Abstract

Industrial onion waste powder (IOWP) was used as an additive in wheat flour at different levels: 0, 1, 2, 3, 4 and 5%. The effect of onion waste addition on the mixing properties of the dough and quality of bread was investigated. The mixing properties of the dough were determined by farinograph. The bread were characterized and evaluated for crumb hardness, crumb porosity, sensory properties, dietary fiber, total phenolic content and total flavonoids. DPPH and FRAP assays were carried out to measure antioxidant activity in vitro. The results indicated that IOWP could be used as a potential health-enhancing functional ingredient up to 3% level to produce bread enriched with dietary fiber, total phenolic compounds and total flavonoids, and characterized by high antioxidant activity and acceptable quality.

Electronic supplementary material

The online version of this article (10.1007/s13197-018-3448-8) contains supplementary material, which is available to authorized users.

Keywords: Onion waste, Addition, Bread, Dietary fibers, Polyphenols, Quality

Introduction

Consumers evaluate food products not only in terms of nutritional needs, but also with regard to the improvement of their health. Nowadays, interest in the production and consumption of functional foods is growing steadily. These foods, defined as innovative and biologically active, provide additional health benefits beyond traditional foods. Food fortification is one of the major techniques used to create functional food products (Abdel-Salam 2010; Świeca et al. 2014).

Cereal products, such as bread, are consumed daily by the majority of the population. Generally, wheat bread has an important role in the human diet. Increased consumer demand for healthy bread has led to considerable efforts aimed at developing breads with combined health benefits and good quality properties (Foschia et al. 2013; Vasileva et al. 2018). The current trends in the enhancement of the antioxidant activity of wheat bread by the addition of plant materials rich in phenolic compounds, such as other cereals, spices, herbs, fruit and by-products from the food industries, have been reviewed recently (Dziki et al. 2014). In another study, the effects of inulin and fructo-oligosaccharide supplementation on bread and their role in weight management have been presented in detail (Morris and Morris 2012).

Onion wastes from industrial processing consist mainly of the top and bottom parts of onion bulbs, and the two outer fleshy scales together with the brown skin. These by-products could be used as a source of phenolic substances with pronounced antioxidant activity, and as food ingredients with high levels of dietary fiber (Benítez et al. 2011).

The addition of dry onion skins increases wheat bread bioactivity, including its antioxidant potential and interference with the cellular traits crucial for gastric cancer promotion and progression. The addition of 2–3 g/100 g of onion skins causes significant improvement of the antioxidant capacity of bread. The supplementation of wheat flour with up to 3 g/100 g of onion skin powder resulted in bread with satisfactory consumer acceptability (Gawlik-Dziki et al. 2013, 2015). On the other hand, bread fortification with onion skins can reduce protein digestibility because of the occurrence of indigestible protein–flavonoid complexes. Therefore, the phenolic components have multiple effects on food quality and health-enhancing properties (Świeca et al. 2013).

To the best of our knowledge, the overall effect of IOWP addition on bread quality and consumer acceptability has not been investigated. Hence in this study IOWP was used as a functional ingredient for enhancing the health properties of wheat bread. The effects of IOWP addition to wheat flour on the properties of the dough and the quality of the bread were assessed.

Materials and methods

IOWP preparation

The material used in this study was obtained from a local Bulgarian canning factory (Bulcons Parvomay JSC, Bulgaria) after the processing of brown-skin onion bulbs. The industrial onion waste consisted of the apical trimmings of the bulbs, and the outer dry and semidry layers. The material was transferred to the laboratory immediately after processing, double washed and cut into small pieces. The pieces of industrial onion waste were dried in a convective oven dryer at 70 °C for 16 h and blended into fine powder (< 250 μm) using a domestic electric mill. The sample was stored in airtight glass containers at 4 °C prior to analysis.

Bread making

The bread samples were prepared as previously described by Gawlik-Dziki et al. (2013) with slight modification. Type 500 wheat flour (500 g), (0.50% average ash content, 14% moisture content) was used in the control bread formula. Additionally, fresh yeast (15 g) and salt (7.5 g) were added to the bread dough formulation. The flour was partially replaced with IOWP at the 1, 2, 3, 4 and 5% levels (OW1–OW5, respectively). The total amount of water necessary for the dough preparation was determined through a water absorption farinograph test (dough consistency of 500 Brabender units). The dough batches were mixed in a kneading machine (Labomix 1000, Hungary) for 5 min and placed in the proofing cabinet for fermentation at 35 °C and 80–85% relative humidity. The dough was taken out of the proofing cabinet after an initial 30 min fermentation and divided into pieces of similar weight (230 g), then each piece was shaped, put in a greased metal pan and placed in the proofing cabinet again for 50 min under the same proofing conditions. After the final fermentation, the pieces of dough were put into an electric oven pre-heated to 230 °C. The baking time was 30 min. After baking, the bread was allowed to cool down for 24 h at room temperature.

