Abstract

Legumes and cereals complement their nutritional quality and there is a need of convenience products made with these grains. The objectives of this study were to determine the rheological and functional properties of precooked red kidney bean (RKB) flours and their effect on viscoelastic properties of gluten free cake batter and cupcake quality including consumer acceptance. RKB flours were thermally processed by boiling at 100 °C (0, 20, 30 and 40 min) and drying at 80 °C (3 and 4 h). Rheological properties of cake batter containing 100% RKB flour were tested by creep-recovery and dynamic frequency tests. Batter of RKB flour boiled for 20 min was significantly stiffer with 100 times less deformable character compared to the control. Increase in batter modulus ranged from 2000 times elastic component (G′), 988 times viscous component (G″) and 1805 times complex viscosity (η*) at 20 min boiling. Drying did not have a significant effect on viscoelastic properties. Firmness and height of gluten free RKB cupcake were not affected by heat treatment. RKB gluten free cake after heat-moisture treatment had improved consumer acceptance scores compared to the control. Our findings showed that 20 min boiling and 3 h drying process is adequate for precooked RKB flour.

Keywords: Gluten free cupcake, Rheological properties, Red kidney bean, Heat-moisture treatment

Introduction

Cakes and cupcakes have a high consumption demand around the world. The majority is made with wheat flour, which contains gluten protein (Bourekoua et al. 2016; Vici et al. 2016). However, gluten has negative health effects to patients with coeliac disease and other related-gluten disorders (Gélinas and McKinnon 2016). The symptoms of coeliac disease are diarrhea, stomachache, sleepless, hair loss, and anemia. The number of patients with gluten sensitivity is increasing every year around the world. One way to control this disease is to avoid consuming gluten-containing food products. Several bakery companies aim to develop new products without gluten protein to meet consumers’ health needs. Gluten free products such as cupcakes generally have challenges including tough texture, low volume, short shelf life, and low in nutrients. To improve gluten free cupcake quality, hydrocolloids, i.e., guar gum, cellulose and xanthan gum are used to replace some functionality aspects of gluten protein. These products are also normally low in dietary fiber and protein, and high in carbohydrate because most of gluten free products are produced from non-gluten cereal such as rice, maize, potato or cassava starches (Capriles and Arêas 2014). In addition, the amount of vitamin D, iron, zinc and calcium are low in gluten free products while the amount of saturated fatty acid, glycemic index and glycemic load are high (Vici et al. 2016).

Conventionally, gluten free products have used rice flour, cassava starch, corn, and flour mixtures for product development (Collar et al. 2015; Gao et al. 2018; Yano 2010). Nowadays, there are other potential flours studied for alternative gluten-free based ingredients, i.e., pseudocereal flours (buckwheat, amaranth, quinoa), roots and tubers flours (yam), legume flours (soy, chickpea, carob, vinal, beans, lentil and pea) and other flours (flaxseed, chia seed, chestnut and unripe banana) (Capriles and Arêas 2014). In addition, pulses have received more attention since FAO announced 2016 the International Year of Pulses (IYP). Various research groups reported alternative flours as ingredients for gluten free products. Composite flour of pearl millet, kidney beans and tiger nut used at the ratio 85:10:5 (w/w/w) had similar rheological properties as wheat flour based on Mixolab profile test (Awolu 2017). A comparison between corn and cassava starch with chickpea and amaranth flours, resulted in a more solid-like behavior of both chickpea and amaranth flours using a dynamic oscillation test (Collar et al. 2015).

Red kidney bean (Phaseolus vulgaris L.) (RKB) is a rich source of fiber, protein and other micronutrients with other health benefits such as lowering the risk of heart disease and colon cancer, and no gluten sensitivity impact (Bennink 2002). Physical and functional properties of dry bean flours (Siddiq et al. 2010a), as well as nutritional characteristics and consumer acceptance of yeasted bread containing up to 30% RKB flour have been reported (Bhol and Bosco 2014). Radiation processing for reducing insect infestation on physicochemical properties showed that radiation at 10 kGy increased cooking quality and antioxidant activity of kidney bean (Marathe et al. 2016). Heat-moisture treatment has also been used in flour processing for improving physical properties of flour (Gómez and Martínez 2016). However, more studies are needed on treatments that can improve the functional properties of RKB flours as a based ingredient in gluten free cupcake. Therefore, this study was attempted to show the effect of thermal treatments of RKB flour on the rheological properties of cake batter as well as its correlation with sensory characteristics and firmness of gluten free RKB cupcake.

Materials and methods

Materials and treatments

Dark red kidney bean (RKB) (Phaseolus vulgaris L.), soybean oil, liquid egg whites, and other ingredients for the cupcakes were purchased from local market. Beans were washed with tap water. Thermal treatments included boiling at 100 °C (0, 20, 30 and 40 min) and drying (3 and 4 h) in a convection oven at 80 °C. The beans were ground in a hammer mill (W.J. Fit Company, Chicago, IL, U.S.A.) and sieved to obtain whole RKB flour particle size less than 250 µm. The bean flour was stored in sealed polyethylene bags at 4 °C temperature until needed for analysis.

