Abstract

To fabricate graphene based electronic and optoelectronic devices, it is highly desirable to develop a variety of metal‐catalyst free chemical vapor deposition (CVD) techniques for direct synthesis of graphene on dielectric and semiconducting substrates. This will help to avoid metallic impurities, high costs, time consuming processes, and defect‐inducing graphene transfer processes. Direct CVD growth of graphene on dielectric substrates is usually difficult to accomplish due to their low surface energy. However, a low‐temperature plasma enhanced CVD technique could help to solve this problem. Here, the recent progress of metal‐catalyst free direct CVD growth of graphene on technologically important dielectric (SiO2, ZrO2, HfO2, h‐BN, Al2O3, Si3N4, quartz, MgO, SrTiO3, TiO2, etc.) and semiconducting (Si, Ge, GaN, and SiC) substrates is reviewed. High and low temperature direct CVD growth of graphene on these substrates including growth mechanism and morphology is discussed. Detailed discussions are also presented for Si and Ge substrates, which are necessary for next generation graphene/Si/Ge based hybrid electronic devices. Finally, the technology development of the metal‐catalyst free direct CVD growth of graphene on these substrates is concluded, with future outlooks.

Keywords: catalyst free, dielectrics, direct chemical vapor deposition (CVD) growth, graphene, semiconductors

1. Introduction

Nowadays, graphene has attracted tremendous research interest due to its extraordinary properties, such as high optical transparency, good electrical and thermal conductivities, mechanical flexibility, high intrinsic carrier mobility, and chemical stability. Owing to its excellent characteristics, 2D graphene sheet is regarded as a next‐generation transparent conductive electrode for applications in various electronic devices.1 To fabricate next generation electronic devices incorporating graphene, it is pertinent to develop a variety of methods for direct synthesis of graphene on any substrate. However, various methods have been adopted for controlled growth of graphene, and it was found that direct growth of graphene especially on dielectrics is difficult to achieve due to their low surface energy.2, 3, 4, 5, 6, 7, 8, 9, 10, 11 However, the surface modification of dielectric substrates can facilitate the ease of nucleation of graphene.10, 12 A low‐temperature growth of graphene on dielectric substrates can be achieved by stimulating the decomposition of the gaseous carbon source through plasma enhanced chemical vapor deposition (PECVD) technique.4, 5, 12 Furthermore, it is cumbersome to control the graphene growth rate and nucleation density on dielectric substrates compared to growth on metallic substrates. Generally, polymer assisted transfer and metal etching processes are employed to transfer the metal‐catalyzed chemical vapor deposition (CVD) grown graphene films on dielectric and semiconducting substrates. The metal‐catalyst free direct growth of graphene via CVD techniques on dielectric and semiconducting substrates is highly desirable to avoid metallic impurities during fabrication of electronic devices. This will also help in avoiding costly, time consuming, and defect inducing transfer process. Moreover, graphene/semiconductor hybrid structures especially graphene/Si and graphene/Ge seem to be very promising candidates for future transistors because of the adjustable Schottky barrier (SB) which forms between graphene/semiconductor. However, SB between graphene and a hydrogen‐terminated semiconductor is different from a conventional SB in two distinct manners. First, the generation of interface states is reduced due to the negligible interaction between chemically inert graphene and entirely saturated (without dangling bonds) semiconductor surface. Second, the work function of graphene can be adjusted by tuning the Fermi energy (E F) over a wide range through the electrostatic field effect.13 Large single‐crystalline Si wafers are easily available for the epitaxial graphene growth. However, the weak carbon diffusivity on Si surface and strong carbon solubility at high temperature deteriorate the quality of graphene grown on Si.14 Ni and Cu are well known for catalyzing the growth of multilayered graphenes (MLG) and monolayer graphenes, respectively. At high temperature, carbon atoms are dissolved in the metal chain followed by segregation to form graphene on their surfaces during lowering of temperature. Ni has higher carbon solubility and provides a larger pool, whereas Cu provides a smaller pool due to the lower solubility. Therefore, multilayer and monolayer graphenes form on Ni and Cu surfaces, respectively. On the other hand, Si provides even lower carbon solubility compared to Cu. According to the phase diagram of Si‐C, a straight SiC line exists at high temperatures ranging from 1000–2545 ± 40 °C. This suggests that single graphene and Si phases do not grow at the same time in this temperature range. Hence, Si substrate temperature should be less than 1000 °C for graphene growth.15 Based on the above discussions, single‐crystalline Ge substrates seem to be better option for the metal‐catalyst free direct CVD growth of single‐crystalline monolayer graphene to fabricate graphene/semiconductor heterostructure. The resulting low energy barrier leads to catalytic decomposition of carbon precursor, and promotes the formation of graphitic carbon on the surface.16 On the contrary, it enables extremely low solubility for carbon even at its melting temperature (<108 atoms per cm3),17 which enables the growth of complete monolayer graphene.18 Merging of multiple seeds into a single‐crystal layer with no grain boundary is possible due to distinct and anisotropic atomic arrangement of single‐crystal Ge surface. Furthermore, epitaxially grown large‐area single‐crystalline Ge layers on Si wafers are easily available, whereas negligible difference in thermal expansion coefficients between Ge and graphene helps in lowering the intrinsic wrinkle formation.19, 20

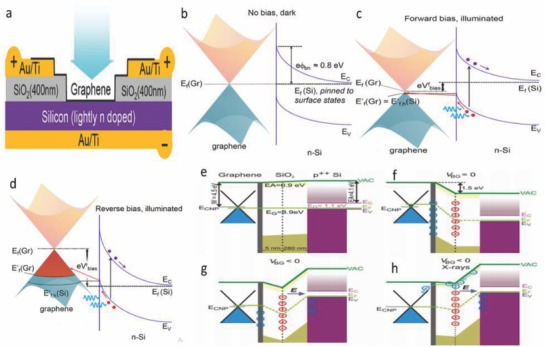

CVD graphene on Si is a planar 2D heterojunction which forms a conventional Schottky‐diode‐like structure.21 This configuration can suitably construct a platform for optoelectronic device applications. In these devices, the photoexcitation takes place in Si, whereas graphene acts as a carrier collector. In addition, the Fermi‐levels of graphene can also be shifted with application of low reverse‐bias voltage despite the large amount of bias voltage required in capacitively coupled gates. Schematic of the device structure consisting of monolayer graphene/Si is shown in Figure 1 a.21 Energy band diagram pertaining to the Fermi levels of graphene (E f(Gr)) and lightly doped Si (E f(Si)) at thermal equilibrium (dark condition) is shown in Figure 1b. Figure 1c shows the condition at low forward bias V f bias, which brings the Fermi level downward with respect to its “unbiased” condition. In this way, the Fermi level comes into close proximity to the quasi Fermi level for holes in Si, and thereby the number of accessible states for photoexcitation is significantly reduced. When reverse bias is applied, E f(Gr) shifts to higher value and generates a large number of available energy states for holes to inject (Figure 1d). Similarly, schematic band alignment (metal‐dielectric‐semiconductor) of the graphene based field effect transistor is shown in Figure 1e.22 The donor‐like defects N D + ionized by X‐rays create a large potential barrier which prevents the electrons to cross graphene/SiO2 interface (Figure 1f). In addition, application of negative voltage creates a potential drop within the gate oxide resulting in decrease of the potential barrier along with transformation into a potential well (Figure 1g). The electron accumulation leads to gradual compensation of the positive charge and consequently lowering of the energy barrier (Figure 1h).22

Figure 1.

a) Schematic of graphene/Si heterojunction device during forward bias condition. b) Thermal equilibrium energy band diagram of the heterojunction in darkness. c) Application of a forward bias minimizes the number of accessible states for the injection of photoexcited holes from Si. d) Reverse bias results a large number of accessible states for photoexcited holes injected from Si under illumination. Reproduced with permission.21 Copyright 2013, American Chemical Society. e) Band alignment for the graphene based transistor. f) For the X‐ray irradiated device the built in positive charge induces n‐doping of graphene and the formation of a potential barrier. g) If the negative VBG is applied to the gate, the potential barrier is partially decreased and transformed into a potential well. h) The photoexcited electrons localized in the SiO2 conduction band will be drifted by an applied electric field and accumulate near the location of the positive charge. Reproduced with permission.22 Copyright 2017, Springer Nature.

As both transfer and fabrication processes of graphene always facilitate poor electrical and optical characteristics, therefore efforts have been made to improve the quality of patterned graphene due to the gradual demand of bandgap engineering and sub‐micrometer scale interconnections for high speed integrated circuits (ICs).8, 9, 10 Therefore, lack of suitable transfer process and the performance degradation caused by mechanical transfer of graphene imply that the metal‐catalyst free direct CVD growth of graphene on solid inorganic insulating and semiconducting substrates will be a niche area of research for graphene based electronics.

Through the above discussion, it is evident that these inventions pave a way toward the production of graphene, in‐depth knowledge of the correlation among products, microscopic processes, and experimental conditions. This motivates the research for the metal‐catalyst free direct CVD growth of graphene on various dielectric and semiconducting substrates. Herein, we present a comprehensive review focused on the recent progress made toward the metal‐catalyst free direct CVD growth of graphene on technologically important dielectric substrates such as SiO2, ZrO2, HfO2, h‐BN, Al2O3, Si3N4, quartz, MgO, SrTiO3, TiO2, AlN, glass, and mica, and semiconducting substrates such as Si, Ge, GaN, and SiC. Merits and demerits of using high and low temperature CVD processes including growth mechanism and morphology of the graphene on these substrates have been discussed. Detailed discussions are presented for Si and Ge substrates, as they are important semiconductors, and suitable for next generation graphene/(Si/Ge) based hybrid electronic devices. Important results have been summarized in tables, and finally conclusions and outlook have been presented.

