Abstract

A new approach for single cell microencapsulation in an oil-in-water (o/w) Pickering emulsion is presented. The water/paraffin emulsions were stabilized by amine-functionalized silica nanoparticles. The droplet size of the emulsions was highly tunable, and ranged from 1 to 30 μm in diameter. The controllable droplet size along with the high colloidal stability of the Pickering emulsionswas harnessed to obtain single cell microencapsulation. Successful encapsulation of the conidia entomopathogenic fungus Metarhizium brunneum by the studied Pickering emulsions was confirmed via confocal laser scanning microscopy. The resulting systems were implemented to develop a novel biopesticide formulation for arthropod pest control. The conidia incorporated in the emulsions were applied to Ricinus communis leaves by spray assay. After drying of the emulsion, a silica-based honeycomb-like structure with an ordered hierarchical porosity is formed. This structure preserves the individual cell encapsulation. The successful single cell encapsulation has led to a high distribution of conidia cells on the leaves. The Pickering emulsion-based formulation exhibited significantly higher pest control activity against Spodoptera littoralis larvae compared to the control systems, thus making it a promising, cost-effective, innovative approach for tackling the pest control challenge.

Introduction

Single cell encapsulation has many major applications in a wide variety of fields including medicine, food industry, and agriculture. Encapsulation protects against harsh external conditions, ensures lower exposure to contamination by foreign organisms, and provides improved isolation.1,2 Cell encapsulation has become an important tool in gene therapy, controlling drug delivery,3 fermentation industry,4 image analysis tool, and genomic analysis in microorganisms.5 The capsule provides synthetic membrane that will be removed in an appropriate environment. Several techniques for single cell microencapsulation have been developed, including solvent evaporation,6 interfacial polymerization,7 and layer-by-layer deposition.8 Nevertheless, these methods may contain toxic chemicals and compounds such as organic solvents or corrosive surfactants that constitute risks for biological organisms.9 This underscores the need for fine biocompatible single cell encapsulation techniques to maintain cell viability for example, hydrogel,10 microfluidic-based methods11 and emulsions.12

Pickering emulsions, which have been extensively studied and implemented in numerous applications during the last century, are excellent candidates for single cell encapsulation, given their high colloidal stability and controllable droplet size.13−15 Pickering emulsions are stabilized by nanoparticles (NPs) that are self-assembled at the oil/water interface and act as a physical barrier.16,17 Pickering emulsions come in the form of oil-in-water (o/w) or inverse (water-in-oil) emulsions. Inorganic NPs such as silica, clays, hydroxyapatites, and organic NPs can act as stabilizers for Pickering emulsions.17 At the interface, the wettability of the particles determines their localization in the water and the oil phase.18 The diameter of the droplets is dictated by the particle size and the composition of the system (o/w ratio and NP content).19−21 Cell encapsulation by Pickering emulsions has become useful for various applications, such as encapsulation of microbial cells to protect from pH changes,22 developing biopesticide formulations based on Bacillus thuringiensis (Bt),23 platform for enzymatic reaction,24,25 cellular capsules based on liquid marbles,26 and encapsulation of adherent cells in water-in-water emulsions for tissue engineering.27

In recent years, in response to growing public demands, health concerns, and new regulations, in addition to the need for increased food production, synthetic pesticides have been removed from the market. Biopesticides are low risk, environmental friendly pesticides based on living microbes. Their active compounds are designed to be a natural and environmentally safe alternative to the synthetic pesticides used in crop protection. However, the difficulties in running efficient field trials and the high cost of biopesticides have prevented them from making a significant global dent.28 The development of new advanced formulation systems for biopesticides could thus lead to more efficient pest control, increased shelf life, and greater persistence in the field.

Entomopathogenic fungi are biopesticides with a unique mode of action in that they penetrate the body integument of the host directly. Most fungus-based biopesticides are ascomycetes belonging to the complex species Metarhizium and Beauveria.29

The development of advanced formulations for biopesticides that can meet the demands for high pest control efficiency is of paramount importance. These formulations must achieve high functionality under a range of environmental conditions. This can be done by (1) maximizing their distribution on the plant canopy, (2) protection against UV, (3) maintaining microenvironmental humidity control, and (4) increasing their shelf life.30,31 The microencapsulation of biopesticides using Pickering emulsions and colloidosomes constitutes an excellent candidate for tailoring new advanced formulations with high protection performance. Pickering emulsions make it possible to tune the emulsion properties in terms of droplet diameter and proper surface functionalization of the NPs to achieve high activity and a prolonged shelf life of the incorporated microorganisms. Silica NPs is an eco-friendly32 emulsion stabilizer, which enables the introduction of additional functionalities to the product, such as UV protection and humidity control. This can be done by chemical modification of the silica NPs with organosilanes.

Single microencapsulation of cells by Pickering emulsion presents a significant potential for the development of new biopesticide formulations. The most commonly used myco-biopesticides are conidia. These microorganisms must remain nongerminated before application in the field; that is, unexposed to water. This means that conidia must be encapsulated in the oil phase of the emulsion, which makes encapsulation in the w/o system impractical. Furthermore, the chemical nature of the outer surface of most conidia is hydrophobic, resulting in their arrangement in the oil phase. Hence, developing advanced o/w Pickering emulsions that can encapsulate conidia in the oil phase is a top priority.

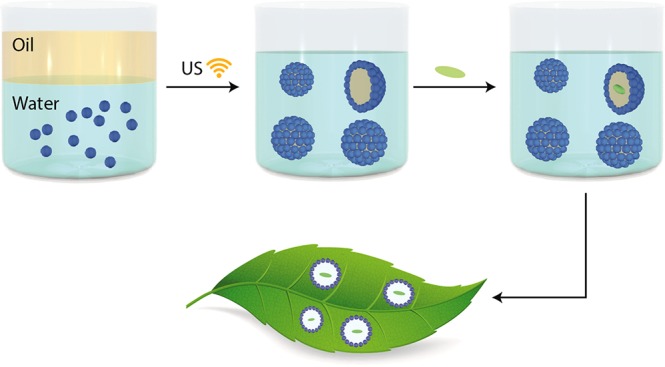

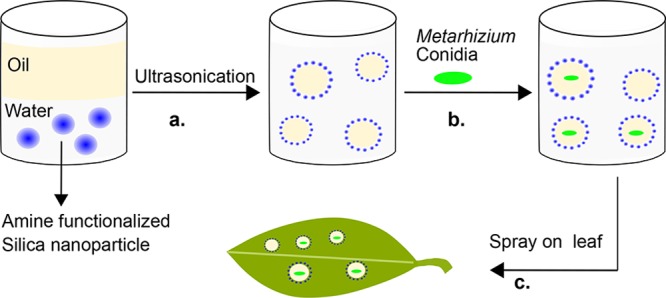

In response to this need, this study presents a new approach for single encapsulation of conidia by an eco-friendly o/w Pickering emulsion. The overall process is illustrated in Figure 1. Silica NPs were functionalized by (3-aminopropyl)triethoxysilane (APTES) to introduce amine-functionalized groups onto the NPs (silica-NH2). Pickering emulsions were prepared in different paraffin/water ratios and at various concentrations of silica NPs (Figure 1a). Metarhizium brunneumMa7 was the model fungal strain chosen for this study, as it exhibits a broad spectrum of hosts, which makes it a suitable strain for commercialization.33−36 The Metarhizium-based products are registered worldwide.37

Figure 1.

