Abstract

For effective application of electrospinning and electrospun fibrous meshes in wound dressing, we have in situ electrospun poly(vinyl pyrrolidone)/iodine (PVP/I), PVP/poly(vinyl pyrrolidone)-iodine (PVPI) complex, and poly(vinyl butyral) (PVB)/PVPI solutions into fibrous membranes by a handheld electrospinning apparatus. The morphologies of the electrospun fibers were examined by SEM, and the hydrophobicity, gas permeability, and antibacterial properties of the as-spun meshes were also investigated. The flexibility and feasibility of in situ electrospinning PVP/I, PVP/PVPI, and PVB/PVPI membranes, as well as the excellent gas permeabilities and antibacterial properties of the as-spun meshes, promised their potential applications in wound healing.

Electronic supplementary material

The online version of this article (10.1186/s11671-018-2733-9) contains supplementary material, which is available to authorized users.

Keywords: In situ electrospinning, PVPI fibrous meshes, Wound dressing

Background

Thanks to the advantages of easy large-scale production, huge surface-area-to-volume ratio, high porosity, and tunable inner structures [1–4], electrospun fibrous meshes have attracted a lot of interests in various fields such as filtration [5, 6], medical care [7–12], and energy [13, 14]. Electrospun fibrous membranes are suitable for wound dressing due to their nanoscale structures which mimic the collagen fibrils of the native extracellular matrix and human organs [9, 11], and then, the as-spun meshes can not only physically protect the wound from contaminants and infections, but also provide an ideal environment for skin regeneration through maintaining an adequate exchange of gases, as well as promoting hemostasis phase and avoiding scar induction [9, 11, 12].

Among the thousands of suitable electrospun materials, poly(vinyl pyrrolidone) (PVP) and poly(vinyl butyral) (PVB) are two important polymers for their excellent biocompatibility, nontoxicity, good solubility in alcohol, and so on [15–18]. Consequently, the as-spun PVP and PVB fibrous materials have been popularly applied for wound dressing [18–20]. Moreover, PVP in combination with iodine forms a complex called PVP-iodine (PVPI) and has been a highly efficient and widely used disinfectant for its small stimulation, low toxicity, light pollution, broad-spectrum bactericidal effect, and nonresistance of the microorganisms for even longtime using [21–24]. Nevertheless, PVPI is not recommended for long-term use or for complex wounds [25]. Electrospun PVP-I-based fibers may be a helpful solution and have been reported by several groups [26–33]. Ignatova et al. had prepared PVPI or poly(ethylene oxide) (PEO)/PVP-I fibers by directly electrospinning PVPI or PEO/PVP-I solutions or by crosslinking PVP and PEO/PVP mats and treating them with iodine vapor or iodine solution [26]. Wang had fabricated PVPI nanofibers by electrospinning PVP, iodine, and absolute ethanol solutions, and the characterization of as-spun fibers from infrared spectra, Raman spectra, and X-ray diffraction ensures the formation of PVPI complex [27]. Uslu et al. have reported series of PVPI-based electrospun fibers such as poly(vinyl alcohol) (PVA)/PVPI [28], PVA/PVPI/poly(ethylene glycol) (PEG) fibers containing (hydroxypropyl)methyl cellulose (HPMC) and aloe vera [29], PVA/PVPI nanofibers with additional chitosan and poloxamer 188 [30], and PVA/poly(acrylic acid) (PAA)/PVPI fibers [31]. All these PVPI fibers were known to show potential applications in wound dressing, however, mostly focused on the morphologies and thermal stability of the as-spun fibers/meshes. Hong et al. have reported PLLA/PVPI/TiO2 multicomponent ultrathin fibrous nonwovens by electrospinning and iodine vapor treatment [32]. It was found that the existence of PVPI endowed the nonwoven with water absorbability, antimicrobial activity, adhesive ability, and transformable characteristic from hydrophilicity to non-hydrophilicity. Sebe et al. have prepared PVP/poly(vinylpyrrolidone-vinylacetate)/iodine nanofibers with different polymer ratios by a high-speed rotary spinning technique. Except for the detailed morphological analysis, the supramolecular structure and antimicrobial activity of the obtained mats were also investigated, which suggested the potential applications in wound dressing [33]. However, for practical applications, these PVPI electrospun fibers can only be fabricated based on predesigned models and then implanted onto the patient wound, which may lead to the second injuries to the wound. In situ electrospinning might solve this problem.

In this paper, we have in situ electrospun iodine-based PVP and PVB solutions into fibrous meshes by a hand-held portable electrospinning apparatus. The morphology, hydrophobicity, gas permeability, and antibacterial property of the as-spun meshes were examined. Moreover, the effects of iodine concentrations on these properties were also investigated. Furthermore, the flexibility and feasibility of in situ electrospun iodine-based fibrous mats were presented, and then, the application for wound dressing can be expected.

