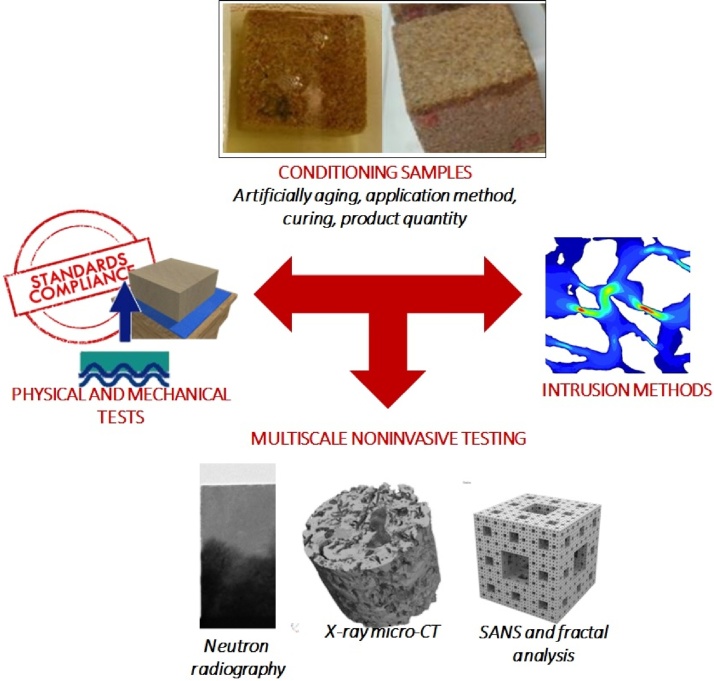

Graphical abstract

Method name: Advanced and multi-scale laboratory investigation

Keywords: Natural stones, Conservative treatments, Consolidants, Efficacy

Abstract

The evaluation of conservative treatments’ efficacy on natural building stones are usually based on standard recommendation routines finalized to evaluate compatibility and harmfulness of products in turn of the substrate. However, the visualization and the quantification of products inside pore structure of natural stones is not immediate through standard tests, so that imaging and advanced techniques are recently proposed in material conservation field to improve knowledge on penetration depth, modification of pore-air interface at different scale and monitor dynamic absorption processes. Moreover, natural stones are usually characterized by complex structure, which changes due to conservative treatments have to be inspected at different scale (from micrometer to nanometer).

In this prospective, the assessment of laboratory practices able to integrate multiscale methods and give back a complete overview on interaction between new conservative formulates and natural stones is of high interest.

In this paper, we propose a methodological routine for efficacy assessment of conservative products, incorporating classical and innovative nondestructive techniques. Validation of the workflow has been verified on a high porous natural stone treated with new hybrid formulates appropriately customized for conservation issues.

-

•

The study intends to add new insights on problems related to consolidation of high porous carbonate stone, application methods in consolidating natural stones and methods to evaluate efficacy of new products.

-

•

A multi-scale laboratory investigation procedure is proposed by integrating standard and innovative nondestructive methods. Merits and limits of each applied method are discussed during validation.

-

•

The possibility to incorporate standard routines and/or substitute destructive testing with non-destructive ones seem to be a valid alternative to evaluate efficiency and monitor behavior of stones treated with consolidating products.