Schematic illustration of the silica-NH2 oil/water Pickering emulsion for biopesticide formulation. (a) Silica-NH2 particle dispersion in water sonicated with paraffin oil to form the silica-NH2 Pickering emulsion. (b) Single cell encapsulation of M. brunneum conidia in the Pickering emulsion. (c) Spray assay on a leaf to assess cell distribution and biofunctionality.

The successful single encapsulation of Metarhizium conidia in the paraffin droplets (Figure 1b) was confirmed by confocal laser scanning microscopy. The hydrophobic outer layer of the conidia, which is critical for the attachment and germination process on the host surface,38,39 is also responsible for their individual arrangement in the oil phase. The biopesticide activity of the Metarhizium conidia was assessed on Spodoptera littoralis larvae. The formulation was sprayed on Ricinus communis leaves (Figure 1c) and exhibited significant pesticidal activity against S. littoralis larvae. These results confirm the high efficiency of the Pickering emulsion-based formulation developed in this study.

Results and Discussion

Preparation of Silica-NH2 Pickering Emulsion

Silica NPs were functionalized by APTES through silanization to introduce amine groups on the surface of the NPs.40 Oil-in-water Pickering emulsions based on amine-functionalized silica NPs were prepared. Different contents of amine-functionalized silica (wt %) and oil/water (vol %) ratios were implemented to determine the proper conditions for a stable Pickering emulsion system that would meet the demands of single cell encapsulation. The silica contents were varied (0.1, 1, 2, 3, and 5 wt %) at oil/water ratios of 5:95, 10:90, 20:80, and 30:70, respectively. A major objective of the current study is to develop an efficient formulation for biopesticides that will maintain the conidia nongerminated. Therefore, the encapsulation of the conidia cells in the oil phase is mandatory.

The stability of the Pickering emulsions was characterized by visual observation over time. Most of the prepared emulsions were stable for 6–7 months (see Table 1). The highest stability was observed at a silica content of 5 wt % at oil/water ratios of 20:80 and 30:70, which were stable for more than a year. However, no emulsification was obtained at a silica content of 0.1 wt %. For highly stable systems, we used confocal microscopy to observe changes in the droplet diameter as a result of droplet coalescence and creaming (data not shown).

Table 1. Stability of the Silica-NH2 Pickering Emulsions.