2. Catalyst‐Free Direct CVD Growth of Graphene on Technologically Important Dielectric Substrates

2.1. Graphene on SiO2 Substrates

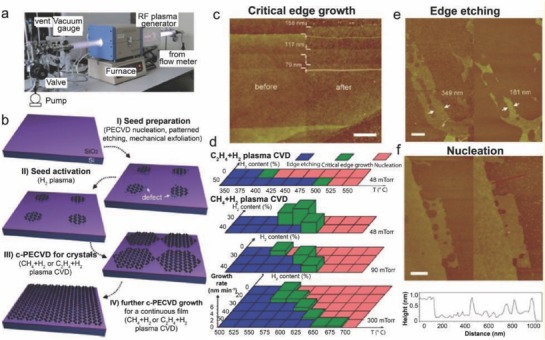

A low temperature growth leads to compatibility and minimizes energy consumption along with cost effectiveness for bulk production in the industry. Therefore, in order to deposit a clean high‐quality graphene directly on dielectric substrates, a controllable, low‐cost, and reliable mode is important at low temperature. The catalyst‐free direct growth of polycrystalline graphene was achieved by the pyrolysis of methane (CH4) on bare SiO2/Si substrates via oxygen aided atmospheric pressure chemical vapor deposition (APCVD) process.23 However, a low‐temperature (550–650 °C) growth of graphene on SiO2 substrates could be achieved by using PECVD.24, 25, 26 A PECVD system with 80 W power and 13.56 mHz radio frequency is shown in Figure 2 a. The SiO2/Si substrate was cleaned and then heated in H2 (99.9995%; 50 mTorr) atmosphere at 1000 °C for 15 min. Three kinds of seeds were prepared onto the substrates, which include 1) mechanical exfoliation using scotch tape peel‐off graphene; 2) graphitic clusters nucleated by C2H4 (99.9%) + H2 plasma CVD (50% H2, 48 mTorr, 550 °C) or CH4 (99.9%) + H2 plasma CVD (30% H2, 48 mTorr, 650 °C); and 3) patterning of nanoislands graphene by oxygen plasma etching and electron beam lithography. The position of the substrate with the seeds was at the center of the furnace. H2 plasma (H2: 250 mTorr) was generated upstream to activate the edge of the seeds at 500 °C. C2H4+H2 plasma CVD (50% H2, 48 mTorr, 500 °C) or CH4+H2 plasma CVD (30% H2, 48 mTorr, 600 °C) was then used for graphene growth. The PECVD growth mechanism of graphene on SiO2/Si substrate is shown in Figure 2b. Before and after PECVD growth, a trilayer peeled‐off graphene flake was observed in atomic force microscopy (AFM) images (Figure 2c). The movement of the edges, i.e., upper, middle, and bottom layer was found to be 158, 117, and 79 nm, respectively. This gave the indication that flake growth occurred at the edges continuously instead of in the plane. The critical parameters, such as H2 content, the pressure, and the growth temperature decided the growth at the edge (Figure 2d). At a lower temperature of 550 °C, the edges of the flakes were etched about 168 nm (Figure 2e). Small graphitic clusters were nucleated on the entire surface of the graphene flakes instead of the edge growth at a lower H2 content during CH4+H2 plasma CVD treatment, whereas SiO2/Si surface having heights less than 1 nm was found (Figure 2f). The heights observed in the images revealed the single‐layered nature of the clusters. Growth took place only at the edges at a well‐controlled critical temperature (Figure 2c). This critical temperature decreased with decreasing H2 concentration (Figure 2d). For edge growth, the critical temperature decreased to as low as 400 °C when C2H4 was used as the source of carbon in c‐PECVD (0% H2, 48 mTorr) (Figure 2d). Moreover, growth rate can be improved at low pressure. At 250 mTorr, the growth rate (30% H2, 600 °C) was found 1 nm min−1 and increased about 4.5 nm min−1 at 48 mTorr.

Figure 2.

a) Photograph of the remote radio frequency PECVD technique used during the experiment. b) Schematic representation of the c‐PECVD technique. c) AFM images of a graphene flake being peeled‐off before (left) and after (right) c‐PECVD growth. d) Experimental data are plotted as a function of the temperature and H2 content at 48, 90, and 300 mTorr. The blue, green, and red colors indicate the parameters for edge etching, critical edge growth, and cluster nucleation, respectively. The height of the green columns denotes the growth rate. e,f) AFM images of peel‐off graphene flakes after activation of the edges with a H2 plasma (250 mTorr, 500 °C) for 20 min (left columns), followed by CH4+H2 plasma CVD (30% H2, 300 mTorr, 550 °C) for 80 min [(e), right column] or CH4+H2 plasma CVD (20% H2, 300 mTorr, 600 °C) for 40 min [(f), right column]. The profile of the height along the red line is shown below the AFM image (f). Scale bars for (c,e,f) are maintained at 500 nm. Reproduced with permission.26 Copyright 2013, Wiley‐VCH.

In addition to this, the metal‐catalyst free direct CVD growth of graphene on SiO2 has been reported by many researchers. Wang et al.27 studied the growth of vertically aligned graphene nanosheets (VAGNs) on SiO2 substrate using CH4 as a precursor via thermal APCVD. Chen et al.28 reported single crystal hexagonal and dodecagonal patterns on SiO2 substrate using CH4 as a precursor via near equilibrium CVD. Few‐layer graphene films on SiO2 substrate using CH4 as a precursor via APCVD were demonstrated by Bi et al.,29 whereas Zhao et al.30 investigated the graphene nanowalls on SiO2 substrate using CH4 as a precursor via PECVD technique. It was observed that a low temperature (400 °C) direct growth of micrometer‐scale graphene crystals on SiO2 substrates could be achieved by using PECVD technique. These graphene crystals can be directly embedded to fabricate electronic devices, thereby eliminating the conventional postdeposition transfer process. Lack of transfer process, good control of the method, excellent quality of grown graphene, and the compatibility of this process with the current microelectronics technology make it a facile approach for future use in graphene electronics.

2.2. Graphene on ZrO2 Substrates

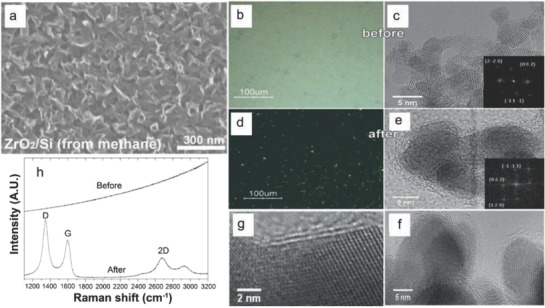

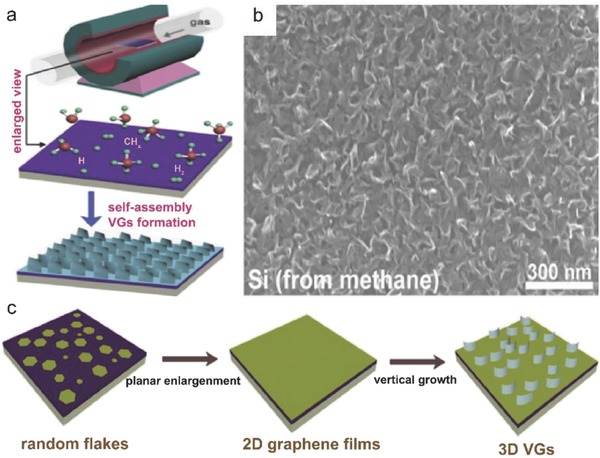

The metal‐catalyst free direct CVD growth of graphene on ZrO2 substrates can be achieved at a temperature lower than 480 °C as reported by Scott et al.31 Growth was carried out on ZrO2 substrates using acetylene (C2H2) as a precursor. As soon as the substrate was placed, the reaction chamber was evacuated followed by the flow of Ar. The substrate was heated to a temperature of 325–650 °C. The flow of Ar was maintained for 10 min and then C2H2 was introduced into the chamber. X‐ray photoemission spectroscopy (XPS) confirmed the formation of zirconium oxide being present in the form of monoclinic baddeleyite, and being slightly oxygen deficient. The low temperature enables catalytically active oxides to form sp2 carbon. Wang et al.27 reported the metal‐catalyst free direct growth of vertically aligned graphene sheets (VGs) on ZrO2 substrate using either CH4 or ethanol (C2H5OH) as a precursor via thermal CVD. First, the substrate was mounted to the central region of the quartz tube, and heated from room temperature to 1130 °C in 50 min with 50 sccm H2 and 50 sccm Ar. Second, the substrate was annealed for 20 min at 1130 °C, and then a certain flow rate of CH4 or C2H5OH vapor was introduced into the chamber to initiate graphene growth. 2D or 3D growth of graphene could be controlled by altering feedstock concentration and reaction time (growth mechanism is described in Section 3.1.2). A typical scanning electron microscopy (SEM) image of VG sheets on ZrO2/Si is shown in Figure 3 a. Till now, direct growth of VGs is mainly achieved by PECVD techniques. Hence, it is observed that plasma plays a crucial role for vertical alignment of graphene sheets. Thus, this work paves a new avenue toward the development of a novel and reliable technique for direct sysnthesis of VGs, and therefore brings a plethora into the intrinsic mechanism of vertical graphene synthesis.

Figure 3.

a) SEM images of VGs on ZrO2/Si substrates. The VGs were grown at a condition having 8 sccm CH4, 50 sccm H2, and 50 sccm Ar for 6 h. Reproduced with permission.27 Copyright 2017, Elsevier Ltd. Optical microscopy image of ≈750 nm HfO2 nanoparticle film grown on SiO2/Si substrate b) before and d) after CVD in CH4/H2 at 950 °C. HRTEM images of the HfO2 nanoparticles scratched from the film c) before and e–g) after CVD. Insets in (b) and (d) show the FFT analysis of the respective HfO2 nanoparticles. h) Raman spectra for the HfO2 nanoparticles before and after CVD with CH4 and H2 at 950 °C. Reproduced with permission.32 Copyright 2011, Wiley‐VCH.

2.3. Graphene on HfO2 Substrates

The metal‐catalyst free direct growth of few layer graphene on HfO2 nanoparticles was achieved by using APCVD technique.32 The monoclinic HfO2 nanoparticles neither form metal nor carbide during nucleation in graphitic domains. The samples were heated in the presence of pure Ar at 900–950 °C and for 10 min in pure H2, and finally exposed to a CH4/H2 mixture for 20 min. Figure 3b,d shows optical microscopy images of the HfO2 nanoparticles film treated at 950 °C. The color of the deposited nanoparticles film was found to be white and it gradually became black after CVD growth, which indicated the deposition of carbon on the particles. Figure 3c shows high resolution transmission electron microscopy (HRTEM) images of the nanoparticles before CVD. The average particle size was found to be ≈4 nm. A fast Fourier transform (FFT) analysis (inset of Figure 3c) revealed the formation of monoclinic HfO2 nanoparticles. The HRTEM images of the nanoparticles after CVD technique are shown in Figure 3e–g.

