Abstract

Background.

In spite of the availability of substitutes for lead and cadmium compounds in paints, manufacturers continue to produce paints with high levels of these metals. As the population continues to grow and there is a continued shift from oil-based to water-based paints, the sales and use of these paints will increase the exposure of humans and the environment to these metals.

Objectives.

We measured the levels of lead (Pb) and cadmium (Cd) in 174 paint samples marketed in Lagos and Ibadan, Nigeria. Paint samples from different manufacturers registered with and without Standards Organization of Nigeria (SON) were considered.

Methods.

Samples were acid digested using a microwave digester and the levels of the elements were determined using inductively coupled plasma optical emission spectroscopy (ICP-OES).

Discussion.

The levels of Cd and Pb (dry weight) in all samples ranged from 98–1999 μg/g and 170–3231 μg/g, respectively. All the samples were above the permissible limits of 90 ppm of the US Consumer Product Safety Commission and 100 ppm limit of the European Union (EU) for Pb and Cd in paint.

Conclusions.

We concluded that water-based paints marketed in Nigeria still contain substantial amounts of lead and cadmium which are detrimental to human health and the entire ecosystem. These metals are among the EU priority metals due to the increased risk of occupational exposure to humans and vulnerable groups such as children.

Keywords: heavy metals, paints, exposure, lead, cadmium, ICP-OES

Introduction

Environmental health hazards caused by heavy metals exposure are a continued threat to human health, particularly in developing countries.1 There is increasing awareness of consumer products with high heavy metal content. Heavy metals such as lead, cadmium, arsenic and so on are constituents of pigments which are added to paint formulations to increase brightness and longevity.2 Paints and coatings play an indispensable role in household appliances, buildings, cars, ships, aeroplanes, computers, furniture, and circuit boards.3

Lead (Pb) is a toxic heavy metal even at very low levels of human exposure. Lead can cause central nervous system damage and is an important disease-causing agent in terms of environmental contribution to the total global burden of disease as measured in disability adjusted life years.4 Lead can also damage the kidney, liver and reproductive system, basic cellular processes and brain function. Its effect on the human body can be both acute or chronic depending on dose and exposure scenarios. Toxic symptoms can include anemia, insomnia, headache, dizziness, irritability, muscle weakness, hallucination and renal damage.5 Lead accumulates in the skeleton and its mobilization from bones during pregnancy and lactation causes exposure to the fetus and breast fed infants.6–8

Cadmium (Cd) is a major pollutant that causes a range of pathological alterations.9–12 It is used in various industrial activities. Major industrial applications of cadmium include the production of alloys, pigments, and batteries.13 Cadmium is a severe pulmonary and gastrointestinal irritant, and can be fatal if inhaled or ingested. It accumulates primarily in the kidneys and has a long biological half-life of 10–35 years in humans. The primary effect of cadmium is kidney damage and bone fragility.14–16 There is evidence that cadmium is carcinogenic through the inhalation route, and humans are exposed to cadmium by inhalation and ingestion.17,18

Both Pb and Cd are widely distributed in the environment (air, soil, surface and ground water, sediment, dust, food, paint) and in biological systems; and occur both naturally and through human activities.5,13,19–23 Unlike organic contaminants, lead and cadmium are not biodegradable and tend to accumulate in living organisms.5 They are readily transferred through the food chain and are not known to serve any essential biological function.

Abbreviations

- Cd

Calcium

- Pb

Lead

Several studies have been conducted on metals in consumer products. Cadmium has been analyzed in cosmetics and personal care products, toys, children's jewelry, and decorative paints.24–37 Global studies on lead in new decorative paints conducted by Toxic Link showed that 68.5% of the 232 enamel samples collected from eleven countries had lead concentrations above the 90 ppm permissible limit of the US Consumer Product Safety Commission and 64.6% of the samples had lead concentrations above 600 ppm, which is the previous permissible limit of the US Consumer Product Safety Commission and the regulatory standard of Argentina, Chile and Uruguay.38 In addition, a study by Clark et al. showed a total of 57 (73%) out of 78 new enamel household paints had at least one sample with a lead concentration above or equal to 600 ppm.39

Various countries have initiated laws that regulate or ban the use of hazardous chemicals and substances in paint with varying degrees of compliance.40,41 There are regulations in place in Nigeria stipulating that paints should contain less than 90 ppm (dry weight) of total lead and 100 ppm of cadmium, but these limits have not been enforced.42–44 Thus, we conducted a survey of decorative paints currently sold in Nigeria using Lagos and Ibadan as case studies. We assessed the levels of lead and cadmium in water-based paints so as to ascertain the levels of exposure to these metals from paint products.

Methods

Sample Collection

Paint samples were purchased in popular paint markets in Ibadan and Lagos, Nigeria based on color availability and the most commonly used water-based paints. Two samples each of the same color produced by 14 different manufacturers were collected. Six manufacturers were registered with the Standards Organization of Nigeria (SON), and 8 manufacturers were unregistered. A total of 12 different paint colors were collected, as shown in Table 1. Samples were stored in air-tight plastic containers and analyzed at the Council of Scientific and Industrial Research-National Environmental Engineering Research Institute Laboratory, Nagpur—Maharashtra, India.