Specifications Table

| Subject area |

|

| More specific subject area |

|

| Method name | Advanced and multi-scale laboratory investigation |

Method details

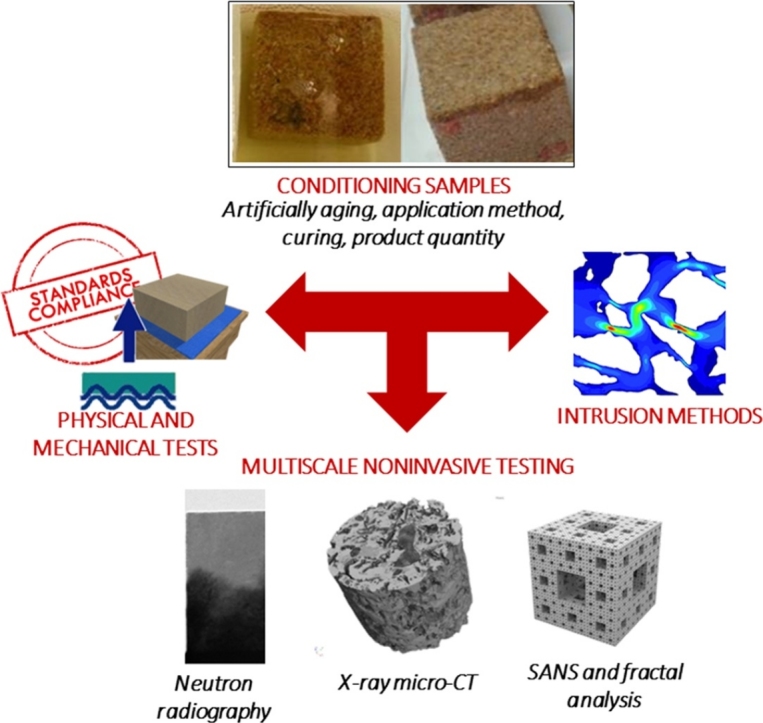

A multi-scale laboratory investigation procedure finalized to inspect consolidants’ efficacy is proposed; it is based on the integration of innovative nondestructive methods to standard well known laboratory tests.

The routine includes two operative steps, namely the application of (a) standard recommendation procedures and (b) the noninvasive advanced testing by X-ray and neutron sources (Fig. 1). All tests have to be performed on laboratory samples which dimension and shape is determined in accordance with standard guidelines, when applicable.

Fig. 1.

Graphical summary of the methodological workflow proposed by this study.

Conditioning laboratory samples

Artificially aged vs Unweathered fresh laboratory samples

As a function of general proprieties of the natural stone to test, preliminary aging procedure aimed to mime the natural weathering state can be performed before the treatment [1]. The selection of aging method can be critical and has to be selected in function of substrate properties and usual decay phenomena. Generally, salt crystallization is the most used one to mime the real weathering conditions; however, limitation and possible by-products due to the test have to be evaluated, as well the kind of single salt and/or salt mixes to use [2].

Treatment method

In order to possible evaluate merits of techniques and efficacy of products in function of treatment method (i.e.: immersion, brushing, poultice) [3], laboratory samples can be treated by following one on more application procedures.

Curing

After treatment with the new product to test, laboratory samples have to be dried at 60 °C until constant mass, according to UNI 10921 [4]. Appropriate curing of laboratory samples has to be assured, in function of employed formulate (usually, almost one month at room temperature and humidity).

Quantity of product

Calculate the quantity of product absorbed by laboratory samples as weight percent gain (WPG%): WPG% = 100 [(Mt – M0)/M0), with M0, the mass of dry sample before the product application, and Mt, the mass of dry sample after product application.

Standard recommendation

Perform physical and mechanical standard tests (UNI EN 15886 [5], UNI EN 15801 [6], NORMAL 7/81 [7], NORMAL 29/88 [8], artificial weathering tests [9,10] DRMS [11]) to evaluate water absorption and desorption at environmental pressure, color difference, resistance to artificial weathering, and microdrilling resistance on reference untreated and treated laboratory samples. Perform mercury intrusion porosimetry (MIP) measurements on volumes of ∼1 cm3 sampled at the surface of treated samples where coated is created. Collect intrusion curves and compare results with untreated reference samples. Perform at least three measurements for each case, to verify repeatability of data. Compare modal pore values and average cumulative volumes before and after the treatment to evaluate where product is located. Limits in inspected range is related to instrumental characteristics; usually, MIP allows to inspect pores in the range 10 nm 0.1/1 mm [12].

