Abstract

At the crossroads of chemistry, electronics, mechanical engineering, polymer science, biology, tissue engineering, computer science, and materials science, electrical devices are currently being engineered that blend directly within organs and tissues. These sophisticated devices are mediators, recorders, and stimulators of electricity with the capacity to monitor important electrophysiological events, replace disabled body parts, or even stimulate tissues to overcome their current limitations. They are therefore capable of leading humanity forward into the age of cyborgs, a time in which human biology can be hacked at will to yield beings with abilities beyond their natural capabilities. The resulting advances have been made possible by the emergence of conformal and soft electronic materials that can readily integrate with the curvilinear, dynamic, delicate, and flexible human body. This article discusses the recent rapid pace of development in the field of cybernetics with special emphasis on the important role that flexible and electrically active materials have played therein.

Keywords: conductive polymers, cyborganics, flexible bioelectronics, nanomaterials, wearable healthcare monitors

1. Introduction

The field of cybernetics emerged in the early 1960s to describe the possible merging of inanimate materials with living organisms.1 The original definition of cybernetics has subsequently been expanded to also encompass technical healthcare monitors for the health‐conscious consumer and implants for the sick and disabled. Indeed, throughout the course of history, the survival of mankind has relied on its ability to develop materials such as textiles, alloys, metals, and various types of rubbers, gums, and clays that could address our biological limitations in relation to a sustainable livelihood in the unfriendly and changing habitats of the Earth. In a broad sense, cybernetics therefore represents an expansion of the material‐making industries of the past. However, in striking contrast to ordinary materials, cybernetic extensions are items that can integrate with the body to overcome the limitations of human biology in an even more daring manner compared to external clothing, tools, or machines for that matter. Therefore, cyborgs (short for “cybernetic organisms”) could ultimately be the logical evolution of humans into a more adaptable, smarter, and stronger organism (Figure 1 ).

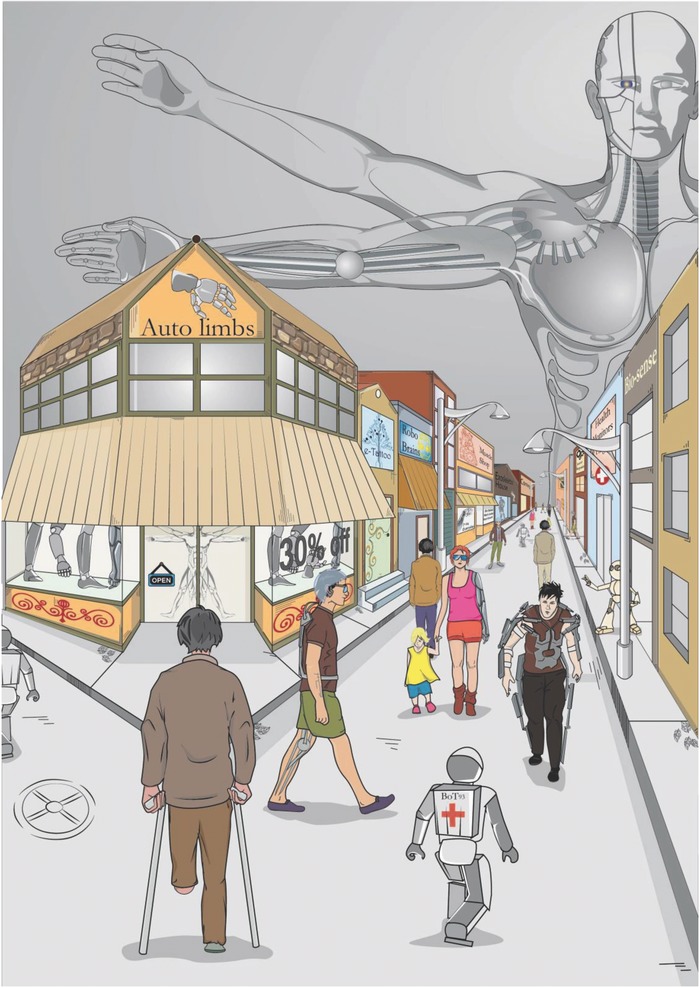

Figure 1.

Recent innovations in materials science are leading humanity on the road to a cybernetic future—a future wherein, the fine‐line between machine and human will slowly fade away and pave the way for cyborg‐like humans.

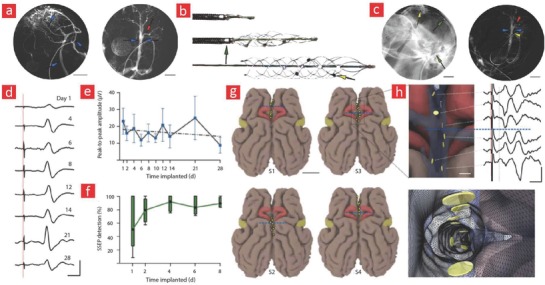

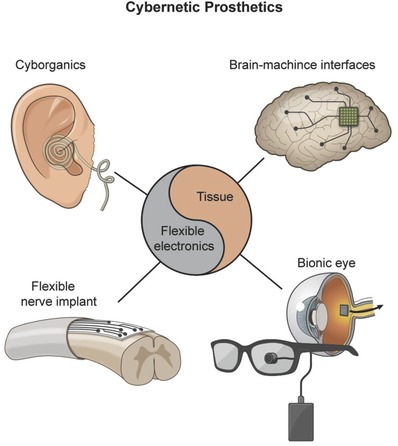

These cybernetic extensions can monitor physiological signals, stimulate tissues, restore lost tissue functions, or even impose new superhuman abilities in their user. A great variety of cybernetic concepts are currently under development, some have already hit the healthcare market, while others are being carefully evaluated in laboratories all over the world.2, 3, 4 Classified broadly, these devices can be organized into three major categories: a) wearable healthcare monitors that can provide the user with individualized health information; b) prosthetics that can replace disabled organs or body parts; and c) implants that possess the ability to transcend human biology beyond its current limitations (Figure 2 ).

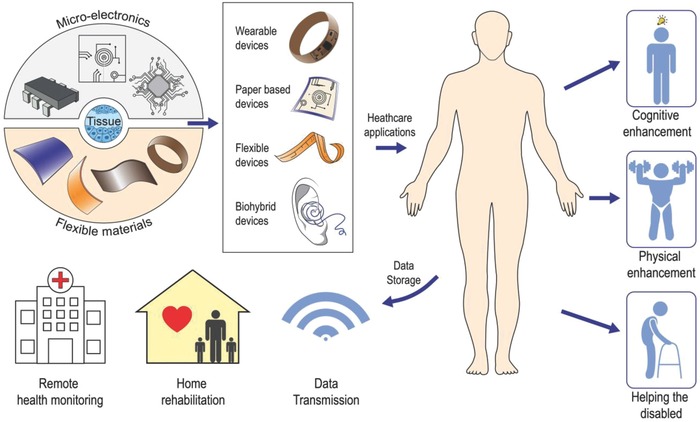

Figure 2.

The union of microelectronics, flexible materials, and living tissues has led to a great variety of cybernetic devices that can bring relief to the lives of those disabled from disease or aging, enhance the physical capabilities of human beings beyond normality, and expand human consciousness toward uncharted territories.

