Abstract

Globally installed solar photovoltaics (PV) capacity has crossed three hundred gigawatts and is increasing each year. As the share of solar PV in the energy mix of a country increases, forecasting PV power available will be crucial. To forecast the instantaneous and long-term PV power output, understanding the factors influencing them is necessary. In this view, this work elaborates on the factors that impact the PV system through tabulation and graphical explanation. Further, a discussion of the articles related to the dust-induced change in performance is made. To understand the impact of dust on solar PV systems in depth, advanced instrumentation and methodologies have been used in the past few years. One of the methods is the measurement of spectral transmittance/reflectance/absorptance of the dust layer on the PV panel. This has led to the question whether a thin layer of some specific dust can be beneficial by absorbing infrared (IR) heat and hence allowing the PV cells to operate at a lower temperature. Many controlled experiments in the laboratory have been made using the artificial dust and sun simulators; and such studies aid in the development of numerical models. Research in modeling, mathematical analysis (from first principles) of dust deposition, and calculation of its impact on panels have been given importance in recent years. Outdoor experiments are relatively more common than other modes of research in this field. Studies involving the interaction of deposited dust with spectral radiation, improving the correlation between artificial and natural dust deposition, the interplay between dust and atmospheric parameters are to be encouraged.

Keyword: Energy

1. Introduction

Solar energy has come into the limelight throughout the world as an alternative to the conventional source of electricity as it is claimed to be a low-carbon energy source and complements the mitigation of climate change. Solar photovoltaic (PV) systems primarily comprise solar PV cells which convert the energy in the photons from the sun and generate DC (direct current), inverters (DC to AC), battery storage (optional), electrical components and others (PV mounting structure, tracking system, etc.). Solar PV systems are typically expected to sustain its energy production for 20–30 years.

To quantify the long-term viability of an energy source (PV), two important metrics: Energy Payback Time (EPBT) and Energy Return on Energy Invested (EROI) are used. EPBT is the period required by the energy source to generate the same amount of energy which was used to create the energy source. EROI is a unit less parameter which gives the ratio of the energy generated by the energy source in its lifetime to energy used to create the energy source.

A systematic review and meta-analysis of around 232 literature during 2000–2013 regarding EROI and EPBT values was done by [1], and the mean harmonized EPBT values varied from 1 to 4.1 years for different technologies. The order from lowest to highest are CdTe, CIGS, a-Si, Poly-Si, and Mono-Si. The mean harmonized EROI values varied from 8.7 to 34.2 years. A single EROI value for a PV system may not be an accurate indicator always as the sensitivity of the EROI to different locations and operational efficiency scenarios are high [2]. This study showed that the EROI values for equal sized system varied from 5.5–19 with different locations and assumptions regarding manufacturing energy inputs and energy outputs. This also indicates that all the parameters which affect the PV energy production have a role to play in the estimated EROI values and more accurate values of the operating conditions should be considered to get a more practical estimate of EROI/EPBT values and in the scaling of PV installations.

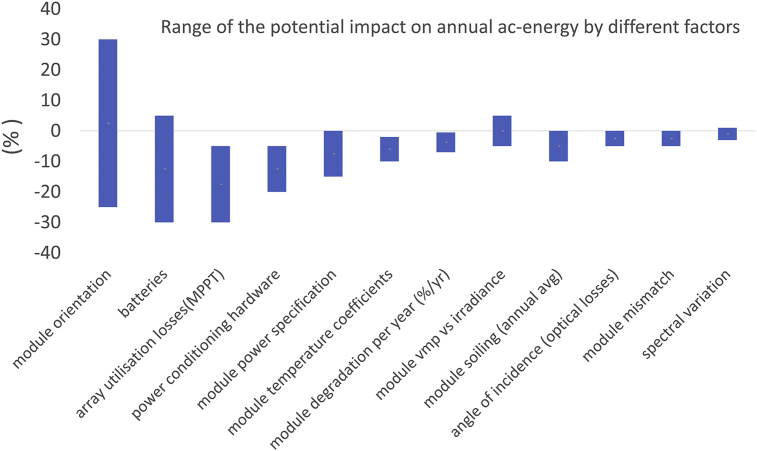

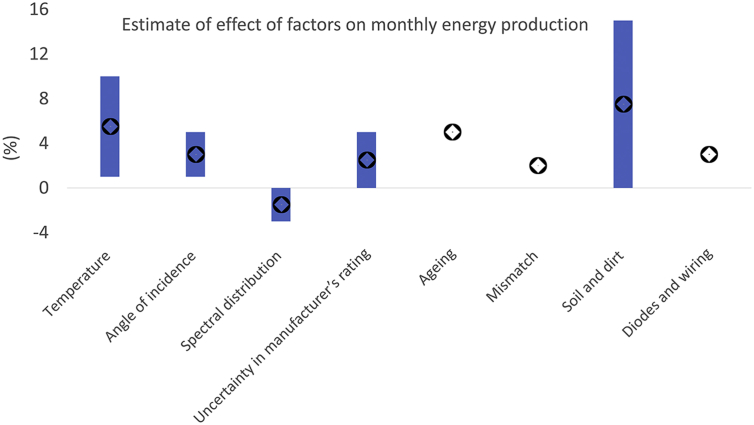

Amongst the factors which affect the PV system yield and not in installer's/designer's control are solar insolation, rain, cloud cover, atmospheric aerosols, wind, ambient temperature, relative humidity, and dust deposition. To explore factors affecting the yield of the PV systems (see Fig. 1), and to arrive at more accurate estimates of EROI/EPBT values, understanding each of these factors is essential. In [3, 4], the range of potential impact on the annual and monthly yield of the PV systems due to different factors have been quantified based on the simulation using SANDIA model and experiments. In [3], the model accounted for module specific electric parameters, temperature coefficient and other factors like module temperature, the angle of incidence, solar spectrum variation and tracking options. The sensitivity analysis was done using the model coupled with solar resource and weather data. Figs. 2 and 3 shows the results of [3, 4]. Fig. 3 estimates that soiling and dirt has a huge range of impact on the PV yield. Dust deposition is one of the factors which strongly affect the PV system output.

Fig. 1.

Factors effecting PV system yield. The factors discussed in [5] are shown in bold/italicized.

Fig. 2.

Factors influencing annual AC energy and range of their potential impact calculated using SANDIA model by [3].

Fig. 3.

Factors influencing monthly AC energy and range of their potential impact estimated by [4].

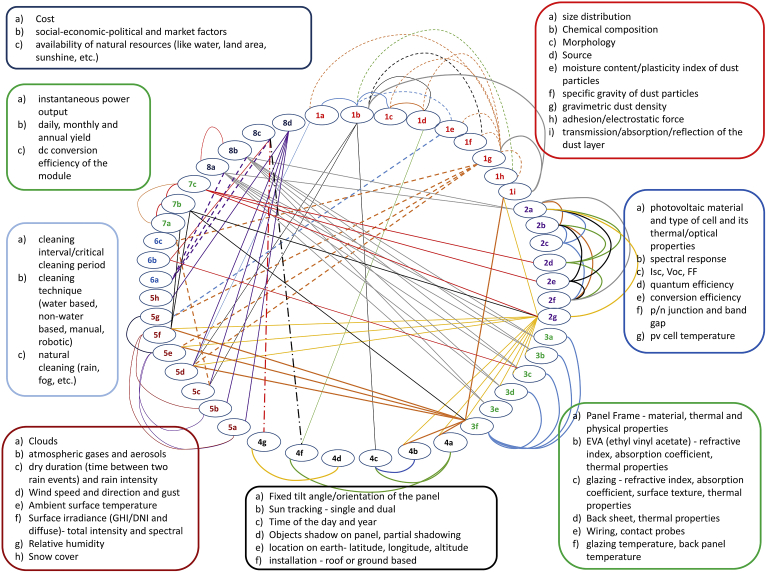

The PV power output is influenced by many factors, Fig. 4 illustrates the complex interaction between the different factors. The link connecting any two factors indicates the possible interaction between the factors. The diagram has been simplified by grouping the factors and number of influences between the groups are represented by the thickness of the arrow (see Fig. 5). Red and blue color arrows indicate a strong and mild impact respectively. The prominent interaction is between ‘radiation and atmosphere’ and the dust followed by the interaction between ‘cost, market and natural resources’ and PV Panel/Module. On following the arrows (see Fig. 5) in the interaction diagram, the influence of different factors on each other can be traced and Table 1 describes the nature of influence in brief. Detailed table is provided in the supplementary material.

Fig. 4.

Complex interaction between the different factors.

Fig. 5.

Simplified diagram showing the significance of the impact of different factors. Red and blue arrows indicate severe and mild impact respectively.

Table 1.