Noninvasive advanced testing

X-ray imaging

Before applying this method verify that products have a different attenuation coefficient with respect to stone [13]; otherwise, use a tracer to dope the product and assure its visualization. In some studies, 3-bromopropyltrimethoxysilane has been successfully employed to better visualize products into the porous structure of the stone [[14], [15], [16]], in the case of both water repellents and silane-based consolidants; however, some metals (such as Ag) can be also used as tracer, exhibiting no interaction with the properties of the tested products [17].

Use X-ray μ-CT [18] to investigate the internal structure of untreated and treated laboratory samples and characterize their 3D pore structure. To set the better measurement conditions evaluate the spatial resolution required to quantify the processes to observe. Remember that critical points are the object source distance and the sample size [19]; for the latter one, keep in mind that voxel size (and thus your resolution in term of smallest features detectable and quantifiable) is a function of sample size.

Images of products inside the pore structure of investigated material can be obtained by collecting scans before and after the treatments on cylinder (which diameter has been determined in function of textural features of studied stone).

The quantification of pore structure before and after the treatment can be therefore obtained by subtracting images before treatment from images after treatment, after registration of both volumes; in this way changes in the pore structure due to consolidant penetration can be inspected. In order to work with differential images it is crucial to acquire the data by using the same parameters before and after the application.

The reconstruction of pore structure can be easily achieved by using different dedicated software [19] allowing to visualize and quantify scanned objects.

Neutron imaging

Use neutron radiography [20] to visualize the distribution of organic products inside the pore structure and monitor movement of water under dynamic conditions in untreated and treated laboratory samples.

As it is well known, by using neutrons the good contrast between water (and water containing products, such as organic protectives and consolidants) and stone allows the visualization of products containing hydrogen as well as water into the samples. In the case of dynamic measurements, consider the possibility to use heavy water [21]. The use of neutrons as investigation probe allows to avoid the doping of the products.

Collect neutron radiographs by using cold neutron source [21].

SDD (sample-detector distance) and SSD (sample-source distance) can be selected in function of experimental set up and resolution required [20].

Collect images in dry condition to visualize the distribution of product inside the natural stone; remember that neutrons are sensitive to polymer/organic –based products containing hydrogen.

For the further corrections and quantitative evaluation, collect dark field and open beam images.

Acquire scans at regular time interval during capillary absorption to monitor water behavior of consolidated stones; manual or automatic filling of water container can be used in function of experimental set up. It is advisable to collect preliminary scans on test samples, to evaluate the speed of the observed process and asses the best time intervals to apply.

Ideally, capillary tests might be performed until saturation; however, carefully consider the possible evaporation processes occurring during the experiments, especially if they are carried out in environmental conditions (T °C. RH%). After these preliminary evaluations, select fixed time intervals and a maximum monitoring time for all the stone substrates and all the studied products allowing the successive comparison evaluation.

A quantification of water content can be obtained by performing calibration measurements at the beginning of your experiments [22].

Process images firstly by correcting and normalizing by dark field and open beam images. Quantify water content distribution according to Kim et al. [23] and determine sorptivity parameter (B) [24] from the radiographs.

Small angle neutron scattering

Use sections of untreated and treated samples (also by using different treatment methods) which thickness avoids multiple scattering effects (usually, < 1 mm). Select Q ranges as a function of experimental set up and resolution required in term of scale range to investigate.

The method allows to obtain information about the size, the number density and the correlation between components of a sample, especially looking at pore-air interfaces. In this prospective, the existence of different arrangements inside the porous structure of the solid matrix can be demonstrated, evaluating how the occurrence of products modify the pore-air interface of the pore system in the studied substrate. The measured parameter (i.e. Q(I)) has in fact relation with the formalism associating roughness and fractal dimension of a surface. In this prospective, by using the following correlation the roughness of the pores surface in terms of surface fractal dimension Ds [25] can be determined and obtained values on different treated samples can be compared to evaluate efficacy in penetration of products as well as the assessment of homogenous product layers onto pore surfaces. To obtain numerical parameters, correct two-dimensional intensity distributions for the background and normalize by measuring the incident beam intensity, transmission, and sample thickness from the I(Q) distributions. Then, determine fractal dimension for each analysed specimen

Incorporation of the results

Changes in pore structure: μ-CT vs MIP vs water absorption vs SANS

Evaluate differences in term of porosity and pore radius determined by MIP, μ-CT and water absorption. Compare results taking in consideration discrepancies among the methods [12].