| oil/water ratio (vol %) |

||||

|---|---|---|---|---|

| silica-NH2 (wt %) | 5:95 | 10:90 | 20:80 | 30:70 |

| 0.1 | no emulsion | no emulsion | no emulsion | no emulsion |

| 1 | 6 months | 6 months | 6 months | 6 months |

| 2 | 6 months | 6 months | 7 months | 7 months |

| 3 | 7 months | 7 months | 7 months | 7 months |

| 5 | 6 months | 6 months | >7 months | >7 months |

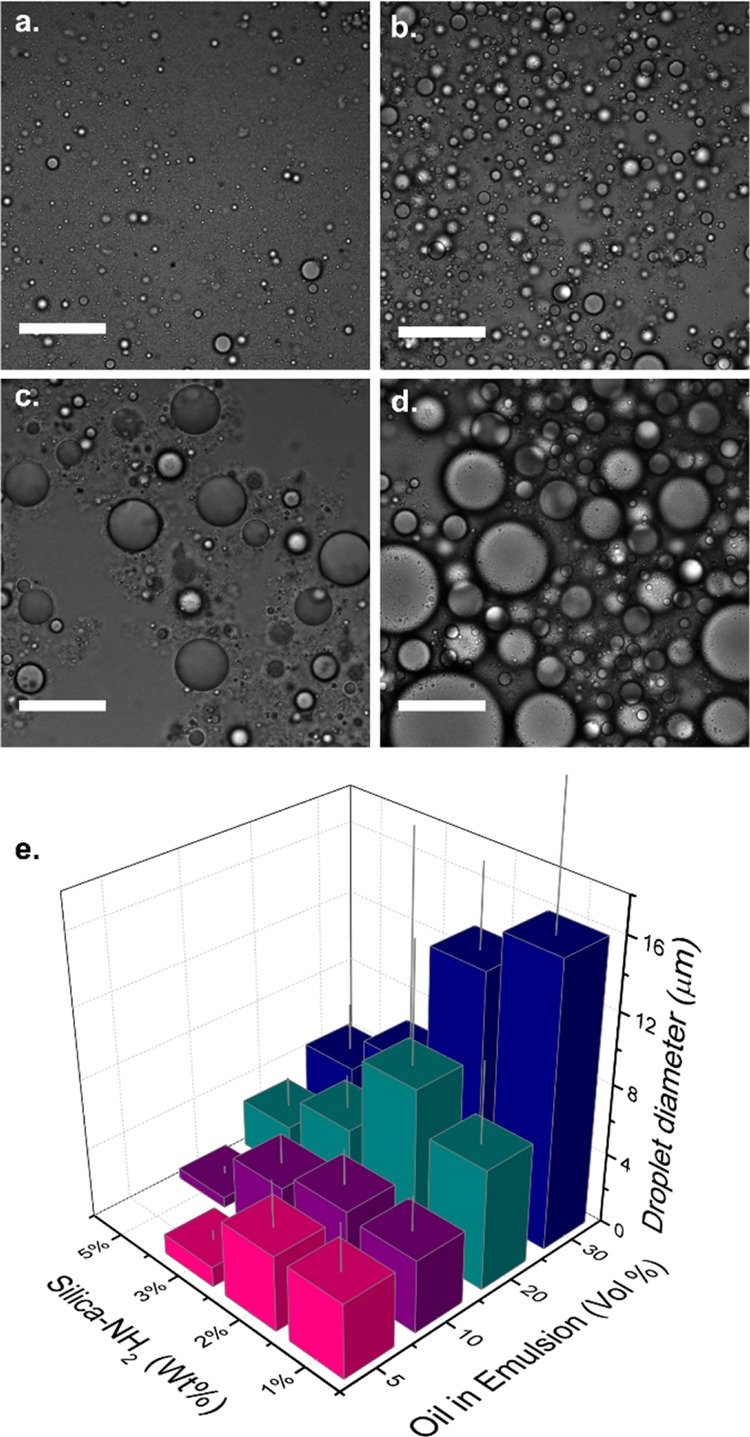

Confocal microscopy images of Pickering emulsions with 1 wt % silica NPs at different oil/water ratios is depicted in Figure 2. The diameter of the paraffin droplets are highly tunable and can be varied in a relatively wide range of 1–30 μm. Figure 2e depicts the paraffin droplet diameter of the emulsions versus the content of the silica-NH2 NPs at four different paraffin/water ratios. It is observed that the higher the silica content, the smaller is the droplet diameter at any studied volume fractions of paraffin oil. This phenomenon is explained by the increase of the total surface area of the o/w interface.20 In addition, under a given content of silica-NH2, the increase of the volume fraction of the paraffin resulted in larger droplet sizes.20 The tuning of the emulsion composition enabled us to fine-tune the resulting droplet size, which is essential for single cell encapsulation. The relatively high stability of the Pickering emulsion is derived from the low coalescence rate of the droplets due to the presence of the NPs at the interface.

Figure 2.

Pickering emulsions with 1% silica-NH2 at different oil/water ratios. (a) 5:95. (b) 10:90. (c) 20:80. (d) 30:70. Scale bar is 50 μm. (e) Droplet diameter as a function of silica-NH2 contents (wt %) and oil percentages in the emulsion (vol %).

Single Cell Encapsulation

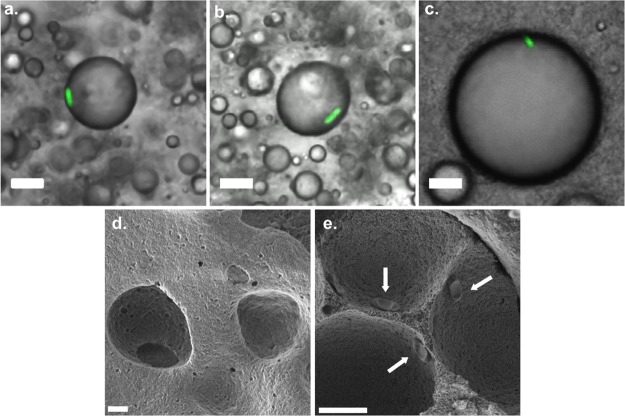

M. brunneumMa7-green fluorescent protein (GFP) conidia41 were added to the different silica-NH2 Pickering emulsions. Single cell encapsulation of the conidia in the paraffin phase of the emulsions was confirmed by confocal microscopy (Figure 3). The confocal microscopy images are representing one focal plane, thus the conidia cells that appear inside the boundaries of the oil droplets are actually located in the internal part of the paraffin droplets.

Figure 3.

Confocal microscopy images of single cell encapsulation of M. brunneumMa7-GFP conidia in a silica-NH2 Pickering emulsion (o/w ratio, 20:80) with different NPs contents of (a) 2, (b) 3 and (c) 5 wt %. Scale bar is 10 μm. SEM micrographs of dried silica-NH2 Pickering emulsion, (d) without conidia and (e) with conidia (arrows).

Successful single cell encapsulation in the paraffin oil droplets was obtained in emulsions with an o/w ratio of 20:80 at three different silica content values of 2, 3, and 5 wt % (Figure 3). The droplet concentration in these emulsions is approximately an order of magnitude higher than the conidia cell concentration, thus very few droplets that host conidia cells could be detected in a given confocal microscopy image even at very low magnification. Figure 3 depicts characteristic confocal microscopy images that conclusively confirm the successful single cell encapsulation of the conidia cells in the paraffin droplets of the emulsions.

The Pickering emulsions that have shown successful single cell encapsulation (at silica contents values of 2, 3, and 5 wt %) had an average droplet diameter of 9.1 ± 6.8, 4.7 ± 1.7, and 2.7 ± 1.5 μm, respectively (Figure 2e), close in their values to the size of the conidia cells, which are ∼4 μm in their length. These results indicate that individual encapsulation can be achieved when the sizes of the droplets and the cells are of the same order of magnitude.

The conidia cells assemble at the oil phase in the water/paraffin biphasic system because of their hydrophobic surface.42,43 Nevertheless, the conidia cells have to overcome the barrier made by the NPs that are located at the interface. The preparation of the silica-NH2 Pickering emulsions is performed by an ultrasonic probe. The exposure of a liquid sample to ultrasonic waves results in vigorous agitation characterized with high shear forces that are responsible for emulsification. However, ultrasonication cannot take place in the presence of the conidia cells because it will lead to cell lysis. Therefore, the conidia cells were incorporated only after the emulsion formation, through gentle agitation by vortex, which enables the penetration of the conidia cells into the paraffin droplets.

The ability of cells or particles to enter the droplets of Pickering emulsions by introduction of shear forces to the system is explained by the work of French et al.44,45 They have shown that the particles in the o/w interface undergo transformations between the droplets upon introducing shear forces, leaving temporary voids at the interface. This phenomenon explains the successful encapsulation of the conidia cells in the paraffin droplets through gentle agitation that is apparently generating proper shear forces. Furthermore, the implementation of NPs with a relatively low diameter (∼40 nm) for the preparation of the Pickering emulsions might also decrease their ability to form a barrier (at the interface) against the penetration of the conidia cells that are 2 orders of magnitude larger (∼4 μm in length) than the NPs.

The obtained fluorescent signal of the GFP conidia is a clear indication of the viability of the cells when encapsulated in the oil phase of the silica-NH2 Pickering emulsions. The conidia in the emulsions remained viable for three weeks. The viability of the Metarhizium conidia cells while encapsulated in the silica-NH2 Pickering emulsions was further characterized by culturing the conidia on a Sabouraud Dextrose Agar (SDA) growth medium (see Materials and Methods). The germination percentages of the encapsulated conidia were 85 ± 8.3%, demonstrating their viability and their ability to germinate. The control system (without emulsion) had germination percentages of 95 ± 5%.

Scanning electron microscopy (SEM) characterization of the applied emulsions (see Materials and Methods) revealed a silica-based honeycomb structure with ordered hierarchical porosity (Figure 3d,e). This structure is formed during the drying process of the emulsion through emulsion templating.46,47 It maintains the basic morphology of the Pickering emulsion and preserves the single cell encapsulation, as shown in Figure 3e. This finding is important as it demonstrates the individual arrangement of the conidia on the leaves, which will lead to high efficiency of the biopesticide activity against the target insect.

