Abstract

The characteristics of frozen rice cakes after thawing them using different methods, such as standing at room temperature (NT), running water (RWT), pan-grill (PT), steam (ST), microwave (MWT), and superheated steam thawing (SHST), were compared. Frozen rice cakes treated by MWT or SHST showed the shortest thawing time of 3 min. The MWT treatment showed the largest thawing loss, while the ST treatment showed the highest moisture content. The ST, RWT, and MWT treatments showed the highest water activity values. The NT treatment exhibited the highest hardness values, whereas the ST treatment showed the lowest values, possibly due to the adverse effects of high temperature on them. Sensory evaluation showed differences in appearance, moistness, and tenderness according to the thawing method, but there was no significant difference in overall acceptability. This study suggests that the qualities of frozen rice cakes varied depending on the different thawing methods.

Keywords: Rice cake, Thawing method, Microwave, Superheated steam, Textural properties

Introduction

The industrialization, urbanization, and globalization of modern society have ushered in various changes, including altered food consumption patterns. These days, people dine out more frequently than they did before, and the demand for convenient food requiring a minimal cooking process is continually increasing.

Home meal replacement (HMR) is defined as ready-to-eat food that can be consumed after heating or precooked foods that partially need to be cooked at home (Chung and Lee, 2007). The size of the domestic HMR market has increased by 35.3% in 2017 compared to the previous year, reaching to 2 trillion KRW (aT, 2016). Recently, the types of HMR foods have diversified. For instance, the consumption of rice cake, which is a suitable dessert, is increasing (Kim et al., 2017). Dduk is Korean traditional rice cakes made with rice flour by steaming, boiling or frying. Rice cake is a popular dessert and can be consumed as a convenience food. Recently, studies on rice cakes have been focused on manufacturing techniques or freezing methods to inhibit retrogradation and minimize changes in food quality during storage (Han et al., 2012; Lee et al., 2017).

A type of steam-cooked rice cake, Garaedduk, is the most widely consumed rice cake in Korea. Garaedduk is the main ingredient of Tteokguk (sliced rice pasta soup), a traditional item during festivals, and Tteokbokki (stir-fried rice cake), a popular street food (Ahn, 2009; Byun, 2014; Kang et al., 2012; Kim and Shin, 2004). Rice cakes contain the nutritional value of a single meal, and are thus a highly promising food product in the Korean market (Yoon and Oh, 2014). However, the main component of rice cakes, starch, undergoes gradual retrogradation with subsequent deterioration in texture and flavor (Kim et al., 1996). In general, retrogradation of starch is influenced by various factors: the specific type of starch, its concentration, the ratio and structure of amylose and amylopectin, storage condition, moisture condition, and additives (Kum et al., 1995). Previous studies of rice cakes have mostly focused on the effect of additives or cooking methods on starch retrogradation, including saccharides (Baker and Rayas-Duarte, 1998), dietary fibers (Kang et al., 1997), emulsifiers (Mun et al., 1996), and enzymes (Song and Park, 2003).

The current market is now distributing ready-to-eat or semi-prepared rice cakes, which can be franchised. Thus, after processing, rice cakes are deep-frozen before delivery to the franchise stores or vendors, where they are thawed before selling to customers. Thawing of frozen food takes more time than freezing because of differences in thermal conductivity and diffusion between ice and water. This indicates that the quality of frozen food products is influenced more greatly by the thawing process than by the freezing process (Hong et al., 2007; Zhu et al., 2004). To thaw food products, air, liquid, or steam can be used to transfer heat from the surface to the center of the food. Recently, microwave thawing has become more popular, as it ensures heat transfer to the interior of a food in a uniform manner within a short period of time in a simple manner (Cho and Park, 2009). Microwave devices are still evolving to ensure more uniformity in cooking, higher energy efficiency, and a shorter length of cooking time. Among such devices, superheated steam has gained attention for improving food quality (Takashi, 2005). Superheated steam has been mainly used to maintain the quality of food products during dehydration or storage. Superheated steam is suggested to reduce the heating time, rendering the food surface crispy and golden with low levels of lipid contents (Kim et al., 2008; Sila et al., 2005). This method is also effective in microbial sterilization, which extends the food shelf-life, and in suppressing browning attributable to vitamin C and lipid oxidation by preventing air contact. Thus, it is important to investigate the effects of different thawing methods on frozen rice cakes, not only to determine the quality of rice cakes, but also to analyze the cost of thawing loss and the time required for the thawing process.

Therefore, this study investigated the quality of Garaedduk rice cakes, which were thawed using various methods: standing at room temperature (NT), running water (RWT), pan-grill (PT), steam (ST), microwave (MWT), and superheated steam thawing (SHST). This study expected to find a suitable thawing method that prevents the loss of rice cake quality. The study also aimed to provide a straightforward method, which can be widely adopted in industries globally, to produce rice cakes in large quantities.