List of the factors influencing the photovoltaic power output and the nature of influence.

| Sl. no | Factors being influenced | Factors influencing |

|---|---|---|

| 1 | Dust | |

| 1a | Size distribution | Chemical composition, Wind speed, and wind direction |

| 1b | Chemical composition | Chemical composition, Atmospheric aerosols, Rain, Wind |

| 1c | Morphology | Dust source, Chemical composition. |

| 1d | Source | Location of the site of a PV system |

| 1e | Moisture content/plasticity index of dust particles | Humidity ratio, Chemical composition |

| 1f | Specific gravity of dust particles | Chemical composition/species |

| 1g | Gravimetric dust density | Size of the particles, Chemical composition, Moisture, Density of the dust particles, Tilt of the panel, Wind speed and direction, Temperature of the glazing, Cleaning interval |

| 1h | Interaction with glazing (adhesion/electrostatic force) | Chemical composition of dust; |

| 1i | Transmission/absorption/reflection of the dust layer | Gravimetric density, Chemical composition/species of dust, Snow cover |

| 2 | PV cell | |

| 2a | Photovoltaic material and type of cell and its thermal/optical properties | Total cost per area of the solar module, Solar PV market |

| 2b | Spectral response | Band-gap of the solar cell |

| 2c | Isc, Voc, FF | Property of the solar cell |

| 2d | Quantum efficiency | Solar cell material |

| 2e | Conversion efficiency | Solar cell material |

| 2f | p/n junction and band gap | Property of the solar cell material |

| 2g | PV cell temperature | Absorption coefficient, Refractive index, Thermal conductivity of the material, Temperature of the back-panel sheet, Ambient temperature, Wind speed and direction, Solar insolation, Optical depth of the dust/snow layer, Tilt angle/angle of incidence |

| 3 | PV panel system | |

| 3a | Panel Frame – material, thermal and physical properties | Strength requirements, cost, and availability |

| 3b | EVA (ethyl vinyl acetate) – refractive index, absorption coefficient, thermal properties | Lamination, chemical inertness, cost and availability |

| 3c | Glazing – refractive index, absorption coefficient, surface texture, thermal properties | Chemical inertness, external damage, optical properties, cost, and availability |

| 3d | Back sheet, thermal properties | Strength requirements, cost, and availability |

| 3e | Wiring, contact probes | Reliability, longevity, cost, and availability |

| 3f | Glazing temperature, back panel temperature | PV cell temperature, thermal resistance, transmittance, reflectivity of the layers, angle of incidence, dust layer/snow layer, wind, ambient temperature, GHI/DNI |

| 4 | Installation of panel and sun geometry | |

| 4a | Fixed tilt angle/orientation of the panel | Location |

| 4b | Sun tracking – single and dual | Seasonal changes in solar earth geometry |

| 4c | Time of the day and year | |

| 4d | Objects shadow on panel, partial shadowing | Trees, surrounding buildings |

| 4f | Location on earth- latitude, longitude, altitude | |

| 4g | Installation – roof or ground-based | Land space/roof space |

| 5 | Radiation and atmosphere | |

| 5a | Clouds | |

| 5b | Atmospheric gases and aerosols | |

| 5c | Dry duration (time between two rain events) and rain intensity (mm) | |

| 5d | Wind speed and direction and gust | |

| 5e | Ambient surface temperature | Aerosols/cloud cover, the intensity of the radiation |

| 5f | Surface irradiance (GHI/DNI and diffuse)- (total and spectral) | Aerosols/cloud cover, the intensity of the radiation |

| 5g | Relative humidity | |

| 5h | Snow cover | |

| 6 | Cleaning maintenance | |

| 6a | Cleaning interval/critical cleaning period | Cost, labor, water/energy |

| 6b | Cleaning technique (water-based, non-water based, manual, robotic) | Glazing hardness, physical properties, availability of the water/energy |

| 6c | Natural cleaning (rain, fog, etc.) | Rain, fog, dew |

| 7 | Performance parameters | |

| 7a | Instantaneous power output | Conversion efficiency, surface irradiance |

| 7b | Daily, monthly and annual yield | Conversion efficiency, surface irradiance, cell temperature |

| 7c | DC conversion efficiency of the module | Quantum efficiency, cell temperature |

| 8 | Others | |

| 8a | Cost | Social, economic, market conditions |

| 8b | Social-economic-political and market factors | |

| 8c | Availability of natural resources (like water, land area, sunshine, etc.) | Location, resources are also seasonal dependent |

It is found in the literature that the temperature of the PV panel is a vital parameter in deciding the PV power output. An increase in the temperature of the PV panel causes an increase in the short circuit current by a small magnitude, but a significant decrease in the open circuit voltage and fill factor. The overall effect is a reduction in the power output. The following block diagram (see Fig. 6) shows the factors which control the temperature of the PV module and the probable impact on short-term or long-term degradation of the PV module caused by variations in the temperature of the PV module. The possibility of the impact of temperature, whether it aggravates or alleviates the different failure modes and quantification of the same needs further research.

Fig. 6.

Block diagram indicating the factors influencing the temperature of the panel and its influence on the reliability of the PV module.

The PV performance loss can occur due to many factors as explained in the previous discussion. Dust is one of the factors which is unavoidable completely but increasing our understanding in its short-term and long-term impact on PV modules, solutions to alleviate the detrimental impacts can be arrived at. Reduction in power generation due to dust deposition ranges from a very negligible value to a high value of 80% when the systems are dirty for many months. The wide range is understandable because dust deposition is dependent on location, many environmental factors like wind and rain, PV panel orientation, cleaning mechanism, etc. Rainfall can be a natural cleaning for panel surfaces, but there is a possibility of formation of dust stains which worsen the transmittance of PV cover surface rather than cleaning it. High wind can avoid the reduction of efficiency of the solar cell by cooling the cell, but it has been found that the performance is reduced as high wind promotes more dust deposition on the panel surface [6]. Hence research in this area is highly necessary to aid the understanding of the combined influence of all the factors on the yield of PV systems and improvisation in PV system design and operation.

Even though the research on dust impact on PV performance started in the 1940s, only in 1990s there was an acceleration in the research with more comprehensive studies and more advanced experimental investigations being carried out. This paper in sequence to the [5], provides the research status of the work done in this field during the years 2010–2018 along with general recommendations which can benefit researchers in this field. The research into the investigation of PV cleaning frequency and mechanism is an exhaustive topic and subject to another study. There are several review literature on mechanisms of PV cleaning and this topic is outside the scope of this paper.

2. Main text

2.1. Instruments and methodologies used in experiments

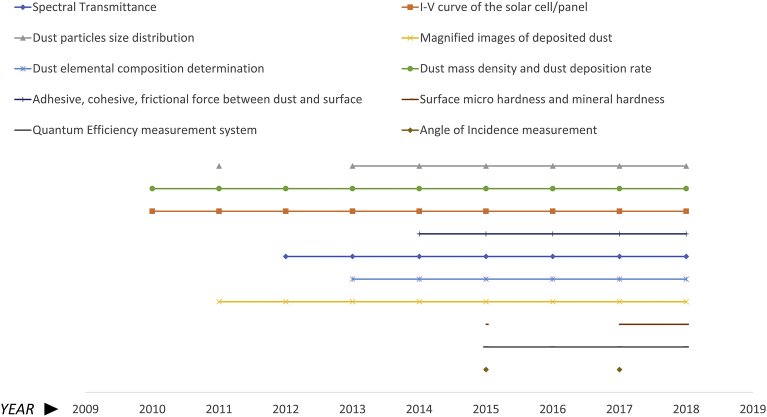

The effect of dust deposition on PV performance has been studied in different ways. The spectrum of experiments ranges from testing a single solar cell to monitoring a mega scale PV power plant. Interaction with dust (natural and artificial) and different types of solar cells, dust and glazing (with and without coatings) are being widely experimented. The artificial dust used in different studies are fly-ash, limestone, red-soil, mud, talcum, silica gel, sand, mosses, white sand, clay, cement, few commercially available test dust like Arizona test dust and ISO 12103-1 A2. The PV solar cell types tested for dust effects are monocrystalline, polycrystalline, amorphous Silicon cell, CdTe, CIS thin film. The computer models and theoretical analysis have been derived and adopted to further understand the soiling effects on photovoltaic panels. The theoretical work ranges from development of mathematical model relating the loss in PV performance and dust densities, the relationship between efficiency drop and rainfall, simulation of hotspots, simulation of tilt angle effect, simulation of dust distribution using ray tracing model, PSPICE model, TRNSYS model, and MATLAB etc. The instruments used and measurement techniques used in the studies range from simple PV power (voltage and current output) measurement to advanced instruments like XRD/XRF, SEM, EDS, Microtribometer, high-resolution Spectroradiometer etc. Table 2 shows the instruments and measurement methods used in the studies which are reviewed in this paper. Fig. 7 shows the technology or methodology used in the experiments used for studying the soiling and dust impact on PV performance over the span of 6 years. Quantum efficiency (QE), the angle of incidence (AOI) and surface microhardness measurements are one of the very recent methodologies/techniques being used. Such advanced measurements have widened the understanding of the losses caused due to soiling and dust.

Table 2.