Methods/Experimental

Materials

Polyvinylpyrrolidone (PVP, 250 kDa, Sinopharm Chemical Reagent Co., Ltd., China) was dissolved in ethanol (Sinopharm Chemical Reagent Co., Ltd., China) at 13 wt%. Poly(vinyl butyral) (PVB) (100 kDa, Sinopharm Chemical Reagent Co., Ltd., China) was dissolved in ethyl alcohol at 10 wt%. Iodine (Analytical reagent, Sinopharm Chemical Reagent Co., Ltd., China) was added into PVP/ethanol solutions at concentration of 1 wt%, 2 wt%, and 5 wt%, respectively. Poly(vinylpyrrolidone)-iodine complex (PVPI, Sinopharm Chemical Reagent Co., Ltd., China) was dissolved in the PVP/ethanol and PVB/ethanol solutions at 1 wt%, 2 wt%, and 5 wt%, respectively. The complex solutions were agitated at room temperature under constant stirring for at least 24 h before electrospinning. Modified simulated body fluid (SBF) was purchased from Sinopharm Chemical Reagent Co., Ltd., China.

Electrospinning Process

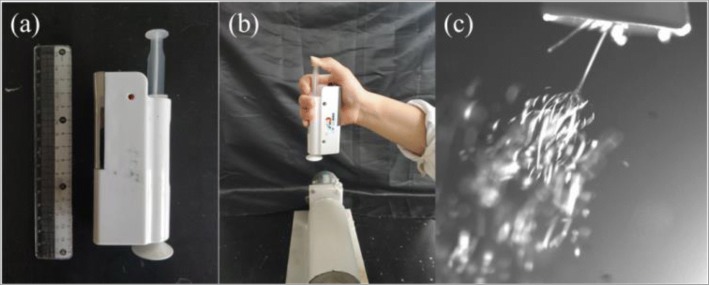

The prepared solutions were placed into a 5-mL syringe equipped with a nozzle with a diameter of 0.1 mm, and then loaded into the hand-held portable electrospinning apparatus (HHE-1, Qingdao Junada Technology Co., Ltd), as shown in Fig. 1a. The high voltage of this device is about 10 kV fixed [34, 35]. During the in situ electrospinning process, one can firstly operate the device and then press the syringe by a finger. The as-spun fibers can be fabricated and then deposited onto the collector, as suggested in Fig. 1b. The electrospinning jets by this device can be caught by a high-speed camera, which is shown in Fig. 1c. For the further examinations of the in situ electrospun fibrous meshes, we also in situ electrospun these fibers onto an aluminum foil collector with distance of 8 cm. The collected meshes were uncovered from the aluminum foil for further characterization.

Fig. 1.

The handheld electrospinning apparatus (a) and the in situ electrospinning process (b). The electrospinning jets can be seen from the spinneret (c)

Characterization

The morphology and energy dispersive system (EDS) of the as-spun fibers were examined by a scanning electron microscope (SEM, Phenom ProX, Phenom Scientific Instruments Co., Ltd., China) at 10 kV, and all samples were coated with gold for 30 s before analysis. The Fourier transform infrared spectroscopy (FTIR) spectrums were measured by a Thermo Scientific Nicolet iN10 spectrometer. The simulated body fluid (SBF) contact angle was examined by a Contact Angle Analyzer (JY-PHb, China) with a 2-μL SBF droplet. Based on ASTM D 737 standard, the air permeability under a pressure drop of 200 Pa was tested by an air permeability tester (Textest FX3300). Pore sizes of the as-spun fibrous meshes were examined by PSM 165 (Germany, Topas GmbH, PSM 165) at pressure of 200 Pa. The antibacterial properties of the as-spun meshes were investigated against Escherichia coli (E. coli, ATCC 10536) and Staphylococcus aureus (S. aureus, ATCC 25923) bacteria. Bacterial cells of E. coli (ATCC 10536) and S. aureus (ATCC 25923) were grown for 24 h on a shaker at 37 °C and 100 rpm.