Determination of red kidney bean flour properties

Whole RKB bean flour samples were evaluated for their proximate composition of protein (Method 46-11A), fat (Method 46-11A), fiber (Method 46-11A) and moisture content (Method 44-15A) according AACCI standard methods.

Rheological properties of red kidney bean batter

Rheological properties of batter were performed by dynamic frequency sweep (mechanical spectra) and creep-recovery tests in a rheometer model AR1000 (TA Instruments, New Castle, DE, U.S.A.). The geometry was cross-hatched parallel plate with a diameter of 25 mm. The dynamic frequency sweep test was performed using frequency between 0.1 and 10 Hz in a linear viscoelastic region (LVR) at 25 °C. Storage modulus (G′), loss modulus (G″) and tan delta (δ) were recorded. Also, the complex viscosity (η*) was obtained based on the Eq. 1. Complex modulus (G*) represents the overall resistance to flow and deformation and is calculated by the ratio of G* to frequency angle.

| 1 |

Creep-recovery test applied to measure viscoelastic properties of RKB batter properties at macromolecular level. RKB batter formula and preparation was the same for both rheological tests. A batter was prepared with RKB flour (treated or untreated) 10 g, oil 1.9 g, egg white 3.4 g and water 9.9 g. The batter was mixed in a modified 10-g bowl mixer (National Manufacturing, Lincoln, NE) for 5 min. The mixing elements were two screws and one pin designed for mixing rate of 100 rpm and more control of the mixing for the small sample size. An aliquot of the batter was directly transferred to the rheometer peltier plate (25 °C). The geometry was cross-hatched parallel plate (25 mm diameter) and the test conditions were 20 Pa of shear stress for 100 s during creep phase and 0 Pa of shear stress for 300 s during recovery phase. In this test, the deformation of RKB batter was recorded in the parameters of compliance J (Pa−1) and strain (%) in both creep and recovery phases. RKB batter behaved as a non-stiff or soggy material, which deformed with time under loading or during creep test. In this phase, the stress was applied with a controlled shear rate and the batter molecules rotated and flowed. The data from creep phase was modeled to 6-parameter Kelvin–Voigt model (Eq. 2). This mechanical analog model is a combination of ideal Hookean bodies and ideal fluid bodies, which represent spring and dashpot, respectively. During recovery phase, the stress was released and the compliance or deformation was measured. Similar to the model during creep phase, the 6-parameter Kelvin-Voigt model was applied to fit the compliance of recovery data without the element of viscous flow or dashpot showed in Eq. 3. A permanent deformation occurred during creep phase which is related to a non-recoverable strain of the sample; therefore, viscous flow parameter was not found in this recovery equation (Hernández-Estrada et al. 2012). The definition of the terms of each parameter in these two equations include: and are creep and recovery compliance; and , instantaneous compliance during creep and recovery; and , retarded elastic compliance during creep and recovery; and and , retardation times.

| 2 |

| 3 |

Preparation of red kidney bean gluten free cupcake

Ingredients in the batter were RKB flour (100 g), granulated white sugar (85 g), baking powder (2 g), emulsifier (1 g), salt (1 g), vegetable oil (30 g), egg (50 g) and water (120 g). Dry and wet ingredients were mixed in a Kitchen Aid Mixer with a flat beater at medium level (stir control setting 2) for 2 min and continued at high level (stir setting 5) for 5 min. The batter was transferred to baking cupcake molds lined with paper cups with 40 g of batter per cupcake. Baking was conducted in a convection oven at 195 °C for 20 min and the cupcakes cooled down for 1 h before measuring. Cupcake method preparation was the same across all of the treatments.

Physical properties of red kidney bean gluten free cupcake

The height of cupcake was measured by a digital caliper. Crumb firmness of RKB gluten free cupcake was measured by 40% compression using approved method 74.09.01 of AACCI for bread by a TA-XT2 texture analyser (Stable Microsystems, Surrey, UK) with a 25-mm diameter cylindrical probe. Measurements were made in six replicates per treatment.

Sensory evaluation

The sensory test of gluten free RKB cupcake samples was determined by using a consumer acceptance test with a 9-point hedonic scale (9 = like extremely and 1 = dislike extremely) and forty untrained panelists. The panelists were students and staff at Maejo University, Thailand, randomly selected to test the samples identified by three random digits.

Statistical analysis

Significant differences of gluten free cupcake attributes for eight treatments of RKB flour processing were tested by Duncan’s New Multiple Range (Statistical Analysis System, SAS Institute Inc., Cary, NC). Principal component analysis (PCA) was used to test the overall relationship between the treatments and parameters. This test is for multivariate interpretation, generated based on variables reduction by transforming numbers of original variables into a smaller number of variables called principal components. PCA test was performed by using Canoco for Windows 4.5 (Biometris, Plant Research International, Wageningen, The Netherlands).

