Abstract

In this review, some recognized modifications utilized in the preparation of soy cheese and cheese analogs produced with soymilk are discussed. Soymilk is an inexpensive, nutritive dairy substitute that is used to make cheese and cheese analogs by people worldwide. The components of soy components, including isoflavones, have beneficial health effects that support the amelioration of chronic and degenerative diseases. However, the quality characteristics of such cheeses can be diminished, especially the taste and structure. Its quality is affected by soybean variety, storage temperature, soymilk-processing conditions, stirring speed, coagulation temperature, type of coagulator, and coagulator’s concentration ratio. Over the years, researchers have studied to improve soy cheese characteristics by improving its structure, flavor, color, and nutrition quality. Structure of cheese types have been developed, including soft cheeses like tofu and cream cheese types, cheese types with different milk type combinations, soy-paneer, soy-mozzarella, and hard type cheeses. Flavor development has attempted to reduce the unpleasant beany flavor by adding spices and other ingredients, or blending with other milk types. Reduction of lipoxygenases in soymilk helps to reduce rancidity and protect the odor. Color is improved with microbes or colored food ingredients like carrots. Using Lactobacillus spp. and Bifidobacterium spp. microbes, probiotic soy cheese types have been developed with improved nutritional quality. Production of soymilk using sprouted and frozen seeds has resulted in nutritionally improved soy cheeses. Soy cheeses and their analogs act as functional foods and improvements to these cheeses upgrade their values and consumer acceptance.

Keywords: Soymilk, Soy cheese, Cheese analog, Flavonoid

Introduction

Cheese is a staple dairy food and highly regulated in numerous countries. It is consumed by many people around the world, and not limited to a particular age or region. Processed dairy cheese types, cheese analogs, and imitation cheeses have emerged over the years and have received the attention of food processors and consumers owing to their many potential benefits (Farahmandfar et al. 2011; Rinaldoni et al. 2014). However, existing cheeses can be problematic to digest and have high contents of saturated fats and sodium (Rinaldoni et al. 2014). The challenge for food formulators is to manufacture inexpensive, healthy, high yielding, nutritious, good quality products that will be preferred by consumers. A dairy industry market assessment declared that the consumer expectations of having a healthy life-styles is fueling a demand for innovative dairy products, and 48% of dairy processors were targeted to achieve health benefits of food choices of the consumers’ with new products that are featured with low fat or fat-free, reduced sodium and sugar, lactose-free, organic, or contain probiotic cultures, and are fortified with nutrients, calcium, and protein (PMMI 2013).

In recent years, the consumption of soymilk and soy curd has increased, perhaps owing to the perceived health problems associated with the high consumption of animal products (Chikpah et al. 2015). For consumers, soymilk is popular as the type of milk that is most closely related to dairy milk among non-dairy milk products. Soymilk has nearly the same nutritional proportions as cow’s milk, including 3.5% protein, 2% fat, 2.9% carbohydrate, and 0.5% ash, and it is also rich in protein, vitamins, and minerals (Raja et al. 2014). In dairy industry soymilk and soybean proteins compete with dairy and milk proteins as a low-cost substitute. Among vegetable proteins, soybean is a protein rich food with a good balance of amino acids and desirable fatty acids (Rinaldoni et al. 2014). Soy-based foods are well recognized for the beneficial health claims such as hypolipidemic, anticholesterolemic, and antiatherogenic properties, and reduced allergenicity. Beyond its health attributes, soymilk fulfills dairy milk shortages in some regions of the world. Global Soymilk Market has been segmented into major regions as North America, Latin America, Western Europe, Eastern Europe, Asia Pacific, Middle East and Africa. However, the United States dominates the share in North America and exports the product to various other countries, which include Canada, China, Mexico, Japan, Indonesia, and others North America holds a major market share followed by Asia Pacific (M2 Presswire 2017). Top exporters of soymilk are the U.S., Brazil, Argentina, Canada, and Paraguay and the Netherlands, China, Mexico, Japan, and Germany are the major importers. Soy milk global market is estimated to grow at a compound annual growth rate over 3.2% from 2017 to 2023 (M2 Presswire 2017). However, due to the presence of the polysaccharide raffinose and stachyose, its consumption may lead to digestion-associated problems. Fermentation is one of the methods used to overcome such problems, and is also used to improve the acceptability of soymilk (Hati et al. 2013).

The coagulation process of soymilk is slow and inefficient compared to that of dairy milk. However, coagulating soymilk with or without other additives to make soy cheese has a long history, and these products have been used by people all over the world (Han et al. 2001; Shurtleff and Aoyagi 2013). Owing to this global expansion, these cheeses appeared with different names, such as tofu, sufu, and furu. Fermented tofu is the most common traditional cheese type among them that prepared using soybean curd, obtained by precipitating proteins from soymilk either with an acid or an alkali salt. Numerous types of soy cheeses are made worldwide, and many have received significant attention. Modern soy cheeses are prepared from soymilk, which is used for whole or partial replacement of cow’s milk and/or other types of milk. Soy cheese has the benefits of high nutritive value, low cost, availability, suitability for those with lactose intolerance, and has been used in the treatment of protein deficiency among undernourished children. The main barrier of the taste of the soymilk products are its beany taste, which does not welcome by the consumers. Also, the grainy texture diminishes the textural quality of cheese spreads made from soy sources while the dairy cheese spreads remain smooth and uniform (Qinghui et al. 2013).

To improve soy cheeses, different methods have been introduced by many researchers. It is important to develop a suitable processing system capable of providing the required textural, functional, and sensory properties of soy cheeses that closely resemble dairy cheese. This review summarizes new approaches to developing soy cheese types, or cheese analogs with soy nutrition, by considering the benefits and defects of existing soy cheese types and suggesting modifications to improve them for higher consumer acceptability.

Chemical composition of soymilk

The chemical composition of soymilk differs depending on the processing conditions and its bean variety. The proteins in soymilk have a well-recognized deficiency of the essential sulfur amino acids methionine and cysteine; however, they are comparatively rich in lysine. Soymilk has high phytate and oxalate compounds that are able to inhibit the absorbance of the essential minerals calcium, magnesium, iron, copper, and zinc in the intestinal tract (Hossein 2011).

Among soymilk proteins, 60% are comprised of glycinin and β-conglycinin, and they exist in an emulsion with soymilk lipids. The lipid component is a triacylglyceride composed of linoleic acid, oleic acid, and phospholipids (Kanauchi et al. 2015). During processing, triacylglyceride fat globules are formed and kept stable by lecithin, phospholipid, and oleosin (Ono et al. 1996). The outside layer of these globules contains soy protein, forming an emulsion. Phytic acid, minerals, and oligosaccharides are soluble and available as dissolving substances in soymilk (Ono et al. 1996).

