Abstract

The passion fruit powder blended rice flour based extrudate was developed and investigated in terms of physicochemical and phytochemical properties. The extrusion process was performed using a twin screw extruder and optimized using rotatable central composite design followed by response surface methodology. The effect of process parameters such as temperature (80–150 °C), screw speed (200–400 rpm), moisture content (20–30%) and passion fruit powder (0–15%) on product quality was investigated. The optimum extrusion conditions of temperature, screw speed, feed moisture content, and passion fruit powder were 97.50 °C, 250 rpm, 25.20% and 11.25%, respectively. At optimum condition, the predicted values of responses were expansion ratio 8.05, water absorption index 2.77, total phenolic content 129.492 mg GAE/100 g and DPPH scavenging activity 65.79%. A comparison between optimized and control extrudates revealed that thermal, crystallinity and morphological properties of extrudates differed significantly. The comparison was also conducted in terms of FT-IR, SEM–EDS and HPLC analysis. The phytochemical properties showed that β-carotene, cyanidin-3-glucoside, peonidin-3-D-glucoside chloride were higher in control whereas the optimized sample evinced more (±)-α-tocopherol and D-α-tocopherol.

Electronic supplementary material

The online version of this article (10.1007/s13197-018-3439-9) contains supplementary material, which is available to authorized users.

Keywords: Red rice, Purple passion fruit, Phytochemical, Extrusion, Morphology

Introduction

Rice is the second largest produced cereal worldwide (Muthayya et al. 2014) and is the main source of carbohydrate and a minor source of protein, vitamins, and minerals. However, epidemiological studies have shown that whole rice grains contain a high amount of fiber and phytochemicals viz., tocopherols, tocotrienols, oryzanols, vitamin B complex and other phenolic compounds. In addition to that, pigmented red rice contains anthocyanin and phenolic acids in substantial amount (Samyor et al. 2016).

In recent past, a considerable approaches have been taken on conversion of fruit into useful products with high shelf life. The reasons behind this, fruits are mostly perishable and increasing disposal and loss of valuable substances, e.g., dietary fiber, lycopene, antioxidants and many other valuable substances. Few studies on fruit-based food product with long shelf life are viz, extruded orange pomace (Huang and Ma 2016), apple spray dried powder, banana spray dried powder, strawberry spray dried powder (Potter et al. 2013), bilberry based food (Hirth et al. 2014). Most of the attempts were made to develop a snack or breakfast cereal. Purple passion fruit is well known for its nutritional benefits and medicinal properties. Its rind has the anti-hypertensive and vasodilatory effect on human body (Ramaiya et al. 2013). The passion fruit from North-East India has not been at all explored to develop a snack or breakfast cereal.

Extrusion cooking is one of the most widely used techniques for the production of snack, breakfast cereals and texturized vegetable protein (Lobato et al. 2011). Extrusion is a continuous cooking and shaping process used in the food induction. Extrusion technology integrates various factors viz, temperature, moisture, shearing, and mixing, to produce fruit-based snacks or breakfast cereal foods. Therefore, to get a desired quality extruded product, it is essentially imperative to optimize the process for extrusion cooking. Response surface methodology (RSM) is a widely used tool for optimization of a design process and efficient mathematical and statistical techniques for analysis of empirical models which could describe the effect of independent variables and their interactions on responses (Sharma et al. 2016). The effect of extrusion cooking on physicochemical and phytochemicals properties in terms of total phenolic content, phenolic acids, anthocyanin and antioxidant activity of passion fruit powder incorporated red rice based extrudates is not well established. Moreover, there is scanty of literature on the extrudate product from red rice with passion fruit powder and justifies the need of extensive research on physicochemical and phytochemical properties of the extrudate from passion fruit powder incorporated red rice. In the present study, the extrusion processing of passion fruit powder incorporated red rice was optimized using RCCD and its effect on the phytochemical properties e.g. total phenolic content, phenolic acids, anthocyanin and antioxidant activity was also investigated. In addition, the thermal, crystallinity and morphological properties of extrudates were also characterized.

Materials and methods

Raw material

Red rice was collected from the Manigong Subdivision of West Siang district, Arunachal Pradesh (India) and milled into flour and kept in an airtight container for further use. Ripened passion fruit (Passiflora edulis) was also collected from the Singchung Circle of West Kameng district, Arunachal Pradesh (India). Passion fruit pulp was obtained by squeezing the fruit, and the pulp was made into powder using foam mat drying. RCCD was used to obtain the optimized conditions for foam mat drying viz., whipping time 2.78 min, methyl cellulose 2.58%, and temperature 44.05 °C and responses viz, vitamin C (34.67 mg/100 g), total phenolic compound (258.12 mg GAE/100 g) and hygroscopicity (21.12%). Foamed samples were monitored every 30 min for moisture loss by weighing the sample plates using an electronic balance with an accuracy of ± 0.01 g and drying was terminated when the final moisture content reached 6.5% (db) (Rajkumar et al. 2007).

Chemicals

All the phenolic acids (viz., ferulic, sinapic, syringic, hydroxybenzoic, p-coumaric, vanillic, caffeic, catechin, chlorogenic acid) and amberlite XAD7 N resin, (±)-α-tocopherol, D-α-tocotrienol and β-carotene were purchased from Sigma-Aldrich (St. Louis, MO, USA).

Extrusion experiments

Extrusion experiments for the production of ready to eat (RTE) product from red rice and passion fruit powder were carried by twin extruder with 28 mm screw diameter and 18 L/D ratio with a co-rotating screw (Model FUE-1F, Flytech Engineering, Chennai, India) (Fig. 1S). During extrusion process, the temperature near the die section (zone 3, zone 4 and die) was varied according to the experimental condition and temperature of the remaining section was constant. It was done following RCCD (Design-Expert software version 7.0, USA) which gave 30 experimental runs and red rice flour (100 g) was kept as the base material. The independent variables were temperature (80–150°), screw speed (200–400 rpm), feed moisture content (20–30%) and amount of passion fruit powder (0–15%) (Table 1) and dependent variables were expansion ratio (ER) (%), water absorption index (WAI), total phenolic acid (TPC) and 2, 2′-diphenyl-1-picrylhydrazyl (DPPH). Following blending, samples were kept in a LDPE zipper pouch to attain equilibrium. The feed rate was maintained constant at 17 kg/h using a volumetric gravity feeder. The experimental data was analyzed and fitted to a second order polynomial equation as follows,

| 1 |

where, y is the predicted response and coefficient of the polynomial equation were (constant), (linear effects), (quadratic effects) and (interaction effects). Xi and Xj are the coded levels of independent variables i and j in the equation given.