Table 1.

Paint Samples Collected in Lagos and Ibadan, Nigeria

| Sample Number | Manufacturer | Number of paint colours collected | Total number of paint samples collected | Standards Organization of Nigeria registration |

|---|---|---|---|---|

| 1 | A | 9 | 18 | Yes |

| 2 | B | 10 | 20 | Yes |

| 3 | C | 9 | 18 | Yes |

| 4 | D | 5 | 10 | Yes |

| 5 | E | 5 | 10 | Yes |

| 6 | F | 6 | 12 | Yes |

| 7 | G | 8 | 16 | No |

| 8 | H | 5 | 10 | No |

| 9 | I | 5 | 10 | No |

| 10 | J | 7 | 14 | No |

| 11 | K | 6 | 12 | No |

| 12 | L | 4 | 8 | No |

| 13 | M | 4 | 8 | No |

| 14 | N | 4 | 8 | No |

Sample Preparation and Pre-treatment

Approximately 5 mL of the paint samples were spread on glass slides using a different brush for each sample to avoid cross contamination. The glass slides were placed in an oven at 120°C for 2 hours. About 1.0 g each of the dried paint film was weighed into closed Teflon vessels and digested in a closed microwave digestion system using 10 mL of 70% nitric acid and 3 mL of 98% sulphuric acid. Samples were analyzed according to the standard procedures for digestion of very difficult samples.45 Digestates were then filtered and analyzed using inductively coupled plasma-optical emission spectrometry (Thermo Scientific iCAP 6300 Duo).

Sample blanks were also prepared alongside the samples. Dilutions were performed when necessary for the samples. Working standard solutions of 1–1000 μg/g were prepared from a multielement standard. A recovery study was carried out and recoveries of 80% for Pb and 110% for Cd were obtained.

Instrument Operation Conditions

Digestion of Paint Samples

A MARS 6 microwave reaction system was used for sample digestion. Samples were weighed into Teflon vessels and digested at 200°C, 25 mins ramp time, 30 mins holding time, and 1000 watt power in one cycle digestion. The temperature guard of the instrument was set to not exceed 210°C. Cooling was automatically carried out by the instrument to 30°C for another 30 minutes.

Inductively Coupled Plasma Optical Emission Spectrometer

Digested samples were analyzed using Thermo Fisher Scientific inductively coupled plasma optical emission spectrometry (model iCAP 6300 Duo) which was coupled with an auto sampler CETAC ASX-52, and spectrometer (Echelle type) equipped with a simultaneous charge injection device detector measuring wavelengths from 166.00 nm to 847.00 nm. The operating condition of ICP-OES was 1150 W RF power, 15 L/min plasma flow, 50 rpm pump rate, 0.5 L/min auxiliary gas flow, and 0.5 L/min nebulizer gas flow. The carrier gas of the instrument was ultra-pure argon.

Results

The levels of Cd and Pb in the paint samples collected in Lagos and Ibadan, Nigeria are presented in the Supplemental Material (42.2KB, docx) , while Table 2 shows a comparison of the concentrations of Pb in the paint samples obtained in this study with previous studies reported in the literature.

Table 2.

Comparison of the Present Study with Other Studies Reported in the Literature for Lead in Paint Samples

| Countries | Samples | Number of Samples | Average concentration | Maximum concentration | Percentage of samples with concentrations ≥ 90 ppma | Percentage of samples with concentrations ≥ 600 ppmb | Reference number |