Curdling of soymilk

Fermentation reduces antinutritional factors by improving the bioavailability of isoflavones, promoting protein digestion, providing more soluble calcium, improving intestinal health, and supporting the immune system (Subrota et al. 2013). Besides its health benefits, fermentation decreases the intrinsic beany (often objectionable) flavor of soymilk, its chalkiness, and content of flatulent sugars such as stachyose and raffinose (Hossein 2011).

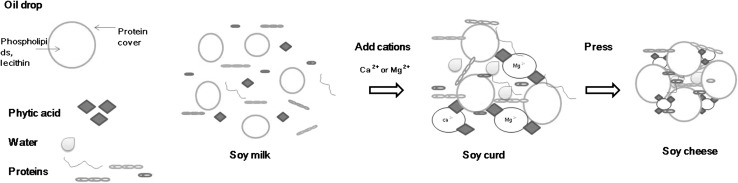

Figure 1 shows a schematic of the process of curdling soymilk by the addition of Ca2+. Calcium bivalent cations in gel are induced into the denatured protein solution and form a filamentous gel structure. During soymilk and tofu production, oil drops are suspended forming an emulsion after crushing of soybeans those stored as oil bodies in soybeans. Due to attraction of disulfide bonds and hydrophobic interactions, protein filaments generates by unfolding the proteins while heating the soybean protein solution (Kao et al. 2003). When bivalent ions (calcium and magnesium) incorporated to soymilk, the ions associates with phytic acid and reduce the electrostatic repulsion between the charged filaments. Rochelle and Mellema (2010) mentioned that the hydration shells of the calcium ion and/or dehydration of the hydrophobic core of the proteins are responsible for providing energy to bind calcium with milk or soy proteins. This induces the charge on the proteins to dissipate by cross linking phytic acid and bivalent cations (Jayasena et al. 2014), and repulsion among their proteins is decreased. This phenomenon decreases the pH of soymilk, immobilizing the protein within it. Moreover, the immobilized proteins easily combine with the external protein layer around the oil drops. Accordingly, the steric network structure of soy protein is formed to gather oil drops with intermediary soy proteins. As the acidity develops in soymilk, hydrophilic structure of soy protein becomes hydrophobic and is taken into the network. The curd forms as a water retaining inflexible gel, with water molecules trapped in it (Kanauchi et al. 2015).

Fig. 1.

Curd formation process in soy cheese

Coagulants of soy cheese

The milk clotting properties are of great importance with regards to both yield and the organoleptic quality of the cheese. The shelf life, nutritional composition, sensory quality, and quantity of cheese produced are consequently affected by the type of coagulants used. These coagulants can be enzymes, salts, or acids, and recent studies have investigated cold-type coagulants. Scientists in cheese industry have been looking for improved coagulation methods of soy milk by altering and optimizing the concentrations of coagulants and temperature and time of coagulating process, aiming upgrade the quality of texture and flavor, and increase the yield of soy cheese (Table 1). Increasing the coagulant concentration tends to decrease the fat content of soy cheese (Jayasena et al. 2014).

Table 1.

Modern types of soymilk coagulants for cheese production

| Coagulator | Type of coagulation | Availability | Function for cheese | References |

|---|---|---|---|---|

| Hagfish slime hydro-gel | Cold | Natural | Increase viscoelasticity, high water retention, high cohesiveness | Boni et al. (2016) |

| Sodom apple (Calotropis procera) extract | Enzymatic | Natural | Substitute to alum, decrease coagulating time, add green color, and decrease sensorial preference | Chikpah et al. (2015) |

| Chitosan | Food Grade | High ash and protein content, long shelf-life | No and Meyers (2004) | |

| Roselle calyces (Hibiscus sabdariffa) extract | Enzymatic | Natural | Increase cheese yield | Fasoyiro (2014) |

| Microbial transglutaminase | Enzymatic | Natural | Increase water retention, smooth, and firm texture | Lim et al. (2011) |

| Citric acid, CaCl2 | Salt | Food Grade | Maximize tofu yield, maximize protein recovery | Mitra et al. (2013) |

| Citric acid | Acid | Food Grade | Increase yield, fat, and protein contents | Singh et al. (2010) |

| Calcium sulfate (0.4%) | Salt | Food Grade | Maximize tofu yield, solid and protein recoveries, maximize water retention, uniform and homogeneous microstructure, | Kao et al. (2003) |

| Glucono-δ-lactone | Enzymatic | Food Grade | Silky and good-flavored curd | Lim et al. (2011) |

| CaCl2 (2%) | Salt | Food Grade | Increase hardness, high protein and fat contents | Ojha et al. (2014) |

| Calcium lactate | Enzymatic | Food Grade | Soft body, smooth texture and desirable elasticity | Mitra et al. (2013) |

| Magnesium sulphate (0.5%) | Salt | Food Grade | High moisture content, fresh yield, low fat tofu | Jayasena et al. (2014) |

Traditional soymilk cheese types

Tofu is a white soft vegan cheese that originated either in China or the islands around Okinawa in about the 1500's (Shurtleff and Aoyagi 2013). Traditional tofu has two main categories, soft and hard types, and can be pickled or/and stinky. Pickled tofu is soaked in brine, vine, vinegar, or other flour mixtures as dry cubes. Stinky-type tofu is the soft type made using fermented milk, meat, vegetables, dried shrimp, amaranth greens, mustard greens, bamboo shoots, and herbs. This type has no specific starter and uses these aforementioned ingredients to introduce the naturally occurring starters that are present in traditional food products. This stinky tofu has a strong pungent odor that is described as rotten or fecal.

Different types of sufu have been manufactured by Chinese from centuries ago and the manufacturing conditions were depended on the geographical areas of China (Han et al. 2001). Although sufu was originally a fungal fermented product, bacterial fermentation is also possible (Liu et al. 2006). Sufu can be commonly seen as the types of red, white, and gray in China. Ethanol and NaCl are the basic components of sufu, which balance the traditional flavor and render the product safe against pathogenic microorganisms (Han et al. 2001).

Recently developed soy cheese types

Soy cheese types based on structural development

Structural development of soft soy cheese types

Owing to the hydrophilic nature of soy proteins, cheese produced using them tends to have increased moisture content (Rinaldoni et al. 2014). Therefore, soymilk is considered a highly suitable ingredient for the manufacture of soft cheese types.

Tofu

As discussed above, tofu is a common soy-based soft cheese type. The procedures used in making soymilk and tofu play a major role in tofu yield and quality. The application of heat to soybeans creates a firmer textured tofu (Yoon and Kim 2007). Tofu prepared from frozen soybeans is reported to have a more organized and thicker network structure when compared to the tofu made from soybeans that didn’t freeze. Cheeses made with soymilk prepared from frozen soybeans showed increases in hardness, springiness, gumminess, and chewiness, also syneresis. Freezing soybeans changes the tofu quality as well, by lowering the yield, reducing fat, and increasing protein content (Noh et al. 2005). Syneresis of tofu can be reduced when using glucono-δ-lactone (GDL) as the cheese coagulant in the presence of carrageenan, a polysaccharide extracted from seaweeds (Karim et al. 1999). Murugkar (2014) suggested that improvements in composition and quality parameters beneficial to tofu production were seen in tofu made with sprouting seed milk. Yield of tofu can be increased when they prepared with soymilk that has high pH levels and total solid contents, or soybeans rich in protein and minerals, and low in phosphorus (Lim et al. 1990).