Dough properties

The effect of IOWP addition on the dough properties during mixing was determined using a Farinograph (Brabender, Duisburg, Germany). The parameters investigated were: water absorption (%), consistency (FU), dough development time (DDT, min), stability (min), elasticity (FU), and degree of softening (FU).

Breadcrumb hardness

Bread hardness was determined using a Stevens-LFRA texture analyzer (Brookfield Enginering Laboratories Inc., Massachusetts, USA) through adaptation of the AACC Method 74-10A (2000) compression test for evaluating sliced loaf freshness. Two 12.5 mm thick slices (25 mm in total) were placed under a 32 mm diameter cylindrical probe. The slices were compressed to 3 mm at a constant crosshead speed of 1 mm/s, and the peak load was used as an indication of freshness.

Image analysis of the breadcrumb

The gas pores in the bread crumb were assessed using a procedure (Image Analysis) based on mathematical morphology and proposed to characterize visual texture in relation to particle size (Bertrand et al. 1992; Rouille et al. 2005). Digital images were taken on an HP Scanjet G4010 color flatbed scanner. The image resolution was 2056 × 1280p, with pixel depth of 300 dpi. One hour after baking, the bread loaves were cut transversely with an electric slicer (Master 182 slicer—Graef, Arnsberg, Germany) in order to obtain slices about 1.5 cm in thickness. Several slices were obtained per each loaf of bread, but only the middle ones were used for analysis. Special attention was paid to avoid cell damage during this procedure. All images were processed and analyzed with Image J (U. S. National Institutes of Health, Bethesda, Maryland, USA). The thresholding technique was based on the Isodata algorithm. Twenty-five dilation and erosion steps were applied to the initially equalized image in order to generate statistical data for the gas pore size distribution.

Ultrasound-assisted extraction

Bread samples were sliced (about 1.5 cm in thickness), dried for 1 h at 40 °C in a laboratory dryer, ground in a mill and screened through a 0.5 mm sieve to obtain bread powder (Gawlik-Dziki et al. 2013). For the extraction of phytochemical compounds, ground bread samples (1.5 g) were extracted with 70% (v/v) ethanol in 1:20 (w/v) solid to liquid ratio. The extraction procedure was performed in an ultrasonic bath (VWR, Malaysia, 45 kHz and 30 W) for 15 min at 45 °C as previously described by Petkova et al. (2014).

Total phenolic and flavonoid content

The total phenolic content (TPC) was determined using Folin–Ciocalteu’s reagent according to Stintzing et al. (2005). Gallic acid was used as a calibration standard and the results were expressed as mg gallic acid equivalents (GAE) per gram on a dry weight basis (dw). The total flavonoid content was determined using an Al(NO3)3 reagent and measuring the absorbance at 415 nm according to Kivrak et al. (2009). The results were presented as mg quercetin equivalents (QE) per gram (dw).

In vitro antioxidant activity

The antioxidant activities were evaluated by two methods: DPPH (1,1-diphenyl-2-picrylhydrazyl) radical based on mixed hydrogen atom transfer (HAT) and FRAP (ferric reducing antioxidant power) based only on the single electron transfer mechanism (Benzie and Strain 1996). The results were expressed as mM Trolox® equivalents (TE) per gram (dw) (Ivanov et al. 2014).

Dietary fiber (DF) content

The total, soluble and insoluble dietary fiber (TDF, SDF and IDF) contents of the samples were determined by the enzymatic-gravimetric method, using the Bioquant 1.12979.0001 total dietary fiber assay kit (Merck, Germany) and the instructions provided by the manufacturer.

Sensory evaluation

Sensory evaluation was carried out using the hedonic test according to the procedure described by Gawlik-Dziki et al. (2013). Briefly, the samples were sliced (slices about 1.5 cm thick), coded and served to untrained consumers. The panel consisted of 16 consumers (24–45 years old), who evaluated the shape, crust color, crumb color, aroma, uniformity of porosity, chewability, taste, aftertaste and overall acceptability of the bread. The degrees of liking for the different bread types were based on a nine-point hedonic scale (1: dislike extremely, 5: neither like nor dislike, 9: like extremely). Plain water was used for mouth rinsing before and after each sample tasting.

