Abstract

The International Organization for Standardization (ISO) standard 16900–1:2014 specifies the use of sodium chloride (NaCl) and corn oil aerosols, and sulfur hexafluoride gas for measuring total inward leakage (TIL). However, a comparison of TIL between different agents is lacking. The objective of this study was to measure and compare TIL for respirators using corn oil and NaCl aerosols. TIL was measured with 10 subjects donning two models of filtering facepiece respirators (FFRs) including FFP1, N95, P100, and elastomeric half-mask respirators (ERs) in NaCl and corn oil aerosol test chambers, using continuous sampling methods. After fit testing with a PortaCount (TSI, Inc., St. Paul, MN) using the Occupational Safety and Health Administration (OSHA) protocol, five subjects were tested in the NaCl chamber first and then in the corn oil chamber, while other subjects tested in the reverse order. TIL was measured as a ratio of mass-based aerosol concentrations in-mask to the test chamber, while the subjects performed ISO 16900–1-defined exercises. The concentration of NaCl aerosol was measured using two flame photometers, and corn oil aerosol was measured with one light scattering photometer. The same instruments were used to measure filter penetration in both chambers using a Plexiglas setup. The size distribution of aerosols was determined using a scanning mobility particle sizer and charge was measured with an electrometer. Filter efficiency was measured using an 8130 Automated Filter Tester (TSI). Results showed the geometric mean TIL for corn oil aerosol for one model each of all respirator categories, except P100, were significantly (p < 0.05) greater than for NaCl aerosol. Filter penetration in the two test chambers showed a trend similar to TIL. The count median diameter was ~ 82 nm for NaCl and ~ 200 nm for corn oil aerosols. The net positive charge for NaCl aerosol was relatively larger. Both fit factor and filter efficiency influence TIL measurement. Overall, TIL determination with aerosols of different size distributions and charges using different methodologies may produce dissimilar results.

Keywords: Corn oil aerosol, faceseal leakage, FFP1, filter efficiency, filter penetration, N95, NaCl aerosol, P100 and elastomeric half-facepiece respirators, total inward leakage

Introduction

The International Organization for Standardization (ISO) defines total inward leakage (TIL) as the leakage of the ambient atmosphere into the respiratory interface from all sources including filters, where present, when measured in the laboratory in the specific test atmosphere.[1] The respiratory interface is the barrier between the respiratory tract and the ambient atmosphere. TIL is measured as a percentage of the ratio of ambient air concentration to in-mask concentration. The TIL values measured for different types of respirators in the laboratory setting provide improved understanding on the protection levels expected for airborne contaminants in workplaces.

TIL is a function of particle leakage through faceseal and any component interfaces, and particle penetration through filter media. Several studies have investigated the significance of faceseal leakage for respiratory protection.[2–4] Coffey et al. evaluated the effect of fit testing on the performance of respirators.[5] The simulated workplace performance of 20 N95 filtering facepiece respirators (FFRs) and an elastomeric half-facepiece respirator (ER) with replaceable filters was measured by conducting 100 total penetration tests for each model. The performance was estimated by determining the 95th percentile of total penetration. The results showed higher than expected protection levels for N95 respirators with fit testing. Another study investigated the correlation between workplace protection factor (WPF) and fit factor (FF).[3] Fifteen workers tested two models of N95 respirators, each with three sizes. The results showed 43 of the 55 donnings had FFs >100. The WPFs showed a geometric mean (GM) of 920 and geometric standard deviation (GSD) of 17.8. The results showed a good correlation of WPFs with FFs indicating that FF was a meaningful indicator of respirator performance in real workplaces.

Similarly, the association of filter efficiency of respirators with TIL has been reported. Han and Lee measured TIL with subjects wearing FFRs certified for 80%, 94%, and 99% filter efficiency [6] and ERs. The results showed an inverse relationship between filter efficiency and TIL of respirator categories. Another study measured the simulated workplace protection factor (SWPF), an inverse factor of TIL, for FFRs (N95 and P100) and ERs with N95 and P100 filters.[7] A comparison of relatively higher- and lower-efficiency respirators (P100 vs. N95 and ER vs. FFR) showed larger SWPF or lower TIL for higher-efficiency respirator categories. Similarly, TIL was found to be inversely related with filter efficiency for five N95 FFR models tested with 35 test subjects in two different laboratories[8] and for four N95 FFR models tested using a manikin head.[9]

Several studies showed the influence of particle size distribution on TIL and respirator performance.[9–15] TIL was measured for five models of N95 FFRs worn by 35 test subjects in two different NIOSH laboratories with particle distribution showing mean count median diameters (CMDs) of 82 nm and 131 nm.[8,15] Results showed that the number of test subjects passing the TIL test (i.e., TIL <1.0%) was significantly lower in the laboratory with a CMD of 82 nm compared to the laboratory with a CMD of 131 nm indicating the effect of particle size distribution on TIL measurement.[8] The results are consistent with the findings in other studies,[12,13] which showed a particle size-dependent increase in protection factor (inverse factor of TIL). Recent studies also showed TIL was particle size-dependent for different types of aerosols.[10,16]

To our knowledge, a comparison of TIL measured using two or more test agents (aerosols and gases) has not been reported in the literature. To address the issue, ISO 16900–1 standard developed a test protocol to measure TIL using test agents such as NaCl and corn oil aerosols, and sulfur hexafluoride gas (SF6).[17] The ISO 16900–1 standard describes the measurement of TIL using specified test agents and incorporating specified body movements, at a specified metabolic work rate.[17] The TIL value is used as a performance requirement to determine the protection class (PC) of the respiratory protective devices (RPDs).[18] The PC is based on the laboratory performance, and not the type of RPD. The protection level (PL) represents the degree of respiratory protection allocated to a RPD for the purposes of selection and use that is expected to be provided to wearers when used within an effective RPD program as described in the ISO 16973 standard.[19] Table 1 shows the TIL value ranges for the six PCs and the corresponding PLs. ISO-16900–1 standard (2014)[17] recommends the use of a mass-based aerosol concentration measurement for corn oil as well as NaCl aerosols for the determination of TIL. This is in contrast to the number-based TIL methods described in other studies.[5,8,20,21]

Table 1.

Total inward leakage (TIL), protection class (PC), and protection level (PL).

| Total Inward Leakage (TIL) Min-Max (%) | Protection Class (PC)A | Nominal Protection Factor (NPF)B | Safety Factor | Protection Level (PL)C |

|---|---|---|---|---|

| 5.0–20.0 | PC 1 | 5 | 1.25 | 4 |

| 1.0–5.0 | PC 2 | 20 | 2 | 10 |

| 0.1–1.0 | PC 3 | 100 | 3.33 | 30 |

| 0.01–0.1 | PC 4 | 1,000 | 4 | 250 |

| 0.001–0.01 | PC 5 | 10,000 | 5 | 2,000 |

| <0.001 | PC 6 | 100,000 | 10 | 10,000 |

ISO classification of respirators.