Traditional tofu has been made in China using fermented soy whey as a coagulant. Li et al. (2017) were identified that JMC-1 strain of Lactobacillus plantarum exists high acid producing activity compared to the other strain consist in fermented soy whey. They have produced a tofu applying strain JMC-1 into the sterile fermented soy whey stream (as a coagulant) for 16 h with pH 4.0 at 37 °C. This tofu had a good flavor and texture compared to the tofu that made with the coagulants such as non-sterilized fermented soy whey, magnesium chloride, and gypsum under the same tofu-making process (Li et al. 2017). Hou et al. (2016) prepared double network-modified tofu using applications of sequential laccase and microbial transglutaminase. Double network-modified tofu had a texture of unique mechanical and tough sensory. It has exhibited a ratio of soy glycinin to soy protein isolate that exceeded by 50%.

The effect of coagulation temperature and providing pressure on texture of tofu were studied by Murdia and Wadhwani (2010). They found no significant difference among treatments in moisture content on tofu, but protein content was significantly higher with higher pressure. Hou et al. (1997) have reported that tofu made using the highest stirring speed (285 rpm) tested had a lower yield, and a higher brittleness, hardness, and elasticity than tofu made with a stirring speed of 207 rpm.

Soy cream cheese

Soy cream cheese is considered as a suitable carrier for probiotics. Several scientists tried to develop trans-fat free soy-based cream cheese types that are similar to commercial cream cheese that made of dairy (Zulkurnain et al. 2008). A spreadable, creamy textured cheese-like product was developed by Rinaldoni et al. (2014) using ultra-filtrated (UF) and freeze-dried soy flour. The soy cheese samples containing soy protein concentrates increased yield as well as protein and fat contents. Soy protein incorporation increased 6.8–17 g/100 g of proteins and 22–32 g/100 g of fats compared to the control cheese. Microbial analysis showed that the incorporation of potassium sorbate more than doubled the shelf-life of the products up to 60 days. A much firmer textured soy cream cheese was prepared by combinations of hard tofu, 5% of palm oil w/w, and 3% of NaCl w/w (Lim et al. 2011). Using tofu, mozzarella, and cheddar cheese blended in ratios of 20:70:10 produced a processed cream cheese spread with a pleasing quality (Verma et al. 2013).

Soy cheese types from combined milk types

Soy cheese types have been developed by mixing soymilk with other milk types in different combinations, basically aiming for improved structural development (Table 2). These combinations have provided different characteristics to soy cheeses and resulted in unique cheese types. Researchers have developed cheeses using non-dairy, plant-based milks (other than soy), including coconut, ground nut, winged bean, and sesame milks. Table 2 shows the best proportions in which to combine these milks with soymilk to achieve the best quality of combined-milk type soy cheese. Among these, there are several traditional soy cheese products that have been in existence for a long time. As an example, ‘Wara’ cheese is an unripened, fresh type cheese that is famous in Nigeria, produced by curdling coconut milk with soymilk. This soybean cheese analog is also known as ‘beske’ in western parts of the Nigeria, and is recognized as a nutritious product (Adejuyitan et al. 2014). These traditional combined types of cheese were the basis of experimentation by researchers to develop better quality products, and newly introduced milk types were also investigated. Arora and Mittal (1991) reported that the addition of skim milk to soymilk increased the shear strength of the product and improved the texture. The soymilk-skim milk in an 80:20 ratio was found to be suitable for the preparation of tofu.

Table 2.

Cheese types developed from combined soy and other milk types

| Milk type | Cheese type | Coagulant | Characteristics of cheese | References | |

|---|---|---|---|---|---|

| Soymilk (%) | Added milk | ||||

| 10 | 90% Cow milk | Mozzarella | Calcium chloride | High sensorial and functional qualities | Jeewanthi et al. (2015) |

| 10 | 90% Skim milk | Mozzarella | Calcium chloride | Low fat, high browning effect | Jeewanthi et al. (2015) |

| 50 | 50% Coconut milk | Soft | Alum | Low moisture content (50%), less fiber (0.55%), high protein (19%), most acceptable sensory characteristics | Adejuyitan et al. (2014) |

| 90 | 10% Buffalo milk | Tofu | Magnesium chloride | Good quality texture | Mitra et al. (2013) |

| 90 | 10% Buffalo milk | Paneer | Citric acid | Good quality sensory value | Uprit and Mishra (2002) |

| 80 | 20% Skim milk | Paneer | Increase shear strength and texture, total solids similar to milk paneer | Mitra et al. (2013) | |

| 15 | 85% Buffalo skim milk | Cottage | Good quality, not bitter flavor | Restogi and Jha (1998) | |

| 90 | 10% Groundnut milk | Paneer | Citric acid | Good quality, maximum yield, reduce beany flavor | Khodke et al. (2014) |

| 50 | 50% Sesame milk | Tofu | Calcium chloride | Good sensory quality and palatability | Ifesan et al. (2012) |

| 50 | 50%, 25% Winged bean milk | Tofu | Calcium sulfate | Acceptable textural properties | Kantha et al. (2006) |

Soy paneer

Soy paneer, commonly called “the cheese of Asia,” is a popular dish in the orient. It is a fresh, cheese-like product that is off-white in color and made by coagulating hot soymilk with food-grade chemicals, such as calcium chloride, magnesium chloride, calcium sulfate, acetic acid, and citric acid. Soy paneer should contain a moisture level lower than 70% and milk fat content higher than 50% in dry matter. Recently, researchers all over the world have focused on value-added soy paneer. Biradar et al. 2012 mentioned that the selection of correct proportions of soymilk, combine with other milk types, and their composition levels are very important factors to consider when making paneer to reach the desired quality levels in terms of texture and sensory. Incorporation of soymilk improved the nutritional quality of paneer by improving the mineral contents, however didn’t change the hardness of the cheese (Biradar et al. 2012).