Materials and methods

Manufacturing process for Garaedduk

Garaedduk used in the present study was manufactured according to the method described by Park et al. (2011). The non-glutinous rice grains (cultivar, Illmi) used in this study were obtained from a local mart. The grains were washed three times in water, immersed in water for 3 h, and drained for 30 min. The rice grains were ground into a powder using a blender (LJ-1000, hibell, Hwaseong, Korea). The ground rice powder was passed through a 20-mesh sieve. The manufacture of Garaedduk involved 20 min of re-sifting the rice powder on a loose sieve while pouring water over it, followed by 20 min of steam-cooking, after the heat was dissipated for additional 10 min. The steam-cooked rice batter was injected into a juicer (NJE-3570, NUC, Daegu, Korea) to form Garaedduk. Garaedduk (dimension: 2.8 cm) was cooled at room temperature (25 °C) for 3 h and then packaged it in a 0.2-mm PE film. The moisture content, water activity, and color (L, a, b Hunter scale) of Garaedduk were measured before freezing with values of 48.52%, 0.999, and 71.85, − 1.72, and 5.95, respectively. After packaging, Garaedduk was stored in a − 20 °C electric magnetic refrigerator (KBL-126DY-4D, Panasonic, Osaka, Japan) for 7 days.

Thawing methods

Garaedduk from the refrigerator was thawed using different methods: NT (incubator, 25 °C), RWT (running water, 25 °C), ST (HY-2004-L, Hanyang, Gyeonggi, Korea, 120 °C), PT (LC-81, L’equip, Gyeonggi, Korea, 120 °C), MWT (RE-551B, 2450 MHz, 200 W, Samsung, Gyeonggi, Korea), and SHST (oven 160 °C, steam 400 °C, DFC-240W, Naomoto, Osaka, Japan). After thawing, the samples were left at room temperature (25 °C) until the temperature at the center reached 25 °C using a connecting fiber optic temperature sensor, and the physicochemical properties and sensory properties were then evaluated. Temperature sensor was used with a data logger (176T4, Testo, Germany) and a thermocouple (NiCr-Ni thermocouple, SEF GmbH, Germany). Temperature sensor was connected to central of sample before freezing. The thawing test was conducted in triplicates for each thawing method.

Thawing loss

According to specific methods of thawing, thawing loss is measured for frozen sample until the temperature in center of sample reaches at 25 °C, after which thawing loss is calculated by following formula.

Moisture content

Moisture content (%) was measured using the AOAC method (2000). One gram of sample was dried using the atmospheric pressure drying method (SW-90D, Sang Woo Scientific Co, Bucheon, Korea).

Water activity (aw)

Sliced sample (2 × 2 × 2 cm) was put into a holding cup and aw was measured using the water activity meter (Novasina, Labmaster-aw, Lachen, Switzerland).

Degree of retrogradation

The degree of retrogradation was measured by the α-amylase-iodine method with modification of Tsuge and Hishida method (Tsuge et al., 1990). The method used in this study determined the starch portion complexed with iodine, which was not digestible by α-amylase (EC 3.2.1.1 Type II-A from Bacillus spp., 873 units/mg solid, Sigma, St. Louis, MO, USA). A quantity of Korean rice cake (250 mg) was dissolved in 50 mL of distilled water and homogenized for 3 min using Ultra-turrax (Model No. T25, Janken & Kunkel, Germany). α-amylase (7 units) was dissolved in 5 mL of the homogenized solution. Distilled water (3 mL) and 0.1 M phosphate buffer (2 mL) were added and placed in a shaking water bath at 37 °C for 10 min. After 5 mL of the homogenized solution was added in 3 mL of distilled water and then 0.1 M phosphate buffer 2 mL, 7 units α-amylase solution (EC 3.2.1.1 Type II-A from Bacillus spp., 873 units/mg solid, Sigma, USA) were added, and incubated in a constant temperature water bath for 10 min at 37 °C. After 4 N NaOH solution (5 mL) was added to stop the enzymatic reaction, the solution was adjusted to 4 N HCl and total volume of 100 mL by adding distilled water. Ten milliliters of this solution was reacted with 5 mL of iodine reagent (0.2% I2, 2% KI, w/v) and kept at room temperature(25 °C) for 20 min. Absorbances were measured using a spectrophotometer at 625 nm. The degree of retrogradation was calculated using the following equation:

a: absorbance of total starch fraction; b: absorbance of starch fraction after enzyme reaction; c: absorbance of starch fraction after completely decomposed by enzyme reaction.

Color

Using a colorimeter (Chroma meter, CR 210, Minolta, Osaka, Japan), surface color of samples was determined. L-values (lightness), a-value (redness), and b-value (yellowness) were measured, and the color value of the calibration plate was: L-value (97.83), a-value (− 0.43), and b-value (1.98).

pH

Five grams of thawed sample was homogenized with 50 mL of distilled water at 8000 rpm by Ultra-turrax (Model NO. T25, Janken & Kunkel, Germany), and pH was measured using a pH meter (Model 340, Mettler-Toledo, Switzerland).

Texture profile analysis

Texture of the sliced sample (2 × 2 × 2 cm) was measured using a texture analyzer (TA-XT2i, Stable Micro Systems Ltd., Surrey, England). The thickness of sample was adjusted such that it was uniform and placed parallel to the center of the plate. A two-bite compression test was used to calculate the hardness (kg), adhesiveness, springiness, cohesiveness, gumminess (kg), and chewiness (kg) of the sample. The analysis was performed at maximum load 2 kg, head speed 2.0 mm/s, post-speed 1.0 mm/s, deformaion rate 30%, probe (φ20 mm cylinder probe), distance 8.0 mm, and force 5 g.