Table 1.

Independent variable values of the extrusion process and their corresponding level

| Variables | Coded value | Level | ||||

|---|---|---|---|---|---|---|

| − α (1.682) | − 1 | 0 | 1 | + α (+ 1.682) | ||

| Temperature (°C) | 80 | 97.5 | 115 | 132.5 | 150 | |

| Screw speed (rpm) | 200 | 250 | 300 | 350 | 400 | |

| Feed moisture (%) | 20 | 22.5 | 25 | 27.5 | 30 | |

| Passion fruit powder (%) | 0 | 3.75 | 7.5 | 11.25 | 15 | |

Analysis

Expansion ratio

Expansion ratio (ER) of the extrudates was determined according to Ding et al. (2006). Vernier caliper was used to measure the cross-sectional diameter of the extrudates.

Water absorption index

Water absorption index (WAI) was determined using the method described by Anderson et al. (1969). Briefly, 2 g of the ground extrudates was dispersed in 25 mL distilled water in a centrifuge tube and sample was kept in a water bath for 30 min at 30 °C and later centrifuged at 3000 g for 10 min. WAI was calculated as the ratio of the mass of the precipitate to the mass of the original sample dry weight.

Total phenolic content

Determination of total phenolic content of ground extrudate was carried out by Folin–Ciocalteu assay (Slinkard and Singleton 1977). Initially, 20 μL of extract was taken, and 1.58 mL of distilled water was added to each of the test tube followed by 100 μL of Folin–Ciocalteu reagent was mixed, and within 8 min, 300 μL of sodium carbonate was added. It was vortexed immediately and incubated in the dark for 30 min at 40 °C. The absorbance was measured at 765 nm in a UV–VIS spectrophotometer (Spectrascan UV-2600, Thermo Fisher Scientific, Nasik, India) and the phenolic content was expressed in mg GAE/100 g.

2, 2′-diphenyl-1-picrylhydrazyl (DPPH) radical scavenging activity

DPPH radical scavenging ability of the extrudates was measured as described by Brand-William et al. (1995).

Fourier transform infrared spectroscopy (FT-IR) analysis

Fourier transform infrared spectroscopy (FT-IR, Nicolet impact 410, Thermoscientific, UK) analysis was carried out to detect functional group present in extruded red rice with passion fruit powder and compared with extruded red rice products. Samples were ground into powder (2 mg) and thoroughly mixed with 50 mg desiccated KBr in a mortar and pestle and then with the help of the hydraulic press the pellets were prepared. The range of scan wavenumbers was from 4000 to 400 cm−1 (Dutta and Mahanta 2012).

Differential scanning calorimetry (DSC) analysis

Thermal analysis of red rice and extruded red rice with passion fruit powder was carried out by differential scanning calorimeter (DSC-60 SHIMADZU, instrument, TA-60WS, Japan). Sample weighing 5 mg was taken for analysis and heating was carried out from 30 to 350 °C at the rate of 10 °C/min. The sample was placed in the silver cup, covered with the silver lid, and sealed very carefully. Another empty cup was used after sealing as reference (air). Software (TA-60WS) was used to analyze Tc (endset temperature), To (onset temperature) and Tp (peak temperature) of the samples.

X-ray diffraction

The X-ray diffraction analysis was carried out for three rice flour samples using an X-ray diffractometer (D8 Focus, Bruker AXS, Germany) with acceleration potential of 35 kV at 25 mA current. The scans adjusted for Bragg angle were in the range of 7–80° on a 2θ scale with a step-size of 0.05 and for data analysis XRD Commander and Diffrac EVA was used. The total area under the curve and the area under each prominent peak were determined using OriginPro 8.0 software, and calculated the percentage crystallinity by using the formula:

| 2 |

Scanning electron microscopy-energy dispersive X-ray analysis (SEM–EDX)

SEM–EDX of samples (1 mg) was carried out to obtain elemental detail by using SEM-Energy Dispersive X-ray absorption spectroscopy (EDX) (make INCA X sight, model 7582, Oxford Instrument) to record the EDX spectra.

Morphological structure analysis

After completion of extrusion processing, samples were investigated for morphological structure by using SEM (JEOL JSM-6390LV, SEM, Oxford). Samples were placed carefully in a metal stud with double-sided tape, using a sputter gold coater. Morphological structure of extrudates was observed at three magnifications viz., 100X, 2500X and 10000X with accelerating voltage of 10 kV.

Phytochemical profiling

The phytochemical profiling of red rice and red rice incorporated with passion fruit extrudates was carried out in terms of (±)-α-tocopherol, D-α-tocotrienol, β- carotene, cyanidin-3-glucoside (C-3-G) and peonidin-3-d-glucoside (P-3-G) in RP-HPLC (Waters Corporation, USA) with UV/Vis Detector.

Determination of (±)-α-tocopherol, D-α-tocotrienol and β-carotene

The (±)-α-tocopherol, D-α-tocotrienol, and β-carotene of extrudates were determined according to the modified method of Aguilar-Garcia et al. (2007). Samples (100 mg) were extracted twice with 6 mL of methanol and centrifuged for 10 min at 825 g. The supernatant was collected and evaporated to 4 mL and then made up to 5.0 mL with HPLC grade methanol in a volumetric flask. This solution was filtered properly through a 0.45 μm syringe filter before injecting in HPLC at 25 °C. The C18 column with 5.0 µm (4.6 mm x 250 mm) was used, and UV/Vis detector was set at two wavelengths viz., 292 and 325 nm. Solvents for mobile phase were a mixture of methanol and acetonitrile (15:85 v/v) and maintained a constant flow rate of 1 mL/min with isocratic mode and the data was analyzed using the EMPOWER-2 software.