Application of M. brunneum Conidia on R. communis Leaves

To test the functionality of the Pickering emulsions as a biopesticide formulation, M. brunneum conidia-GFP encapsulated in silica-NH2 Pickering emulsions were sprayed on R. communis leaves until full coverage (see Materials and Methods).

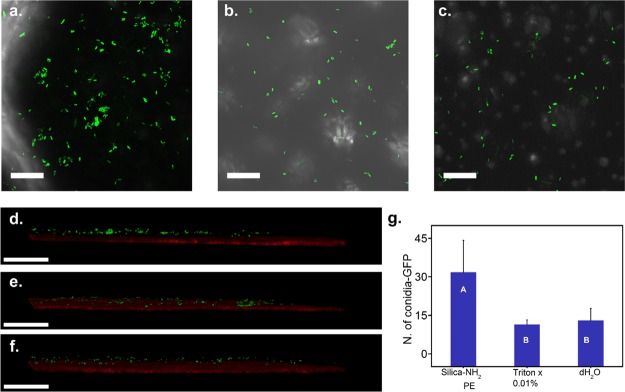

The distribution of the conidia cells on the leaves was characterized by confocal microscopy. The Z projection (Figure 4a–c) and the three-dimensional (3D) images (Figure 4e,f) are presented in Figure 4. The silica-NH2 Pickering emulsion (Figure 4a,d) exhibited a significantly higher distribution of conidia cells on the leaves compared to the controls (0.01% Triton X-100, Figure 4b,e; and water, Figure 4c,f). The higher cell distribution of the silica-NH2 Pickering emulsion is thus derived from the single cell encapsulation in the emulsions. These findings were supported by SEM analysis showing individual encapsulation of the conidia in the compartments of the silica/paraffin honeycomb structure (Figure 3e). Single cell encapsulation is required for efficient distribution of conidia cells on the leaf surface. The conidia cells, which are hydrophobic, will localize in the oil phase. Obtaining the suitable droplet size and composition has led to single cell encapsulation. After the spray assay on the leaves with the Pickering emulsion formulation, higher cell distribution was observed on the leaf surface compared to water and Triton X-100 samples.

Figure 4.

Distribution of M. brunneum conidia-GFP on R. communis leaves. (a–c) Z projection and (d–f) cross section of confocal microscopy images of M. brunneum-GFP conidia after spray application on the surface of the leaves. (a,d) Conidia in silica-NH2 Pickering emulsion; (b,e) conidia in 0.01% Triton X-100 in water; (c,f) conidia in distilled water. (g) Number of conidia on leaves. Bars with the same letter do not differ significantly in the number of spores; Students t-test (P = 0.05). Scale bar: (a–c), 100 μm. (d–f), 200 μm.

In order to quantify the number of conidia cells on the leaves, a Z series was taken and a Z projection was performed. The results of the Z projection showed a higher count of conidia on the studied system than the controls (Figure 4g, one-way ANOVA: F = 4.5042, df = 2, P = 0.0372). The single cell encapsulation in the Pickering emulsions maintains the dispersibility of the cells during the spray assay resulting in a higher number of conidia cells on leaves. On the contrary, the lower amount of conidia cells in the control samples resulted from cell agglomeration during the spraying process because of poor dispersibility of the cells in the aqueous medium. Triton X-100-based suspension was used as a standard in the screening of entomopathogenic fungi in many studies.41,48,49 In addition, surfactants including Triton X-100, are being extensively used in commercial formulations of microbial control agents.50,51

Biological Functionality of Conidia Incorporated in Silica-NH2 Pickering Emulsions

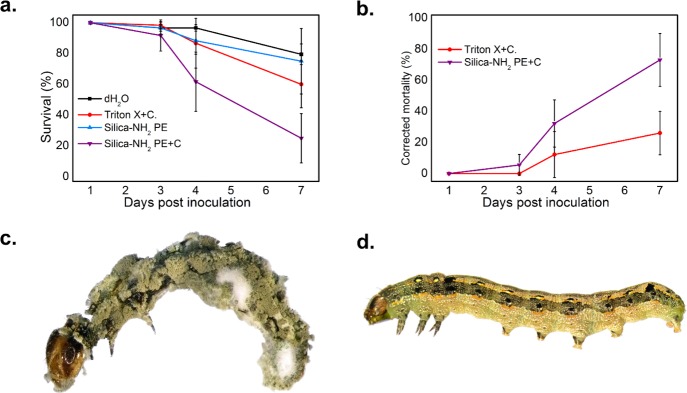

The S. littoralis larvae were indirectly exposed to the conidia by inoculation of the R. communis leaves with conidia (see Materials and Methods and Table 2) incorporated in the silica-NH2 Pickering emulsions. The larvae were kept for seven days and the mortality of the larvae was monitored at days 3, 4, and 7 (Figure 5a). Larvae treated with conidia incorporated in the Pickering emulsion showed 75% mortality, whereas the formulation alone resulted in a mortality of only 25%. Treatment with conidia in 0.01% Triton X-100 led to 40% mortality. Corrected mortality and probability tests were performed on the data. The analysis of corrected mortality is based on Abbott’s formula52 and is the adjustment of insect mortality rates used worldwide in insecticide trials. The results are presented in Figure 5b and Table 3, respectively. Table 3 clearly shows the higher pesticidal activity of conidia incorporated in the Pickering emulsions compared to the controls. The sporulation processes started seven days postinoculation. The dead larvae were kept separately under moist conditions to promote sporulation and confirm mycosis. Cadavers were monitored daily for sporulation. Of the 14 dead larvae, 13 were mycosed. An example of a sporulated larva cadaver is presented in Figure 5c; nontreated larva from the control group is shown in Figure 5d.

Table 2. List of Samples Used in the Biological Functionality Bioassay.

| # | sample | conidia presence |

|---|---|---|

| 1 | dH2O | – |

| 2 | 0.01% Triton X-100 | + |

| 3 | silica-NH2 Pickering emulsion | – |

| 4 | silica-NH2 Pickering emulsion | + |

Figure 5.

(a) Survival curve of S. littoralis third-instar larvae after spray application of dH2O, 0.01% Triton X-100 with conidia, silica-NH2 Pickering emulsion with and without M. brunneum formulation. Larvae were incubated for seven days at 25 °C, 85% RH. (b) Corrected mortality % of S. littoralis larvae seven days postinoculation with M. brunneum conidia in a water based formulation (Triton X-100) and silica-NH2 Pickering emulsion. Mortality correction was calculated for each system with the respective blank. Data are the average of three independent experiments. S. littoralis third instar larva assay. (c) Larva treated with M. brunneum Pickering emulsion formulation 10 days postinoculation. (d) Nontreated larva.