Statistical analysis

All experimental results were given as mean ± standard deviation of three independent measurements. The experimental data were subjected to statistical evaluation using analysis of variance (ANOVA) with Statgraphics Centurion XVI Version 16.2.04 software (StatPoint Technologies, Inc., USA). Duncan’s multiple range tests were used to determine the difference among the means, and the significance was defined at p < 0.05.

Results and discussion

Effect of IOWP addition on dough mixing properties

The addition of IOWP led to differences in the dough mixing behavior measured by a farinograph test. Farinograph parameters are presented in Table 1. The water absorption increased significantly (p < 0.05) due to the addition of IOWP. The sample with 5% onion waste had the highest water absorption, which was probably due to the increased hydration capacity resulting from the addition of the dietary fiber contained in the onion waste powder. Substances known as dietary fibers possess a large number of hydroxyl groups, which interact with the hydrogen bonds of water as reported by Wang et al. (2002). A similar effect on water absorption has been observed recently by Kohajdová et al. (2012), Mohammed et al. (2012) and Messia et al. (2016) for the addition of carrot pomace powder, chickpea flour and wheat bran in wheat dough. The dough development time (DDT) increased from 2.5 to 3.0 min with 3% addition of IOWP, whereas no significant difference was observed (p > 0.05) between the samples with 3, 4 and 5% onion waste. The differences in DDT could be explained with the changes in the physicochemical properties of the onion waste supplemented samples. A similar trend in DDT was observed by Mohammed et al. (2012) for addition of chickpea flour in wheat dough. This could also be attributed to the fiber-gluten interaction, which prevents protein hydration as reported by Gómez et al. (2011). Dough stability time is a major index for dough strength. The results indicated that the addition of up to 3% IOWP reduced dough stability significantly (p < 0.05) compared to the control. This effect could be explained by the increased interaction between dietary fiber, water and flour proteins. Similar results were observed by Gómez et al. (2011) for the addition of extruded wheat bran in wheat dough. The data on the degree of dough softening showed that IOWP increased the degree of softening significantly (p < 0.05) compared to the control. This can be explained by the dilution of wheat gluten which was also reported by Mohammed et al. (2012). Regarding the dough consistency and elasticity, a significant decrease (p < 0.05) was detected with 2, 3 and 4% addition of IOWP.

Table 1.

Farinograph analysis of wheat dough containing different levels of IOWP

| Sample | Water absorption (%) | Dough development time (min) | Consistency (FU) | Stability (min) | Elasticity (FU) | Degree of softening (FU) |

|---|---|---|---|---|---|---|

| Control | 58.8 ± 0.1a | 2.5 ± 0.2a | 522 ± 2.9a | 14.0 ± 0.5a | 180 ± 5.0a | 70 ± 0.0a |

| OW1 | 59.9 ± 0.1b | 2.5 ± 0.2a | 530 ± 5.0b | 7.7 ± 0.8b | 180 ± 5.0a | 180 ± 5.0b |

| OW2 | 61.6 ± 0.2c | 2.5 ± 0.2a | 500 ± 0.0c | 5.0 ± 0.5c | 162 ± 2.9b | 170 ± 5.0c |

| OW3 | 62.8 ± 0.1d | 3.0 ± 0.1b | 492 ± 2.9d | 4.0 ± 0.5d | 162 ± 2.9b | 160 ± 0.0d |

| OW4 | 63.2 ± 0.2e | 3.0 ± 0.1b | 500 ± 0.0c | 4.0 ± 0.5d | 162 ± 2.9b | 160 ± 0.0d |

| OW5 | 63.9 ± 0.2f | 3.0 ± 0.1b | 540 ± 5.0e | 4.0 ± 0.5d | 180 ± 5.0a | 160 ± 0.0d |

The data are mean ± standard deviation of three independent measurements. Values within column followed by different letters (a–f) differ significantly from each other (p < 0.05)