Soy paneer has been prepared by using soymilk in the proportion of 70:30 (v/v) with 1% acetic acid as a coagulant at 85 °C (Kinjal et al. 2015). The resultant paneer had a high sensory profile and yield, and a low microbial count. Paneer can also be prepared using soymilk and skimmed milk in 75:25 proportions with citric acid as a coagulant at a concentration of 1.5% (Raja et al. 2014). Using citric acid for coagulation at 90 °C in the production of soy paneer, increased the yield, and fat and protein contents (P < 0.05) compared with those achieved using lactic acid as a coagulant at 70 and 80 °C (Singh et al. 2010). The yield of paneer and the fat content decreased (P < 0.05) as the proportion of soymilk in the mixture increased (Singh et al. 2010). Incorporation of soy protein isolates (SPI) into low-fat paneer improves its textural properties and water binding capacity, by acting as an emulsifier. SPI can be used to replace fat in low-fat paneer. Paneer with 0.2% SPI and CaCl2 (0.2%, w/v as coagulant) has higher protein, lactose, and ash contents, lower fat content, and better textural, and sensory qualities (Kinjal et al. 2015).

Soy mozzarella cheese

Mozzarella cheese is generally consumed after heating at melted state, since it is a key ingredient of pizza. Mozzarella is acceptable with its functional qualities such as stretchability, meltability, browning effect, and oiling off. Therefore heat-induced functional properties determine the quality of mozzarella cheese. Farahmandfar et al. (2011) made soy mozzarella cheeses mixing several proportions of soy curd and natural cheese curd together with different concentrations of trisodium citrate. The researchers expected to achieve a smooth and consistent cheese mass on final cheese by adding trisodium citrate to cheese milk, owing to its emulsifying properties that separates hydrophobic and hydrophilic regions on the casein molecules. However, the results of this experiment suggested that the addition of trisodium citrate decreased the meltability and increased the oiling off effect of soy mozzarella cheese. Kumar and Jha (1997) prepared mozzarella by adding soy solids to buffalo milk. Increasing the content of soy solids in cheese milk resulted in increased moisture contents, and decreased fat and ash contents of the final cheese. Rheological values of cheese such as hardness, springiness, gumminess, and chewiness values were significantly (P < 0.01) reduced for the 80:20 combinations and decreased further during storage. However, soy mozzarella structure seemed collapsing faster through glycolysis, proteolysis, and lipolysis than that of mozzarella made by only cow’s milk.

Production of soy mozzarella using UF cow’s and soymilk blends showed improved qualities over other soy cheeses, such as longer shelf life, and improved nutritional, structural, and functional qualities (Jeewanthi et al. 2015). Combinations of 10–20% soymilk or UF soymilk addition into cow’s milk upgrade the quality of mozzarella cheese by improving its nutritional values. Also, these proportions of soymilk can be blend with skim milk to make soy mozzarella during a fresh cow’s milk shortage. The nutritive quality of the mozzarella proportionally increased with soymilk content, however, the physical and functional qualities like meltability and stretchability, were decreased (Kumar and Jha 1997; Jeewanthi et al. 2015).

Other soft cheese types

Edima et al. (2014) produced soft soy cheese type with the given name of “queen’s cheese”. They prepared it using cow’s milk and soymilk blends, where the soymilk was produced using soy flour. Preparing fresh soft soy cheese by blending of 10% soy flour and 90% cow’s milk improved the sensory qualities of soy cheese such as color, taste, flavor, and overall acceptability (Edima et al. 2014). They noted that coagulation time and elasticity were decreased, while pH was increased, in soy cheese when the soymilk content was increased. Lee et al. (2015) developed a soft yogurt-type cheese using cow’s milk, UF cow’s milk, and soymilk. Yogurt-cheese made with soymilk had higher protein contents and titratable acidity than yogurt-cheese than that of cheeses untreated and UF cow’s milk. After adding soymilk, the yield, and fat and lactose contents of the resulting cheese were lower than those of a UF-fortified yogurt cheese. Minas frescal cheese is also a fresh-type soft cheese. This cheese can be produced using hydrosoluble soybean extract powder, bovine rennet, and a microbiological coagulant. The traditional cheeses and other cheeses with added bovine rennet are higher in hardness. The traditional cheese was more fracturable, cohesive, and masticable while the cheese with added of soybean extract powder and microbial coagulant was more elastic (Piazzon-Gomes et al. 2010).

Structural development of hard type soy cheese

Gouda cheese is a medium-hard-type cheese. Amar (1996) found that satisfactory texture properties of a Gouda analog made from soy protein could be produced by heating and optimal formulation as follows: SPI:skim milk proteins:palm fat:water = 14:6:20:60. Cheddar type is a semi-hard- or hard-type cheese. Mahdy et al. (2004) suggested improving the cheese quality by incorporating soy protein into cheese milk. The researchers were recommended that addition of 5% SPI was ideal to improve the texture of cheddar-type soy-based cheese. El-ella (2006), a substitute for “Ras,” a hard cheese, was made successfully from soymilk. The product has ripened for 3 months to develop the distinctive flavor of a hard type cheese. However, flavor, texture, and color of cheeses were improved by increasing the proportions of cow’s milk.

Soy cheese types based on sensory property development

Flavor and odor development of soy cheese

The limiting factor of soybean usage as a human food is its beany flavor. The flavor was found to be the most influential characteristic that affected the acceptability of a cheese analog containing soymilk. These flavor developments are affected by n-hexanal and pentanal, that are found in beans after the breakdown of unsaturated fatty acids (Scalabrini et al. 1998).

Soybean seed holds three lipoxygenase (Lox) enzymes that are controlled by separate genes, Lox1, Lox2, and Lox3. Lox enzymes are responsible in generating unpleasant flavors in soy-based food via the oxidation of polyunsaturated fatty acids. Soy tofu lacking all three major Lox isozymes was rated as having the lowest rancid/grassy odor due to the reduction of undesirable aroma compounds (Hou et al. 2016, Yang et al. 2016). Soy petit-Suisse cheese made from Lox-free soybeans and enriched with calcium and strawberry pulp was reported to have a greater acceptance and higher nutritional quality (Boatto et al. 2010). Butool and Butool (2015) prepared a soy paneer by incorporating carrot pulp in two different ratios of 10 and 20%. The soy paneer incorporated with 20% carrot was almost equally as good as milk paneer in terms of taste, nutritional value, and acceptability. Paneer made from a blend of buffalo milk (4.5% fat) and soymilk in the proportion of 90:10 was found to have the most acceptable sensory quality attributes (Uprit and Mishra 2002). Combinations of soymilk with buffalo milk up to the level of 40% has improved the quality of the final cheese and preferred by the consumers, although it decreased the physical quality of the paneer (Biradar et al. 2012).

Amar (2012) suggested that mixing fats (50% butter fat with 50% palm fat) and mixing the cheese starter culture together with Brevibacterium linens for a soy based cheese is a suitable approach to develop the flavor of gouda-type cheese during ripening. Maintaining low levels of sodium chloride, without using ethanol, and adding novel milk cheese starter and non-starter cultures such as Lactococcus lactis ssp. lactis (formerly L. lactis ssp. lactis biovar. diacetylactis), Lactobacillus helveticus, Lactobacillus casei, Streptococcus lactis var. maltigenes, and Lactococcus lactis ssp. cremoris, can help to improve the flavor of soy cheese (Ahmad 2008).