Results and Discussion

Morphologies of Electrospun Fibers

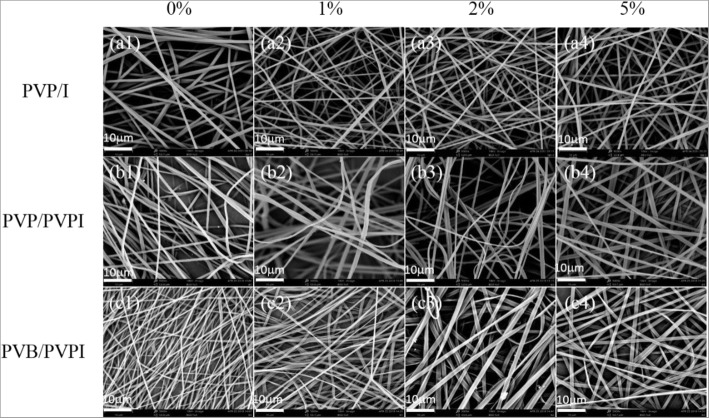

By the HHE-1 apparatus as shown in Fig. 1, the prepared PVP/I, PVP/PVPI, and PVB/PVPI solutions can be electrospun into fibers conveniently. The morphologies of the as-fibers could be found from the SEM images shown in Fig. 2. From the SEM images, one can obviously find that the electrospun fibers displayed smooth surfaces, while the diameters of the as-spun fibers showed different distributions because of the different materials and concentrations. Combining SEM images and the data in Table 1 comprehensively, it is shown that for PVP/I fibers, as the concentration of iodine increasing, the average diameter of the as-spun fibers decreased obviously, which may due to the higher conductivity of the solutions as iodine is added [36]. While for PVP/PVPI and PVB/PVPI, the average diameters of the as-spun fibers were both increased with higher concentration of PVPI, which may result from the increasing of viscosities of the mixed solutions [37].

Fig. 2.

SEM images of the as-spun PVP/I (a1–a4), PVP/PVPI (b1–b4), PVB/PVPI (c1–c4) fibers with I or PVPI concentrations of 0%, 1%, 2%, and 5%, respectively

Table 1.

The average diameter of PVP/I, PVP/PVPI, and PVB/PVPI fibers with different doping concentrations of iodine and PVPI, with unit of nanometer

| Materials | 0% | 1% | 2% | 5% |

|---|---|---|---|---|

| PVP-I | 857 ± 14 | 852 ± 259 | 724 ± 132 | 511 ± 134 |

| PVP-PVPI | 857 ± 14 | 948 ± 89 | 1092 ± 216 | 1445 ± 351 |

| PVB-PVPI | 523 ± 81 | 849 ± 194 | 1231 ± 332 | 1485 ± 242 |

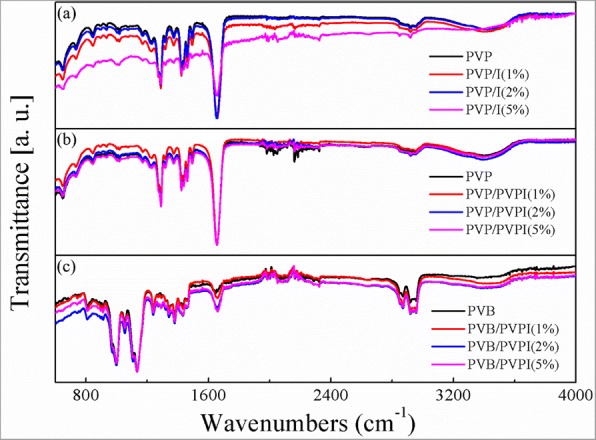

EDS and FTIR

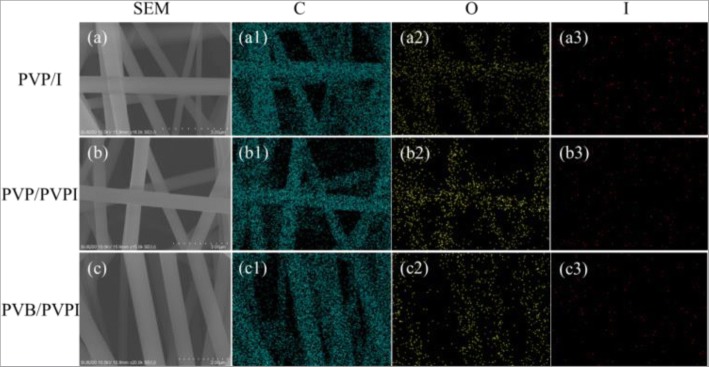

To achieve the antibacterial properties and then benefit the wound healing application, iodine played the crucial role in the electrospun fibers. To verify the existence of iodine, EDS was examined in the model of full spectrum analysis. As displayed in Fig. 3, we chose the as-spun fibers with higher concentrations of I/PVPI, 5%, for example, and the images showed that in each kind of electrospun fibers, except for the mainly carbon (Fig. 3 (a1), (b1), and (c1)) and oxygen (Fig. 3 (a2), (b2), and (c2)) elements in the polymers, extra iodine element was also observed (Fig. 3 (a3), (b3), and (c3)). Moreover, the iodine added into the PVP solutions directly showed a high concentration of iodine other than PVPI added. Although the iodine could be found in the EDS images, one can obviously find from Fig. 3 that the content of iodine is small compared with other elements. The same conclusion can be obtained from the FTIR spectra in Fig. 4.