FU farinograph units

Effect of IOWP addition on bread quality

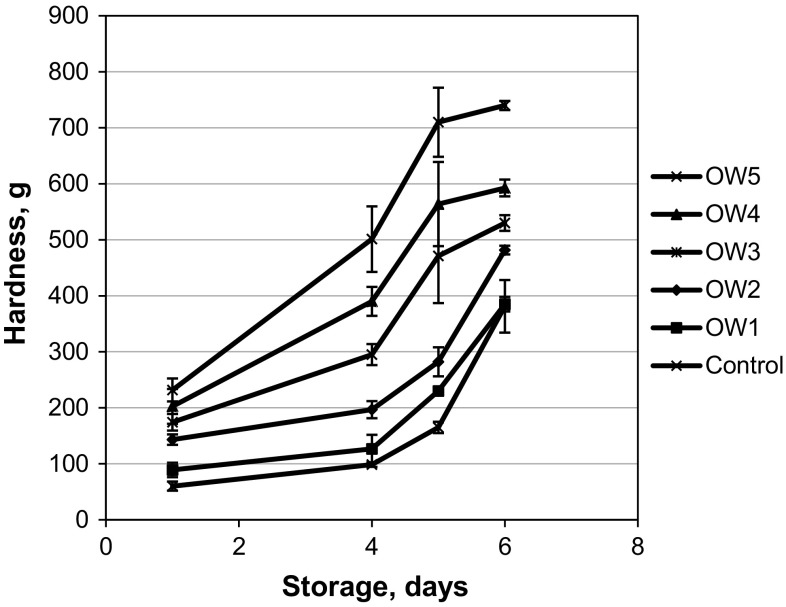

Crumb hardness is an important attribute that determines the bread quality. The hardness of breads supplemented with different levels of IOWP is presented in Fig. 1. The statistical analysis showed that the levels of onion waste addition and storage time affected the hardness of the breadcrumb significantly (p < 0.05). The results suggested that breadcrumb hardness increased significantly (p < 0.05) with the increase in the onion waste powder levels. Similar results were presented by Lim et al. (2011) for bread supplemented with turmeric powder. Breads with low levels of onion waste were softer compared to those with higher levels throughout the period of storage. The maximum hardness of the breads with 3%, 4% and 5% onion waste was reached after 5 days of storage whereas hardness increased rapidly in the samples with 0%, 1% and 2% onion waste after 4 days of storage. During the starch gelatinization, the partially swollen granules can be stretched into elongated forms that allow gas cells to expand. Therefore, bread texture is dependent on starch gelatinization. The fibers and polyphenols present in IOWP may compete for water with native wheat starch granules in the dough and result in higher hardness (Pasrija et al. 2015). Recently, Boubaker et al. (2016) reported gradual hardening of crumb texture related to the addition of artichoke powder, probably due to a dilution effect decreasing the gluten content and modifying the viscoelastic properties of gluten.

Fig. 1.

Evolution of the crumb hardness of breads with different levels of IOWP during storage

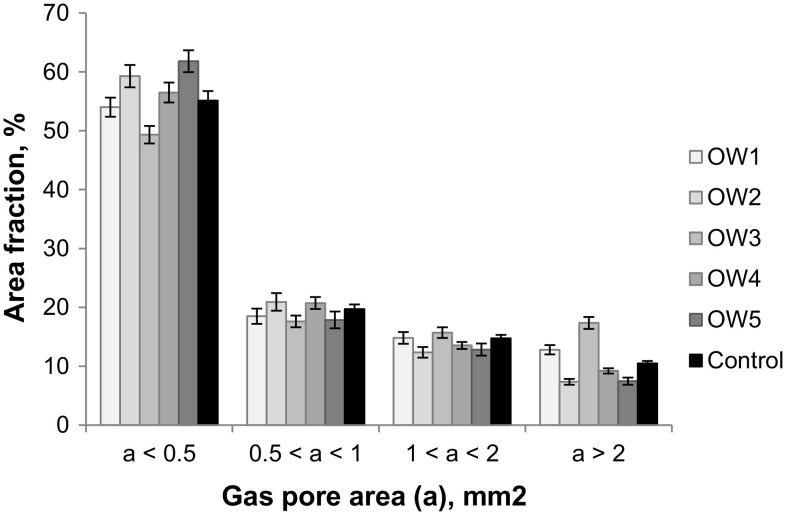

Crumb porosity is another important bread quality parameter. Good quality bread is characterized by high porosity and open crumb structure. The image analysis data have been reported in Fig. 2, where the gas pore area distribution among selected classes is shown in percentages. It may be that breads supplemented with IOWP could not entrap and retain gas bubbles therefore the crumb structure was denser compared to the control bread (Figure 1S, see Online Resource). The results obtained were consistent with those for breadcrumb hardness. Fibers have been reported to reduce bread volume due to their interaction with gluten that led to a decrease in the gas retention capacity, and to restrict the expansion of the gas cells producing pores with small mean cell area (Angioloni and Collar 2013; Dall’Asta et al. 2013; Gómez et al. 2003). Our results indicated that for all analyzed bread samples the prevailing gas pore area fraction was in area class a < 0.5 mm2 (Fig. 2). An increase in the IOWP addition of more than 3% led to a higher area fraction of small pores (area class a < 0.5 mm2) and respectively, a lower area fraction of larger gas pores (area class a > 2 mm2) compared to the control bread.