NPF = 100%/Maximum TIL(%) for each PC.

PL = NPF/Safety factor (assigned based on experience and professional judgment on the performance of a respirator).

The objective of this study was to compare the TIL values measured using NaCl and corn oil aerosols and SF6 gas as specified in the ISO 16900–1 test protocol.[17] Testing with SF6 was not possible because of the lack of a dedicated chamber for it. In this study, two models of European certified CE-marked FFP1 respirators and two models each of three categories of NIOSH approved respirators (N95, P100, and ER) were tested. Two models each of four different respirator categories worn by human subjects were tested in NaCl and corn oil aerosol test chambers, side-by-side. The TIL values obtained for the two aerosols were used to assign the PCs and the corresponding PLs for two models of four different categories of respirators. The TIL values measured using the two aerosols were compared for each respirator model. Similar comparisons of PCs as well as PLs for the two aerosols were performed. The authors hypothesize that because of the difference in the size distribution of the two aerosols and different methodologies used for measuring aerosol concentrations dissimilar TIL values will be obtained. Similarly, the PCs and PLs will be different for the same respirators tested with the two different aerosols.

Materials and methods

Respirators

Two models of European CE-marked FFP1 FFRs and two models each of NIOSH certified N95 FFR, P100 FFR, and ER models with N95 filters were tested in the study. Respirator models were selected based on the commonly used models in NIOSH studies, and the availability of the devices in the market. The CE-marked FFR models were selected based on their availability. The manufacturers and models are shown in parentheses: FFP1 (Blackrock and 3M Model 8710E), N95 FFR - (3M Model 1870 and Sperian Model N1105; Small, Medium/Large, and Extra-Large sizes), P100 FFR - (Sperian Model P1130; Small, Medium/Large, and Extra-Large sizes) and 3M Model 8293), and ER (with N95 rated filters) (North Model 7700–30; Small, Medium, and Large sizes) and MSA (Model Comfo Classic; Small, Medium, and Large sizes). The two models of FFP1 FFRs were labeled as A and B, N95 FFRs as C and D, P100 FFRs as E and F, and ERs as G and H, in a random manner. The FFP1 FFR category is certified at 80% filter efficiency.[22] NIOSH approves the N95 FFRs and P100 FFRs, and ERs with replaceable N95 filters at 95, 99.97, and 95% efficiencies, respectively.[23]

NaCl and corn oil aerosol test chambers

The TIL values for corn oil and NaCl aerosols were measured in two separate chambers. The dimensions of the corn oil aerosol chamber are 3.05 X 3.05 X 2.74 m. Corn oil aerosol is generated using the MSP Corporation Model 2045-S High Output Aerosol Generator (MSP Corp., Shoreview, MN). The aerosol generator injects corn oil aerosol into the vertical section of a 20.3 cm in diameter duct approximately 213 cm upstream of a horizontal header connected to the intake plenum. The corn oil aerosol/air mixture flows into the corn oil chamber through four vents (0.3 X 2.1 m) equally spaced on the aerosol inlet plenum. The dimensions of the NaCl aerosol chamber are 2.43 X 3.05 X 2.74 m. NaCl aerosol is generated using a 2% salt solution by an SFP Services (Dorset, UK) 4100/250F single collision atomizer with an integral fan. The air supplied by the fan conveys the NaCl aerosol into the chamber through a 20.3 cm in diameter duct to the chamber, approximately 5.8 m downstream of the NaCl aerosol generator.

The two chambers share a common air lock entry-way. The interior/exterior walls are covered with fiber-glass reinforced plastic (Class C Fire Rating) facilitating ease of cleaning. A description of the NaCl and corn oil aerosol chambers and the measurement of aerosol concentrations are provided (Supplemental: Materials and Methods, available at the Journal of Occupational and Environmental Health online).

Size distribution of aerosols in TIL test chambers

The distribution of aerosol particles between 20–1000 nm diameter sizes in the two test chambers was measured using a Scanning Mobility Particle Analyzer (SMPS) (TSI 3080; TSI, Inc., St. Paul, MN). An aerosol sample from the test chamber was analyzed for the number concentration of different size particles over 240 sec in scanning mode with an ultra-fine condensation particle counter (TSI 3776). The measurement was repeated after an interval of 30 sec. From the scans, the average count median diameter (CMD) of the aerosol was obtained.

Test subjects

Ten subjects tested each respirator model and the NIOSH bivariate panel was used for placement of test subjects in specific face length by face width cells.[24]The ISO 16900–1 recommended principal component analysis (PCA) panel was not used because of the difficulty in recruiting subjects with larger face sizes. The bivariate panel has 10 cells and covers face lengths from 98.5–138.5 mm and face widths from 120.5–158.5 mm. Fit testing subjects of small, medium, and large face sizes achieved the highest geometric mean (GM) FFs with the small, medium, and large respirator sizes, respectively.[24] Fit test results obtained in that study indicated that good fitting on human faces could be achieved by selection of proper size respirators for the facial dimensions.[24] Of theeight models of respirators tested in the present study, four models were in three different sizes while the others were one-size-fits-all type. The NIOSH Human Subjects Institutional Review Board approved this study and all subjects gave written consent to participate.

Fit testing

Subjects were fit tested in a room adjacent to the TIL test chambers prior to TIL testing. A PortaCount Pro+ (Model 8038, TSI, Inc., Shoreview, MN), with the N95-Companion mode turned off, was used to measure the FF. The use of a PortaCount to measure FF for similar species (positive, negative, and neutral) of aerosols would be more appropriate for the comparison of different types of respirators than using the conventional FFs by the N95-Companion for N95 FFRs and the PortaCount for P100 FFRs. Test subjects were instructed to don the respirator in accordance with the information supplied by the respirator manufacturer. The test administrator tried to ensure that the subjects followed the information supplied by the respirator manufacturer including the instructions when donning the device to complete the user seal check. The test subjects were allowed to adjust the respirator before fit testing. Subjects performed the eight exercises described in the standard OSHA fit test protocol.[25] The eight exercises were performed in the following order: (1) normal breathing, (2) deep breathing, (3) turn head side to side, (4) move head up and down, (5) speak out loud (recitation of the “rainbow” passage), (6) reach for floor and ceiling, (7) grimace, and (8) normal breathing. The duration of time for each exercise is approximately 1 min for a total of 8 min for the test. At the end of the test, the PortaCount calculates the FF for each individual exercise (FFi) and provides a harmonic mean (FF) for seven exercises, excepting the grimace exercise. After fit testing, the subject continued to wear the respirator, with the sampling tube removed. After a 5 min break, the subject was tested for measuring TIL.

