limited: Melbourne, Victoria, Australia, Feb 2014; http://www.asx.com.au/spotlight/newyork/2014/documents/presentations/140226___SPL_Corp_Presentation_NYC_pg1-33.pdf (accessed April 20, 2017).

- Vive Crop Protection. Products; Vive Crop Protection: Toronto, Ontario, Canada, 2017; http://vivecrop.com/products/ (accessed May 12, 2017).

- United States Environmental Protection Agency (U.S. EPA). Ecological Risk Assessment for Pesticides: Technical Overview; U.S. EPA: Washington, D.C., 2017; https://www.epa.gov/pesticide-science-and-assessing-pesticide-risks/ecological-risk-assessment-pesticides-technical (accessed May 8, 2017).

- European Food Safety Authority (EFSA). Pesticides; EFSA: Parma, Italy, 2017; https://www.efsa.europa.eu/en/topics/topic/pesticides (accessed May 8, 2017).

- Organisation for Economic Co-operation and Development (OECD). Report of the Workshop on Risk Assessment of Manufactured Nanomaterials in a Regulatory Context; OECD: Paris, France, 2010; Series on the Safety of Manufactured Nanomaterials 21, http://www.oecd.org/science/nanosafety/publications-series-safety-manufactured-nanomaterials.htm (accessed April 18, 2017).

- Organisation for Economic Co-operation and Development (OECD). Important Issues on Risk Assessment of Manufactured Nanomaterials; OECD: Paris, France, 2012; Series on the Safety of Manufactured Nanomaterials 33, http://www.oecd.org/science/nanosafety/publications-series-safety-manufactured-nanomaterials.htm (accessed March 29, 2017).

- United States Environmental Protection Agency (U.S. EPA). Guidelines for Ecological Risk Assessment; U.S. EPA: Washington, D.C., 1998; EPA/630/R-95/002F, https://www.epa.gov/sites/production/files/2014-11/documents/eco_risk_assessment1998.pdf. (accessed April 18, 2017).

- National Research Council (NRC). Science and Decisions: Advancing Risk Assessment; National Academies Press: Washington, D.C., 2009; DOI: 10.17226/12209. [DOI] [PubMed]

- Division of Specialized Information Services (SIS), U.S. National Library of Medicine (NLM). Hazardous Substances Data Bank (HSDB). Toxicology Data Network: Pendimethalin; SIS, NLM: Bethesda, MD, 2011; https://toxnet.nlm.nih.gov/cgi-bin/sis/search/a?dbs+hsdb:@term+@DOCNO+6721 (accessed May 8, 2017).

- University of Hertfordshire. Pesticide Properties DataBase (PPDB): Pendimethalin; University of Hertfordshire: Hertfordshire, U.K., 2007; http://sitem.herts.ac.uk/aeru/ppdb/en/Reports/511.htm (accessed March 13, 2017).

- Hamidi M.; Azadi A.; Rafiei P. Hydrogel nanoparticles in drug delivery. Adv. Drug Delivery Rev. 2008, 60, 1638–1649. 10.1016/j.addr.2008.08.002. [DOI] [PubMed] [Google Scholar]

- Guilherme M. R.; Aouada F. A.; Fajardo A. R.; Martins A. F.; Paulino A. T.; Davi M. F. T.; Rubira A. F.; Muniz E. C. Suprasorbent hydrogels based on polysaccharides for application in agriculture as soil conditioner and nutrient carrier: A review. Eur. Polym. J. 2015, 72, 365–385. 10.1016/j.eurpolymj.2015.04.017. [DOI] [Google Scholar]

- Campos E. V. R.; de Oliveira J. L.; Fraceto L. F.; Singh B. Polysaccharides as safer release systems for agrochemicals. Agron. Sustainable Dev. 2015, 35, 47–66. 10.1007/s13593-014-0263-0. [DOI] [Google Scholar]

- Neu M.; Sitterberg J.; Bakowsky U.; Kissel T. Stabilized nanocarriers for plasmids based upon cross-linked poly(ethylene imine). Biomacromolecules 2006, 7, 3428–3438. 10.1021/bm060788z. [DOI] [PubMed] [Google Scholar]

- Yang F. L.; Li X. G.; Zhu F.; Lei C. L. Structural characterization of nanoparticles loaded with garlic essential oil and their insecticidal activity against Tribolium castaneum (Herbst) (Coleoptera: Tenebrionidae). J. Agric. Food Chem. 2009, 57, 10156–10162. 10.1021/jf9023118. [DOI] [PubMed] [Google Scholar]

- Kookana R. S.; Boxall A. B. A.; Reeves P. T.; Ashauer R.; Beulke S.; Chaudhry Q.; Cornelis G.; Fernandes T. F.; Gan J.; Kah M.; Lynch I.; Ranville J.; Sinclair C.; Spurgeon D.; Tiede K.; Van den Brink P. J. Nanopesticides: Guiding principles for regulatory evaluation of environmental risks. J. Agric. Food Chem. 2014, 62, 4227–4240. 10.1021/jf500232f. [DOI] [PubMed] [Google Scholar]

- Kah M.; Beulke S.; Tiede K.; Hofmann T. Nanopesticides: State of knowledge, environmental fate, and exposure modeling. Crit. Rev. Environ. Sci. Technol. 2013, 43, 1823–1867. 10.1080/10643389.2012.671750. [DOI] [Google Scholar]