Summary

The effect of Lactobacillus plantarum fermentation on the functional and physicochemical properties of pea protein-enriched flour (PPF) was investigated. Over the course of the fermentation the extent of hydrolysis increased continuously until reaching a maximum degree of hydrolysis of 13.5% after 11 h. The resulting fermented flour was then adjusted to either pH=4 or 7 prior to measuring the surface and functional attributes as a function of fermentation time. At pH=4 surface charge, as measured by zeta potential, initially increased from +14 to +27 mV after 1 h of fermentation, and then decreased to +10 mV after 11 h; whereas at pH=7 the charge gradually increased from –37 to –27 mV over the entire fermentation time. Surface hydrophobicity significantly increased at pH=4 as a function of fermentation time, whereas at pH=7 fermentation induced only a slight decrease in PPF surface hydrophobicity. Foam capacity was highest at pH=4 using PPF fermented for 5 h whereas foam stability was low at both pH values for all samples. Emulsifying activity sharply decreased after 5 h of fermentation at pH=4. Emulsion stability improved at pH=7 after 5 h of fermentation as compared to the control. Oil-holding capacity improved from 1.8 g/g at time 0 to 3.5 g/g by the end of 11 h of fermentation, whereas water hydration capacity decreased after 5 h, then increased after 9 h of fermentation. These results indicate that the fermentation of PPF can modify its properties, which can lead towards its utilization as a functional food ingredient.

Key words: pea protein-enriched flour, fermentation, functional properties, lactic acid bacteria

Introduction

Dry edible pea (Pisum sativum) is widely consumed around the globe as a healthy food. Peas are rich in proteins, carbohydrates, fibre, and vitamins/minerals, and are low in fat (1). The protein content of pea is higher than many other staple foods, thus pea is considered a good protein source. Pea protein is rich in lysine, but deficient in the thiol-containing amino acids (cysteine and methionine) (2, 3). As such, it is commonly recommended that one consume pulses such as pea along with cereal grains in order to obtain a complete essential amino acid profile (4), especially in places where animal protein is limited and expensive due to issues of food insecurity. While peas are a good protein source, they also contain secondary metabolites considered to be anti-nutritional factors, such as enzyme inhibitors (trypsin and chymotrypsin inhibitors), oxalates, phytates, oligosaccharides, phenolics, tannins and lectins, that inhibit protein digestion or mineral absorption when consumed (5).

Peas are usually eaten whole or split, milled into flour (21–24% protein), air classified into either a protein-enriched flour (30–50% protein) or a protein concentrate (50–80% protein), or wet processed into a protein isolate (>80% protein) (6). Each particular fraction may be incorporated into different products, applications or sectors. Animal-derived proteins from milk (casein, whey) and egg (ovalbumin), along with plant sources such as wheat (gluten) and soy (glycinin, conglycinin) dominate the protein ingredient market (7). However, consumers are demanding an increase in alternative protein sources due to the allergen content of the current protein products. Accordingly, a rise in the demand for pea protein products has occurred since they tend to have low allergenicity. In addition, pea protein products have other market benefits, including not being genetically modified, low in cost, nutritious and functional (8, 9). As the demand for pea increases, so too does the need for greater variations and choice in pea protein ingredients; processing, such as infrared heating, germination, enzymatic modification and fermentation can alter the ingredients (9). Fermentation is of great interest to industry as it is a non-thermal process whose technology acts to partially unravel the protein conformation to expose buried reactive amino acids and improve its digestibility (10). The use of bacteria or fungi to produce proteases is essential to fermentation processes, as they not only initiate partial protein unfolding but also facilitate the release of low-molecular-mass peptides with potential bioactive properties (11-13). Fermentation also acts to reduce the content of anti-nutritional factors within pulse ingredients, and help improve mineral absorption through the production of organic acids which form soluble complexes with minerals, rendering the minerals unavailable to react with phytates and become insoluble (14-16).

Fermented pulses are consumed primarily in Asia, Africa and Europe, with less uptake in North America. However, limited research efforts have been reported on the effects of fermentation conditions on the functional properties of commercial pea protein ingredients, such as a protein-enriched flour. The overall goal of the present study is to examine the impact of fermentation of pea protein-enriched flour by Lactobacillus plantarum on the protein surface and functional properties at pH=4 (indicative of an acidic food, and near pea protein isoelectric point; pI) and pH=7 (indicative of the neutralization process in wet processing, and away from pea protein pI) in order to diversify the pea ingredient line for greater market integration. Fermentation studies commonly use L. plantarum due to its generally recognized as safe (GRAS) status, growth ability and its ubiquitous nature in fermented food products (17). We chose it for this study because of its growth requirements, i.e. the required fermentation conditions do not affect the pea protein quality.

Materials and Methods

Materials

Parrheim Foods (Saskatoon, SK, Canada) kindly donated the air-classified pea protein-enriched flour (PPF). 8-Anilino-1-naphthalenesulfonic acid (ANS) and 5,5’-dithiobis-2-nitrobenzoic acid (DNTB) were products of Sigma-Aldrich (Oakville, ON, Canada), MRS broth was a product of Oxoid (Nepean, ON, Canada), whereas all other chemicals used were of reagent grade and purchased through Fisher Scientific (Ottawa, ON, Canada). A Millipore Milli-Q™ water purification system (Millipore Corp., Etobicoke, ON, Canada) produced the water used in this stidy. Canola oil (Great Value™, Wal-Mart Canada Corp., Mississauga, ON, Canada) was purchased from a local supermarket. Lactobacillus plantarum NRRL B-4496 was obtained from the Agricultural Research Service Culture Collection, USDA (Peoria, IL, USA).