The HfO2 nanoparticles were found to be encapsulated by 2–3 layers of graphitic carbon (Figure 3e). No phase transition occured in the HfO2 nanoparticles during CVD process. Particularly, no metallic hafnium or hafnium carbide was observed during post‐CVD FFT analysis. This suggested that the nanoparticles were of monoclinic HfO2 phase (inset of Figure 3c). The HfO2 nanoparticles were coated by multilayer graphitic carbon (Figure 3f). Two layers of graphitic carbon anchored along (111) direction of the HfO2 nanoparticles for a projection along (011) plane (Figure 3g). 1–5 layers of carbon showed an interlayer spacing of ≈0.35 nm corresponding to few‐layer nanographene (FLG). The HfO2 nanoparticles before CVD treatment showed no signatures of carbon in Raman study, whereas the post CVD samples exhibited G (≈1600 cm−1, full width at half maxima (FWHM) = 86 cm−1), D (≈1360 cm−1, FWHM = 83 cm−1), and 2D (≈2700 cm−1, FWHM = 88 cm−1) bands (Figure 3h). Nanosized graphitic domains on nanoparticles of a high‐k dielectric material find its limitations in terms of direct application for integration into electronics, however, they act as a model system for catalytic CVD of graphene on oxides. Hence, HfO2 is an interesting platform for basic studies pertaining to growth as well as future integration of graphene into the electronic devices.

2.4. Graphene on Hexagonal Boron Nitride Substrates

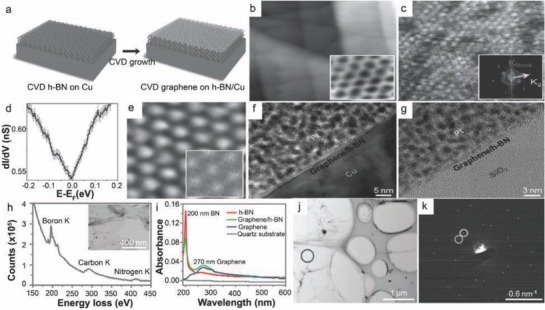

Considerable research interest was gained for the h‐BN because its lattice parameter was found to be same with graphene.33, 34 When CVD grown graphene was transfered onto CVD‐grown h‐BN, a device on h‐BN having large area of graphene and threefold high mobility than that on SiO2 was fabricated.35 Graphene on h‐BN structures can be transferred either by mechanical exfoliation or via CVD growth onto h‐BN layers.35, 36, 37, 38 The metal‐catalyst free direct CVD growth of graphene onto h‐BN film was demonstrated in order to achieve pristine graphene/h‐BN interfaces with high area coverage. BN layer grown by CVD technique on Cu foil was taken as the substrate. The growth of graphene on h‐BN/Cu at 1000 °C for 40 min with 5 sccm H2 and 20 sccm CH4 at a total pressure of 210 mTorr was achieved. The structure of CVD graphene on h‐BN film/Cu foil is shown in Figure 4 a. It was found that h‐BN layers were coated with a single layer graphene (SLG) (Figure 4b). Honeycomb lattice of graphene was grown (inset Figure 4b) and owing to the same kind of atomic structures, a hexagonal Moiré pattern having a period of 0.55 nm was observed (Figure 4c). The stacking angle between graphene and h‐BN layers was observed to be 26° for 0.55 nm period.39 Electronic states of graphene were supported by the inert and flat h‐BN layers, similar to that of intrinsic graphene.33, 40, 41 dI/dV spectrum was determined by the scanning tunneling spectroscopy (STS) analysis which in turn was conducted through Moiré pattern region of 0.55 nm (Figure 4d). Spectrum having a sharp and symmetric V‐shape found its consistency to that of intrinsic graphene. Moiré pattern with a period of 4.2 nm and an angle of 3.2° between graphene and BN lattices was observed in the scanning tunneling microscopy (STM) image (Figure 4e).

Figure 4.

a) Schematic of the CVD grown graphene on h‐BN film/Cu foil. b) STM image with the straight step edges of the underlying h‐BN layers. Image area: 60 nm × 60 nm; parameters: V b = 1.0 V, I t = 0.1 nA. Inset: STM image of the graphene honeycomb lattice. c) STM image related to the Moiré pattern with a 0.55 nm period. Inset: The FFT result of (c). Image area: 10 nm × 10 nm; parameters: V b = −0.8 V, I t = 0.12 nA. d) Average value of the dI/dV data was determined on the region of 0.55 nm Moiré pattern with the error bars overlaid at each energy point; parameters: V b = 0.2 V, I t = 0.2 nA. e) STM image showing the Moiré pattern having period of 4.2 nm. Image area: 23 nm × 23 nm. Parameters: V b = − 0.14 V, I t = 0.11 nA. Inset: A simulated Moiré pattern (4.2 nm) having angle of 3.2° between the graphene and the h‐BN. Cross‐sectional TEM images of f) CVD‐grown graphene/h‐BN film on Cu foil; g) CVD grown graphene/h‐BN film on SiO2/Si substrate. h) EELS spectrum indicates the elements B, N, and C. Inset: Top view TEM image of graphene/h‐BN film. i) UV–Vis spectroscopy of h‐BN grown by CVD technique. j) TEM image of a graphene/h‐BN film. k) SAED pattern of graphene/h‐BN. Reproduced with permission.42 Copyright 2013, Wiley‐VCH.

Honeycomb lattice, Moiré patterns, sharp and symmetric V‐shape spectrum with the Dirac point at the Fermi level gave a clear notion that a high quality monolayer graphene was grown on h‐BN/Cu without any contribution of charge or doping. Cross‐sectional transmission electron microscopy (TEM) image confirmed the presence of a graphene/h‐BN film having a thickness of 2 nm (Figure 4f). The image dictated layered structure of graphene/h‐BN (Figure 4g). In the electron energy loss spectroscopy (EELS) spectrum (Figure 4h), three distinct edges of 200, 290, and 410 eV were observed, which indicated the characteristic K‐shell ionization edges of B, C, and N, respectively. Two distinct peaks at 200 and 270 nm appeared due to optical bandgap43 and π plasmon peak,44 respectively, and thus as‐grown graphene/h‐BN sample indicated the coexistence of graphene and h‐BN (Figure 4i). Figure 4k shows selected‐area electron diffraction (SAED) pattern of graphene/h‐BN in the marked zone (Figure 4j). The obtained data described two sets of hexagonal diffraction data in graphene/h‐BN sample, and hence confirmed the coexistence of single crystal graphene and h‐BN.

Similarly, Ding et al.45 investigated a few layer graphene on h‐BN substrate using CH4 as a precursor via metal catalyst free CVD technique. Stacked‐layers on h‐BN substrate using hexane (C6H14) (vapor) as a precursor via APCVD technique was demonstrated by Liu et al.46 However, it was observed that the sequential CVD is a robust technique for the direct growth and fabrication of stable graphene/h‐BN hybrid structure onto CVD grown h‐BN film on Cu. Also, it is possible to grow uniformly distributed, large‐scale SLG directly on h‐BN films. Moreoever, CVD grown graphene/h‐BN devices exhibit superior carrier mobility and reduced defects compared to mechanically transferred graphene onto h‐BN film. Furthermore, CVD‐grown graphene/h‐BN films were found to be significantly versatile to sustain during postgrowth transfer process. There is a flurry of demand for the development of high performance electronic devices using large area graphene/h‐BN hybrid structures having negligible defects.

2.5. Graphene on Quartz Substrates

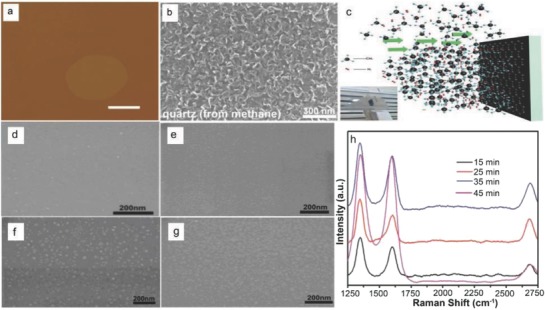

Owing to the high melting point along with structural stability, quartz has a flat surface having roughness about 0.414 nm. Chen et al.28 demonstrated the metal‐catalyst free direct growth of single crystal hexagonal and dodecagonal pattern on quartz substrate using CH4 as a precursor via near equilibrium CVD technique. Quartz having smooth face toward the downward side was placed in a high‐temperature horizontal silica tube furnace. The furnace was heated at 1180 °C and stabilized for about 30 min in 250 sccm H2 and 300 sccm Ar. During entire growth, a gas mixture (CH4:H2 = 1.9–2.3:50) was taken as the carbon source. AFM phase image of graphene grain on quartz substrate is shown in Figure 5 a. Zhang et al.24 demonstrated the direct growth of uniform graphene films onto quartz substrate using CH4 as a precursor via remote (r)‐PECVD technique. Nanographene films having good uniformity were grown on 4 inch wafer. By controlling the growth duration, the value of transmittance on quartz was found to be greater than 92%, whereas it exhibited a low resistance of 40 kΩ sq−1 at 550 nm. The direct growth of VGs on quartz substrate can also be achieved using either CH4 or ethanol (C2H5OH) as a precursor via thermal CVD, as demonstrated by Wang et al.27 SEM image of VGs on quartz substrate is shown in Figure 5b (growth mechanism is described in Section 3.1.2).

Figure 5.

a) AFM images of graphene grains on quartz substrate. Scale bar 500 nm. Reproduced with permission.28 Copyright 2014, Wiley‐VCH. b) SEM images of VGs on quartz at a condition of 8 sccm CH4, 50 sccm H2, and 50 sccm Ar for 6 h. Reproduced with permission.27 Copyright 2017, Elsevier Ltd. c) Schematic illustration of graphene growth on glass substrate by vertical‐glass model (the inset shows the vertical glass substrate set up). High‐magnification SEM images of graphene islands on glass surface with growth time of d) 15 min, e) 25 min, f) 35 min, and g) 45 min. h) Raman spectroscopy of graphene grown on glasses with different growth time. Reproduced with permission.47 Copyright 2018, Elsevier Ltd.