Sensory evaluation

Sensory characteristics were evaluated by selecting 15 panelists and their preferences of the thawing methods. The rice cake was sliced into 2 × 2 × 2 cm. The evaluation was conducted by the 9-point scale method in terms of appearance, degree of moistness, taste, degree and preference of the texture, and overall acceptability. The degree of likelihood was rated on a scale of 1–9 with 1 being very hard and 9 being very moist and soft. The degree of acceptability was also expressed on a scale of 1–9, with 1 being very bad and 9 being very good.

Statistical analyses

Each measurement of the physical characteristic was conducted in triplicate, and subjected to statistical analysis to obtain mean values within the triplicates. To determine significance of the observed differences among the thawing methods, statistical analyses was performed using the general linear model (GLM) procedure of the Statistics Analytical System (SAS) program (version 9.12, SAS Inst., Inc., Cary, NC, USA) (p < 0.05). Duncan’s multiple range test (p < 0.05) was used to determine the differences between treatment means.

Results and discussion

Temperature changes in Garaedduk

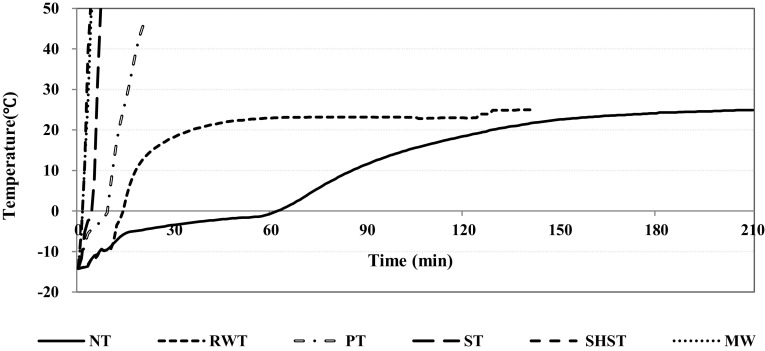

Changes in the temperature of Garaedduk after applying the different thawing methods are showed in Fig. 1. The MWT and SHST treatments required only 3 min for thawing until the interior of the rice cake reached 25 °C, followed by 6 min for the ST treatment, 15 min by the PT treatment, 137 min by the RWT treatment, and 211 min by the NT treatment. The SHST treatment exhibited the fastest rate of 17.70 °C/min, while SHST or MWT treatments (13.48 °C/min) showed approximately 70-fold faster thawing rate compared to the NT treatment (0.18 °C/min). General thawing proceeds from the surface of the food products, followed by slow transfer towards the center (Kum et al., 1998). In contrast, microwave thawing allows rapid heat transfer due to the unique property of microwaves, which can penetrate into the center of the food products and release heat, reducing the thawing time (Tong et al., 1993). In the present study, the thawing methods showed variation in thawing times, because of differences in specific heat transfer rate within the thawing methods.

Fig. 1.

Changes in temperature of Korean rice cakes (Garedduk) according to thawing methods. NT (incubator, 25 °C), RWT (water bath, 25 °C), ST (HY-2004-L, Hanyang, Gyeonggi, Korea, 120 °C), PT (LC-81, L’equip, Gyeonggi, Korea, 120 °C), MWT (RE-551B, 2450 MHz, 200 W, Samsung, Gyeonggi, Korea), and SHST (oven 160 °C, steam 400 °C, DFC-240W, Naomoto, Osaka, Japan)