Results and discussion

Red kidney bean flour properties

The red kidney bean flour had higher protein (20.5%) and dietary fiber (14.7%) compared to cereal flours. The values are comparable to the proximate chemical composition of previous studies (Manonmani et al. 2014; Siddiq et al. 2010b).

Rheological properties of red kidney bean batter

Effect of heat treatment on mechanical spectra from dynamic frequency sweep test

The fundamental rheological properties of RKB batter from the eight treatments, four boiling times (0, 20, 30 and 40 min) and two drying times (3 and 4 h) were measured. In the dynamic oscillatory frequency sweep test, solid-like behavior parameter (G′) was higher than liquid-like behavior parameter (G″) in all treatments (Table 1). This indicated that RKB batter without boiling had characteristics of a weak gel and low in strength. With the boiling treatments, the magnitude of G′ and G″ of RKB batters increased while their angle decreased with flatter tracings compared to the upward curves without boiling. Thus, precooking or heat-moisture treatments of RKB flour improved elastic-solid like behavior of RKB batter with both drying times; with 4 h drying the curves of G′ and G″ were more separated with lower values for G″. Therefore, thermal treatments induced major structural changes in the structure of the major components including starch gelatinization and retrogradation upon cooling, as well as protein denaturation during heating. The formation of a paste with a more organized structure and hydrogen bonds compared to the native structures account for the increase in G′ and G″. This observation could also be related to the structural alteration of red kidney bean protein. A study of rheological properties of red kidney bean protein isolate during heating found the gelation temperature between 87.4 and 94.5 °C. Thus, gel formation could occur at this stage (Shevkani et al. 2015b).

Table 1.

Effect of thermal treatments (boiling and drying time) on characteristics of red kidney bean batter and gluten free cupcake

| Drying time (h) | Boiling time (min) | Batter characteristics | Cake characteristics | Cake sensory characteristics | ||||

|---|---|---|---|---|---|---|---|---|

| G′ (× 105) | G″ (× 105) | η* | Tan delta | Firmness (N) | Height (cm) | Overall acceptance | ||

| 3 | 0 | 1.8g | 1.0d | 34g | 0.58b | 13.6a | 4.7a | 5.9b |

| 20 | 38.5c | 11.3abc | 642c | 0.29e | 12.3a | 5.4a | 6.8a | |

| 30 | 30.7e | 9.1c | 513e | 0.30d | 11.8a | 5.1a | 6.9a | |

| 40 | 51.4b | 14.3ab | 855b | 0.28g | 12.7a | 4.9a | 7.1a | |

| 4 | 0 | 1.1h | 0.6d | 20h | 0.59a | 12.5a | 4.8a | 4.9b |

| 20 | 24.5f | 7.4d | 410f | 0.30c | 13.3a | 5.3a | 6.3a | |

| 30 | 33.6d | 9.9bc | 557d | 0.30d | 13.0a | 4.8a | 6.8a | |

| 40 | 54.0a | 15.4a | 899a | 0.29f | 12.4a | 5.2a | 6.8a | |

Mean values (n = 3) followed by different letters within the same column are significantly different (p < 0.05)