Fig. 2.

Gas pore area distribution of breads with different levels of IOWP

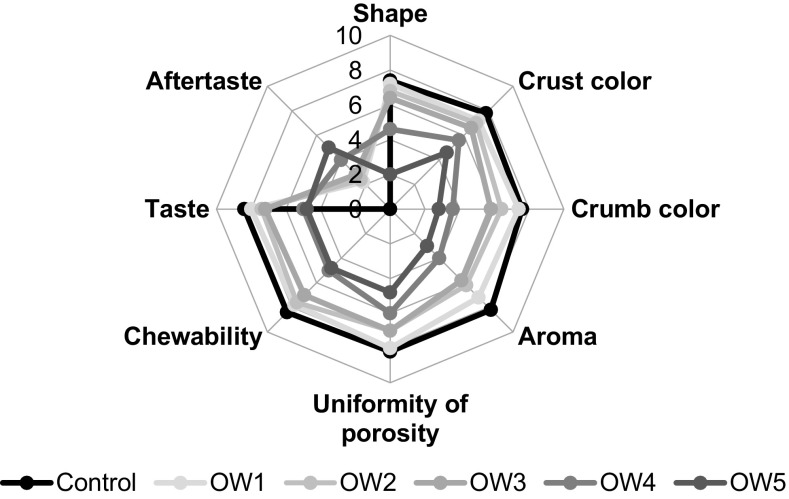

Data regarding the sensory evaluation of the formulated wheat breads are presented in Fig. 3, and the results from the statistical analysis, including overall acceptability of the bread samples, have been given in Table 1S (see Online Resource). The statistical analysis of the results revealed that the addition of IOWP influenced the sensory attributes of the resultant breads significantly (p < 0.05). The colors of both the crust and the crumb of breads with more than 3% onion waste were much darker than those of the control bread. Higher levels of IOWP caused significant (p < 0.05) changes in taste and aroma. The sensory evaluation results showed that a partial replacement of wheat flour in bread by up to 3% IOWP led overall to satisfactory acceptability to consumers. Samples supplemented with 4% and 5% IOWP indicated significant (p < 0.05) decreases of overall acceptability compared to the control bread by 38.5% and 48.7% respectively. Our results were consistent with those obtained in other research for wheat bread supplemented with dry onion skin (Gawlik-Dziki et al. 2013).

Fig. 3.

Sensory characteristics of breads with different levels of IOWP

Effect of IOWP addition on the dietary fiber composition of bread

Benítez et al. (2011) found that industrial onion wastes could be used as a potential source of dietary fibers in human diet. They reported that dietary fibers of onion were cultivar dependent, and the onion by-products showed the highest TDF content with predominant IDF and a tendency towards an increase in dietary fibers from the inner to the outer scales. The characterization of IOWP for potential use in the food sector was carried out in our previous study (Prokopov et al. 2018), and data on dietary fiber content are shown in Table 2S (see Online Resource). The results obtained on the TDF, IDF and SDF content in bread supplemented with different levels of IOWP in this study have been presented in Table 2S (see Online Resource). The TDF, IDF and SDF content in the bread samples gradually increased with the increase in the IOWP levels. The lowest dietary fiber content was observed in the control bread, and the maximum dietary fiber content was found in the bread supplemented with 5% IOWP. Significant differences (p < 0.05) in the TDF, IDF and SDF content between the control bread and the supplemented breads were detected at a 2% substitution level where the increase in dietary fiber was by 1.82, 1.86 and 1.66 times, respectively. Similarly, Acosta-Estrada et al. (2014) reported a 1.56-fold higher dietary fiber content in bread supplemented with 9% nejayote food additive compared to the control. Our data indicated that an IOWP substitution level of 3% which led to satisfactory consumer overall acceptability of bread caused an significant (p < 0.05) increase of TDF content by approximately 2.6 times compared to the quantity content in the control bread. These results suggested that a daily intake of 50 g of white bread with 36.54% moisture content supplemented with 3% IOWP could deliver approximately 1.51 g of TDF (about 6% of the recommended daily intake) which could be used as an additional source of dietary fiber for the human diet.