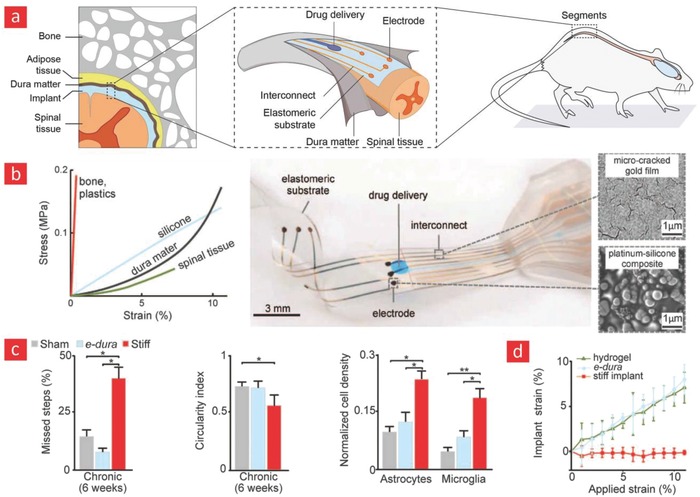

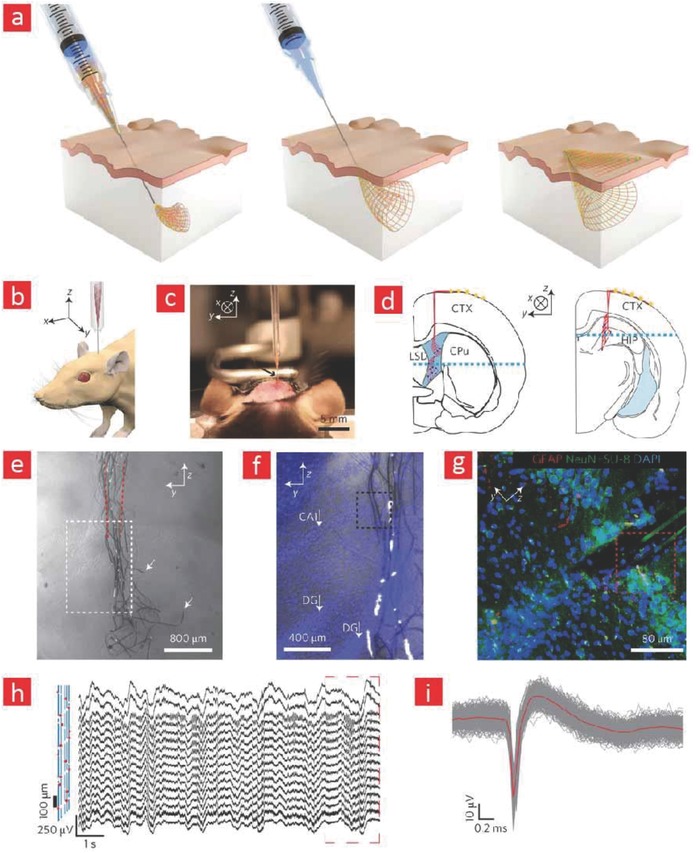

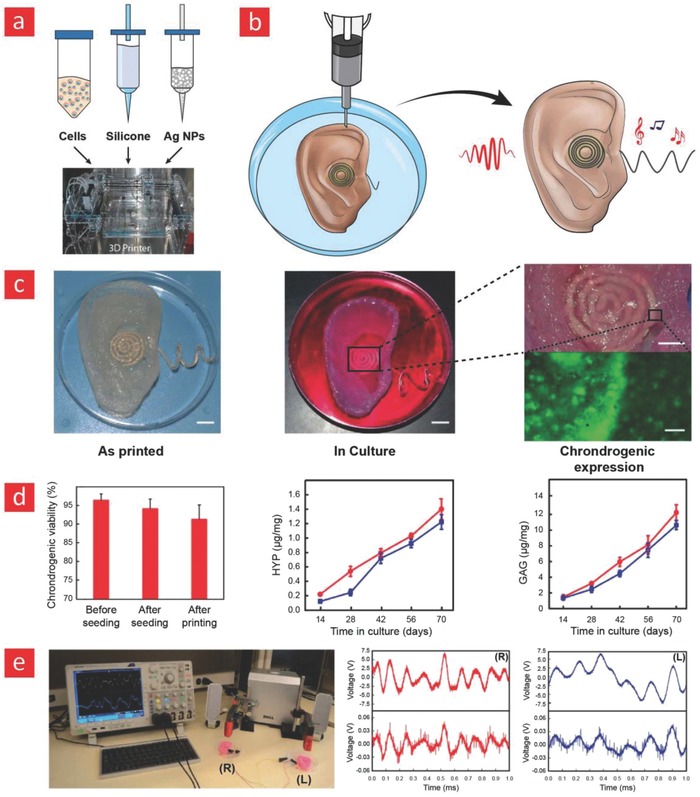

The manufacturing of the abovementioned cybernetics relies on a number of challenges that have only recently begun to be addressed in depth. First, one of the key requirements of any device intended to interface with the human body is a proper integration between the device and the body to assure long‐term performance. To this end, a number of challenges related to the mechanical mismatch between conventional rigid electronic materials and the dynamic, soft, and curvilinear human body need to be solved as the elastic moduli of silicon and metal‐based electronics range from 1–170 GPa,5 which are in a stark contrast to the moduli of soft tissues in the order of 1–1000 kPa.6 Moreover, most of these electronic parts are made on 2D rigid silicon wafers with sharp edges that do not conform well to the curved human body. Finally, conventional rigid electronics are not flexible and typically break at ultralow strains (≈1%),7 and therefore, they are unable to withstand the high physiological strains of organs and tissues. The mismatch between conventional electronics and the human body ultimately hinders a good physiological contact with biological tissues and is thus a limiting factor for proper device performance. To remedy the current situation, flexible bioelectronics have emerged, which enable an unusually facile and intimate integration with biological tissues, such as skin, heart, and brain. Notably, they have been applied as brain–machine interfaces8, 9 to treat various neurological disorders, for real‐time monitoring of the beating heart,10, 11 as skin‐based devices that can monitor important health‐markers12, 13 and sophisticated prosthetics with the ability to reestablish a normal life for the hearing disabled,14 the paralyzed,15 and the blind.16 These devices are unequivocally opening new possibilities for studying chronic diseases, improving surgical procedures, and empowering patients to self‐manage their own health. Building on these groundbreaking results, bioengineers from Harvard University have recently begun to interweave living tissues within intricate nanowire‐based materials to create hybrid constructs that are half man, half machine,17, 18 or cyborg organic constructs (cyborganics) as the authors prefer to refer to them.

Overall, the gateway into the field of flexible bioelectronics is currently heavily related to the development of new multifunctional materials, which are flexible, resilient, and electrically active at the same time. In this review, we will highlight the recent advances of such electronic and flexible materials with a special focus on how these formidable materials currently are being used by scientist all over the world to reshape the field of cybernetics into a readily implementable technology. To this end, we will exclusively focus on healthcare monitoring devices, cybernetic prosthetics, brain–machine interfaces, and the exciting emergence of cyborganics. The review will begin with a brief overview of flexible and conductive polymers, since these materials are instrumental in the engineering of flexible bioelectronics. We will then proceed to discuss the incorporation of liquid metals and 2D nanoelectronic materials into such polymers, as the research and development of such composite systems in our opinion will soon lead to a number of scientific breakthroughs in the field of cybernetics. We will initially focus on the application of these materials in wearable and implantable healthcare monitors before highlighting their use in cybernetic prosthetics. As a new standpoint, we have also reviewed the recent progress in the development of cyborganics and the possible new directions that this emerging field might spearhead in the future. Finally, some of the current material‐based limitations in the field of cybernetics and how they can be successfully addressed will be discussed.

2. Flexible and Insulating Polymers

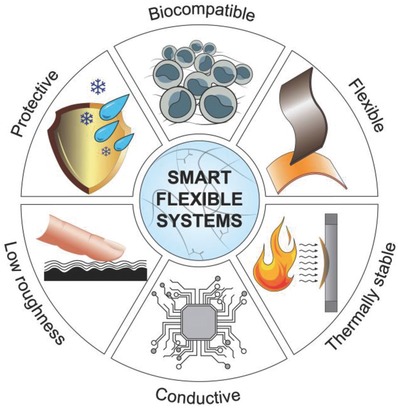

Flexible bioelectronics enable a great variety of biomedical applications that would otherwise be impossible to achieve using conventional rigid electronics, as these devices need to conform well to the human body in order to yield high‐quality recordings of physiological events.19, 20 They also need to sustain their operational capacity in the dynamic in vivo environment without succumbing to the cyclic movements of tissues and organs. For these reasons, materials used in flexible bioelectronics must have exceptional flexibility, toughness, and good biocompatibility to blend with the human body.7 Optical transparency is also instrumental in bioelectronics, as it makes wearable devices fit in visually with the human body, while at the same time providing the means for applications in which imaging is combined with multifunctional sensing. Polymers are promising material candidates in flexible bioelectronics, as they have many key advantages, including transparency, biocompatibility, and flexibility (Figure 3 ).21, 22, 23 In addition, polymers are inexpensive, scalable via roll‐to‐roll processing, and enable reasonable tradeoffs in optical transparency, chemical performance, and thermal stability compared to metals and glass‐based materials.24 Flexible polymers are therefore currently considered as the material of choice for flexible bioelectronics, and thus they are the prime focus of this section.

Figure 3.

Special materials with special properties are required for proper interfacing between the electrical and biological components of cybernetic devices.

2.1. Material Requirements

Electronic devices are mainly fabricated at high temperatures; this may lead to expansion or shrinkage due to internal stresses in the underlying polymeric material and therefore dimensional instability of the device.24 The relation between the thermal stability and device operation has made the coefficient of thermal expansion (CTE) and glass transition temperature important parameters for polymer materials in electronics. Obviously, the glass transition temperature of potential polymer candidates must be compatible with the process temperature to avoid dimensional changes during fabrication, while the CTE of the polymer should match with the low CTE of the conductive layers of the device to prevent strain accumulation and cracking during the fabrication process. Hence, polymers with a high glass transition point and low CTE are desired for flexible electronics.24

Another key requirement is a high barrier property because moisture and gas permeation may lead to dimensional instability of the polymer material. Still, there are many applications for flexible bioelectronics where the materials need not to be fully impermeable—but semi‐permeable—to allow biosensors to operate, such as in smart bandages.25 Polymers are also exposed to various chemicals and solvents during coating, patterning, etching, and other manufacturing processes and must have good chemical and solvent resistance.26

Surface roughness is another important parameter in the fabrication of flexible electronics, since the current transport in such devices is limited by surface defects and cracks.26 In a similar way, the surface defects can also catalyze crack formation when the device is bent and provide an easy pathway for unwanted diffusion of moisture and oxygen into the device.24 Overall, a number of different organic or inorganic barrier coatings such as paralyne C, polyethylene terephthalate (PET), aluminum and indium tin oxides have been used to prevent solvent or moisture diffusion into flexible electronics, reduce surface roughness, and improve the adhesion between the electronic parts and polymer.26

2.2. Amorphous Polymers

Polymers are essentially made from long chains of repeating monomer units held together by strong intermolecular interactions.27 The intermolecular interaction type, which varies a lot from polymer to polymer, plays a prominent role in many polymer properties. Depending on whether the polymer chains are nicely ordered or disorganized, polymers are also classified as either crystalline, semi‐crystalline, or amorphous.28 Notably, amorphous polymers typically exhibit a crystallinity <10% and crystalline polymers typically contain more than 80% crystalline structures, while semi‐crystalline polymers display a crystallinity ranging from 10% to 80%.29 They are also categorized into these different groups in terms of their glass transition temperature (T g) and melting temperature (T m). In this respect, the amorphous polymers have no clear melting point and their glass transition temperatures are approximately between −125 and 350 °C. On the other hand, semi‐crystalline polymers have a distinct T m, while their T g in general is higher than amorphous polymers and typically in the range 75–260 °C.24 Highly crystalline polymers, however, only exhibit a T m and do not have any T g associated to them. Crystalline polymers can especially have extraordinary properties such as high stability, strength, and good resistance toward the surrounding environment.30, 31 These incredible properties of crystalline polymers are mainly associated with their well‐ordered molecular arrangements. For instance, such arrangements can severely restrict the molecular chain mobility, which in turn makes the polymer stronger mechanically and more rigid. However, in spite of this, crystalline polymers are in most cases not suited as materials for flexible electronics because of their rigidity, high surface roughness, and opaqueness.24, 32 To this end, the transparencies of polymers are intimately linked to their crystallinity degree, due to the intensified light scattering taking place within crystalline regions.33 Moreover, crystalline polymers have higher surface roughness due to the presence of growth facets on the crystallites. For these reasons, amorphous polymers are typically a preferred choice over crystalline polymers in flexible bioelectronics, as they are excellent transmitters of light, stretchable, and display smooth surface topographies. However, this comes at a high cost in terms of low barrier properties, dimensional instability, and high CTE coefficients.24 Examples of amorphous polymers include polycarbonate and polyethersulfone, which have high optical transparency and good flexibility but show poor solvent resistance, high gas permeability, and dimensional instability at high temperatures.24 In general, the CTE, optical transparency, and gas barrier properties of such amorphous polymers typically range between 54 and 75 ppm °C−1, 89–92%, and 50–80 g m−2 d−1, respectively.24 These listed values are relatively higher than that of semi‐crystalline polymers.24 Moreover, amorphous polymers exhibit modulus, flexural strength, and tensile strength in the range of 2.1–2.6 GPa, 93–115 MPa, and 50–84 MPa, respectively.34, 35, 36 They tend to bend and deform, but are not highly stretchable, as they typically only can stretch up to 60–200%.36