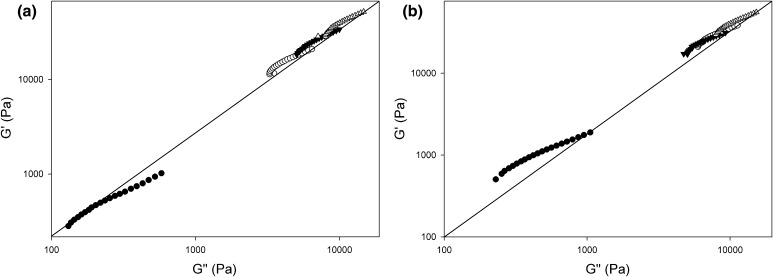

Alteration of the structure of RKB batter was depicted in log–log plots of G′ and G″ (Fig. 1). Drying at 3 and 4 h at 80 °C showed overall superimposed patterns solid and viscous characters (Fig. 1a, b). The curves displayed a shift to higher values of G′ and G″ after boiling with ranges of 17.1–28.6 fold increase for G′ at 3 h and 22.3–49.1 folds increase for G′ at 4 h (p < 0.05) (Fig. 1a, b and Table 1). The microstructure of the RKB batter significantly increased its solid character with a higher rate of change than the viscous character with the heat-moisture treatment. In addition, incorporation of various protein isolates i.e., kidney bean, field pea, amaranth and wheat to starch in gluten free muffin showed an improvement in viscoelasticity behavior compared to starch-based gluten free muffin measured by frequency sweep test (Shevkani and Singh 2014). Thus, this research study showed that not only types of protein isolate but also heating process could strengthen the viscoelastic properties of batter. The superposition of the curves indicated that RKB batters after boiling formed more homogeneous structures compared to the sample without boiling since the curves superimpose with each other (Ahmed et al. 2012, 2013). The complex viscosity showed a significant increase in η* of 18.9 times at 20 min boiling at 10 Hz; while, the tan delta (ratio of viscous and elastic behavior) at 10 Hz decreased value in the range of 48–51% after boiling (p < 0.05) (Table 1). In summary, the thermal treatments applied increased a maximum of 49.1 folds the elastic behavior of the RKB batter while the viscous behavior only increased a maximum of 25.7 folds; thus, the fold increase was almost half in the viscous behavior. Shevkani and collaborators compared gelation temperature and gelation reinforcement of red kidney bean protein isolate versus field pea protein isolate (Shevkani et al. 2015b). Red kidney bean protein isolate had a higher gel reinforcement calculated by the difference value between G′ at the highest heating temperature (95 °C) and G″ at the lowest cooling temperature (40 °C), suggesting that red kidney bean protein isolate had a greater intermolecular interactions between protein molecules within gel network (Shevkani et al. 2015b).

Fig. 1.

G′ as function of G″ of red kidney bean batter drying at 80 °C for a 3 h and b 4 h. Symbols represent boiling treatments: 0 min, filled circle; 20 min, open circle; 30 min, filled triangle; and 40 min, open triangle

Effect of heat treatment on parameters from creep-recovery test

Fundamental viscoelastic properties of RKB batter were also measured using creep-recovery test with 20 Pa shear stress during creep for 100 s and 0 Pa shear stress during recovery phase for 300 s. The experimental data obtained was fitted into the Burgers model explained in Eqs. 2 and 3 of both creep and recovery phases. During a constant shear stress, RKB batter flowed (molecules aligned to the stress as they were displaced) and partially recovered in a non-linear deformation behavior as a function of time. Some parts of RKB batter structure stored energy which resulted in permanent deformation less than the total deformation due to recoil recovery (Steffe 1996). Thus, the Burgers model in Eq. 3 had no viscous flow because the free dashpot represents permanent deformation which could be attributed to a loss of energy from liquid-like behavior.

The creep-recovery curve of RKB batter showed typical viscoelastic behavior (data not shown). The longer drying time (4 h) increased the stiffness of red kidney bean batter compared to 3 h without boiling (p < 0.05) (Table 2). However, there was no significant difference in deformation on RKB batter with an increase of boiling time (Table 2). The RKB batter after heat-moisture treatment had a significantly decrease in deformation expressed by MaxS, FinalS, Jmax, Jfinal, Jc0, Jc1, Jc2, Jr0, Jr10 and Jr2 in both creep and recovery phases (p < 0.05) (Table 2). The relationship between rheological parameter and secondary structure proportion of red kidney bean protein isolate showed that tan δ (ratio of viscous and elastic moduli) was negatively correlated with proportion of β-sheets and anti-parallel β-sheets (Shevkani et al. 2015b). Thus, it is possible that boiling treatment favored red kidney bean protein isolate to form more interaction associated with the secondary structure β-sheets and anti-parallel β-sheets.

Table 2.

Effect of drying and boiling treatments on parameters of estimated regression Burgers model for creep-recovery of red kidney bean batter

| Drying time (h) | Boiling time (min) | MaxS (%) | FinalS (%) | RCY (%) | Jmax (Pa−1 × 10−3) | Jfinal (Pa−1 × 10−3) | Jc0 (Pa−1 × 10−5) | Jc1 (Pa−1 × 10−5) |

|---|---|---|---|---|---|---|---|---|

| 3 | 0 | 34a | 21.4a | 37b | 17.0a | 6.3a | 22.4a | 257.7a |

| 20 | 0.23c | 0.04c | 82.3a | 0.12c | 0.09c | 2.2b | 1.7c | |

| 30 | 0.29c | 0.07c | 75.2a | 0.15c | 0.11c | 2.8b | 2.1c | |

| 40 | 0.23c | 0.06c | 71.3a | 0.12c | 0.08c | 2.2b | 1.6c | |

| 4 | 0 | 21.8b | 11.2b | 48.9b | 10.9b | 5.3b | 17.2a | 172.0b |

| 20 | 0.29c | 0.08c | 70.5a | 0.15c | 0.10c | 2.7b | 2.1c | |

| 30 | 0.27c | 0.06c | 75.5a | 0.14c | 0.10c | 2.6b | 1.9c | |

| 40 | 0.22c | 0.04c | 79.9a | 0.11c | 0.09c | 2.4b | 1.7c |

| Drying time (h) | Boiling time (min) | t1 (s) | Jc2 (Pa−1 × 10−5) | t2 (s) | η0 (Pa s × 105) | Jr0 (Pa−1 × 10−5) | Jr10 (Pa−1 × 10−4) | tr10 (s) | Jr2 (Pa−1 × 10−5) | tr2 (s) |