|---|---|---|---|---|---|---|---|

| Nigeria | water-based | 174 | 811 | 3231 | 100 | 72 | This study |

| Nigeria | water-based | 8 | 86 | 516 | 5 | none | 46 |

| oil-based | 11 | 45 | 159 | 11 | none | ||

| Nigeria | oil-based | 25 | 14500 | 50000 | NA | 96 | 47 |

| Cameroon | oil-based | 61 | NA | 500000 | 66 | 64 | 48 |

| Brazil | oil-based | 20 | 5600 | 5900 | 35 | 30 | 41 |

| Sri Lanka | water-based | 11 | 4177 | 45743 | 10 | 10 | 38 |

| oil-based | 19 | 25210 | 137325 | 68 | 68 | ||

| Philippines | water-based | 10 | 11 | 40 | none | none | 38 |

| oil-based | 15 | 28354 | 189163 | 67 | 60 | ||

| Thailand | water-based | 10 | 3 | 15 | none | none | 38 |

| oil-based | 17 | 61893 | 505716 | 47 | 47 | ||

| Tanzania | water-based | 6 | 22 | 40 | none | none | 38 |

| oil-based | 20 | 14537 | 120862 | 100 | 95 | ||

| South Africa | oil-based | 29 | 19862 | 195289 | 65 | 62 | 38 |

| Nigeria | water-based | 7 | 8458 | 34598 | 100 | 100 | 38 |

| oil-based | 23 | 36989.5 | 129837 | 100 | 100 | ||

| Senegal | water-based | 9 | 5.5 | 29 | none | none | 38 |

| oil-based | 21 | 5866 | 29717 | 86 | 76 | ||

| Belarus | water-based | 8 | 58 | 418 | none | none | 38 |

| oil-based | 22 | 5558 | 59387 | 82 | 68 | ||

| Mexico | water-based | 10 | 6 | 16 | none | none | 38 |

| oil-based | 20 | 51860 | 163812 | 100 | 100 | ||

| Brazil | water-based | 7 | 10 | 14 | none | none | 38 |

| oil-based | 24 | 15004 | 170258 | 42 | 37 | ||

| India | oil-based | 22 | 9411 | 49593 | 36 | 36 | 38 |

| India | oil-based | 26 | 16600 | 134000 | 42 | 35 | 41 |

| India | oil-based | 5 | 106000 | 290000 | 100 | 100 | 49 |

| India | water-based | 38 | NA | 140000 | 38 | 49 | 50 |

| oil-based | 31 | NA | NA | 84 | NA | ||

| India | oil-based | 17 | NA | NA | 100 | NA | 51 |

| India | oil-based | 148 | NA | 80350 | 85 | NA | 52 |

| Armenia | oil-based | 26 | 25000 | 130000 | 77 | 77 | 41 |

| Kazakhstan | oil-based | 26 | 15700 | 71000 | 81 | 77 | 41 |

Note: NA-not available;

a Present permissible limit of 90 ppm for Pb and

b previous permissible limit of 600 ppm for Pb by the US Consumer Product Safety Commission.

Concentrations of Lead and Cadmium in Paint Samples by Manufacturer

The levels of Cd and Pb (μg/g, dry weight) in all the samples ranged from 98 1999 and 170–3231, respectively (Supplemental Material (42.2KB, docx) ). The highest mean concentration of Cd was 1946±75 μg/g obtained in paints produced by manufacturer C, a registered manufacturer. This was followed by 1877±22 and 1845±24 μg/g in products produced by manufacturer L (unregistered) and C, respectively, while the lowest concentration was 98.5±1 μg/g in paints produced by manufacturer K, an unregistered manufacturer. The highest mean concentration of Pb was obtained in paints produced by manufacturer H (3117±161 μg/g), an unregistered manufacturer. This was followed by manufacturer L (3013±16 μg/g) and (2121±19 μg/g) from the same manufacturer, while the lowest concentration, 173±4 μg/g, was found in paints produced by manufacturer K.

The order of metal concentrations in the paint samples with respect to manufacturers was: Cd: M > A > L> E > F > J > C > G > D > N > B > I > H >K; and Pb: L > N > A > M > H > I > C > E > G > J > B > K> D > F.

The lowest concentrations of Cd and Pb were found in paint samples produced by unregistered and registered manufacturers, respectively. The lowest mean Cd and Pb concentrations (98.5±1 μg/g and 186±1 μg/g) were found in products produced by manufacturers K and F, respectively.

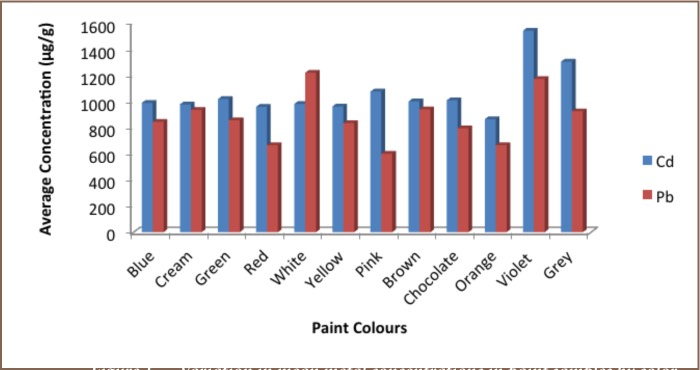

Concentrations of Lead and Cadmium in Paint Samples by Color

The range of levels of Cd and Pb in all the paint samples with respect to color was 98–1999 μg/g in red color and 170 (green)–3231 μg/g (cream) (Supplemental Material (42.2KB, docx) ), respectively. Variation in mean metal concentrations with respect to color is presented in Figure 1. The highest Cd concentration was in red paint (1999 μg/g), followed by green (1893 μg/g) and red (1893 μg/g) colored paint products. The highest Pb concentration was in cream colored paint (3231 μg/g) (S 1) produced by manufacturer H, followed by green (3024 μg/g) produced by manufacturer L and cream (3003 μg/g) (S 2) also produced by manufacturer H. The highest mean Cd concentration was found in red colored paints (1946±75 μg/g), followed by pink (1845±24 μg/g) and cream (1813 ±28 μg/g), while the lowest concentration was in red (98.5±1 μg/g) colored paints. The highest mean Pb concentration was in cream (3117 ±161 μg/g) paints produced by manufacturer H, followed by green (3013 ±16 μg/g) and blue (2121 ±19 μg/g), both produced by manufacturer L while the lowest concentration was also in green paints (173±4 μg/g) produced by manufacturer K.