Fermentation

A growth curve for Lactobacillus plantarum NRRL B-4496 was initially prepared within MRS broth (Oxoid) for approx. 24 h at 32 °C under anaerobic conditions. For fermentation experiments cell cultivation lasted until the late exponential phase of growth (approx. 10 h), followed by centrifugation (10 000×g, 20 min, 4 °C; centrifuge model 5810R; Eppendorf, Mississauga, ON, Canada), and then washing twice with peptone solution. The resulting pellet was used as the inoculum for fermentation. Lactobacillus plantarum was added to a 25% (m/V) PPF solution (400 mL) in an Erlenmeyer flask at a content of 7 log CFU per g PPF, which was then incubated under anaerobic conditions at 32 °C for 11 h. Enumeration of L. plantarum was carried out by plating onto MRS medium (Oxoid) at 37 °C for 48 h under anaerobic conditions. Anaerobic conditions were maintained by placing the experiments within a rectangular jar with Anaerogen anaerobic gas generating kit (Thermo Scientific, Waltham, MA, USA). Aliquots (60 mL) were taken at 0, 1, 5, 9 and 11 h of fermentation and then freeze-dried for 48 h using a freeze dryer (Labconco, Freezone 12, Kansas City, MO, USA). All dried samples were then ground using a coffee grinder (model 80365; Hamilton Beach Custom Grind™, Glen Allen, VA, USA). Fermentation experiments were run in triplicate, yielding three separate fermented PPF for each time point.

Composition

Moisture content was determined gravimetrically by calculating the mass loss after drying 2 g sample in an oven (APT.line™ ED, BINDER GmbH, Tuttlingen, Germany) at 130 °C for 1 h, according to AOAC method 925.10 (18). Protein content (N/%·6.25) was determined according to AOAC method 920.87 (19) using a Kjeldahl micro digestor (model 6030000; Labconco) and distillation unit (Rapid Still I; Labconco). Ash content was determined according to AOAC method 923.03 (20) in which 3 g sample was placed overnight in a muffle furnace (Isotemp®; Thermo Fisher Scientific, Waltham, MA, USA) at 550 °C and expressed as the difference of the mass of the sample before and after heating. Crude lipid was determined gravimetrically after solvent extraction with ether according to AOAC method 920.39 (21) using a Labconco Goldfisch fat extractor. Proximate analysis was reported on a dry mass basis. To determine the pH, 15 g of PPF fermentation medium at each time interval (0, 1, 5, 9, and 11 h) were transferred to a 25-mL beaker and the pH was measured under stirring conditions using a pH meter (B10P Benchtop Meter; VWR, Mississauga, ON, Canada) and magnetic stirrer plate (RO 5; IKA Works Inc., Wilmington, NC, USA).

Degree of hydrolysis

The degree of hydrolysis (DH/%) of fermented PPF samples was calculated according to Adler-Nissen (22) using the following formulae:

and

where Yh is the yield of hydrolysis equivalents (of α-amino groups formed during the hydrolysis reaction; or α-NH2-Gly equivalent), ct is the millimolar concentration of α-NH2-Gly equivalent (measured using a glycine standard curve) obtained from the trypsin-catalyzed protein hydrolysis reactions, cc is the millimolar concentration of α-NH2-Gly equivalent from the non-trypsin treated PPF (control), ctot is the millimolar concentration of α-NH2-Gly equivalent from the total PPF hydrolysis, and DF is a dilution factor.

Surface properties

Surface charge

The surface charge (or zeta potential) of each fermented sample was determined according to Can Karaca et al. (23). In brief, 0.05% (by mass) of protein was dissolved in Milli-Q water (Millipore Corp.) and adjusted to pH=4.0 or 7.0 with 0.5 M NaOH or HCl. The solution was then stirred overnight at 500 rpm using a magnetic stirrer plate (RO 5; IKA Works Inc.) at room temperature (21–23 °C). The electrophoretic mobility was measured using a Zetasizer Nano (Malvern Instruments, Westborough, MA, USA). The zeta-potential (ζ/mV) was determined from the electrophoretic mobility (μE) using Henry’s equation, as follows:

|

where η is the dispersion viscosity, ε is the permittivity, and ƒ(κα) is a function related to the ratio of particle radius (α) and the Debye length (κ).

Surface hydrophobicity

Surface hydrophobicity of fermented samples was determined with 8-anilino-1-naphthalenesulfonic acid (ANS) fluorescent probe (Sigma-Aldrich) using the modified method of Kato and Nakai (24). Briefly, a 0.025% (by mass) protein solution was prepared in Milli-Q water (Millipore Corp.), adjusted to pH=4 or 7.0 using 0.5 M NaOH or HCl, and stirred overnight at 500 rpm using a magnetic stirrer (RO 5; IKA Works Inc.) at room temperature. The stock solution was then diluted to final protein mass fractions of 0.005, 0.010, 0.015, and 0.020%. A 20-µL aliquot of 8 mM ANS solution (in Milli-Q water, pH=4 or 7) was added to 1.6 mL of each protein mass fraction, vortexed for 10 s and kept in the dark for 5 min. The fluorescence intensity was measured with a FluoroMax-4 spectrofluorometer (Horiba Jobin Yvon Inc., Edison, NJ, USA) using excitation and emission wavelengths of 390 and 470 nm, respectively, and a slit width of 1 nm. Sample blanks were prepared by adding 20 µL of Milli-Q water (pH=4 or 7) to the protein solutions instead of the ANS probe (Sigma-Aldrich). The initial slope of the plot of the fluorescence intensity (protein solution with probe minus the same protein solution with water) vs. protein mass fraction was calculated using linear regression analysis and used as an index of the surface hydrophobicity. All intensity data were arbitrarily divided by 10 000 prior to statistical analysis and graphing.