Freeze–thaw stability of Garaedduk

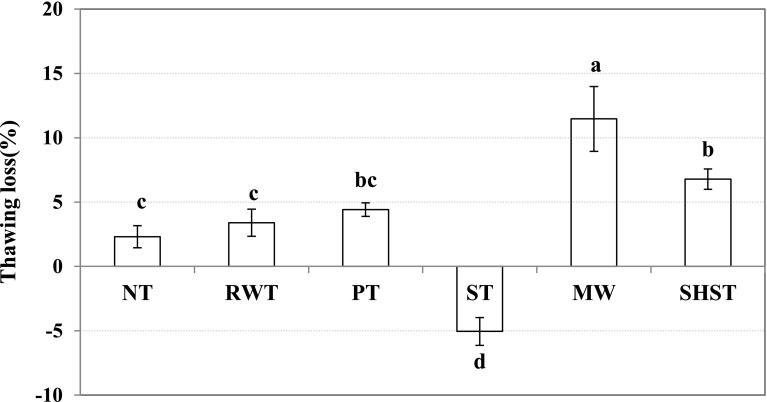

The thawing loss of Garaedduk from various thawing methods is shown in Fig. 2. The largest thawing loss was observed after the MWT treatment (11.46%), followed by those after the SHST (6.79%) and PT treatments (4.83%). Smaller thawing values were recorded for RWT (3.71%) and NT (2.47%). It was noted that ice crystals formed during the freezing process of food products were prone to hamper freeze–thaw stability and water-holding capacity, leading to thawing loss (Lee and Park, 1999). Thawing loss value is an important quality indication as it decreases their water-soluble nutritional components as well as it negatively influences the physicochemical and sensory properties of food products (Park et al., 2012; Xu et al., 2014). It was reported that the value of syneresis (percent of water separation) decreased as the frozen rice flour gel was thawed in a water bath at high temperatures (90 °C < 60 °C < 30 °C) or boiled in a microwave (Varavinit et al., 2002). In that case, the frozen rice flour gel was thawed in a sealed container, making the overall content more intact during the thawing process. However, the thawing loss values in this study appeared to be consistent with the results of thawing rate (Fig. 1). The high rank of MW, SHST, and PT in thawing rate showed large values of thawing loss, except for ST. The large thawing loss after MW, SHST, and PT is thought to be due to uneven distribution of water molecules throughout the Garaedduk sample. These thawing processes were terminated only within minutes until the internal temperature of the sample reached 25 °C by exposing the material to a high temperature (120 °C for PT and 160 °C for SHST). This might remain some regions near to surface of the sample readily dried, and some inner parts of the sample moist, resulting in overall decrease in the intact material. MW has been also suggested to cause localized overheating (Li and Sun, 2002). It can be also thought that the rate of drying would exceed the rate of temperature rise during the thawing process. This might be the case observed by the sample in SHST. It was reported that the rate water evaporation in superheated steam is higher than in dry air (Chu et al., 1953), which makes this type of steam possible to be used as a powerful drying medium (Moreira, 2001). A negative value of thawing loss was observed for ST treatment (–5.05%), which indicates an increase in the weight from the original sample weight before freezing. This is attributed to resorption of water under the moist condition while the internal temperature increased to the final temperature. Thus, the present study suggests that different thawing methods led to variation in freeze–thaw stability.

Fig. 2.

Thawing loss of Korean rice cakes(Garedduk) according to thawing methods. a–dMeans with different superscripts in the same row are significantly different at p < 0.05 by Duncan’s multiple range test. NT (incubator, 25 °C), RWT (water bath, 25 °C), ST (HY-2004-L, Hanyang, Gyeonggi, Korea, 120 °C), PT (LC-81, L’equip, Gyeonggi, Korea, 120 °C), MWT (RE-551B, 2450 MHz, 200 W, Samsung, Gyeonggi, Korea), and SHST (oven 160 °C, steam 400 °C, DFC-240W, Naomoto, Osaka, Japan)

Moisture content and water activity of Garaedduk

The moisture content and water activity of Garaedduk after different thawing methods are shown in Table 1. In the present study, rice cakes differed in their moisture content after using various thawing methods, although this value was less than 50% for all the tested methods. The highest moisture content value was 49.63% in the NT treatment, but this value was not significantly different from those observed after the ST and RWT treatments. Compared to other treatments, the PT and SHST treatments showed lower values of 45.16 and 45.52%, respectively. The values of moisture content appeared to be somewhat negatively correlated with the values of thawing loss (Fig. 2), suggesting that the thawing loss is mostly due to loss of moisture. During thawing, thawing loss resulted in cells releasing moisture, thereby lowering the moisture content and water activity concurrently. For water activity, the NT, RWT, and MW treatments exhibited relatively high values between 0.993 and 0.997, but were not significantly different. However, MW sample showed a significantly higher value than PT in moisture content and higher than ST and SHST in water activity, despite the great thawing loss observed in Fig. 2. This may indicate that the MW treatment produce a thawed Garaedduk in which water molecules were less uniformly distributed compared to the other thawing methods. The sample from ST showed low water activity comparable to that from SHST, although the moisture content of ST sample was as high as the value of NT sample. This result corroborates water reabsorption during ST process, which was discussed by the negative value of thawing loss for ST sample.

Table 1.

Moisture content and water activity(aw) of Korean rice cakes (Garedduk) according to thawing methods

| NT(1) | RWT | PT | ST | MW | SHST | |

|---|---|---|---|---|---|---|

| Moisture content (%) | 49.63 ± 0.84a | 48.25 ± 0.43ab | 45.16 ± 0.46d | 49.07 ± 1.81a | 46.97 ± 0.28bc | 45.52 ± 0.18cd |

| Water activity (aw) | 0.993 ± 0.004ab | 0.997 ± 0.001a | 0.990 ± 0.002bc | 0.987 ± 0.002c | 0.993 ± 0.003ab | 0.985 ± 0.001c |

All values are mean ± standard deviation of three replicates

(1)NT (incubator, 25 °C), RWT (water bath, 25 °C), ST (HY-2004-L, Hanyang, Gyeonggi, Korea, 120 °C), PT (LC-81, L’equip, Gyeonggi, Korea, 120 °C), MWT (RE-551B, 2450 MHz, 200 W, Samsung, Gyeonggi, Korea), and SHST (oven 160 °C, steam 400 °C, DFC-240W, Naomoto, Osaka, Japan)

a–dMeans with different superscripts in the same row are significantly different at p < 0.05 by Duncan’s multiple range test

Degree of retrogradation of Garaedduk

The degree of retrogradation of Garaedduk after different thawing methods differed, as described in Table 2. The highest degrees of retrogradation was observed for the MWT and SHST treatments were 14.94 and 14.74%, respectively (p < 0.05), followed by the PT. NT, ST, and RWT treatments. The MWT and SHST treatments, which showed high degrees of retrogradation, also exhibited larger thawing loss and lower moisture content, indicating a correlation between the degree of retrogradation and thawing loss and moisture content. Several studies have reported that structural changes in products were induced by the loss of moisture accompanied by weight loss upon dry heating (Berglund and Hertsgaard, 1986; Son et al., 1997). The results of MWT, SHST, and PT treatments suggest that starch structures were changed by the great extent of thawing and moisture loss in a way that increased non-digestible starch toward α-amylase activity.