Fig. 3.

Different elements of EDS images of the as-spun PVP/I (a–a3), PVP/PVPI (b–b3), PVB/PVPI (c–c3) fibers with 5% I/PVPI doping

Fig. 4.

FTIR spectra of the as-spun fibers PVP/I (a), PVP/PVPI (b), PVB/PVPI (c)

Fig. 4a–c showed the FTIR spectra of the as-spun fibers with different concentration of different additions. As can be seen from Fig. 4, the additions of iodine or PVPI do not change the chemical structures of the polymers obviously, which may due to the small quantity of the additions. The unchanged polymers also ensured the stability of the polymers for wound healing, without any other uncertainties.

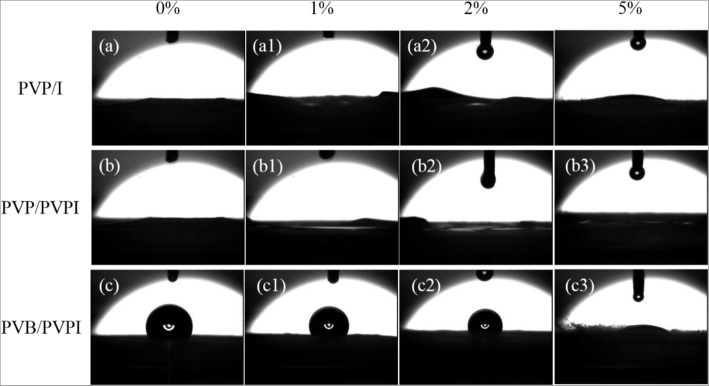

Wettability

Furthermore, it was believed that an ideal wound dressing should include some advantages such as maintenance of wound hydration and absorption of excess wound exudate, which may require the wettability of the designed wound dressing [5, 7–9]. Consequently, we also examined the hydrophilicity of the as-spun fibrous meshes by measuring their SBF contact angles. As suggested in Fig. 5, the three kinds of electrospun fibrous membranes all exhibited good hydrophilicity with the increasing concentration of iodine and PVPI. For PVP-based meshes, due to the hydrophilicity of the polymer, the electrospun fibrous meshes also established small SBF contact angles, and the angle increased to 19.5° for PVP/I, as shown in Fig. 5 (a–a3) and (b–b3). The increased SBF contact angles may result from the increasing surface roughness of these meshes. However, the case in PVB-based meshes was different. In our previous study, it had been pointed out that electrospun PVB fibrous meshes showed hydrophobicity due to its unequal structures [38]. In the absence of PVPI, the PVB electrospun meshes showed the similar contact angle case as can be seen in Fig. 5(c). As PVPI is doped in PVB, the SBF contact angle decreased and rapidly to zero with PVPI higher than 2%, which indicated that PVPI increased the hydrophilicity of the as-spun fibrous meshes. The good hydrophilicity of these fibrous meshes ensured the ability of absorption of excess wound exudate and then would be beneficial for wound dressing applications.

Fig. 5.

SBF contact examination of the as-spun fibers PVP/I (a–a3), PVP/PVPI (b–b3), PVB/PVPI (c–c3) with different iodine/PVPI concentrations

Air Permeability

An ideal wound dressing also requires good air permeability to provide a positive environment for wound healing [9, 11–13]. Here, we also investigated the air permeability of these kinds of iodine-doped fibrous meshes, as shown in Table 2. As can be found in Table 2, with the increasing doping of iodine in PVP, the air permeability was also increased from 59.92 to 324.3 mm s−1, which may result from the decreased diameter and increased porosity, while the air permeability of fibrous meshes with PVPI doped in PVP and PVB does not show obviously trends. Nevertheless, the 5% doping ones show better gas permeability than the pure polymers. For comparison, we also tested the air permeability of two traditional wound dressings (TWD) bought from the market. It is clear that the designed electrospun fibrous wound dressings establish better air permeability than the ones on the market.

Table 2.

