Abstract

Cheese emulsion is an intermediate product for the production of cheese powder and needs to be stable, homogeneous and pumpable characteristics to convey to the spray drier. This study was conducted to evaluate the effects of fat reduction and emulsifying salt (ES) amount in cheese emulsion systems on the physicochemical characteristics. Reduced-fat (RF) and full-fat (FF) white-brined cheese emulsions were produced with different dry matters (DM; 15%–25% excluding ES) and ES concentrations (0%–3% based on cheese weight). Stable cheese emulsion was obtained at lower DM in RF cheese emulsion than that of FF cheese emulsion. Reduction in the amount of ES resulted in instability of both emulsions. Apparent viscosity with pseudoplastic flow behavior significantly increased with the decrease of fat content in stable cheese emulsions. Microstructure of emulsions appeared to be related to the fat content, stability and degree of emulsification. Reduction of fat content caused to get less lightness and more greenness in color, whereas yellowness was significantly decreased by increase in the amount of ES. In conclusion, fat reduction resulted in higher viscosities of cheese emulsion due to inducing the increment of protein, and the addition amount of ES considered as very important factor to produce stable cheese emulsion without protein precipitation or cream separation. Therefore, for preparation of RF cheese emulsion using a variety of white-brined cheese, lower amounts of DM would be suggested in this study to obtain homogenous droplets in the atomizing process of spray drying.

Keywords: reduced-fat, cheese emulsions, cheese powder, rheology, microstructure

Introduction

Spray drying is mostly used to produce cheese powder by removing the water from the feed which is in liquid state of cheese. Therefore, the first step for the production of spray dried cheese powder is to prepare the liquid form of the cheese, described as cheese emulsion. This emulsion is commonly produced by heating mainly grated cheese in the presence of water and emulsifying salt (ES; mainly sodium salts of phosphates, polyphosphates, citrates, or a combination of them), and preferably different additives such as dairy ingredients, maltodextrin, starch and flavor enhancers (Koca et al., 2015; Varming et al., 2014). Although the preparation of cheese emulsions is very similar to the process used for the production of spreadable processed cheese, the expectations for emulsion differ due to the requirements of the spraying process. Homogenous, uniform, stable (without protein precipitation and cream separation) and pumpable emulsions are necessary to be prepared before the atomization step and to be kept constant until and during spray drying (Kelimu et al., 2017; Varming et al., 2014). The atomization process provides a very large surface area between dry air and emulsion droplets to optimize heat and mass transfers and determines the characteristics of cheese powder (Koca et al., 2015). In order to have a homogeneous atomization and to ensure correct droplet formation, the viscosity of emulsion is the key factor. High solid content of emulsions can be resulted in a high viscosity which can cause blocking of atomizer. On the other hand, the spray-drying of emulsion with low dry matter is not cost-effective due to its lower product efficiency, and also can cause foaming problems due to its lower viscosity.

In recent years, production of reduced fat dairy products has increased because of increase in consumer demand. The reduction of fat in cheese causes an increase in its protein content and some negative effects on its textural and functional properties. Of course, the emulsion produced from reduced-fat (RF) cheese will have different characteristics than its full-fat (FF) counterpart. Fat emulsification and protein stabilization play important roles in keeping cheese emulsions stable (Kelimu et al., 2017). However, there is a lack of information relating to the effect of fat content on the properties of cheese emulsion used for cheese powder production in literature. Knowing the issues related to fat reduction of cheese emulsions before spray drying will be beneficial to improving the products for industry.

ESs have an important role in the production of cheese emulsions. They have the ability to sequester calcium from the casein matrix by exchanging sodium ions leading to emulsification in the cheese system (Guinee et al., 2004). Although a few studies reported that ES increase the stability of cheese emulsion (Hougaard et al., 2015; Varming et al., 2014), the information on the relation of fat reduction and ES for the production of cheese emulsion is missing in the literature. The physical stability and rheological properties of emulsions made from different types of cheeses are needed to investigate before undertaking a spray drying process. White cheese with salty acidic taste and semi-soft texture is salted and kept in brine, which is one of the most consumed cheese in Turkey. It is defined as different names in the Mediterranean region and in other countries such as Turkey (Beyaz), Greece (Feta), Yugoslavia (Beli Sir U Kriskama), Bulgaria (Bjalo Salamureno Sirene), Egypt (Domiati), Israel (Brinza), Romania (Teleme), Denmark (Feta) and the United States of America (Queso Blanco) (Hayaloglu et al., 2002). The aim of this study was to determine the effects of fat reduction and its relation with ES and dry matter contents on the key properties of emulsions of white-brined cheese.

Materials and Methods

Cheese samples and preparation of cheese emulsions

RF and FF Turkish white-brined cheeses were produced by Pınar Dairy Company (Izmir, Turkey). The moisture, fat, protein contents and pH values of FF and RF cheese samples were 56.35%, 24.75%, 13.87%, 4.65, and 58.54%, 12.75%, 23.26%, 4.85 respectively.