TIL measurement using test subjects

All subjects participated in the TIL testing, irrespective of passing or failing the fit test. The rationale for this is to understand whether all subjects passing or failing the fit test consistently yield relatively lower or higher TIL values expected for the different categories of respirators. The subject was not allowed to adjust the respirator fit until the completion of the TIL test in the two test chambers. Five subjects were tested in the NaCl aerosol chamber first and then continued testing in the corn oil aerosol chamber. The other five subjects were tested in the reverse order. After the test subject entered the chamber, the sample tubing was connected to the respirator and the subject stood on the non-moving treadmill for about 2 min to keep the equipment ready for measurement. The test subject performed the exercise regimen continuously as specified in the ISO16900–1[17] (Annex B). The TIL for each exercise and for the entire test regimen was measured. After completing the exercise regimen, the sampling tube was removed and the test subject exited the chamber, continued to wear the device without any adjustment or repositioning for a resting period of 5–10 min, and then entered the second test chamber for testing. The sampling tube was connected to the respirator. The subject continued testing in the second testing chamber following the same exercise regimen as in the previous chamber. A continuous sampling method was used to measure the in-mask and test chamber aerosol concentrations. In the case of NaCl aerosol testing, the aerosol sample was withdrawn at 1 liter per minute and was mixed with filtered air at 1 liter per minute (used to reduce the relative humidity of the exhaled sample) at a distance of 22 cm downstream of the sample point. The upstream and downstream aerosol samples of NaCl aerosol and corn oil aerosol were measured using a flame photometer (SFP Services, Type 1250) and a light scattering photometer (TSI 8587A), respectively. A LabVIEW program collected the data and provided the overall TIL value for the two aerosols.

TIL calculation

The arithmetic mean of the TIL level measured for all exercises for each subject was calculated using the following formula:

| (1) |

where C1 is the concentration of corn oil in the test chamber C2 is the concentration of corn oil in the respiratory interface.

Although corn oil aerosol is not hygroscopic, some deposition is expected in the airways during inhalation. ISO 16900–1 did not recommend any correction factor for corn oil aerosol deposition.

In the case of NaCl aerosols, ISO 16900–1 recommends a correction factor to account for NaCl aerosol deposition in the airways of the test subject during breathing. The correction factor for a continuous sampling method used in the study is calculated using the sample drawn from the inhalation portion (50%) and exhalation portion (50%) of breathing which is actually measured by the flame photometer. The correction factor also assumes that 80% of NaCl aerosol is absorbed by the airways.

| (2) |

| (3) |

| (4) |

| (5) |

where Cm – concentration of aerosol measured by the photometer Cin – concentration of inhaled aerosol Cex – concentration of exhaled aerosol.

Based on the above equation (5), the measured concentration was multiplied by 1.6 to get the inhaled concentration. The inhaled concentration is the same as the in-mask concentration measured by the photometer. A sample dilution factor of 2 was used in the TIL calculation. The sample was withdrawn at 1 mL/min and diluted with 1 mL drying air per minute. The percentage of TIL was calculated as follows:

| (6) |

where C1 is the concentration of NaCl in the test chamber C2 is the concentration of NaCl inside the respiratory device S is the sample flow rate (L/min) D is the drying airflow rate (L/min).

Filter penetration against NaCl and corn oil aerosols of the TIL test chambers

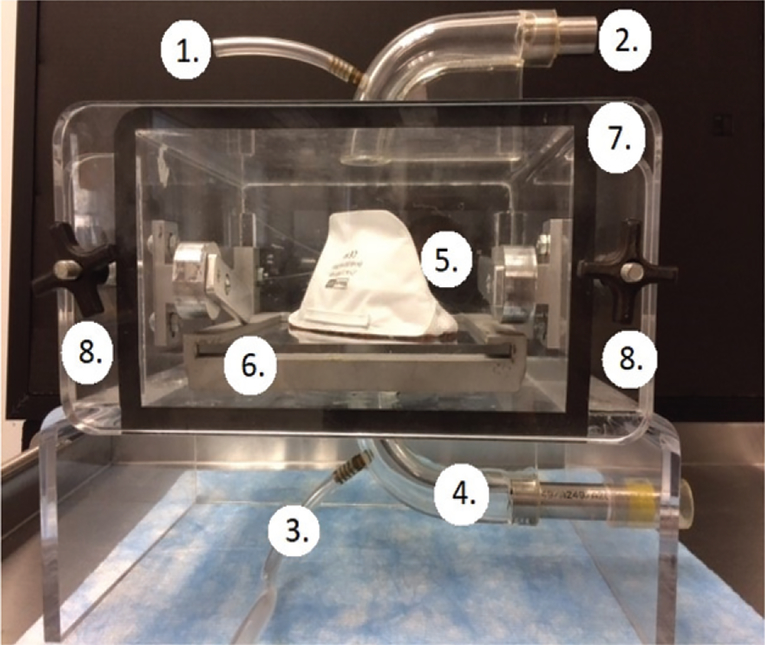

Previous studies described the influence of filter penetration on TIL.[8,9,14] To study this, filter penetration of respirators was measured with NaCl as well as corn oil aerosols in the TIL test chambers using a Plexiglas test set-up (Figure 1), as described previously.[8]Briefly, the test set-up consisted of a Plexiglas box (25 × 25 × 15 cm) with a Plexiglas plate holder in the center. A respirator was mounted on a Plexiglas plate (20 × 20 × 0.5 cm), with its concave side facing a hole (5 cm in diameter) in the center of the plate and sealed with beeswax. The respirator plate was secured in the Plexiglas plate holder. The respirator plate was clamped against a rubber O-ring at the outlet in the bottom of the box to prevent aerosol leakage downstream. The front cover of the box was secured with two nuts on either side. The top and bottom holes of the test box were fixed to inlet and outlet tubes (2.5 cm diameter). The top inlet tube allowed ambient aerosol to enter inside the test box. The bottom outlet was connected to a vacuum line containing a mass flow meter to monitor and maintain an aerosol carrier gas flow rate of 85 L/min. An aerosol sampling tube (0.5 cm diameter) was attached to the inlet and outlet close (2.5 cm) to the Plexiglas box. The upstream and downstream aerosol concentrations of the samples of NaCl aerosol and corn oil aerosol were measured for 5 min using a flame photometer (SFP Services, Type 1250) and a light scattering photometer (TSI 8587A), respectively. Two samples were tested in the NaCl aerosol chamber first and then in the corn oil aerosol chamber, while two other samples were collected in the reverse order. The mean penetration and standard deviation were calculated. The filter penetration measured at 85 L/min is not the same as the filter penetration that might occur during breathing of the test subject. In this study, filter penetration was measured at a higher flow rate to obtain larger values to show any difference between the two aerosols. The difference would be much smaller at a lower flow rate (e.g., 30 L/min) which may not show any difference between the two aerosols.