Recently (2018), Chen et al. demonstrated direct growth of graphene on vertically placed quartz substrates via APCVD.47 Figure 5c is the schematic of the vertical‐quartz substrate (20 mm × 20 mm × 1 mm) APCVD model. The substrate was heated to 1000 °C and stabilized for about 10 min under Ar (100 sccm) and H2 (20 sccm) and then CH4 (10 sccm) was introduced for 15, 25, 35, and 45 min, respectively. Figure 5d–g shows the SEM images of the graphene islands on quartz substrates grown for 15, 25, 35, and 45 min, respectively. Large number of graphene nanocrystals (<10 nm) were observed on the quartz surface. As the growth time increased from 15 to 35 min, the size of the graphene islands increased (10–30 nm). Finally, quartz surface was mainly covered by the larger graphene islands as the growth time increased to 45 min (Figure 5g). The density of the mixed gas facing the quartz substrate was greater as compared to the surrounding gas which significantly enhanced the collision probability of the reactive fragments with the quartz surface, and finally led to the higher growth rate of graphene on the front surface. For all the samples, the intensity of the D peaks was higher as compared to the G peaks as observed from Raman spectra (Figure 5h), and the intensity ratio of the G peak to the 2D peak was >1. It was inferred that a large number of defects were present and the grown graphene was multilayered. These findings indicated that these materials have potential applications in future transparent and conductive electronics. The direct growth of large size and high‐quality graphene on quartz substrates with a clean, wrinkle‐free, and breakage‐free morphology is important for fundamental research and practical applications.

2.6. Graphene on Si3N4 Substrates

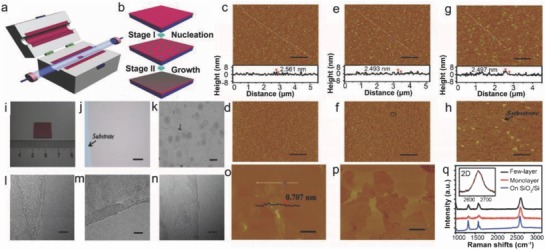

The metal‐catalyst free direct growth of large‐area graphene films on silicon nitride (Si3N4) substrates can be achieved by a two‐stage CVD process.48 Graphene in the form of sheets can successively grow on Si3N4 surface, and at a later stage merged together to form a polycrystalline graphene film. These graphene films can be used to fabricate field‐effect transistors (FETs). A clean Si3N4/SiO2/Si substrate was kept into a quartz furnace at high‐temperature (Figure 6 a). The growth was followed by the nucleation of graphene and subsequently the growth of graphene on a Si3N4 surface (Figure 6b). The flow rates of CH4 and Ar were taken as 2.3 and 300 sccm, respectively. The formation of discrete graphene nanocrystal on the Si3N4 substrates was observed. CH4 and H2 in the ratio of 5:50 were used as the carbon source for the growth of high‐quality graphene film. Figure 6c–h depicts the AFM images of Si3N4 surface profile before and after graphene growth. The polycrystalline Si3N4 layer was deposited on SiO2/Si substrate via low pressure CVD (LPCVD) (Figure 6c,d). The average roughness of the Si3N4 surface was found to be 0.702 nm, whereas height of raised Si3N4 particles was about 2.561 nm (Figure 6c). The variation was found in the surface roughness (R a ≈ 0.775 nm) (Figure 6e). The surface underwent rigorous modifications and was coated with graphene nanocrystals (Figure 6f). The AFM image (Figure 6f) is marked with black circle, which indicated contrast between the graphene and the Si3N4 substrate. The lateral dimensions of the graphene nanocrystals were observed to be of 30–40 nm. The morphology of graphene is shown in AFM image (Figure 6g).

Figure 6.

a) Schematic diagram of the CVD system where graphene growth on a Si3N4 substrate was carried out. b) Schematic representation of the two‐stage process for graphene growth. c,d) AFM images of Si3N4 substrate. e,f) AFM images of the Si3N4 substrate after nucleation. g,h) AFM images of the Si3N4 substrate. c,e,g) Height images and d,f,h) phase images are shown. Scale bars = 1 µm. i) Photograph of graphene film on Si3N4 substrate. j) Optical image of a graphene film on a Si3N4 substrate. Scale bar 50 µm. k) SEM image of graphene film. Scale bar = 500 nm. l–n) HRTEM images of graphene films. Scale bars: 5 nm. o,p) AFM images of transferred graphene on SiO2/Si substrates: height image (o), phase image (p); scale bars = 300 nm. q) Raman spectra of the graphene films on a Si3N4 substrate and the transferred graphene on a SiO2/Si substrate. The inset shows the enlarged 2D peak of single‐layer graphene. Reproduced with permission.48 Copyright 2013, Wiley‐VCH.

The film was not distinguished properly from the underlying Si3N4 layer caused by the surface roughness (R a ≈ 0.887 nm). The graphene film was observed to be clearly separated from Si3N4 substrate, and formation of wrinkles took place along the boundary of the sheets (Figure 6h). It was confirmed that polycrystalline substrate did not affect the growth of graphene. It was observed that graphene covered the surface at the end of CVD growth (Figure 6i). The graphene films were uniformly distributed as shown in Figure 6j. SEM image of the graphene film is shown in Figure 6k. A clear layered structure was observed in the TEM images (Figure 6l–n). Figure 6o,p shows AFM images of transferred graphene on SiO2/Si substrates. The line scan (Figure 6o) illustrates that the step height between the surface of the sheet and the substrate was about 0.707 nm. Raman analyses also (Figure 6q) confirmed the growth of single and few‐layer graphene. The carrier mobility (1510 cm2 V−1 s−1 in air, 1518 cm2 V−1 s−1 in N2) was found to be three times higher than those grown on SiO2/Si substrates as well as better than graphene grown using metal catalyst.23, 49 Thus, large area high quality graphene films were grown on Si3N4 substrates via two‐stage metal catalyst‐free CVD process where the detrimental effects of the substrate were minimized. In addition, the graphene sheets were successively grown along rough Si3N4 surface followed by merging together to form a high quality polycrystalline graphene film. The difficulties that arise during postgrowth transfer method can be eleminated by adopting two‐stage metal‐catalyst‐free‐growth technique, which finds its compatibility with current Si processing technology.

2.7. Graphene on AlN Substrates

Aluminum nitride (AlN) is a promising material due to its versatile applications such as microelectronic and optoelectronic devices, short wavelength emitters, electronic packaging, and acoustic wave resonators.50 However, a semiconductor template is pertinent in order to grow high quality graphene. In this regard, AlN grown on Si finds its potential as a suitable template by replacing 3C‐SiC for wide range of nitride and UV application. Direct growth of graphene on AlN/Si template was carried out by Michon et al.51 In this study, graphene was grown on AlN/Si (111) templates via propane CVD, where N2/H2 mixture was used as the carrier gas. A rotational disorder along with wrinkles was formed onto the graphene films grown on AlN/Si. Here, temperature played an important role to improve the structural quality of the film. Again, high temperature growth might have influenced rough surface, but there was no impact on the structural quality of the graphene film as determined by Raman analysis. Moreover, the temperature for optimum growth might be higher (1350 °C), which suggests the growth of high‐quality graphene on bulk AlN substrates. Furthermore, during processing, AlN etching was minimized by the growth of graphene compared to the annealing (i.e., without propane), which enabled the growth of AlN at 1250 °C for 6 min without etching effects. It may be mentioned here that thermal treatment of nitrides films finds an ease with this method to enhance the quality of crystal, and favors the activation of doping at the time of ion implantation.51 Thus, growth of graphene on semiconductor template without using carbon based derivatives opens up a new possibility of direct growth.

2.8. Graphene on MgO Substrates

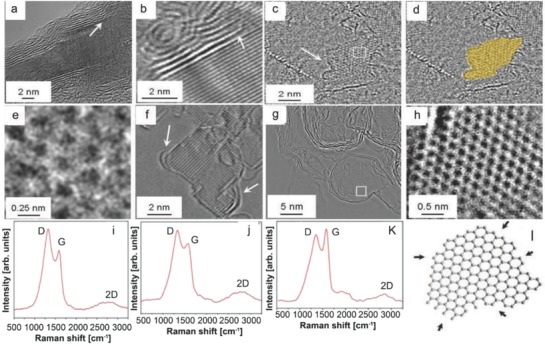

MgO is considered to be advantageous for the growth of nanographene and few‐layer nanographene (nFLG) directly using CVD technique. However, calibration of the reaction time or temperature needs to be undertaken to grow nFLG and nanographene. The growth can be done at temperatures of 325 °C using acetylene as a precursor.31 Figure 7 a–h shows TEM images of the samples prepared by catalytic CVD reactions on MgO using cyclohexane as the feedstock. Figure 7a,b shows the formation of MgO crystal at 875 °C after CVD treatment where reaction was undertaken for 5 min. The interspacing between graphitic layers (2–10) was found to be 3.5 Å. Alignment of the graphitic layers with MgO lattice planes100 had a spacing of 0.21 nm. It was also observed that the graphene layers were attached to the MgO crystal. This observation was found to be same as the graphitic layers growth by SiC decomposition.52 The number of graphene layers formed was 2 and 10 at reaction times of 5 min and 1 h, respectively. Growth of graphene nanoislands on the surface of oxide crystals and nanographene shells is shown in Figure 7c–f and Figure 7g,h, respectively. A strong D mode and broadened G mode along with a weak and broad 2D mode were observed in the Raman spectra (Figure 7i–k). A large number of edge states existed in nanographene compared to its bulk counterpart (Figure 7l).

Figure 7.

a,b) TEM images of few‐layer graphene on MgO crystal. c,d) Formation of graphene island on the surface of a MgO crystal. e) Magnified region from the box in panel (c) indicating the graphene structure. f) Cross‐sectional image of graphene on the surface of an MgO crystal. g) Growth of graphene shells when MgO is removed. h) Magnified region from the box in panel (g) highlighting graphene structure. Raman spectra of i,j) nanographite and k) a purified sample prepared at 325 °C over MgO. l) Schematic representation of a nanographene flake. Reproduced with permission.53 Copyright 2010, American Chemical Society.

Ferrari54 investigated the effects of edge states in detail, which were mainly defects. These effects exactly matched with Raman spectra along with nanographitic species. Gaddam et al.55 reported monolayer on MgO substrate using C2H4 as a precursor via free radical assisted CVD. Zhao et al.56 reported single or few layers on MgO substrate using benzene and pyridine as a precursor via APCVD. Thus, MgO is found to be a suitable candidate for the metal‐catalyst free direct growth of nanographene through CVD technique. Moreover, the growth can be undertaken at low temperature (325 °C) using this technique. Owing to low temperature growth, this technique is promising for the growth of large area nanoribbon graphene using present Si‐based technologies.