Polydimethylsiloxane (PDMS) is another interesting amorphous polymer that has found wide usage in bioelectronics due to its biocompatibility, nontoxicity, excellent optical transparency, and reasonable chemical resistance.22, 37, 38 Due to its very low glass transition temperature (T g ≈ −125 °C) PDMS is a highly flexible and stretchable (≈1000%) material with a relatively low shear modulus ranging between 100 kPa and 3 MPa and flexural modulus ≈54 MPa.39, 40, 41, 42, 43 Importantly, the mechanical properties of PDMS are intimately linked with the way it is manufactured,44 and it displays an unusually high CTE value (≈310 ppm °C−1) as compared to other amorphous polymers.45 To date, PDMS has been used in many biological applications such as wound‐bandages,46, 47 microfluidics,48, 49, 50 and recently in various organs‐on‐a‐chip platforms.51, 52

Polyimides (PIs) are an interesting class of amorphous polymers that offer most of the advantages of semi‐crystalline polymers along with a high glass transition temperature (350 °C) and low CTE (8–20 ppm °C−1).26 They are also remarkably strong (2–4 GPa), flexible, and have an astonishing resistance toward chemicals and heat.26, 53 PI has been used in the electronics industry for decades and has begun to gain momentum as a polymer for flexible bioelectronics in recent years.9, 13, 54 Despite, the many advantages that PI‐based materials offer, they are not optically transparent (30–60%).24 However, current cutting‐edge technology has enabled the incorporation of fluorine, sulfonic, or nonaromatic groups into PI to make it optically transparent.55 PI‐based materials therefore hold great promise for flexible bioelectronics and have in recent years significantly advanced the field.

2.3. Semi‐Crystalline Polymers

Semi‐crystalline polymers are the most widely used group of polymers because they have unique properties that combine the best characteristics of amorphous and crystalline polymers.56 Semi‐crystalline polymers are typically very flexible, whereas highly crystalline polymers are rigid, as briefly mentioned in the previous section.31 Semi‐crystalline polymers also have a sharp melting point and do not soften gradually like amorphous polymers, which is a contributing factor to their superior dimensional stability at elevated temperatures as compared to amorphous polymers.24 However, the sudden phase transition above the glass transition temperature significantly impairs the temperature operating range of semi‐crystalline polymers.

Various semi‐crystalline polymers can be used for bioelectronics including PET, polyethylene naphthalate (PEN), and polyetheretherketone (PEEK).24 These semi‐crystalline polymers show desirable mechanical flexibility, solvent resistance, high clarity, low CTE (≈20–45 ppm °C−1), and good moisture barrier properties (0.1–0.5%).24 Notably, the mechanical and physical properties of semi‐crystalline polymers strongly depend on their morphology and the crystalline content within them.57 Their elastic modulus, flexural strength, and tensile strength have been reported in the range of 2.3–5 GPa, 70–170 MPa, and 55–200 MPa, respectively.36, 58, 59, 60 Importantly, they are highly flexible and bendable, and can stretch up to 50–300%.36 Although semi‐crystalline polymers have many of the aforementioned advantages, they do not possess the required upper operating temperature to match with the processing temperature of conventional electronic circuits (up to 350 °C),24 since PET, PEN, and PEEK have glass transition temperatures in the range of 80–150 °C.26 Another disadvantage of semi‐crystalline polymers is their high surface roughness, which significantly limits their performance in a range of applications.24 However, flexible bioelectronics such as transparent electrodes, sensors, and actuators based on PET61, 62, 63 and PEEK64, 65 materials with acceptable performances have still been successfully fabricated. Parylene C is yet another promising semi‐crystalline polymer for flexible bioelectronics, as it is biocompatible66 with a high T g point (80–100 °C), low CTE (35 ppm °C−1),24, 26, 67 and displays excellent barrier properties toward water vapor, corrosive molecules, and various gases.68, 69, 70 Moreover, parylene C is a low‐cost polymer that can be easily processed into a protective ultrathin layer on almost any material, making it an ideal choice for the fabrication of cheap and ultrathin conformal bioelectronics.71, 72

Due to a growing technological demand, a significant amount of electronics are discarded and trashed every year.73 There are serious environmental concerns about the hazardous and toxic materials present in such discarded electronics.74 Therefore, the field is moving toward fabrication of flexible bioelectronics based on biodegradable and nontoxic materials in order to reduce the consequent accumulation of toxic waste. Flexible bioelectronics that can dissolve inside the body are also gaining momentum, as they can help to reduce the electronic waste materials and assure swift elimination of the bioelectronics once their mission in the body is accomplished.75, 76

Extensive research has been done on flexible and degradable electronics made from cellulose (paper) and silk‐based biopolymers. The degradation pathway of cellulose is typically driven through hydrolysis mediated by the family of cellulose enzymes, whereas silk—in its low‐crystalline state—is a highly water‐soluble protein, which disperses in physiological relevant solutions. Out of these materials, paper is particularly recognized for being a good material candidate in flexible electronics due to its high availability, flexibility, light weight, and sustainability.77 Various electronic items such as thin film transistors,78, 79 organic solar cells,80, 81 disposable radio frequency identification tags,82 batteries,83 and wearable diagnostic devices2, 84 have been made from paper‐based materials. Nanocellulose85, 86, 87 and silk88, 89, 90, 91 are also interesting biopolymers, as they are simultaneously strong, flexible, biocompatible, thermally stable, and recyclable at the same time. For instance, the decomposition temperature of nanocellulose has, in some instances, been shown to exceed 300 °C,92 while CTE values of around 8 ppm K−1 have been reported,93, 94 which are in the same range as that of glass95 and metals96 and are significantly lower than most commercial plastics (>200 ppm K−1).26 The amazing properties of nanocellulose have prompted its use as a material in electronics, with device performance comparable to its rigid counterparts.97, 98, 99 Silk also displays similar remarkable thermal and mechanical properties as nanocelluose, and in addition to its biodegradability, it can be easily tuned, making it a prime candidate in implantable bioelectronics.10, 75 Therefore, there is no doubt that various paper formats and biopolymers will open new avenues for fabrication of high‐performance flexible bioelectronics that are cost‐effective, nontoxic, biodegradable, and eco‐friendly.

3. Polymeric Conductors and Semiconductors

Many important biological processes such as neuronal activity,100 the synchronous beating of heart,101, 102 and muscle contraction103 are all tightly controlled by electricity. For this reason, most bioelectronic devices base their functionality on the conversion of biological signals into electricity104, 105—a signal format that can be easily recorded, modulated, and analyzed—and thus enable a great variety of bioelectronics. Electrodes play a major role in this direction, as they can connect the world of electronics with the world of living tissues. Among the many materials, gold (Au) and platinum (Pt) electrodes are still the standard choice in bioelectronics; however, their high cost and low flexibility represent critical issues for their application in flexible bioelectronics. Over the years, significant progress has been made by chemists to develop conductive, biocompatible, and flexible polymers that can address the aforementioned challenges. These multifunctional polymers are beyond doubt the primus motor behind the exponential speed at which the field of bioelectronics is currently evolving with. Therefore, the main focus of this section is directed toward conductive polymers.

3.1. Conductive Polymers

Electrically active polymers have emerged as a new class of mechanically robust and biocompatible materials for flexible bioelectronics.20, 106, 107 One of the most remarkable properties of these conductive polymers are the many functionalization pathways that they offer to fine‐tune the electrical and mechanical properties. They also offer other interesting features because some of them have intrinsic semiconductor properties that are essential for the design of basic electronic components such as transistors and field‐effect transistors.108 Due to their formidable multifunctional properties, the research and development of new polymeric conductors has dramatically expanded during the last decades; the most‐studied ones being polypyrrole (PPY), polyaniline (PANI), and poly(3,4‐ethylenedioxythiophene) (PEDOT).