Integrate MIP, μ-CT and SANS data to evaluate pore structure characteristics (before and after conservative treatments) in the range from nanometer to millimeter.

Water behavior: Absorption tests vs neutron imaging

Quantify water absorption changes by gravimetric tests; evaluate sorpivity and quantify water content at subsequent time step from neutron images. Compare results and describe water behavior, and possible preferential pathway in water absorption due to distribution of consolidant in pore network.

Penetration depth: DRMS vs neutron imaging vs μ-CTvs SANS

Compare obtained results obtained by drilling resistance measurement system with images collected in dry condition by neutron source; take advantage from visualization of product distribution to explain possible discrepancies in indirect DRMS values. Use μ-CT 3D reconstructions to visualize in 3D the product distribution, improving information obtained by DRMS and neutron imaging.

Finally, evaluate the small scale structural changes and penetration in nano-sized pores on the basis of fractal dimension determined by Q(I) scattering data. Remember that ideally the presence of products at pore-air interface should determine a smoothing of pore surface, with a consequential change in fractal dimension calculated respect to untreated samples.

Method validation

In order to validate the proposed routine, we present an example applied on high porous limestone. The complete characterization of the stone, the description of tested products as well the evaluation of their suitability and compatibility with substrate is out of the scope of the present paper; details about stone, consolidants and efficacy of products are reported in [17]. Briefly, the stone used for consolidating test exhibits a porosity of about ∼27%, with a total pore volume of 0.14 cm3 g−1 and a modal pore radius of about 8.5 μm. Compositionally, it is constitutes mainly by calcite, with low amount of dolomite; the stone suffers mainly of granular disintegration, for which it requires consolidation actions. The used products consist in new hybrids formulations customized for cultural heritage conservation; they include a patented consolidant modified by amine to promote interaction with limestone and inorganic commercial products which shrinkage process was improved by the addition of organic chains.

In the case study, water absorption, mercury intrusion porosimetry, and μCT methods offered together an overview on the changes in pore structure of the studied stone in the range 0.007–200 μm after the application of consolidating products. They provided consistent results, even if some discrepancies due to the intrinsic differences among the applied methods were highlighted.

Neutron imaging was demonstrated as a powerful technique for investigating the presence and the distribution of products into the stone, even if possible limits due to the low interaction between neutron beam and polymeric consolidants were evidenced; the obtained data were indirectly confirmed by microdrilling, indicating a very sharp increase over the first millimeters underneath the surface. As regards water behavior, neutron imaging provided also measurements of the water absorption dynamic, quite in accordance with gravimetric tests; advantages were represented by the possibility to visualize the water distribution inside the stone, highlighting possible preferential uptake paths due to presence/absence of products. SANS data provided information on product penetration in nano-pores. The technique was also useful to evidence surface roughness changes related to treatment method; in the case study, relevant changes were observed for products applied by immersion, suggesting that this method is preferable because it ensures higher bonding of the product to the pore surface and the complete penetration of consolidants into nano-sized pores.

Overall, stone-product interaction was investigated from micrometric to nanometric scale (by integrating μ-CT - MIP - water absorption - SANS), bonding ability was verified and evaluated (by integrating DRMS vs neutron imaging vs μ-CT vs SANS), water behavior was quantified and visualized (by integrating absorption tests vs neutron imaging), and preferable application methods was assessed (by SANS).

Conclusions

In this work, a laboratory multiscale methodology for assessing consolidant’s efficacy on natural stones has been presented and described. The routine is highly customizable; in fact, set up of standard and non-destructive testing can be established case by case taking in consideration substrate features, products characteristics and potential of different methods to inspect the whole range of textural and porosimetric properties. The methodology has been demonstrated to be suitable in better understanding interactions between consolidating products and natural stones, supplying quantitative data about pore ranges in which consolidants interact with stone, and adequately supporting the interpretation of material behavior especially against water.