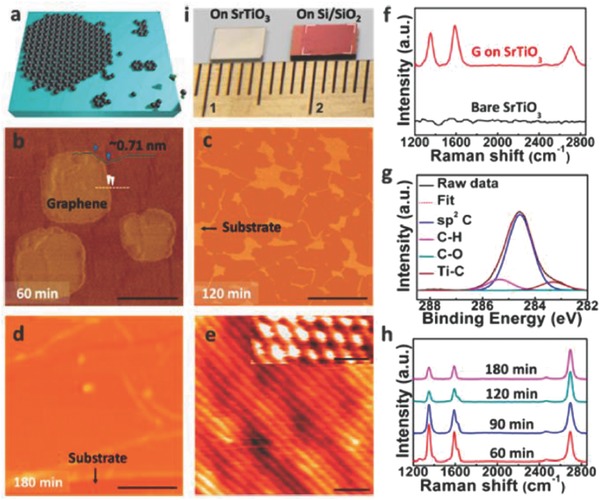

2.9. Graphene on SrTiO3 Substrates

The use of high‐k dielectric as a substrate by replacing low‐k (SiO2) leads to better gate modulation, improved gate capacitance, and reduced gate leakage.57 However, the difficulties associated with SiO2 are carrier scattering due to charge fluctuations and surface roughness. These results are obstruction for further integration of FETs based on SiO2‐gated graphene.57, 58, 59 Therefore, direct growth of graphene on the surface of high‐k dielectric and scatter‐screening dielectric substrates becomes significant. SrTiO3 (STO), a transparent, high‐k perovskite dielectric may have great thermal stabilities and potentials.60, 61, 62 Sun et al. demonstrated the metal‐catalyst free direct CVD growth of graphene on STO (001) substrates using a simple APCVD technique (Ar/H2/CH4:100/50/2.5 sccm).63 They successfully fabricated STO‐gated bipolar FET and studied their low voltage operation along with magnetotransport properties of as‐grown graphene/STO samples. The growth of graphene on STO substrate was attributed to the in‐plane propagation process of carbon species (Figure 8 a). AFM images (Figure 8b–d), taken from the graphene nanoislands, exhibited the formation of continuous film with irregular voids along with complete layers of graphene wrinkles obtained for 60, 120, and 180 min, respectively. The height of the nanoislands was found to be ≈0.71 nm, and the formation of a uniform film may be attributed to the size elongation of nanoislands followed by the agglomeration. From STM images of the as‐grown graphene on STO (Figure 8e and inset), the lattice constant was determined to be ≈0.246 nm. Three distinct peaks were observed in the Raman spectrum of as‐grown graphene on STO (Figure 8f). The peaks corresponding to D, G, and 2D bands were located at 1350, 1597, and 2695 cm−1, respectively. However, the 2D peak of graphene grown on the STO substrate did not appear due to the substrate screening effect (lattice mismatch and/or strong interaction due to the chemical bonding between the graphene and substrate). XPS analysis (Figure 8g) confirmed the signature of Ti–C peak, sp2 carbon peak, and C–H peak at 283.4, 284.8, 285.3 eV, respectively.

Figure 8.

a) Schematic of graphene growth on STO (001) substrates. b–d) AFM images of the graphene grown by CVD technique for different duration. Scale bars: (b) 250 nm. (c,d) 1 µm. e) STM image (V s = 0.7 µV, I t = 18 nA) of a graphene film. Scale bar: 1 nm. Inset: STM image of graphene honeycomb lattice. Scale bar: 0.5 nm. f) Raman analysis of as‐grown graphene and bare STO substrates. g) XPS spectrum of as‐grown graphene. h) Raman analysis of graphene for the evolution of graphene growth. i) Photograph of an as‐grown graphene film on STO and a transferred graphene film to Si/SiO2 substrate. Reproduced with permission.63 Copyright 2014, American Chemical Society.

High quality and single layer graphene was grown after CVD treatment for 180 min (Figure 8h). Photograph of the as‐grown and as‐transferred samples on Si/SiO2 (Figure 8i) indicated that STO substrate size limits the area of entire monolayer having uniform contrast. Recently, Karamat et al.64 and He et al.65 reported the growth of nanographene and few‐layer graphene shell on SrTiO3 using CH4 as a precursor via APCVD method, respectively. Thus, from the above discussion it is evident that large‐area monolayer graphene with good uniformity can be grown on single crystal STO substrates directly using CVD techniques. Owing to unique electronic and optical properties of the as‐grown graphene on STO, it holds a strong potential toward energy‐saving devices, high‐performance FETs, and transparent electrodes. Therefore, from device point of view, further studies need to be undertaken in this area especially its growth optimization, band structure, and chemical bonding with the substrate.

2.10. Graphene on Al2O3 Substrates

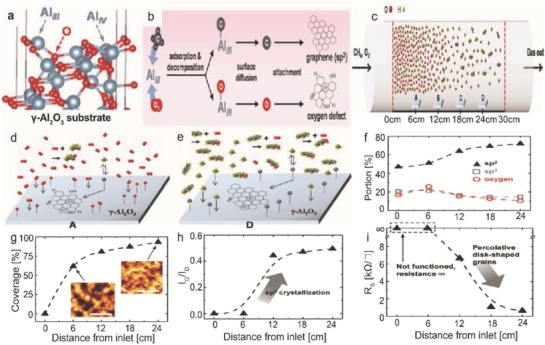

Generally, CVD growth of graphene involves metal catalyst such as Cu or Ni66, 67, 68, 69, 70 and there exists strong adhesion between the metal and the graphene which causes several issues such as contaminations in the product, undesired doping by the metal ions, and chemical exposure in the metal etching, and polymer residues from the transfer process.71, 72, 73 Ceramic catalyst25, 31, 53, 74 was proposed as a metal‐free alternative. One of the most promising candidates is γ‐Al2O3 due to its insulating properties, lower adhesion energy to graphene, and reusability as a catalyst.75, 76 A dielectric ceramic material such as γ‐Al2O3 can itself serve as a device substrate, where a device may be directly fabricated onto the synthesized graphene without any need for a transfer process. The γ‐Al2O3 has highly reactive tri‐coordinated Al (Al‐III) sites on the surface (Figure 9 a), which acts as catalytic sites due to strong reactivity by adsorbing various molecules.77, 78 During an actual graphene synthesis, CH4 was used as the carbon precursor, whereas O2 from the leakage reacted to the Al‐III sites of γ‐Al2O3. These were decomposed to generate adatoms, which attached themselves for graphene nucleation through surface diffusion.76, 78, 79 The carbon adatoms soon progressed into sp2 crystallization; the oxygen adatoms instead developed oxygen defects and consequently acted as a growth inhibitor (Figure 9b). Figure 9c shows the gradient change of the gas composition with respect to the substrate positions within a CVD heating zone. When the gas molecules passed through the actual heating zone of a tube furnace in the CVD system, heat was generated through spontaneous dehydrogenation followed by the polymerization and elongation.80 More CxHy‐type linear hydrocarbons were produced while travelling along the gas flow, which then reacted with O2 in the following manner81

| (1) |

| (2) |

| (3) |

Figure 9.

a) Structure of the γ‐Al2O3 surface. b) Schematic flow process of CH4 or O2 to graphene or oxygen defect through adsorption on Al III sites. c) Change of gas composition within a CVD heating zone. Gas composition at a location d) closer and e) further from the oxygen influx. f) Comparison of sp2, sp3, and oxygen portion of graphene with respect to the distance from the inlet. g) Coverage variation of graphene grown on γ‐Al2O3 with respect to the distance from the inlet. Plots of h) I G/I D, and i) R S for the graphene with respect to the distance from the inlet. Reproduced with permission.82 Copyright 2017, Wiley‐VCH.

These reactions created a difference in O2 concentration along the heating zone (Figure 9d,e). As the substrate was placed further from the inlet, the source of the O2 leakage, the oxygen, and sp3 portions showed a decreasing trend, ranging from 25.76% to 10.59%, and from 21.15% to 14.70%, respectively (Figure 9f). The graphene formation was strongly suppressed near to the inlet or when exposure to O2 was at the highest (Figure 9g). The grown graphene was composed of the nanosized grains connected to one another. The values of I G/I D corresponding to the sp2 portion/defect with respect to the substrate position from inlet are shown in Figure 9h. The sp2 crystallization was significantly enhanced at distances over 6 cm, which was consistent with the XPS results (Figure 9f). The samples grown at 0 and 6 cm position had the sheet resistance (R S) values at infinity due to the insufficient graphene growth (Figure 9i), which was apparent from the low percolative graphene coverage of 0% and 61.7%, respectively (Figure 9g). The sample grown at 6 cm position formed small disk‐shaped graphene grains without any overlap to form an electrical percolative channel. The samples grown at the position of 12, 18, and 24 cm exhibited the R S values of 6.64, 1.06, and 0.64 kΩ sq−1, respectively. From the above discussion, it was oberserved that a quantitative and systematic analysis helps to clearly elucidate the impact of oxygen exposure on the growth as well as device characteristics of graphene grown on γ‐Al2O3 using CVD technique.

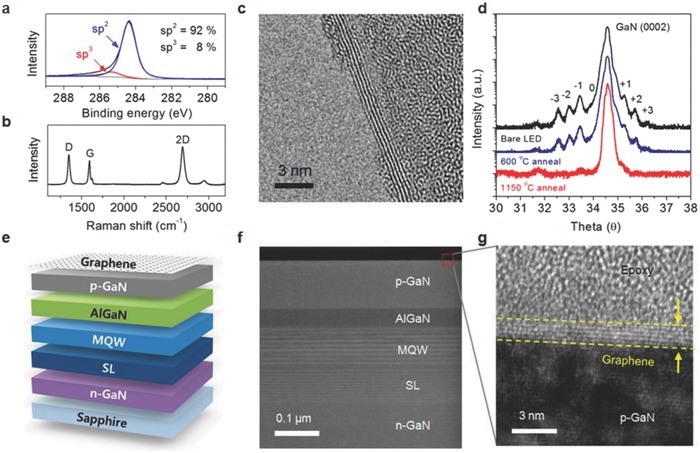

The graphene is considered to play a pivotal role in optoelectronic devices as a transparent conducting film (TCF). However, the manufacturing process available in the literature utilizes graphene as a TCF which follows transfer procedures. These steps are time‐consuming and sometimes chemical contaminations are encountered during processing which may impose detrimental effects to optoelectronic devices. Therefore, the metal‐catalyst free direct CVD growth of graphene on crystalline Al2O3 (sapphire) was demonstrated by many researchers. Chen et al.28 reported single crystal hexagonal and dodecagonal patterns on sapphire substrate using CH4 as a precursor via near equilibrium CVD technique, whereas Song et al.83 reported the growth of single layer graphene on sapphire substrate using CH4 as a precursor via metal catalyst‐free APCVD. Zhang et al.24 studied uniform graphene films on sapphire substrate using CH4 as a precursor by PECVD technique. A study pertaining to graphene crystal onto sapphire substrate was accomplished using C2H4 as a precursor using PECVD technique.26