Mahdy et al. (2004) reported that the use of SPI in cheddar cheese improved the sensory properties of cheese after 5 months’ ripening and did not impart any bitter off-flavor. It was suggested incorporating 5 g/L of soy protein concentrates into the soy cream cheese made it more acceptable in terms of flavor (Lim et al. 2011). A gouda analog with soy proteins was not sour and had a good taste, due to some flavor substances such as different fatty acids, diacetyl, and acetoin produced from 0.5% sodium citrate (Amar 2012).

Tofu is actually tasteless, and has sponge like qualities, so it can soak up all the delicious spices and flavor that one may like to add to it (Mitra et al. 2013). Sharma et al. (2015) suggested the addition of spices such as cinnamon and bay leaf, cardamom, sugar, and non-roasted and roasted grounded cumin seeds, to soymilk to improve the flavor. Roasted cumin seed tofu was liked by the panelists, although they suggested that the color needed to be improved. Flavor can be developed by replacing a percentage of the soymilk with other milk types. Using 30% or more buffalo milk with soymilk to make tofu improves the flavor (Mitra et al. 2013). Cow’s milk can be replaced by up to 15% with soymilk without affecting the sensory characteristics of the cheese (Edima et al. 2014).

Color development of soy cheese

Tofu with lighter or whiter color is favored by the consumers and expected to have higher L* (whiteness) values. The coagulant using for produce tofu should result greater L* values of final cheese (Tay et al. 2006). Lighter yellow color is also accepted in good quality tofu (Li et al. 2017).

Carrot incorporation into soy paneer reportedly improved the color, appearance, flavor, texture, and nutritional value (Butool and Butool 2015). Lorrungruan et al. (2014) produced a soy-based red cheese using Monascus purpureus and Lactobacillus casei. This red color cheese type had higher sensory acceptance than cow’s milk and blue cheeses. Hydrosoluble soybean extract powder added to cheese made with bovine rennet showed a creamier color than the traditional Minas frescal cheese (Piazzon-Gomes et al. 2010).

Soy cheese types based on nutritional development

Soy protein-added soy cheese types

The biological value of soy protein is higher than that of casein. Soy proteins are much larger in molecular size than milk proteins, possess complex quaternary structures, and they are not phosphor-proteins like those of casein. Researchers have experimented with modified starches or soy isolates and gelatin as a caseinate replacement in soy milk to produce cheese analogs.

Arunkumar (2014) prepared a filled paneer spread using soy flour. A sensory panel found 5% soy flour acceptable because of the stable consistency and absence of beany flavor. Homogenization of soy filled milk for spread making has been found to be beneficial in relation to whiteness, brightness, and silky appearance of the product. Kashar cheese made with soy protein had lower dry matter and protein contents, and higher fat in dry matter values than non-soy kashar cheese. Meltability was also reduced in SPI-added cheese (Balkir and Metin 2011). However, addition of SPI into cheese milk tended to reduce fat and trans-fat free in cream cheese (Lim et al. 2011). Cheese analogs were prepared from proteolytically modified SPI, replacing 60% of casein lowered both hardness and fracturability while increasing meltability than that of cheese analogs made with non-hydrolyzed SPI. Treatments of SPI with alcalase and trypsin have reported to improve the textural properties of cheese analogs (Kim et al. 1992).

Probiotic-added soy cheese types

Probiotic food products should contain enough viable cells in the food product until the consumption to provide the expecting health benefits. Meanwhile, the probiotics must be able to maintain the characteristics of the final product in terms of sensorial characteristics. The metabolites such as acids and proteases produced by probiotics are mainly responsible for the quality characteristics of the final cheese especially on aged cheeses, owing to moisture content and aging process. Probiotics also improve the palatability of soy cheese (Zielińska et al. 2015).

The most commonly used probiotic-associated bacteria are Lactobacilli and Bifidobacteria. The role of lactic acid bacteria (LAB) in soymilk fermentation is to produce acid and flavor, and to remove the undesirable beany taste and improve the shelf life of the fermented product (Choi et al. 2015). A spreadable soy cheese type that was made by combining GDL and LAB fermentation methods exhibited a more stable and less easily fractured structural system, and achieved higher scores of sensory acceptance (Qinghui et al. 2013). Zielińska et al. (2015) concluded that tofu produced under laboratory conditions is a good medium for the growth of LAB, the number of which was maintained at a high level (109–1010 CFU/g), and particularly with probiotic bacteria from the Lactobacillus genus (108–109 CFU/g). In response to the production of β-glucosidase activity by probiotic lactobacilli, isoflavone aglycones increase the antioxidative activity of soymilk during fermentation (Subrota et al. 2013). Oligosaccharides can be reduced during fermentation of soymilk using either pure or mixed cultures of the following bacteria: Lactobacillus cellobiosis, Lactobacillus plantarum, Lactobacillus fermentum, Lactobacillus delbrueckii, Lactobacillus fermenti, Lactobacillus pentosaceus, and Lactobacillus bulgaricus. Probiotic lactobacilli applications provide additional benefits, such as enhancement of immune functions (Choi et al. 2015).

Lactobacillus acidophilus FTCC 0291 in soy cream cheese, developed as a probiotic career, stored at two different temperatures maintained a viability exceeding 107 CFU/g during storage for 20 days. Oligosaccharide and reducing sugar analyses specified that L. acidophilus FTCC 0291 was capable of utilizing the existing reducing sugars in soymilk and concurrently hydrolyzing the oligosaccharides into simpler sugars for growth (Liong et al. 2009). This probiotics added-soy cheese has been reported to have angiotensin-I converting enzyme (ACE) inhibitory effective bioactive peptides that are responsible for reduction of high blood pressure.

Good quality probiotic soy cheese was made by Liu et al. (2006) using soymilk fermented with L. rhamnosus 6013. L. rhamnosus 6013 can favorably utilize soy oligosaccharides, and no technical or sensorial defects were detected. During fermentation L. rhamnosus C6 strain was found to reduce oligosaccharides viz. raffinose, stachyose and sucrose mostly present in soymilk and maximize α-galactosidase production. Lactobacillus casei NCDC17 also exhibited similar activity during soymilk fermentation (Hati et al. 2013). Matias et al. (2014) developed a probiotic soy-based product similar to petit-suisse cheese. The formulations were produced with an ABT culture containing Lactobacillus acidophilus La-5, Bifidobacterium animalis Bb-12, and starter Streptococcus thermophiles. Bb-12 viability remained above 8 log CFU/g for all trials, whereas viability of La-5 was satisfactory at the end of storage for milk cheese (7.56 log CFU/g) and soy mixed milk cream cheese (6.49 log CFU/g). Soymilk-based cheese had the highest sensorial scores. Petit-suisse cheese with soy showed high viability of the probiotic microorganism B. animalis subsp. lactis Bb-12 during the storage period and acts as a good probiotic career (Matias et al. 2014).