3.1.1. PPY

PPY is considered to be one of the pioneering polymeric conductors in bioelectronics due to its ease of functionalization and unique electrochemical properties (high conductivity and stability in oxidized states).105, 109 Depending on the conditions and reagents utilized in the oxidation, the electrical conductivity of PPy can range from 10 to 100 S cm−1.110, 111 It has been widely used as the outer electrode material for neural implants112 and for recording neural impulses.105, 113 PPY has also been used as a material for controlling cell‐fate through electrical stimulation and is recognized for its ability to yield high‐resolution electrical recordings from electroactive tissues and cells.105 Despite of their exciting electrical properties most PPy films are brittle and mechanically unstable due to their conjugated chain structure, which significantly limits their usage in many flexible electronics applications.114 To remedy this drawback, efforts have been dedicated for enhancing the strength of the PPy matrix by optimizing its manufacturing process115, 116, 117, 118 and reinforcing it with other polymers.114, 119, 120

3.1.2. PANI

PANI was discovered as early as 1862,121 but it was not before the beginning of the 1980s that it started to garner the attention of scientists in the medical sciences.122, 123 Due to its exceptional stability,124 reasonable biocompatibility,125, 126, 127 and high conductivity,128 its range of applications encompasses a variety of fields including biomedical engineering,129 flexible electronics,130, 131 and electromechanical engineering.132 Moreover, because of PANI's good biocompatibility and high conductivity, it also holds great promise for use in the engineering of electroactive tissues.133, 134 To this end, the electrical conductivity of PANI has been reported within the range of 10–100 S cm−1; a parameter that can be fine‐tuned through molecular weight,135 temperature,136oxidation level,137 crystallinity degree,138 degree of doping,139 and film morphology.137, 140 However, unfortunately, since PANI is synthesized from acidic solutions, it tends to degrade in physiological environments significantly impacting its electrical stability in such environments.141 One possibility to address this problem is to functionalize PANI with specific dopants via either noncovalent or covalent approaches, or by utilizing PANI nanomaterials such as nanowires, nanofibers, and nanorods instead.142

3.1.3. PEDOT

PEDOT is perhaps the most‐investigated electroactive polymer to date,129, 143 as it keeps its ability to conduct electricity over a broad pH range.144 It is also electronically stable in physiological environments105, 145 and can merge with in vivo tissues without inducing toxic and foreign body responses.46, 146 The polymeric backbone of PEDOT can also be easily functionalized to increase its conductivity, biocompatibility, and stability through the incorporation of various dopants, counter ions, and biological moieties.147, 148 The most frequently used PEDOT derivative is PEDOT doped with poly(styrene‐sulfonate) (PSS)—PEDOT:PSS—an optically transparent polymer with an electrical conductivity that can go as high as 4600 S cm−1.149 Even though, PEDOT:PSS films can be stretched up to ≈60%, the electrical conductivity in such strain regimes is highly compromised, and ultimately can present a great hindrance for the utilization of PEDOT:PSS in flexible electronics.150 Recently, this grand challenge has been tackled by incorporating ionic additives and various electrical conductivity enhancers to generate highly conductive and stretchable PEDOT:PSS films.151 These materials display a conductivity that can reach 4100 S cm−1 under 100% strains, because of their enhanced crystallinity and more interconnected polymeric networks.151

3.1.4. Poly(3‐hexylthiophene) (P3HT)

P3HT is another interesting semi‐conducting polymer, which has been widely used in various types of electronics—in particular organic solar cells—since its discovery in 1980.152, 153 P3HT is easy to modify, nontoxic, and conductive, and is typically generated from monomers of 2,5‐polythiopene (2,5‐PT) by using various metals to initiate the polymerization process.153 Besides its usage in solar cells, P3HT has also recently found its ways into the field of flexible bioelectronics, as it has been used in several flexible electronic devices capable of sensing various biomolecules.154

3.2. Semiconductors

Replacing inorganic semiconductors with their organic counterparts involves a number of trade‐offs. The advantages include decreased manufacturing expenses, higher flexibility, and light‐weight.108, 155, 156 On the negative side, however, organic semiconductors can be electrically unstable in physiological environments,157, 158 they are more fragile than their inorganic counterparts,108, 159, 160 and they display a weak long‐term in vivo performance due to faster biodegradation in the body.

Over the years, several modification strategies aimed at strengthening intermolecular polymer bonds have been used to increase the stability of organic semiconductors. Especially, PEDOT:PSS has garnered significant attention, as it can be easily functionalized and is susceptible to electrical dopants.147 PEDOT:PSS is a p‐type organic semiconductor that is very sensitive to the surrounding electrolyte concentrations,156 and it is able to electrically respond to electrolytes through its amazing cation uptake ability.161 This property provides PEDOT:PSS devices with an unusually facile pathway to measure the many electrolyte‐sensitive events inside physiological environments. The unique electrical properties of PEDOT‐based polymers have sparked tremendous interest in the past few years with the primary focus being directed toward their applications as organic bipolar junction transistors and field‐effect transistors.105, 156

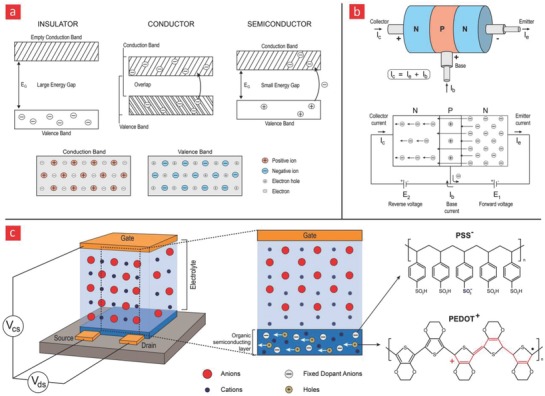

In simple terms, a bipolar junction transistor consists of three semiconductors: a collector, base, and an emitter.162 A field‐effect transistor (FET) is a further extension of a transistor, as its operating principle is basically the same as a transistor with one exception, namely, the inclusion of an electrode (gate) above the transistor channel (base).162 By regulating the gate voltage, it is possible to control the current through the transistor channel and into the source. FETs therefore possess an extra feature compared to an ordinary transistor because of their ability to switch between two states, that is, a low current state (off) and a high current state (on) (Figure 4 ). In most bioelectronic applications, the channel and the gate are separated by an electrolyte solution. By applying a positive potential to the gate, the “on” and “off” states, and ultimately the current across the channel, can be tightly regulated, as the positive gate potential drives cations from the electrolyte solution into the transistor channel (Figure 4), which in turn makes the FETs sensitive toward various forms of currents with a typical response time around 100 Hz. Another important electrical effect in some polymer‐based FETs is the formation of an electrical double layer, which can significantly improve the response time, as this double layer provides the FETs with high‐capacitance, and thus enables them to operate with much higher frequencies (≈10 kHz).163 This current sensitivity enables various sensing and detection schemes depending on the application. For instance, in a landmark study led by Malliaras and co‐workers, a simple but yet elegant PEDOT:PSS transistor was developed for glucose monitoring.164 The PEDOT:PSS transistor was capable of monitoring glucose concentrations through a mechanism that involved the enzymatic conversion of glucose into the byproducts gluconic acid and hydrogen peroxide (H2O2) by glucose oxidase. The formation of hydrogen peroxide was quite essential, as it significantly alters the gate potential resulting in a huge current drop across the transistor channel.165 In another study, the same principle was used to measure the lactate concentration in blood, which is a well‐known marker for monitoring the effect of exercise, wellness, and physical fitness.166 Instead of glucose oxidase, another enzyme (i.e., lactate oxidase) was used to convert lactate into pyruvate. The generation of pyruvate changed the gate voltage and thus the current across the transistor channel. Despite the many interesting applications of PEDOT:PSS‐based transistors, they are still behind inorganic transistors in terms of their conductivity and response time.

Figure 4.

Energy bands and semiconductor‐related devices. a) Energy‐band diagrams for insulators, conductors, and semiconductors. The current in semiconductors are either generated from electrons (−) or electron holes (+). b) A transistor is basically made from three different semiconductors. The current can only run in one direction in a transistor, and the current that passes through it is typically enhanced with a sustainable gain factor, making them suitable for various sensing applications. c) A qualitative illustration of the working principles behind a sensor that is based on a field‐effect transistor made from PEDOT:PSS, which is an organic semiconductor capable of absorbing electrolytes (anions) from a solution. The uptake of anions abolishes the mobile holes within PEDOT:PSS and thus changes the current that passes through it; it thereby enables it to sense biological processes that either diminish or increase the amount of electrolytes in the surrounding environment.

In summary, organic semiconductors hold great promise in flexible bioelectronics due to their reasonable sensitivity, high flexibility, biodegradability, and low cost. They have already successfully been used in a wide range of biological and medical applications, and further applications are expected once their response time and conductivity are made to match their inorganic counterparts.

4. Conductive Polymer Composites

One avenue to bridge the current gap between conductive polymers and their inorganic counterparts is to reinforce them with inorganic fillers. The prime components of most of today's inorganically reinforced polymers are 2D and 1D nanomaterials.167 A wide selection of such materials exists; the most studied ones are 2D graphene sheets and 1D carbon nanotubes (CNT) and silicon nanowires, however, other emerging nanomaterials are also worthy of consideration, such as boron nitride, silicene, germanene, and phosphorene.167 Owing to their remarkable electronic, thermal, piezoelectric, mechanical, and moisture‐sensing properties, these nanomaterials have found widespread importance in flexible electronics.167, 168, 169 Indeed, it is anticipated that their inclusion in electronics could revolutionize the entire industry and facilitate the emergence of better, faster, and smarter electronics that can be readily implemented within existing electronic formats.168 The unique portfolio of properties that nanomaterials bring to the table can also be readily utilized in flexible bioelectronics to yield even more flexible and electrosensitive devices.169, 170, 171

Another area that avenues to improve the electrical properties of flexible polymers is the incorporation of liquid metals into them, as liquid metals are conductive, self‐healing, and reconfigurable. It has therefore been foreseen that their incorporation into polymers can lead to sophisticated electronic circuits that can spontaneously repair upon damage.

Even though the research and development of the abovementioned inorganic fillers is still in its infancy, the achievements obtained to date are truly remarkable and have already surpassed those reported by conventional organic‐based polymers. We are therefore confident that these fillers will be a game‐changer in flexible bioelectronics. One concern, however, is their cytotoxicity and biocompatibility in vivo, which still has not been carefully evaluated. This is beyond doubt one of the major challenges that needs to be addressed before their potential can be translated into devices that can integrate seamlessly with the human body.