Summary of the important instruments used and corresponding references.

| Sl.no | Measured parameter | Instrument/measuring technique | References |

|---|---|---|---|

| 1 | Spectral transmittance | Spectroradiometer/spectrophotometer/spectrometer | [7, 8, 9, 10, 11, 12, 13, 14] |

| 2 | I-V curve of the solar cell/panel | I-V curve tracer | [8, 9, 13, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27] |

| 3 | Dust particles size distribution | Particle Counter/optical microscope/laser diffraction Particle Size Analyzer/sieve analysis | [7, 11, 12, 16, 19, 24, 27, 28, 29, 30, 31, 32, 33] |

| 4 | Magnified images of deposited dust | Scanning Electron Microscope (SEM)/FESEM/Microscope/Transmission Electron Microscope (TEM) | [6, 8, 9, 11, 19, 20, 23, 24, 29, 30, 31, 32, 34, 35, 36, 37, 38] |

| 5 | Dust elemental composition determination | Energy Dispersive Spectroscopy (EDS)/XRF/XRD/X-ray photoelectron spectroscopy (XPS)/secondary ion mass spectrometry (SIMS)/Auger electron spectroscopy (AES) | [11, 19, 24, 27, 29, 30, 31, 35] |

| 6 | Meteorological parameters (solar irradiance, RH, Ambient Temperature, rainfall, pressure, Wind speed and direction) | Automatic Weather station (AWS)/individual parameter measuring devices | Except [1, 2, 3, 4, 5, 7, 8, 10, 16, 27, 28, 30, 31, 34, 35, 39, 40, 41, 42, 43, 44, 45, 46] |

| 7 | Dust mass density and dust deposition rate | Dust collector and Precision weighing balance | [7, 8, 9, 10, 11, 12, 13, 15, 17, 19, 20, 23, 25, 27, 28, 32, 35, 36, 39, 47, 48, 49, 50] |

| 8 | Adhesive, cohesive, frictional force between dust and surface | Atomic Force microscope (AFM)/Microtribometer | [11, 30, 31] |

| 9 | Surface micro hardness and mineral hardness | micro hardness tester/Mohs scale of mineral hardness | [30, 32] |

| 10 | Power output DC/AC of solar cell/module/power plant | (Digital/analog) energy meter/Multi-meter | Except [1, 2, 3, 4, 5, 10, 30, 31, 44, 45, 51] |

| 11 | Quantum Efficiency | Multi frequency Quantum Efficiency measurement system | [13, 27] |

| 12 | Angle of Incidence measurement | Microstrain, 3DM-GX3-25 | [13] |

Fig. 7.

Yearly advancement of the instruments or methodology used in experiments on dust impact on PV performance.

This review further categorizes the research work during the years 2010–2018 into three major categories: (1) Experiments with natural dust, (2) Experiments with artificial dust, (3) Modeling and theoretical work.

2.2. Experiments with natural dust

2.2.1. Field measurement of PV performance with and without soiling

The field experiments on the impact of natural dust deposition on PV performance is very crucial since the dust deposition depends on various factors which are very hard to model. An outdoor experiment in Athens [15] was carried out for two months under natural urban environment. Two sets of PV panels were installed in which one of them was kept clean all the time and the other was allowed to accumulate dust. Dust density of around 1 g/m2 and a power output reduction of around 6.5% was observed according to the experimental conditions. A similar twofold experiment was conducted in Kuwait [52], where the loss in the yield ranged from 6.6% to 25% in different months. The range was attributed to the amount and duration of the rain as it can significantly clean or aid in dust adhesion. A study group in Israel [17] conducted an experiment with weekly, monthly cleaning cycles for one set and another set kept clean all the time. The results showed a 5 to 6% decrease in direct current (DC) conversion efficiency of PV per week. An experiment was conducted for one year in Malaga, Spain [53], where they have used two multi-crystalline Silicon solar cells, one of them was kept clean and other never cleaned throughout one year. The annual mean of the daily energy loss was 4.4% and it exceeded 20% during long drought periods. Major concerns over dust impact on PV exists in the locations where dust storms are frequent. In the urban coastal area of Cyprus (Limassol) where the dust is transferred from the Sahara Desert, a group conducted an experiment [22] where the change in the PV performance after the dust episodes was measured and 12%, 10%, 13% reduction in power output was observed in mono-crystalline, multi-crystalline, and amorphous solar panels respectively. Performance losses between 2 - 2.5% was observed in a study done in Libya [54] where weekly cleaning was scheduled. Influence of the Harmattan dust on the PV system in the tropical area was investigated in Nigeria [40] and the results showed that cleaned PV system performed 20% more than the dirty ones. A study in Dhahran, Saudi Arabia [19] and Baghdad [29] reported that power output decreased by around 50% and 26% when the panels were not cleaned for over 6 months and one month respectively. A threefold experiment to study the effect of the pollution due to vehicles in highway was done in Baghdad, Iraq where one panel was clean all the time, next one was shielded by rain and third was completely exposed to natural dust all the time. The results showed 8% and 12% reduction in the naturally cleaned (by rain) panels and polluted panels respectively. A thin-film based PV system which was installed as a canopy covering 4-car parking space at Jordan, a semi-arid region, experienced around a 10% reduction in efficiency due to the accumulation of dust [55].

The above experiments are direct measurements of the performance losses. Different authors have reported the performance losses differently based on their measured parameters (Isc, Voc, Pmax, η, FF). As different authors have conducted the experiments in different conditions and with different sources of dust, the reported values of losses exhibit a wide range. Figs. 8, 9, 10, 11 and 12 shows the soiling effect on different measured parameters like short-circuit current (Isc,), open circuit voltage (Voc,), maxmum power (Pmax,) efficiency (η,) and fill factor (FF). An interesting observation lies in the variation of the FF with the dust density. As the dust density increases, initially FF dips, then increases reach a peak and thereafter decreases continuously. A three-stage explanation is provided by [41]. In the first stage, as dust deposits on the panel randomly, a partial shadowing on a few cells is caused which causes the dip in the power output. The second stage is where the dust particles deposits uniformly over the panel, wherein the partial shadowing is diminished and a uniform power generation from all the cells are possible and hence the increase in the FF and peak occurs. In the third stage, as the dust density increases, the illumination drops, and the FF decreases thereafter. In addition to the above explanation to the phenomenon of the FF increasing, a dust-temperature interplay wherein, as the dust deposition is uniform over the panel, temperature drop due to uniform shading could also be considered.

Fig. 8.

Ratio of polluted PV panel short-circuit current to clean PV panel short-circuit current versus corresponding dust density derived from measurements reported by different authors [16, 26, 28, 41, 71, 72, 73].

Fig. 9.

Ratio of polluted PV panel power output to clean PV panel power output versus corresponding dust density derived from measurements reported by different authors [9, 41, 72, 74].

Fig. 10.

Ratio of polluted PV panel open circuit voltage to clean PV panel open circuit voltage and corresponding dust density derived from measurements reported by different authors [16, 72].

Fig. 11.

Ratio of polluted PV panel fill factor to clean PV panel fill factor and corresponding dust density derived and measurements reported by different authors [41, 72].

Fig. 12.

Ratio of polluted PV panel efficiency to clean PV panel efficiency and corresponding dust density derived and measurements reported by different authors [15, 16, 48, 49, 71, 73, 75, 76].

Another observation is that, for the same ratio of the measured parameters (polluted to clean), there is a range of dust density values, which indicates that the dust density alone cannot be used to estimate the soiling loss and therefore measurements of the dust properties like chemical composition, size distribution, etc. are required.

According to [13], Isc is affected by transmission only, whereas Pmax may be affected by both transmission and shunt resistance depending on the cell quality and technology and Pmax loss is not the true measure of soiling losses as compared to Isc loss. Thus, to compare different soiling experiments conducted at different conditions and locations, reporting the Isc loss is more revealing in terms of soiling impact on PV performance.

2.2.2. Experiments on tilt angle effect on dust deposition

The tilt angle of the PV panels is the angle from the horizontal and it directly controls the amount of dust deposition because of the gravity which tends to pull down the particles as the orientation of the PV panel gets more vertical. An intensive study in Arizona was conducted using a setup built for this purpose [70]. The setup had 2 sets of PV panels each having nine PV panels with 0°, 5°, 10°, 15°, 20°, 23°, 30°, 33° and 40° tilt angles. Understanding the effect of different tilt angle provides an explanation of the behavior of dust deposition on the PV panels located at different latitudes. Dust deposition promoted due to wind/gust over PV have been reported in [6], in addition to this, influence of the geometry of the on-site installations, BiPV (Building integrated Photovoltaics), BAPV (Building Applied Photovoltaics) on dust deposition needs more exploration. The soiling losses were reported to be 2.02% at horizontal position and 0.69% at 40° tilt angle and the soiling loss reduced linearly at each tilt angle and these observations reiterated that flatter the solar PV modules are placed more is the soiling loss.

Sun-Tracking of flat PV collectors is used to increase the amount of solar energy that can be captured throughout the day. A study in Dhahran, Saudi Arabia [19] tested the influence of sun tracking on dust deposition and PV performance loss due to soiling. It was found that Sun Tracker improved the power output of the solar modules by reducing the dust effects by 50%. The dust dislodging in the event of a gust or rain during the sun tracking movement is yet to be understood and these studies can provide a clue to designers to allow for a more efficient cleaning mechanism without use of additional water or energy. As the tilt angle changes, the dust deposition varies due to the gravity but the spatial distribution over the panel also changes. A study in India [33], collected dust samples over PV panels at five locations in the Shekhawati region, India. The collected dust was artificially deposited, illuminated and performance was measured for 18 tilt angles which were 0°, 15°, 30°, 45°, 55°, 60°, 61°–70°, 75°, 90°. This study intended to measure the tilt angle for maximum power production before and after soiling, and deviation from the optimum tilt angle. Table 3 shows the optimum tilt angle for the clean and soiled panels for the soil from five locations.

Table 3.

Optimum tilt angle comparison of clean and soiled panels for the five dust samples collected at Shekhawati region [33].

| Soil on the panel | Location it belongs | Optimum tilt angle (clean panel) (°) | Optimum tilt angle (soiled panel) (°) |

|---|---|---|---|

| Soil 1 | Raghunathgarh | 64 | 66 |

| Soil 2 | Neem ka thana | 63 | 64 |

| Soil 3 | Khetri | 62 | 66 |

| Soil 4 | Sikar | 62 | 70 |

| Soil 5 | Pilani | 62 | 63 |

All the above studies translate that the tilt angle is a strong factor for dust deposition and higher is the soiling loss as the panels are more horizontal. But the relative differences in the soiling losses at different tilt angles depend on the characteristics of the dust at that location. The studies wherein the spatial distribution variation with the change in the tilt angle are studied are equally important as the soiling losses reported in the above studies is an average over the entire area of the module and spatial distribution gives more insight.