Table 2.

Degree of retrogradation Korean rice cakes (Garedduk) according to thawing methods by α-amylase iodine method

| NT(1) | RWT | PT | ST | MW | SHST | |

|---|---|---|---|---|---|---|

| Retrogradation (%) | 3.58 ± 0.75c | 2.24 ± 0.27d | 10.08 ± 2.04b | 2.56 ± 1.00 cd | 14.94 ± 1.66a | 14.74 ± 2.04a |

All values are mean ± standard deviation of three replicates

(1)NT (incubator, 25 °C), RWT (water bath, 25 °C), ST (HY-2004-L, Hanyang, Gyeonggi, Korea, 120 °C), PT (LC-81, L’equip, Gyeonggi, Korea, 120 °C), MWT (RE-551B, 2450 MHz, 200 W, Samsung, Gyeonggi, Korea), and SHST (oven 160 °C, steam 400 °C, DFC-240W, Naomoto, Osaka, Japan)

a–dMeans with different superscripts in the same row are significantly different at p < 0.05 by Duncan’s multiple range test

pH and color of Garaedduk

The pH and color of Garaedduk after thawing methods are described in Table 3. The pH values obtained for all treatments were 6.33–6.37, with no significant differences among treatments. The pH of rice cakes has been reported to affect its qualities such as storage and textural properties (Shin and Park, 2007). However, the results of this study revealed that the thawing methods did not affect the pH of rice cakes. In contrast, lightness was higher in the ST and MW treatments within the range of 73.81–75.47, while the SHST and PT treatments showed lower values in the range of 70.14–70.87. Redness was higher in the SHST and ST treatments within the range of − 2.32 to 2.39. Yellowness was significantly higher in the PT and SHST treatments, with respective values of 4.17 and 4.49. In the current study, the PT and SHST methods exhibited lower lightness and higher yellowness in color, because they involved dry heat, which grilled the surface of the rice cakes.

Table 3.

pH and colors of Korean rice cakes (Garedduk) according to thawing methods

| NT(1) | RWT | PT | ST | MW | SHST | |

|---|---|---|---|---|---|---|

| pH | 6.37 ± 0.06 | 6.33 ± 0.06 | 6.37 ± 0.06 | 6.37 ± 0.06 | 6.37 ± 0.06 | 6.33 ± 0.06 |

| L*-value | 71.60 ± 0.46 cd | 72.75 ± 0.31bc | 70.87 ± 1.73 cd | 75.47 ± 2.21a | 73.81 ± 1.78ab | 70.14 ± 1.44d |

| a*-value | − 2.54 ± 0.03c | 2.64 ± 0.05d | − 2.44 ± 0.14b | − 2.39 ± 0.05ab | − 2.54 ± 0.04c | − 2.32 ± 0.11a |

| b*-value | 3.11 ± 0.15d | 3.65 ± 0.40c | 4.49 ± 0.26a | 2.92 ± 0.45d | 3.86 ± 0.40bc | 4.17 ± 0.54ab |

All values are mean ± standard deviation of three replicates

(1)NT (incubator, 25 °C), RWT (water bath, 25 °C), ST (HY-2004-L, Hanyang, Gyeonggi, Korea, 120 °C), PT (LC-81, L’equip, Gyeonggi, Korea, 120 °C), MWT (RE-551B, 2450 MHz, 200 W, Samsung, Gyeonggi, Korea), and SHST (oven 160 °C, steam 400 °C, DFC-240W, Naomoto, Osaka, Japan)

a–dMeans with different superscripts in the same row are significantly different at p < 0.05 by Duncan’s multiple range test

Textual properties of Garaedduk

The textual properties of Garaedduk, including hardness, adhesiveness, springiness, cohesiveness, and chewiness, differed after the different thawing methods, as shown in Table 4. The NT treatment showed the highest hardness value of 1.21 kg (p < 0.05), while the ST treatment showed the lowest hardness value of 0.65 kg. The values obtained from the other treatments ranged between 0.79 and 0.89 kg and were not significantly different from one another. For adhesiveness, the values were − 638.86 to − 904.90, with no significant differences among the thawing methods. For springiness, the NT treatment showed the highest value, although there was no significant difference compared to the other treatments, except for the RWT treatment, which was lower than others. For cohesiveness, the SHST treatment showed the lowest value of 0.86, while the other treatments shared the value of 0.90 with no significant differences among treatments. For chewiness, the NT treatment showed the highest value of 1.01 kg, while the ST treatment showed the lowest value of 0.54 kg, thus exhibiting a similar trend with hardness. The close relationship between hardness and chewiness seems reasonable, since chewiness was determined by taking the hardness values into account. Overall, the NT thawing process appeared to produce a Garaedduk with higher values of hardness and chewiness. Lee (1989) compared the hardness of glutinous rice cakes after thawing over time. He reported that the rice cakes thawed in a room temperature required a longer time than those in an electric rice cooker or a microwave to recover the original state of textual properties of a freshly prepared rice cake. This implies that the NT sample might need longer time to recover their original hardness and chewiness properties, even though the sample was thawed until the internal temperature increased up to room temperature. Increase of hardness is also manifested in storage of starch-based food products due to starch retrogradation (Lee et al., 1983). It is also plausible that aging of Garaedduk proceeded to a certain extent during the long length of NT process (210 min), enhancing hardness of the sample. However, starch retrogradation involved in hardening the NT sample would be more likely to be reversible considering the low degree of retrogradation determined enzymatically (Table 2). The low value of either hardness or chewiness for ST is in line with a great retention of moisture content and possible reabsorption of water into the sample during ST treatment (Fig. 2 and Table 1).