Functional properties

Emulsifying properties

The emulsifying activity (EA) and emulsion stability (ES) were determined according to Yasumatsu et al. (25). In brief, 1 g of fermented PPF was suspended in 14.3 mL of Milli-Q water (Millipore Corp.) and adjusted to pH=4.0 or 7.0 with either 0.5 M NaOH or HCl. The solution was stirred for 30 min using a mechanical stirrer (500 rpm) (RO 5; IKA Works Inc.) at room temperature (21–23 °C). Then, 14.3 mL of canola oil were added, followed by homogenization using an Omni macro-homogenizer (Omni International, Marietta, GA, USA), equipped with a 20-mm saw tooth probe, at speed 4 (approx. 7200 rpm) for 1 min. A 10-mL aliquot of the emulsion was poured into two 15-mL centrifuge tubes and centrifuged at 1300×g for 5 min (model 5810R; Eppendorf, Mississauga, ON, Canada). The emulsifying activity was determined as follows:

where h0 is the total height of the emulsion layer prior to centrifugation and h1 is the total height of the emulsion layer after centrifugation. Emulsion stability was determined by preparing the emulsion as previously described, then heating it at 80 °C for 30 min using a water bath. The emulsion was then cooled to room temperature using tap water over a 30-minute period. A 10-mL aliquot of the cooled to room temperature emulsion was then placed into two 15-mL centrifuge tubes and centrifuged at 1300×g for 5 min. Emulsion stability was determined as follows:

where EAH is the emulsifying activity of the heated emulsion and EA of the unheated emulsion.

Foaming properties

The foam capacity (FC) and foam stability (FS) were determined according to Liu et al. (26). In brief, 1 g of fermented PPF was dispersed within 25 mL of Milli-Q water (Millipore Corp.) and adjusted to pH=4.0 or 7.0 with either 0.5 M NaOH or HCl, and stirred for 30 min on a mechanical stirrer (500 rpm; RO 5; IKA Works Inc.) at room temperature (21–23 °C). A 15-mL aliquot was then transferred into a 400-mL beaker for foaming using an Omni Macro Homogenizer (Omni International), equipped with a 20-mm saw tooth probe, at speed 4 (aprox. 7200 rpm) for 5 min. The resulting foamed sample was transferred to a 100-mL graduated cylinder and the foam volume measured at time 0 and after 30 min. FC and FS were determined as follows:

and

where VF0 is the volume of the foam at 0 min, Vsample is the initial volume of sample used (15 mL), and VF30 is the foam volume after 30 min.

Nitrogen solubility index

Fermented PPF samples (1 g) were suspended in 25 mL of Milli-Q water (Millipore Corp.) and adjusted to pH=4.0 or 7.0 with either 0.5 M NaOH or HCl at room temperature (21–23 °C) and stirred on a mechanical stirrer (RO 5; IKA Works Inc.) at 500 rpm for 30 min. The suspension was centrifuged at 3070×g for 10 min (model 5804R; Eppendorf). The nitrogen solubility index (in %) was determined by dividing the nitrogen measured in the supernatant by the original amount in the fermented samples, multiplied by 100. Nitrogen mass fraction within the fermented PPF and the supernatant after extraction were determined using AOAC method 920.87 (19).

Water hydration capacity and oil-holding capacity

Water hydration capacity (WHC) and oil-holding capacity (OHC) values for fermented PPF samples were determined according to Stone et al. (27) with slight modifications. In brief, 10 mL of canola oil (or water, pH=4.0 or 7.0 for WHC) were added to 1 g of PPF in a 50-mL centrifuge tube. The mixture was vortexed for 10 s every 5 min for 30 min, followed by centrifugation at 11 180×g for 15 min (model 5804R; Eppendorf). OHC or WHC values were determined as the mass change in fermented protein samples after decanting (wet protein PPF mass minus dry PPF mass) relative to the dry PPF mass (1 g).

Statistical analysis

All data is reported as the mean value±standard deviation of PPF derived from triplicate fermentation batches (N=3). A one-way ANOVA with a Tukey’s test was used to detect statistical differences in response to fermentation time within compositional, degree of hydrolysis and OHC data. A two- -way ANOVA was used to test for significant differences between the main effects of fermentation time and pH, along with their interaction for all surface and functional (except for OHC) properties tested. All statistical analyses were performed with Systat v. 10 software (28).

Results and Discussion

Physicochemical properties

Table 1 shows changes to the proximate composition and pH of the freeze-dried PPF as a function of fermentation time. All crude protein, ash, and lipid mass fractions changed significantly during fermentation (p<0.05), presumably due to an increase in the bacterial biomass present and loss of carbohydrates during the process. In the case of the latter, carbohydrates decreased from approx. 53 to 37% (based on calculated difference) during fermentation. Crude fat content increased from 2.5 to 3.5% after 11 h of fermentation, most likely due to the loss of carbohydrates. Literature reports various effects of fermentation on the crude fat content of pulses. For instance, solid-state fermentation of chickpea tempeh flour decreased the fat content from 6.1% in the raw chickpea flour to 2.6% in the tempeh flour (29), whereas cowpea fat content slightly increased after fermentation, from 0.9 to approx. 2% (30). In the current study, protein mass fraction increased sharply from 42.9 to approx. 47% between 1 and 5 h of fermentation before leveling off, a result hypothesized to be associated with the exponential growth of the L. plantarum cells and the loss of carbohydrates. In contrast, the ash mass fraction increased steadily from 4.2 to 11.0% over the 11-hour fermentation time, again thought to be due to the loss of carbohydrates.

Table 1. Changes to the composition (on dry mass basis), degree of hydrolysis and pH of pea protein-enriched flour fermented by Lactobacillus plantarum over an 11-hour time course.

| t/h | w(crude protein)/% | w(crude ash)/% | w(crude lipid)/% | w(crude CHO)/% | DH/% | pH |

|---|---|---|---|---|---|---|

| 0 | (40.1±1.2)a | (4.2±1.2)a | (2.5±0.1)a | 53.2 | - | (7.5±0.0)a |

| 1 | (42.9±1.3)a | (5.9±0.9)ab | (2.9±0.4)ab | 48.3 | (6.1±0.2)a | (7.2±0.0)b |

| 5 | (46.6±0.7)b | (5.9±0.7)ab | (2.6±0.0)a | 44.9 | (9.7±0.5)b | (6.3±0.0)c |

| 9 | (46.4±0.1)b | (8.4±1.4)bc | (3.4±0.0)b | 41.8 | (10.6±0.8)c | (4.4±0.1)d |

| 11 | (48.1±0.4)b | (11.0±0.4)c | (3.5±0.0)b | 37.4 | (13.5±0.0)d | (4.3±0.0)e |