|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 0 | 0.18ab | 616.3a | 9.37a | 0.1c | 66.2a | 197.7a | 0.58b | 330.0a | 25.5c |

| 20 | 0.25ab | 3.3c | 9.48a | 21.3ab | 2.3c | 2.0c | 0.99a | 5.0c | 46a | |

| 30 | 0.23ab | 4.2c | 9.73a | 16.6b | 3.1c | 2.5c | 0.72b | 5.1c | 36b | |

| 40 | 0.22ab | 3.2c | 8.87a | 20.1ab | 2.3c | 1.8c | 0.71b | 3.9c | 35.3b | |

| 4 | 0 | 0.15b | 371.3b | 8.59a | 0.2c | 60.7b | 161.3b | 0.66b | 279.0b | 28.6bc |

| 20 | 0.26a | 4.3c | 9.8a | 16.2b | 2.7c | 2.3c | 0.82ab | 5.0c | 36.6ab | |

| 30 | 0.23ab | 3.8c | 9.6a | 17.3ab | 2.8c | 2.3c | 0.79ab | 4.9c | 37.4ab | |

| 40 | 0.19ab | 3.0c | 8.55a | 22.5a | 2.7c | 2.0c | 0.69b | 3.9c | 35.7b |

Mean values (n = 3) followed by different letter within a column are significantly different (p < 0.05)

Creep-recovery test: Gluten under 20 Pa of shear stress hold for 100 s and recover (0 Pa of shear stress) for 300 s

Creep-recovery test: MaxS, maximum strain during creep; FinalS, final strain during recovery; RCY, recoverability; Jmax, maximum compliance during creep; Jfinal, final compliance during recovery; Jc0, instantaneous elastic compliance during creep phase; Jc1 and Jc2, retarded elastic compliance during creep phase; t1 and t2, retardation time during creep phase; η0, pure viscosity; Jr0, instantaneous elastic compliance during recovery phase; Jr10 and Jr2, retarded elastic compliance during recovery phase; tr10 and tr2, retardation time during recovery phase

As explained before in the formation of a paste after the gelatinization and retrogradation process of starch and the denaturation of proteins, intermolecular bonds were altered by allowing more ordered H-bond sites engaged with water, starch and proteins resulting in a lower flowability of the batter. Moreover, the zero shear viscosity parameter (η0) showed remarkable increase up to 212 times after heat-moisture treatment compared to the sample without boiling (p < 0.05) (Table 2). This could be due to an improvement of water absorption during batter mixing. A study of pre-gelatinization using heat treatments, i.e., microwave, boiling, and roasting of buckwheat flour revealed that physical modification of starch increased water holding capacity (Sun et al. 2018). This could be attributed to a change in surface of starch granule to a more porous structure. The pre-gelatinized starch with high viscosity in cold-solution found to be related to higher crystalline peaks based on X-ray diffraction measurement (Román et al. 2016). The retardation time (t1 and t2) remained constant after heat-moisture treatment (Table 2). These regressed parameters also remained unchanged in a study of gluten with various additives (Chompoorat et al. 2013). However, the regressed parameter tr2 (second retardation time of recovery phase) revealed significant changes in the structure (p < 0.05) (Table 2). Heat-moisture treatment increased the second retardation time during recovery up to 80.3% (p < 0.05). This second retardation time during recovery from the mechanical analog models is associated with parallel ideal Hookean bodies (springs) and ideal fluid bodies (dashpots) attributed to an increase in entanglements of long chain polymers in starch structure after heat-moisture treatment (Hernández-Estrada et al. 2017). Our results confirmed an improvement of elastic mechanical spectra from dynamic oscillatory test after boiling. It is possible that the structures of the batters were partially modified by the annealing process and needs further investigation. Annealing occurs above glass transition temperature (Tg) but below the gelatinization temperature (Tester and Debon 2000).

Physical properties of red kidney bean gluten free cupcake

Physical properties of gluten free RKB cupcakes containing RKB flours from the eight treatments are presented in Table 1. Cake firmness is an important parameter associated with sensory attributes of cake products. RKB flour with different heat treatments showed that there was no significant differences in firmness and height of gluten free RKB cupcake (p > 0.05). These results agree with the findings on carob flour for gluten free cake with short and medium roasting time with no impact on cake volume (Ma et al. 2016; Román et al. 2017). During cupcake mixing and baking, the bubbles were stabilized and showed a high expansion with proper viscosity characteristic cake batter. An excess viscosity can prevent bubbles expansion. The viscosity of RKB batter measured by fundamental rheological tests showed that heat-moisture treatment increased the zero shear viscosity and elastic modulus of the batter (Tables 1 and 2). However, the gluten free RKB cupcakes had similar height, indicating that the batter viscosity obtained with RKB flours had acceptable range for making this type of cupcakes. A study of gluten free rice muffin with an incorporation of cowpea protein isolates revealed that volume was dependent mainly on types of protein isolates not cowpea protein isolate level. It was suggested that foaming and emulsification activity of protein isolates also influence volume and texture of muffin products (Shevkani et al. 2015a).