Table 4.

Texture properties of Korean rice cakes (Garedduk) according to thawing methods

| NT(1) | RWT | PT | ST | MW | SHST | |

|---|---|---|---|---|---|---|

| Hardness (kg) | 1.21 ± 0.36a | 0.89 ± 0.17b | 0.89 ± 0.16b | 0.65 ± 0.08c | 0.79 ± 0.11bc | 0.87 ± 0.17b |

| Adhesiveness | − 728.19 ± 108.83 | − 809.84 ± 190.93 | − 904.90 ± 422.98 | − 638.86 ± 144.22 | − 763.98 ± 212.32 | − 802.44 ± 191.97 |

| Springiness | 0.93 ± 0.02a | 0.90 ± 0.03b | 0.91 ± 0.04ab | 0.92 ± 0.02ab | 0.91 ± 0.02ab | 0.91 ± 0.03ab |

| Cohesiveness | 0.90 ± 0.01a | 0.91 ± 0.01a | 0.90 ± 0.05a | 0.90 ± 0.01a | 0.90 ± 0.02a | 0.86 ± 0.06b |

| Chewiness (kg) | 1.01 ± 0.30a | 0.73 ± 0.14b | 0.72 ± 0.10b | 0.54 ± 0.06c | 0.64 ± 0.09bc | 0.67 ± 0.09bc |

All values are mean ± standard deviation of three replicates

(1)NT (incubator, 25 °C), RWT (water bath, 25 °C), ST (HY-2004-L, Hanyang, Gyeonggi, Korea, 120 °C), PT (LC-81, L’equip, Gyeonggi, Korea, 120 °C), MWT (RE-551B, 2450 MHz, 200 W, Samsung, Gyeonggi, Korea), and SHST (oven 160 °C, steam 400 °C, DFC-240W, Naomoto, Osaka, Japan)

a–cMeans with different superscripts in the same row are significantly different at p < 0.05 by Duncan’s multiple range test

Sensory properties of Garaedduk

Sensory properties of Garaedduk after thawing methods were investigated in terms of appearance, moistness, taste, and texture, where moistness and texture were measured in terms of intensity and acceptability (Table 5). The NT, RWT, and ST treatments showed a high degree of preservation, but the differences among them were not significant. For moistness, the ST treatment showed the highest intensity, although there was no significant difference in its value, as compared to that observed with the NT and SHST treatments. In terms of acceptability, the ST, NT, and SHST treatments showed higher values, indicating that the higher moistness values were linked to higher acceptability (p < 0.05). For texture, the ST, NT, RWT, and SHST treatments exhibited higher values of intensity (tenderness), which is similar to the trend of moistness intensity. In terms of acceptability, the thawing methods did not seem to significantly affect the texture. For overall acceptability, there was no significant difference among the different thawing methods. In summary, the impact of thawing methods differed in physical characteristics of frozen Garaedduk. Garaedduk thawed by MW and SHST methods showed a higher thawing efficiency than other thawing methods. However, some deterioration in qualities was observed for these methods in aspects of moisture retention, degree of retrogradation, and color change. A great retention in quality was found in ST, though the thawing rate is much lower than SHST or MW. Thus, application of each thawing method will vary depending on the way to consume Garaedduk products. For example, MW and SHST thawing might have advantages to be applied in a convenient food, as it can cook in a short time and can be consumed immediately after thawing.

Table 5.

Sensory properties of Korean rice cakes (Garedduk) according to thawing methods (unit: point)

| NT(1) | RWT | PT | ST | MW | SHST | |

|---|---|---|---|---|---|---|

| Appearance | 8.22 ± 0.67a | 8.17 ± 0.50a | 6.89 ± 0.78b | 7.90 ± 0.57a | 6.70 ± 0.95b | 7.10 ± 0.74b |

| Moistness (degree) | 7.56 ± 0.88ab | 7.17 ± 1.22bc | 6.39 ± 1.11c | 8.20 ± 0.42a | 6.70 ± 0.82bc | 7.40 ± 0.70ab |

| Moistness (acceptability) | 7.44 ± 1.01ab | 7.06 ± 1.18b | 6.11 ± 0.78c | 8.20 ± 0.42a | 6.90 ± 0.74b | 7.50 ± 0.71ab |

| Taste | 7.78 ± 0.83 | 7.44 ± 1.24 | 7.78 ± 0.67 | 8.10 ± 0.74 | 7.60 ± 0.84 | 7.90 ± 0.74 |

| Tenderness (degree) | 7.22 ± 1.30ab | 6.89 ± 1.90ab | 6.39 ± 0.78b | 7.90 ± 0.57a | 6.70 ± 0.82b | 7.15 ± 1.11ab |

| Tenderness (acceptability) | 7.22 ± 1.30 | 6.89 ± 1.90 | 6.67 ± 0.71 | 7.80 ± 1.03 | 6.80 ± 0.79 | 7.50 ± 0.85 |

| Overall acceptability | 7.22 ± 1.09 | 6.78 ± 1.79 | 7.00 ± 0.71 | 7.80 ± 1.03 | 7.00 ± 0.47 | 7.35 ± 0.75 |