2.2.3. Experiments on optical loss due to dust deposition

Primarily effect of the dust is to reflect or absorb the radiation falling on it and hence affecting the transmittance of the glazing of the solar module. A study in Kuwait [28] measured the transmittance of the glass samples with natural dust in different sections (top, middle and bottom) using a spectrophotometer at different tilt angles. The non-uniformity in transmission between the top, middle and bottom section (calculated as where max(T) and min(T) is maximum and minimum of the transmissions of the three sections respectively) which also indicate non-uniformity in dust deposition. Interestingly 30° has the highest non-uniformity followed by horizontally placed panels and needs more theoretical insight.

The primary investigation made in [10, 11, 28, 30, 31], are the change in the transmission of the PV cover surface due to the dust deposition. A linear relationship between the transmission loss and dust deposition was observed according to [10]. Transmission loss was observed to be around 0.05% for every increase in 1 g/m2 of dust deposited.

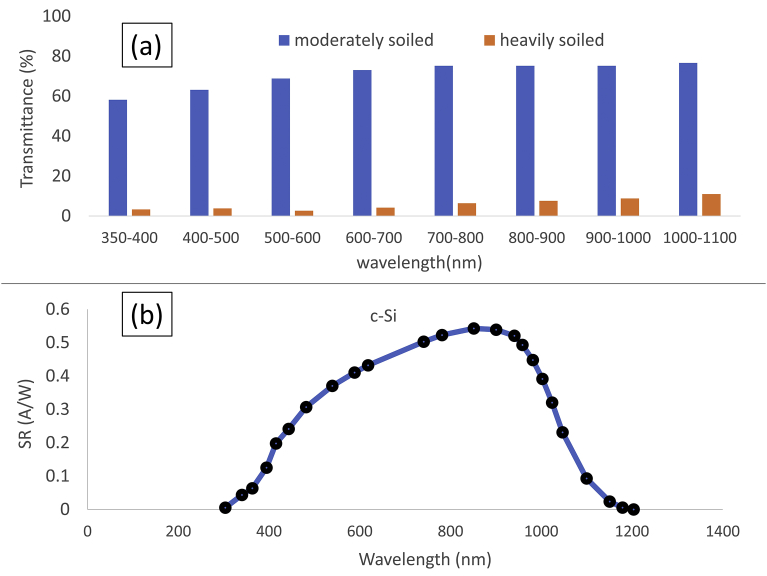

Studies involving spectral transmittance measurements like [28] show the variation of transmittance as a function of wavelength with different magnitude of dust deposition. Mostly, 350 nm–570 nm region is affected by dust. The spectral response of Crystalline Silicon PV cell is typically around 350–1200 nm [56]. The spectrally sensitive effect may be attributed to the difference in the size of the dust.

Group of researchers in India [13], having used the spectroradiometer, reflectance of the soiled PV module was measured, and the net light reflected by the soil layer was determined by taking the difference between the reflectance of the clean and soiled PV module. Absorption was calculated based on quantum efficiency measurements and consequently, transmission of the dust layer was calculated (transmittance + absorptance + reflectance = 1). Fig. 13(a) shows the transmission for the moderately and heavily soiled PV module. The spectral transmittance trend is similar to the spectrum reported in [28]. Mie scattering theory can explain the results shown in Figure 13(a), where the transmission beyond 600 nm is less wavelength dependent.

Fig. 13.

(a) Transmittance spectra of moderately and heavily soil layer [13]. (b) Spectral responses of the c-Si at AM1.5G spectrum (up to 1300 nm) [56].

Fig. 13b shows the spectral response of the Crystalline Silicon PV cell at 1.5 AM solar spectrum. The wavelength of the peak spectral response and the peak solar irradiance are different. The peak dust absorption lies in the 300–600 nm zone which is evident from Fig. 13. Hence, the existence of dust can diminish the absorption of energy falling on the panel which is responsible to increase in its temperature. Also, authors in [14, 57], claim that specific dust absorbs the radiation in the infrared region of solar spectrum and hence could potentially alleviate heating up of the solar PV panel. The phenomenon of a thin layer of a specific type of dust on the PV panel being beneficial needs strong investigation.

The angle of incidence (AOI) is the angle between the solar beam and the module normal vector. The critical angle of incidence is defined as the angle above which there is a loss of 3%, or above as compared with the 0° AOI. Soiling of the PV modules reduce the critical AOI dramatically and this causes high optical losses during dawn and dusk. A study in India [13], have measured the AOI and response of the module using the Microstrain, 3DM-GX3-25 and pyranometers fixed on two axis sun tracker devices. The relative difference between soiling and clean module's optical response which shows that the magnitude of soiling increases the angular losses at high AOIs.

A variety of methods have been used by different authors to quantify the angular losses due to soiling. Quantifying the absorption and reflection by the dust layer, through the measurements of quantum efficiency and quantification of the change in angle of incidence curve due to soiling is a novel technique. The transmission (spectral) loss due to soiling as reported by different authors agrees with the aspect that the transmission is wavelength dependent mostly only in the visible region (till around 700 nm). This phenomenon is well explained through Mie-scattering theory in many literatures.

2.2.4. Experiments on dust characterization

To investigate the size distribution of the deposited dust, group of researchers from Saudi Arabia [11] have used the Particle size analyzer and the fraction of the number of particles along with a fraction of area and volume have been measured. Maximum number of particles were observed to be around 1 μm.

The particle size of the dust samples was measured using the Beckman Coulter Laser Diffraction Particle Size Analyzer in a study in India [27] where samples were taken from Jodhpur and Mumbai. In either location, maximum number of particles are around 8–31 μm. In another study in India [33], sieve analysis was performed on the dust samples collected over five different locations around Shekhawati region in Rajasthan, India. Soil samples are from Raghunathgarh (Soil 1), Neem Ka Thana (Soil 2), Khetri (Soil 3), Sikar (Soil 4) and Pilani (Soil 5).

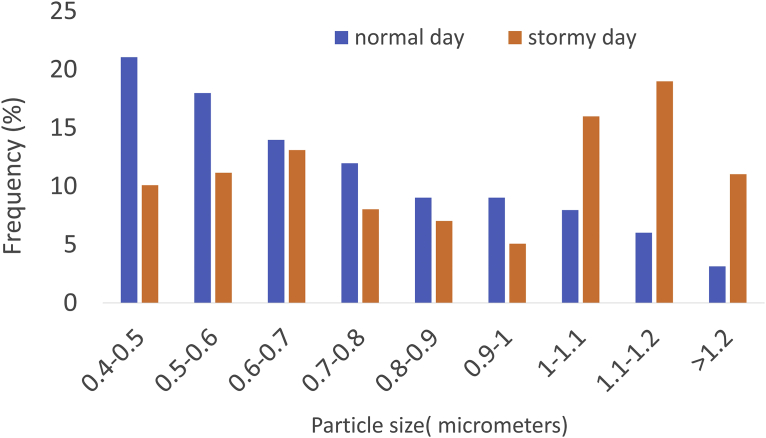

An experiment conducted in Iraq [58], where dust storms are observed, shows the effect of dust deposition on PV performance over an exposure period of daily, weekly and monthly. The efficiency drop was 5.8%, 10.57% and 15.78% for panels cleaned daily, weekly and monthly respectively. Another interesting measurement in the study was the size distribution of the particles during a normal day and a stormy day. Measurements show that particles during a storm are bigger compared to the particles deposited on a non-stormy day (see Fig. 14).

Fig. 14.

Particle size distribution during normal and stormy days, adapted from [58].

The chemical composition of the naturally deposited dust was analyzed through X-ray Diffractometer in a study in Saudi Arabia [11] and the test showed that Calcite and Quartz compounds occupied more than 60%. In the study [27] dust samples from six locations (Agra, Mumbai, Hanle, Gurgaon, Pondicherry, and Jodhpur) in India have been collected and the XRD elemental analysis was used to determine the mineral composition of the dust particles. Quartz (SiO2) was present in all the locations with a minimum fraction of 30%. Samples from Pondicherry contained more than 90% of Quartz (SiO2) whereas samples from Hanle and Mumbai contained around 30–40% of Quartz (SiO2). The remaining constituents were Montmorillonite, Langasite, Eucryptite, Magnetite, Muscovite, Dolomite, Illite, Gupeiite, Albite, and Calcite.

To study the effect of the coefficient of friction of the glass surface on dust deposition [30], natural dust was collected and laboratory experiments were performed. The dust particles were mixed with desalinated water to form mud and subsequently mud properties and its interaction with glass surface was analyzed. The frictional force required for the mud removed glass surface was larger than that of the as-received glass surface. The pH of the mud solution was around 8.4 as it consisted of alkali and alkaline earth hydroxides. The solution attacks the glass surface by forming fine-sized cavities and the potassium diffuses into the surface region causing toughening and increasing the surface microhardness. The overall effect and damage to glass surface due to mud deposition can be seen as a change in its transmittance. This study was further extended to understand the behavior of formation of dust and its effects on the surface of glass and polycarbonate surface [59]. Spectral transmission measurements were made for glass surface and polycarbonate surface before and after mud was deposited. The transmission was around 50% in polycarbonate surface and around 30–40% in the glass surface with mud being deposited. After the removal of dust, polycarbonate surface transmitted around 80% throughout visible spectrum and glass surface transmitted around 70–80%. Micro-tribometer measurements suggested that the adhesion and cohesion work or tangential force required to remove mud from the glass surface is relatively higher than polycarbonate surface. The [32] study investigated moisture content, plastic limit, liquid limit, and plasticity index of the samples collected at regions around Oman.