2.11. Graphene on Glass and Mica Substrates

The metal‐catalyst free direct growth of graphene on glass and mica substrates can be achieved via r‐PECVD system at a substrate temperature of ≈550 °C using pure CH4 as a precursor.24 The growth temperature (550 °C) was found to be lower than the temperatures for CVD graphene growth (≈900–1000 °C).84, 85, 86, 87 Therefore, it enabled the growth of graphene on glass substrates. Moreover, direct growth of nanographene films can be done on any substrate using this technique. The growth of graphene films on atomic layer deposited mica and 4 inch glass wafers was also demonstrated. The growth rate on different substrates changed to some extent due to different adsorption rate, as plasma can dissociate CH4 into different species such as CHx, C2Hy, C3Hz, and atomic hydrogen. These radicals could play a pivotal role during nucleation followed by the growth of nanographene. Apart from the above discussions in Sections 2.5, 2.10, and 2.11 about the direct CVD growth of graphene on transparent substrates, reports are also available in the literature where uniform graphene films were grown on glass substrates using PECVD technique.88 High temperature CVD growth of nanographene on quartz (transparent substrate) was carried out without using any metal catalyst.89 Furthermore, high‐temperature direct CVD growth of graphene on quartz and sapphire substrates was undertaken and future prospects of the transfer‐free graphene for transparent electrodes were explored.90

2.12. Graphene on TiO2 Substrates

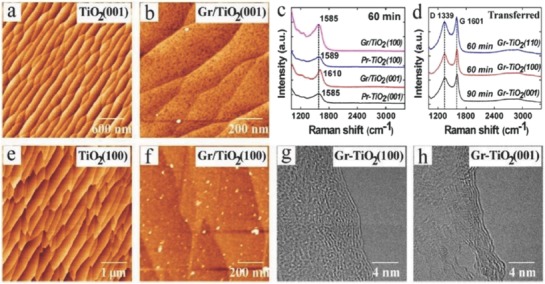

Recently, photocatalysis effect based on titania (TiO2) has gained tremendous research interest due to its green impact on environment.91, 92 Direct fabrication of graphene on TiO2 surface results in the contamination free graphene‐TiO2 interface. Liu et al.93 demonstrated the metal‐catalyst free direct CVD growth of graphene films on the as‐prepared r‐TiO2 surfaces such as (001) and (100) faces. Both substrates were cleaned using wet chemical etching followed by flattening into atomic smoothness.94 The AFM images of the as‐prepared pristine surfaces are shown in Figure 10 a,e. After the CVD growth, both surfaces exhibited changes similar to that of the (110) substrate (small islands having low surface roughness) (Figure 10b,f). Raman spectra exhibited the features similar to carbonaceous species (Figure 10c). When graphene was transferred onto the SiO2/Si substrate, the sharp G‐bands and D‐bands of the graphene became prominent (Figure 10d). Graphitic layers were seen at the edges of the films (Figure 10g,h). Quality of the graphene structures grown on the (100) and (001) r‐TiO2 surfaces was found to be lower than the (110) plane for the same growth parameter. Similarly, Bansal et al.95 demonstrated direct growth of few‐to‐monolayer of graphene on TiO2 substrate using CH4 as a precursor via APCVD/LPCVD technique. Moreover, graphitic nanostructures were grown on titania nanowire aerogel at 750 °C via CVD using ethylene. Three layer thick graphitic nanostructures gave a clear indication that titania nanowire surface enabled the graphitization to few‐layer graphene. The growth mechanism of few‐layer graphene on nanostructured metal oxides paved a way toward facile and controllable processing of metal oxide‐nanocarbon fiber–shell composites.96 Since the heterostructure (graphene‐on‐titania) has applications in energy and electrochemical technologies, it is highly recommended to study its properties and performance in these applications as future work. The summary of the growth of graphene on different dielectric substrates is mentioned in Table 1 .

Figure 10.

Graphene is grown by CVD technique on r‐TiO2 (100) and (001) substrates. a,e) AFM images of the pristine TiO2 after cleaning. b,f) AFM images of the graphene‐TiO2 film grown by CVD technique for 30 min. g,h) TEM images are taken from the graphene films stripped on TiO2 (Gr‐TiO2). c) Raman spectra of the graphene films taken from different TiO2 substrates. d) Raman spectra of the graphene films deposited on SiO2/Si substrates. Reproduced with permission.93 Copyright 2016, American Chemical Society.

Table 1.

Summary of different parameters for the direct growth of graphene on various dielectric substrates

| Substrates | Deposition techniques | Precursors used | Type of growth | Flow rate [sccm] | Growth time [min] | Temperature [°C] | Morphology | Ref. |

|---|---|---|---|---|---|---|---|---|

| SrTiO3 | APCVD | CH4 | Direct | CH4 = 5, 3, 1.5, 0.5, H2 = 20, Ar = 100 | 20 | 1050 | Few‐layered graphene shell | 65 |

| SrTiO3 | Catalyst‐ free CVD | CH4 | Direct | Ar:H2:CH4 = 100:50:2.5 | 60, 120 and 180 | – | Uniform monolayer | 63 |

| SrTiO3 | APCVD | CH4 | Direct | CH4:Ar:H2 = 8:100: 50 | 180, 240, and 420 | 1000 | Nanographene | 64 |

| h‐BN | Metal‐ catalyst‐free CVD | CH4 | Direct | CH4:Ar = 50:180 to 90:180 | 3–8 | 1000 | Few layers | 45 |

| h‐BN | APCVD | C6H14 (vapor) | Direct | – | 10 | 950 | Stacked layers | 46 |

| MgO | Free radical‐assisted CVD | C2H4 | Direct | – | – | – | Monolayer | 55 |

| MgO | APCVD | Benzene, pyridine | Direct | Ar = 40 | 20 | 650, 700, 750, and 800 | Single or few layers | 56 |

| MgO | APCVD (thermal CVD) | Acetylene | Direct | – | – | 325–650 | Single and multilayered nanoflakes | 31 |

| ZrO2 | Thermal CVD | CH4 | Direct | CH4:H2:Ar = 8:50:50 | 360 | – | Vertically aligned graphene nanosheets (VAGNs) | 27 |

| ZrO2 | APCVD (thermal CVD) | Acetylene | Direct | – | – | 325–650 | Single and multilayered nanoflakes | 31 |

| HfO2 | APCVD | CH4 | Direct | – | 20 | 950 | Few layers | 32 |

| Si3N4 | Metal‐catalyst‐ free CVD | CH4 | Direct | CH4:Ar:H2 = 2.3:300:5 | 60 | 1150 | Polycrystalline films | 48 |

| Al2O3 | PECVD | CH4 | Direct | – | 180 | 525 | Uniform films | 24 |

| Al2O3 | APCVD | CH4 | Direct | – | – | – | Nanosized grains | 82 |

| Sapphire | PECVD | CH4 | Direct | – | 240 | 500 | Uniform films | 24 |

| Sapphire | Metal‐ catalyst‐free APCVD | CH4 | Direct | H2:CH4 = 50:30 | 120 | 950 | Single layer | 83 |

| TiO2 | APCVD/ LPCVD | CH4 | Direct | H2 = 20, Ar = 300, CH4/Ar = 300 | 60 | 1100 | Few‐to‐monolayer | 95 |

| TiO2 | CVD | C2H4 | Direct | – | – | – | Few layered graphene | 96 |

| Quartz | PECVD | CH4 | Direct | – | 300 | 500 | Uniform films | 24 |

| SiO2, Si, and quartz | APCVD (thermal CVD) | CH4 | Direct | CH4:H2:Ar = 8:50:50 | 60, 120, and 360 | 1130 | VAGNs | 27 |

| SiO2 | APCVD | CH4 | Direct | CH4:H2:Ar = 3–10:10–50:450 | 60–120 | 1100–1200 | Few‐layered Films | 29 |

| SiO2 | PECVD | CH4 | Direct | Ar/H2:CH4 = 20:3 | 30–120 | 400–700 | Nanowalls | 30 |

| SiO2/Si and sapphire | PECVD | CH4 or C2H4 | Direct | – | – | 550–650 | Crystal | 26 |

| SiO2/Si, Si3N4/SiO2/Si, quartz, ST‐cut quartz, and sapphire | Near equilibrium CVD | CH4 | Direct |

CH4:H2 = 1.9/2.3:50 Ar = 300 |

30 | 1180 | Single crystal hexagonal and dodecagonal pattern | 28 |

| Glass | PECVD | CH4 | Direct | Ar/H2:CH4 = 20:3 | 30–120 | 400–700 | Nanowalls | 30 |

| Glass | PECVD | CH4 | Direct | CH4 = 5.6, 6, 10 | 60 | 400–600 | Uniform Films | 88 |

| Mica | PECVD | CH4 | Direct | – | 240 | 525 | Uniform films | 24 |

3. Catalyst‐Free Direct CVD Growth of Graphene on Technologically Important Semiconducting Substrates

Apart from Ge, there are only few reports available on the metal‐catalyst free direct CVD growth of graphene on important semiconducting substrates such as Si, GaN, and SiC. To the best of our knowledge, there are no reports avalaible on the metal‐catalyst free direct CVD growth of graphene on other important arsenide and phosphide based semiconductors. Therefore, in the successive sections, direct CVD growth mechanism and morphology of graphene on Si, Ge, GaN, and SiC substrates will be discussed. Detailed discussion is being presented for Si and Ge, as they are important semiconductors for the next generation graphene/Si and graphene/Ge based hybrid electronic devices.