One month after production, the cheese samples were used in the preparation of cheese emulsions. Cheeses were ground into small pieces, stored at 4°C, and processed within 48 h. The JOHA® ES (S 85 including E339 and E452), providing stable emulsion with lower viscosity, was selected as a result of the preliminary experiments and company suggestions (Kipa Chemical Company, Istanbul, Turkey). The RF cheese emulsions were prepared at different DM (15%, 20%, and 25% excluding ES) using different ES concentrations (0%, 1%, 2%, and 3% based on cheese amount). Full-fat cheese emulsions (FF) were also prepared in the same dry matter ratios and ES concentrations for comparison. All cheese emulsion groups consisting of ground white cheese, hot water and ESs were prepared according to Koca et al. (2015). The slurry was first pre-mixed in a blender (LB10S, Waring, Torrington, CT) at 6,000 rpm for 1 min, then heated in a water bath to 80°C, and mixed again at 6,000 rpm for 10 min. Stability and rheological measurements of the prepared cheese emulsions were analyzed at 45°C, which is the temperature of feed used for spray drying process. Cheese emulsions were produced in triplicate.

Compositional analysis

The moisture and ash content of cheese emulsions were determined gravimetrically (IDF, 1982; AOAC, 2007). Fat and protein contents were analyzed using Gerber method (IDF, 1981) and the Kjeldahl method (AOAC, 2007), respectively. Mohr method was used for determination of salt content (IDF, 1988). The pH was measured using a digital pH meter (pH 320, WTW, 82362, Weilheim, Germany).

Cheese emulsion stability

The stability of cheese emulsions at 45°C which is the temperature of feed used for spray drying process were measured by centrifugation method according to Hougaard et al. (2015) with some modifications. Thirty milliliter of emulsion was transferred into a 50-mL centrifuge tube, and centrifugation test was performed at 1,600×g for 5 min. The intent was to obtain stable emulsions with no phase separation. If the emulsion is separated into three phases, the emulsion was described as unstable. The instability of cheese emulsion was determined by measuring the weight of each phase separated after the centrifugation. To determine the endurance of the emulsion’s stability, their stabilities were determined after 30- and 60-min holding.

Rheological measurements

Rheological measurements were conducted for each of the cheese emulsions by using a rotational cylinder viscometer (Haake 550 Viscotester, Thermo Scientific, USA), equipped with a SV-DIN sensor at 45°C regulated by a thermostatic bath (Haake DL 30 Thermo, Electron Corporation). For each measurement, about 25 mL of sample was used. The viscosity and shear stress were measured by increasing shear rates from 1 to 1,000 s–1 in 360 s. The shear stress and apparent viscosity data were plotted against the shear rate from the average measurements of 3 trials. In addition, Power Law model (Eq. 1) based on shear stress and shear rate was tested to find the flow behavior in stable emulsions:

| (1) |

τ is the shear stress (Pa), and γ is the shear rate (1/s) and K and n are the consistency index (Pa.sn) and flow behavior index, respectively.

The root square mean error (RSME) and chi-square (χ2) values were calculated using Equation 2 and 3, respectively.

| (2) |

| (3) |

x is the measured value, y is the predicted value, N is the number of data points, and n is number of parameters in model.

Microscopic evaluation

Emulsions were examined with a motorized light microscope (PSARON Floptik HPTS 150, AIV Labs, Turkey) which has 4×, 10×, 40×, and 100× objective lenses for imaging. Samples were carefully dropped on a glass slide and examined.

Color evaluation

The color values of cheese emulsions were measured using a Hunter ColorFlex colorimeter (Hunter Associates Laboratory, Reston, VA) in terms of CIE L* (lightness), a* (redness and greenness) and b* (yellowness and blueness).

Statistical analysis

Data analyses were performed, using SPSS version 20.0 for Windows (SPSS Inc., Chicago, IL). Significant differences between the means were determined by analysis of variance (ANOVA) and Duncan's multiple range test. Statistical differences were set at p<0.05.

Results and Discussion

Composition of cheese emulsions

The suitable dry matter of emulsion to be pumped to dryer changes according to the cheese type, melting characteristics, composition and pH levels of cheese. White-brined cheese had low pH values which causes a characteristic flavor such as a salty acid taste. White-brined cheese melts poorly due to its low pH level, resulting in some difficulties in emulsification process and causing high viscosity in emulsions. For this reason, DM of white-brined cheese emulsions needs to be lower than that of cheese which more readily melt, i.e. Cheddar cheese. In addition, white-brined cheese already has a low DM. Koca et al. (2015) determined the ideal DM to be 25% for FF (excluding ES) for effective spray drying process in the pilot plant. Therefore, the highest DM in the experiments was chosen to be 25% considering the possible increases in viscosity of reduced-fat cheese emulsions (RF). In addition, our aim was to create White cheese flavor in cheese emulsion, which is salty acid flavor. Therefore, we tried to keep the acid taste during emulsion preparation without changing the chemical modifications such as pH adjustment.

The fat content of FF varied from 8.80% to 14.40%, while RF had values between 5.20%–8.00% depending on DM of emulsions (Table 1). Fat reduction in emulsion was compensated by an increase in protein due to the high protein content of RF cheese, which may cause adverse effects on viscosity, flowability and droplet formation during the atomization of emulsion. As expected, DM, ash and salt contents of RF and FF emulsions increased as the ES amount increased, because the ES amount was excluded in the calculation of DM content of mix. In all emulsion groups, there was a shift upwards in pH levels with an increase in the ES concentration. The results obtained for pH are in good agreement with those of Varming et al. (2014) which reported for cheese emulsion with different levels of ES, using Cheddar, Camembert and Soft cheese. In addition, the pH shift was lower for RF compared to FF. The extent of pH shift is related to buffering of the cheese used, pH of ES solution and buffering capacity of ES (Fox et al., 2017). It is also reported that the buffering capacity in milk systems is largely determined by the concentration of protein and phosphate contents (Lawrence et al., 1993).