Figure 1.

Variation in mean metal concentrations in paint samples by color.

The order of Cd and Pb in the paint samples collected with respect to colors was: Cd: violet > grey > yellow > pink > green > chocolate > brown > blue > white > cream > red > orange; and Pb: violet > brown > cream > grey> green > blue > yellow > chocolate > white > orange > red > pink.

Only one manufacturer (A) out of the fourteen manufacturers considered in this study produced violet colored paints, which ranked first with respect to the levels of Cd and Pb. In addition, only two manufacturers (B and A) produced grey colored paints, which also ranked second and fourth with respect to the levels of Cd and Pb, respectively.

Discussion

In all the paint samples analyzed in this study, the levels of Pb was above the 90 ppm permissible limit of the US Consumer Product Safety Commission, which came into effect on August 14, 2009, while the levels of Cd were above the 100 ppm permissible limit of the European Union (EU), which came into effect on March 7, 2016.42,43 The concentrations of Cd and Pb in all of the 174 samples collected in Lagos and Ibadan, Nigeria were above the permissible limits of the EU and US Consumer Product Safety Commission, respectively (Supplemental Material (42.2KB, docx) and Table 2). These results could be attributed to the raw materials used in the production of paint samples and weak product regulation and enforcement, as registered manufacturers had the highest mean Cd (M) and Pb (L) concentrations in their products. It has been reported that only about 15 paint companies in Nigeria have met the SON product standard.44 The health hazards associated with exposure to lead and cadmium in the domestic environment have been insufficiently studied in developing countries, although their importance as a source of morbidity is widely recognized.53 Previous studies in Nigeria have shown that over 70% of children have blood lead levels above 10 μg/dL and that flaking paints are an important exposure source.54,55 Recently, studies showed that blood lead levels once thought safe are associated with increased risk of death from many causes.56

The levels of Pb obtained in this study were higher than those reported in Nigeria, Brazil, Mexico, Belarus, Senegal, Tanzania and the Philippines, but lower than some previous studies in Nigeria, Thailand and Sri Lanka (Table 2). However, in most cases, the numbers of samples considered in previous studies were far lower than those reported in this study.

Conclusions

The present study examined the levels of Cd and Pb in paint samples sold in Lagos and Ibadan, Nigeria. In all the 174 paint samples collected and analyzed, the levels of Cd and Pb were above the permissible limits of 100 ppm and 90 ppm of the EU and US Consumer Product Safety Commission, respectively.

The order of metal concentrations with respect to manufacturers were: Cd: M > A > L > E > F > J > C > G > D > N > B > I > H > K; and Pb: L > N > A > M > H > I > C > E > G > J > B > K> D > F.

The order of metal concentrations with respect to color were: Cd: violet > grey > yellow > pink > green > chocolate > brown > blue > white > cream > red > orange; and Pb: violet > brown > cream > grey> green > blue > yellow > chocolate > white > orange > red > pink.

Presently, there are regulations in place in Nigeria that stipulate that paints should contain less than 90 ppm (dry weight) of total lead and 100 ppm of cadmium, but these limits have yet to be enforced, leading to high concentrations of these toxic metals in the paint samples. There is a need for the enforcement of permissible limits in paints produced in Nigeria to safeguard public health and to prevent possible exposure of the population to these metals, which are known to be particularly dangerous to humans.

Supplementary Material

Acknowledgments

Ajoke F. I. Apanpa-Qasim is grateful to The World Academy of Sciences for the Advancement of Science in developing countries and the Council of Scientific and Industrial Research for funding this research (FR number: 3240275040). In addition, the director of the National Environmental Engineering Research Institute, Nehru Marg, Nagpur, India is highly appreciated.

References

- 1. Millennium development goals [Internet]. New York, NY: United Nations; 2015. [cited 2016 Feb 2]. Available from: http://www.un.org/millenniumgoals/ [Google Scholar]

- 2. Lead and zinc statistics [Internet]. Lisboa, Portugal: United Nations; c2016. [cited 2016 Jun 1]. Available from: www.ilzsg.org/static/statistics.aspx?from=1 [Google Scholar]

- 3. Osemeahon SA. Effect of different polyols on the esterification of monomethylol urea with polyol. Res J Pharm Bio Chem Sci [Internet]. 2014. May-Jun [cited 2016 Apr 3]; 5 3: 2002– 11. Available from: http://www.rjpbcs.com/pdf/2014_5(3)/[213].pdf [Google Scholar]

- 4. Pruss-Ustun A, Corvalan C. Preventing disease through healthy environments: towards an estimate of the environmental burden of disease [Internet]. Geneva, Switzerland: World Health Organization; 2006. [cited 2016 May 23] 104 p. Available from: www.who.int/quantifying_ehimpacts/publications/preventingdisease.pdf [Google Scholar]