Determination of cyanidin-3-glucoside (C-3-G) and peonidin-3-d-glucoside (P-3-G)

Samples (3 g) were weighed and extracted with 70% ethanol. Purification of anthocyanin compound was done using activated amberlite XAD7 N resin as described by Fu et al. (2007) with slight modification. The purified sample was filtered through 0.45 μm syringe filter before injecting to HPLC. The HPLC pumps (LC-10AT, Shimadzu) and column were connected with a dual wavelength UV/VIS detector (SPD-10A, Shimadzu) for analysis. HPLC analysis was carried out (25 °C) with C18 column (4.6 mm x 250 mm) at 530 nm. The solvents mixture used was water, methanol and formic acid (75:20:5 v/v) as a mobile phase with isocratic elution at 0.5 mL/min flow rate.

Statistical analysis

Statistical analysis was conducted using a Design-Expert version 7.00 (Stat-Ease Inc., Minneapolis, USA) and significance of the dependent and independent terms was analyzed by analysis of variance (ANOVA) for each response.

Results and discussion

Model fitting

The ANOVA of the experimental data (Table 2) shows the F and p values of linear, quadratic and interaction terms. It was observed that the independent parameters viz, temperature, screw speed, feed moisture content and the amount of passion fruit powder had significant (p ≤ 0.05) effect on dependent parameters. The R2 values for ER (%), WAI (%), TPC and DPPH scavenging activity were 0.90, 0.88, 0.84 and 0.87, respectively and implied that the second order quadratic model is most suitable, and the developed model could efficiently depict the relationship between dependent and independent parameters.

Table 2.

Analysis of variance (ANOVA) for the fitted quadratic polynomial model

| Source | Degree freedom | ER | WAI | TPC | DPPH | ||||

|---|---|---|---|---|---|---|---|---|---|

| F value | p value | F value | p value | F value | p value | F value | p value | ||

| Model | 14 | 10.79 | 0.0002 | 8.00 | 0.0001 | 5.99 | 0.0001 | 7.78 | 0.0002 |

| 1 | 115.79 | < 0.0001 | 5.55 | 0.0325 | 8.19 | 0.0119 | 71.95 | < 0.0001 | |

| 1 | 4.64 | 0.1026 | 40.14 | < 0.0001 | 4.74 | 0.0459 | 5.01 | 0.0407 | |

| 1 | 0.44 | 0.0044 | 42.59 | < 0.0001 | 2.90 | 0.1092 | 2.05 | 0.1732 | |

| 1 | 0.68 | 0.8284 | 0. 047 | 0.8305 | 5.56 | 0.0323 | 7.69 | 0.0142 | |

| 1 | 1.75 | 0.1716 | 0.36 | 0.5571 | 0.31 | 0.5835 | 4.48 | 0.0515 | |

| 1 | 0.016 | 0.8948 | 0.79 | 0.3893 | 0.51 | 0.4880 | 2.12 | 0.1658 | |

| 1 | 1.40 | 0.6762 | 0.18 | 0.6746 | 1.46 | 0.2454 | 0.033 | 0.8588 | |

| 1 | 0.30 | 0.7348 | 0.93 | 0.3504 | 1.25 | 0.2816 | 0.58 | 0.4585 | |

| 1 | 0.45 | 0.9956 | 0. 31 | 0.5885 | 13.26 | 0.0024 | 0.43 | 0.5198 | |

| 1 | 3.28 | 0.3671 | 0. 57 | 0.4627 | 4.18 | 0.0588 | 9.581E−003 | 0.9233 | |

| 1 | 6.70 | 0.0218 | 0.12 | 0.7302 | 17.40 | 0.0008 | 12.31 | 0.0032 | |

| 1 | 0.74 | 0.5321 | 0.43 | 0.5197 | 20.08 | 0.0004 | 1.24 | 0.2996 | |

| 1 | 2.00 | 0.2928 | 11.37 | 0.0042 | 7.26 | 0.0167 | 4.53 | 0.0425 | |

| 1 | 6.09 | 0.1735 | 3.77 | 0.0712 | 14.60 | 0.0017 | 0.37 | 0.2507 | |

| Lack of fit | 10 | 2.01 | 0.2283 | 01.39 | 0.3758 | 1.99 | 0.2318 | 3.07 | 0.1136 |