Figure 1.

Filter penetration test set-up. A respirator sample was mounted on a Plexiglas plate and positioned inside the test set-up to measure filter penetration at 85 L/min flow rate. Keys: (1) Upstream sampling tube, (2) ambient air inlet tube, (3) downstream sampling tube, (4) vacuum line, (5) A respirator sealed to a Plexiglas plate, (6) Plexiglas plate holder, (7) front door, and (8) nut.

Filter efficiency estimation using initial penetration

The efficiency measured in the study is not the same as the efficiency measured by NIOSH for respirator certification purposes.[27] Initial penetration for 1 min was measured to estimate the filter efficiency. The initial penetration for two models of FFP1, N95, and P100 FFRs and ER filters was measured with NaCl aerosol used in the NIOSH respirator certification protocol. Each FFR was sealed to a Plexiglas plate and then initial penetration for 1 min was measured at 85 L/min flow rate using a TSI 8130 (TSI, Inc., St. Paul, MN) automated filter tester.[8] Five samples of each model were tested and the mean penetration was calculated to obtain the initial filtration efficiency.

Aerosol charge measurement

An electrometer (Model 3068B; TSI, Inc., St. Paul, MN) was used to measure the net charge (fA) of NaCl and corn oil aerosols in the TIL test chambers. The aerosol flow rate was kept at 1.5 L/min during the current measurement at room temperature. The current measurement data were reported as an average of over 30 min to minimize the impact of noise. The charge of the two aerosols was measured on 3 different days when the subjects were tested in the chambers.

Data analysis

All TIL values were common logarithmically-transformed to calculate the GM TIL and geometric standard deviation (GSD) by respirator model and test aerosol (corn oil or NaCl). For each respirator model, analysis of variance (ANOVA) tests using the PROC GLM command (general linear model in SAS software: V9.3 SAS Institute, Inc., Cary, NC) were performed on the dependent variable of log-transformed TIL to test the effects variable of test aerosol type (NaCl and corn oil) at the significance level (P-value) of 0.05.

Results

TIL in NaCl and corn oil aerosol test chambers

Table 2 shows the GM TIL values obtained for NaCl and corn oil aerosols with 10 subjects, donning two models each of FFP1, N95, P100 FFRs, and ERs (with N95 rated filters) categories. TIL values for the two aerosols showed wide variation for all respirator models as shown by the maximum and minimum values. The GM TIL values were larger for corn oil aerosol than for NaCl aerosol for all eight models tested in the study. The GM TIL values of corn oil aerosol for one model each of FFP1 (A), N95 (D), and ER (H) models were significantly (p < 0.05) greater than the values for NaCl aerosol. The GM TIL for NaCl and corn oil aerosols were not significantly different for the two P100 models tested.

Table 2.

The geometric mean (GM) and geometric standard deviation (GSD) of TIL for FFP1, N95, P100, and ER respirators.

| Respirator | Model | Aerosol | TILGM | GSD | Min | Max | Filter Penetration (Aerosol Chamber) (%)* |

|---|---|---|---|---|---|---|---|

| FFP1 | A | NaCl | 0.89 | 2.14 | 0.22 | 2.57 | 0.416 ± 0.44 |

| Corn oil* | 4.03 | 1.71 | 1.81 | 11.47 | 1.253 ± 0.87 | ||

| B | NaCl | 18.50 | 2.62 | 4.34 | 69.25 | 0.011 ± 0.11 | |

| Corn oil | 21.63 | 1.62 | 11.05 | 38.89 | 0.023 ± 0.01 | ||

| N95 | C | NaCl | 12.84 | 2.26 | 2.31 | 42.00 | 0.156 ± 0.17 |

| Corn oil | 14.20 | 2.24 | 3.45 | 37.04 | 0.347 ± 0.06 | ||

| D | NaCl | 0.82 | 4.05 | 0.07 | 6.02 | 0.501 ± 0.95 | |

| Corn oil* | 2.95 | 2.70 | 0.63 | 13.81 | 0.651 ± 1.28 | ||

| P100 | E | NaCl | 0.48 | 15.89 | 0.020 | 12.50 | 0.027 ± 0.38 |

| Corn oil | 1.19 | 4.48 | 0.08 | 12.08 | 0.069 ± 0.13 | ||

| F | NaCl | 0.44 | 8.47 | 0.025 | 22.20 | 0.008 ± 0.0 | |

| Corn oil | 0.76 | 24.45 | 0.00 | 16.53 | 0.01 ± 0.0 | ||

| ER** | G | NaCl | 0.33 | 4.49 | 0.03 | 2.38 | 0.429 ± 0.17 |

| Corn oil | 0.73 | 3.01 | 0.16 | 6.87 | 4.680 ± 0.17 | ||

| H | NaCl | 0.19 | 2.83 | 0.06 | 1.05 | 0.147 ± 0.09 | |

| Corn oil* | 1.09 | 1.97 | 0.40 | 4.52 | 2.965 ± 0.56 |

Significantly higher TIL than for NaCl aerosol.

ERs were used with replaceable N95 filters.

ISO specifies TIL as the second highest value from the list of TIL values obtained for 15 subjects for each respirator model.[18] Table 3 shows the second highest TIL value obtained for each respirator with the 10 subjects tested in the study. For comparison purposes, the GM TIL values for the different respirator models were used.

Table 3.