Table 3. Median Lethal Time in Days (LT50) of the Treatments in the S. littoralis Larvae Assay.

| type | conidia | LT50 | lower 95% | upper 95% | prob > ChiSq |

|---|---|---|---|---|---|

| dH2O | – | 11.48 | 7.94 | ||

| 0.01% Triton X-100 | + | 8.25 | 6.99 | 13.77 | 0.5594 |

| silica-NH2 Pickering emulsion | – | 16.97 | 8.8 | <0.001 | |

| silica-NH2 Pickering emulsion | + | 4.89 | 4.23 | 5.69 | <0.013 |

These results confirm the successful bioassay of encapsulated M. brunneum conidia on S. littoralis third instar larvae after spray application. The results also demonstrate the low toxicity of the Pickering emulsions (without conidia) against the larvae and leaves. The activity of the conidia was enhanced by their incorporation in the o/w silica-NH2 Pickering emulsions. The increased efficiency of the Pickering emulsion-based formulation can thus be attributed to the successful single encapsulation of the conidia cells, which resulted in a significantly higher cell distribution on the leaves.

In addition, the silica-based honeycomb structure should decrease the exposure rate of the conidia to humidity, resulting in a controlled germination rate that will ensure the higher effectivity of the conidia against target insects, and prolonged field persistence.

Conclusions

In summary, we presented a new approach for single cell encapsulation by eco-friendly o/w Pickering emulsions stabilized by amine-functionalized silica NPs. The emulsions were stable for months. M. brunneum conidia cells, a well-studied biopesticide, were incorporated into the Pickering emulsions. Single cell encapsulation of the conidia was confirmed by confocal microscopy. The M. brunneum is localized in the oil droplets due to the hydrophobic nature of their outer layer. The high tunability of the droplet size along with high colloidal stability of the emulsions enabled single cell microencapsulation. The silica-NH2 Pickering emulsions were implemented to develop formulations for biopesticides. The conidia incorporated in the emulsions were applied on leaves via the spraying process. The studied formulation resulted in a higher cell distribution on the leaves, leading to a high mortality rate of S. littoralis larvae. The silica-based honeycomb-like structure resulting from emulsion drying preserves the single cell encapsulation on the leaf surface. The formulation exhibited significantly higher pest control activity in comparison to the controls. This successful single cell encapsulation along with its high biopesticide activity is thus a promising, cost-effective, innovative approach for tackling the pest control challenge.

Materials and Methods

Salinization of Silicon Dioxide Surfaces with APTES

Silica (1 g) (AEROSIL OX 50, with an estimated primary particle size of 40 nm, obtained from Evonik, Germany) was added to 40 mL of methanol and stirred for complete dispersion. Then, APTES (99% Sigma-Aldrich) was added slowly to the solution for a final concentration of 0.5 M. The reaction was carried out at ambient temperature for 45 min. After silanization, the particles were collected by centrifugation (9000 rpm, 10 min) and rinsed four times with methanol. Afterward, the silica-NH2 NPs were dried at 35 °C under vacuum for ca. 3 h.

Silica-NH2 Pickering Emulsion Preparation

Pickering emulsions were prepared from amine-functionalized silica in water and paraffin oil (Sigma-Aldrich, analytical grade). First, silica-NH2 NPs were dispersed in distilled water by sonication for 5 min (Sonics Vibra-Cell 750 W, 25% amplitude) with increasing silica content: 0.1, 1, 2, 3, and 5 wt %. Then, paraffin oil was added at the o/w ratios of 5:95, 10:90, 20:80, and 30:70 vol %,respectively. The mixture was sonicated for 5 min for emulsification.

Fungal Strains and Culture Conditions

M. brunneumMa7(53) and M. brunneumMa7-GFP mutant41 were cultured on SDA (Difco, Becton–Dickinson, MD) for 2 weeks at 28 °C until sporulation. Conidial suspensions were prepared by harvesting conidia by scraping the fungal colony, suspending the collected material in sterile distilled water containing 0.01% Triton X-100, followed by vortexing. The suspension was filtered through three layers of gauze, and conidial concentrations were determined using a hemocytometer.

Viability Assay

Conidia viability in different suspensions was determined by germination assay. Aliquots of conidial suspension were applied over SDA plates and incubated for 18 h at 28 °C. Conidia viability in the emulsion was measured at different time points using confocal microscopy. Conidial fluorescence was the indication for viability as described previously.41 Viability was satisfactory if rates were above 95% for germination and fluorescent conidia.

Conidia Encapsulation in Silica-NH2 Pickering Emulsion

For single cell encapsulation in the Pickering emulsion, for each of the silica-NH2 NPs content, two different ratios of oil/water were chosen: 20:80 and 30:70. 10 mg of M. brunneumMa7-GFP conidia were added to 10 mL of emulsion. The mixture was vortexed at high speed in vortex mixers for 5 min. Cell samples (10 μL) were placed onto a glass slide and analyzed by confocal microscopy.

Conidia Distribution on R. communis Leaves

For the leaf spray assays, three conidia samples of M. brunneumMa7-GFP were prepared: silica-NH2 Pickering emulsion, 0.01% Triton X-100, and distilled water. Conidia (10 mg) were added to 10 mL of each sample, mixed well, and then sprayed on R. communis leaves using a 50 mL hand sprayer (∼100 μL liquid per spray) for full coverage. The plant tissues were left to dry at room temperature. To characterize the distribution of conidia on plant tissues, leaf discs from each treatment were analyzed by confocal microscopy.

Biological Functionality of Microencapsulated Conidia as a Biopesticide Formulation

To test the functionality of the silica-NH2 Pickering emulsion as a biopesticide formulation, a bioassay was conducted to assess the LT50 of the different samples. R. communis leaves were sprayed with Pickering emulsions and controls with and without conidia (see Table 2). Both sides of the R. communis leaves were treated using a 50 mL hand sprayer (∼100 μL liquid per spray). The suspension contained 10 mL of 108 conidia/mL. After spraying, the leaves were dried for 30 min in the hood. The dried treated leaves were hand cut and inserted into a 55 mm Petri dish lined with filter paper impregnated with 500 μL distilled water to maintain high humidity and a single S. littoralis third-instar larva. For each sample, 20 larvae were used. The plates were sealed and incubated at 25 °C under a 12:12 L/D photoperiod. The larvae were examined at days 3, 4, and 7 for mortality. Food was supplied during examination. Dead larvae were removed from the Petri dishes and incubated in a moist chamber until sporulation occurred. The experiment was repeated three times.