Air permeability of the electrospun fibrous mats and two kinds of TWD (traditional wound dressing), with unit of mm s−1

| Materials | 0% | 1% | 2% | 5% |

|---|---|---|---|---|

| PVP/I | 59.92 ± 8.51 | 68.3 ± 12.87 | 95.68 ± 4.83 | 324.3 ± 31.74 |

| PVP/PVPI | 59.92 ± 8.51 | 143 ± 16.83 | 89.93 ± 7.12 | 73.19 ± 2.64 |

| PVB/PVPI | 44.99 ± 5.54 | 21.66 ± 2.60 | 72.08 ± 7.75 | 74.16 ± 7.41 |

| TWD 1 | 8.45 ± 1.56 | – | – | |

| TWD 2 | 17.82 ± 2.12 | – | – |

For further examination of the air permeability, we tested the pore size and pore distribution of the as-spun meshes. As shown in Table 3, the average pore sizes of the as-spun meshes were listed. Generally, the bigger the average pore size, the better air permeability, compared with the data in Table 2. Moreover, the pore sizes of the as-spun fibrous meshes were mainly uniform, with the largest portion at the mean sizes, which can be found in Additional file 1: Figure S1. The pore sizes of these electrospun meshes were in the region of 1.936–9.152 μm, matching the human tissue cells sizes, which would be beneficial for wound healing. However, due to the instrument precision, the pore sizes of the TWD were too small to be tested, which may result in the poor air permeability of them.

Table 3.

Average pore sizes of the electrospun fibrous mats, with unit of micrometer

| Materials | 0% | 1% | 2% | 5% |

|---|---|---|---|---|

| PVP/I | 2.357 ± 0.395 | 2.831 ± 0.634 | 4.353 ± 1.211 | 9.152 ± 2.274 |

| PVP/PVPI | 2.357 ± 0.395 | 5.996 ± 2.306 | 5.185 ± 0.904 | 4.274 ± 1.174 |

| PVB/PVPI | 3.732 ± 0.964 | 1.936 ± 0.518 | 3.792 ± 1.366 | 4.786 ± 1.192 |

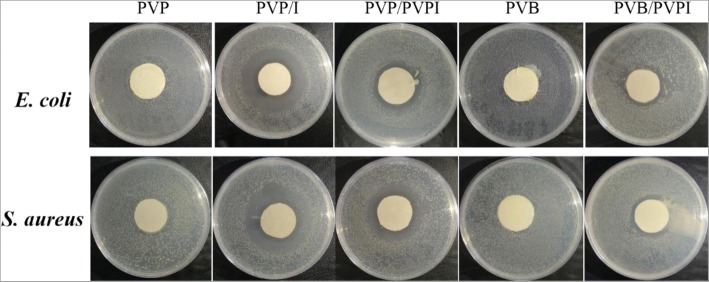

Antibacterial Activity

Another requirement for ideal wound dressing is asepsis and even antibiosis to prevent and treat wound infections [11–13]. In this work, the iodine and PVPI doping are rightly to achieve that. The antibacterial activities of the as-spun fibrous meshes were assessed against typical pathogenic bacteria, such as E. coli and S. aureus, as displayed in Fig. 6. From Fig. 6, one can find that no bacteriostatic circle was formed for pure PVP or PVB. Once iodine or PVPI was doped in the polymer, the as-spun fibrous membranes showed obvious inhibition zones for the two bacterial strains after 24 h intervals. Moreover, the iodine-doped PVP showed the best antibacterial properties against both E. coli and S. aureus, the PVPI-doped PVP taking the second place and PVB/PVPI last. The good antibacterial properties ensured that the iodine-based electrospun fibrous meshes could be used for wound healing against bacterial infections of the wound. Moreover, it can be expected that the higher the concentration of the additional antibacterials, the better the antibacterial properties of the meshes. Consequently, one can easily get better antibacterial properties by adding more iodine or PVPI in their solutions.

Fig. 6.

The antibacterial activity of the as-spun membranes against E. coli and S. aureus

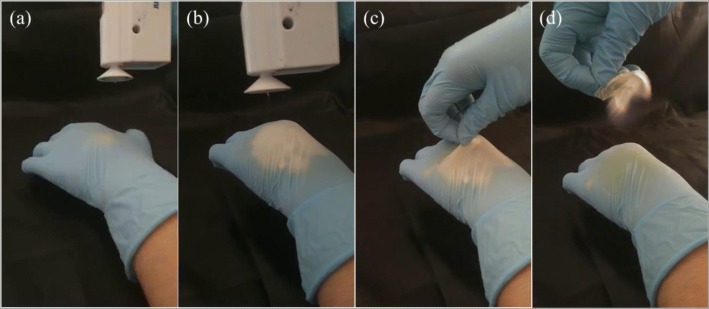

In Situ Applications

It is believed that in situ wound dressing will benefit their efficiency due to additional superiority such as conformability without wrinkling or fluting in the wound bed, ease of application, and improved patient compliance and comfort [39]. Consequently, in situ electrospinning is considered as a useful concept to produce appropriate substitutes for tissue repairing and wound healing directly on the patient’s lesion independently of wound size and depth [18, 34, 35, 40, 41]. As shown in Fig. 7a, b, the iodine-based fibrous meshes can be in situ electrospun onto the “injured hand” by the HHE-1 device and form a thin film on the surface of the skin like a second layer of skin due to electrostatic attraction forces. The electrospun PVP-I fibrous membrane shows good flexibility and compactness and can be easily removed if needed [see Fig. 7c, d). The more vivid details of in situ electrospinning of PVP-I wound dressing can be found in Additional file 1: Video S1 and S2 and Figure S2.