All values are mean ± standard deviation of three replicates

Appearance, moistness (1 = extremely dry, 9 = extremely moist), taste, tenderness (1 = extremely hard, 9 = extremely tender), and overall acceptability (1 = extremely bad, 9 = extremely good)

(1)NT (incubator, 25 °C), RWT (water bath, 25 °C), ST (HY-2004-L, Hanyang, Gyeonggi, Korea, 120 °C), PT (LC-81, L’equip, Gyeonggi, Korea, 120 °C), MWT (RE-551B, 2450 MHz, 200W, Samsung, Gyeonggi, Korea), and SHST (oven 160 °C, steam 400 °C, DFC-240W, Naomoto, Osaka, Japan)

a–cMeans with different superscripts in the same row are significantly different at p < 0.05 by Duncan’s multiple range test

Acknowledgements

This research was supported by Main Research Program (E0164800-01) of the Korea Food Research Institute (KFRI) funded by the Ministry of Science, ICT & Future Planning (Republic of Korea).

Compliance with ethical standards

Conflict of interest

No potential conflict of interest relevant to this article was reported.

References

- Ahn JW. Properties of rice cakes for Topokki with curry powder. Korean J. Food Cookery Sci. 2009;25:467–473. [Google Scholar]

- AOAC. Official Method of Analysis of AOAC. Association of Official Analytical Chemists, Washington DC, USA (2000)

- aT. Key indicators for the food industry in 2016. Korea Agro-Fisheries & Food Trade Corp. (2016)

- Baker L, Rayas-Duarte P. Retrogradation of amaranth starch at different storage temperatures and the effects of salt and sugars. Cereal Chem. 1998;75:308–314. doi: 10.1094/CCHEM.1998.75.3.308. [DOI] [Google Scholar]

- Berglund P, Hertsgaard D. Use of vegetable oils at reduced levels in cake, pie crust, cookies, and muffins. J. Food Sci. 1986;51:640–644. doi: 10.1111/j.1365-2621.1986.tb13899.x. [DOI] [Google Scholar]

- Byun JI. Keimyung University, Daegu, Korea (2014)

- Cho KH, Park SH. The development of high efficiency tempering system using microwave. J. Korean Inst. IIIum. Electr. Install. Eng. 2009;23:69–74. [Google Scholar]

- Chu JC, Lane AM, Conklin D. Evaporation of liquids into their superheated vapors. Ind. Eng. Chem. 1953;38:86–87. [Google Scholar]

- Chung L, Lee HY. The structural correlation between consumer’s attitudes and intention of repurchase of home meal replacement (HMR) according to the product categories. Korean J. Community Nutr. 2007;12:344–351. [Google Scholar]

- Han SY, Han GJ, Park HY. Study on the application indigenous pigmented rice for Garraedduk adapted with mechanically impacting technology. Korean J. Food Cookery Sci. 2012;28:17–23. doi: 10.9724/kfcs.2012.28.1.017. [DOI] [Google Scholar]

- Hong GP, Min SG, Ko SH, Shim KB, Seo EJ, Choi MJ. Effects of brine immersion and electrode contact type low voltage ohmic thawing on the physico-chemical properties of pork meat. Korean J. Food Sci. An. 2007;27:416–423. doi: 10.5851/kosfa.2007.27.4.416. [DOI] [Google Scholar]

- Kang KJ, Kim K, Lee SK, Kim SK. Relationship between molecular structure of acid-hydrolyzed rich starch and retrogradation. Korean J. Food Sci. Technol. 1997;29:876–881. [Google Scholar]

- Kang HJ, Lee JK, Lim JK. Quality characteristics of Topokki Garaedduk with different moisture ratios. J. Korean Soc. Food Sci. Nutr. 2012;41:561–565. doi: 10.3746/jkfn.2012.41.4.561. [DOI] [Google Scholar]

- Kim OS, Shin MJ. A study on the recognition and preference of Korean traditional rice cake according to age in capital area. Korean J Food Cookery Sci. 2004;20:444–452. [Google Scholar]

- Kim JO, Choi CR, Shin MS, Kim SK, Lee SK, Kim WS. Effects of water content and storage temperature on the aging of rice starch gels. Korean J. Food Sci. Technol. 1996;28:552–557. [Google Scholar]

- Kim IS, Jang AR, Jin SK, Lee MH, Jo CR. Effect of marination with mixed salt and kiwi juice and cooking methods on the quality of pork loin-based processed meat product. J. Korean Soc. Food Sci. Nutr. 2008;37:217–222. doi: 10.3746/jkfn.2008.37.2.217. [DOI] [Google Scholar]

- Kim SE, Homg SK, Kim DS. A study on E-commerce consumer dissatisfaction of HMR Products. J. Soc. e-Bus. Stud. 2017;22:29–42. [Google Scholar]