The particle size distribution measured by different authors at different locations are very different which is understandable as the dust properties are highly dependent on the source and mechanism by which it is generated and dispersed. Similarly, the chemical composition is specific to each location as they are also dependent on the mechanism of production and source.

2.2.5. Experiments on other environmental factors on dust deposition

Studying the influence of each environmental factors in isolation like wind, dust, temperature, rain, RH on PV performance individually gives a narrow and incomplete understanding [42]. A study in Bangalore, India [6], attempted to study the interplay between wind speed, dust deposition, and cell temperature and its influence on PV performance. An outdoor test bed with three identical PV panels was set up with the first one kept polluted, the second one cleaned with water and subject to artificial wind and the third one was not cleaned but subject to artificial wind. Interestingly, even though artificial wind reduced the cell operating temperature by 10° and increased the cell efficiency, there was a drop in the performance. The dust was found to adhere more during high wind speeds scenarios. Thus, locations with high airborne dust and high prevalent wind should be avoided for PV installations unless they are equipped with efficient cleaning mechanisms [6]. Natural cleaning due to rain can save a lot of investment in manual cleaning mechanisms. To understand the natural cleaning, KU Leuven conducted a study [8] where SEM images of the dust collected samples were analyzed and they concluded that rain seemed to have a smaller effect on particles (2–10 μm), but the effect on bigger particles such as pollen, etc. (appx 60 μm) was very visible. A study in Surabaya, Indonesia [60] investigated the weather conditions and dust impact on PV performance. After two weeks of exposure, reduction in power output was around 10.8% with an average humidity of 52.24%. A Study was continued in rainy and cloudy conditions as well. The study could conclude that local environmental conditions can have a significant impact on PV performance. A continuation of such studies to understand the behavior of dust deposition in different environmental conditions will help in estimating the times of high and low dust deposition and to develop efficient cleaning strategies. A study in Isfahan, Iran [61], measured the dust deposition density for different tilt angles along with wind speed and direction measurements. In general, as the tilt angle increased the dust deposition density reduces as gravity pulls the particles. Interestingly, in this study, an increase in the dust deposition density was observed with an increase in the tilt angle. This was attributed to the wind direction. The authors explain that if the panel was facing the wind direction, wind can sweep away the dust particles whereas if the panel was away from the wind direction, due to the creation of the vertex more dust tends to get settled. This observation and explanation can be used to expand the study to understand the optimization of the orientation of the panels to utilize the wind direction to clean the panels with minimal additional cost and resources spent on cleaning. Studying the environmental factors individually, will give an incomplete understanding and hence studies considering the interplay between the factors are recommended.

2.2.6. Experiments on the quantum efficiency loss due to dust deposition

Quantum Efficiency (QE) of the solar cell is the ratio of the electrons collected as photocurrent to the photons that entered the solar cell through glazing. Due to soiling the photons entering the solar cell is either absorbed or reflected by the dust layer. Measurement of the spectral quantum efficiency gives the spectral-specific influence of the dust on the solar cell. The QE measurements were conducted in a study [13], using QEX12M with custom built X-Y stage. The measurements were taken at 5 nm increments in the range of 350–1100 nm and the beam width of the monochromatic light was set at 1.5 mm × 5 mm. The magnitude of soiling in this study was classified based on (a) Light – 0–2 g/m2, (b) Moderate – 2–10 g/m2, (c) Heavy – greater than 10 g/m2. The lightly soiled module showed a very little decrease in QE with respect to the cleaned module, moderately soiled showed a significant reduction. The reduction in QE of moderately soiled PV module is explained to be due to absorption by dust layer and a small fraction of reflection. But in the heavily soiled module, reduction in QE is largely dominated by absorption and reflection by dust layer and hence such a large reduction is seen. A different instrument (Bentham PVE300 quantum efficiency measurement system), was used in [27] and QE measurements for dust collected from six locations in India were conducted. Mumbai and Pondicherry dust samples showed higher QE loss compared to other locations which could be due to a high fraction of clay sediments (0–4 μm in size). Also, spectrally, Mumbai dust samples showed a higher loss at higher wavelengths compared to Pondicherry dust and this could be due to its chemical composition. Thus, from the studies related to QE measurements indicate that QE loss depends on the scattering, absorption, and reflectance of the dust layer which is in turn dependent on the size distribution of the dust particles.

2.3. Experiments with artificial dust

Natural dust and natural dust-deposition do not always allow the researchers to conduct a controlled experiment. When experiments are to be performed in a controlled environment with specific dust under study, artificial dust and artificial dust-deposition play a major role. In [47] an outdoor experiment under natural sunlight was set up with two sets of PV panels (one maintained clean and the other dusty) to understand the impact of carbonaceous fly-ash on the performance of the polycrystalline silicon solar panels. The reduction of power output, efficiency, and energy with an increase in the dust deposition mass density were determined. With the difference in the dust deposition mass density of around 4 g/m2, efficiency drop of 1.5% (absolute terms) was seen and energy yield was reduced by around 30% per hour. The study was continued in [48] with red soil and limestone along with fly-ash. The relative effects of the three artificial dusts on PV performance were analyzed. With dust density of 0.35 g/m2 of red soil, 0.33 g/m2 of limestone and 0.63 g/m2 of fly-ash, the corresponding energy reduction were 7.5%, 4%, and 2.3% respectively. The difference in the magnitude of reductions was attributed to the color, composition, size and other physical and chemical properties of the dust particles. Similar to the previous two studies, [50] has compared five dust types (ash, sand, red-soil, silica gel, and calcium carbonate) on polycrystalline PV panels in an indoor experiment. Ash considered in this study had a significant effect on voltage reduction compared to other dust types (dust density of around 10 g/m2). A study in China [16] have used ISO 12103-1 A2 fine test dust made by Powder Technology Inc. and set up an indoor experiment with sun simulator and allowed dust to naturally deposit on PV panels using a fan. The reduction of the efficiency was around 26% of the initial value with a dust accumulation of 22 g/m2.

A more insight into understanding the effect of dust on PV was achieved by analyzing the variation in its I-V curve as it is unique to each PV element because it depends on solar insolation, ambient and cell temperature, wind speed and mismatch losses, etc. In [62], an indoor experiment was conducted with five dust types, viz. talcum, dust, moss and sand and I-V curve tracers were used to measure I-V curves. From the measured I-V curve, maximum power output at different loads was measured. Moss had a significant reduction in maximum power (86%) followed by sand (74%), dust (71%), talcum (31%) and water droplets (5.4%). Further in [34], effect of presence of mud and talcum was studied under constant radiation source at an indoor facility. The PV power output was measured with and without the presence of the dust and the reduction in peak power was up to 18% and the difference between mud and talcum was around 6%. Dust deposition primarily blocks the radiation at the glazing and hence due to lesser photons striking the solar cells, PV modules show a reduction in their electrical performance. Understanding the change in transmission of the glazing due to dust deposition is very essential and such measurements have been made with natural dust. Out of the other experiments done in [9], the experiment on the effect of artificial dust (different particle size) on PV cover glass was done. White sand (250 μm), clay (68 μm) and cement (10 μm) were used. This experiment reiterated that smaller particles cause greater performance degradation than larger particles with the same dust density which is attributed to the clustering or non-uniform distribution of particles. The quantification of the influence of the particle size and type needs more exploration.

To understand how dust particle adhere to the PV cover surfaces in wet surface condition, a laboratory test done in [11], was conducted where adhesion force measurement between 48 μm silica bead and silica surface at different relative humidity was made. According to the results, the force of adhesion increases almost linearly with an increase in relative humidity. It was attributed to the formation of water capillary bridge between particle and surface due to condensed water in the gap between particle and surface. Hence, an uncleaned panel will have a greater adhesion over repeated cycles of dew formation. This gives an indication to consider cleaning the panels in the morning during the dew formation to avoid a stronger adhesion.

An indoor study in Jordan [63], showed that particles with smaller grain size caused more reduction in power output of modules compared to particles with bigger grain size particles. Experiments conducted with different sized dust particles, by different authors have also agreed on the phenomenon that small sized particles cause more soiling loss than larger particles. Also, the artificial dust considered in all the studies are very limited. There is a huge scope to develop a correlation between artificial and natural dust deposition density and types. Currently, any field experiment consists of natural dust of a specific location. The correlation allows for a variety of indoor experiments involving estimation of the impact of different types of dust and to study the cleaning efficiency of different mechanisms.

2.4. Modeling and theoretical work

Analytical studies complement field studies in understanding the overall performance degradation due to dust accumulation on PV panels. In a study by [53], a simple model has been developed using ray tracing technique to simulate the behavior of the PV power loss as a function of angle of incidence of sunlight. In this model, initially, only the direct component of solar radiation was considered which did not agree with the experimental data. Later when diffuse radiation was included, a good match was seen between experiment and simulation. This highlighted the role of interaction with dust and diffuse component of radiation in the given scenario.