- 5. Fu F, Wang Q. Removal of heavy metal ions from wastewaters: a review. J Environ Manag [Internet]. 2011. March [cited 2016 Feb 2]; 92 3: 407– 18. Available from: www.sciencedirect.com/science/article/pii/S0301479710004147 Subscription required to view. [DOI] [PubMed] [Google Scholar]

- 6. Health risks of heavy metals from long-range transboudary air pollution [Internet]. Geneva, Switzerland: World Health Organization; 2007. [cited 2016 Oct 21]. Available from: http://www.euro.who.int/__data/assets/pdf_file/0007/78649/E91044.pdf [Google Scholar]

- 7. Yurdakok K. Lead, mercury, and cadmium in breast milk. J Pediatr Neonatal Individ Med [Internet]. 2015. [cited 2016 Sep]; 4 2: e040223– 53. Available from: http://www.jpnim.com/index.php/jpnim/article/download/040223/314 [Google Scholar]

- 8. Agrawal A. Toxicity and fate of heavy metals with particular reference to developing foetus. Adv Life Sci [Internet]. 2012. [cited 2016 Sep 1]; 2 2: 29– 38. Available from: http://article.sapub.org/pdf/10.5923.j.als.20120202.06.pdf [Google Scholar]

- 9. Zheng X, Ding Z, Xu Y, Monroig O, Morais S, Tocher DR.. Physiological roles of fatty acyl desaturases and elongases in marine fish: characterisation of cDNAs of fatty acyl Δ6 desaturase and elovl5 elongase of cobia (Rachycentron canadum). Aquac [Internet]. 2009. May [cited 2016 Sep 1]; 290 1–2: 122– 31. Available from: http://www.sciencedirect.com/science/article/pii/S0044848609001392 Subscription required to view. [Google Scholar]

- 10. Khoshnood Z, Mokhlesi A, Khoshnood R.. Bioaccumulation of some heavy metals and histopathological alterations in liver of Euryglossa orientalis and Psettodes erumei along North Coast of the Persian Gulf. Afr J Biotechnol [Internet]. 2010. October [cited 2016 Sep 1]; 9 41: 6966– 72. Available from: http://www.academicjournals.org/journal/AJB/article-abstract/791E8E020311 [Google Scholar]

- 11. Senthamilselvan D, Chezhian A, Suresh E, Ezhilmathy R.. Toxic effects of heavy metals (cadmium plus mercury) on haematological parameters and DNA damage in Lates calcarifer. J Toxcol Environ Health Sci [Internet]. 2012. November [cited 2016 Sep 1]; 4 9: 156– 61. Available from: http://www.academicjournals.org/article/article1381160675_Senthamilselvan%20et%20al.pdf [Google Scholar]

- 12. Toxicological profile for Cadmium [Internet]. Atlanta, GA: Agency for Toxic Substances and Disease Registry; 2012. September [cited 2016 Jan 4]. [about 4 screens] Available from: http://www.atsdr.cdc.gov/ToxProfiles/tp.asp?id=48&tid=15 [PubMed] [Google Scholar]

- 13. Draft final review of scientific information on cadmium [Internet]. Nairobi, Kenya: United Nations Environment Programme; 2008. November [cited 2016 Jan 3] 188 p. Available from: http://www.unep.org/hazardoussubstances/Portals/9/Lead_Cadmium/docs/Interim_reviews/Final_UNEP_Cadmium_review_Nov_2008.pdf [Google Scholar]

- 14. Wallin M. Cadmium, kidney and bone [Internet]. Gothenburg, Sweden: Department of Occupational and Environmental Medicine Institute of Medicine, Sahlgrenska Academy at University of Gothenburg; 2015. [cited 2016 Sep 1] 65 p. Available from: https://gupea.ub.gu.se/bitstream/2077/39550/1/gupea_2077_39550_1.pdf [Google Scholar]

- 15. Tchounwou PB, Yedjou CG, Patlolla AK, Sutton DJ.. Heavy metal toxicity and the environment. : Luch A, . editor Molecular, clinical and environmental toxicology [Internet]. Vol. 3: Environmental Toxicology. Basel, Switzerland: Springer Basel; 2012. [cited 2016 Sep 1]. p 133– 64. Available from: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4144270/ [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16. Chemical Fact Sheets [Internet]. Geneva, Switzerland: World Health Organization: 2006. [cited 2016 Feb 2] 177 p. Available from: http://www.who.int/water_sanitation_health/dwq/gdwq0506_12.pdf [Google Scholar]

- 17. Bernard A. Cadmium & its adverse effects on human health. Indian J Med Res [Internet]. 2008. October [cited 2016 Sep 1]; 128 4: 557– 64. Available from: http://www.ijmr.org.in/temp/IndianJMedRes1284557-4980748_135007.pdf [PubMed] [Google Scholar]