Table 1. Chemical composition of RF and FF white-brined cheese emulsions.

| Samples | DM excluding ES (%) | ES ratio1) (%) | Dry matter (%) | Fat (%) | Ash (%) | Protein (%) | Salt (%) | pH |

|---|---|---|---|---|---|---|---|---|

| FF | 25 | 0 | 26.37±0.17aA | 14.40±0.00 | 2.13±0.05aA | 9.82±0.04aA | 0.83±0.03aA | 4.15±0.15aA |

| 1 | 26.83±0.01abABC | 14.40±0.00 | 2.61±0.03bC | 9.81±0.05aA | 1.16±0.10bC | 4.54±0.09bB | ||

| 2 | 27.15±0.36bcCD | 14.40±0.00 | 3.04±0.09cE | 9.81±0.02aA | 1.75±0.01cE | 4.87±0.05cD | ||

| 3 | 27.70±0.13cEF | 14.40±0.00 | 3.52±0.01dF | 9.79±0.01aA | 2.32±0.01dG | 5.11±0.01dEF | ||

| RF | 25 | 0 | 26.60±0.27aAB | 8.00±0.00 | 2.43±0.01aB | 16.16±0.04cC | 0.99±0.01aB | 4.65±0.04aBC |

| 1 | 27.00±0.02abBCD | 8.00±0.00 | 2.87±0.03bD | 16.13±0.07bcC | 1.29±0.04bD | 4.79±0.01bCD | ||

| 2 | 27.41±0.16bcDE | 8.00±0.00 | 3.46±0.03cF | 16.03±0.01abB | 1.91±0.01cF | 4.95±0.07cDE | ||

| 3 | 27.94±0.10cF | 8.00±0.00 | 3.83±0.03dG | 16.01±0.02aB | 2.43±0.01dH | 5.16±0.01dF | ||

| FF | 20 | 0 | 21.31±0.10aA | 12.00±0.00 | 1.31±0.01aA | 8.03±0.07aA | 0.71±0.02aA | 4.35±0.07aA |

| 1 | 21.72±0.01bB | 12.00±0.00 | 1.73±0.02bB | 8.01±0.07aA | 1.07±0.02bB | 4.47±0.11aA | ||

| 2 | 22.15±0.19cC | 12.00±0.00 | 2.07±0.02cC | 7.99±0.05aA | 1.52±0.03cC | 4.90±0.07bC | ||

| 3 | 22.51±0.09dD | 12.00±0.00 | 2.49±0.01d | 7.95±0.05aA | 1.97±0.01dE | 5.18±0.07cD | ||

| RF | 20 | 0 | 21.75±0.06aB | 6.80±0.00 | 1.95±0.02aC | 12.99±0.01dE | 0.74±0.01aA | 4.70±0.01aB |

| 1 | 22.13±0.01abC | 6.80±0.00 | 2.43±0.04bD | 12.88±0.04cD | 1.09±0.01bB | 4.89±0.01bC | ||

| 2 | 22.38±0.23bCD | 6.80±0.00 | 2.86±0.03cE | 12.72±0.02bC | 1.58±0.01cD | 5.05±0.04cD | ||

| 3 | 22.91±0.16cE | 6.80±0.00 | 3.10±0.01dF | 12.46±0.03aB | 1.96±0.01dE | 5.19±0.04dD | ||

| FF | 15 | 0 | 16.19±0.09aC | 8.80±0.00 | 1.17±0.18aA | 6.19±0.04aA | 0.56±0.02aA | 4.23±0.11aA |

| 1 | 16.48±0.04bD | 8.80±0.00 | 1.44±0.03bB | 6.18±0.03aA | 0.84±0.02bB | 4.62±0.07bB | ||

| 2 | 17.02±0.12cE | 8.80±0.14 | 2.05±0.03cC | 6.16±0.07aA | 1.20±0.02cD | 4.94±0.04cCD | ||

| 3 | 17.53±0.06dF | 8.80±0.00 | 2.58±0.02dE | 6.15±0.03aA | 1.53±0.02dF | 5.25±0.04dF | ||

| RF | 15 | 0 | 15.50±0.02aA | 5.20±0.00 | 1.52±0.07aB | 8.76±0.09aB | 0.59±0.01aA | 4.73±0.01aB |

| 1 | 15.85±0.03bB | 5.20±0.00 | 1.97±0.01bC | 8.73±0.02aB | 1.06±0.01bC | 4.89±0.05bC | ||

| 2 | 16.40±0.01cD | 5.20±0.00 | 2.46±0.06cD | 8.73±0.02aB | 1.32±0.01cE | 5.05±0.01cDE | ||

| 3 | 16.98±0.01dE | 5.20±0.00 | 3.05±0.02dF | 8.72±0.03aB | 1.69±0.01dG | 5.17±0.07dEF |

1) ES ratio, emulsifying salt ratio based on cheese amount.

a–d means with the different letter in the column for each sample group having different emulsifying salt contents (eg. FF 25) are significantly different (p<0.05).

A–H means with the different letter in the column for FF and RF emulsions with the same DM (eg. FF 25 and RF 25) are significantly different (p<0.05).

The results are presented as mean±SD.

RF, reduced-fat; FF, full-fat; DM, dry matters.