Other types of soy cheese

Improving soymilk nutrition is a good approach to elevate the nutritive quality of soy cheese. Soymilk made from 28 h germinated soybeans offered enhanced nutritional values and comparable physicochemical properties to conventional soymilk (Jiang et al. 2013). As mentioned before, the sprouting soy seeds used to make soymilk for the production of soy cheese imparted a better quality. Tofu from sprouted seeds milk had higher protein content and whiteness index, but the tofu strength was around 43% lower than its non-sprouted counterpart. When non-sprouted tofu compared with sprouted varieties, taste acceptability, flavor, and overall acceptability were increased by 6.3, 11.6, and 4.4%, respectively (Murugkar 2014). Ojha et al. (2014) reported that there was a significant difference in the retention of major isoflavones (daidzein and genistein) in soy paneer with increasing soaking time. A soaking time of 16 h was shown to give the highest isoflavones retention.

Powder type enzyme modified soy cheese has been developed with soymilk and cow milk blends as a bioactive cheese paste (Ali et al. 2017). Optimal conditions for this cheese type’s production has revealed as inlet air temperature of 150 °C, a feeding rate of 10%, and an air flow rate of 600 L h−1. This cheese powder also has the functionality of ACE inhibitory activity. These ACE inhibitory bioactive peptides were activated after performing a multivariable-dependent process. It has been developed with extensive hydrolysis of combined milk (soy and cow’s) proteins (Ali et al. 2017). Whey protein concentrates 70% was found to enhance bacterial growth by nurturing fermenting bacteria and also increase physiological activity during fermentation in soymilk medium (Hati et al. 2013).

Conclusion

Soy cheese types have been developed recently for their high nutritional quality and lower cost, in response to consumer awareness and milk shortages in certain areas. Their flavonoid content, and trans-fat free and lactose free qualities improve these cheese products in comparison with dairy cheese. To surpass the traditional types, new approaches for structural development has been performed using different techniques and new coagulant types at different concentrations, temperatures, and times. The textural properties of tofu also vary with the density of the gel network and the size of the protein granules in the network. Soft cheese type development from soymilk has focused on higher water retention in soy cheeses. Tofu, cream cheese types, and spreadable cheeses have all been developed. Maintaining cheese structure is challenging with the addition of certain proportions of soymilk. Therefore, mozzarella-, paneer-, and hard-type cheeses have also been developed using various different technologies. Milk combinations have also been used to improve the structure. The beany and chalky odor and flavor of traditional soy cheese types reduces their favor for consumers. Addition of spices, such as roasted cumin seeds, increasing the ripening time, adding new milk cheese starters and non-starter cultures, and using different milk blends can ameliorate this defect. Nutrition quality has been improved by the addition of soy flour, soy protein isolates, and soy protein hydrolysates. Probiotic cheese types have also been developed to improve the nutritional quality of cheese. Soy cheese has good potential for development within the global market to fulfill the nutritional requirements of the consumers around the world.

Acknowledgements

This work was supported by Priority Research Centers Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science, and Technology (2009-0093824).

References

- Adejuyitan JA, Olanipekun BF, Moyinwin OA. Production and evaluation of cheese-like product from the blend of soymilk and coconut milk. Arch Appl Sci Res. 2014;6:263–266. [Google Scholar]

- Ahmad N. Soy cheese flavour improvement. Food Technol Biotechnol. 2008;46:252–261. [Google Scholar]

- Ali B, Khan KY, Majeed H, Abid M, Xu L, Wu F, Xu X. Soymilk-cow’s milk ACE-inhibiting enzyme modified cheese. Food Chem. 2017;237:1083–1091. doi: 10.1016/j.foodchem.2017.06.068. [DOI] [PubMed] [Google Scholar]

- Amar A (1996) Texture properties of Gouda analog made from soy protein. [Dissertation] Hohenheim University Stuttgart, Germany

- Amar A. Physico-chemical, and sensory properties of soy based Gouda cheese analog made from different concentration of fat, sodium citrate and various cheese starter cultures. Makara J Technol. 2012;16:149–156. [Google Scholar]

- Arora S, Mittal BK. Preparation and evaluation of soy paneer. J Food Sci Technol. 1991;28:15–17. [Google Scholar]

- Arunkumar H. Effect of soy flour and soy oil on the composition and sensory characteristics of paneer spread. J Res Agric Anim Sci. 2014;2:1–5. [Google Scholar]

- Balkır P, Metin M. Physicochemical and textural properties of imitation fresh kashar cheeses prepared from casein, caseinates and soy protein. GIDA J Food. 2011;36:17–24. [Google Scholar]

- Biradar GS, Gujar SK, Dande KG, Gaikwad SM. Studies on physico-chemical quality of paneer (Indian cheese) papered from blends of soymilk and buffalo milk. J Anim Prod Adv. 2012;2:142–145. [Google Scholar]

- Boatto DA, Mesomo MC, Madrona GS, Branco IG, Matumoto-Pintro PT. Characterization and elaboration of ordinary soy and lipoxygenase-free soybean petit Suisse cheese enriched with calcium. Food Sci Technol (Campinas) 2010;30:766–770. doi: 10.1590/S0101-20612010000300031. [DOI] [Google Scholar]

- Boni L, Patrick AR, Erich JW, Fischer P, Kuster S. Gelation of soymilk with hagfish exudate creates a flocculated and fibrous emulsion and particle gel. PLoS ONE. 2016;11:E0147022. doi: 10.1371/journal.pone.0147022. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Butool M, Butool S. Studies on carrot incorporated soy paneer. Int J Dev Res. 2015;5:4124–4130. [Google Scholar]

- Chikpah SK, Teye M, Annor JAF, Teye GA. Potentials of Sodom apple (Calotropis procera) extract as a coagulant to substitute Alum in soy cheese production in Ghana. Elixir J. 2015;79:30166–30170. [Google Scholar]

- Choi HJ, Lee NK, Paik HD. Health benefits of lactic acid bacteria isolated from kimchi, with respect to immunomodulatory effects. Food Sci Biotechnol. 2015;24:783–789. doi: 10.1007/s10068-015-0102-3. [DOI] [Google Scholar]

- Edima HC, Nji QN, Awono ET, Abossolo SLD, Mbofung CM. Optimization of the extraction of soymilk and formulation of soft cheese from cow milk and soymilk. Int J Biol Pharm Allied Sci. 2014;3:1886–1895. [Google Scholar]

- El-Ella WM. Hard cheese substitute from soy milk. J Food Sci. 2006;45:1777–1778. doi: 10.1111/j.1365-2621.1980.tb07610.x. [DOI] [Google Scholar]

- Farahmandfar R, Tehrani MM, Razavi SMA, Najafi HMB. Effect of trisodium citrate and soy cheese on meltability of pizza cheese. Int J Food Prop. 2011;14:697–707. doi: 10.1080/10942910903367621. [DOI] [Google Scholar]