Confocal Laser Scanning Microscopy and Image Analysis

The samples were analyzed by laser scanning confocal microscopy (Olympus, FluoView 500) using argon laser 488 nm excitation. Fluorescence emission of GFP was recorded at 500–520 nm. For 3D images, acquisition used a Leica SP8 laser scanning microscope (Leica, Wetzlar, Germany) equipped with a solid state laser with 488 nm light, HC PL APO CS 20×/0.75 objective (Leica, Wetzlar, Germany) and Leica Application Suite X software (LAS X, Leica, Wetzlar, Germany). Imaging of the GFP signal was done using the argon laser, and the emission was detected in a range of 500–525 nm. Autofluorescence of the chloroplasts was detected in a range of 650–700 nm. For Metarhizium conidia counting, image stacks were first projected using a Z projection (as maximum intensity) to find all the fluorescent conidia, then counted by a cell counter using Fiji software.54 The droplet average diameter was measured for every sample by the particles analysis tool of Fiji software based on confocal microscopy images. 12 droplets were sampled from each image and plotted as a 3D graph with Origin (OriginLab, Northampton, MA).

Scanning Electron Microscopy

SEM measurements were performed using a MIRA3 field-emission SEM microscope (TESCAN, Brno/Czech Republic) with an acceleration voltage of 1.0 kV and a secondary electron detector. Pickering emulsion samples were drop-cast on a conductive double stick carbon tape and dried under ambient conditions. Prior to imaging, a thin layer of carbon was evaporated onto them to render them electrically conductive and to avoid surface charging by the electron beam.

Statistical Analysis

The JMP package (SAS Institute, 2002) was used for all statistical analyses. Mortality data were corrected by Abbott’s formula.52 Differences in the number of conidia on the leaves and larvae survival were analyzed by a one-way ANOVA followed by a Tukey–Kramer honestly significant difference (HSD) for comparisons for all pairs. Difference in the number of attached conidia to the leaf surface was analyzed to the Student-t test. Probit analysis was used to obtain the LT50 data.

Acknowledgments

This work was supported by the Office of the Chief Scientist, Ministry of Agriculture and Rural Development, Israel, grant no. 20-06-0037. The authors are grateful to Dr. Yafit Itzhaik Alkotzer for her scientific advice and Dr. Alex Protasov for the larvae photographing.

Glossary

Abbreviations

- NPs

nanoparticles

- o/w

oil-in-water

- w/o

water-in-oil

- SEM

scanning electron microscope

- APTES

(3-aminopropyl)triethoxysilane

Author Contributions

⊥ N.Y. and K.A.M. contributed equally.

The authors declare no competing financial interest.

References

- Park J. K.; Chang H. N. Microencapsulation of Microbial Cells. Biotechnol. Adv. 2000, 18, 303–319. 10.1016/s0734-9750(00)00040-9. [DOI] [PubMed] [Google Scholar]

- Yoshida M.; Mardriyati E.; Tenokuchi D.; Uemura Y.; Kawano Y.; Hatate Y. Structural Control of Core/Shell Polystyrene Microcapsule-Immobilized Microbial Cells and Their Application to Polymeric Microbioreactors. J. Appl. Polym. Sci. 2003, 89, 1966–1975. 10.1002/app.12383. [DOI] [Google Scholar]

- Orive G.; Santos E.; Poncelet D.; Hernández R. M.; Pedraz J. L.; Wahlberg L. U.; De Vos P.; Emerich D. Cell Encapsulation: Technical and Clinical Advances. Trends Pharmacol. Sci. 2015, 36, 537–546. 10.1016/j.tips.2015.05.003. [DOI] [PubMed] [Google Scholar]

- Westman J. O.; Ylitervo P.; Franzén C. J.; Taherzadeh M. J. Effects of Encapsulation of Microorganisms on Product Formation during Microbial Fermentations. Appl. Microbiol. Biotechnol. 2012, 96, 1441–1454. 10.1007/s00253-012-4517-y. [DOI] [PubMed] [Google Scholar]

- Zhang Q.; Wang T.; Zhou Q.; Zhang P.; Gong Y.; Gou H.; Xu J.; Ma B. Development of a facile droplet-based single-cell isolation platform for cultivation and genomic analysis in microorganisms. Sci. Rep. 2017, 7, 41192. 10.1038/srep41192. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lorenceau E.; Utada A. S.; Link D. R.; Cristobal G.; Joanicot M.; Weitz D. A. Generation of Polymerosomes from Double-Emulsions. Langmuir 2005, 21, 9183–9186. 10.1021/la050797d. [DOI] [PubMed] [Google Scholar]

- Arshady R. Preparation of Microspheres and Microcapsules by Interfacial Polycondensation Techniques. J. Microencapsul. 1989, 6, 13–28. 10.3109/02652048909019898. [DOI] [PubMed] [Google Scholar]

- Oliveira M. B.; Hatami J.; Mano J. F. Coating Strategies Using Layer-by-Layer Deposition for Cell Encapsulation. Chem.—Asian J. 2016, 11, 1753–1764. 10.1002/asia.201600145. [DOI] [PubMed] [Google Scholar]

- Keen P. H. R.; Slater N. K. H.; Routh A. F. Encapsulation of Yeast Cells in Colloidosomes. Langmuir 2012, 28, 1169–1174. 10.1021/la204183u. [DOI] [PubMed] [Google Scholar]

- Selimović Š.; Oh J.; Bae H.; Dokmeci M.; Khademhosseini A. Microscale Strategies for Generating Cell-Encapsulating Hydrogels. Polymers 2012, 4, 1554–1579. 10.3390/polym4031554. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mao A. S.; Shin J.-W.; Utech S.; Wang H.; Uzun O.; Li W.; Cooper M.; Hu Y.; Zhang L.; Weitz D. A.; et al. Deterministic Encapsulation of Single Cells in Thin Tunable Microgels for Niche Modeling and Therapeutic Delivery. Nat. Mater. 2017, 16, 236–243. 10.1038/nmat4781. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kakran M.; Antipina M. N. Emulsion-Based Techniques for Encapsulation in Biomedicine, Food and Personal Care. Curr. Opin. Pharmacol. 2014, 18, 47–55. 10.1016/j.coph.2014.09.003. [DOI] [PubMed] [Google Scholar]

- Pickering S. U. CXCVI.—Emulsions. J. Chem. Soc., Trans. 1907, 91, 2001–2021. 10.1039/ct9079102001. [DOI] [Google Scholar]