Fig. 7.

In situ applications of the handheld apparatus and iodine-based electrospun fibrous mats. By the HHE-1, one can easily in situ electrospun iodine-based PVP/I mesh onto the “injured hand” (a–b), the electrospun mats can be easily removed from the “wound bed” (c–d)

Conclusions

In summary, we have in situ electrospun PVP/I, PVP/PVPI, and PVB/PVPI into fibrous membranes by a hand-held electrospinning apparatus. These electrospun meshes show uniform diameters and better hydrobilicity with doping of iodine or PVPI. Moreover, the good air permeability of blend PVP/I, PVP/PVPI, and PVB/PVPI electrospun meshes ensures their application in wound dressing. The increased concentrations of iodine and its complex favor the antibacterial properties of these meshes and then improve the effects as wound dressing. Furthermore, the in situ electrospinning also benefits the electrospinning process and the as-spun fibrous meshes for wound healing.

Additional File

Figure. S1. Pore size distribution of the as-spun PVP/I (a-a3), PVP/PVPI (b-b3) and PVB/PVPI(c-c3) fibrous mats with concentration of I/PVPI 0%, 1%, 2% and 5%, respectively. Figure S2. Electrospun PVP-I meshes onto human injured finger, can stem the bleeding quickly, and then heal the wound well. Figure S3. In situ electrospun PVP/I meshes onto human hand and finger, the as-spun meshes showed good conformability on the finger. (ZIP 24007 kb)

Acknowledgments

Funding

This work was supported by the Shandong Provincial Natural Science Foundation, China (ZR2016EMB09), the National Natural Science Foundation of China (51703102, 51373082 and 51673103), and the Shandong Provincial Key Research and Development Plan (2016GGX102011 and 2018GGX103049).

Availability of Data and Materials

All data generated or analyzed during this study are included in this published article and its supplementary information files.

Abbreviations

- E. coli

Escherichia coli

- EDS

Energy dispersive system

- FTIR

Fourier transform infrared spectroscopy

- HPMC

(Hydroxypropyl)methyl cellulose

- PAA

Poly(acrylic acid)

- PEG

Poly(ethylene glycol)

- PEO

Poly(ethylene oxide)

- PVA

Poly(vinyl alcohol)

- PVB

Poly(vinyl butyral)

- PVP

Poly(vinyl pyrrolidone)

- PVP/I

Poly(vinyl pyrrolidone)/iodine

- PVPI

Poly(vinyl pyrrolidone)-iodine

- S. aureus

Staphylococcus aureus

- SEM

Scanning electron microscope

- WCA

Water contact angle (WCA)

Authors’ Contributions

GSL, XY, and SJC designed the experiments. GSL and FFY prepared the fibrous meshes. GSL, FXC, TL, and LYH collected and analyzed the data of the scanning electron microscopy, FTIR, and pore sizes. GSL and SJC collected and analyzed the antibacterial properties. FXC, XN, and YZL revised the manuscript. All authors read and approved the final manuscript.

Competing Interests

The authors declare that they have no competing interests.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Guo-Sai Liu, Email: rl19900628@163.com.

Xu Yan, Email: yanxu-925@163.com.

Fang-Fang Yan, Email: 17863940072@163.com.

Fu-Xing Chen, Email: fuxing1991@gmail.com.

Long-Yun Hao, Email: hly1978@163.com.

Shao-Juan Chen, Email: qdchshj@126.com.

Tao Lou, Email: taolou72@aliyun.com.

Xin Ning, Email: xning@qdu.edu.cn.

Yun-Ze Long, Email: yunze.long@163.com.