The methodological routine can be easily incorporated into studies about conservative treatments, claiming the advantages in integrating or even substituting nondestructive testing to classical methods.

Acknowledgments

This research has been supported by: University funds bestowed by Dept. of Biological, Geological and Environmental Sciences of the University of Catania, University funds bestowed by Dept. of Chemistry of the University of Parma, and Financing Fund of basic research activities (FFABR) of MIUR.

Contributor Information

S. Raneri, Email: simona.raneri@unipi.it.

G. Barone, Email: gbarone@unict.it.

P. Mazzoleni, Email: pmazzol@unict.it.

I. Alfieri, Email: ilaria.alfieri@unipr.it.

L. Bergamonti, Email: laura.bergamonti@unipr.it.

T. De Kock, Email: Tim.DeKock@UGent.be.

V. Cnudde, Email: Veerle.Cnudde@UGent.be.

P.P. Lottici, Email: pierpaolo.lottici@unipr.it.

A. Lorenzi, Email: andrea.lorenzi@unipr.it.

G. Predieri, Email: predieri@unipr.it.

E. Rabot, Email: eva.rabot@gmail.com.

J. Teixeira, Email: jose.teixeira@cea.fr.

References

- 1.Ban M., Baragona A., Ghaffari E., Weber J., Rohatsch A. Artificial aging techniques on various lithotypes for testing of stone consolidants. In: Hughes J., Howind T., editors. Sci. Art A Futur. Stone. Proc. 13th Int. Congr. Deterior. Conserv. Stone. University of the West of Scotland; Paisley: 2016. pp. 253–260. [Google Scholar]

- 2.Lubelli B., Cnudde V., Diaz-Goncalves T., Franzoni E., van Hees R.P.J., Ioannou I., Menendez B., Nunes C., Siedel H., Stefanidou M., Verges-Belmin V., Viles H. Towards a more effective and reliable salt crystallization test for porous building materials: state of the art. Mater. Struct. 2018;51:55. [Google Scholar]

- 3.Franzoni E., Graziani G., Sassoni E., Bacilieri G., Griffa M., Lura P. Solvent-based ethyl silicate for stone consolidation: influence of the application technique on penetration depth, efficacy and pore occlusion. Mater. Struct. 2015;48:3503–3515. [Google Scholar]

- 4.UNI 10921 . 2001. Cultural Heritage – Natural and Artificial Stones – Water Repellents – Application on Samples and Determination of their Properties in Laboratory. [Google Scholar]

- 5.UNI EN 15886 . 2010. Conservation of Cultural Property – Test Methods – Colour Measurement of Surfaces. [Google Scholar]

- 6.UNI EN 15801 . 2010. Determination of Water Absorption by Capillarity Immersion. [Google Scholar]

- 7.NORMAL 7/81 Natural Stones Test Methods: Determination of Water Absorption by Total Immersion, CNR - ICR, 1981.

- 8.NORMAL 29/88 Determination of Drying Index, CNR - ICR, 1988.

- 9.Franzoni E., Sassoni E., Scherer G.W., Naidu S. Artificial weathering of stone by heating. J. Cult. Herit. 2013;14:e85–e93. [Google Scholar]

- 10.UNI EN 12370 . 2001. Natural Stones Test Methods: Determination of Resistance to Salt Crystallization. [Google Scholar]

- 11.Rodrigues J.D., Pinto A.F., da Costa D.R. Tracing of decay profiles and evaluation of stone treatments by means of microdrilling techniques. J. Cult. Herit. 2002;3:117–125. [Google Scholar]

- 12.Cnudde V., Cwirzen A., Masschaele B., Jacobs P.J.S. Porosity and microstructure characterization of building stones and concretes. Eng. Geol. 2008;103:76–83. https://research.aalto.fi/en/publications/porosity-and-microstructure-characterization-of-building-stones-and-concretes(26bcc18e-bf24-4baf-8a5a-c4ae9ac863d9)/export.html (Accessed 16 September 2017) [Google Scholar]