| R 2 | 0.90 | 0.88 | 0.84 | 0.87 | |||||

| Adjusted R 2 | 0.86 | 0.84 | 0.79 | 0.86 | |||||

Response surface analysis of expansion ratio

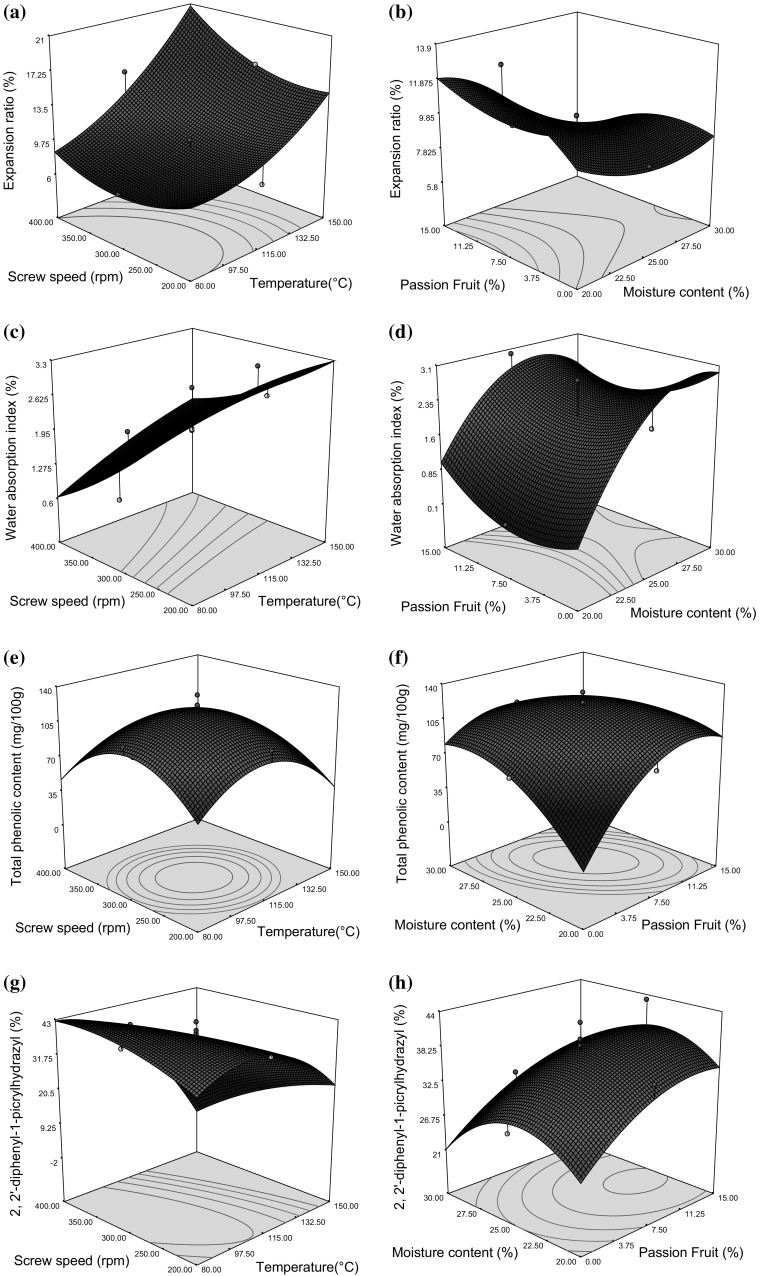

The ER of the extruded product was significantly affected by the independent parameters of extrusion cooking. The R2 value (0.90) of Eq. (3) was quite high (Table 2) which implied that the developed equation could efficiently represent the relationship of ER and independent parameters. The Fig. 1a, illustrated the relationship among screw speed (rpm), temperature (°C) and moisture content (%) on the ER of extrudates.

| 3 |

Fig. 1.

Response surface graphs for effect of screw speed (rpm), temperature (°C) and moisture content (%) on (a, b) expansion ratio (%); (c, d) water absorption index (%); (e, f) total phenolic content (mg/100 g); (g, h) 2, 2′-diphenyl-1-picrylhydrazyl (%)

The increase of screw speed caused a slight decrease in ER till it attained 300 rpm, however, with further increase a marginal increase was noted (Fig. 1a). For the increase in barrel temperature, ER of the product increased significantly (Fig. 1a). With increase of temperature from 80 to 150 °C, proportional increase in the ER was also observed from 0 to 20% and similar types of results were reported by Ding et al. (2006). They suggested that an increase in the barrel temperature might increase the degree of superheating of water in the extruder that enhances the bubble formation in finished product and thereby increased in ER. The effects of moisture content on the ER of the extruded product have been presented in Fig. 1b. As the moisture content of the extrudate increased from 20 to 30%, there was decrease in the ER. A similar type of observation was reported during the development of wheat-based expanded snacks and corn-broad beans spaghetti type pasta (Giménez et al. 2013). It might be attributed to the increased feed moisture content during extrusion which could reduce the elasticity of the dough through plasticization of the melt, and resulted in reduced bubble formation and considered as the driving force for the expansion. In food processing industries, higher ER properties of products are desirable which are again dependent on feed moisture of products, extrusion temperature, die diameter, feed rate and screw speed (Ali et al. 1996). The effect of passion fruit powder on the ER of the extruded product was observed (Fig. 1b) and with the increase of passion fruit powder (0–15%) in the dough, there was an increase in ER of the extrudate.

Response surface analysis of water absorption index

After multiple regression analysis of WAI of the finished product and experimental data of independent variables, a second order polynomial equation (Eq. 4) with good R2 (0.88) was predicted. The lack of fit of the developed model was also insignificant (Table 2), which implied that the developed model could efficiently explain the relationship of WAI and independent parameters.

| 4 |

The effects of screw speed and barrel temperature on the WAI are presented in Fig. 1c and could be inferred that the increase of screw speed (200–400 rpm) led to a sharp decrease in the WAI, whereas increased temperature (80–150 °C) showed an abrupt increase in the WAI (0.9–4.3). The results are in line with several workers who reported the extrusion of legumes (Oikonomou and Krokida 2012) and rice (Alam et al. 2016). At higher screw speed the length of polymeric chain reduced due to shear and hence the WAI of extrudate decreased. The results are in agreement with the observation reported by Alam et al. (2016). Various researchers have reported the phenomenon of starch granule disruption in high-temperature processing and thereby increased dextrinization, which enhanced the water binding capacity of the finished product and hence increased WAI (Kaur et al. 2015) and are in agreement with Kumar et al. (2010) during extrusion of carrot pomace and rice flour.

Figure 1d illustrated the effect of feed moisture content and showed an increase in WAI up to the moisture content of 25% and its further increase showed a slight decrease of it. Previously, various researchers reported that in higher feed moisture content, viscosity of starch in the flour might decrease and allows the starch molecules to move freely and thereby enhanced the penetration of heat and resulted in greater gelatinization and increase in WAI of the finished product (Singh et al. 2007; Chakraborty et al. 2011). WAI decreased with increase in moisture content, which might be attributed to the reduction of elasticity of dough through plasticization of the melt at higher moisture content (Ding et al. 2006). Even though there was marginal decrease in WAI at 7.5% passion fruit powder but later on it increased with increase in powder (Fig. 1f). The results indicated that the presence of more passion fruit powder in the mixture reduced the availability for gelatinization of the starch granules, and thus reduced viscosity and WAI which could be attributed to the replacement of the starch by fiber component.