References

- 1.Wang Q, Yu DG, Zhang LL, Liu XK, Deng YC, Zhao M. Carbohyd Polym. 2017;174:617–625. doi: 10.1016/j.carbpol.2017.06.075. [DOI] [PubMed] [Google Scholar]

- 2.Yang C, Yu DG, Pan D, Liu XK, Wang X, Bligh SWA, Williams GR. Acta. Biomater. 2016;35(15):77–86. doi: 10.1016/j.actbio.2016.02.029. [DOI] [PubMed] [Google Scholar]

- 3.Yang YY, Liu ZP, Yu DG, Wang K, Liu P, Chen XH. Int J Nanomedicine. 2018;13:2395–2404. doi: 10.2147/IJN.S154849. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Wang K, Liu XK, Chen XH, Yu DG, Yang YY, Liu P. ACS Appl Mater Inter. 2018;10(3):2859–2867. doi: 10.1021/acsami.7b17663. [DOI] [PubMed] [Google Scholar]

- 5.Wang N, Yang Y, Al-Deyab SS, El-Newehy M, Yu JY, Ding B. J Mater Chem A. 2015;3:23946. doi: 10.1039/C5TA06543G. [DOI] [Google Scholar]

- 6.Zhang B, Zhang ZG, Yan X, Wang XX, Zhao H, Guo J, Feng JY, Long YZ. Nanoscale. 2017;9:4154–4161. doi: 10.1039/C6NR09525A. [DOI] [PubMed] [Google Scholar]

- 7.Sun XM, Lang Q, Zhang HB, Cheng LY, Zhang Y, Pan GQ, Zhao X, Yang HL, Zhang YG, Santos HA, Cui WG. Adv Funct Mater. 2017;27:1604617. doi: 10.1002/adfm.201604617. [DOI] [Google Scholar]

- 8.Zahedi P, Rezaeian I, Ranaei-Siadat SO, Jafari SH, Supaphol P. Polym Adv Technol. 2010;21:77–95. doi: 10.1016/S0921-8831(09)00247-7. [DOI] [Google Scholar]

- 9.Pereira RF, Barrias CC, Granja PL, Bartolo PJ. Nanomedicine. 2013;8:603–621. doi: 10.2217/nnm.13.50. [DOI] [PubMed] [Google Scholar]

- 10.Abrigo M, Mcarthur SL, Kingshott P. Macromol Biosci. 2014;14:772. doi: 10.1002/mabi.201300561. [DOI] [PubMed] [Google Scholar]

- 11.Dias JR, Granja PL, Bártolo PJ. Prog Mater Sci. 2016;84:314–334. doi: 10.1016/j.pmatsci.2016.09.006. [DOI] [Google Scholar]

- 12.Mele E. J Mater Chem B. 2016;4:4801–4812. doi: 10.1039/C6TB00804F. [DOI] [PubMed] [Google Scholar]

- 13.Nie GD, Lu XF, Chi MQ, Gao M, Wang C. J Colloid Interface Sci. 2018;509:235–244. doi: 10.1016/j.jcis.2017.09.017. [DOI] [PubMed] [Google Scholar]

- 14.You MH, Wang XX, Yan X, Zhang J, Song WZ, Yu M, Fan ZY, Ramakrishna S, Long YZ. J Mater Chem A. 2018;6:3500. doi: 10.1039/C7TA10175A. [DOI] [Google Scholar]

- 15.Yang QB, Li Z, Hong Y, Zhao Y, Qiu S, Wang C, Wei Y. J Polym Sci B Polym Phys. 2004;42:3721–3726. doi: 10.1002/polb.20222. [DOI] [Google Scholar]

- 16.Teodorescu M, Bercea M. Polym-Plast Technol. 2015;54:923–943. doi: 10.1080/03602559.2014.979506. [DOI] [Google Scholar]

- 17.Posavec D, Dorsch A, Bogner U, Bernhardt G, Nagl S. Microchim Acta. 2011;173:391–399. doi: 10.1007/s00604-011-0573-8. [DOI] [Google Scholar]

- 18.Chui CY, Mouthuy PA, Ye H. Biotechnol Lett. 2018;40:737–744. doi: 10.1007/s10529-018-2522-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Wang L, Chang MW, Ahmad Z, Zheng H, Li JS. Chem Eng J. 2017;307:661–669. doi: 10.1016/j.cej.2016.08.135. [DOI] [Google Scholar]

- 20.Rosa RM, Silva JC, Sanches IS, Henriques C. Mater Lett. 2017;207:145–148. doi: 10.1016/j.matlet.2017.07.046. [DOI] [Google Scholar]

- 21.Eliassaf J. Eur Polym J. 1966;2:269–278. doi: 10.1016/0014-3057(66)90047-4. [DOI] [Google Scholar]

- 22.Rackur H. J Hosp Infect. 1985;6 A:13–23. doi: 10.1016/S0195-6701(85)80041-4. [DOI] [PubMed] [Google Scholar]