Stability of cheese emulsions

The major criterion in producing a cheese emulsion is to obtain a stable emulsion without protein precipitation or creaming. In order to obtain stable RF and FF, it was revealed that the lowest dry matters were found as 20% and 25% with 3% ES, respectively (Table 2). In other words, lower percentages of DM, to some extent, is enough for obtaining a stable emulsion for RF compared to FF due to the high protein level. Proteins are the primary emulsifiers in the cheese emulsion system and their higher levels improved the degree of emulsification. A high degree of cross-linking of protein molecules results in networks exhibiting high resistance to changes in centrifugation (Lobato-Calleros et al., 2006). That is why, for high fat emulsion groups, a high dry matter ratio is needed for stability when compared to RF system. However, in other emulsion groups having lower DM (FF 20, FF 15 and RF 15), three phases were evaluated after centrifugation - precipitated (bottom), liquid (middle) and fat (top) phases after centrifugation. The further decrease in DM of emulsion could also result in the decreased emulsifying ability of system because of low amounts of protein. The dry matter content of an emulsion needs to be matched with an appropriate protein level to allow the coating of the interfacial area of the fat globules for the stabilization of the emulsion.

Table 2. Phase separation of white-brined cheese emulsions after 0, 30, and 60 min.

| Samples | ES ratio1)(%) | Precipitated phase (%) | Liquid phase (%) | Fat phase (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 30 | 60 | 0 | 30 | 60 | 0 | 30 | 60 | |||

| FF | 25 | 0 | 39.6±0.9dX | 44.2±0.1dY | 48.4±0.2dZ | 46.3±2.7bY | 41.9±0.6bXY | 39.7±0.2bX | 13.4±0.9bX | 13.6±0.8bX | 12.6±0.3bX |

| 1 | 33.7±0.8cx | 37.0±0.2cy | 38.9±0.3cz | 52.3±0.5cY | 50.3±0.8cY | 48.1±0.8cX | 13.9±1.2bX | 13.2±0.7bX | 12.9±0.6bX | ||

| 2 | 25.8±1.1bX | 32.3±0.9by | 42.7±1.9bz | 61.9±0.1dZ | 53.7±0.9dY | 44.7±1.2dX | 12.9±0.1bX | 13.8±0.0bX | 12.9±0.6bX | ||

| 3 | -a | -a | -a | -a | -a | -a | -a | -a | -a | ||

| RF | 25 | 0 | 52.1±0.3dX | 58.1±0.4dY | 59.9±0.9dY | 43.3±0.1bZ | 36.5±0.2bY | 34.7±0.6bX | 5.3±0.1cX | 5.3±0.1bX | 5.4±0.1bX |

| 1 | 50.5±0.2cX | 55.1±0.3cY | 57.6±0.6cZ | 43.9±0.1cY | 40.1±0.1cY | 37.3±0.5cX | 5.1±0.1cX | 5.2±0.1bX | 5.2±0.1bX | ||

| 2 | 47.8±0.5bX | 49.1±0.3bY | 52.6±0.4bZ | 47.9±0.4dY | 45.9±0.2dY | 42.4±1.1dX | 4.2±0.3bX | 5.1±0.2bY | 5.3±0.1bY | ||

| 3 | -a | -a | -a | -a | -a | -a | -a | -a | -a | ||

| FF | 20 | 0 | 30.9±1.4cX | 35.7±0.1cY | 36.5±0.3cY | 57.55±0.6aY | 53.9±0.3aX | 52.7±0.1aX | 11.8±0.4aX | 10.4±0.4aX | 10.9±0.6aX |

| 1 | 28.8±1.9cX | 31.2±0.5bX | 32.34±0.7bX | 59.23±0.2bY | 58.4±0.7bY | 55.9±0.3bX | 11.6±1.2aX | 10.2±0.2aX | 11.1±1.8aX | ||

| 2 | 24.6±0.1bX | 30.0±0.9bY | 36.24±1.0cZ | 64.52±0.4cZ | 59.6±0.1bY | 52.7±0.1aX | 10.8±0.1aX | 10.6±0.9aX | 10.9±0.3aX | ||

| 3 | 9.5±0.6aX | 11.0±0.5aXY | 13.02±1.3aY | 79.92±0.5dY | 77.9±1.0cXY | 75.3±1.9cX | 10.1±0.2aX | 10.8±1.2aX | 11.7±0.1aX | ||

| RF | 20 | 0 | 40.4±0.9dX | 42.2±0.2dX | 43.4±1.9cX | 56.2±0.6bY | 54.4±0.5bXY | 52.7±1.7bX | 3.9±0.1bX | 4.0±0.1bX | 4.0±0.1bX |

| 1 | 37.7±0.5cX | 40.3±0.3cY | 42.9±0.1cZ | 58.6±0.8bZ | 56.4±0.4cY | 53.6±0.4bX | 3.8±0.1bX | 3.9±0.1abX | 3.9±0.1bX | ||

| 2 | 32.1±1.3bX | 36.4±0.1bY | 39.1±0.9bY | 64.7±1.6cY | 59.7±0.1dX | 56.9±1.1cX | 3.7±0.3bX | 3.8±0.1bY | 3.8±0.4bY | ||