- 18. Cadmium and cadmium compounds. : IARC Monographs on the evaluation of carcinogenic risk of chemicals to humans: beryllium, cadmium, mercury and exposures in the glass manufacturing industry [Internet]. Vol. 58 Lyon, France: International Agency for Research on Cancer; 1993. [cited 2016 Mar 22]. p 121– 45. Available from: https://monographs.iarc.fr/ENG/Monographs/vol100C/mono100C-8.pdf [PMC free article] [PubMed] [Google Scholar]

- 19. Suruchi, Khanna P.. Assessment of heavy metal contamination in different vegetables grown in and around urban areas. Res J Environ Toxicol [Internet]. 2011. [cited 2016 Sep 1]; 5 3: 162– 79. Available from: http://scialert.net/fulltext/?doi=rjet.2011.162.179 [Google Scholar]

- 20. Musoke L, Banadda N, Sempala C, Kigozi J.. The migration of chemical contaminants from polyethylene bags into food during cooking. Open Food Sci J [Internet]. 2015. [cited 2016 Sep 1]; 9: 14– 8. Available from: http://benthamopen.com/contents/pdf/TOFSJ/TOFSJ-9-14.pdf [Google Scholar]

- 21. Final review of scientific information on lead: version of december 2010 [Internet]. Nairobi, Kenya: United Nations Environment Programme; 2010. December [cited 2016 May 4] 332 p. Available from: http://www.unep.org/hazardoussubstances/Portals/9/Lead_Cadmium/docs/Interim_reviews/UNEP_GC26_INF_11_Add_1_Final_UNEP_Lead_review_and_apppendix_Dec_2010.pdf [Google Scholar]

- 22. Appenroth KJ. Definition of “heavy metals” and their role in biological systems. : Sherameti I, Varma A, . Soil heavy metals [Internet]. Vol. 19 Berlin, Germany: Springer Berlin Heidelberg; 2010. [cited 2016 Sep 3]. p 19– 29. Available from: http://link.springer.com/chapter/10.1007%2F978-3-642-02436-8_2 Subscription required to view. [Google Scholar]

- 23. Fränzle S, Markert B. Metals in biomass. Environ Sci Pollut Res Int [Internet]. 2007. September [cited 2016 Sep 3]; 14 6: 404– 13. Available from: http://link.springer.com/article/10.1065/espr2006.12.372 Subscription required to view. [DOI] [PubMed] [Google Scholar]

- 24. Ackah M, Osei J, Anim AK, Zakaria N, Nyarko ES, Gyamfi ET, Enti-Brown S, Hanson JE, Bentil NO, Tulasi D.. Status of some metals contained in imported nail polish and lipsticks on the Ghanaian market. Proc Int Acad Ecol Environ Sci [Internet]. 2015. [cited 2016 Sep 1]; 5 4: 142– 7. Available from: http://www.iaees.org/publications/journals/piaees/articles/2015-5(4)/status-of-some-metals-in-imported-nail.pdf [Google Scholar]

- 25. Borowska S, Brzoska MM. Metals in cosmetics: implications for human health. J Appl Toxicol [Internet]. 2015. June [cited 2016 Sep 1]; 35 6: 551– 72. Available from: http://onlinelibrary.wiley.com/doi/10.1002/jat.3129/full [DOI] [PubMed] [Google Scholar]

- 26. Zulaikha SR, Norkhadijah SS, Praveena SM.. Hazardous ingredients in cosmetics and personal care products and health concern: a review. Public Health Res [Internet]. 2015. [cited 2016 Sep 1]; 5 1: 7– 15. Available from: http://article.sapub.org/10.5923.j.phr.20150501.02.html [Google Scholar]

- 27. Omenka SS, Adeyi AA. Heavy metal content of selected personal care products (PCPs) available in Ibadan, Nigeria and their toxic effects. Toxicol Rep [Internet]. 2016. [cited 2016 Sep 1]; 3: 628– 35. Available from: http://www.sciencedirect.com/science/article/pii/S2214750016300555 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28. Adepoju-Bello AA, Oguntibeju OO, Adebisi RA, Okpala N, Coker HA.. Evaluation of the concentration of toxic metals in cosmetic products in Nigeria. Afr J Biotechnol [Internet]. 2012. December 4 [cited 2016 May 12]; 11 97: 16360– 4. Available from: http://pajooheshyar.sums.ac.ir/attachments/93-01-04-8612/article1380726928_Adepoju%20Bello%20et%20al.pdf [Google Scholar]

- 29. Omolaoye JA, Uzairu A, Gimba CE.. Heavy metal assessment of some soft plastic toys imported into Nigeria from China. J Environ Chem Ecotoxicol [Internet]. 2010. October [cited 2016 Sep 1]; 2 8: 126– 30. Available from: http://www.academicjournals.org/journal/JECE/article-full-textpdf/08D28803014 [Google Scholar]

- 30. Korfali SI, Sabra R, Jurdi M, Taleb RI.. Assessment of toxic metals and phthalates in children's toys and clays. Arch Environ Contam Toxicol [Internet]. 2013. October [cited 2016 Sep 1]; 65 3: 368– 81. Available from: http://link.springer.com/article/10.1007/s00244-013-9925-1 Subscription required to view. [DOI] [PubMed] [Google Scholar]