Response surface analysis of total phenolic content

The effect of extrusion parameters on the TPC of the extruded product was mathematically expressed using the following Eq. (5). It was observed that the R2 (0.84) of TPC for the product was good and lack of fit was insignificant which implied that the developed second-degree polynomial equation could efficiently be used to predict the relationship (Table 2).

| 5 |

The effect of process variables viz, screw speed (rpm) and temperature (°C) on TPC (mg/100 g) (Fig. 1e) increased until 300 rpm of screw speed, but later on it decreased with increasing screw speed. The increase in phenolic content in the finished product might be attributed to the release of the bound phenolics from the rice at high screw speed for the breakdown of endosperm (Gujral et al. 2012). Further increase in screw speed during extrusion showed a decreasing pattern of TPC content in the finished product. The decrease in TPC might be due to the disintegration of phenolic compounds at high shearing during extrusion or to the change in the molecular arrangement of phenolic compounds. Temperature variable also showed the same pattern with screw speed and with the increase in temperature from 80 to 150 °C, the TPC also increased till 110 °C, later it decreased with the increasing temperature (Fig. 1f). The increase in TPC during extrusion could be due to the damage of cell structures and facilitate the release of bioactive compounds from the matrix, thus enhanced the extractability of bound phenolics in the materials. The decrease in the phenolic content after 110 °C might be due to its heat labile nature and lesser resistant to thermal processing. Owing to increase in temperature, decomposition or alteration of the molecular structure of phenolic compounds took place and led to a reduced chemical reactivity due to a certain degree of polymerization in the sample (Brennan et al. 2011). In the Fig. 1h, TPC increased with the increase in moisture content (20–25%), and later it showed a negligible decrease when moisture content further increased up to 30% and the results are in line with Dlamini et al. (2007). The higher moisture content probably upgraded phenolic and tannin polymerization, which affected extractability of polyphenols viz, phenols and tannins, and degraded antioxidant activity. In the Fig. 1i, the TPC showed an increasing pattern in the finished product, however, beyond 7.5% increase in passion fruit powder the TPC content remained constant. The increase in the TPC amount might be attributed to the high phytochemical content of passion fruit and extrusion possibly helped to release from the cell which caused an increase in the TPC.

Response surface analysis of DPPH scavenging activity

The second order polynomial relationship between DPPH scavenging activity and independent parameters is presented in Eq. (6). The R2 value (0.87) was fairly good and the lack of fit of the model was insignificant which implied that the developed model (Eq. 6) can efficiently depict the relationship (Table 2).

| 6 |

Screw speed showed a significant effect on DPPH scavenging activity, and with the increase of screw speed from 200 to 300 rpm, the activity also increased (Fig. 1g) and it decreased with further increase in screw speed. The DPPH scavenging activity is directly dependent on the TPC of the sample. Change in TPC content due to screw speed in the extrudate product proportionately changed the DPPH scavenging activity. As the temperature increased from 80 to 110 °C, DPPH scavenging activity increased, and beyond that, a decrease pattern in scavenging activity was observed till 150 °C (Fig. 1g). A similar type of observation was also reported by Sharma et al. (2012). The increase in scavenging activity might be due to the increase in TPC in the product for the lysis of cell structure or Maillard reaction. The decrease in scavenging activity could be attributed to the decrease in TPC during higher temperature extrusion (Brennan et al. 2011). Moisture content showed a significant effect on the DPPH content, and when it increased from 20 to 30%, DPPH scavenging activity also increased which was similar to the behavior of TPC in the product. Passion fruit powder gave a significant effect on DPPH content, and an increase from 0 to 7.5%, the DPPH content increased and beyond that, there was a slight decrease in scavenging activity (Fig. 1h). This observation was quite similar as observed in TPC in the product.

Optimization and validation

After the response surface analysis, the extrusion process was optimized by using the developed equations (Eqs. 3, 4, 5 and 6) and the process was optimized in terms of maximum desirability value. The highest desirability value was 0.906, and the extrusion conditions were temperature 97.50 °C, screw speed 250 rpm, feed moisture content 25.20% and passion fruit powder 11.25%. At optimum condition, the predicted values of responses of ER, WAI, TPC and DPPH scavenging activity were 8.05, 2.77, 129.492 mg GAE/100 g and 65.79%, respectively. After optimization, the responses were validated, and during validation, the experiment was conducted at the optimized condition and observed experimental values of ER (7.08%), WAI (2.18), TPC (130.10 mg GAE/100 g) and DPPH scavenging activity (63.01%) did not differ significantly.