| 3 | -a | -a | -a | -a | -a | -a | -a | -a | -a | ||

| FF | 15 | 0 | 21.9±0.2dX | 28.4±0.2cY | 30.2±0.1cZ | 67.7±0.4aZ | 61.7±0.7aY | 59.3±0.2aX | 10.8±0.1aX | 10.4±0.4aX | 11.0±0.3aX |

| 1 | 19.7±0.5cX | 20.9±0.5bX | 22.0±0.8bX | 70.6±1.1bY | 69.0±0.2bXY | 67.5±0.6bX | 10.6±0.3aX | 10.7±0.1aX | 10.9±0.9aX | ||

| 2 | 17.5±0.5bX | 19.4±0.4bY | 22.8±0.4bZ | 71.8±0.1bZ | 70.1±0.4bcY | 67.2±0.1bX | 10.4±0.3aX | 10.6±0.1aX | 10.7±0.1aX | ||

| 3 | 15.0±0.6aX | 16.7±1.2aXY | 19.1±0.9aY | 74.9±1.4cX | 73.1±2.0cX | 70.9±0.4cX | 10.3±0.4aX | 10.2±0.7aX | 10.3±0.2aX | ||

| RF | 15 | 0 | 30.2±0.3cX | 40.8±0.1dY | 47.3±1.3cZ | 66.6±0.3aZ | 55.9±0.1aY | 49.3±1.4aX | 3.3±0.1bX | 3.4±0.0cX | 3.4±0.1bX |

| 1 | 27.8±0.4bcX | 37.3±0.9cY | 41.4±0.1bZ | 69.1±0.3abZ | 59.7±0.8bY | 55.5±0.2bX | 3.1±0.1abX | 3.2±0.1bX | 3.2±0.1aX | ||

| 2 | 26.6±2.1bX | 31.0±0.3bY | 41.2±0.2bZ | 70.4±2.1bZ | 65.9±0.2cY | 55.7±0.2bX | 3.1±0.1abX | 3.1±0.1abX | 3.2±0.1aX | ||

| 3 | 19.3±1.2aX | 28.9±1.0aY | 39.2±0.4aZ | 77.9±1.3cZ | 68.4±0.7dY | 57.8±0.3cX | 2.9±0.2aX | 3.0±0.0aX | 3.1±0.1aX | ||

1) ES ratio, emulsifying salt ratio based on cheese amount.

a–d means with the different letter in the column for each sample group having different emulsifying salt contents (eg. FF 25) are significantly different (p<0.05).

x–z means with the different letter in the same row for each phase of every sample are significantly different (p<0.05).

The results are presented as mean±SD.

FF, full-fat; RF, reduced-fat.

Reducing the ES resulted in an increase in the precipitated phase and a decrease in the liquid phase (p<0.05). The lowest stability was found in samples produced without ES. ES affects the hydration of the protein which has an ability to emulsify the fat released during heating and/or shearing steps of the emulsion formation and to increase fat emulsification (Guinee and O'Kennedy, 2012). Similar findings for the ES concentration were reported by Hougaard et al. (2015), Ray et al. (2016) and Varming et al. (2014).

Maintaining the stability of cheese emulsion is also important key factor during cheese powder production. The emulsion must remain stable prior to the atomization step and this directly affects the efficiency of the drying process and the quality of final product. Stable emulsions kept their stability without phase separation during 60 min of holding whereas an increase in precipitated phase and a decrease in liquid phase for unstable emulsions were found with holding (Table 2).