DH=degree of hydrolysis, CHO=carbohydrates determined based on the percentage difference between 100% and the mean values of protein, ash, and lipid mass fractions. Data represent the mean value±standard deviation (N=3). Data with different superscript letters in the same column are significantly different (p<0.05)

Like other Lactobacillus spp., growth of L. plantarum during fermentation leads to the production of weak acids and the release of small peptides from the proteins, resulting in a reduction in pH from pH=7.5 at time 0 to pH=4.3 after 11 h of fermentation. Chandra-Hioe et al. (31) have previously reported a reduction in pH during fermentation of fermented chickpea and faba bean flour. Because of the pH reduction, the pH of the starting material and the fermented PPF (taken at different fermentation times) was readjusted to pH=4 (near the protein pI) and pH=7 (representative of the neutralization process commonly used in commercial wet processing of protein ingredients) prior to measuring their surface and functional characteristics. Increase in protein mass fraction during fermentation appears to be system-dependent. Chandra-Hioe et al. (31) reported no change in the protein content of desi or kabuli chickpea flour after 16 h of fermentation; however, the protein content of faba bean flour rose from 23 to 30% over the same fermentation period. Reyes-Moreno et al. (29) and Akubor and Chukwu (32) reported a 22 and 18% increase in protein mass fraction of fermented chickpea flour and full fat African oil bean seed flour, respectively.

Changes to the degree of hydrolysis (DH) of PPF during fermentation showed a sigmoidal increase with a maximum value of approx. 13% after 11 h (Table 1). A one-way analysis of variance found that changes to the degree of hydrolysis with fermentation time were significant (p<0.05), where values increased from 0% at time 0 to 9.7% after 5 h, 10.6% after 9 h, and a further increase to 13.5% after 11 h. During a preliminary study (data not shown), fermentation up to 48 h did not yield any further changes to the DH values, possibly because: (i) the low pH of the medium (approx. 4.3) restricted further cleavage of the proteins, and (ii) no additional proteinase production occurred during the stationary phase of growth (22).

Surface properties

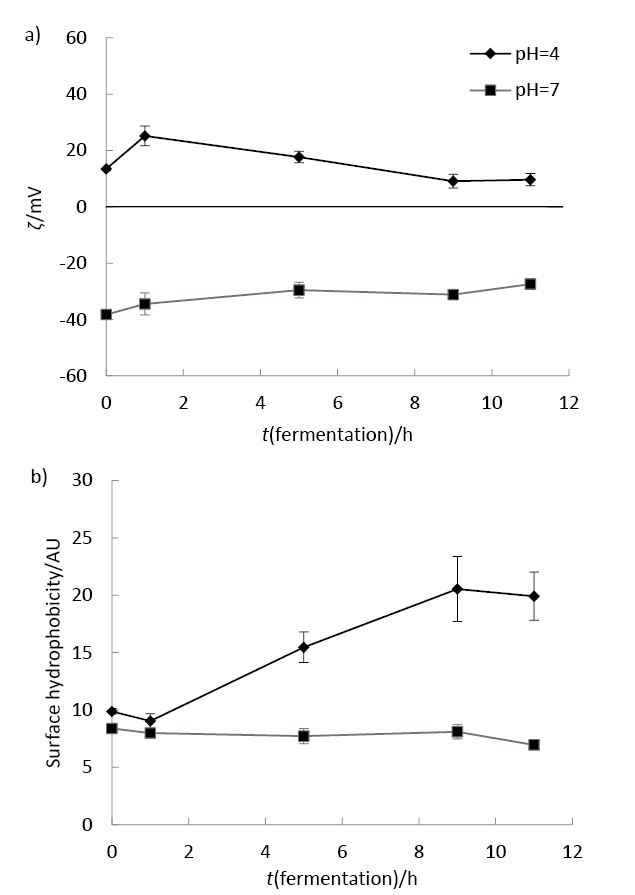

The surface charge (zeta potential) and hydrophobicity of all PPF samples at both pH=4 and 7 are given in Figs. 1a and 1b, respectively. Overall, the zeta potential (ZP) of the PPF was positive when adjusted to pH=4 and negative when at pH=7, as the proteins would be below and above, respectively, the isoelectric point of pea protein (pI~4.6) (Fig. 1a). As determined by a two-way ANOVA for ZP data, both the effects of fermentation time and pH, and their interaction, were significant (p<0.001). At pH=4 the ZP increased from approx. +14 mV in the unfermented sample to a maximum of +27 mV in 1-hour fermented samples, followed by a gradual decline to +10 mV by 11-hour fermentation. In contrast, at pH=7 the ZP increased gradually from –37 mV at time 0 to –27 mV at 11 h of fermentation (Fig. 1a). The decreases in charge density at both pH values may indicate that limited hydrolysis of PPF leads to exposure of few numbers of both positively- and negatively-charged groups since changes in net charge at both pH values were low. A decrease in ZP at pH=7 due to an increase in degree of hydrolysis was reported by Ghribi et al. (33) where chickpea protein isolate was modified via enzymatic hydrolysis.

Fig. 1.

Effect of fermentation time and pH on: a) surface charge (ζ), and b) hydrophobicity of pea protein-enriched flour fermented by Lactobacillus plantarum. Data represent the mean value±standard deviation (N=3)

A two-way ANOVA for surface hydrophobicity data found that both the fermentation time and pH, and their interaction, were all significant (p<0.001). In samples at pH=4 surface hydrophobicity remained constant (approx. 9 arbitrary units, AU) between 0 and 1 h of fermentation, and then steadily increased to approx. 21 AU in 9-hour samples, at which time it plateaued (Fig. 1b). In contrast, at pH=7 surface hydrophobicity declined very slightly from approx. 8 AU in the unfermented samples to approx. 7 AU in 11-hour fermented samples (Fig. 1b). It is hypothesized that at pH=4.0, after 1 h of fermentation hydrolysis of the PPF leads to a partial unraveling of the protein and release of peptides which exposed buried reactive charged and hydrophobic sites (34). However, after 1 h, fermentation-induced changes to the surface properties reflect the continued unraveling of the protein structure and the increase in bacterial biomass protein. Since the protein would be only weakly charged at this pH, conformational entropy would be greater allowing it to unravel more, as evidenced by an increase in hydrophobicity and a slight decline in charge. In contrast, for samples at pH=7, sufficient electrostatic repulsion between particles would overshadow the minor changes that would occur in protein conformation (and hence surface charge and hydrophobicity) as the result of fermentation.