Sensory properties of gluten free red kidney bean cupcake

Overall consumer acceptance of gluten free RKB cupcake based on a 9-hedonic scale point is reported in Table 1. The gluten free RKB cupcake had a significantly higher score of overall consumer acceptance. From the consumers’ comments, gluten free cupcakes made with RKB flour without heat-moisture treatments had a dominant beany flavor, while it was not present in the cupcakes made with flour treated with heat-moisture treatments. The beany flavor is a limitation of dry bean for consumer acceptance. The beany flavor is produced from substances of chemical compounds created during physical disruption of the RKB tissues occurred in reaction of aerobic oxidation of linoleic and linolenic acids with lipoxygenase and alcohol oxidoreductase as biological catalysts (Ma et al. 2016). A study of light red kidney bean porridge also found that using heat process by extrusion helped lowering the detection of beany flavor in porridge (Nyombaire et al. 2011). This study confirms that the thermal treatments used in producing RKB flour reduce the beany flavor and thus improve the potential of RKB flour use as ingredient for cake products.

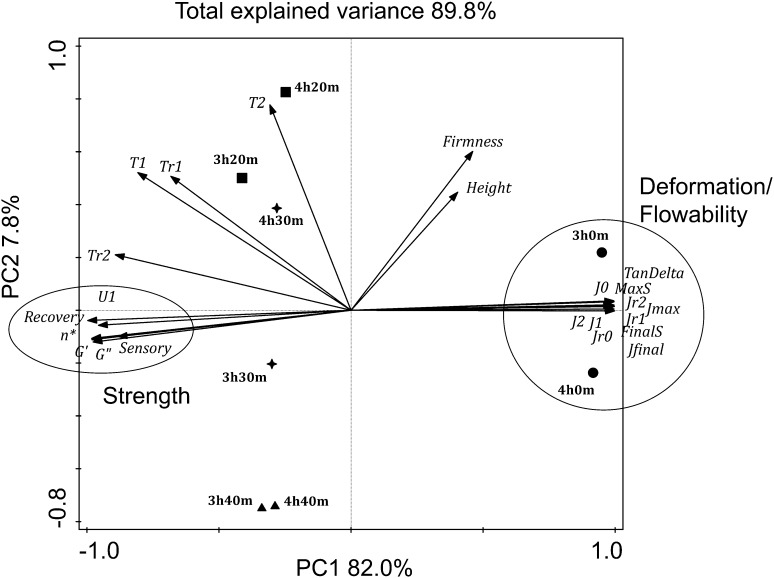

Discriminant analysis

The principal component analysis (PCA) by ordination procedure was used to depict relationships among parameters from batter rheological viscoelastic behavior, physical properties of gluten free RKB cupcake and sensory characteristics with treatment samples (Fig. 2). The parameters that were in vicinity to each other were positively correlated; whereas, the parameters that were opposite to each other were negatively associated. Moreover, the parameters that are perpendicular to each other indicated that they were independent. The most important contributors for explaining the variance were the parameters with the highest magnitude and closest to PC1. The total explained variance obtained from this sample set was 89.8% (Fig. 2). This sample set can be discriminated based on strength and deformation/flowability of gluten free RKB batter (Fig. 2). The parameters of strength and sensory characteristics were positively correlated, while, the deformation/flowability variables were in the same direction as firmness and height of gluten free RKB cupcake. Most of retardation time parameters from creep-recovery test were independent from strength and deformation/flowability characteristics. Samples incorporated with flour without heat-moisture treatment were highly correlated with deformation/flowability properties. In addition, the samples from flour with thermal treatment moved towards strength vectors and scattered on quadrant 3 and 4 compared to samples without thermal treatment. Boiling time at 40 min showed that samples (3 h 40 min and 4 h 40 min) were weakly correlated with retardation time. Overall, the results showed that using 20 min boiling with 3 h drying time is sufficient to produce red kidney bean flour for this gluten free cupcake application.

Fig. 2.

Biplot graph of principal component analysis (PCA) of parameters from fundamental rheological properties, physical properties, and sensory characteristics showing the effect of thermal treatments. Symbols: boiling 0 min, filled circle; boiling 20 min, filled square; boiling 30 min, filled star; and boiling 0 min, filled triangle

Conclusion

Boiling and drying RKB flour improved batter viscoelasticity and overall consumer acceptance of gluten free cupcakes. No significant differences in firmness and height of gluten free RKB cupcakes due to thermal treatments of RKB flour were observed. Boiling process increased elastic-like behavior and zero shear viscosity of RKB batter. Overall, boiling for 20 min with 3 h drying at 80 °C is sufficient to obtain RKB flour acceptable for gluten free cupcake production. Thus, this thermal process can be helpful to apply in flour production for legume industry.