Rheological properties of cheese emulsions

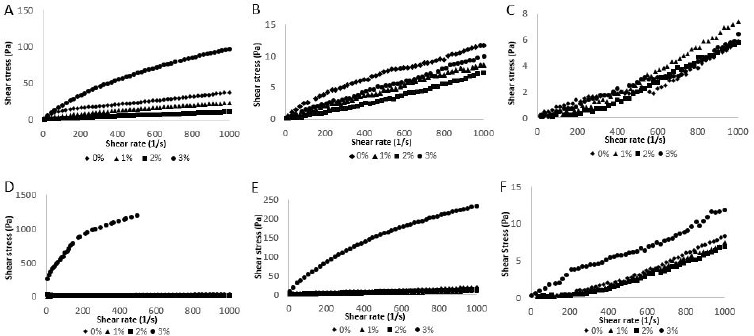

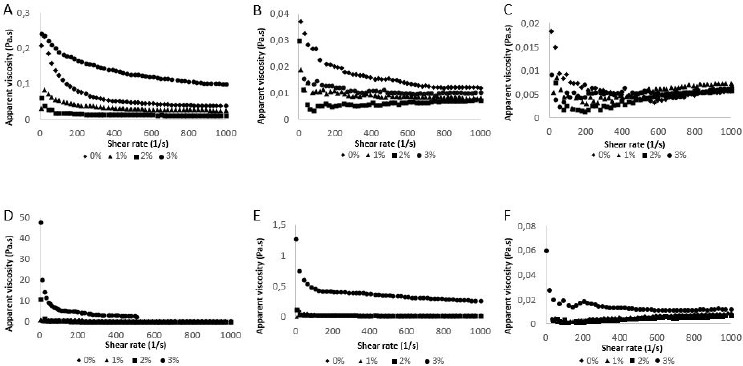

Viscosity of emulsions before spray drying influences the atomization of the feed and hence the characteristics of cheese powder. All the emulsions exhibited non-Newtonian flow behavior because their apparent viscosities are dependent on shear rate (Figs. 1 and 2). Shear stress values increased as DM of the emulsion increased for both RF and FF. Higher apparent viscosities were obtained in stable samples including FF with 25% DM and RF with both 25% and 20% DM containing 3% ES compared to unstable white-brined cheese emulsions. On the other hand, the unstable emulsions had lower viscosities. These results showed that when the emulsion was stabilized, its apparent viscosity had the highest value. This finding is very important in order to avoid the misconception of selecting low viscosity without testing the stability of the emulsion. It was also interesting to follow the change in stability of samples looking at the data series in Fig. 1 and Fig. 2. Irregularity of data became evident with increased instability because of the effect of insolubilized particles during measurement such as Fig. 2B, C, and F. It was also found that the addition of ES had an important effect on the rheological properties of cheese emulsions. This effect became more evident when DM of emulsion increased. Similarly, Kelimu et al. (2017) reported increased apparent viscosity with addition of ES. ES resulted in increased protein hydration and formation of continuous protein network structure, thus causing an increase in degree of emulsification and viscosity.

Fig. 1. The shear stress values of RF and FF cheese emulsions with different dry matter and emulsifying salt contents.

(A) FF with 25% dry matter, (B) FF with 20% dry matter, (C) FF with 15% dry matter, (D) RF with 25% dry matter, (E) RF with 20% dry matter, (F) RF with 15% dry matter. RF, reduced-fat; FF, full-fat.

Fig. 2. Apparent viscosities of FF and RF cheese emulsions with different dry matter and emulsifying salt contents.

(A) FF with 25% dry matter, (B) FF with 20% dry matter, (C) FF with 15% dry matter, (D) RF with 25% dry matter, (E) RF with 20% dry matter, (F) RF with 15% dry matter. FF, full-fat; RF, reduced-fat.

The reduction in fat levels resulted in significant increases in shear stress (apparent viscosity) values in stable cheese emulsion groups. RF with 25% DM and 3% ES, which was stable, had the highest apparent viscosity, which was too viscous. Visually, even the emulsion with 20% DM, which was stable, was still too viscous to feed to drier. Therefore, the reduction in fat content of the sample will negatively affect the flowability causing problems in pumping and droplet formation during atomization of emulsion due to the high viscosity. In addition, the high viscosity results in a significant decrease in solubility, a small increase in particle density and thus formation of scorched particles and less free flowing powder (Baldwin et al., 1980; Kelimu et al., 2017). On the other hand, the emulsions with the lower DM were found unstable even with 3% ES. Therefore, it is necessary to prepare stable cheese emulsion with an intermediate viscosity with respect to fat content of cheese for a fine atomization and high quality of powder. To come from above, some approaches can be suggested such as preparing a stable emulsion with high viscosity and then diluting it to an appropriate viscosity while keeping its stability, or using some ingredients to decrease viscosity and increase stability, or making some chemical modifications such as pH adjustment. Some trials in our lab were carried out for the former approach. It was not possible to add all of the water needed for dilution at one time because the emulsion stability would break. After the stable RF was prepared, it was possible to prepare the RF emulsion having desired flowability without phase separation by adding the water, at the same temperature as emulsion, drop by drop.

Power law model has been tested to ascertain the correct flow behavior of stable emulsions (RF 25, RF 20, FF 25 with 3% ES). Rheological parameters of these emulsions were reported in Table 3. The stable emulsion samples exhibited a pseudoplastic behavior because the n values of the model were lower than 1.

Table 3. Power law model parameters of stable white-brined cheese emulsions.

| Samples | FF 25 | RF 25 | RF 20 |

|---|---|---|---|

| K | 0.512 | 152.79 | 1.777 |

| n | 0.786 | 0.333 | 0.730 |

| R2 | 0.999 | 0.998 | 0.999 |

| RMSE | 0.282 | 1.634 | 0.431 |

| χ2 | 0.087 | 3.337 | 0.204 |

FF, full-fat; RF, reduced-fat; K, consistency index (Pa.sn); n, flow behavior index; R2, determination coefficient; χ2, chi-square.