- 23.Chaudhary U, Nagpal RC, Malik AK, Kumar A. J Ind Med Assoc. 1998;96:202–204. [PubMed] [Google Scholar]

- 24.Yanai R, Yamada N, Ueda K, Tajiri M, Matsumoto T, Kido K, Nakamura S, Saito F, Nishida T. Cont Lens Anterior Eye. 2006;29:85–91. doi: 10.1016/j.clae.2006.02.006. [DOI] [PubMed] [Google Scholar]

- 25.Daunton C, Kothari S, Smith L, Steele D. Wound Pract Res. 2012;20:174. [Google Scholar]

- 26.Ignatova M, Manolova N, Rashkov I. Eur Polym J. 2007;43:1609–1623. doi: 10.1016/j.eurpolymj.2007.02.020. [DOI] [Google Scholar]

- 27.Wang J. J Jilin Normal Univ (Nat Sci Ed) Chin. 2010;04:033. [Google Scholar]

- 28.Uslu İ, Aytimur A. J Appl Polym Sci. 2012;124:3520–3524. doi: 10.1002/app.35525. [DOI] [Google Scholar]

- 29.Gökmeşe F, Uslu İ, Aytimur A. Polym-Plast Technol. 2013;52:1259–1265. doi: 10.1080/03602559.2013.814144. [DOI] [Google Scholar]

- 30.Aytimur A, Kocyigit S, Uslu İ. Polym-Plast Technol. 2013;52:661–666. doi: 10.1080/03602559.2012.762662. [DOI] [Google Scholar]

- 31.Aytimur A, Uslu İ. Polym-Plast Technol. 2014;53:655–660. doi: 10.1080/03602559.2013.874031. [DOI] [Google Scholar]

- 32.Hong Y, Li Y, Zhuang X, Chen X, Jing X. J Biomed Mater Res A. 2010;89A:345–354. doi: 10.1002/jbm.a.31968. [DOI] [PubMed] [Google Scholar]

- 33.Sebe I, Szabó B, Nagy ZK, Szabó D, Zsidai L, Kocsis B, Zelkó R. Int J Pharm. 2013;458:99–103. doi: 10.1016/j.ijpharm.2013.10.011. [DOI] [PubMed] [Google Scholar]

- 34.Xu SC, Qin CC, Yu M, Dong RH, Yan X, Zhao H, Han WP, Zhang HD, Long YZ. Nanoscale. 2015;7:12351. doi: 10.1039/C5NR02922H. [DOI] [PubMed] [Google Scholar]

- 35.Dong RH, Jia YX, Qin CC, Zhan L, Yan X, Cui L, Zhou Y, Jiang XY, Long YZ. Nanoscale. 2016;8:3482. doi: 10.1039/C5NR08367B. [DOI] [PubMed] [Google Scholar]

- 36.Zhong XH, Kim KS, Fang DF, Ran SF, Hsiao BS, Chu B. Polymer. 2002;43:4403. doi: 10.1016/S0032-3861(02)00275-6. [DOI] [Google Scholar]

- 37.Tan SH, Inai R, Kotaki M, Ramakrishna S. Polymer. 2005;46:6128. doi: 10.1016/j.polymer.2005.05.068. [DOI] [Google Scholar]

- 38.Yan X, You MH, Lou T, Yu M, Zhang JC, Gong MG, Lv FY, Huang YY, Long YZ. Nanoscale Res Lett. 2016;11:540. doi: 10.1186/s11671-016-1763-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Balakrishnan B, Mohanty M, Umashankar PR, Jayakrishnan A. Biomaterials. 2005;26:6335–6342. doi: 10.1016/j.biomaterials.2005.04.012. [DOI] [PubMed] [Google Scholar]

- 40.Mouthuy PA, Groszkowski L, Ye H. Biotechnol Lett. 2015;37:1107–1116. doi: 10.1007/s10529-014-1760-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Yan X, Yu M, Zhang LH, Jia XS, Li JT, Duan XP, Qin CC, Dong RH, Long YZ. Nanoscale. 2016;8:209. doi: 10.1039/C5NR06858D. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Figure. S1. Pore size distribution of the as-spun PVP/I (a-a3), PVP/PVPI (b-b3) and PVB/PVPI(c-c3) fibrous mats with concentration of I/PVPI 0%, 1%, 2% and 5%, respectively. Figure S2. Electrospun PVP-I meshes onto human injured finger, can stem the bleeding quickly, and then heal the wound well. Figure S3. In situ electrospun PVP/I meshes onto human hand and finger, the as-spun meshes showed good conformability on the finger. (ZIP 24007 kb)

Data Availability Statement

All data generated or analyzed during this study are included in this published article and its supplementary information files.