Acknowledgements

This research was funded by Agricultural Research Development Agency (Public Organization), Oklahoma State University and U.S. Department of Agriculture-National Institute of Food and Agriculture (USDA-NIFA). The authors are grateful to acknowledge our funding providers.

References

- AACC International. Approved methods of analysis, 11th edn. Method 30-10.01. Crude fat in flour, bread, and baked cereal products not containing fruit. Approved November 3, 1999. AACC International, St. Paul, MN

- AACC International. Approved methods of analysis, 11th edn. Method 32-05.01. Crude fiber in flours, feeds, and feedstuffs. Approved November 3, 1999. AACC International, St. Paul, MN

- AACC International. Approved methods of analysis, 11th edn. Method 44-15.02. Moisture—air-oven methods. Approved November 3, 1999. AACC International, St. Paul, MN

- AACC International. Approved methods of analysis, 11th edn. Method 46-10.01. Crude protein-improved Kjeldahl Method. Approved November 3, 1999. AACC International, St. Paul, MN

- Ahmed J, Auras R, Kijchavengkul T, Varshney SK. Rheological, thermal and structural behavior of poly (ε-caprolactone) and nanoclay blended films. J Food Eng. 2012;111:580–589. doi: 10.1016/j.jfoodeng.2012.03.014. [DOI] [Google Scholar]

- Ahmed J, Almusallam AS, Al-Salman F, AbdulRahman MH, Al-Salem E. Rheological properties of water insoluble date fiber incorporated wheat flour dough. LWT Food Sci Technol. 2013;51:409–416. doi: 10.1016/j.lwt.2012.11.018. [DOI] [Google Scholar]

- Awolu OO. Optimization of the functional characteristics, pasting and rheological properties of pearl millet-based composite flour. Heliyon. 2017;3:e00240. doi: 10.1016/j.heliyon.2017.e00240. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bennink M. Consumption of black beans and navy beans (Phaseolus vulgaris) reduced azoxymethane-induced colon cancer in rats. Nutr Cancer. 2002;44:60–65. doi: 10.1207/S15327914NC441_8. [DOI] [PubMed] [Google Scholar]

- Bhol S, Bosco SJD. Influence of malted finger millet and red kidney bean flour on quality characteristics of developed bread. LWT Food Sci Technol. 2014;55:294–300. doi: 10.1016/j.lwt.2013.08.012. [DOI] [Google Scholar]

- Bourekoua H, Benatallah L, Zidoune MN, Rosell CM. Developing gluten free bakery improvers by hydrothermal treatment of rice and corn flours. LWT Food Sci Technol. 2016;73:342–350. doi: 10.1016/j.lwt.2016.06.032. [DOI] [Google Scholar]

- Capriles VD, Arêas JAG. Novel approaches in gluten-free breadmaking: interface between food science. Nutr Health Compr Rev Food Sci Food Saf. 2014;13:871–890. doi: 10.1111/1541-4337.12091. [DOI] [Google Scholar]

- Chompoorat P, Ambardekar A, Mulvaney S, Rayas-Duarte P. Rheological characteristics of gluten after modified by DATEM, ascorbic acid, urea and DTT using creep-recovery test. J Mod Phys. 2013;4:1–8. doi: 10.4236/jmp.2013.410A2001. [DOI] [Google Scholar]

- Collar C, Conte P, Fadda C, Piga A. Gluten-free dough-making of specialty breads: significance of blended starches, flours and additives on dough behaviour. Food Sci Technol Int. 2015;21:523–536. doi: 10.1177/1082013214552862. [DOI] [PubMed] [Google Scholar]

- Gao Y, Janes ME, Chaiya B, Brennan MA, Brennan CS, Prinyawiwatkul W. Gluten-free bakery and pasta products: prevalence and quality improvement. Int J Food Sci Technol. 2018;53:19–32. doi: 10.1111/ijfs.13505. [DOI] [Google Scholar]

- Gélinas P, McKinnon C. Gluten weight in ancient and modern wheat and the reactivity of epitopes towards R5 and G12 monoclonal antibodies. Int J Food Sci Technol. 2016;51:1801–1810. doi: 10.1111/ijfs.13151. [DOI] [Google Scholar]

- Gómez M, Martínez MM. Changing flour functionality through physical treatments for the production of gluten-free baking goods. J Cereal Sci. 2016;67:68–74. doi: 10.1016/j.jcs.2015.07.009. [DOI] [Google Scholar]