- Fasoyiro SB. Physical, chemical and sensory qualities of Roselle water extract-coagulated tofu compared with tofu from two natural coagulants. Niger Food J. 2014;32:97–102. doi: 10.1016/S0189-7241(15)30123-5. [DOI] [Google Scholar]

- Han BZ, Rombouts FM, Nout MJR. A Chinese soybean fermented food. Int J Food Microbiol. 2001;65:1–10. doi: 10.1016/S0168-1605(00)00523-7. [DOI] [PubMed] [Google Scholar]

- Hati S, Vij S, Mandal S, Malik RK, Vandna K, Khetra Y. α-Galactosidase activity and oligosaccharides utilization by lactobacilli during fermentation of soymilk. J Food Process Preserv. 2013;38:1065–1071. doi: 10.1111/jfpp.12063. [DOI] [Google Scholar]

- Hossein J. Soy products as healthy and functional foods. Middle East J Sci Res. 2011;7:71–80. [Google Scholar]

- Hou HJ, Chang KC, Shih MC. Yield and textural properties of soft tofu as affected by coagulation method. J Food Sci. 1997;62:824–827. doi: 10.1111/j.1365-2621.1997.tb15464.x. [DOI] [Google Scholar]

- Hou JJ, Yang XQ, Fu SR, Xiao F. Preparation of double-network tofu with mechanical and sensory toughness. Int J Food Sci Technol. 2016;51(4):962–969. doi: 10.1111/ijfs.13043. [DOI] [Google Scholar]

- Ifesan BOT, Olawumi T, Olakanmi O. Production of tofu from blends of soybean (Glycine max Merr) and sesame seed (Sesamum indicum) Afr J Food Sci. 2012;6:386–391. doi: 10.5897/AJFS12.043. [DOI] [Google Scholar]

- Jayasena V, Tah WY, Nasar-Abbas SM. Effect of coagulant type and concentration on the yield and quality of soy-lupin tofu. Qual Assur Saf Crop. 2014;6:159–166. doi: 10.3920/QAS2012.0176. [DOI] [Google Scholar]

- Jeewanthi RKC, Lee NK, Lee KA, Yoon YC, Paik HD. Comparative analysis of improved soy-mozzarella cheese made of ultrafiltrated and partly skimmed soy blends with other Mozzarella types. J Food Sci Technol. 2015;52:5172–5179. doi: 10.1007/s13197-014-1542-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jiang S, Weixi C, Baojun X. Food quality improvement of soymilk made from short-time germinated soybeans. Foods. 2013;2:198–212. doi: 10.3390/foods2020198. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kanauchi M, Sakiko H, Shimoyamada M. New cheese-like food production from soymilk utility of soymilk curdling yeast. In: Eissa AHA, editor. Food production and industry. Rijeka: Intech; 2015. pp. 79–100. [Google Scholar]

- Kantha SS, Hettiarachchi NS, Erdman JW. Laboratory scale production of winged bean curd. J Food Sci. 2006;48:441–444. doi: 10.1111/j.1365-2621.1983.tb10761.x. [DOI] [Google Scholar]

- Kao FJ, Su NW, Lee MK. Effect of calcium sulphate concentration in soymilk on the microstructure of firm tofu and the protein constituents in tofu whey. J Agric Food Chem. 2003;51:6211–6216. doi: 10.1021/jf0342021. [DOI] [PubMed] [Google Scholar]

- Karim AA, Sulebele GA, Azhar ME, Ping CY. Effect of carrageenan on yield and properties of tofu. Food Chem. 1999;66:159–165. doi: 10.1016/S0308-8146(98)00258-1. [DOI] [Google Scholar]

- Khodke S, Pardhi M, Pramodini M, Kakade A. Characteristic evaluation of soy-groundnut paneer. IOSR J Environ Sci Toxicol Food Technol. 2014;8:12–16. doi: 10.9790/2402-08921216. [DOI] [Google Scholar]

- Kim (Lee) SY, Park PSW, Rhee KC. Textural properties of cheese analogs containing proteolytic enzyme-modified soy protein isolates. J Am Oil Chem Soc. 1992;69:755–759. doi: 10.1007/BF02635911. [DOI] [Google Scholar]

- Kinjal D, Patel HG, Gokhale AJ (2015) Advancements in manufacture of paneer. In: National seminar on Indian dairy industry - opportunities and challenges, 11th alumni convention, Gujarat, India

- Kumar S, Jha YK. Soymilk substitution on quality attributes of mozzarella cheese made from buffalo milk. J Food Sci Technol. 1997;342:113–118. [Google Scholar]

- Lee NK, Mok BR, Jeewanthi RKC, Yoon YC, Paik HD. Physicochemical and microbiological properties of yogurt-cheese manufactured with ultrafiltrated cow’s milk and soymilk blends. Korean J Food Sci Anim. 2015;35:205–210. doi: 10.5851/kosfa.2015.35.2.205. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li C, Rui X, Zhang Y, Cai F, Chen X, Jiang M. Production of tofu by lactic acid bacteria isolated from naturally fermented soy whey and evaluation of its quality. LWT-Food Sci Technol. 2017;82:227–234. doi: 10.1016/j.lwt.2017.04.054. [DOI] [Google Scholar]

- Lim BT, Deman JM, Deman L, Buzzell RI. Yield and quality of tofu as affected by soybean and soymilk characteristics: calcium sulfate coagulant. J Food Sci. 1990;55:1088–1092. doi: 10.1111/j.1365-2621.1990.tb01605.x. [DOI] [Google Scholar]

- Lim TJ, Easa AM, Karim AA, Bhat R, Liong MT. Development of soy-based cream cheese via the addition of microbial transglutaminase, soy protein isolate and maltodextrin. Br Food J. 2011;113:1147–1172. doi: 10.1108/00070701111174587. [DOI] [Google Scholar]

- Liong MT, Easa AM, Lim PT, Kang JY. Survival, growth characteristics and bioactive potential of Lactobacillus acidophilus in a soy-based cream cheese. J Sci Food Agric. 2009;89:1382–1391. doi: 10.1002/jsfa.3598. [DOI] [Google Scholar]

- Liu DM, Li L, Yang XQ, Liang SZ, Wang JS. Survivability of L. rhamnosus in soy cheese. Food Technol Biotechnol. 2006;44:417–422. [Google Scholar]

- Lorrungruan C, Sinma K, Pantagrud P, Wannasirisuk S, Khucharoenphaisan S. Red cheese production from soymilk by Monascus purpureus and Lactobacillus casei. J Appl Sci. 2014;14:2819–2824. doi: 10.3923/jas.2014.2819.2824. [DOI] [Google Scholar]

- M2 Presswire; Coventry (2017) Soy milk market is estimated to grow at a CAGR over 3.2% from 2017 to 2023, Stoke, UK