Capacity factor (CF) is defined as the ratio between actual and rated power output over given time. On an average, CF gives an idea of how efficiently the power plant is running and this parameter can compare different energy sources. In [39] performance drop due to three artificial dust (red soil, limestone, and fly-ash) was studied and subsequently a theoretical model was developed to relate dust density and CF. An exponential model was proposed, and the experimental data was fit to obtain the coefficients. The exponential function was of the general form CFj = CFo. exp (−Aj. ΔMj) where ‘j’ and ‘o’ represents polluted and unpolluted panels. The coefficients ‘A’ for ash, limestone and red soil was found to be 0.06 ± 0.024, 0.10 ± 0.034 and 0.24 ± 0.085 respectively which indicates that red soil impact on reduction in CF is greater amongst the three pollutants.

A model was set up in TRNSYS (Transient System Simulation Tool) to study the effect of cleanness on the performance of the PV module by [22]. The model was input with TMY (Typical meteorological year) data and libraries involving two PV cell technologies (polycrystalline and thin film silicon) were used. The model could simulate for one year of PV energy output for all hours and the same was recorded. The calculation of drop in performance and annual energy drop was made. Percentage drop in performance and energy production increased linearly with an increase in transmittance-absorptance product (τα).

A study by University of Lucknow, India [64] attempted to find an empirical relation between the difference in the efficiency and the thickness of the dust deposited. The dust thickness and efficiency data were collected thrice every month and this was conducted for one whole year. A linear equation model (y = a + bx) was proposed and least square method was used to determine the coefficient in the equation. A one MW PV power plant was studied [65] to understand the effect of soiling on the performance of the PV plant. A regression model that takes input as solar insolation, temperature, and output as PV generated power. This study used data from two power plants (1 MW each), one sandy site and another on a compact ground. Their analysis showed that the sandy site power plant and compact ground power plant suffered 6.9% and 1.1% loss respectively due to soiling. The difference was attributed to the surroundings of the power plants. Another regression analysis was conducted by a study in Kathmandu [66], where measurements of meteorological factors and PV performance were made and percentage drop in efficiency as a function of temperature, rainfall, solar insolation, dust deposition density, humidity, and cell temperature was considered. This study also compared the performance of a daily cleaned panel with the panel without cleaning and found that efficiency reduced by 29.76% over a span of 5 months.

A study in Jordan [67], developed two models using multivariate linear regression (MLR) and artificial neural network (ANN) to estimate PV system conversion efficiency. The independent variables in the models were dust accumulation and ambient temperature. The model was developed based on the experimental performance data collected during Mar–Sep 2014.

To quantify the soiling losses over 186 PV plant sites in California [68], three methods were discussed. In the first method, the difference between weekly average efficiency one week before and after the rain event is divided by a number of days of the drought period. The second method was similar to the first method except that the difference is between one week after the previous rain and one week before the next rain event. The third method was a regression fit to the data during the draught period and the slope was deduced as the soiling rate. The study used the third method throughout and the average soiling loss was estimated to be 0.051% per day and also, locations with a tilt angle of less than 5° had larger soiling losses. Similar to the method three, the ratio of dirty to clean insolation over time was plotted and the regression line was fit in [69]. The slope of the line was the soiling rate.

The mechanism of dust accumulation over the PV panels is simulated in the laboratory study [43]. Here SiO2 particles were deposited on the glass slide while a microscope and computer were used to monitor the deposition. A simple one-dimensional model was proposed to model the exponential decay of the free fraction area (fraction of area of glass slide visible or unoccupied area by particles) with an increase in a number of particles. As this model does not account for the clustering in two dimensions another model was suggested which accounted for multi-layer clustering of the particles. The models were compared with the experimental observations and a Monte Carlo simulation and the models matched well with observations and within experimental uncertainties. Such studies help in the development of computer simulation tools which will be capable of modeling natural dust deposition. In summary, analytical studies and modeling approaches by different researchers have been categorized in Table 4.

Table 4.

Categorization of the studies involving theoretical and modeling work.

| Category | References | |

|---|---|---|

| Use of complex models (TRNSYS, PSPICE, raytracing, etc.) | With indoor measurements | |

| With outdoor measurements | [22] | |

| Only theoretical or modeling | [44, 51] | |

| Use of power-plant power output, meteorological data, statistical analysis, Analytical models, Monte Carlo simulations, etc. | With indoor measurements | [33, 43] |

| With outdoor measurements | [39, 53, 64, 65, 66, 67, 68, 69] | |

| Only theoretical or modeling | ||

The theoretical works ranged from the fundamental understanding of the mechanism of the dust particle deposition, clustering and how it influences the transmission of the glazing to generating an empirical equation which relates the power output of the module/power plant and the input variables, such as soiling parameters and few natural factors which affect the power production.

2.5. Geographical distribution of research

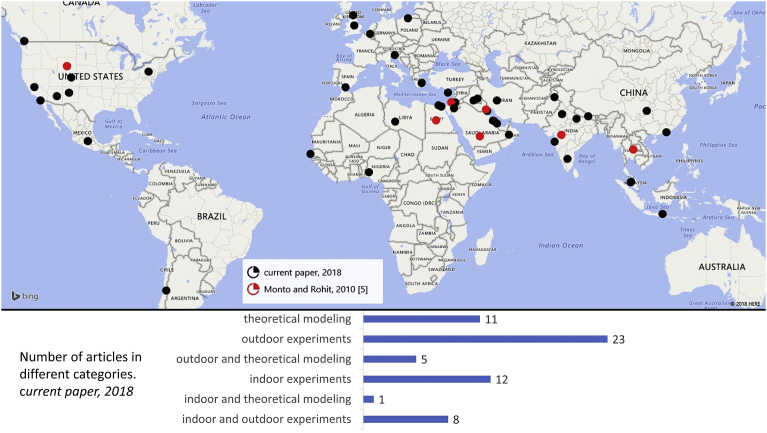

The research on dust effects on PV performance was mostly in the MENA (Middle East and North Africa) regions where the solar energy potential is high and exposed to desert dust. Due to many factors in the recent years like China Manufacturing, the decline in solar PV panel cost, policies promoting solar PV, there is an increase in the scale of the solar PV installed capacity worldwide, etc. [45]. Also, understanding all the factors which maximized the PV yield are gaining priority, to make solar PV a promising source of energy and hence research on dust impact on PV performance has spread widely in USA, Europe, middle east, south-east Asia and within India as well which is shown in Fig. 15.

Fig. 15.

Geographical distribution of research on dust impact on photovoltaic performance. Red dots represent the distribution during 2010 and black dots represent the current distribution.

2.6. General critical appraisal

-

(1)

The Field studies where experiments with and without soiling have been performed have reported the losses in terms of Isc, Voc, Pmax, η, and FF. But, Isc losses represent true loss due to dust and soiling compared to other parameters and hence it is recommended to the authors to report the Isc losses which aid in understanding the soiling loss at that specific location.

-

(2)

Studies with quantum efficiency loss have been recently performed to understand the influence of the dust particles on the solar cell photocurrent. There exists a scope in quantum efficiency loss measurements along with theoretical support can improve the understanding of the soiling and radiation interaction and its influence on solar cell photocurrent.

-

(3)

Artificial dust experiments conducted by many authors have some limited types of dust explored as of now. There is a scope to develop a correlation between artificial and natural dust deposition density and types. Currently, any field experiment consists of natural dust of a specific location. The correlation allows for a variety of indoor experiments involving estimation of the impact of different types of dust and to study the cleaning efficiency of different mechanisms.

-

(4)

The time period of exposure to dust alone and corresponding performance loss can be misleading and does not help in deciding the cleaning interval as each study gives a different value which is specific to a particular dust condition which depends on location and season. Dust density and (or) rate of dust deposition are vital parameters which must be measured along with the analysis of performance loss which is missing in most of the field studies.

-

(5)

To have a comprehensive idea on dust deposition, dust characterization and measurements must be conducted in all the seasons throughout one year for a given location. Very few studies have extended their measurements for all the seasons till now.

-

(6)

Tilt angle effect on dust deposition density or performance losses has been established well but spatial dust distribution around the panel surface variation with tilt angle required more attention. The dust dislodging in the event of a gust or rain during the sun tracking movement is yet to be understood and these studies can provide a clue to designers to allow for a more efficient cleaning mechanism without use of additional water or energy.

-

(7)

The energy transfer between the surrounding environment and PV panel depends on the material and surface properties of the PV panels and the ambient meteorological conditions. For example, the dust deposition on the surface modifies the effective thermal conductivity of the whole module, humidity and ambient temperature control the heat transfer to and from the PV panel. Thus, simultaneous measurements of thermal conductivity, meteorological parameters, power, and dust, etc. can give a more insight into the perturbance of energy balance. On the other hand, field experiments on studying the influence of the environmental factors on PV performance must account for its interplay and only very few studies have attempted such studies till now. In summary, a table (see Table 5) is made to show the relative influence of few major factors which affect the performance of PV.

Table 5.