- 31. Dahab AA, Elhag DE, Ahmed AB. Al-Obaid HA.. Determination of elemental toxicity migration limits, bioaccessibility and risk assessment of essential childcare products. Environ Sci Pollut Res [Internet]. 2016. February [cited 2016 Sep 1]; 23 4: 3406– 13. Available from: http://link.springer.com/article/10.1007/s11356-015-5594-0 Subscription required to view. [DOI] [PubMed] [Google Scholar]

- 32. Sindiku OK, Osibanjo O. Some priority heavy metals in children toy's imported to Nigeria. J Toxicol Environ Health Sci [Internet]. 2011. April [cited 2016 May 3]; 3 4: 109– 15. Available from: http://www.academicjournals.org/article/article1379428542_Sindiku%20and%20Osibanjo.pdf [Google Scholar]

- 33. Cui XY, Li SW, Zhang SJ, Fan YY, Ma LQ.. Toxic metals in children's toys and jewelry: coupling bioaccessibility with risk assessment. Environ Poll [Internet]. 2015. May [cited 2016 Sep 1]; 200: 77– 84. Available from: http://www.sciencedirect.com/science/article/pii/S0269749115000718 Subscription required to view. [DOI] [PubMed] [Google Scholar]

- 34. Guney M, Zagury GJ. Contamination by ten harmful elements in toys and children's jewelry bought on the North American market. Environ Sci Technol [Internet]. 2013. [cited 2016 Sep 1]; 47 11: 5921– 30. Available from: http://pubs.acs.org/doi/abs/10.1021/es304969n Subscription required to view. [DOI] [PubMed] [Google Scholar]

- 35. Kameti CM. Determination of lead and cadmium levels in decorative paints sold in Nairobi, Kenya [master's thesis]. [Nairobi City, Kenya]: Kenyatta University; 2013. Aug. 85 p. [Google Scholar]

- 36. Lead in enamel decorative paints, national paint testing results: a nine country study [Internet]. Nairobi, Kenya: United Nations Environment Programme; 2013. [cited 2016 May 4] 43 p. Available from: http://www.unep.org/chemicalsandwaste/Portals/9/Mercury/Documents/publications/Lead_in_Enamel_decorative_paints.pdf [Google Scholar]

- 37. Raheem AA, Olowu OA. Production of household paint using clay materials. Int J Eng Res Appl [Internet]. 2013. Mar-Apr [cited 2016 Apr 3]; 3 2: 85– 93. Available from: www.ijera.com/papers/Vol3_issue2/K32085093.pdf [Google Scholar]

- 38. Toxic Link and IPEN. . Lead in New Decorative paints. A Global Study. New Delhi, Chennai India; 2009. 1– 59 p. [cited 2016 November 20] Available from: http://www.ipen.org/ipenweb/documents/work%20documents/global_paintstudy.pdf). [Google Scholar]

- 39. Clark CS, Rampal KG, Thuppil V, Roda SM, Succop P, Menrath W, Chen CK, Adebamowo EO, Agbede OA, Sridhar MK, Adebamowo CA, Zakaria Y, El-Safty A, Shinde RM, Yu J.. Lead levels in new enamel household paints from Asia, Africa and South America. Environ Res [Internet]. 2009. October [cited 2016 Feb 2]; 109 7: 930– 6. Available from: http://www.sciencedirect.com/science/article/pii/S0013935109001315 Subscription required to view. [DOI] [PubMed] [Google Scholar]

- 40. Clark CS, Speranskaya O, Brosche S, Gonzalez H, Solis D, Kodeih N, Roda S, Lind C.. Total lead concentration in new decorative enamel paints in Lebanon, Paraguay and Russia. Environ Res [Internet]. 2015. April [cited 2016 Jul 5]; 138: 432– 8. Available from: http://www.sciencedirect.com/science/article/pii/S0013935115000481 Subscription required to view. [DOI] [PubMed] [Google Scholar]

- 41. Clark CS, Kumar A, Mohapatra P, Rajankar P, Nycz Z, Hambartsumyan A, Astanina L, Roda S, Lind C, Menrath W, Peng H.. Examination of lead concentrations in new decorative enamel paints in four countries with different histories of activity in lead paint regulation. Environ Res [Internet]. 2014. July [cited 2016 Jul 6]: 132: 233– 43. Available from: http://www.sciencedirect.com/science/article/pii/S0013935114000516 Subscription required to view [DOI] [PubMed] [Google Scholar]

- 42. Consumer Product Safety Improvement Act of 2008, Pub. L. 110–314, 122 Stat. 3016 (Aug 14, 2008).