The protection class (PC) and protection level (PL) for FFP1, N95, P100, and ER respirators using the Second Highest TIL and GM TIL Methods.

| PC | PL | |||||||

|---|---|---|---|---|---|---|---|---|

| Respirator | Model | Aerosol | Second Highest TIL (%)* | GM TIL (%) | Second Highest TIL Method |

GM TIL Method | Second Highest TIL Method |

GM TIL Method |

| FFP1 | A | NaCl | 2.01 | 0.89 | 2 | 3 | 10 | 30 |

| Corn oil | 6.83 | 4.03 | 1 | 2 | 4 | 10 | ||

| B | NaCl | 49.02 | 18.50 | (1) | 1 | <4 | 4 | |

| Corn oil | 37.04 | 21.63 | (1) | (1) | <4 | <4 | ||

| N95 | C | NaCl | 29.60 | 12.84 | (1) | 1 | <4 | 4 |

| Corn oil | 33.33 | 14.20 | (1) | 1 | <4 | 4 | ||

| D | NaCl | 3.06 | 0.82 | 2 | 3 | 10 | 30 | |

| Corn oil | 8.79 | 2.95 | 1 | 2 | 4 | 10 | ||

| P100 | E | NaCl | 8.41 | 0.48 | 1 | 3 | 4 | 30 |

| Corn oil | 14.58 | 1.19 | 1 | 2 | 4 | 10 | ||

| F | NaCl | 8.87 | 0.44 | 1 | 3 | 4 | 30 | |

| Corn oil | 7.89 | 0.76 | 1 | 3 | 4 | 30 | ||

| ER** | G | NaCl | 2.18 | 0.33 | 2 | 3 | 10 | 30 |

| Corn oil | 1.81 | 0.73 | 2 | 3 | 10 | 30 | ||

| H | NaCl | 0.66 | 0.19 | 3 | 3 | 30 | 30 | |

| Corn oil | 2.10 | 1.09 | 2 | 2 | 10 | 10 | ||

ISO/CD (2018) recommended method.

ERs were used with replaceable N95 filters.

Number in parentheses indicates that TIL exceeded the ISO specified upper limit of PC.

Size distribution of aerosols in TIL test chambers

The size distribution of aerosols in the NaCl and corn oil aerosol chambers ranged from 20–1000 nm. The average for the two scans showed CMDs of ~82 nm for NaCl aerosol and ~200 nm for corn oil aerosol.

Filter penetration in TIL test chambers

Filter penetration for NaCl and corn oil aerosols was measured in the test chambers using a filter penetration test setup under TIL test conditions (Table 2). In general, higher penetration for corn oil aerosol compared to NaCl aerosol was obtained for all models. In addition, filter penetrations up to 20% for FFP1 FFRs and up to 5% for N95 FFRs can be expected. This indicates that penetrations would be larger for FFP1 FFRs than for N95 FFRs. However, one of FFP1 models (model B) showed lower penetrations compared to the N95 FFR models. Model B can be considered as an outlier. It should be noted that the FFP1 respirators used for filter penetration experiments were from a lot different from that used for the measurement of TIL.

PC and PL determination

Table 3 shows the second highest TIL from the list of 10 subjects tested with eight models using corn oil and NaCl aerosols. Results showed that FFP1 model A, N95 models C and D, and P100 models E and F exceeded the ISO 17420–1 specified maximum TIL limits for one or both aerosols.[18] The PCs for corn oil and NaCl were generally different for all respirator models tested in the study. None of the eight models tested in the study showed similar PCs for the two aerosols. On the other hand, the PCs obtained using the GM TIL values showed good agreement between the two aerosols for one model each of N95 (modelC), P100 (model F), and ER (model G) categories.

The PLs were obtained from PCs for all models tested in the study. Because of this, the PL results showed a trend similar to PCs for the two aerosols for all respirator models. None of the eight models showed similar PLs using the second highest TIL method. The PLs obtained using the GM TIL method showed good agreement between the two aerosols for one model each of N95 (model C), P100 (model F), and ER (model G) categories.

Fit factor

Table 4 shows the effect of GM FF on TIL obtained for the eight respirator models. The results showed that TIL values for both aerosols were inversely related to GM FFs. This is evident by the smaller TIL values corresponding to larger FFs and vice versa, for FFP1 and N95 models, while other category respirators produced mixed results. The P100 (model E) and ER (model H) showed lower TIL for NaCl aerosol only. In general, all subjects passing the fit test showed relatively lower TIL values. Two subjects passed the fit test with one FFP1 model (model A), which showed TIL values of 0.12 and 0.15, whereas other subjects who failed the fit test showed TIL values >0.25. Similar results were obtained for N95 FFR model D which passed the fit test by five subjects. Four subjects showed TIL between 0.02–0.29 and the fifth subject with 0.42. Interestingly, two subjects who failed the fit test showed lower TIL (<0.42). Similar exceptions were observed with fit test passing and TIL for P100 and ER models.

Table 4.

A comparison of TIL, and fit factor and filter efficiency for FFP1, N95, P100, and ER respirators.

| TIL (%) | ||||||

|---|---|---|---|---|---|---|

| Respirator | Model | Aerosol | GM | GSD | GM Fit Factor (*) | Efficiency (Filter Penetration) (%)* |

| FFP1 | A | NaCl | 0.89 | 2.14 | 53 ± 2 | 99.34 (0.66 ± 0.17) |

| Corn oil | 4.03 | 1.71 | ||||

| B | NaCl | 18.50 | 2.62 | 8 ± 2 | 91.75 (8.25 ± 2.7) | |

| Corn oil | 21.63 | 1.62 | ||||

| N95 | C | NaCl | 12.84 | 2.26 | 11 ± 3 | 99.48 (0.52 ± 0.11) |

| Corn oil | 14.20 | 2.24 | ||||

| D | NaCl | 0.82 | 4.05 | 71 ± 3 | 99.973 (0.027 ± 0.07) | |

| Corn oil | 2.95 | 2.70 | ||||

| P100 | E | NaCl | 0.48 | 15.89 | 150 ± 8 | 99.975 (0.025 ± 0.19) |

| Corn oil | 1.19 | 24.45 | ||||

| F | NaCl | 0.44 | 8.47 | 51 ± 6 | 99.992 (0.008 ± 0.0) | |

| Corn oil | 0.76 | 4.48 | ||||

| ER | G | NaCl | 0.33 | 2.83 | 89 ± 2 | 99.723 (0.277 ± 0.88) |

| Corn oil | 0.73 | 1.97 | ||||

| H | NaCl | 0.19 | 4.18 | 91 ± 2 | 99.629 (0.371 ± 0.41) | |

| Corn oil | 1.09 | 3.01 | ||||

Indicates Mean ± Standard Deviation

Filter efficiency

The effect of filter efficiency on TIL was evaluated using inter-respirator (between respirator categories) and intra-respirator categories (between two models of each respirator category) methods. In general, with the inter-respirator category method, an increase in efficiency showed a decrease in TIL except the ER category (Table 4). The ER models with N95 filters (95% efficiency) showed smaller or comparable TIL values to those of P100 models. The inter-respirator method compared the efficiencies of the four respirator categories with the TIL for the two aerosols.