Level of influence (low, medium, high) of the factors affecting the performance parameters of PV generation.

| Sl no | PV performance factors | Insolation |

Ambient temperature | Wind | Dust | Size of the PV system | Type of PV panel | Location | Shading/cloud cover | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Spectral | Total | ||||||||||

| 1 | Conversion efficiency | Ratio of the electric power (DC) generated to the incident irradiance | High | Med | High | Low | Med | Low | Med | Low | Med |

| 2 | Quantum efficiency | Ratio of the electrons collected as photocurrent to the photons that entered the solar cell through glazing | High | Med | Med | Low | High | Low | High | Low | Low |

| 3 | Fill Factor (FF) | Pmax = ImVm = FF(IscVoc), Pmax = max power, Im = cell current at max power, Vm = cell voltage at max power, Isc = short circuit current, Voc = open circuit voltage | High | High | High | Low | High | Low | High | Low | Med |

| 4 | Yield | Ratio of the total energy generated per year per kWp installed | High | High | High | Low | High | Low | Med | High | High |

| 5 | Capacity factor | Capacity factor (CF) is defined as the ratio between actual and rated power output over given time | High | High | High | Low | High | Low | Low | High | High |

| 6 | Performance ratio | Ratio of the actual electricity generated to energy generated if the plant was under standard testing condition | High | High | High | Low | High | Low | Low | High | High |

3. Conclusions

A vast literature has been reviewed and classified into broad categories based on the studies related to natural dust, artificial dust and theoretical or modeling work. Further, the status on experimental techniques, instrumentation, methodology have been tabulated, advances in the instrument's technology over the span of years have been shown. The improvement and application of a variety of instruments to soiling impact studies have benefited in understanding the unexplored areas related to the soiling impact study. The factors affecting the dust and its performance are discussed, the status of the modeling and theoretical works have been tabulated and finally, the geographical distribution of the research work is discussed. The large-scale solar PV capacity is increasing worldwide and subsequently, its share in the energy sector widens in most of the countries. This creates the need for optimization and forecasting. This can be accomplished only if clear understanding is achieved in every aspect of solar PV functioning, specifically the unexplored factors like soiling.

Declarations

Author contribution statement

All authors listed have significantly contributed to the development and the writing of this article.

Funding statement

This research is partly based upon work supported by the Solar Energy Research Institute for India and the U.S. (SERIIUS) funded jointly by the U.S. Department of Energy subcontract DE AC36-08G028308 (Office of Science, Office of Basic Energy Sciences, and Energy Efficiency and Renewable Energy, Solar Energy Technology Program, with support from the Office of International Affairs) and the Government of India subcontract IUSSTF/JCERDC-SERIIUS/2012 dated 22nd Nov. 2012.

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Appendix A. Supplementary data

The following is the supplementary data related to this article:

References

- 1.Bhandari Khagendra P., Collier Jennifer M., Randy J. Energy payback time (EPBT) and energy return on energy invested (EROI) of solar photovoltaic systems: a systematic review and meta-analysis. Renew. Sustain. Energy Rev. 2015;47:133–141. [Google Scholar]

- 2.Lundin Johan. Uppsala University, Disciplinary Domain of Science and Technology, Physics, Department of Physics and Astronomy; 2013. EROI of Crystalline Silicon Photovoltaics Variations Under Different Assumptions Regarding Manufacturing Energy Inputs and Energy Output. Independent thesis Basic level (professional degree) [Google Scholar]

- 3.D.L. King, W.E. Boyson, J.A. Kratochvil, Analysis of factors influencing the annual energy production of photovoltaic systems, in: Proc. 29th IEEE PVSC (May 20–24, 2002): New Orleans.

- 4.D. Thevenard, Didier, Review and recommendations for improving the modelling of building integrated photovoltaic systems, in: Ninth International IBPSA Conference Montréal, Canada (August 15–18, 2005).

- 5.Mani Monto, Pillai Rohit. Impact of dust on solar photovoltaic (PV) performance: research status. Renew. Sustain. Energy Rev. 2010;14:3124–3131. [Google Scholar]

- 6.Rao Abhishek. 12th International Conference on Sustainable Energy Technologies (SET-2013). Hong Kong. 2013. An experimental investigation into the interplay of wind, dust and temperature on photovoltaic performance in tropical conditions. [Google Scholar]

- 7.Qasem H. 7th Photovoltaic Science Application and Technology (PVSAT-7) Conference and Exhibition. Edinburgh, Scotland. 2011. Dust effect on PV modules. [Google Scholar]

- 8.Appels R., Muthirayan B., Beerten A., Paesen R., Driesen J., Poortmans J. 38th IEEE Photovoltaic Specialists Conference. Austin, Texas. 2012. The effect of dust deposition on photovoltaic modules. [Google Scholar]

- 9.Appels Reinhart. Effect of soiling on photovoltaic modules. Sol. Energy. 2013;96:283–291. [Google Scholar]

- 10.Boyle Liza, Flinchpaugh Holly, Hannigan Michael. 39th Photovoltaic Specialists Conference (PVSC) IEEE; Florida: 2013. Impact of natural soiling on the transmission of PV cover plates. [Google Scholar]

- 11.Said Syed A.M., Walwil Husam M. Fundamental studies on dust fouling effects on PV module performance. Sol. Energy. 2014;107:328–337. [Google Scholar]

- 12.Webera Bernd. Performance reduction of PV systems by dust deposition. Energy Procedia. 2014;57:99–108. [Google Scholar]

- 13.John Jim J., Rajasekar Vidyashree, Boppana Sravanthi, Chattopadhyay Shashwata, Kottantharayil Anil, TamizhMani Govindasamy. Quantification and modeling of spectral and angular losses of naturally soiled PV modules. IEEE J. Photovolt. November 2015;5(6) [Google Scholar]

- 14.Khanum Khadija K. 2016 IEEE 43rd Photovoltaic Specialists Conference. Portland, OR. 2016. Performance evaluation for PV systems to synergistic influences of dust, wind and panel temperatures: spectral insight. [Google Scholar]

- 15.Kaldellis J.K., Kokala A. “Quantifying the decrease of the photovoltaic panels’ energy yield due to phenomena of natural air pollution disposal. Energy. 2010;35:4862–4869. [Google Scholar]

- 16.Jiang Hai, Lu Lin, Sun Ke. Experimental investigation of the impact of airborne dust deposition on the performance of solar photovoltaic (PV) modules. Atmos. Environ. 2011;45:4299–4304. [Google Scholar]

- 17.Boykiw Elizabeth. Allegheny College; Meadville, PA: 2011. The Effect of Settling Dust in the Arava valley on the Performance of Solar Photovoltaic Panels. Senior thesis. [Google Scholar]

- 18.Ndiaye Ababacar. Impact of dust on the photovoltaic (PV) modules characteristics after an exposition year in Sahelian environment: the case of Senegal. Int. J. Phys. Sci. 2013;8(21):1166–1173. [Google Scholar]

- 19.Adinoyi Muhammed J., Said Syed A.M. Effect of dust accumulation on the power outputs of solar photovoltaic modules. Renew. Energy. 2013;60:633–636. [Google Scholar]

- 20.Rao A., Pillai R., Mani M., Ramamurthy P. Influence of dust deposition on photovoltaic panel performance. Energy Procedia. 2014:690–700. [Google Scholar]

- 21.Piliougine M. Comparative analysis of energy produced by photovoltaic modules with anti-soiling coated surface in arid climates. Appl. Energy. 2013;112:626–634. [Google Scholar]

- 22.Kalogirou Soteris A., Agathokleous Rafaela, Panayiotou Gregoris. On-site PV characterization and the effect of soiling on their performance. Energy. 2013;51:439–446. [Google Scholar]

- 23.Ahmed M.A.M., Ali Ahmed Hamza H. International Conference on Renewable Energy Research and Applications. Madrid, Spain. 2013. Effect of dust deposition on performance of thin film photovoltaic module in harsh humid climate. [Google Scholar]

- 24.Klugmann-Radziemska Ewa. Degradation of electrical performance of a crystalline photovoltaic module due to dust deposition in northern Poland. Renew. Energy. 2015;78:418–426. [Google Scholar]

- 25.Ali Hafiz Muhammad. Effect of dust deposition on the performance of photovoltaic modules in taxila, Pakistan. Therm. Sci. 2014 [Google Scholar]

- 26.Urrejola Elias. Effect of soiling and sunlight exposure on the performance ratio of photovoltaic technologies in Santiago, Chile. Energy Convers. Manag. 2016;114:338–347. [Google Scholar]

- 27.John Jim J., Warade Sonali, Tamizhmani Govindasamy, Kottantharayil Anil. Study of soiling loss on photovoltaic modules with artificially deposited dust of different gravimetric densities and compositions collected from different locations in India. IEEE J. Photovolt. JANUARY 2016;6:1. [Google Scholar]

- 28.Qasem Hassan. Dust-induced shading on photovoltaic modules. Prog. Photovoltaics Res. Appl. 2014;22:218–226. [Google Scholar]

- 29.Al-Ammri . 2013 International Renewable and Sustainable Energy Conference (IRSEC) IEEE; Morocco: 2013. Dust effects on the performance of PV street light in Baghdad city. [Google Scholar]

- 30.Bekir Sami Yilbas. Influence of dust and mud on the optical, chemical, and mechanical properties of a pv protective glass. Sci. Rep. 2015;5:15833. doi: 10.1038/srep15833. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Kazmerski Lawrence L. Fundamental studies of adhesion of dust to pv module surfaces: chemical and physical relationships at the microscale. IEEE J. Photovolt. 2016;6(3):719–729. [Google Scholar]

- 32.Kazem H.A., Chaichan M.T., Saif S.A., Dawood A.A., Salim S.A., Rashid A.A., Alwaeli A.A. Experimental investigations of dust type effect on photovoltaic systems in North region, Oman. Int. J. Sci. Eng. Res. 2015;6(7):293–298. [Google Scholar]

- 33.Mani Fani, Subrahmanyam Pulipaka, Kumar Rajneesh. Characterization of power losses of a soiled PV panel in Shekhawati region of India. Sol. Energy. 2016;131:96–106. [Google Scholar]