Functional properties

Emulsification

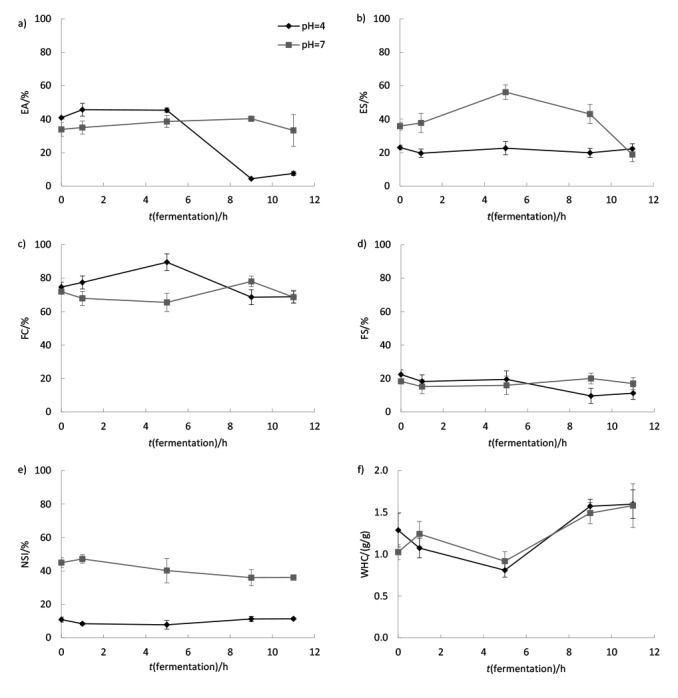

The emulsifying activity (EA) and emulsion stability (ES) of fermented PPF as a function of fermentation time and pH are given in Figs. 2a and 2b. A two-way ANOVA found that fermentation time, pH and their associated interaction have a highly significant effect on both EA and ES (p<0.001). The EA, a measure of emulsion forming ability, was constant (approx. 45%) between 0 and 5 h of fermentation, and then declined significantly to approx. 5–7% after 9 h of fermentation (Fig. 2a) at pH=4. This decline corresponds to the sharp increase in hydrophobicity observed at the corresponding pH in 5-hour fermented samples. The increased hydrophobicity may have impacted the protein’s ability to migrate to the oil-water interface to lower interfacial tension and facilitate emulsion formation and possibly favour the aggregation of released peptides and unhydrolyzed proteins (35). Emulsion formation was lower (EA approx. 35%) at pH=7 compared to pH=4 between fermentation time 0 and 5 h, however, EA remained relatively constant over the 11 h of fermentation at pH=7, possibly due to the higher charge density and conformational flexibility of peptide and protein molecules (35). However, the emulsions formed at pH=4 were inherently less stable than those formed at pH=7, except after 11 h of fermentation where the ES was similar at each pH. At pH=4, ES values were relatively constant at approx. 20% over the entire fermentation time course; whereas, at pH=7, ES values increased from approx. 37% at time 0 to approx. 56% at 5 h, and then declined to approx. 20% by the end of fermentation (Fig. 2b). Unfortunately, a clear mechanism underlining emulsion stability could not be reached in this study, due to several confounding effects associated with changes in surface characteristics and solubility during the fermentation time/pH, as well as other factors, not measured as part of this study such as differences in droplet sizes and rate of creaming based on Stokes’s law, and the concentration and viscoelasticity of the film formed at the oil-water interface.

Fig. 2.

Effect of fermentation time and pH on: a) emulsifying activity (EA), b) emulsion stability (ES), c) foam capacity (FC), d) foam stability (FS), e) nitrogen solubility index (NSI), and f) water hydration capacity (WHC) of pea protein-enriched flour fermented by Lactobacillus plantarum. Data represent the mean value±standard deviation (N=3)

Foaming

The foam capacity (FC) and stability of PPF and fermented PPF as a function of fermentation time and pH is given in Figs. 2c and 2d. Fermentation time, pH and their associated interaction all had a very significant effect on FC (p<0.001). In contrast, for FS data only the effect of fermentation time and the interaction of fermentation time with pH were significant (p<0.001). The foam-forming properties of PPF at pH=4 increased FC from approx. 80% at time 0 to approx. 90% FC after 5 h of fermentation, and thereafter declined to approx. 70% after 9 h of fermentation (Fig. 2c). Similar to emulsions, the foam forming properties of a protein depend on its ability to migrate to the air-water interface to lower surface tension, and then realign its hydrophobic groups towards the apolar phase and the hydrophilic groups towards the polar phase. At pH=4, an increase in FC was observed as the protein unravels and exposes hydrophobic groups; however, after 5 h of fermentation, it was presumed that an overabundance of hydrophobic groups were exposed, reducing the ability of the protein to migrate to the interface and therefore decreasing FC. At pH=7, some variability was evident within the fermentation period, but FC values remained relatively constant at approx. 70% (Fig. 2c), which was most likely due to the relatively constant surface properties at this pH (Fig. 1). Foam stability at pH=4 was relatively constant at approx. 20% for samples up to 5 h of fermentation, but then dropped to 9% after 9 h of fermentation. It was hypothesized that longer fermentation times lead to greater hydrophobicity, which may have inhibited the migration of protein to the air-water interface where bubbles continually broke and reformed. In contrast, at pH=7, FS of samples remained relatively constant at approx. 20% over the entire fermentation period (Fig. 2d). No large changes in the surface properties of the PPF were evident at pH=7, leading to the observed constant FS. The foaming properties of African oil bean seed (Pentaclethra macrophylla) flour (32), African breadfruit seed (Treculia africana) flour (36), and peanut protein concentrate (37) all improved after fermentation.