Effect of IOWP addition on the total phenolic and total flavonoid content and the antioxidant activity of bread

In order to evaluate the IOWP contribution to the antioxidant activity of the resulting bread, the total phenolic and total flavonoid content, the DPPH and FRAP values in bread supplemented with different levels of IOWP were determined and the results have been presented in Table 3S (see Online Resource). Data on the total phenolic and total flavonoid content, and on the DPPH and FRAP values in IOWP obtained in our previous study (Prokopov et al. 2018) are presented in Table 3S (see Online Resource). The antioxidant activity of white bread is usually attributed to the presence of Maillard reaction products that are known to possess free-radical scavenging activities (Kitts et al. 2012). Industrial onion wastes contain significant amounts of phenolic compounds and flavonoids, mainly quercetin, resulting in high antioxidant activity (Benítez et al. 2011). In our research, bread containing IOWP showed significantly (p < 0.05) higher total phenolic and total flavonoid content, and antioxidant activity evaluated by DPPH and FRAP methods in comparison with the control bread. The data on the total phenolic content were similar to those observed by Lim et al. (2011) for turmeric bread, and the data on total flavonoids were in accordance with those reported by Świeca et al. (2013) for bread enriched with onion skin. The results in Table 3S (see Online Resource) indicate that the total phenolic and total flavonoid content and the antioxidant activity increased significantly (p < 0.05) with the increase in the IOWP levels up to 5%. There were no significant differences detected for total phenolic content between the 4 and 5% substituted samples and the DPPH value of these breads slightly decreased. The bread samples showed higher antioxidant activity evaluated by FRAP (ferric reducing antioxidant power) based only on the single electron transfer mechanism. We observed that an IOWP level of 3% caused an significant (p < 0.05) increase in the total phenolic content, and the DPPH and FRAP values of approximately 2.5, 13.0 and 6.2 times, respectively, compared to the control bread. The antioxidant activity of bread demonstrated a strong positive correlation with the total phenolic and total flavonoid content, with correlation coefficients of 0.98 and 0.95, respectively. According to the energy intake of the diet, some authors recommend 5000–15,000 μmol TE (5–15 mM TE) as necessary to cover the human daily antioxidant needs (Denev et al. 2013). In our study, the levels were within the recommended values, and this information is valuable both for consumers and for nutritionists. Significant enhancement of the antioxidant activity of bread enriched with different materials has also been observed in several other studies (Balestra et al. 2011; Gawlik-Dziki et al. 2013; Lim et al. 2011; Vasudevaiah et al. 2017). Our results suggested that a daily intake of 50 g of white bread with 36.54% moisture content and 3% wheat flour substitution with IOWP could deliver approximately 32.97 mg GAE of total phenols and 24.11 mg QE of total flavonoids which could render additional health benefits to the human body. For instance, Lim et al. (2011) observed that a daily intake of 50 g or two slices of bread having 4% turmeric powder could deliver 40.12 mg GAE of total phenolic compounds. Our data supported the possible application of IOWP to the formulation of bread with increased health-enhancement. Similar results have been reported for white bread enriched with 3% ground onion skin (Gawlik-Dziki et al. 2013).

Conclusion

IOWP significantly increased in water absorption dough development time and degree of softness while dough stability, consistency and elasticity was decreased compared to the control. The addition of IOWP increased considerably the total phenolic and total flavonoid content and the antioxidant activity of the bread. The supplemented bread also showed higher dietary fiber content compared to the control bread. The quality assessment and sensory analysis results indicated that IOWP could be added successfully at 3% level to produce white bread with acceptable quality and enhanced health benefits.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

The authors thank the management of the Bulgarian local canning plant, Bulcons Parvomay JSC, Bulgaria, for their help in the provision of industrial onion waste and to Tsveta Horeva, Ph.D., for the language support.

Compliance with ethical standards

Conflict of interest

All authors declare that they have no conflict of interest.

References

- AACC Method 74-10A . Measurement of bread firmness–compression test. St Paul: AACC International; 2000. [Google Scholar]

- Abdel-Salam AM. Functional foods: hopefulness to good health. Am J Food Technol. 2010;5:86–99. doi: 10.3923/ajft.2010.86.99. [DOI] [Google Scholar]

- Acosta-Estrada B, Lazo-Vélez M, Nora-Valdez Y. Improvement of dietary fibre, ferulic acid and calcium contents in pan bread enriched with nejayote food additive from white maize (Zea mays) J Cereal Sci. 2014;60:264–269. doi: 10.1016/j.jcs.2014.04.006. [DOI] [Google Scholar]

- Angioloni A, Collar C. Suitability of oat, millet and sorghum in breadmaking. Food Bioprocess Technol. 2013;6:1486–1493. doi: 10.1007/s11947-012-0786-9. [DOI] [Google Scholar]

- Balestra F, Cocci E, Pinnavaia G, Romani S. Evaluation of antioxidant, rheological and sensorial properties of wheat flour dough and bread containing ginger powder. LWT Food Sci Technol. 2011;44:700–705. doi: 10.1016/j.lwt.2010.10.017. [DOI] [Google Scholar]