4.1. Graphene

In brief, graphene consists of a monolayer of carbon atoms that are packed densely into a 2D hexagonal honeycomb lattice with a carbon–carbon bond length of 1.42 Å172 and a thickness of only one atomic layer (≈0.3 nm), which makes it the “thinnest” material ever discovered.173 This ultrathin 2D nanomaterial displays really high electrical conductivity (2.50 × 105 cm2 V−1 s−1),174 good thermal conductivity (≈3000 W m−1 K−1),174 amazing mechanical flexibility (ultimate tensile strength (130 GPa), high Young's modulus (≈1 TPa),174, 175 and low coefficient of thermal expansion (CTE) (≈−8 × 10−6 K−1).176, 177 Moreover, due to its high specific surface area (up to 2600 m2 g−1),178 large aspect ratio (up to 2000),179 chemical reactivity, and tunable interface properties, graphene is much easier to functionalize compared to many other nanomaterials.

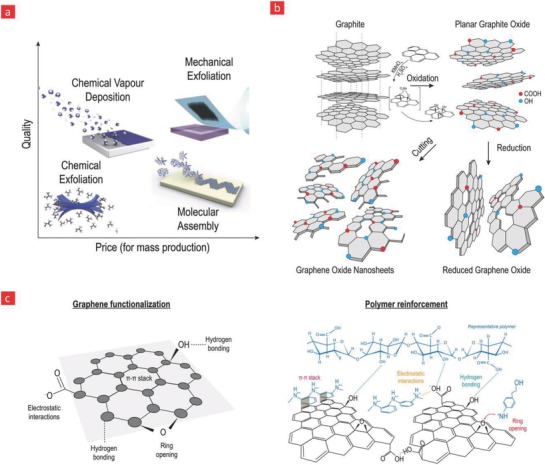

Typically, graphene is synthesized by either top‐down or bottom‐up strategies.180 In the top‐down approach, graphene sheets are exfoliated from the bulk graphite via chemical reactions or mechanical forces to get single or few‐layers of graphene (Figure 5 ). In the bottom‐up strategy, graphene nanosheets are directly grown onto a substrate—starting from single atoms or molecules—by using chemical vapor deposition (CVD), organic synthesis, or solvothermal synthesis methods.181, 182 Until now, different types of graphene have been successfully achieved by using these two strategies. These different varieties include graphene oxide (GO), graphene oxide quantum dots, graphene quantum dots, and reduced graphene oxide (rGO) (Figure 5).182, 183 Among them, GO has received most attention owing to its highly oxidized nature due to its large numbers of surface residual epoxides, hydroxyl, and carboxylic acid group, which in turn provides many chemically reactive groups for various functionalization purposes. GO can also easily be reduced into highly conductive graphene (rGO) by eliminating oxygen‐containing functional groups through chemical, thermal, or irradiation treatment.183

Figure 5.

Various a) manufacturing methods of graphene. Reproduced with permission.447 Copyright 2012, Nature Publishing Group, b) graphene oxide, reduce graphene oxide, and graphene oxide nanosheets are highlighted here. c) Graphene contains numerous functionalities, which can be used to firmly attach it to the backbone of polymers.

Given these unique features of graphene, it has attracted tremendous attention as an electroactive and mechanical nanoreinforcer with the capacity to turn nonconductive polymer‐based materials into amazing conductors of electricity with impressive mechanical properties.184, 185 However, it should be emphasized that the electrical conductivity and sensitivity of graphene are typically greatly affected by other factors such as the presence of adverse functional groups on the graphene sheets, various intrasheet and intersheet structures, intersheet junctions, the aspect ratio of the sheets, and the processing methods used to manufacture them.184, 186, 187 Overall, they are therefore potential candidates for the development of even better conductive and polymer‐based electrode–tissue interfaces for flexible bioelectronics.

As an example, graphene incorporation within PEDOT has resulted in significant improvement of mechanical and electrical properties, features that were used to enhance the performance of neural and microelectrode interfaces.188 In this case, the positive charge of oxidized PEDOT chains was ionically bonded to the negatively charged group of GO to form a stable conductive polymer film. An advantage of this functionalization strategy is that it prevents GO from dispersing into the target tissue during electro‐physiological recordings, and can thus minimize any possible cytotoxicity caused by graphene inside the body. Aside from chemical incorporation of graphene into PEDOT, graphene can also be physically mixed with PEDOT polymer chains to form a free‐standing film. This approach relies on the polymeric structure of PEDOT, which consists of many conjugated π bonds, that enable strong π–π stackings between PEDOT molecules and graphene sheets. For instance in one study, it was shown that such free‐standing graphene–PEDOT composite films can lead to an almost sixfold increase in mechanical strength and more than twofold improvement in electrical conductivity as compared to a pristine PEDOT polymer film.189

Graphene may also be used to effectively reinforce PEDOT:PSS polymer film for flexible bioelectronics. Toward this endeavor, studies have shown that the graphene–PEDOT:PSS composites can be formed by either in situ polymerization or various blending processes.190, 191 In the in situ polymerization method, graphene is typically dispersed in the PSS solution after which the EDOT monomer is gently added. Then, the polymerization process is initiated in the presence of a Fe3+.190 Compared to PEDOT:PSS film, the electrical conductivity of the graphene–PEDOT:PSS composite film was increased with up to 41% (637 S cm−1) at only 3 wt% graphene loading. Although this approach is effective for homogeneous dispersion of graphene sheets in the polymer matrix, it is limited, as the rate of polymerization is decreased at high graphene content. By contrast, the solution blending method is the most straightforward approach to use for developing polymer films at high graphene concentrations. To this end, Seol et al. recently developed a stretchable and transparent conducting electrode based on mixing PEDOT:PSS with rGO.191 Specifically, the authors managed to reduce the adverse agglomeration of rGO by functionalizing rGO with a surfactant—(phenyl isocyanate)—that could reduce possible π–π interactions between rGO nanosheets and PEDOT:PSS. This flexible composite system displayed significantly higher optical transmittance (≈86%) and a greater electrical conductivity (1010 S cm−1), as compared to rGO–PEDOT:PSS and pristine PEDOT:PSS.

Graphene has also in recent years been used in wearable sensor systems due to its ability to improve the accuracy in position, acceleration, and velocity detection of its wearer at high strains and strain rates.192, 193, 194 In an enlightening study, Boland et al. showed that by loading graphene into a natural rubber, it is possible to produce conducting composites with electrical conductivity as high as 0.1 S m−1.193 In this system, the graphene nanosheets could quickly respond to polymeric deformations caused by dynamic movements in a time dependent manner, due to mechanically induced changes in electrical conductivity within the polymeric matrix. Moreover, this flexible composite system could stretch up to 8 times its original length without losing electrical functionality and mechanical integrity. Other noteworthy application of graphene is its inclusion into piezoresistive/piezoelectric polymer‐based sensors for converting the kinetic energy of the moving body into harvestable energy and in electronic skin (e‐skin) devices.169, 170, 171

Other properties of graphene such as electrical and mechanical stability can be further coupled with control over the specific interactions between graphene and polymers to generate a self‐healing and conductive composite system.195 The impartation of self‐healing function empowers the electronics to be revamped not only mechanically but also electrically, which is of great interest for electrical functional restoration after damage during large mechanical strain regimes. To this end, graphene has been incorporated into a self‐healing polyvinyl alcohol (PVA) polymer matrix to generate highly stretchable and self‐healing strain sensors.196 The conductive graphene‐hydrogel based strain sensors displayed fast electrical healing speed (within 3.2 s), remarkable self‐healing performance (≈98%), and was able to sustain high elastic deformation (≈1000%) with gauge factor of 0.92.196 Although this system is unequivocally opening new possibilities for usage in robotics, healthcare monitoring, and various human motion detection systems, further efforts should be focused on enhancing their stability and sensitivity to bring this interesting technology into the mainstream market.

4.2. Carbon Nanotubes (CNTs)

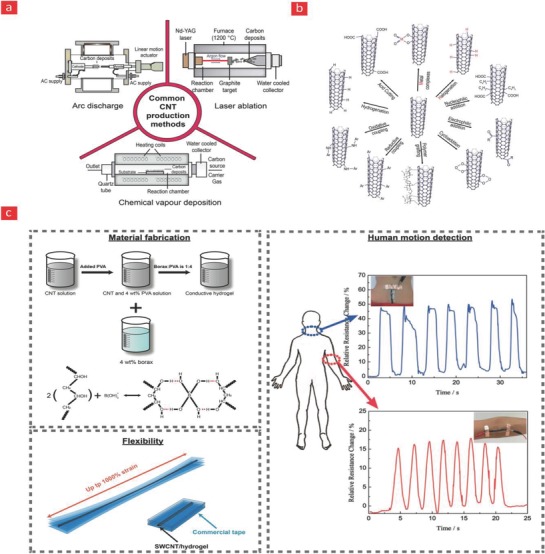

CNTs belong to the fullerene family of nanomaterial's and consist of graphene sheets that are rolled‐up into high‐aspect ratio tubes (>1000).197 They come both as single‐wall carbon nanotubes (SWCNTs) and multiwall carbon nanotubes (MWCNTs), and for the most part “the two” show similar properties, however, the tensile strength of SWCNTs is significantly lower than MWCNTs, which makes SWCNTs more flexible than their multiwalled counterpart.198 Over the years CNTs, have found widespread application in diverse fields ranging from electronics, medicine, and drug‐delivery, as they pose unique properties such as formidable tensile strength (11–63 GPa),199 high Young's modulus (1–1.8 TPa),200 excellent intrinsic conductivity (109 A cm−2),201 high thermal conductivity (2000–6000 W m−1 K−1 at room temperature),202 and are thermally stable up to 2800 °C in vacuum conditions.203 They are also perfect reinforcers for flexible electronics, as they are readily bendable and squeezable, and display spring‐like properties under constant loading. Furthermore, CNTs can be synthesized via various methods with the most frequently applied ones being electrical arc‐discharge, laser ablation, and CVD (Figure 6 ).204, 205, 206 With each of these methods, the surface chemistry, surface area, surface charge, and CNT size distribution can be uniquely fine‐tuned to yield desired CNT batches for further downstream applications.204 In laser ablation, laser pulses are applied to pure graphite blocks to vaporize them into ultrathin pieces that subsequently can generate CNTs on a water cooled collector,204 while in the electrical discharge process a high current is applied between two graphene electrodes—anode and cathode—in the presence of metallic catalysts, which catalyze the growth of CNTs on the cathode (Figure 6).204 The most standard method employed however is CVD, which is based on the pyrolysis of hydrocarbons in a tube furnace and the usage of metallic‐catalysts to polymerize them into CNTs. As the CVD method is the most practical, economical, and pure pathway for CNT synthesis, it is also the one most commonly used for commercial‐scale production of CNTs.205

Figure 6.