In the case of the intra-respirator method, the efficiency vs. TIL comparison was made for the two models of each respirator category for the two aerosols. Filter efficiency showed an inverse relationship with TIL using the two aerosols for FFP1, N95 and P100 models (Table 4). For each respirator category, the relatively higher efficiency model showed lower TIL values for the two aerosols, compared to the TIL values for the lower efficiency model. For ER models, higher efficiency was related to lower TIL only for the corn oil aerosol.

Charge measurement

The net charge measured for NaCl and corn oil aerosols in the test chambers were +70.5 to +72.6 fA and + 0.02 to +1.13 fA, respectively. The higher net positive charge for NaCl aerosol indicates higher proportion of positively charged particles compared to neutral and negatively charged particles. The results show that NaCl aerosol is highly charged relative to corn oil aerosol.

Discussion

All eight respirator models tested by human subjects showed larger TIL values with corn oil aerosol than with NaCl aerosol. The order of testing between NaCl and corn oil aerosols did not show any influence on TIL results obtained in the study. Three models (FFP1 - A), (N95 - D), and ER (H) showed significantly (p = 0.05) higher TIL values with corn oil aerosol. Neither of the two P100 FFR models (E and F) showed any significant difference. The results indicate that a test agent yielding larger TIL would provide a conservative estimate of TIL. The higher TIL values obtained for corn oil aerosol may partly be explained by the difference in aerosol characteristics such as particle size distribution. The CMD for NaCl and corn oil aerosols were ~82 nm and ~200 nm, respectively. Also, the most penetrating particle size (MPPS) is <100 nm for the disposable FFRs and N95 filters tested in the study. The difference in the CMD of the two aerosols indicate relatively larger numbers of NaCl aerosol would pass into the respirator, which may not be contributing significantly to the mass compared to corn oil aerosol.[28,29] Thus, the smaller CMD for NaCl aerosol may have produced lower TIL values compared to corn oil aerosol. Second, the concentration measurement of corn oil aerosol by the TSI model 8587A light scattering photometric method and NaCl aerosol by the flame photometric method yielding similar results is not well studied. A previous study showed comparable filter efficiencies by the flame photometer and the light-scattering photometer used in the TSI model 8130 Automated Filter Tester (AFT).[30] A comparison of the flame photometer and the TSI 8587A photometer is lacking.

Moreover, the filter penetration measured in the two aerosol chambers showed a trend similar to the TIL values measured with corn oil and NaCl aerosols, for all categories of respirator models. The higher filter penetration in the corn oil chamber corresponded to the higher TIL values obtained for corn oil aerosol. The results indicate that higher filter penetration measured for corn oil aerosol may partly be associated with the higher TIL observed for corn oil aerosol. It is possible that the ionic nature of NaCl aerosol makes it highly charged over wide size ranges,[31] and more easily captured by the filter medium to produce a lower in-mask concentration and thereby a lower TIL value. Dioctyl sebacate (DOS), an oily aerosol, was found to have lower charge compared to NaCl aerosols.[31] Corn oil is similar to the DOS used for testing respirator filters. In the present study, the charge measurement for the aerosols in the test chambers showed relatively higher net positive charge (+70.5 fA) for NaCl aerosol compared to the charge (+0.02 fA) for corn oil aerosol. Because of the lower charge, corn oil aerosol may easily penetrate through the filter medium resulting in higher in-mask concentration or larger TIL compared to NaCl aerosol. The aerosol charge results obtained in the present study are comparable to the findings from a recent paper, which showed that NaCl aerosol generated by a nebulizer carried more positive charge relative to the electrically neutral diethyl hexyl sebacate aerosol.[32]

Faceseal leakage may not be related to the higher TIL values obtained with corn oil aerosol because the subjects were fit tested and then TIL was measured in the NaCl and corn oil aerosol chambers. Although respirator fit can change during TIL testing between the two chambers, five subjects were tested in the NaCl aerosol chamber first and then in the corn oil aerosol chamber and the other five subjects were tested in the reverse order. Regardless of the order of testing with the two aerosols, a larger TIL was measured with corn oil aerosol compared to NaCl aerosol, indicating that faceseal leakage had negligible effect on the higher TIL with corn oil aerosol.

The GM FFs were inversely related to TIL measured for the respirators using the two aerosols. Larger GM FFs corresponded to smaller TIL values and vice versa. The relationship is apparent for FFP1 and N95 FFR models, but not for P100 and ER models, for both NaCl and corn oil aerosols. Larger GM FFs were associated with smaller TIL values for only NaCl aerosol. One possible explanation is that the TIL values measured for P100 and ER models are relatively smaller. Evaluation of the data showed reasonably good correlation of GM FFs and TIL for NaCl and corn oil aerosols for FFP1 (R2 =0.695 and 0.838, respectively) and N95 FFRs (R2=0.727 and 0.774, respectively). P100 FFRs showed medium correlations for NaCl (R2 = 0.56) and corn oil aerosols (R2 =0.54). ER models showed poor correlations for both NaCl (R2 = 0.38) and corn oil (R2 =0.07) aerosols. Further studies are needed to confirm the results.

The TIL results obtained in the study have implications to the ISO 16900–1[17] and 17420–1 standards.[18] The TIL values failed to show similar PCs for the two aerosols with the ISO 17420–1 recommended “second highest TIL” method for the two models of all categories of respirators. The dissimilar PCs for the two aerosols showed a large difference in the PL expected in workplaces. Alternatively, the PCs obtained with the GM TIL values agreed between the two aerosols for one model each of N95 (model C), P100 (modelF), and ER (model G) categories. The results indicate that the GM TIL method may underestimate the difference in TIL as well as PL between the two aerosols.

The classification of respirators into six PCs needs further consideration. The decrease in TIL with an increase in PC level suggests that it may be difficult to differentiate the PCs between respirator categories at higher PC levels. This could partly be due to the equipment (flame photometer and light-scattering photometer) used for measuring TIL for the two aerosols, which may have limitations to measure TIL accurately.[28,29] Further studies are needed to understand whether a particle number-based method is advantageous to differentiate PCs between two categories of respirators. Overall, the results suggest that the number of PCs may be reduced to fewer than six, because of the difficulty to distinguish between respirator categories at higher PCs.