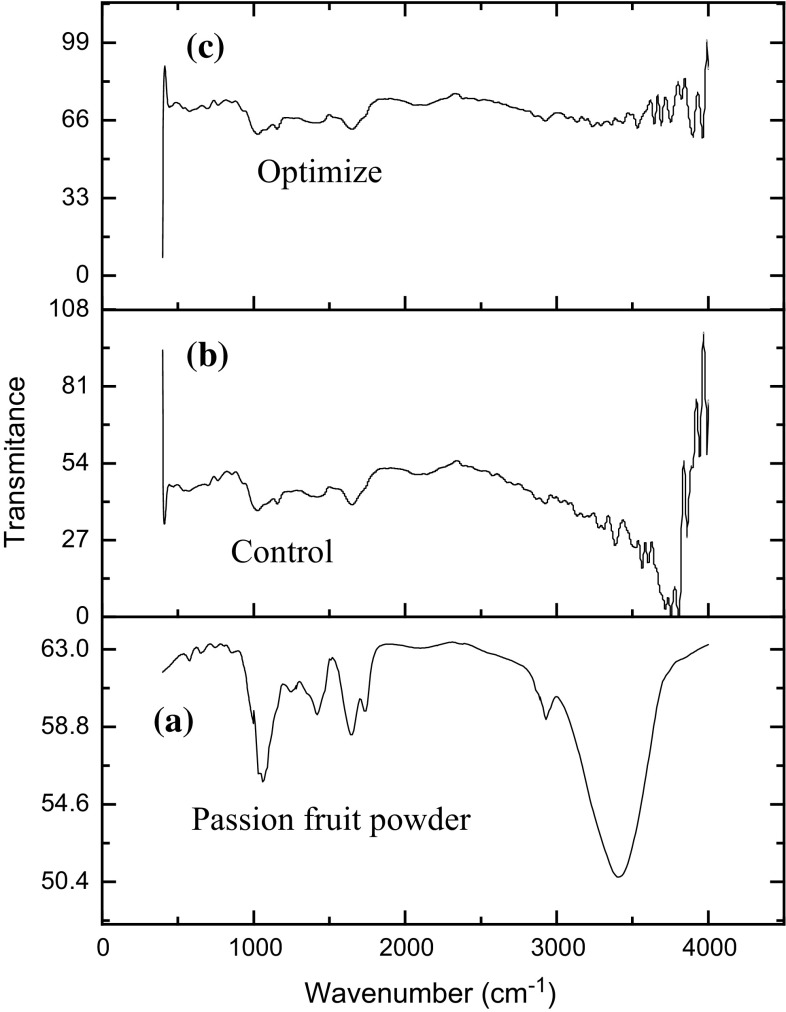

FT-IR analysis

The FT-IR spectrum of the optimized sample (Fig. 2) was compared with the control and passion fruit powder. The figure shows various peaks at different wavelengths which ranged from 503.70 to 3821.87 cm−1 and revealed major functional groups. The band peaks found approximately in the region of 826.60 cm−1 indicated α-glycosidic linkages of the glycosyl residues (Tsumuraya and Misaki 1979) which confirmed the samples were of carbohydrate in nature. The frequency of the vibration at 1498 cm−1 corresponded to COOH group. There were numbers of sharp peaks in between 3350 and 3821.87 cm−1 in both the samples. Various researchers have suggested that these broad bands observed from 3610–3640 to 3200–3500 cm−1 could be attributed to –OH stretching vibrations and hence, indicated the presence of phenolic OH. The products showed that even after applying the extrusion technology, the wavelengths predicted the presence of various functional groups in both the samples.

Fig. 2.

FTIR graph of control and optimized extrudates

Thermal properties

The thermal properties of the optimized product were analyzed using DSC, and its thermograph showed an endothermic behavior of the extruded product. The endothermic behavior indicates the heat absorbed characteristic of extrudate with larger crystallinity not only for the water release, but also during the melting of parts of the crystalline granule regions. The onset (61.31 °C) and peak temperatures (62.81 °C) of the control were higher than the onset (45.77 °C) and peak temperatures (50.53 °C) of the optimized sample (Fig. 2S). However, end set temperature (84.43 °C) of the optimized sample showed higher range than control (65.55 °C). The enthalpy of gelatinization of control and optimized sample was 2.75 and 2.42 J/g, respectively. The range of gelatinization for optimized sample (45.77–84.43 °C) was higher than control (61.31–65.55 °C) and could be attributed to the presence of passion fruit powder. In our previous study (Samyor et al. 2016) it was reported that the red rice has onset (To), peak (Tp) and endset (Tc) temperatures which varied significantly when compared with extrudates samples. Raw rice flour showed higher thermal properties than processed extruded products. Kaur et al. (2016) reported that this type of phenomena in cereal flour might be attributed to the extrusion technology that helps the starch to become pre-gelatinized. Loss of birefringence was also observed which indicated the disorder of the starch molecules. Therefore, extruded products flour attained gelatinization temperature at a lower temperature as compared to the raw cereal flours.

X-ray diffraction

XRD pattern provides “fingerprint” information of the crystal structure within starch of grains (Zeng et al. 2011). The analysis of the control sample revealed strong peaks at 15, 17, 18.2, 20.05 and 23.30 (Fig. 3S). According to various researchers, strong peaks obtained at 15, 18 and 23 confirmed the presence of A-type and are the characteristics of starch present in cereals (Taylor et al. 1961). Weak peaks were also observed at 14.95 and 20.05. Moorthy (2002) reported that peak at 2 = 15 and 23.5 shows a mixed pattern and at 18 possesses C-type pattern (Zobel 1988). For the optimized sample, the strong peaks were observed at 13, 18.1, and 19.75, which are the characteristic peaks for V-type crystallinity. The changes of A-type crystals in the raw material to V-type crystals in the optimized product might be due to the formation of amylose–lipid and amylose-phytochemical complex compounds. However, a weak peak was observed at 17.1 which is typical of the A-type starch crystalline structure (Gat and Ananthanarayan 2015). The % crystallinity of control and optimized extruded product was 17.04% and 17.84%, respectively. The observations were supported by Gat and Ananthanarayan (2015), and they also revealed that degree of crystallinity decreased due to increase in heat moisture treatment (80–120 °C). Moreover, the other extrusion parameter such as screw speed, feed rate, moisture content also affected the crystallinity (Escalante-Aburto et al. 2016).

SEM–EDX analysis

EDX is a micro-analytical technique, used with SEM for the local determination of elements in samples. SEM–EDX was used to determine mineral distribution in cereal grains (Buttrose 1978). The aim of the EDX analysis in the present study was to identify the effect of passion fruit powder on the mineral profile of the extrudate product. The results of control and optimized extrudate products showed that both the samples contained six elements viz, C, O, P, K, Mg and Fe.

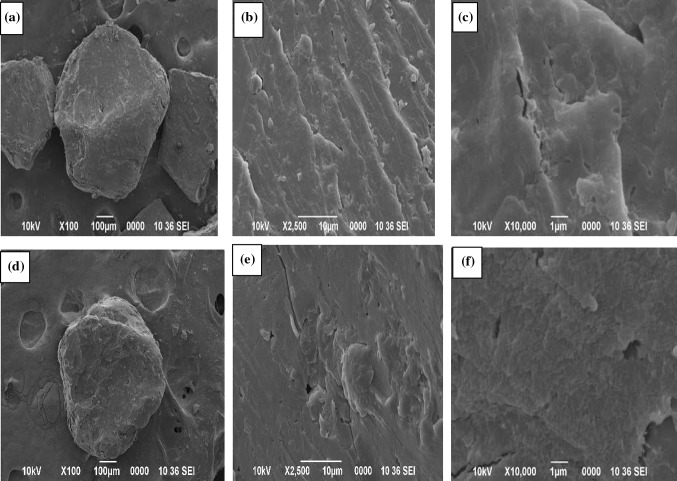

Morphological analysis

SEM images of the surface and cross sections of two extrudate products at three magnifications viz, 100X, 2500X and 10000X (Fig. 3) revealed that control had a smoother surface than the optimized sample. The internal structures of the product were affected by the addition of passion fruit powder and the control exhibited a continuous structure that appeared smoother and aggregated. Marked changes were observed by incorporating passion fruit powder where surface became scratched, cracked, and irregular. The optimized extruded product had large numbers of flattened and sheared granules than the control product.

Fig. 3.