- 43. Tsang HW. EU specifies restriction limit for cadmium in certain paints [Internet]. Geneva, Switzerland: SGS; 2016. February 25 [cited 2016 Jul 23]. [about 2 screens]. Available from: http://www.sgs.com/en/news/2016/02/safeguards-04316-eu-specifies-restriction-limit-forcadmium-in-certain-paints-under-reach [Google Scholar]

- 44. SON, stakeholders partner on lead reduction in paints [Internet]. Lagos, Nigeria: Standard Organisation of Nigeria; 2016. [cited 2016 Oct 21]. [about 3 screens]. Available from: http://son.gov.ng/son-stakeholders-partner-on-lead-reduction-in-paints/ [Google Scholar]

- 45. MARS 6: microwave digestion system [Internet]. Belfast, Northern Ireland: CEM; c2016. [cited 2015 Oct 21]. Available from: http://cem.com/mars-6/ [Google Scholar]

- 46. Adebamowo EO, Agbede OA, Sridhar MK, Adebamowo CA.. An evaluation of lead levels in paints for residential use sold in the Nigerian market. Indoor Built Environ [Internet]. 2006. December [cited 2016 Sep 1]; 15 6: 551– 4. Available from: ibe.sagepub.com/content/15/6/551.full.pdf Subscription required to view [Google Scholar]

- 47. Adebamowo EO, Clark CS, Roda S, Agbede OA, Sridhar MK, Adebamowo CA.. Lead content of dried films of domestic paints currently sold in Nigeria. Sci Total Environ [Internet]. 2007. December 15 [cited 2016 Sep 1]; 388 1–3: 116– 20. Available from: http://www.eh.uc.edu/assets/news/7-19-07-clark.pdf [DOI] [PubMed] [Google Scholar]

- 48. Gottesfeld P, Kuepouo G, Tetsopgang S, Durand K.. Lead concentrations and labeling of new paint in Cameroon. J Occup Environ Hyg [Internet]. 2013. [cited 2016 Oct 21]; 10 5: 243– 9. Available from: http://www.tandfonline.com/doi/abs/10.1080/15459624.2013.768934 Subscription required to view [DOI] [PubMed] [Google Scholar]

- 49. Rajankar P, Sinha S, Brosche S, Denney V, Clark CS.. National report: lead in India's enamel household paints [Internet]. New Delhi, India: Toxics Link; 2013. November [cited 2016 Aug 23] 64 p. Available from: http://toxicslink.org/docs/lead_in_paints/Lead-in-Paint2013.pdf [Google Scholar]

- 50. Kumar A, Gottesfeld P. Lead content in household paints in India. Sci Total Environ [Internet]. 2008. December 15 [cited 2016 Aug 23]; 407 1: 333– 7. Available from: http://www.sciencedirect.com/science/article/pii/S0048969708008954 Subscription required to view. [DOI] [PubMed] [Google Scholar]

- 51. Clark CS, Rampal KG, Thuppil V, Chen CK, Clark R, Roda S.. The lead content of currently available new residential paint in several Asian countries. Environ Res [Internet]. 2006. September [cited 2016 Aug 23]; 102 1: 9– 12. Available from: http://www.sciencedirect.com/science/article/pii/S0013935105001751 Subscription required to view. [DOI] [PubMed] [Google Scholar]

- 52. Mohanty A, Budhwani N, Ghosh B, Tarafdar M, Chakravarty S.. Lead content in new decorative paints in India. Environ Dev Sustain [Internet]. 2013. December 1 [cited 2016 Aug 23] 15 6: 1653– 61. Available from: http://link.springer.com/article/10.1007/s10668-013-9455-z Subscription required to view. [Google Scholar]

- 53. Nriagu JO, Blankson ML, Ocran K.. Childhood lead poisoning in Africa: a growing public health problem. Sci Total Environ [Internet]. 1996. March 15 [cited 2016 Feb 23]; 181 2: 93– 100. Available from: http://www.sciencedirect.com/science/article/pii/0048969795049541 Subscription required to view. [DOI] [PubMed] [Google Scholar]

- 54. Pfitzner MA, Thacher TD, Pettifor JM, Zoakah AI, Lawson JO, Fischer PR.. Prevalence of elevated blood lead levels in Nigerian children. Ambul Child Health [Internet]. 2000. June [cited 2016 Sep 1]; 6 2: 115– 23. Available from: http://onlinelibrary.wiley.com/doi/10.1046/j.1467-0658.2000.00069.x/abstract Subscription required to view. [Google Scholar]

- 55. Wright NJ, Thacher TD, Pfitzner MA, Fischer PR, Pettifor JM.. Causes of lead toxicity in a Nigerian city. Arch Dis Child [Internet]. 2005. March [cited 2016 Sep 1]; 90 3: 262– 6. Available from: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC1720320/pdf/v090p00262.pdf [DOI] [PMC free article] [PubMed] [Google Scholar]

- 56. Menke A, Muntner P, Batuman V, Silbergeld EK, Guallar E.. Blood lead below 0.48 micromol/L (10 microg/dL) and mortality among US adults. Circulation [Internet]. 2006. September 26 [cited 2016 Jan 12]; 114 13: 1388– 94. Available from: http://circ.ahajournals.org/cgi/pmidlookup?view=long&pmid=16982939 [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.