Nitrogen solubility indices

The nitrogen solubility indices (NSI) of PPF as a function of fermentation time and pH are shown in Fig. 2e. The effect of fermentation time, pH and their associated interaction, all had a significant effect on NSI (p<0.001). Overall, NSI were relatively low at approx. 8–11% at pH=4 regardless of the fermentation time; whereas, at pH=7, NSI decreased from approx. 43 to 36% after 11 h of fermentation (Fig. 2e). Increased nitrogen solubility at the higher pH is associated with the greater surface charge and amount of electrostatic repulsive forces present relative to pH=4, which is closer to the pI of PPF. The slight decline in NSI at pH=7 is hypothesized to be attributed to the increase in biomass protein which was presumed to have lower solubility than the pea protein.

Water hydration capacity

The WHC of fermented PPF as a function of fermentation time and pH is given in Fig. 2f. A two-way ANOVA of WHC data found only the effect of fermentation time (p<0.001) and its interaction with pH (p<0.01) to be significant, but not the effect of pH alone (p>0.05). WHC values declined from approx. 1–1.2 g/g at time 0 to 0.8–0.9 g/g after 5 h of fermentation, and then increased to 1.5–1.6 g/g after 9 h of fermentation at both pH values, however, which one was greater (pH=4 vs. 7) seemed to fluctuate a little within this trend (Fig. 2f). For instance, WHC at pH=4 was slightly greater than WHC at pH=7 at t=0 and 9 h, whereas WHC at pH=7 was slightly greater than WHC at pH=4 for t=1 and 5 h, with both pH values being similar in magnitude at t=11 h (Fig. 2f). We hypothesized these findings were associated with protein hydrolysis to a point where the pea proteins unravel to expose buried hydrophilic sites which then interact with more water. Similarly, Xiao et al. (38) found that the fermentation of chickpea with Cordyceps militaris SN-18 significantly increased the WHC. In another study, Oloyede et al. (39) reported that the WHC of Moringa oleifera seed flour increased during the first 24 h of fermentation and then, after 72 h, it declined. Similarly, Akubor and Chukwu (32) reported that the water absorption properties of African oil bean (Pentaclethra macrophylla) seed flour increased by 36% when fermented.

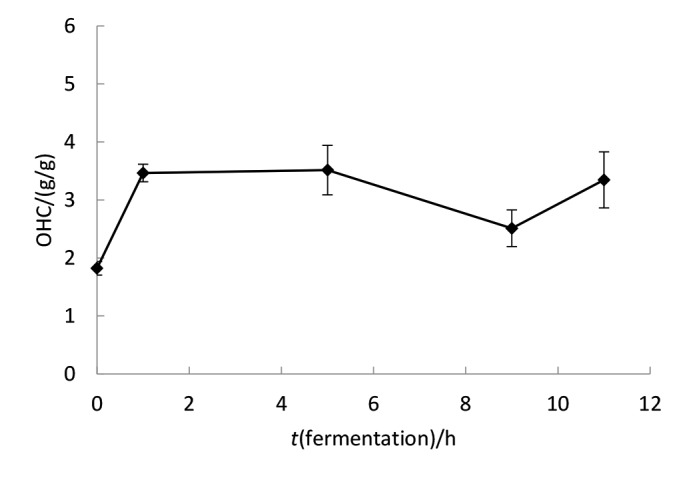

Oil-holding capacity

Fig. 3 shows the OHC of PPF as a function of fermentation time. Fermentation time had a significant effect on OHC (p<0.001) as determined by a one-way ANOVA. Overall, OHC increased from approx. 1.8 g/g at time 0 h to approx. 3.5 g/g after 1 h of fermentation, after which it declined to 2.5 g/g at 9 h of fermentation and then increased again to 3.5 g/g after 11 h (Fig. 3). Since we did not adjust the pH during the OHC test, the pH would have differed depending on the fermentation time (Table 1). The pH declined from pH=7.5 to 4.3 over the 11 h of fermentation, which resulted in a decrease in protein surface charge and solubility as well as an increase in hydrophobicity to allow for increased protein interactions with oil. As evident in Fig. 1b, surface hydrophobicity increased greatly at pH=4 relative to pH=7. During fermentation, the proteins become partially unraveled to expose buried hydrophobic groups that can bind oil. Fermentation also increased bacterial biomass in the PPF, which in this case altered OHC in a positive manner. There are also reports on an increase in OHC in fermented chickpea and faba bean flours (31). Periago et al. (40) reported a similar increase in OHC with an increase in degree of hydrolysis (via enzymatic modification) of pea flour.

Fig. 3.

Effect of fermentation time on the oil-holding capacity (OHC) of pea protein-enriched flour fermented by Lactobacillus plantarum. Data represent the mean value±standard deviation (N=3)

CONCLUSIONS

Lactobacillus plantarum fermentation of pea protein-enriched flour over the course of 11 h achieved 13.5% degree of hydrolysis, a drop in pH and significant changes to the protein surface and functional properties. Crude protein and ash mass fractions of the PPF increased as fermentation time increased due to the microbial proliferation, as the amount of biomass increased and the amount of carbohydrates declined. During fermentation, enzymes cleave part of the protein causing the changes in conformation, exposing the buried hydrophobic sites and resulting in higher hydrophobicity of the PPF, at pH=4, after longer fermentation times. Depending on the time, different levels of hydrolysis led to different surface characteristics and functionality of PPF. The final functionality of the fermented ingredients, like other proteins, can be further tailored depending on extrinsic factors, such as solution pH. For instance, fermented PPF exhibited relatively better emulsion stability at pH=7 after 5 h of fermentation and improved foam capacity at pH=4 after 5 h of fermentation. It is important to note that the final ingredient is a blend of both pea protein and microbial biomass, giving its novel properties, which is highly dependent on both pH and length of fermentation. Overall, the fermented PPFs have the potential to be incorporated into food products, such as beverages, sports bars, nutritional supplements, and so on. The use of fermented pea protein may be advantageous or disadvantageous, depending on the level of hydrolysis and food environment, all of which could influence its functional attributes. Although not tested as part of this study, fermented ingredients also tend to have unique flavour profiles, reduced non-nutritive compounds and bioactive peptides for enhanced nutrition.