Various CNT a) production and b) functionalization strategies. c) A self‐healing and flexible PVA‐CNT based composite for human motion detection. Adapted with permission.196 Copyright 2017, Wiley‐VCH.

The outstanding properties of CNTs have turned them into widely used nanofillers in polymer matrixes for the construction of flexible, stretchable, and deformable electronics.22, 207, 208, 209, 210 Until now, several methods have been proposed to incorporate CNTs into polymers such as solution mixing, melt processing, and in situ polymerization.211 However, untreated CNTs are chemically inert and too hydrophobic to disperse with ease in organic or inorganic solvents, and are therefore unable to establish strong interactions with the polymer backbone. The key to overcome this obstacle is the functionalization (covalent or noncovalent) of CNTs with hydrophilic groups such as hydroxyl, carbonyl, carboxyl, and amines to improve the dispersion stability and chemical reactivity of CNTs, and ultimately yield reinforced polymers with good electronic, magnetic, optical, thermal, and mechanical properties.212 Moreover, the performance of stretchable CNT‐based electronics could be enhanced by alignment of the nanomaterials. Indeed, studies have shown that horizontally or vertically aligned CNTs within polymer matrixes can significantly improve the conductivity and mechanical performance of flexible electronics.213, 214, 215, 216, 217

Notably, CNTs typically form a percolation network within the matrix, which in turn significantly enhances the electrical conductivity within the polymer. For instance, several studies have shown that CNTs networks can be formed within polymers to yield highly conductive and stretchable strain sensors.22, 207, 208, 216, 218, 219 In one paramount study, SWCNTs were embedded into a stacked nanohybrid structure within polyurethane (PU)–PEDOT:PSS to provide a transparent, stretchable, and patchable strain sensor.208 This strain sensor displayed good optical transparency (≈63%), a high gauge factor (62.3), and could stretch up to 100% before breakage. In a similar vein, SWCNTs were embedded into PDMS to generate a sensor that could sense mechanical deformations arising at the “bone–skin” interface to enable the detection of joint‐movements in the human body with a mechanical sensitivity ranging as low as 105 MPa−1 at 0.9 MPa pressure.22 Despite of its incredible sensitivity this system, however, could only perform at strains at 30% as the conductive CNT percolation network otherwise would breakdown.

One avenue to improve the CNT percolation network is based on generating a PDMS foam consisting of 3D‐interconnected networks and then dip the entire polymeric foam into a CNT solution.209, 220 In this procedure the CNTs will adhere to the PDMS network to generate a percolated network of conductive wires. For example, in a recent groundbreaking study, this concept was successfully used to develop a highly sophisticated wearable strain sensor with an excellent gauge factor of 134 at a 40% strain value.209 Another strategy to achieve a more favorable CNT network within a polymer matrix is the use of graphene sheets to form a hybrid CNT/graphene structure, which efficiently inhibits the bending and bundling deformation of CNT networks during successive stretchings.220 In this scenario, the graphene nanosheets are able to disperse and adsorb pristine CNTs, whereas the CNTs are capable to function as bridges and avert the restacking of graphene nanosheets through π–π interactions.

As previously mentioned, the integration of self‐healing properties into polymers has speared a major paradigm shift toward the development of flexible and stretchable electronic devices with higher durability during successive loadings. Toward this endeavor, a self‐healing piezoresistive strain sensor device, which is able to detect the dynamic movement of the human body was recently developed by incorporating SWCNTs into a self‐healing PVA polymer matrix (Figure 6).196 The self‐healing mechanism was built into the system via reversible hydrogen bonds in the PVA matrix mediated by borate ions through a simple one‐pot mixing of CNT, PVA, and borax. These weak hydrogen bonds could easily break and reform, and were thus one of the main driving mechanisms behind the self‐healing properties of the manufactured device. Specifically, the device was incorporated into a Scotch permanent clear mounting tape, which acted as an elastomeric substrate, and enabled the system as a whole to stretch 1000% with an amazing self‐healing efficiency of 98%, after only 3 s of healing time. In addition to this formidable stretching ability, which according to the authors was the highest value ever recorded for such device, the SWCNTs themselves also established spring‐like and conductive links between the individual polymer chains, and thus contributed to a significant improvement of the elasticity, conductivity, and flexibility of the composite system relative to pristine PVA. The sensor device was then mounted onto human joints, and the authors demonstrated its capacity to monitor various human motions in real time through changes in resistivity brought about by the mechanical strains, that the PVA‐CNT polymer experienced during human joint motions.

4.3. Metallic Nanowires

Existing bioelectronic devices primarily use metal electrodes such as Au, Pt, and Ag because of their suitable electrical properties, biocompatibility and corrosion resistance.221, 222, 223, 224, 225, 226 Especially, Au has been extensively used for bioelectronics due to its high ductility, good corrosion resistance, good biocompatibility, and long‐term operational stability. Au‐based electrodes have found many interesting applications in bioelectronics; some of the most noteworthy are as electrical conductors for glucose biosensors,227 cochlear implants,228 and in electrodes that enable communication between the brain and various machine formats.72

For instance, Au nanostructures in the form of nanowires have gained great interests in flexible and stretchable bioelectronics, owing to their remarkable aspect ratio (≈10 000), mechanical and electrical properties.229, 230 To this end, Gong et al. fabricated a wearable and highly sensitive pressure sensor by sandwiching ultrathin gold nanowires (AuNWs) between PDMS sheets.229 This system was able to detect pressures as low as 13 Pa with a response time of <17 ms, and sensitivity of 1.14 kPa−1 in the pressure range of 0–5 kPa. Due to its excellent sensing, flexibility, and robustness, this device was used for real‐time monitoring of blood pressure and various acoustic vibrations. Although, AuNWs‐based devices are quite promising for the field of flexible electronics their conductivity could be improved even more. A possible approach for improving the conductivity of such devices is by combining them with conductive polymers. For example, PANI microparticles have been doped into AuNWs films to yield a tenfold improvement in conductivity and eightfold enhancement in electrical sensitivity in comparison to pristine AuNW‐based strain sensors.231

Silver nanowires (AgNWs) are another interesting class of metallic nanowires, which has been widely used in various types of wearable and flexible bioelectronics.226, 232, 233, 234 AgNWs can form highly conductive percolative networks to yield a good optical transparency and a high structural flexibility. For instance, Ho et al. developed a transparent stretchable strain sensor based on percolating networks of both AuNWs and AgNWs on an elastomeric PDMS substrate.232 This strain sensor displayed good optical transparency (≈66.7%), high gauge factor (≈236), and could stretch up to 70% of its original length. Due to their high conductivity, compatibility, and mechanical deformability, AgNWs‐based polymer‐based electronics have also been recognized as promising nanomaterials for electrophysiological recordings.226, 235 For instance, in a recent study, AgNWs were patterned into styrene–butadiene–styrene (SBS) elastomers to form serpentine‐like meshes capable of mimicking the elastic and electrical properties of cardiac tissue.226 In this scenario, the AgNWs formed a highly conductive percolation network, while the SBS rubber acted as a binder to maintain the mechanical elasticity. This stretchable cardiac mesh was readily integrated with the curvilinear and dynamic in vivo heart and could ultimately improve cardiac contractile function in a post‐myocardial‐infarction model.

Although, AgNWs and AuNWs have demonstrated promising results in the field of flexible electronics, they are relatively expensive compared to their organic counterparts Hence, copper nanowires (CuNWs) have become an appealing alternative, since they are cheaper, but yet, display an electrical conductivity similar to that of silver (Ag) and Au.236, 237 So far, different types of wearable and flexible devices have been developed by incorporating CuNWs into various elastic polymers, such as poly (acrylate),238 polyurethane,239 PVA,240 Eco‐flex,241 and SBS.242 Although, CuNWs have many of the aforementioned advantages, CuNWs display some disadvantages related to their easiness to become oxidized, which significantly limits their electrical performance in a range of applications as oxidative layers are highly insulating.237, 239 One strategy to overcome this obstacle is by coating CuNWs with corrosion‐resistant metals such as nickel, Pt or Ag.237, 243, 244 For example, Song et al. coated CuNWs with nickel (Ni) to improve their oxidation‐resistant stability.237 Subsequently, the CuNW–Ni composite was embedded into PDMS to provide a conductive elastomer composite with transparency of 80% and resistance of 62.4 ohm sq−1. This composite system could endure up to 600 cycles of bending, stretching, and twisting tests without breaking.

4.4. Silicon Nanowires

1D silicon nanowires (SiNWs) are also steadily gaining a foothold in bioelectronics—albeit to a lesser degree compared to graphene and CNTs—due to their unique electrical, mechanical, and optical properties.245, 246, 247 Indeed, compared to the other nanomaterials discussed here, SiNWs have an advantage in terms of their better semiconductor properties,248, 249 which in turn makes them amenable in the development of nanoscaled transistors and FETs.250, 251 Notably, the nanoscale diameter and high‐aspect ratio of silicon nanowires significantly alter, and in some cases improve their electrical properties as compared to solid silicon, due to quantum effects arising from quantum confinement within the wires. The small size of silicon nanowires also makes it much easier to control their electrical properties. For instance, one can significantly widen the band‐gap of silicon nanowires by simply decreasing their diameter and the orientation of the wire axis also have an important say on the many interesting properties of silicon nanowires.252, 253, 254

Various techniques based on both top‐down and bottom‐up manufacturing have over the years been developed to generate silicon nanowires.245, 246 In the bottom‐up process individual Si atoms are lined up into silicon nanowires with diameters between a few nanometers to several hundred nanometers via CVD and vapor–liquid–solid based methods. In the top‐down approach different lithography methods such as electron beam lithography and reactive‐ion etching are employed to carve out ultrathin silicon nanowires from solid silicon wafers. Even though, top‐down approaches are the most attractive to employ due to the high precision and flexibility they offer, these benefits come at a huge cost, as conventional lithography methods are time‐consuming, costly, and difficult to upscale to meet an industrial scale production.