- van Wijk J.; Salari J. W. O.; Zaquen N.; Meuldijk J.; Klumperman B. Poly(Methyl Methacrylate)–Silica Microcapsules Synthesized by Templating Pickering Emulsion Droplets. J. Mater. Chem. B 2013, 1, 2394–2406. 10.1039/c3tb20175a. [DOI] [PubMed] [Google Scholar]

- Bon S. A. F.; Chen T. Pickering Stabilization as a Tool in the Fabrication of Complex Nanopatterned Silica Microcapsules. Langmuir 2007, 23, 9527–9530. 10.1021/la7016769. [DOI] [PubMed] [Google Scholar]

- Tambe D. E.; Sharma M. M. Factors Controlling the Stability of Colloid-Stabilized Emulsions: I. An Experimental Investigation. J. Colloid Interface Sci. 1993, 157, 244–253. 10.1006/jcis.1993.1182. [DOI] [Google Scholar]

- Yang Y.; Fang Z.; Chen X.; Zhang W.; Xie Y.; Chen Y.; Liu Z.; Yuan W. An Overview of Pickering Emulsions: Solid-Particle Materials, Classification, Morphology, and Applications. Front. Pharmacol. 2017, 8, 287. 10.3389/fphar.2017.00287. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Linke C.; Drusch S. Pickering Emulsions in Foods - Opportunities and Limitations. Crit. Rev. Food Sci. Nutr. 2017, 58, 1971. 10.1080/10408398.2017.1290578. [DOI] [PubMed] [Google Scholar]

- Binks B. P.; Lumsdon S. O. Pickering Emulsions Stabilized by Monodisperse Latex Particles: Effects of Particle Size. Langmuir 2001, 17, 4540–4547. 10.1021/la0103822. [DOI] [Google Scholar]

- Frelichowska J.; Bolzinger M.-A.; Chevalier Y. Effects of Solid Particle Content on Properties of o/w Pickering Emulsions. J. Colloid Interface Sci. 2010, 351, 348–356. 10.1016/j.jcis.2010.08.019. [DOI] [PubMed] [Google Scholar]

- Qi F.; Wu J.; Sun G.; Nan F.; Ngai T.; Ma G. Systematic Studies of Pickering Emulsions Stabilized by Uniform-Sized PLGA Particles: Preparation and Stabilization Mechanism. J. Mater. Chem. B 2014, 2, 7605–7611. 10.1039/c4tb01165a. [DOI] [PubMed] [Google Scholar]

- van Wijk J.; Heunis T.; Harmzen E.; Dicks L. M. T.; Meuldijk J.; Klumperman B. Compartmentalization of Bacteria in Microcapsules. Chem. Commun. 2014, 50, 15427–15430. 10.1039/c4cc04901b. [DOI] [PubMed] [Google Scholar]

- Bashir O.; Claverie J. P.; Lemoyne P.; Vincent C. Controlled-Release of Bacillus Thurigiensis Formulations Encapsulated in Light-Resistant Colloidosomal Microcapsules for the Management of Lepidopteran Pests of Brassica Crops. PeerJ 2016, 4, e2524 10.7717/peerj.2524. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wei L.; Zhang M.; Zhang X.; Xin H.; Yang H. Pickering Emulsion as an Efficient Platform for Enzymatic Reactions without Stirring. ACS Sustainable Chem. Eng. 2016, 4, 6838–6843. 10.1021/acssuschemeng.6b01776. [DOI] [Google Scholar]

- Zhang M.; Wei L.; Chen H.; Du Z.; Binks B. P.; Yang H. Compartmentalized Droplets for Continuous Flow Liquid–Liquid Interface Catalysis. J. Am. Chem. Soc. 2016, 138, 10173–10183. 10.1021/jacs.6b04265. [DOI] [PubMed] [Google Scholar]

- Zhang G.; Wang C. Pickering Emulsion-Based Marbles for Cellular Capsules. Materials 2016, 9, 572. 10.3390/ma9070572. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Das A. A. K.; Filby B. W.; Geddes D. A.; Legrande D.; Paunov V. N. High Throughput Fabrication of Cell Spheroids by Templating Water-in-Water Pickering Emulsions. Mater. Horiz. 2017, 4, 1196–1200. 10.1039/c7mh00677b. [DOI] [Google Scholar]

- Glare T.; Caradus J.; Gelernter W.; Jackson T.; Keyhani N.; Köhl J.; Marrone P.; Morin L.; Stewart A. Have Biopesticides Come of Age?. Trends Biotechnol. 2012, 30, 250–258. 10.1016/j.tibtech.2012.01.003. [DOI] [PubMed] [Google Scholar]

- de Faria M. R.; Wraight S. P. Mycoinsecticides and Mycoacaricides: A Comprehensive List with Worldwide Coverage and International Classification of Formulation Types. Biol. Control 2007, 43, 237–256. 10.1016/j.biocontrol.2007.08.001. [DOI] [Google Scholar]

- Dara S. K.; Goble T. A.; Shapiro-Ilan D. I.. Leveraging the Ecology of Invertebrate Pathogens in Microbial Control. Ecology of Invertebrate Diseases; Wiley-Blackwell, 2017; pp 469–493. [Google Scholar]

- Jackson M. A.; Dunlap C. A.; Jaronski S. T. Ecological Considerations in Producing and Formulating Fungal Entomopathogens for Use in Insect Biocontrol. Biol. Control 2010, 55, 129–145. 10.1007/s10526-009-9240-y. [DOI] [Google Scholar]

- Zhao X.; Yu G.; Li J.; Feng Y.; Zhang L.; Peng Y.; Tang Y.; Wang L. Eco-Friendly Pickering Emulsion Stabilized by Silica Nanoparticles Dispersed with High-Molecular-Weight Amphiphilic Alginate Derivatives. ACS Sustainable Chem. Eng. 2018, 6, 4105–4114. 10.1021/acssuschemeng.7b04508. [DOI] [Google Scholar]

- Brooks A.; Wall R. Horizontal Transmission of Fungal Infection by Metarhizium Anisopliae in Parasitic Psoroptes Mites (Acari: Psoroptidae). Biol. Control 2005, 34, 58–65. 10.1016/j.biocontrol.2005.03.016. [DOI] [Google Scholar]

- Kirkland B. H.; Westwood G. S.; Keyhani N. O. Pathogenicity of Entomopathogenic Fungi Beauveria Bassiana and Metarhizium Anisopliae to Ixodidae Tick Species Dermacentor Variabilis, Rhipicephalus Sanguineus, and Ixodes Scapularis. J. Med. Entomol. 2004, 41, 705–711. 10.1603/0022-2585-41.4.705. [DOI] [PubMed] [Google Scholar]