Acknowledgements

The Global Institute for Food Security at the University of Saskatchewan (Saskatoon, SK) and the Saskatchewan Ministry of Agriculture Development Fund (ADF#: 2014-0283) provided financial support for this research.

References

- 1.Tulbek MC, Lam RSH, Wang Y, Asavajaru P, Lam A. Pea: A sustainable vegetable protein crop. In: Nadathur SR, Wanasundara JPD, Scanlin L, editors. Sustainable protein sources. Cambridge, MA, USA: Academic Press; 2017. pp. 145–64. https://doi.org/ 10.1016/B978-0-12-802778-3.00009-3 [DOI] [Google Scholar]

- 2.Leterme P, Monmart T, Baudart E. Amino acid composition of pea (Pisum sativum) proteins and protein profile of pea flour. J Sci Food Agric. 1990;53(1):107–10. 10.1002/jsfa.2740530112 [DOI] [Google Scholar]

- 3.Reinkensmeier A, Bußler S, Schlüter O, Rohn S, Rawel HM. Characterization of individual proteins in pea protein isolates and air classified samples. Food Res Int. 2015;76(Pt. 1):160–7. 10.1016/j.foodres.2015.05.009 [DOI] [Google Scholar]

- 4.Multari S, Stewart D, Russell WR. Potential of fava bean as future protein supply to partially replace meat intake in the human diet. Compr Rev Food Sci Food Saf. 2015;14(5):511–22. 10.1111/1541-4337.12146 [DOI] [Google Scholar]

- 5.Patterson CA, Curran J, Der T. Effect processing on antinutrient compounds in pulses. Cereal Chem. 2017;94(1):2–10. 10.1094/CCHEM-05-16-0144-FI [DOI] [Google Scholar]

- 6.Kiosseoglou V, Paraskevopoulou A. Functional and physicochemical properties of pulse proteins. In: Tiwari BK, Gowen A, McKenna B, editors. Pulse foods: Processing, quality and nutraceutical applications. Oxford, UK: Academic Press; 2011. pp. 57–90. https://doi.org/ 10.1016/B978-0-12-382018-1.00003-4 [DOI] [Google Scholar]

- 7.Global protein ingredients market size, industry report, 2018–2025. San Francisco, CA, USA: Grand View Research; 2018. Report ID: 978-1-68038-451-2.

- 8.Hall C, Hillen C. Garden Robinson J. Composition, nutritional value, and health benefits of pulses. Cereal Chem. 2017;94(1):11–31. 10.1094/CCHEM-03-16-0069-FI [DOI] [Google Scholar]

- 9.Sozer N, Holopainen-Mantila U, Poutanen K. Traditional and new food uses of pulses. Cereal Chem. 2017;94(1):66–73. 10.1094/CCHEM-04-16-0082-FI [DOI] [Google Scholar]

- 10.Shiba K, Negishi Y, Okada K, Nagao S. Chemical changes during sponge-dough fermentation. Cereal Chem. 1990;67(4):350–5. [Google Scholar]

- 11.Fernandez-Orozco R, Frias J, Muñoz R, Zielinski H, Piskula MK, Kozlowska H, et al. Fermentation as a bio-process to obtain functional soybean flours. J Agric Food Chem. 2007;55(22):8972–9. 10.1021/jf071823b [DOI] [PubMed] [Google Scholar]

- 12.Lee IH, Hung YH, Chou CC. Solid-state fermentation with fungi to enhance the antioxidative activity, total phenolic and anthocyanin contents of black bean. Int J Food Microbiol. 2008;121(2):150–6. 10.1016/j.ijfoodmicro.2007.09.008 [DOI] [PubMed] [Google Scholar]

- 13.Tavano OL. Protein hydrolysis using proteases: An important tool for food biotechnology. J Mol Catal, B Enzym. 2013;90:1–11. 10.1016/j.molcatb.2013.01.011 [DOI] [Google Scholar]

- 14.Hemalatha S, Platel K, Srinivasan K. Influence of germination and fermentation on bioaccessibility of zinc and iron from food grains. Eur J Clin Nutr. 2007;61:342–8. 10.1038/sj.ejcn.1602524 [DOI] [PubMed] [Google Scholar]

- 15.Martín-Cabrejas MA, Sanfiz B, Vidal A, Mollá E, Esteban R, López-Andréu FJ. Effect of fermentation and autoclaving on dietary fiber fractions and antinutritional factors of beans (Phaseolus vulgaris L.). J Agric Food Chem. 2004;52(2):261–6. 10.1021/jf034980t [DOI] [PubMed] [Google Scholar]

- 16.Mohite BV, Chaudhari GA, Ingale HS, Mahajan VN. Effect of fermentation and processing on in vitro mineral estimation of selected fermented foods. Int Food Res J. 2013;20(3):1373–7. [Google Scholar]

- 17.de Vries MC, Vaughan EE, Kleerebezem M, de Vos WM. Lactobacillus plantarum-survival, functional and potential probiotic properties in the human intestinal tract. Int Dairy J. 2006;16(9):1018–28. 10.1016/j.idairyj.2005.09.003 [DOI] [Google Scholar]

- 18.Official Method AOAC. 925.10. Solids (total) and moisture in flour. Gaithersburg, MD, USA: AOAC International; 2005. [Google Scholar]

- 19.Official Method AOAC. 920.87. Protein (total) in flour. Gaithersburg, MD, USA: AOAC International; 2005. [Google Scholar]