- 34.Sulaiman Shaharin A. Effects of dust on the performance of PV panels. World Acad. Sci. Eng. Technol. 2011:588–593. [Google Scholar]

- 35.Alnaser N.W. Dust accumulation study on the Bapco 0.5 MWp PV project at University of Bahrain. Int. J. Power Renew. Energy Syst. 2015;2(1):38–54. [Google Scholar]

- 36.Chaichan Miqdam T., Mohammed Bashar A., Kazem Hussein A. Effect of pollution and cleaning on photovoltaic performance based on experimental study. Int. J. Sci. Eng. Res. 2015;6(4):594–601. [Google Scholar]

- 37.Isaifan R.J. Theoretical and experimental characterization of efficient anti-dust coatings under desert conditions. J. Thin Films Res. 2018;2(1):25–29. [Google Scholar]

- 38.Roesch C. American Geophysical Union, Fall General Assembly; San Francisco: 2016. The Influence of mineral Dust Particles on the Energy Output of Photovoltaic Cells. abstract id. GC51C-1168. [Google Scholar]

- 39.Kaldellis J.K., Kapsali M. Simulating the dust effect on the energy performance of photovoltaic generators based on experimental measurements. Energy. 2011;36:5154–5161. [Google Scholar]

- 40.Sanusi Y.K. The performance of amorphous silicon PV system under Harmattan dust conditions in a tropical area. Pac. J. Sci. Technol. 2012;13(1):168–175. [Google Scholar]

- 41.El-Shobokshy Mohammad S., Hussein Fahmy M. Degradation of photovoltaic cell performance due to dust deposition on to its surface. Renew. Energy. 1993;3(6/7):585–590. [Google Scholar]

- 42.Mekhilefa S., Saidurb R., Kamalisarvestani M. Effect of dust, humidity and air velocity on efficiency of photovoltaic cells. Renew. Sustain. Energy Rev. 2012;16:2920–2925. [Google Scholar]

- 43.Beattie Neil S. Understanding the effects of sand and dust accumulation on photovoltaic modules. Renew. Energy. 2012;48:448–452. [Google Scholar]

- 44.Hassan Qasem, Betts Thomas R., Gottschalg Ralph. 2011 37th IEEE Photovoltaic Specialists Conference (PVSC) IEEE; 2011. Effect of shading caused by dust on cadmium telluride photovoltaic modules. [Google Scholar]

- 45.Suellen C.S. Costa, Diniz Antonia Sonia A.C., Lawrence Kazmerski. Dust and soiling issues and impacts relating to solar energy systems: literature review update for 2012–2015. Renew. Sustain. Energy Rev. 2016;63:33–61. [Google Scholar]

- 46.Ibrahim A. Effect of shadow and dust on the performance of silicon solar cell. J. Basic Appl. Sci. Res. 2011;1(3):222–230. [Google Scholar]

- 47.Kaldellis J.K., Fragos P. Ash deposition impact on the energy performance of photovoltaic generators. J. Clean. Prod. 2011;19:311–317. [Google Scholar]

- 48.Kaldellis J.K., Fragos P., Kapsali M. Systematic experimental study of the pollution deposition impact on the energy yield of photovoltaic installations. Renew. Energy. 2011;36:2717–2724. [Google Scholar]

- 49.Ju Fali, Fu Xiangzhao. 2011 International Conference on Electrical and Control Engineering (ICECE) IEEE; 2011. Research on impact of dust on solar photovoltaic (PV) performance. [Google Scholar]

- 50.Kazem, Hussein A. Effect of dust deposition on the performance of multi-crystalline photovoltaic modules based on experimental measurements. Int. J. Renew. Energy Resour. 2013;3(4):850–853. [Google Scholar]

- 51.Qasem H., Betts T.R., Gottschalg R. Spatially-resolved modelling of dust effect on cadmium telluride photovoltaic modules. Sol. Energy. 2013;90:154–163. [Google Scholar]

- 52.Al-Busairi Hasan Ali, Möller Hans Joachim. 25th European Photovoltaic Solar Energy Conference and Exhibition/5th World Conference on Photovoltaic Energy Conversion. Valencia, Spain. 2010. Performance evaluation of CdTe PV modules under natural outdoor conditions in Kuwait. [Google Scholar]

- 53.Zorrilla-Casanova J. World Renewable Energy Congress-2011. Linkoping, Sweden. 2011. Analysis of dust losses in photovoltaic modules. [Google Scholar]

- 54.Mohamed Ali Omar, Hasan Abdulazez. Effect of dust accumulation on performance of photovoltaic solar modules in Sahara environment. J. BasicAppl. Sci. Res. 2012;2(11):11030–11036. [Google Scholar]

- 55.Bashar H., Ali A.-S., Mohammad A.A., Salem N., Ahmed A.-G. Performance and economic comparison of fixed and tracking photovoltaic systems in Jordan. Renew. Sustain. Energy Rev. 2017;80:827–839. [Google Scholar]

- 56.Kenny Robert P. Performance of thin film PV modules. Thin Solid Films. 2006:663–672. [Google Scholar]

- 57.Khanum Khadija K., Mani Monto, Ramamurthy Praveen C. 32nd European Photovoltaic Solar Energy Conference and Exhibition (EUPVSEC). Munich. 2016. Spectral studies investigating the influence of dust on solar transmittance. [Google Scholar]

- 58.Motasem Saidan. Experimental study on the effect of dust deposition on solar photovoltaic panels in desert environment. Renew. Energy. 2016;92:499–505. [Google Scholar]

- 59.Umer Mehmood, Al-Sulaiman Fahad A., Yilbas B.S. Characterization of dust collected from PV modules in the area of Dhahran, Kingdom of Saudi Arabia, and its impact on protective transparent covers for photovoltaic applications. Sol. Energy. 2017;141:203–209. [Google Scholar]

- 60.Makbul A.M. Ramli. On the investigation of photovoltaic output power reduction due to dust accumulation and weather conditions. Renew. Energy. 2016;99:836–844. [Google Scholar]

- 61.Aslan Gholami, Ahmad Saboonchi, Ali Akbar Alemrajabi. Experimental study of factors affecting dust accumulation and their effects on the transmission coefficient of glass for solar applications. Renew. Energy. 2017;112:466–473. [Google Scholar]

- 62.Sulaimana Shaharin Anwar. Influence of dirt accumulation on performance of PV panels. Energy Procedia. 2014;50:50–56. [Google Scholar]

- 63.Ghadeer Al-Shabaan. Effects of dust grain size and density on the monocrystalline PV output power. Int. J. Appl. Sci. Technol. 2016;6(1):81–86. [Google Scholar]

- 64.Siddiqui Rahnuma, Bajpai Usha. Correlation between thicknesses of dust collected on photovoltaic module and difference in efficiencies in composite climate. Int. J. Energy Environ. Eng. 2012;3:26. [Google Scholar]

- 65.Pavan A. Massi, Mellit A., De Pieri D. The effect of soiling on energy production for large-scale photovoltaic plants. Sol. Energy. 2011;85:1128–1136. [Google Scholar]

- 66.Basant Raj Paudyal, Shree Raj Shakya. Dust accumulation effects on efficiency of solar PV modules for off grid purpose: a case study of Kathmandu. Sol. Energy. 2016;135:103–110. [Google Scholar]

- 67.Bashar Hammad. Modeling and analysis of dust and temperature effects on photovoltaic systems' performance and optimal cleaning frequency: Jordan case study. Renew. Sustain. Energy Rev. 2018;82(3):2218–2234. [Google Scholar]

- 68.Mejia Felipe A., Jan Kleissl. Soiling losses for solar photovoltaic systems in California. Sol. Energy. 2013;95:357–363. [Google Scholar]

- 69.Caron J. Riley, Littmann Bodo. Direct monitoring of energy lost due to soiling on first solar modules in California. IEEE J. Photovolt. 2013;3(1):336–340. [Google Scholar]

- 70.Cano Jose. Arizona State University; 2011. Photovoltaic Modules: Effect of Tilt Angle on Soiling. Diss. [Google Scholar]

- 71.El-Shobokshy M.S., Mujahid A., Zakzouk A.K.M. IEE Proceedings. 1985. Effects of dust on the performance of concentrator photovoltaic cells. [Google Scholar]

- 72.Dirk Goossens, Van Kerschaever Emmanuel. Aeolian dust deposition on photovoltaic solar cells: the effects of wind velocity and airborne dust concentration on cell performance. Sol. Energy. 1999;6(4):277–289. [Google Scholar]

- 73.Zakzouk A.K.M. IEE Proceedings. 1984. On the dust-equivalent series resistance of a photovoltaic concentrator. [Google Scholar]

- 74.Cynthia M. Katzan, Brinker David J., Robert Kress. NASA Lewis Research Center; Cleveland, Ohio: 1991. The Effects of Lunar Dust Accumulation on the Performance of Photovoltaic Arrays. [Google Scholar]

- 75.Suresh Kumar E., Sarkar Bijan, Behera D.K. Soiling and dust impact on the efficiency and the maximum power point in the photovoltaic modules. Int. J. Eng. Res. Technol. 2013;2(2) [Google Scholar]

- 76.Al Hasan Ahmad Y., Ghoneim Adel A. A new correlation between photovoltaic panel's efficiency and amount of sand dust accumulated on their surface. Int. J. Sustain. Energy. 2007;24(4):187–197. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.