SEM of control (a, b, and c) and optimized (d, e, f) samples at 100, 2500, and 10000X

Phytochemical profile

The phytochemical properties of control and optimized samples were analyzed by quantification of compounds viz, vitamins and anthocyanin (Table 3). In control, the β-carotene (1333.1 µg/L) content was more than the optimized sample whereas, the (±)-α-tocopherol (9571.40 µg/L) and D-α-tocopherol (9036.90 µg/L) content were higher in the optimized sample than the control. Anthocyanins viz, cyanidin-3-glucoside (C-3-G) and peonidin-3-D-glucoside (P-3-G) content in control were also higher than the optimized sample. It might be attributed to the addition of passion fruit powder which could be a source of anthocyanin (Kidøy et al. 1997).

Table 3.

Quantification of vitamins and anthocyanin of control and optimized extruded product

| Compounds (µg/L) | Retention time (min) | Control | Optimized |

|---|---|---|---|

| Vitamins | |||

| β-Carotene | 3.00 | 1333.10 | 1310.90 |

| (±)-α-Tocopherol | 3.50 | 3998.10 | 9571.40 |

| D-α-Tocopherol | 3.80 | 3996.90 | 9036.90 |

| Anthocyanin | |||

| Cyanidin-3-glucoside (C-3-G) | 11.00 | 0.03 | 0.003 |

| Peonidin-3-D-glucoside (P-3-G) | 13.00 | 9.93 | 5.46 |

Conclusion

Extrusion cooking of passion fruit powder incorporated with rice-based material was optimized successfully using RCCD. Results revealed that the incorporation of passion fruit powders significantly affected the physical and phytochemical properties of extrudates. The optimal extrusion process condition was found to be temperature 97.50 °C, screw speed 250 rpm, feed moisture content 25.20% and passion fruit powder 11.25%. The thermal and morphological properties of the product revealed that the incorporation of passion fruit powder significantly affected the properties. Phytochemical studies by RP-HPLC in both the samples evinced that β-carotene (1333.1 µg/L) was higher in control but (±)-α-tocopherol and D-α-tocopherol content was higher in the optimized sample. Results of the present investigation have the high credentials to support the various physicochemical and phytochemical properties of extrudate product that differed significantly in comparison to control.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

The authors would like to thank the Ministry of Food Processing Industries, Govt. of India, New Delhi for financial assistantship.

References

- Aguilar-Garcia C, Gavino G, Baragano-Mosqueda M, Hevia P, Gavino VC. Correlation of tocopherol, tocotrienol, γ-oryzanol and total polyphenol content in rice bran with different antioxidant capacity assays. Food Chem. 2007;102:1228–1232. doi: 10.1016/j.foodchem.2006.07.012. [DOI] [Google Scholar]

- Alam MS, Pathania S, Sharma A. Optimization of the extrusion process for development of high fibre soybean-rice ready-to-eat snacks using carrot pomace and cauliflower trimmings. LWT Food Sci Technol. 2016;74:135–144. doi: 10.1016/j.lwt.2016.07.031. [DOI] [Google Scholar]

- Ali Y, Hanna MA, Chinnaswamy R. Expansion characteristics of extruded corn grits. LWT Food Sci Technol. 1996;29:702–707. doi: 10.1006/fstl.1996.0109. [DOI] [Google Scholar]

- Anderson RA, Conway HF, Griffin EL. Gelatinization of corn grits by roll and extrusion cooking. Cereal Sci Today. 1969;1:4–12. [Google Scholar]

- Brand-William W, Cuvelier ME, Berset C. Use of a free radical method to evaluate antioxidant activity. LWT Food Sci Technol. 1995;28:25–30. doi: 10.1016/S0023-6438(95)80008-5. [DOI] [Google Scholar]

- Brennan C, Brennan M, Derbyshire E, Tiwari BK. Effects of extrusion on the polyphenols, vitamins and antioxidant activity of foods. Trends Food Sci Technol. 2011;22(10):570–575. doi: 10.1016/j.tifs.2011.05.007. [DOI] [Google Scholar]

- Buttrose MS. Manganese and iron in globoid crystals of protein bodies from a vena and casuarina. Aust J Plant Physiol. 1978;5:631–639. doi: 10.1071/PP9780631. [DOI] [Google Scholar]

- Chakraborty SK, Singh DS, Kumbhar BK, Chakraborty S. Millet legume blended extrudates characteristics and process optimization using RSM. Food Bioprod Process. 2011;89:492–499. doi: 10.1016/j.fbp.2010.10.003. [DOI] [Google Scholar]

- Ding Q, Ainsworth P, Plunkett A, Tucker G, Marson H. The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. J Food Eng. 2006;73(2):142–148. doi: 10.1016/j.jfoodeng.2005.01.013. [DOI] [Google Scholar]

- Dlamini NR, Taylor JRN, Rooney LW. The effect of sorghum type and processing on the antioxidant properties of African sorghum-based foods. Food Chem. 2007;105:1412–1419. doi: 10.1016/j.foodchem.2007.05.017. [DOI] [Google Scholar]

- Dutta H, Mahanta CL. Effect of hydrothermal treatment varying in time and pressure on the properties of parboiled rice with different amylose content. Food Res Int. 2012;49(2):655–663. doi: 10.1016/j.foodres.2012.09.014. [DOI] [Google Scholar]

- Escalante-Aburto A, Ponce-García N, Ramírez-Wong B, Santiago-Ramos D, Véles-Medina JJ, de Dios Figueroa Cárdenas J. Effect of extrusion factors and particle size on starch properties of nixtamalized whole blue corn snacks. Starch/Stärke. 2016;68(11–12):1111–1120. doi: 10.1002/star.201500316. [DOI] [Google Scholar]

- Fu YJ, Zu YG, Liu W, Hou CL, Chen LY, Li SM, Shi XG, Tong MH. Preparative separation of vitexin and isovitexin from pigeonpea extracts with macroporous resins. J Chromatogr A. 2007;1139(2):206–213. doi: 10.1016/j.chroma.2006.11.015. [DOI] [PubMed] [Google Scholar]

- Gat Y, Ananthanarayan L. Effect of extrusion process parameters and pregelatinized rice flour on physicochemical properties of ready-to-eat expanded snacks. Int J Food Sci Technol. 2015;52(5):2634–2645. doi: 10.1007/s13197-014-1378-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Giménez MA, González RJ, Wagner J, Torres R, Lobo MO, Samman NC. Effect of extrusion conditions on physicochemical and sensorial properties of corn-broad beans (Vicia faba) spaghetti type pasta. Food Chem. 2013;136(2):538–545. doi: 10.1016/j.foodchem.2012.08.068. [DOI] [PubMed] [Google Scholar]