A correction factor for NaCl aerosol deposition in the airway of test subjects has been recommended.[17] The deposition of NaCl aerosol is apparent because of its hygroscopic nature. Previous studies showed hygroscopic aerosols grow in the airways and shift to a larger size distribution. The larger size NaCl particles readily deposit in the airways.[33,34] The deposition of aerosols in the airways appears to be size-dependent, and minimum for sizes in the ~0.3 μm (mass median aerodynamic diameter) particle range.[33,34] The deposition of three salts, NaCl, CoCl2.6H2O, and ZnSO4.7H2O, representing large, medium, and small increase in size, respectively, in the human airways has been reported.[35] The deposition increased for the highly hygroscopic NaCl particles with an initial size between 0.3 and 5.0 μm and the increase is a factor of two for 0.5 to 3.0 μm particles. On the other hand, ISO 16900–1 standard did not consider the deposition of corn oil aerosol in the airways. Although corn oil aerosol is not hygroscopic, a comparatively lower level of deposition is likely to occur in the airways. When adjusted for corn oil deposition, the TIL should be larger than the values presented in the current study, which would show wider difference in the TIL between the two aerosols.

Although this article focuses on the ISO 16900–1 proposed comparison of TIL between test agents, the results obtained in the study show the influence of factors such as fit testing and filter efficiency on TIL values. The importance of a larger FF to obtain lower TIL is evident between the two models of both FFP1 and N95 category respirators for the two aerosols. A similar relationship was obtained for other categories of respirator models for either NaCl or corn oil aerosol. The significance of faceseal leakage can be seen from the TIL result for ER models with N95 rated filters. The TIL values were lower for ER models with N95 rated filters compared to the TIL for N95 FFR and P100 FFR models indicating relatively lower faceseal leakage for ER models.

The data obtained in the study showed that filter efficiency of respirators has a major influence on TIL as shown by the inter-respirator and intra-respirator comparisons. In the case of the inter-respirator category, TIL for FFP1, N95, P100, and ER (rated for 80%, 95%, 99.7%, and 95% efficiencies, respectively) showed a decrease with increasing efficiency presenting an inverse relationship. The results are corroborated by the TIL obtained for subjects wearing respirator categories rated for 80%, 94%, and 99% filter efficiency,[6] which showed a decrease in TIL with increasing efficiency of respirator categories. A recent study measured the simulated workplace protection factor (SWPF), an inverse factor of TIL, for FFRs (N95 and P100) and ERs with N95 and P100 filters.[7] Higher filter efficiency respirator categories (ER vs FFR and P100 vs N95) showed relatively larger SWPF confirming the filter efficiency dependence of TIL.

The intra-respirator comparison showed that the relatively higher efficiency model of FFP1 and N95 respirator category had lower TIL for the two aerosols compared to the lower efficiency model. Similar results were obtained for the other two categories of respirators for corn oil aerosol. The association between filter efficiency and TIL has been reported for N95 FFR models.[8,9] One study measured TIL for five N95 FFR models with 35 subjects in two test laboratories.[8] Two relatively higher efficiency models yielded relatively lower TIL values compared to the other three lower efficiency models in the two test laboratories showing that efficiency is inversely related to TIL.

Limitations of the study include that only 10 subjects were tested for TIL measurement, instead of 15 subjects recommended by ISO 17420–1. Further studies with additional 10 subjects are underway. Although ISO 16900–1 specifies the use of the principal component analysis (PCA) panel, the NIOSH bivariate panel was used for the placement of subjects in specific face length by face width cells in the study. The bivariate panel used in the study is unlikely to affect the results.

Conclusions

All eight respirator models tested in the study showed larger TIL values with corn oil aerosol compared to NaCl aerosol. Three of the eight models showed significant difference in TIL between the two aerosols. The difference in particle size distribution between the two aerosols is likely to produce different TIL values. The higher filter penetration obtained in the corn oil chamber showed a trend similar to TIL, indicating that filter penetration is related to TIL. Corn oil aerosol showed lower net charge compared to NaCl aerosol, which might have partly increased the filter penetration and thereby TIL. The TIL for the two aerosols varied widely to produce dissimilar PCs as well as PLs for each respirator model. Fit factor and filter efficiency influence the TIL measured for all respirator models tested in the study. Overall, the results showed that corn oil aerosol would provide a conservative estimate of TIL as well as PL compared to NaCl aerosol. The results suggest that TIL measured using test agents of different characteristics may produce dissimilar results.

Acknowledgments

The authors acknowledge NIOSH colleagues, including Ron Shaffer, Raymond Roberge, Jeff Peterson, and Andrew Palmiero, for their useful suggestions and critical review of the manuscript.

Funding

This research work was supported by NIOSH funding CAN# 93902 JS.

Footnotes

Supplemental data for this article can be accessed at tandfonline.com/uoeh. AIHA and ACGIH members may also access supplementary material at http://oeh.tandfonline.com/.

Publisher's Disclaimer: Disclaimer

Publisher's Disclaimer: Mention of commercial product or trade name does not constitute endorsement by the National Institute for Occupational Safety and Health. The findings and conclusions of this report are those of the authors and do not necessarily represent the views of the National Institute for Occupational Safety and Health.

References

- [1]. International Organization for Standardization (ISO): Respiratory Protective Devices – Terms, Definitions, Graphical Symbols and Units of Measurement (ISO 16972) [Standard]. Geneva, Switzerland: ISO, 2010. [Google Scholar]

- [2]. Coffey CC, Zhuang Z, Campbell DL, and Myers WR: Quantitative fit-testing of N95 respirators: Part II - Results, effect of filter penetration, fit-test, and pass/fail criteria on respirator performance. J. Int. Soc. Res. Prot 25–36 (1998). [Google Scholar]

- [3]. Zhuang Z, Coffey CC, Jensen PA, Campbell DL, Lawrence RB, and Myers WR: Correlation between quantitative fit factors and workplace protection factors measured in actual workplace environments at a steel foundry. Am. Ind. Hyg. Assoc. J 64:730–738 (2003). [DOI] [PubMed] [Google Scholar]

- [4]. Reponen T, Lee S-A, Grinshpun SA, Johnson E, and McKay R: Effect of fit testing on the protection offered by N95 filtering facepiece respirators against fine particles in a laboratory setting. Ann. Occup. Hyg 55:264–271 (2011). [DOI] [PubMed] [Google Scholar]

- [5]. Coffey CC, Campbell DL, and Zhuang Z: Simulated workplace performance of N95 respirators. Am. Ind. Hyg. Assoc. J 60:618–624 (1999). [DOI] [PubMed] [Google Scholar]

- [6]. Han DH, and Lee J: Evaluation of particulate filtering respirators using inward leakage (IL) or total inward leakage (TIL) testing—Korean experience. Ann. Occup. Hyg 49:569–574 (2005). [DOI] [PubMed] [Google Scholar]