- Samish M.; Ginsberg H. S.; Glazer I.. Anti-Tick Biological Control Agents: Assessment and Future Perspectives. Ticks; Cambridge University Press: 2008; 447–469. [Google Scholar]

- Samuels K. D. Z.; Pinnock D. E.; Allsopp P. G. The Potential of Metarhizium Anisopliae (Metschikoff) Sorokin (Deuteromycotina: Hyphomycetes) as a Biological Control Agent of Inopus Rubriceps (Macquart) (Diptera: Stratiomyidae). Aust. J. Entomol. 1989, 28, 69–74. 10.1111/j.1440-6055.1989.tb01197.x. [DOI] [Google Scholar]

- van Lenteren J. C.; Bolckmans K.; Köhl J.; Ravensberg W. J.; Urbaneja A. Biological Control Using Invertebrates and Microorganisms: Plenty of New Opportunities. Biol. Control 2018, 63, 39–59. 10.1007/s10526-017-9801-4. [DOI] [Google Scholar]

- Hajek A. E.; Eastburn C. C. Attachment and Germination of Entomophaga Maimaiga Conidia on Host and Non-Host Larval Cuticle. J. Invertebr. Pathol. 2003, 82, 12–22. 10.1016/s0022-2011(02)00198-2. [DOI] [PubMed] [Google Scholar]

- James R. R.; Buckner J. S.; Freeman T. P. Cuticular Lipids and Silverleaf Whitefly Stage Affect Conidial Germination of Beauveria Bassiana and Paecilomyces Fumosoroseus. J. Invertebr. Pathol. 2003, 84, 67–74. 10.1016/j.jip.2003.08.006. [DOI] [PubMed] [Google Scholar]

- Pasternack R. M.; Amy S. R.; Chabal Y. J. Attachment of 3-(Aminopropyl)Triethoxysilane on Silicon Oxide Surfaces: Dependence on Solution Temperature. Langmuir 2008, 24, 12963–12971. 10.1021/la8024827. [DOI] [PubMed] [Google Scholar]

- Ment D.; Churchill A. C. L.; Gindin G.; Belausov E.; Glazer I.; Rehner S. A.; Rot A.; Donzelli B. G. G.; Samish M. Resistant Ticks Inhibit Metarhizium Infection Prior to Haemocoel Invasion by Reducing Fungal Viability on the Cuticle Surface. Environ. Microbiol. 2012, 14, 1570–1583. 10.1111/j.1462-2920.2012.02747.x. [DOI] [PubMed] [Google Scholar]

- Boucias D. G.; Pendland J. C.. Entomopathogenic Fungi: Fungi Imperfecti. In Principles of Insect Pathology; Boucias D. G., Pendland J. C., Eds.; Springer US: Boston, MA, 1998; pp 321–364. [Google Scholar]

- Luke B.; Faull J.; Bateman R. Using Particle Size Analysis to Determine the Hydrophobicity and Suspension of Fungal Conidia with Particular Relevance to Formulation of Biopesticide. Biocontrol Sci. Technol. 2015, 25, 383–398. 10.1080/09583157.2014.979396. [DOI] [Google Scholar]

- French D. J.; Taylor P.; Fowler J.; Clegg P. S. Making and Breaking Bridges in a Pickering Emulsion. J. Colloid Interface Sci. 2015, 441, 30–38. 10.1016/j.jcis.2014.11.032. [DOI] [PubMed] [Google Scholar]

- French D. J.; Brown A. T.; Schofield A. B.; Fowler J.; Taylor P.; Clegg P. S. The Secret Life of Pickering Emulsions: Particle Exchange Revealed Using Two Colours of Particle. Sci. Rep. 2016, 6, 31401. 10.1038/srep31401. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Imhof A.; Pine D. J. Ordered Macroporous Materials by Emulsion Templating. Nature 1997, 389, 948–951. 10.1038/40105. [DOI] [Google Scholar]

- Yang T.; Hu Y.; Wang C.; Binks B. P. Fabrication of Hierarchical Macroporous Biocompatible Scaffolds by Combining Pickering High Internal Phase Emulsion Templates with Three-Dimensional Printing. ACS Appl. Mater. Interfaces 2017, 9, 22950–22958. 10.1021/acsami.7b05012. [DOI] [PubMed] [Google Scholar]

- Gindin G.; Samish M.; Zangi G.; Mishoutchenko A.; Glazer I. The Susceptibility of Different Species and Stages of Ticks to Entomopathogenic Fungi. Exp. Appl. Acarol. 2002, 28, 283–288. 10.1023/a:1025379307255. [DOI] [PubMed] [Google Scholar]

- Rot A.; Gindin G.; Ment D.; Mishoutchenko A.; Glazer I.; Samish M. On-Host Control of the Brown Dog Tick Rhipicephalus Sanguineus Latreille (Acari: Ixodidae) by Metarhizium Brunneum (Hypocreales: Clavicipitaceae). Vet. Parasitol. 2013, 193, 229–237. 10.1016/j.vetpar.2012.11.020. [DOI] [PubMed] [Google Scholar]

- Gasic S.; Tanovic B. Biopesticide Formulations, Possibility of Application and Future Trends. Pestic. Fitomedicina 2013, 28, 97–102. 10.2298/pif1302097g. [DOI] [Google Scholar]

- Behle R.; Birthisel T.. Formulations of Entomopathogens as Bioinsecticides. In Mass Production of Beneficial Organisms; Morales-Ramos J. A., Rojas M. G., Shapiro-Ilan D. I., Eds.; Academic Press: San Diego, 2014; Chapter 14, pp 483–517. [Google Scholar]

- Abbott W. S. A Method of Computing the Effectiveness of an Insecticide. J. Econ. Entomol. 1925, 18, 265–267. 10.1093/jee/18.2.265a. [DOI] [Google Scholar]

- Bischoff J. F.; Rehner S. A.; Humber R. A. A Multilocus Phylogeny of the Metarhizium Anisopliae Lineage. Mycologia 2009, 101, 512–530. 10.3852/07-202. [DOI] [PubMed] [Google Scholar]

- Schindelin J.; Arganda-Carreras I.; Frise E.; Kaynig V.; Longair M.; Pietzsch T.; Preibisch S.; Rueden C.; Saalfeld S.; Schmid B.; et al. Fiji: An Open-Source Platform for Biological-Image Analysis. Nat. Methods 2012, 9, 676–682. 10.1038/nmeth.2019. [DOI] [PMC free article] [PubMed] [Google Scholar]