3.1. Catalyst‐Free Direct CVD Growth of Graphene on Si Substrates

3.1.1. Low Temperature Growth

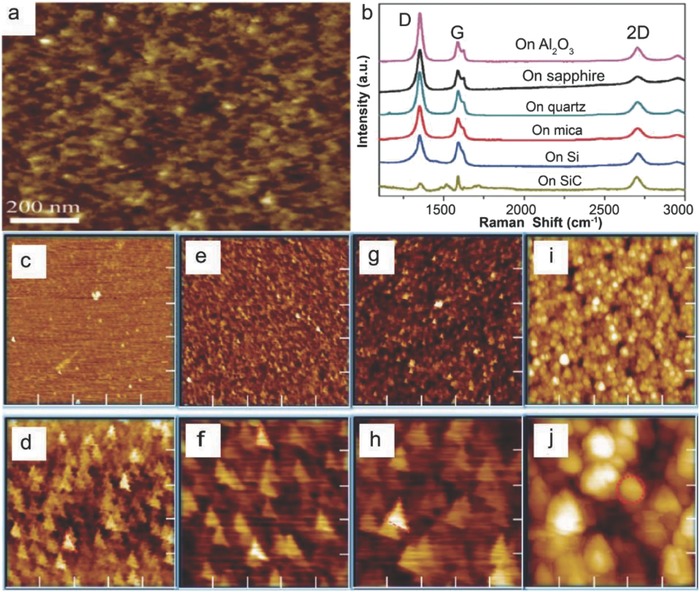

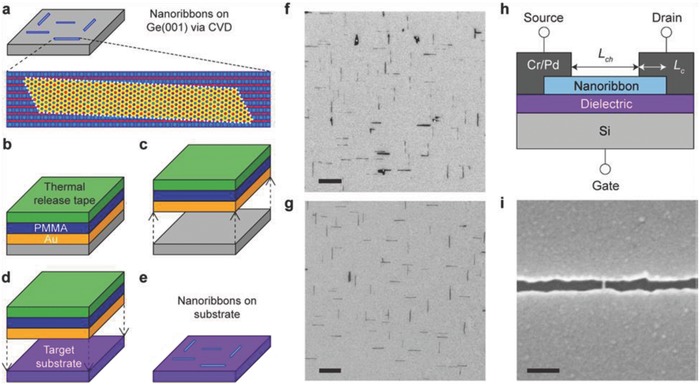

Takami et al. reported the catalyst‐free direct growth of networked graphite on Si and SiO2 substrates by using photoemission‐assisted plasma enhanced CVD system.97 They grew MLG particles (diameter of ≈10 nm) on Si (001) substrates at 700 °C by using Ar‐diluted CH4. Particles were closely connected to each other, and shared some graphene sheets between them. The advantage of using this system is that the DC discharge plasma assisted by photoelectrons emitted from the substrate under ultraviolet (UV) light irradiation could be generated close to the substrate with a controllable volume. Similarly, Zhang et al. reported the catalyst‐free direct graphene growth on various substrates including Si and SiC.24 Nanocrystalline graphene was directly grown on Si substrate via r‐PECVD system at a relatively low temperature of ≈550 °C by using pure CH4. This graphene growth process was quite unconventional as compared to high temperature (≈900–1000 °C) CVD graphene growth.85, 86, 87 It also enabled direct deposition of graphene films on low melting point substrates. Nanographene growth on Si substrate was carried out at 525 °C, 0.204 Torr (CH4), for 3 h under the plasma power of 100 W. Figure 11 a is the AFM micrograph showing the morphology of directly grown graphene. Islands type nanographene growth was observed instead of uniform film. Raman spectra of the graphene on different substrates are shown in Figure 11b, which did not vary significantly for different substrates. It was observed that the graphene growth on SiC was much faster, and the crystal size was much bigger with low surface roughness and less lattice mismatch. This may be attributed to the fact that adsorption abilities of hydrocarbon radical species on different substrates in plasma are different, which results in the different growth rate on different substrates. In plasma, CH4 can dissociate itself into various reactive radicals, such as CHx, C2Hy, C3Hz, and atomic H2. These species play a key role during the nanographene nucleation and growth stages. The carbon‐containing radicals continuously get adsorbed onto the substrate surface, and bonded with each other by diffusion and collision to form graphene nanoclusters with H‐terminations. Nucleation on the as‐grown graphene was much easier as compared to clean substrates. Moreover, due to atomic H2, strong etching effect was there which helped in the suppression of formation of amorphous carbon. Similarly, some other low temperature (500 and 780 °C) direct CVD growth of multilayer graphene films and graphene nanowalls on Si substrates with the help of microwave surface wave plasma CVD and PECVD were reported by Adhikari et al. and Zhou et al., respectively.98, 99

Figure 11.

a) AFM image of nanographene film grown on Si at 525 °C, 0.204 Torr, for 3 h and b) Raman spectra of nanographene films grown on various substrates under different conditions. The plasma power was 100 W in each case. Reproduced with permission.24 Copyright 2011, Springer Nature. AFM images of nanographene directly grown on silicon substrates for c,d) 1 h at 800 °C, e,f) at 900 °C, g,h) 1000 °C, and i,j) 1100 °C using the topography mode except (d) (phase mode). The scan size is 5 µm × 5 µm for (c), (e), (g), and (i) and 1 µm × 1 µm for (d), (f), (h), and (j). Reproduced with permission.89 Copyright 2011, American Chemical Society.

3.1.2. High Temperature Growth on Flat Substrates

Kim et al.89 reported the direct growth of graphene on 500 µm thick Si (100) wafers at high temperatures (800–1100 °C) by using thermal LPCVD system. Once the system pressure reached to 1 mTorr at the desired growth temperature, C2H2 and Ar with flow rates of 25 and 50 sccm, respectively, were introduced. Graphene growth at different temperatures was carried out by maintaining the pressure in the range of 2–100 Torr for 1 h. Figure 11c–h shows the AFM images of graphene grown at 800–1000 °C. Nanoscale triangle‐shaped planar graphitic carbon structures and triangle nanographenes (TNGs) were observed instead of a continuous uniform layer, whereas spherical nonplanar carbon clusters were observed at 1100 °C (Figure 11i,j). The right triangular shape of grown NG was anisotropic, and indicated that TNGs were crystalline in nature, as the crystal growth largely depended on the orientation owing to orientation‐dependent formation energy. TNGs became larger, as the growth temperature increased from 800 to 1000 °C (Figure 11c–h). They were like isosceles right TNG on Si, and the number density of the triangles was continuously reduced, which indicated that isosceles triangle formation on Si was more favorable, as the growth temperature increased. Thus, it was concluded that at high growth temperatures, the growth was less dependent on the diffusion than on the crystal orientation. However, spherical carbon clusters growth on Si was more favorable than the planar structure at 1100 °C (Figure 11i,j). This was due to the high thermal stress driven by the large thermal expansion coefficient with a significant lattice mismatch between graphene and Si.100, 101 The thermal stress relaxed by forming spherical graphitic clusters, which ultimately reduced the defect formation unlike the case for the planar structure. The position of the G bands in the Raman spectra of these TNGs grown at different temperatures was located at 1600 cm−1. This was higher than the typical large scale graphene or graphite (1580 cm−1), which confirmed the growth of NG.102

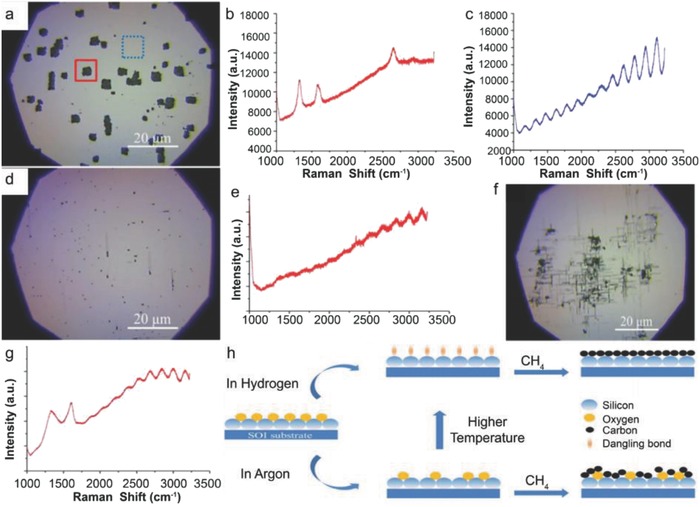

Moreover, Hong et al. attempted the metal‐catalyst free direct growth of graphene on Si substrates, eventhough they had succeeded in growing few‐layers graphene films on Si‐on‐insulator surface (SOI), but they were in the form of small dots and patches instead of continuous uniform graphene films.15 A number of growth experiments were carried out in a LPCVD system. The SOI substrates were heated in H2 atmosphere with a flow rate of 6 sccm at 300 mTorr and then kept for 20 min to activate the substrate surface, followed by 35 sccm of CH4 for 30 min at desired growth temperatures (870–970 °C). After growth at 920 °C, two kinds of surface features were observed: 1) the rectangular black dots highlighted by the solid red box, and 2) the large white area highlighted by the dashed blue box (Figure 12 a). Figure 12b shows the Raman spectrum taken from the black region, three peaks positioned at around 1331, 1589, and 2650 cm−1 were attributed to the D, G, and G′ bands of graphene, respectively.103 Intensity of the D band was stronger as compared to the intensity of G band. This was attributed to the very strong interaction between carbon and Si, as carbon atoms had very low diffusivity on Si surface, and did not move as freely as on metal surfaces. Raman spectrum taken from the white region (Figure 12c) shows the vibration curve, which was due to the optical interference in the sandwich structure of SOI, and confirmed that no graphene growth took place in that region. Several black dots and lines were observed on the sample surface grown at 870 °C (Figure 12d). However, their sizes were very small as compared to the sample grown at 970 °C (Figure 12a), which indicated that the reaction just started. No graphene signal was observed in the Raman spectrum taken from a black dot (Figure 12e). However, the interference signal of the substrate was much weaker in this case, which indicated that the surface was partially modified and started to grow graphene. Again, the growth was carried out at 895 °C and more lines along with the larger black dots were observed on the surface (Figure 12f). Raman spectrum taken from a black region is shown in Figure 12g. The peaks positioned at 1331 and 1594 cm−1 were attributed to the D and G bands of graphene, respectively.

Figure 12.

Graphene growth on SOI at 920 °C in hydrogen atmosphere. a) The optical image. The rectangle black dots (highlighted in solid red box) are covered with graphene, while the white area (highlighted in dashed blue box) is the unreactive SOI surface. b,c) Raman spectra collected in the solid red and dashed blue box, respectively. The three peaks located at 1331, 1589, and 2650 cm−1 are, respectively, associated with the D, G, and G′ modes of graphene. The oscillation curve in (c) is due to optical interference in the sandwich structure of SOI. The peaks at 1000 cm−1 are from silicon. d,f) The optical images of SOI after graphene growth at 870 and 895 °C, respectively. e,g) The Raman spectra detected at the black spot in (d) and (f). h) Schematic of graphene growth mechanismon SOI substrate. Reproduced with permission.15 Copyright 2012, American Institute of Physics.