- Kum JS, Lee CH, Baek KH, Lee SH, Lee HY. Influence of cultivar on rice starch and cooking properties. Korean J. Food Sci. Technol. 1995;27:365–369. [Google Scholar]

- Kum JS, Lee CH, Han O. Effects of height for microwave defrosting on frozen food. J. Korean Soc. Food Nutr. 1998;27:109–114. [Google Scholar]

- Lee SM. Time pressure perceived by housewife and housework performance strategy. Master’s thesis. Seoul National University (1989)

- Lee JK, Park JY. Rapid thawing of frozen pork by 915 MHz microwave. Korean J. Food Sci. Technol. 1999;31:54–61. [Google Scholar]

- Lee IE, Rhee HS, Kim SK. Textural changes of glutinous rice cakes during storage. Korean J. Food Sci. Technol. 1983;15:379–384. [Google Scholar]

- Lee HJ, Ku SK, Choi HD, Park JD, Sung JM, Kim YB, Choi HW, Choi YS. Quality characteristics of Korean rice cake by freezing methods. Korean J. Food Cook Sci. 2017;33:148–154. doi: 10.9724/kfcs.2017.33.2.148. [DOI] [Google Scholar]

- Li B, Sun DW. Novel methods for rapid freezing and thawing of foods—a review. J. Food Eng. 2002;54:175–182. doi: 10.1016/S0260-8774(01)00209-6. [DOI] [Google Scholar]

- Moreira RG. Impingement drying of foods using hot air and superheated steam. J. Food Eng. 2001;49:291–295. doi: 10.1016/S0260-8774(00)00225-9. [DOI] [Google Scholar]

- Mun SH, Kim JO, Lee SK, Shin MS. Retrogradation of sucrose fatty acid ester and soybean oil added rice flour gels. Korean J. Food Sci. Technol. 1996;28:305–310. [Google Scholar]

- Park YK, Kim HS, Park HY, Han GJ, Kim MH. Retarded retrogradation effect of garaetteok with apple pomace dietary fiber powder. J. Korean Soc. Food Cult. 2011;26:400–408. [Google Scholar]

- Park MH, Kwon JE, Kim SR, Won JH, Ji JY, Hwang IK, Kim MR. Physicochemical and microbiological properties of pork by various thawing methods. J. East Asian Soc. Diet. Life. 2012;22:298–304. [Google Scholar]

- Shin YJ, Park GS. Quality characteristics of apricot Sulgidduk by the saccharides assortment. J. Korean Soc. Food Sci. Nutr. 2007;36:233–240. doi: 10.3746/jkfn.2007.36.2.233. [DOI] [Google Scholar]

- Sila DN, Smout C, Vu ST, Loey A, Hendrickx M. Influence of pretreatment conditions on the texture and cell wall components of carrots during thermal processing. J. Food Sci. 2005;70:E85–E91. doi: 10.1111/j.1365-2621.2005.tb07095.x. [DOI] [Google Scholar]

- Son HS, Park SO, Hwang HJ, Lim ST. Effect of oligosaccharide syrup addition on the retrogradation of a Korean rice cake (Karedduk) Korean J. Food Sci. Technol. 1997;29:1213–1221. [Google Scholar]

- Song JC, Park HJ. Effect of starch degradation enzymes on the retrogradation of a Korean rice cakes. J. Korean Soc. Food Sci. Nutr. 2003;32:1262–1269. doi: 10.3746/jkfn.2003.32.8.1262. [DOI] [Google Scholar]

- Takashi Y. Collection of superheated steam technology. Tokyo: NTS Inc.; 2005. pp. 3–83. [Google Scholar]

- Tong CH, Lentz RR, Lund DB. A microwave oven with variable continuous power and a feedback temperature controller. Biotechnol. progress. 1993;9:488–496. doi: 10.1021/bp00023a600. [DOI] [Google Scholar]

- Tsuge H, Hishida M, Iwasaki H, Watanabe S, Goshima G. Enzymatic evaluation for the degree of starch retrogradation in foods and foodstuffs. Starch-Stärke. 1990;42:213–216. doi: 10.1002/star.19900420603. [DOI] [Google Scholar]

- Varavinit S, Shobsngobb S, Varanyanondc W, Chinachotid P, Naivikule O. Freezing and thawing conditions affect the gel stability of different varieties of rice flour. Starch/Stärke. 2002;54:31–36. doi: 10.1002/1521-379X(200201)54:1<31::AID-STAR31>3.0.CO;2-E. [DOI] [Google Scholar]

- Xu Z, Guo Y, Ding S, An K, Wang Z. Freezing by immersion in liquid CO2 at variable pressure: Response surface analysis of the application to carrot slices freezing. Innov. Food Sci. Emerg. Technol. 2014;22:167–174. doi: 10.1016/j.ifset.2013.06.005. [DOI] [Google Scholar]

- Yoon SJ, Oh IS. Usage status of traditional rice cake as a meal substitute and analysis on the selection attributes affecting purchase. Culi. Sci. Hosp. Res. 2014;20:38–53. [Google Scholar]

- Zhu S, Ramaswamy HS, Simpson BK. Effect of high-pressure versus conventional thawing on color, drip loss and texture of Atlantic salmon frozen by different methods. LWT-Food Sci. Technol. 2004;37:291–299. doi: 10.1016/j.lwt.2003.09.004. [DOI] [Google Scholar]