- Hernández-Estrada ZJ, Figueroa JDC, Rayas-Duarte P, Peña RJ. Viscoelastic characterization of glutenins in wheat kernels measured by creep tests. J Food Eng. 2012;113:19–26. doi: 10.1016/j.jfoodeng.2012.05.033. [DOI] [Google Scholar]

- Hernández-Estrada ZJ, Rayas-Duarte P, Cárdenas JDDF. Creep recovery of wet gluten and high-molecular-weight glutenin subunit composition: relationship with viscoelasticity of dough and breadmaking quality of hard red winter wheat. Cereal Chem. 2017;94:223–229. doi: 10.1094/CCHEM-03-16-0049-R. [DOI] [Google Scholar]

- Ma Z, Boye JI, Azarnia S, Simpson BK. Volatile flavor profile of Saskatchewan grown pulses as affected by different thermal processing treatments. Int J Food Prop. 2016;19:2251–2271. doi: 10.1080/10942912.2015.1121494. [DOI] [Google Scholar]

- Manonmani D, Bhol S, Bosco S. Effect of red kidney bean (Phaseolus vulgaris L.) flour on bread quality. Open Access Libr J. 2014;1:1–6. [Google Scholar]

- Marathe S, Deshpande R, Khamesra A, Ibrahim G, Jamdar SN. Effect of radiation processing on nutritional, functional, sensory and antioxidant properties of red kidney beans. Radiat Phys Chem. 2016;125:1–8. doi: 10.1016/j.radphyschem.2016.03.002. [DOI] [Google Scholar]

- Nyombaire G, Siddiq M, Dolan K. Physico-chemical and sensory quality of extruded light red kidney bean (Phaseolus vulgaris L.) porridge. LWT Food Sci Technol. 2011;44:1597–1602. doi: 10.1016/j.lwt.2011.02.016. [DOI] [Google Scholar]

- Román L, Dura Á, Martínez MM, Rosell CM, Gómez M. Combination of extrusion and cyclodextrin glucanotransferase treatment to modify wheat flours functionality. Food Chem. 2016;199:287–295. doi: 10.1016/j.foodchem.2015.12.040. [DOI] [PubMed] [Google Scholar]

- Román L, González A, Espina T, Gómez M. Degree of roasting of carob flour affecting the properties of gluten-free cakes and cookies. J Food Sci Technol. 2017;54:2094–2103. doi: 10.1007/s13197-017-2649-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shevkani K, Singh N. Influence of kidney bean, field pea and amaranth protein isolates on the characteristics of starch-based gluten-free muffins. Int J Food Sci Technol. 2014;49:2237–2244. doi: 10.1111/ijfs.12537. [DOI] [Google Scholar]

- Shevkani K, Kaur A, Kumar S, Singh N. Cowpea protein isolates: functional properties and application in gluten-free rice muffins. LWT Food Sci Technol. 2015;63:927–933. doi: 10.1016/j.lwt.2015.04.058. [DOI] [Google Scholar]

- Shevkani K, Singh N, Kaur A, Rana JC. Structural and functional characterization of kidney bean and field pea protein isolates: a comparative study. Food Hydrocoll. 2015;43:679–689. doi: 10.1016/j.foodhyd.2014.07.024. [DOI] [Google Scholar]

- Siddiq M, Ravi R, Harte J, Dolan K. Physical and functional characteristics of selected dry bean (Phaseolus vulgaris L.) flours. LWT Food Sci Technol. 2010;43:232–237. doi: 10.1016/j.lwt.2009.07.009. [DOI] [Google Scholar]

- Siddiq M, Ravi R, Harte JB, Dolan KD. Physical and functional characteristics of selected dry bean (Phaseolus vulgaris L.) flours. LWT Food Sci Technol. 2010;43:232–237. doi: 10.1016/j.lwt.2009.07.009. [DOI] [Google Scholar]

- Steffe JF, editor. Rheological methods in food process engineering. 2. New York: Freeman Press; 1996. [Google Scholar]

- Sun X, et al. Comparison of pregelatinization methods on physicochemical, functional and structural properties of tartary buckwheat flour and noodle quality. J Cereal Sci. 2018;80:63–71. doi: 10.1016/j.jcs.2018.01.016. [DOI] [Google Scholar]

- Tester RF, Debon SJ. Annealing of starch—a review. Int J Biol Macromol. 2000;27:1–12. doi: 10.1016/S0141-8130(99)00121-X. [DOI] [PubMed] [Google Scholar]

- Vici G, Belli L, Biondi M, Polzonetti V. Gluten free diet and nutrient deficiencies: a review. Clin Nutr. 2016;35:1236–1241. doi: 10.1016/j.clnu.2016.05.002. [DOI] [PubMed] [Google Scholar]

- Yano H. Improvements in the bread-making quality of gluten-free rice batter by glutathione. J Agric Food Chem. 2010;58:7949–7954. doi: 10.1021/jf1003946. [DOI] [PubMed] [Google Scholar]