- Benítez V, Mollá E, Martin-Cabrejas M, Aguilera Y, López-Andréu F, Cools K, Terry L, Esteban R. Characterization of industrial onion wastes (Allium cepa L.): dietary fibre and bioactive compounds. Plant Food Hum Nutr. 2011;66:48–57. doi: 10.1007/s11130-011-0212-x. [DOI] [PubMed] [Google Scholar]

- Benzie I, Strain J. The ferric reducing ability of plasma (FRAP) as a measure of antioxidant power: the FRAP assay. Anal Biochem. 1996;239:70–76. doi: 10.1006/abio.1996.0292. [DOI] [PubMed] [Google Scholar]

- Bertrand D, Le Guerneve C, Devaux MF, Robert P. Description of the textural appearance of bread crumb by video image analysis. Cereal Chem. 1992;69:257–261. [Google Scholar]

- Boubaker M, Damergi C, Marzouk C, Blecker C, Bouzanita N. Effect of artichoke (Cynara scolymus L.) by-product of the quality and total phenol content of bread. Mediterr J Chem. 2016;5:548–553. doi: 10.13171/mjc55/01606041425/bouzouita. [DOI] [Google Scholar]

- Dall’Asta C, Cirlini M, Morini E, Rinaldi M, Ganino T, Chiavaro E. Effect of chestnut flour supplementation on physico-chemical properties and volatiles in bread making. LWT Food Sci Technol. 2013;53:233–239. doi: 10.1016/j.lwt.2013.02.025. [DOI] [Google Scholar]

- Denev P, Lojek A, Ciz M, Kratchanova M. Antioxidant activity and polyphenol content of Bulgarian fruits. Bulg J Agric Sci. 2013;19:22–27. [Google Scholar]

- Dziki D, Róžylo R, Gawlik-Dziki U, Świeca M. Current trends in the enhancement of antioxidant activity of wheat bread by the addition of plant materials rich in phenolic compounds. Trends Food Sci Technol. 2014;40:48–61. doi: 10.1016/j.tifs.2014.07.010. [DOI] [Google Scholar]

- Foschia M, Peressini D, Sensidoni A, Brennan C. The effects of dietary fibre addition on the quality of common cereal products. J Cereal Sci. 2013;58:216–227. doi: 10.1016/j.jcs.2013.05.010. [DOI] [Google Scholar]

- Gawlik-Dziki U, Świeca M, Dziki D, Baraniac B, Tomilo J, Czyż J. Quality and antioxidant properties of breads enriched with dry onion (Allium cepa L.) skin. Food Chem. 2013;138:1621–1628. doi: 10.1016/j.foodchem.2012.09.151. [DOI] [PubMed] [Google Scholar]

- Gawlik-Dziki U, Kaszuba K, Piwowarczyk K, Świeca M, Dziki D, Czyż J. Onion skin—raw material for the production of supplement that enhances the health-beneficial properties of wheat bread. Food Res Int. 2015;73:97–106. doi: 10.1016/j.foodres.2015.02.008. [DOI] [Google Scholar]

- Gómez M, Ronda F, Blanco C, Caballero P, Apesteguía A. Effect of dietary fibre on dough rheology and bread quality. Eur Food Res Technol. 2003;216:51–56. doi: 10.1007/s00217-002-0632-9. [DOI] [Google Scholar]

- Gómez M, Jiménez S, Ruiz E, Oliete B. Effect of extruded wheat bran on dough rheology and bread quality. LWT Food Sci Technol. 2011;44:2231–2237. doi: 10.1016/j.lwt.2011.06.006. [DOI] [Google Scholar]

- Ivanov I, Vrancheva R, Marchev A, Petkova N, Aneva I, Denev P, Georgiev V, Pavlov A. Antioxidant activities and phenolic compounds in Bulgarian fumaria species. Int J Curr Microbiol Appl Sci. 2014;3:296–306. [Google Scholar]

- Kitts D, Chen X, Jing H. Demonstration of antioxidant and anti-inflammatory bioactives from sugar-amino acid Maillard reaction products. J Agr Food Chem. 2012;60:6718–6727. doi: 10.1021/jf2044636. [DOI] [PubMed] [Google Scholar]

- Kivrak I, Duru M, Öztürk M, Mercan N, Harmandar M, Topçu G. Antioxidant, anticholinesterase and antimicrobial constituents from the essential oil and ethanol extract of Salvia potentillifolia. Food Chem. 2009;116:470–479. doi: 10.1016/j.foodchem.2009.02.069. [DOI] [Google Scholar]