- 20.Official Method AOAC. 923.03. Ash of flour. Gaithersburg, MD, USA: AOAC International; 2005. [Google Scholar]

- 21.Official Method AOAC. 920.39. Fat (crude) or ether extraction in animal feed. Gaithersburg, MD, USA: AOAC International; 2005. [Google Scholar]

- 22.Adler-Nissen J. Determination of the degree of hydrolysis of food protein hydrolysates by trinitrobenzenesulfonic acid. J Agric Food Chem. 1979;27(6):1256–62. 10.1021/jf60226a042 [DOI] [PubMed] [Google Scholar]

- 23.Can Karaca A, Low N, Nickerson M. Emulsifying properties of chickpea, faba bean, lentil and pea proteins produced by isoelectric precipitation and salt extraction. Food Res Int. 2011;44(9):2742–50. 10.1016/j.foodres.2011.06.012 [DOI] [Google Scholar]

- 24.Kato A, Nakai S. Hydrophobicity determined by a fluorescence probe method and its correlation with surface properties of proteins. Biochim Biophys Acta. 1980;624(1):13–20. 10.1016/0005-2795(80)90220-2 [DOI] [PubMed] [Google Scholar]

- 25.Yasumatsu K, Sawada K, Moritaka S, Misaki M, Toda J, Wada T, et al. Whipping and emulsifying properties of soybean products. Agric Biol Chem. 1972;36(5):719–27. 10.1080/00021369.1972.10860321 [DOI] [Google Scholar]

- 26.Liu S, Elmer C, Low NH, Nickerson MT. Effect of pH on the functional behaviour of pea protein isolate–gum Arabic complexes. Food Res Int. 2010;43(2):489–95. 10.1016/j.foodres.2009.07.022 [DOI] [Google Scholar]

- 27.Stone AK, Karalash A, Tyler RT, Warkentin TD, Nickerson MT. Functional attributes of pea protein isolates prepared using different extraction methods and cultivars. Food Res Int. 2015;76(Pt.1):31–8. 10.1016/j.foodres.2014.11.017 [DOI] [Google Scholar]

- 28.Systat v. 10 software, Systat Software Inc., San Jose, CA, USA; 2000.

- 29.Reyes-Moreno C, Cuevas-Rodríguez EO, Milán-Carrillo J, Cárdenas-Valenzuela OG, Barrón-Hoyos J. Solid state fermentation process for producing chickpea (Cicer arietinum L) tempeh flour. Physicochemical and nutritional characteristics of the product. J Sci Food Agric. 2004;84(3):271–8. 10.1002/jsfa.1637 [DOI] [Google Scholar]

- 30.Prinyawiwatkul W, Beuchat LR, McWatters KH, Phillips RD. Fermented cowpea flour: Production and characterization of selected physico-chemical properties. J Food Process Preserv. 1996;20(4):265–84. 10.1111/j.1745-4549.1996.tb00747.x [DOI] [Google Scholar]

- 31.Chandra-Hioe MV, Wong CHM, Arcot J. The potential use of fermented chickpea and faba bean flour as food ingredients. Plant Foods Hum Nutr. 2016;71(1):90–5. 10.1007/s11130-016-0532-y [DOI] [PubMed] [Google Scholar]

- 32.Akubor PI, Chukwu JK. Proximate composition and selected functional properties of fermented and unfermented African oil bean (Pentaclethra macrophylla) seed flour. Plant Foods Hum Nutr. 1999;54:227–38. 10.1023/A:1008100930856 [DOI] [PubMed] [Google Scholar]

- 33.Mokni Ghribi A, Gafsi IM, Sila A, Blecker C, Danthine S, Attia H, et al. Effects of enzymatic hydrolysis on conformational and functional properties of chickpea protein isolate. Food Chem. 2015;187:322–30. 10.1016/j.foodchem.2015.04.109 [DOI] [PubMed] [Google Scholar]

- 34.Zheng L, Zhao Y, Xiao C, Sun-Waterhouse D, Zhao M, Su G. Mechanism of the discrepancy in the enzymatic hydrolysis efficiency between defatted peanut flour and peanut protein isolate by Flavorzyme. Food Chem. 2015;168:100–6. 10.1016/j.foodchem.2014.07.037 [DOI] [PubMed] [Google Scholar]

- 35.Liang HN, Tang CH. pH-dependent emulsifying properties of pea [Pisum sativum (L.)] proteins. Food Hydrocoll. 2013;33(2):309–19. 10.1016/j.foodhyd.2013.04.005 [DOI] [Google Scholar]

- 36.Fasasi OS, Eleyinmi AF, Oyarekua MA. Effect of some traditional processing operations on the functional properties of African breadfruit seed (Treculia africana) flour. Lebensm Wiss Technol. 2007;40(3):513–9. 10.1016/j.lwt.2005.11.009 [DOI] [Google Scholar]

- 37.Yu J, Ahmedna M, Goktepe I. Peanut protein concentrate: Production and functional properties as affected by processing. Food Chem. 2007;103(1):121–9. 10.1016/j.foodchem.2006.08.012 [DOI] [Google Scholar]

- 38.Xiao Y, Xing G, Rui X, Li W, Chen X, Jiang M, et al. Effect of solid-state fermentation with Cordyceps militaris SN-18 on physicochemical and functional properties of chickpea (Cicer arietinum L.) flour. Lebensm Wiss Technol. 2015;63(2):1317–24. 10.1016/j.lwt.2015.04.046 [DOI] [Google Scholar]

- 39.Oloyede OO, James S, Ocheme OB, Chinma CE, Akpa VE. Effects of fermentation time on the functional and pasting properties of defatted Moringa oleifera seed flour. Food Sci Nutr. 2015;4(1):89–95. 10.1002/fsn3.262 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Periago MJ, Vidal ML, Ros G, Rincón F, Martínez C, López G, et al. Influence of enzymatic treatment on the nutritional and functional properties of pea flour. Food Chem. 1998;63(1):71–8. 10.1016/S0308-8146(97)00199-4 [DOI] [Google Scholar]