Due to their amazing electronic properties, silicon nanowire devices display impressive sensitivity when it comes down to measuring bioelectrical signals in the body.255, 256 For instance, silicon nanowires have recently been employed in implantable bioelectronics with the purpose of enabling even better electrophysiological recordings as well as controlled drug release in response to important biological events inside the body.15, 17, 257 Despite of these interesting advances, which will be elaborated in a more detailed manner in Section 6.4, silicon nanowires have not been as widely used in the field of bioelectronics as compared to their carbon‐based counterparts, and the focus have for their part so far mainly been directed toward photovoltatic, electronic, and energy storage devices. The authors therefore anticipate that the incorporation of silicon nanowires into biocompatible polymers represent an interesting area ripe for investigations, and could therefore enable significant breakthroughs in the field.

4.5. Liquid Metals

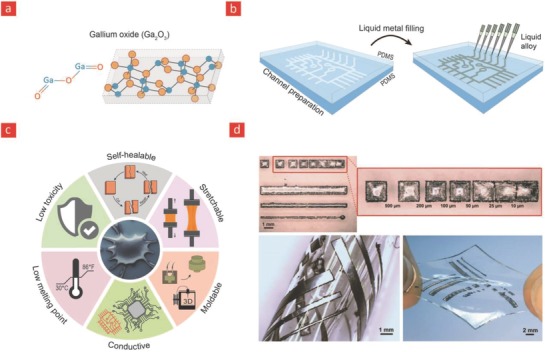

Another class of inorganic materials for flexible electronics is liquid metals, as these materials are liquid near room temperature and therefore flow readily in response to stress (Figure 7 ).258 This enables them to deform and stretch in response to stress in a reversible manner, which makes them ideal candidates for stretchable and self‐healable electronics.259, 260, 261 Especially, in recent years, there have been tremendous advancements in the emerging technology of stretchable electronics based on liquid metals such as mercury and gallium oxide (Ga2O3).262 However, mercury is a well‐known environmental toxicant,263 gallium oxide on the other hand has a relatively low toxicity making it ideal for flexible bioelectronics.262 Moreover, gallium has a number of interesting properties that makes gallium an attractive component to include in flexible bioelectronics,264, 265 as gallium has high electrical conductivity (2.2 × 106 S cm−1),266 good thermal conductivity (28W m−1 K−1 at ≈37 °C),267 is highly stretchable,258, 262, 265 and reconfigurable due its inherent oxide film that considerably decreases its surface tension without significantly impacting its other properties (Figure 7);268, 269 gallium oxide thin film thus permits liquid metal droplets to wet polymer surfaces and also enables an inconsequential barrier to form for optimal electrical charge transport. Moreover, the wettable nature of gallium also allows it to adhere to the polymer surfaces to form almost any shape for soft and stretchable circuits. Other gallium‐based liquid metal alloys such as ternary alloys (galinstan; 68% gallium, 22% indium, and 10% tin) and eutectic gallium–indium alloys (EGaIn; 75% gallium and 25% indium) have also attracted much interest, as gallium alloys are easier to shape due to their below room temperature melting points, while displaying otherwise similar physical properties to conventional gallium oxide films.270

Figure 7.

Gallium oxide, its properties, and application in flexible bioelectronics. a) The chemical structure of gallium oxide. b) The many unique properties that gallium oxide has to offer. c) Incorporation into polymers to yield flexible and electrical circuits. d) A gallium embedded PDMS substrate with high‐fidelity and stretchable circuits. Reproduced with permission.272 Copyright 2013, Wiley‐VCH.

Due to their unique material properties and below room temperature melting point (gallium melts at 30°), gallium alloys have recently been used as conductive fillers in place of rigid filler particles to improve the electrical and mechanical properties of elastomeric polymers.271, 272, 273 In brief, viscoelastic gallium droplets are shaped into the desired electrical circuits by injection of the liquid metal into premade hollow architectural geometries within elastomers. The gallium‐based circuit is subsequently hardened by freezing the composite system—as a whole—below the melting temperature of the liquid metal solution. Gallium‐based alloys can thus readily be used to generate highly complex stretchable circuits by simple injecting them into such elastomeric materials (Figure 7).265, 274 For instance, injection of EGaln into hollow poly[styrene‐b‐(ethylene‐co‐butylene)‐b‐styrene] fibers have lead to stretchable and electrically conductive circuits that could stretch up to 800% before mechanical failure, without losing their electrical continuity.265 These elastomeric circuits could find widespread importance in many exciting applications ranging from flexible electronics, electronic textiles, stretchable wires, and flexible bioelectronics.

Liquid alloys composed of gallium are also ideal candidates for creating conductive circuits within elastomeric substrates, which spontaneously can self‐heal electrical and mechanical defects imposed on them during wear and tear.260, 275 A recent study accomplished this daring task through a simple system composed of a hollow self‐healing polymer (Reverslink@) into which EGaln was injected. This marvelous system—in the advent of damage—could spontaneously heal its electrical properties and mechanical properties after 10 minutes. In another recent study flexible galinstan‐based electronics was generated through inkjet printing of the liquid metal onto a stretchable PDMS substrate. Notably, the galinstan‐based circuit could spontaneously heal itself after damage, and was engineered in a manner, that enabled it to remain electrically and mechanically stable even after 2000 stretching cycles at strain of 60%.276

The incorporation of liquid metals within polymers and then the deposition of the entire system onto a conductive metal trace is another avenue for achieving a self‐healing circuit, as this ingenuity enables liquid metals to readily reconnect distal parts emerged during tear caused by either wear or mechanical failure.261 In perspective, owing to its unique self‐healing properties, stretchability and conductivity, we anticipate that the integration of liquid metals into self‐healing elastomers will pave the way for many exciting opportunities for highly flexible bioelectronics in the near future.

Indeed, the aforementioned multifunctional properties of gallium and its alloys have also made them attractive candidates for bioelectronics. For instance, it has been reported that the EGaIn electrodes can be used to both record and stimulate electrical activity in individual neurons.277 Another particularly interesting application utilized the electrical and physical properties of Ga‐based liquid metals to achieve an injectable soft 3D electronic circuit that could be delivered to target tissues, such as heart and sciatic nerve.278 In detail, this electrode was made from a Ga67In20.5Sn12.5 alloy encased in a biodegradable gelatin hydrogel to achieve a minimally invasive integration between electrode and tissue. Although gelatin is widely recognized as a biocompatible and degradable polymer, it however is not conductive and stretchable. To this end, we anticipate that it is possible to use other types of polymers such as conductive PEDOT‐based polymers to improve electrical and mechanical properties of the system.

Another interesting feature of the liquid metals is their ability to change shape via a variety of mechanisms such as mechanical and electrical stimuli, because this unique trait could be useful for a number of applications such as reconfigurable electronics and bioactuators. Furthermore, recent studies have also shown that the combination of fluidity, deformation reversibility, and conductivity in liquid metals can yield artificial microrobots that can move through blood vessels or intestines to fulfill numerous biomedical purposes.279, 280, 281, 282 For instance, the ability to reshape liquid metals by near‐infrared irradiation has recently been utilized to develop an innovative toolbox for controlled drug delivery and optical manipulation of artificial blood vessels.282 These studies have opened a new avenue for the construction of intelligent biorobots that could not be obtained through conventional rigid materials.282 Nevertheless, the in vitro and in vivo application of flexible microrobots require rigorous testing before they can be applied to combat and monitor various diseases.

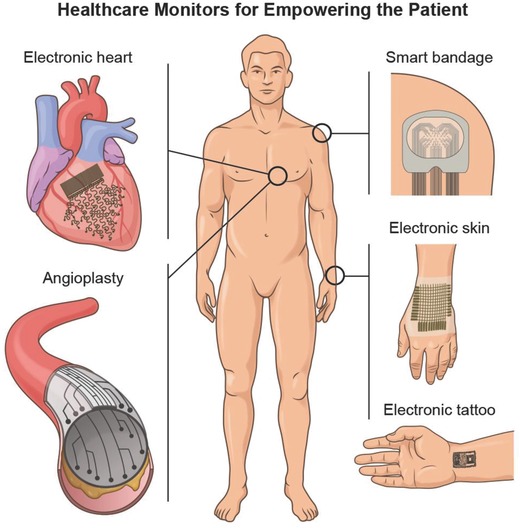

5. Healthcare Monitors for Empowering the Patient

Currently, there are a growing number of breakthroughs in bioelectronics driven by the emergence of better and smarter materials that can readily integrate with the dynamic human body. These technological breakthroughs are aiming to empower the patient through technical health aids that enable real‐time monitoring of medical risk factors.283 This is accomplished by providing the healthcare consumer with individualized health data for self‐diagnosis and self‐management of their personal health. Such wearable healthcare monitors will also allow doctors to check on patients remotely instead of costly and frequent in‐person visits at the clinic. As a result of their projected importance in the healthcare industry, the market for healthcare monitors is growing quickly, and this year alone it is anticipated that over 19 million of such devices will be sold over the counter and over 100 million devices by the end of 2018.4 In spite of the great promise that they hold, the reliability and validity of the data obtained from wearable healthcare monitors are still under intensive investigation. At the moment, there is a lot of ongoing research in the design and development of flexible and biocompatible materials that ultimately can be integrated into the field of bioelectronics to enable more reliable healthcare monitors. Most of the current efforts are directed toward incorporating these materials into devices such as e‐skin,284 smart wound bandages,283 and tattoo‐based sensors (Figure 8 );285, 286 however, the research and development of materials for invasive and flexible bioelectronics that enable the monitoring of the beating heart and neurological activity in the brain are also slowly gaining momentum.287 Here, we will highlight the recent progress in these emerging areas and briefly outline the possible future directions that they may take.