Microscopic evaluation of cheese emulsions

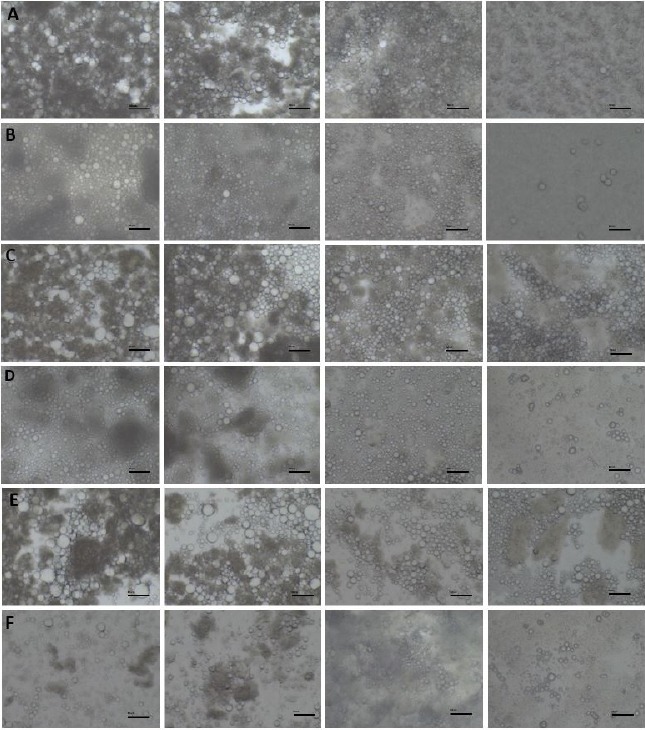

The micrographs of the cheese emulsions are given in Fig. 3. Images were recorded from 10× objective lenses of the microscope. It was difficult to use higher magnification lenses for imaging, especially for stable groups. The images were directly related to emulsification degree of the emulsions stabilities. The fat globule size and the existence of protein strands were indicative of the extent of emulsification. The larger fat particles were observed in the microstructure of the cheese emulsions without ES. In addition, the fat globules were in various sizes and larger in FF comparing to RF with the same DM. These large fat particles were emulsified into smaller droplets using ES during emulsification process. In addition, the size of the fat particles decreased as the ES content increased for both FF and RF. Increasing ES content led to the development of more homogeneous and compact structure in emulsions. This could be associated with the solubilization of casein by the action of the calcium sequestering melting salts.

Fig. 3. Microscopic images of white cheese emulsions produced with different emulsifying salt.

Images were represented 0%, 1%, 2%, 3% emulsifying salt from left to right. (A) FF with 25% dry matter, (B) RF with 25% dry matter, (C) FF with 20% dry matter, (D) RF with 20% dry matter, (E) FF with 15% dry matter, (F) RF with 15% dry matter. RF, reduced-fat; FF, full-fat.

Color of cheese emulsions

The color of an emulsion is an important parameter that can affect the powder quality. The color parameters of cheese emulsions were noted to be significantly affected by ES concentration when considering the same dry matter (Table 4) (p<0.05). L* and a* values significantly increased with the increased concentrations of added ES, while b* values of the treatments decreased (p<0.05). Lightness is directly related to degree of emulsification of fat globules in the protein matrix, emulsions produced with ES generally showed a better degree of luminosity. There is also a significant relationship between L* values and fat reduction in emulsions (p<0.05). The higher lightness values were found in FF when compared to RF due to the high light scattering ability of fat globules. However, fat reduction did not change b* values of the emulsions. Therefore, it was concluded that the final color of the emulsion depends not only on fat content, but also the fat dispersion in protein matrix during emulsifying process.

Table 4. Color values of white-brined cheese emulsions.

| Samples | DM excluding ES (%) | ES ratio1) (%) | L* | a* | b* |

|---|---|---|---|---|---|

| FF | 25 | 0 | 92.39±0.01aD | –0.74±0.02aE | 15.10±0.01dF |

| 1 | 93.03±0.04bF | –0.71±0.02bF | 14.44±0.02cE | ||

| 2 | 93.55±0.02cG | –0.64±0.01cG | 12.85±0.03bB | ||

| 3 | 93.81±0.01dH | –0.63±0.01cG | 12.53±0.02aA | ||

| RF | 25 | 0 | 90.42±0.03aA | –1.72±0.04aA | 15.09±0.06dF |

| 1 | 90.70±0.05bB | –1.44±0.01bB | 13.67±0.01cD | ||

| 2 | 92.15±0.01cC | –1.31±0.02cC | 13.44±0.09bC | ||

| 3 | 92.63±0.01dE | –1.26±0.01dD | 12.86±0.01aB | ||

| FF | 20 | 0 | 91.67±0.01aC | –1.11±0.02aE | 13.99±0.05cF |

| 1 | 92.86±0.01bF | –0.82±0.02bF | 13.20±0.07bC | ||

| 2 | 93.52±0.01cG | –0.76±0.01cG | 12.60±0.08aA | ||

| 3 | 93.57±0.01dG | –0.77±0.01cG | 12.51±0.13aA | ||

| RF | 20 | 0 | 89.76±0.03aA | –2.22±0.02aA | 13.77±0.03dE |

| 1 | 90.13±0.08bB | –1.74±0.01bB | 13.59±0.02cD | ||

| 2 | 91.86±0.01cD | –1.39±0.01cC | 12.84±0.08bB | ||

| 3 | 92.29±0.01dE | –1.28±0.01dD | 12.64±0.02aA | ||

| FF | 15 | 0 | 90.72±0.18aC | –1.46±0.02aD | 14.23±0.11cF |

| 1 | 92.68±0.05bF | –1.24±0.02bE | 12.95±0.13bD | ||

| 2 | 93.29±0.01cG | –1.12±0.02cF | 12.10±0.15abB | ||

| 3 | 93.52±0.02cH | –1.07±0.01dF | 11.77±0.21aA | ||

| RF | 15 | 0 | 89.22±0.01aA | –2.33±0.01aA | 14.74±0.04dG |

| 1 | 89.88±0.16bB | –1.84±0.06bB | 13.35±0.07cE | ||

| 2 | 91.00±0.02cD | –1.81±0.03bB | 12.51±0.09bC | ||

| 3 | 91.28±0.02dE | –1.66±0.02cC | 12.20±0.11aBC |

1) ES ratio, emulsifying salt ratio based on cheese amount.

a–d means with the different letter in the column for each sample group having different emulsifying salts (eg. FF 25) are significantly different (p<0.05).

A–H means with the different letter in the column for FF and RF emulsions with the same DM (eg. FF 25 and RF 25) are significantly different (p<0.05). The results are presented as mean±SD.

DM, dry matter; FF, full-fat; RF, reduced-fat.