- Mahdy A, Wenshui X, Guonong Z. Effect of soy protein supplementation on the quality of ripening Cheddar-type cheese. Int J Dairy Technol. 2004;57:209–214. doi: 10.1111/j.1471-0307.2004.00107.x. [DOI] [Google Scholar]

- Matias NS, Bedani R, Castro IA, Saad MIS. A probiotic soy-based innovative product as an alternative to petit-suisse cheese. LWT-Food Sci Technol. 2014;59:411–417. doi: 10.1016/j.lwt.2014.05.054. [DOI] [Google Scholar]

- Mitra J, Jha A, Tanweer A, Singh DS, Ranjan SK, Pathak S, Naz A. Sensory and textural properties of tofu manufactured by blending buffalo milk. Asian J Dairy Food Res. 2013;32:135–138. [Google Scholar]

- Murdia LK, Wadhwani R. Effect of processing parameters on texture and yield of tofu. As J Food Ag-Ind. 2010;3:232–241. [Google Scholar]

- Murugkar D. Effect of sprouting of soybean on the chemical composition and quality of soymilk and tofu. J Food Sci Technol. 2014;51:915–921. doi: 10.1007/s13197-011-0576-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- No HK, Meyers SP. Preparation of tofu using chitosan as a coagulant for improved shelf life. Int J Food Sci Technol. 2004;39:133–141. doi: 10.1046/j.0950-5423.2003.00772.x. [DOI] [Google Scholar]

- Noh EJ, Park SY, Pak JI, Hong ST, Yun SE. Coagulation of soymilk and quality of tofu as affected by freeze treatment of soy beans. Food Chem. 2005;91:715–721. doi: 10.1016/j.foodchem.2004.06.050. [DOI] [Google Scholar]

- Ojha A, Kulkarni DN, Sharma A, Joshi S. Effect of concentration of coagulant and soaking time on retention of major isoflavones and quality of soy-paneer. Asian J Dairy Food Res. 2014;33:251–254. doi: 10.5958/0976-0563.2014.00612.5. [DOI] [Google Scholar]

- Ono T, Takeda M, Guo ST. Interaction of protein particles with lipids in soybean milk. Biosci Biotechnol Biochem. 1996;60:1165–1169. doi: 10.1271/bbb.60.1543. [DOI] [PubMed] [Google Scholar]

- Piazzon-Gomes J, Prudencio SH, Silva RSSF. Minas frescal cheese with soy products: physical, chemistry, and sensorial characteristics. Food Sci Technol. 2010;30:77–85. doi: 10.1590/S0101-20612010000500013. [DOI] [Google Scholar]

- PMMI . Dairy industry market assessment, Industry reports. Reston, VA: The Association for Packaging and Processing Technologies; 2013. [Google Scholar]

- Qinghui L, Yuelan X, Li Z, Jingli X. Evaluation of the rheological, textural, microstructural and sensory properties of soy cheese spreads. Food Bioprod Process. 2013;91:429–439. doi: 10.1016/j.fbp.2013.03.001. [DOI] [Google Scholar]

- Raja J, Punoo HA, Masoodi FA. Comparative study of soy paneer prepared from soymilk. J Food Process Technol. 2014;5:1–5. [Google Scholar]

- Restogi G, Jha YK. Quality characteristics of cottage cheese prepared from buffalo skim milk and soymilk. J Dairy Food Home Sci. 1998;17:157–164. [Google Scholar]

- Rinaldoni AN, Palatnik DR, Zaritzky N, Campderrós ME. Soft cheese-like product development enriched with soy protein concentrates. LWT-Food Sci Technol. 2014;55:139–147. doi: 10.1016/j.lwt.2013.09.003. [DOI] [Google Scholar]

- Rochelle LSC, Mellema M. Physical-chemical comparison of cow’s milk proteins versus soy proteins in their calcium-binding capacities. Colloids Surf A Physicochem Eng Asp. 2010;366:110–112. doi: 10.1016/j.colsurfa.2010.05.030. [DOI] [Google Scholar]

- Scalabrini P, Rossi M, Spettoli P, Matteuzzi D. Charaterization of Bifidobacterium strains for use in soymilk fermentation. Int J Food Microbiol. 1998;39:213–219. doi: 10.1016/S0168-1605(98)00005-1. [DOI] [PubMed] [Google Scholar]

- Sharma D, Aditi R, Aruna K, Shivani Siddharth H, Tanya S. Preparation of flavored tofu. DU J Undergrad Res Innov. 2015;1:102–106. [Google Scholar]

- Shurtleff W, Aoyagi A (2013) History of soymilk. In: History of soymilk and other non-dairy milks. Soyinfo Center, California, USA, p 1541

- Singh J, Tanweer A, Srivastava P, Yadav RK. Effect of blending soymilk with buffalo milk on the quality of paneer. Milchwissenschaft. 2010;65:63–65. [Google Scholar]

- Subrota H, Shilpa V, Brij S, Vandna K, Surajit M. Antioxidative activity and polyphenol content in fermented soymilk supplemented with WPC-70 by probiotic Lactobacilli. Int Food Res J. 2013;20:2125–2131. [Google Scholar]

- Tay S, Tan HY, Perera AC. The coagulating effects of cations and anions on soy protein. Int J Food Prop. 2006;9:317–323. doi: 10.1080/10942910600596340. [DOI] [Google Scholar]

- Uprit S, Mishra HN. Fuzzy multiattribute decision making approach for development and comparison of soy fortified paneer. J Sens Stud. 2002;17:163–176. doi: 10.1111/j.1745-459X.2002.tb00340.x. [DOI] [Google Scholar]

- Verma SK, Sangeeta U, Ramesh C, Aman P. Preparation of processed cheese spread using tofu, mozzarella and cheddar cheese. Int J Food Sci Nutr. 2013;2:19–23. [Google Scholar]

- Yang A, Smyth H, Chaliha M, James A. Sensory quality of soymilk and tofu from soybeans lacking lipoxygenases. Food Sci Nutr. 2016;4:207–215. doi: 10.1002/fsn3.274. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yoon HH, Kim M. Physicochemical and sensory properties of tofu prepared with heat-treated soybeans. J Texture Stud. 2007;38:393–403. doi: 10.1111/j.1745-4603.2007.00103.x. [DOI] [Google Scholar]

- Zielińska D, Kamińska A, Kołożyn-Krajewska D. Development of tofu production method with probiotic bacteria addition. J Microbiol Biotechnol Food Sci. 2015;4:485–490. doi: 10.15414/jmbfs.2015.4.6.485-490. [DOI] [Google Scholar]

- Zulkurnain M, Goh MH, Karim AA, Liong MT. Development of a soy-based cream cheese. J Texture Stud. 2008;39:635–654. doi: 10.1111/j.1745-4603.2008.00163.x. [DOI] [Google Scholar]