- Kohajdová Z, Karovičová J, Jurasová M. Influence of carrot pomace powder on the rheological characteristics of wheat dough and on wheat rolls quality. Acta Sci Pol Technol Aliment. 2012;11:381–387. [Google Scholar]

- Lim H, Park S, Ghafoor K, Hwang S, Park J. Quality and antioxidant properties of bread containing turmeric (Curcuma longa L.) cultivated in South Korea. Food Chem. 2011;124:1577–1582. doi: 10.1016/j.foodchem.2010.08.016. [DOI] [Google Scholar]

- Messia M, Reale A, Maiuro L, Candigliota T, Sorrentino E, Marconi E. Effects of pre-fermented wheat bran on dough and bread characteristics. J Cereal Sci. 2016;69:138–144. doi: 10.1016/j.jcs.2016.03.004. [DOI] [Google Scholar]

- Mohammed I, Ahmed A, Senge B. Dough rheology and bread quality of wheat-chikpea flour blends. Ind Crop Prod. 2012;36:196–202. doi: 10.1016/j.indcrop.2011.09.006. [DOI] [Google Scholar]

- Morris C, Morris G. The effect of inulin and fructo-oligosaccharides supplementation on the textural, rheological and sensory properties of bread and their role in weight management: a review. Food Chem. 2012;133:237–248. doi: 10.1016/j.foodchem.2012.01.027. [DOI] [PubMed] [Google Scholar]

- Pasrija D, Ezhilarasi P, Indrani D, Anandharamakrishnan C. Microencapsulation of green tea polyphenols and its effect on incorporated bread quality. LWT Food Sci Technol. 2015;64:289–296. doi: 10.1016/j.lwt.2015.05.054. [DOI] [Google Scholar]

- Petkova N, Ivanov I, Denev P, Pavlov A. Bioactive substance and free radical scavenging activities of flour from Jerusalem artichoke (Helianthus tuberosus L.) tubers—a comparative study. Turk J Agric Nat Sci. 2014;2:1773–1778. [Google Scholar]

- Prokopov T, Slavov A, Petkova N, Yanakieva V, Bozadzhiev B, Taneva D. Study of onion processing waste powder for potential use in food sector. Acta Aliment. 2018;47:181–188. doi: 10.1556/066.2018.47.2.6. [DOI] [Google Scholar]

- Rouille J, Della-Valle G, Devaux MF, Marion D, Dubreil L. French bread loaf volume variations and digital image analysis of crumb grain changes induced by the minor components of wheat flour. Cereal Chem. 2005;82:20–27. doi: 10.1094/cc-82-0020. [DOI] [Google Scholar]

- Stintzing F, Nerbach K, Mosshammer M, Carle R, Yi W, Sellappan S, Acoh C, Bunch R, Felker P. Color, betalain pattern and antioxidant properties of cactus pear (Opuntia spp.) clones. J Agric Food Chem. 2005;53:442–451. doi: 10.1021/jf048751y. [DOI] [PubMed] [Google Scholar]

- Świeca M, Gawlik-Dziki U, Dziki D, Baraniak B, Czyż J. The influence of protein–flavonoid interactions on protein digestibility in vitro and the antioxidant quality of breads enriched with onion skin. Food Chem. 2013;141:451–458. doi: 10.1016/j.foodchem.2013.03.048. [DOI] [PubMed] [Google Scholar]

- Świeca M, Sęczyk Ł, Gawlik-Dziki U, Dziki D. Bread enriched with quinoa leaves—the influence of protein-phenolics interactions on the nutritional and antioxidant quality. Food Chem. 2014;162:54–62. doi: 10.1016/j.foodchem.2014.04.044. [DOI] [PubMed] [Google Scholar]

- Vasileva I, Denkova R, Chochkov R, Teneva D, Denkova Z, Dessev T, Denev P, Slavov A. Effect of lavender (Lavandula angustifolia) and melissa (Melissa Officinalis) waste on quality and shelf life of bread. Food Chem. 2018;253:13–21. doi: 10.1016/j.foodchem.2018.01.131. [DOI] [PubMed] [Google Scholar]

- Vasudevaiah A, Chaturvedi A, Kulathooran R, Dasppa I. Effect of green coffee extract on rheological, physico-sensory and antioxidant properties of bread. J Food Sci Technol. 2017;54:1827–1836. doi: 10.1007/s13197-017-2613-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang J, Rosell CM, de Barber CB. Effect of the addition of different fibres on wheat dough performance and bread quality. Food Chem. 2002;79:221–226. doi: 10.1016/s0308-8146(02)00135-8. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.