Conclusion

The key characteristics of RF cheese emulsions with different dry matter and ES contents were determined prior to the production of RF white cheese powder. Fat reduction caused an increase in the apparent viscosity of cheese emulsion. In addition, the highest apparent viscosity was found when the emulsion was stable. The lowest DM for obtaining stable emulsion were found to be 20% and 25% with 3% ES based on cheese amount for RF and FF, respectively, which meant that lower DM is sufficient to obtain a stable emulsion from RF cheese due to its high protein level. On the other hand, the further decreases in DM and ES contents resulted in instability and low apparent viscosities in emulsions. Additionally, stability was related with ES concentration which led to the development of more homogeneous and compact structure in both FF and RF. This investigation provided valuable information about the emulsions made from RF cheese by filling the research gap in this field. Our results also showed that preparation of stable RF with an appropriate viscosity before spray-drying was challenging. Recently, pH adjustment of emulsion and the addition of fat replacers have been underway in our laboratories to decrease the viscosity of stable emulsion or to increase the stability of emulsion. In addition, the effects of fat reduction on cheese powder characteristics currently have been under investigation.

Acknowledgements

The authors are grateful to Pınar Dairy Company (Izmir, Turkey) for providing cheese and Kipa Chemical Company (Istanbul, Turkey) for providing ES used in this study.

References

- AOAC. Official methods of analysis of AOAC International. 18th ed. AOAC International; Gaithersburg, MD, USA: 2007. [Google Scholar]

- Baldwin AJ, Baucke AG, Sanderson WB. The effect of concentrate viscosity on the properties of spray dried skim milk powder. New Zeal J Dairy Sci. 1980;15:289–297. [Google Scholar]

- Fox PF, Guinee TP, Cogan TM, McSweeney PLH. In Fundamentals of cheese science. Springer; Boston, MA, USA: 2017. Processed cheese and substitute/imitation cheese products; pp. 589–627. [Google Scholar]

- Guinee TP, Caric M, Kalab M. Pasteurized processed cheese and substitute/imitation cheese products. In: Fox PF, McSweeney PLH, Cogan TM, Guinee TP, editors. In Cheese: Chemistry, physics and microbiology. 2nd ed. Elsevier/Academic Press; London, UK: 2004. pp. 349–394. Major cheese groups. [Google Scholar]

- Guinee TP, O'Kennedy BT. Reducing the level of added disodium phosphate alters the chemical and physical properties of processed cheese. Dairy Sci Technol. 2012;92:469–486. [Google Scholar]

- Hayaloglu AA, Guven M, Fox PF. Microbiological, biochemical and technological properties of Turkish White cheese ‘Beyaz Peynir’. Int Dairy J. 2002;12:635–648. doi: 10.1016/S0958-6946(02)00055-9. [DOI] [Google Scholar]

- Hougaard AB, Sijbrandij AG, Varming C, Ardö Y, Ipsen R. Emulsifying salt increase stability of cheese emulsions during holding. LWT-Food Sci Technol. 2015;62:362–365. doi: 10.1016/j.lwt.2015.01.006. [DOI] [Google Scholar]

- IDF. IDF standard. Vol. 105. Brussels, Belgium: 1981. Milk determination of fat content–Gerber butyrometers. [Google Scholar]

- IDF. IDF Standard 4A. Brussels, Belgium: 1982. Determination of total solids content of cheese. [Google Scholar]

- IDF. IDF Standard 12B. Brussels, Belgium: 1988. Determination of salt content (Mohr method) [Google Scholar]

- Kelimu A, da Silva DF, Geng X, Ipsen R, Hougaard AB. Effects of different dairy ingredients on the rheological behaviour and stability of hot cheese emulsions. Int Dairy J. 2017;71:35–42. doi: 10.1016/j.idairyj.2017.02.005. [DOI] [Google Scholar]

- Koca N, Erbay Z, Kaymak-Ertekin F. Effects of spray-drying conditions on the chemical, physical, and sensory properties of cheese powder. J Dairy Sci. 2015;98:2934–2943. doi: 10.3168/jds.2014-9111. [DOI] [PubMed] [Google Scholar]

- Lawrence RC, Gilles J, Creamer LK. Cheddar cheese and related dry-salted cheese varieties. In: Fox PF, editor. In Cheese: Chemistry, physics and microbiology, major cheese groups. Chapman & Hall; London, UK: 1993. pp. 1–39. [Google Scholar]

- Lobato-Calleros C, Rodríguez E, Sandoval-Castilla O, Vernon-Carter EJ, Alvarez-Ramirez J. Reduced-fat white fresh cheese-like products obtained from W1/O/W2 multiple emulsions: Viscoelastic and high-resolution image analyses. Food Res Int. 2006;39:678–685. doi: 10.1016/j.foodres.2006.01.006. [DOI] [Google Scholar]

- Ray CA, Gholamhosseinpour A, Ipsen R, Hougaard AB. The effect of age on Cheddar cheese melting, rheology and structure, and on the stability of feed for cheese powder manufacture. Int Dairy J. 2016;55:38–43. doi: 10.1016/j.idairyj.2015.11.009. [DOI] [Google Scholar]

- Varming C, Hougaard AB, Ardö Y, Ipsen R. Stability of cheese emulsions for spray drying. Int Dairy J. 2014;39:60–63. doi: 10.1016/j.idairyj.2014.05.005. [DOI] [Google Scholar]