- 13.Bultreys T., Boone M.A., Boone M.N., De Schryver T., Masschaele B., Van Hoorebeke L., Cnudde V. Fast laboratory-based micro-computed tomography for pore-scale research: illustrative experiments and perspectives on the future. Adv. Water Resour. 2016;95:341–351. [Google Scholar]

- 14.Cnudde V., Dierick M., Vlassenbroeck J., Masschaele B., Lehmann E., Jacobs P., Van Hoorebeke L. Determination of the impregnation depth of siloxanes and ethylsilicates in porous material by neutron radiography. J. Cult. Herit. 2007;8:331–338. [Google Scholar]

- 15.Dewanckele J., De Kock T., Fronteau G., Derluyn H., Vontobel P., Dierick M., Van Hoorebeke L., Jacobs P., Cnudde V. Neutron radiography and X-ray computed tomography for quantifying weathering and water uptake processes inside porous limestone used as building material. Mater. Charact. 2014;88 [Google Scholar]

- 16.Cnudde V., Cnudde J.P., Dupuis C., Jacobs P.J.S. X-ray micro-CT used for the localization of water repellents and consolidants inside natural building stones. Mater. Charact. 2004;53:259–271. [Google Scholar]

- 17.Raneri S., Barone G., Mazzoleni P., Alfieri I., Bergamonti L., De Kock T., Cnudde V., Lottici P.P., Lorenzi A., Predieri G., Rabot E., Teixeira J. Efficiency assessment of hybrid coatings for natural building stones: advanced and multi-scale laboratory investigation. Constr. Build. Mater. 2018;180:412–424. [Google Scholar]

- 18.Cnudde V., Boone M.N. High-resolution X-ray computed tomography in geosciences: a review of the current technology and applications. Earth-Sci. Rev. 2013;123:1–17. [Google Scholar]

- 19.Cnudde V., De Kock T., Boone M., De Boever W., Bultreys T., Van Stappen J., Vandevoorde D., Dewanckele J., Derluyn H., Cárdenes V., Van Hoorebeke L. Conservation studies of cultural heritage: X-ray imaging of dynamic processes in building materials. Eur. J. Mineral. 2015;27:269–278. [Google Scholar]

- 20.Perfect E., Cheng C.L., Kanga M., Bilheux M.Z., Lamanna J., Gragg M.J., Wright D.M. Neutron imaging of hydrogen-rich fluids in geomaterials and engineered porous media: a review. Earth-Sci. Rev. 2014;129:120–135. [Google Scholar]

- 21.Vlassenbroeck J., Cnudde V., Masschaele B., Dierick M., Van Hoorebeke L., Jacobs P. A comparative and critical study of X-ray CT and neutron CT as non-destructive material evaluation techniques. In: Prikryl R., Smith B., editors. Build. Stone Decay from Diagnosis to Conserv. The Geological Society of London; Bath, UK: 2007. pp. 277–285. [Google Scholar]

- 22.Kang M., Bilheux H.Z., Voisin S., Cheng C.L., Perfect E., Horita J., Warren J.M. Water calibration measurements for neutron radiography: application to water content quantification in porous media. Nucl. Instr. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2013;708:24–31. [Google Scholar]

- 23.Kim F.H., Penumadu D., Hussey D.S. Water distribution variation in partially saturated granular materials using neutron imaging. J. Geotech. Geoenviron. Eng. 2012;138:147–154. doi: 10.1061/(asce)gt.1943-5606.0000583. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Philip J.R. The theory of infiltration. Soil Sci. 1957;83:345–358. [Google Scholar]

- 25.Bale Harold D., Paul S. Small-angle X-ray-scattering investigation of submicroscopic porosity with fractal properties. Phys. Rev. Lett. 1984;53:596–599. [Google Scholar]