- [7]. Vo E, Zhuang Z, Horvatin M, Liu Y, He X, and Rengasamy S: Respirator performance against nanoparticles under simulated workplace activities. Ann. Occup. Hyg 59:1012–1021 (2015). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [8]. Rengasamy S, Walbert G, Newcomb W, et al. : Total inward leakage measurement of particulates for N95 filtering facepiece respirators - A comparison study. Ann. Occup. Hyg 58:206–216 (2013) [DOI] [PubMed] [Google Scholar]

- [9]. Rengasamy S, and Eimer B: Nanoparticle penetration through filter media and leakage through faceseal interface of N95 filtering facepiece respirators. Ann. Occup. Hyg 56:568–580 (2012). [DOI] [PubMed] [Google Scholar]

- [10]. Gao S, Kim J, Yermakov M, et al. : Performance of N95 FFRs against cumbustion and NaCl aerosols in dry and moderately humid air: A manikin-based study. Ann. Occup. Hyg 60:748–760 (2016). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [11]. He X, Grinshpun SA, Reponen T, et al. : Laboratory evaluation of the particle size effect on the performance of an elastomeric half-mask respirator against ultrafine combustion particles. Ann. Occup. Hyg 57:884–897 (2013). [DOI] [PubMed] [Google Scholar]

- [12]. Cho KJ, Reponen M, McKay R, et al. : Larger particle penetration through N95 respirator filters and facepiece leaks with cyclic flow. Ann. Occup. Hyg 54:68–77 (2010). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [13]. Lee S-A, Grinshpun SA, and Reponen T: Respiratory performance offered by N95 respirators and surgical masks: Human subject evaluation with NaCl aerosol representing bacterial and viral particle size range. Ann. Occup. Hyg 52:177–185 (2008). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [14]. Rengasamy S, Eimer B, and Szalajda J: A quantitative assessment of the total inward leakage of NaCl aerosol representing sumicron size bioaerosol through N95 filtering facepiece respirators and surgical masks. J. Occup. Environ. Hyg 11:388–396 (2014). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [15]. Rengasamy S, Walbert G, Newcomb W, Coffey CC, Wassell JT, and Szalajda J: Protection factor for N95 filtering facepiece respirators exposed to laboratory aerosols containing different concentrations of nanoparticles. Ann. Occup. Hyg 59:373–381 (2014). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [16]. He X, Reponen T, McKay RT, and Grinshpun SA: Effect of particle size on the performance of an N95 filtering facepiece respirator and a surgical mask at various breathing conditions. Aerosol Sci. Technol 47:1180–1187 (2013). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [17]. International Organization for Standardization (ISO): Respiratory Protective Devices - Methods of Test and Test Equipment - Part 1: Determination of Inward Leakage (ISO 16900–1) [Standard]. Geneva, Switzerland: ISO, 2014. [Google Scholar]

- [18]. International Organization for Standardization (ISO): Respiratory Protective Devices - Performance Requirements - Part 1: General (ISO 17420–1) [Committee Draft]. Geneva, Switzerland: ISO, 2018. [Google Scholar]

- [19]. International Organization for Standardization (ISO): Respiratory Protective Devices - Classification for Respiratory Protective Devices (RPD), Excluding RPD for Underwater Application (ISO 16973) [Standard]. Geneva, Switzerland: ISO, 2016. [Google Scholar]

- [20]. Duling MG, Lawrence RB, Slaven JE, and Coffey CC: Simulated workplace protection factors for half-facepiece respiratory protective devices. J. Occup. Environ. Hyg 4:420–431 (2007). [DOI] [PubMed] [Google Scholar]

- [21]. Zhuang Z, Coffey CC, and Ann RB: The effect of subject characteristics and respirator features on respirator fit J. Occup. Environ. Hyg 2:641–649 (2005). [DOI] [PubMed] [Google Scholar]

- [22]. British Standards Institution (BSI): Respiratory Protective Devices - Particle Filters - Requirements, Testing, Marking (BS EN 143) [Standard]. London, UK: BSI, 2000. [Google Scholar]

- [23]. “Respiratory Protection Devices”, Code of Federal Regulations Title 42, Part 84, 1995. pp. 30335–30398. [Google Scholar]

- [24]. Zhuang Z, Groce D, Ahlers HW, et al. : Correlation between respirator fit and respirator fit test panel cells by respirator size. J. Occup. Environ. Hyg 64:617–628 (2008). [DOI] [PubMed] [Google Scholar]

- [25]. “Occupational Safety and Health Standards. Fit Testing Procedures (Mandatory),” Code of Federal Regulations Title 29, Part 1910134 App., 1998. [Google Scholar]

- [26]. British Standards Institution (BSI): Specification for Filtering Facepiece Dust Respirators (BS 6016) [Standard]: London, UK: BSI, 1980. [Google Scholar]

- [27]. “Procedure No. TEB-APR-STP-0059, Revision 2.0. Determination of particulate filter efficiency level for N95 series filters against solid particulates for non-powered, airpurifying respirators standard testing procedure (STP)”: National Institute for Occupational Safety and Health (NIOSH), National Personal Protective Technology Laboratory, Pittsburgh, PA, 2007. [Google Scholar]

- [28]. Biermann AH, and Bergman W: Filter penetration measurements using a condensation nuclei counter and an aerosol photometer. J. Aerosol. Sci 19:471–483 (1988). [Google Scholar]

- [29]. Eninger RM, Honda T, Reponen T, McKay R, and Grinshpun SA: What does respirator certification tell us about filtration of ultrafine particles? J. Occup. Environ. Hyg 5:286–295 (2008). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [30]. Wilkes AR: Comparison of two techniques for measuring penetration of sodium chloride particles through breathing system filters. Brit. J. Anaesth 89:541–545 (2002). [DOI] [PubMed] [Google Scholar]

- [31]. Biermann AH, and Bergman W: Measurement of aerosol concentration as a function of size and charge. Aerosol Sci. Technol 3:293–304 (1984). [Google Scholar]

- [32]. Chen H, Zhang Z, Zhang Z-Z, Jiang F, and Du R: Enhancement of filtration efficiency by electrical charges on nebulized particles. Particuology 37:81–90 (2018). [Google Scholar]

- [33]. Darquenne C: Aerosol deposition in health and disease. J. Aerosol Med. Pulm. Drug Delivery 25:140–147 (2012). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [34]. Heyder J, Gebhart J, Rudolf G, Schiller CF, and Stachhofen W: Deposition of particles in the human respiratory tract in the size range 0.005–15 mm. J. Aerosol Sci 5:811–825 (1986). [Google Scholar]

- [35]. Ferron GA, Oberdörster G, and Henneberg R: Estimation of the deposition of aerosolized drugs in the human respiratory tract due to hygroscopic growth. J Aerosol Med. 2:271–284 (1989). [Google Scholar]