Figure 8.

The field of patient empowerment is currently driven by wearable healthcare monitors (e.g., smart bandages, electronic skin devices, tattoo‐based sensors) and implantable monitors (e.g., flexible electrodes for electrocardiography [ECG] and smart stents for angioplasty). Made by Harder&Muller.

5.1. Wearable

5.1.1. Electronic Skin (E‐Skin)

The human skin can reveal important information about the overall health status of the patient as the mechanical metrics of skin are intimately linked to the circulatory function of the body288 as well as various skin‐related diseases such as melanoma, psoriasis, and eczema.4, 289 Therefore, conformal bioelectronics that enables real‐time monitoring of the mechanical properties of skin can be used to detect potentially life‐threatening and chronic diseases in the home rather than in the clinic.290, 291 Over the years a wide‐range of these so‐called “e‐skin” devices have been developed for healthcare monitoring purposes.12, 62, 284, 289, 292, 293 In simple terms, e‐skin devices are flexible sensing networks with accurate spatial mapping and detection capabilities that enable unmatched recordings of the mechanical metrics of skin. This utility stems in part from the incorporation of 2D nanoelectronics, organic light‐emitting diodes (OLED), and pressure sensors within biocompatible, conformable, and stretchable plastic‐like materials that can withstand high strain deformations while still maintaining their electrical performance.290, 291 The nanoelectronics and pressure sensors work in coherence to transform the viscoelastic changes of the skin into electrical signals for OLED processing into pixelated signals.13, 284, 293 In this direction it is essential to use a mode of synthesis that can yield uniform devices, wherein the individual components are matched perfectly within the e‐skin system. Some of the most noteworthy examples of e‐skin devices include an elastomeric pressure sensor based on the incorporation of CNTs within a PDMS substrate,12 elastomeric dielectrics integrated within an organic field‐effect transistor for measuring the artery pulse from the wrist,62 and a PI‐based system that converts viscoelastic changes of skin into a pixelated and user‐friendly format through an intricate interplay between CNT‐based transistors and OLEDs incorporated within the PI‐substrate.13 Building on these results, an e‐skin system was recently developed with the capability of in‐depth characterization of various skin lesions related to invasive melanomas.289 This concept could potentially be used for rapid characterization of pathological skin conditions and become a platform for at‐home management of skin‐related diseases (Figure 9 ).

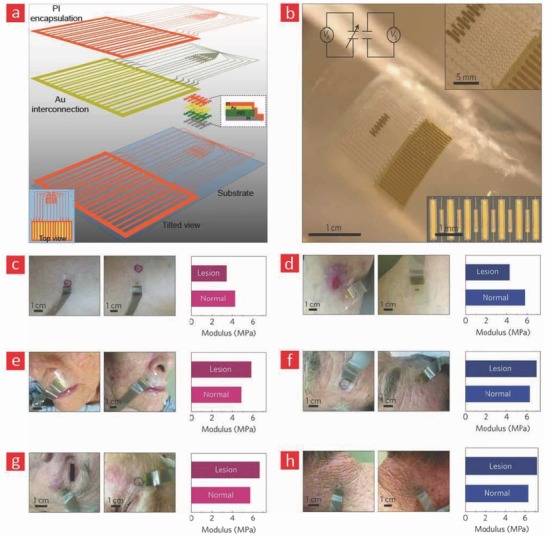

Figure 9.

An e‐skin device for monitoring melanoma and skin lesions. a) The device was fabricated through a layer‐by‐layer assembly of Pt/Au electrodes, a piezoelectric component, and a soft and biocompatible PI‐based polymer interfacing the device with the human skin. b) A bright‐field image of the generated e‐skin device. Mechanical mapping of various skin pathologies located c) below the breast, d) on the leg, e) around the nose, f) on the forehead, g) close to the eye, and h) on the neck. Adapted with permission.289 Copyright 2015, Macmillan Publishers Ltd.

Recently, more sophisticated circuits have been built to expand the sensing capabilities of e‐skin to encompass changes in temperature,294, 295 humidity,169 and chemical variables.296 These additional features enable the patient to detect potentially dangerous foreign bodies from entering the body through the skin and to monitor the effect of various lotions targeted against pathological skin lesions. Moreover, the temperature of the skin is intimately linked to the blood‐flow and therefore presents an important operational parameter that ideally needs to be incorporated into e‐skin devices.295 Such multimodal e‐skin devices have so far mostly been based on CNT and graphene‐based nanoelectronics169, 296 due to the excellent sensitivity of CNTs and graphene toward temperature and humidity changes. To this end, an e‐skin device that is capable of detecting chemical, temperature, and pressure stimuli has recently been developed by sandwiching CNT‐based circuits between PDMS substrates to yield a piezocapacitive system with an ultralow pressure sensitive (0.4 Pa) and fast response time (63 ms).296 Notably, this e‐skin system enabled the detection of a range of chemical fluids and could therefore be used as a wearable electronic nose capable of detecting potentially dangerous fluids.

Overall, the abovementioned advancements have led to the development of multifunctional and mechanically robust e‐skin platforms with formidable sensory capabilities for wireless diagnostics.297 These advancements highlight the amazing potential of e‐skin technologies and foresee the introduction of e‐skin devices that have the capacity to perceive additional stimuli for various healthcare monitoring.

5.1.2. Smart Wound Bandages

Chronic wounds represent a global healthcare challenge that is expected to grow at a tremendous speed in the coming years as the population ages.298 With the current lack of methodology to properly treat the growing number of patients suffering from chronic wounds a cumbersome bottleneck is expected.298 This hurdle is intimately linked to today's time‐consuming, costly, and passive wound management scheme, wherein the wound site, is neither monitored nor attended properly. To remedy the current situation, smarter solutions that offer a better insight into the healing process rather than passive wound management are needed. With the recent advancements in biosensors, a new generation of highly sophisticated wound dressings are rapidly emerging to revolutionize the classical wound care concept.299 These platforms act as conformal point‐of‐care bandages that consist of sensors capable of detecting important biomarkers of relevance for the wound‐healing process.300 They also provide the possibility of remote diagnostics through wireless communication technology and can therefore result in reduced nursing and hospitalization costs.301, 302

Over the years, a comprehensive list of potential biomarkers for wound healing has been established, which include markers such as pH value, temperature, proteins, inflammatory mediators, cytokines, enzymes, hormones, and nutritional factors.303 The most widely used markers are temperature and pH‐value, as they are intimately linked with the extent of inflammation and infection at the wound site.299, 304 Therefore, a range of temperature and pH sensors have been incorporated into flexible, permeable and biocompatible materials to yield smart wound bandages.305, 306, 307, 308, 309, 310, 311 A recent example, is a surgical suture made from silk—a water‐soluble protein—for wound closure and real‐time monitoring of wound‐healing processes. A silicon‐based temperature sensor was incorporated within this silk suture to enable high‐resolution sensing (≈0.2 °C) of temperature changes caused by inflammation at the wound sites.307 The system was tested in an animal model and showed promising results that highlighted its potential as a bioresorbable suture capable of monitoring the progress of inflammation within the target site. Building on these results, a multimodal wound bandage was developed with the ability to provide highly accurate temperature readings from the wound site.308 The system was multimodal, since it provided readings on both temperature changes and temperature conductivity. As previously mentioned, temperature mapping of the wound site captures the inflammation progress; temperature conductivity, on the other hand, correlates with the moisture content of the wound, which is another important marker that is intimately linked to the state of the wound. In simple terms, this system consists of a PI substrate containing a sensor array that is connected with ultrathin and flexible copper wires. The conformability of the PI‐based device and its capacity to record temperature‐related readings from the wound site were confirmed on human subjects. The reported results were indeed promising and indicated that the developed wound bandage could be readily implemented in a clinical setting.

In addition to monitoring the infection and inflammation status of a wound, other approaches can be explored to promote the healing process by administrating drugs and growth factors to the site. In a recent study by Bagherifard et al.,312 thermoresponsive drug‐carriers were incorporated into a hydrogel‐based dressing with a flexible heater for controlled delivery of drugs and growth factors to the wound site. The platform enabled a controlled release of various compounds in response to temperature changes and could therefore potentially be used in smart wound bandages, wherein drugs and growth factors can be released in response to increases in temperature from inflammation and infection.

Bandages with textile‐like materials have also been extensively used for covering wounds, since they are porous, biocompatible, and capable of delivering oxygen and removing exudates from the wound site.313, 314 They can be fabricated in large scales using well‐known and simple techniques, such as weaving, knitting, and embroidering. Another key advantage of using textiles is that the mechanical properties of individual strands and the entire fabric can be tuned by changing the properties of the fibers or the architecture of the fabric during the manufacturing process.314 To this end, a flexible and fiber‐based pH sensor was recently fabricated by loading pH‐sensitive microspheres into alginate‐based microfibers.23 The level of acidity at the wound site was measured by taking images of the fibers with a smartphone camera and analyzing the images using an in‐house application. Such hydrogel‐based fibers can also be easily knitted into intricate native‐like architectures and therefore enable the generation of customized bandages for wound‐healing applications. In a another recent study, an advanced wound bandage was developed from conductive threads that were embroidered onto a textile to form interconnected electrodes.315 A range of physical and chemical sensors was later incorporated into the bandage to enable high‐fidelity measurements of temperature, glucose, and pH from biological fluids. It was also shown that the developed platform could potentially be used for measuring the physiological conditions at the wound surface through an external device, such as a smartphone or personal computer.