- Gujral HS, Sharma P, Kumar A, Singh B. Total phenolic content and antioxidant activity of extruded brown rice. Int J Food Prop. 2012;15(2):301–311. doi: 10.1080/10942912.2010.483617. [DOI] [Google Scholar]

- Hirth M, Leiter A, Beck SM, Schuchmann HP. Effect of extrusion cooking process parameters on the retention of bilberry anthocyanins in starch based food. J Food Eng. 2014;125:139–146. doi: 10.1016/j.jfoodeng.2013.10.034. [DOI] [Google Scholar]

- Huang Y-L, Ma Y-S. The effect of extrusion processing on the physiochemical properties of extruded orange pomace. Food Chem. 2016;192:363–369. doi: 10.1016/j.foodchem.2015.07.039. [DOI] [PubMed] [Google Scholar]

- Kaur A, Kaur S, Singh M, Singh N, Shevkani K, Singh B. Effect of banana flour, screw speed and temperature on extrusion behaviour of corn extrudates. J Food Sci Technol. 2015;52(7):4276–4285. doi: 10.1007/s13197-014-1524-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kaur A, Shevkani K, Katyal M, Singh N, Ahlawat AK, Singh AM. Physicochemical and rheological properties of starch and flour from different durum wheat varieties and their relationships with noodle quality. J Food Sci Technol. 2016;53(4):2127–2138. doi: 10.1007/s13197-016-2202-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kidøy L, Nygård AM, Andersen ØM, Pedersen AT, Aksnes DW, Kiremire BT. Anthocyanins in fruits of Passiflora edulis and P. suberosa. J Food Comp Anal. 1997;10(1):49–54. doi: 10.1006/jfca.1996.0514. [DOI] [Google Scholar]

- Kumar N, Sarkar BC, Sharma HK. Development and characterization of extruded product using carrot pomace and rice flour. Afr J Food Sci. 2010;4(11):703–717. [Google Scholar]

- Lobato LP, Anibal D, Lazaretti MM, Grossmann MVE. Extruded puffed functional ingredient with oat bran and soy flour. LWT Food Sci Technol. 2011;44:933–939. doi: 10.1016/j.lwt.2010.11.013. [DOI] [Google Scholar]

- Moorthy SN. Physicochemical and functional properties of tropical tuber starches: a review. Starch/Stärke. 2002;54:559–592. doi: 10.1002/1521-379X(200212)54:12<559::AID-STAR2222559>3.0.CO;2-F. [DOI] [Google Scholar]

- Muthayya S, Sugimoto JD, Montgomery S, Maberly GF. An overview of global rice production, supply, trade, and consumption. Ann N Y Acad Sci. 2014;1324(1):7–14. doi: 10.1111/nyas.12540. [DOI] [PubMed] [Google Scholar]

- Oikonomou NA, Krokida MK. Water absorption index and water solubility index prediction for extruded food products. Int J Food Prop. 2012;15(1):157–168. doi: 10.1080/10942911003754718. [DOI] [Google Scholar]

- Potter R, Stojceska V, Plunkett A. The use of fruit powders in extruded snacks suitable for children’s diets. LWT Food Sci Technol. 2013;51(2):537–544. doi: 10.1016/j.lwt.2012.11.015. [DOI] [Google Scholar]

- Rajkumar P, Kailappan R, Viswanathan R, Raghavan GSV, Ratti C. Foam mat drying of alphonso mango juice. Dry Technol. 2007;25:357–365. doi: 10.1080/07373930601120126. [DOI] [Google Scholar]

- Ramaiya DS, Bujang JS, Zakaria MH, King WS, Sahrir MAS. Sugars, ascorbic acid, total phenolic content and total antioxidant activity in passion fruit (Passiflora) cultivars. J Sci Food Agric. 2013;93:1198–1205. doi: 10.1002/jsfa.5876. [DOI] [PubMed] [Google Scholar]

- Samyor D, Deka SC, Das AB. Phytochemical and antioxidant profile of pigmented and non-pigmented rice cultivars of Arunachal Pradesh, India. Int J Food Prop. 2016;19(5):1104–1114. doi: 10.1080/10942912.2015.1055761. [DOI] [Google Scholar]

- Sharma P, Gujral HS, Singh B. Antioxidant activity of barley as affected by extrusion cooking. Food Chem. 2012;131(4):1406–1413. doi: 10.1016/j.foodchem.2011.10.009. [DOI] [Google Scholar]

- Sharma P, Ramchiary M, Samyor D, Das AB. Study on the phytochemical properties of pineapple fruit leather processed by extrusion cooking. LWT Food Sci Technol. 2016;72:534–543. doi: 10.1016/j.lwt.2016.05.001. [DOI] [Google Scholar]

- Singh B, Sekhon KS, Singh N. Effects of moisture, temperature and level of pea grits on extrusion behaviour and product characteristics of rice. Food Chem. 2007;100:198–202. doi: 10.1016/j.foodchem.2005.09.042. [DOI] [Google Scholar]

- Slinkard K, Singleton VL. Total phenol analysis: automation and comparison with manual methods. Am J Enol Viticult. 1977;28(1):49–55. [Google Scholar]

- Taylor NW, Zobel HF, White M, Senti FR. Deuterium exchange in starches and amylose. J Physl Chem. 1961;65(10):1816–1820. doi: 10.1021/j100827a030. [DOI] [Google Scholar]

- Tsumuraya Y, Misaki A. Structure of the water-insoluble a-Dglucan of Streptocossus salivarius HHT. Carbohydr Res. 1979;74:217–225. doi: 10.1016/S0008-6215(00)84778-3. [DOI] [PubMed] [Google Scholar]

- Zeng J, Li G, Gao H, Ru Z. Comparison of a and b starch granules from three wheat varieties. Molecules. 2011;16:10570–10591. doi: 10.3390/molecules161210570. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zobel HF. Molecules to granules: a comprehensive starch review. Starch/Starke. 1988;40(2):44–50. doi: 10.1002/star.19880400203. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.