Furthermore, growth at 945 °C yielded larger black areas and almost fully covered the substrate surface. However, the Raman spectrum only exhibited a strong fluorescence curve in this case. This may be attributed to the fact that after strong surface reaction, the surface optical properties of SOI might have changed reasonably. They also claimed that H2 was not necessary to grow graphene on SOI and just replaced 6 sccm of H2 with 50 sccm of Ar at 920 °C. Small black dots were observed and the SOI surface seemed to be less reactive. When the growth was carried out at 970 °C, the size of the black dots increased and stronger graphene bands were observed. Based on the above results, they proposed a growth mechanism for graphene on nonmetal or semiconducting surfaces as surface reaction, adsorption, decomposition, and accumulation (Figure 12h). At high temperatures, the native oxide layer decomposed and Si surface became reactive with free dangling bonds. The surface got clean, especially under H2 flow by etching out SiOx species. Carbon atoms released from thermal cracking of CH4 were adsorbed on a clean reactive Si surface and strongly bonded with surface dangling bonds. Consequently, surface‐adsorbed carbon atoms did not move freely on Si surface and CH4 molecules continued to accumulate at this spot and neighboring Si atoms. Eventually, the accumulated carbon atoms combined together to form graphene.

Tai et al. obtained much better results by using APCVD system as they demonstrated direct growth of atomically flat SLG or bilayer graphene (BLG) domains, concave BLG domains, and bulging FLG domains on the upside‐down placed single crystalline Si substrates at 900–930 °C for 1 h using the composition of CH4 and H2 gases.104 It was observed that a higher growth temperature caused larger domain size and higher nucleation density. However, uniform‐continuous‐large area graphene films could not be achieved, as the surface of Si was damaged at higher temperatures (>950 °C). Large graphene domains on Si could be achieved with the help of trace oxygen in this temperature range as obtained on dielectric and metallic substrates.23, 105

Recently, Wang et al. demonstrated the direct synthesis of uniform VAGNs on Si substrates via catalyst‐free thermal CVD for the first time.27 The VAGNs were grown using either CH4 or ethanol as the carbon feedstock in a conventional thermal APCVD system. It was also established that the concentration of active carbon species in CVD system exerts significant impact on the growth mode of graphene. The carbon precursor flow rate and reaction time during the CVD process controlled the growth dynamics, which ultimately led to a well‐controlled morphology of the obtained carbon material, such as 2D graphene film or VAGNs. The growth morphology was found to be independent of substrate as well as carbon source precursor. This growth strategy suggested that VAGNs can be fabricated on variety of substrates using different carbon precursors in a thermal APCVD system without using plasma, and offers a new insight for intrinsic growth mechanism. System was heated to 1130 °C in 50 min with 50 sccm H2 and 50 sccm Ar. The substrates were annealed for 20 min at 1130 °C, and then CH4 or ethanol (vapors) was introduced into the chamber to initiate graphene growth. The graphene growth morphology could be controlled by varying the precursor concentration and/or reaction time. The VAGNs growth process is schematically depicted in Figure 13 a. The height of VAG sheet was around 200 nm as observed from the 45° tilt side‐view image. The evolution of VAGNs was monitored by varying the growth time, and the detailed process is schematically depicted in Figure 13c.

Figure 13.

a) Schematic illustration of the template‐free and catalyst‐free CVD growth process of VAGNs. b) SEM image of VAGNs grown on Si substrate by using CH4 as carbon precursor. Conditions: VAGNs were grown at 8 sccm CH4, 50 sccm H2, and 50 sccm Ar for 6 h. c) Schematic illustration of time‐dependent evolution of the VAGNs growth. Reproduced with permission.27 Copyright 2017, Elsevier Ltd.

Initially, graphene flakes were randomly nucleated on the substrate surface and enlarged to form continuous film, as time progressed. Once a buffer layer formed, initial planar graphene growth eventually altered to upward growth. Consequently, the carbon atoms from precursor thermal cracking were continuously incorporated into the open edges to make the unique vertical growth proceed. VAGNs were obtained with the CH4 flow rate between 7 and 14 sccm, whereas planar growth was observed for less than 7 sccm CH4 flow rate. The carbon precursor decomposition under low CH4 flow rate synchronized with the adsorption of carbon atoms on active sites and the growth of graphene. Therefore, the diffusion of carbon species to edge of graphene proceeded under a thermodynamic equilibrium condition, and had enough time to reach the desired positions with minimum energy to form stable crystalline phases.106 Consequently, only 2D stacked nanometer‐sized or micrometer‐sized graphene flakes and films were observed even after 10 h growth.28 However, at higher CH4 flow rates, the effective diffusion of carbon species was limited on the substrate or graphene surface. Therefore, a multiple graphene nucleation and simultaneous enlargement took place, which was induced by the supersaturation of active carbon species concentration, and finally led to the shrinking of available surface on the substrate into narrow channels. In this way, surface diffusion of carbon species reduced drastically and the direct deposition of carbon species started at the graphene edges. Hence, the edge reaction occurred very fast, and led to the vertical growth instead of boundary coalescence when two graphene domains approached each other.107, 108, 109

3.1.3. High Temperature Growth on Textured Substrates

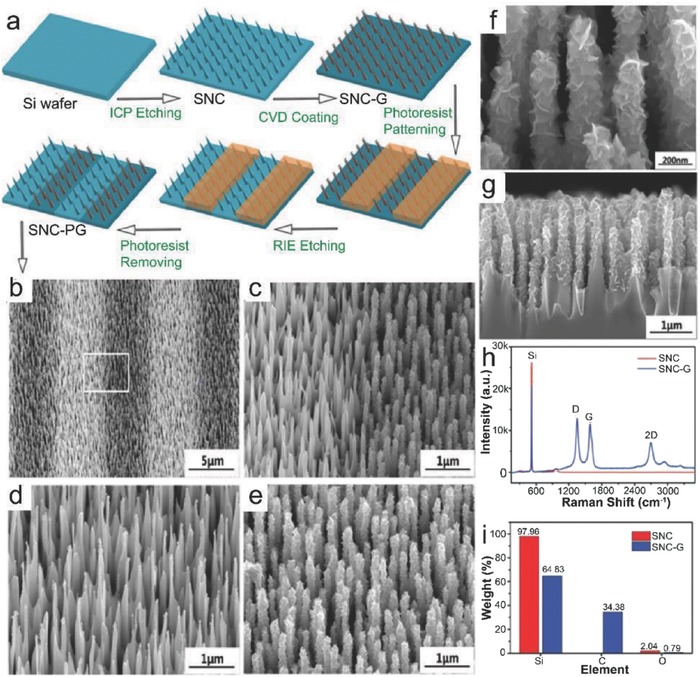

Instead of using flat Si surfaces for the metal‐catalyst free direct CVD growth of graphene, researchers have used textured Si substrates to grow graphene.110, 111 Li et al.110 and Wang et al.111 reported the direct growth of VG on Si nanocones (SNCs) with the help of hot‐filament CVD (HFCVD) system for field emission and electrochemical applications, respectively. The SNC electrode was fabricated by an inductively coupled plasma (ICP) reactive ion etching system. The SNC‐graphene (SNC‐G) electrode was patterned to get SNC‐patterned G (SNC‐PG) electrode by using UV‐lithography (UVL) and reactive ion etching (RIE), which enabled the SNC structure and SNC‐G structure got tested on the same electrode. The whole fabrication process of the SNC, SNC‐G, and SNC‐PG electrodes is schematically depicted in Figure 14 . First, the SNC electrode was fabricated by etching the Si wafer using O2 and SF6 in an ICP reactive ion etching system. Second, the VG was directly grown on the SNCs using CH4, H2, and Ar in the ratio of 1:5:45 at 1000 °C for 3 min. The chamber pressure was maintained at 2.5 kPa, and a bias voltage was applied between the filament and the substrate to facilitate the growth of graphene. Finally, SNC‐ PG electrode was fabricated by patterning the SNC‐G electrode with the help of UVL and RIE techniques. The tilted angle SEM images of the SNC electrode and SNC‐G electrode are shown in Figure 14d,e, respectively. Whereas, high magnification tilted angle and cross‐sectional SEM images of SNC‐G electrode are shown in Figure 14f,g, respectively.

Figure 14.

a) Schematic diagram of the fabrication process of the SNC, SNC‐G, and SNC‐PG electrodes. b) A SEM image of the SNC‐PG electrode corresponding to the schematic diagram. c) A higher magnification SEM image for the SNC‐PG electrode from the white box in (b). d) Tilted angle SEM image of the SNC electrode. e) Tilted angle, f) high‐magnification tilted angle, and g) cross‐section SEM images of the SNC‐G electrode. h) Raman spectra and i) energy dispersive X‐Ray (EDX) element weight ratios of the SNC electrode and the SNC‐G electrode. Reproduced with permission.111 Copyright 2017, the Royal Society of Chemistry.

It was observed that the graphene nanosheets (GNs) were vertically grown on the SNCs and resembled to petaloid clusters. The average height and half‐width of the vertically aligned SNCs were found to be 2 µm and 100 nm, respectively, and the average half width of the SNCs with VG coating was 200 nm. The GNs grew vertically after covering the SNCs surface and formed 3D petaloid structures due to the internal stress and the applied bias voltage.110 Raman spectra of the SNC electrode as well as the SNC‐G electrode are shown in Figure 14h. The peak positioned at ≈520 cm−1 belongs to Si, whereas the characteristic peaks of few‐layered graphene marked as D, G, and 2D were observed for the SNC‐G electrode.112 Elemental analyses of the SNC electrode and the SNC‐G electrode are shown in Figure 14i. For the SNC electrode, carbon was absent while the presence of a small amount of O2 (2.04%) was due to the surface oxidation. The SNC‐G electrode contained carbon along with Si, and a very small amount of O2 (0.79%). Similarly, Son et al.113 demonstrated the direct growth of high quality MLG on Si nanoparticles at 900–1100 °C via APCVD using a gas mixture of CH4, CO2, and H2. CO2 was used as a mild oxidant which helped in achieving robust and uniform growth of MLG around each Si nanoparticle by generating catalytic sites.

3.2. Catalyst‐Free Direct CVD Growth of Graphene on Ge Substrates

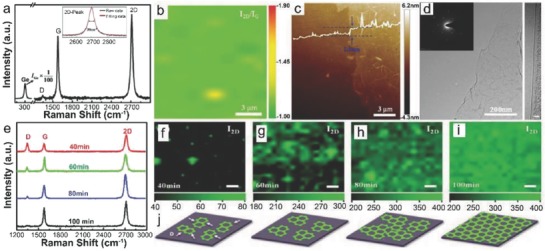

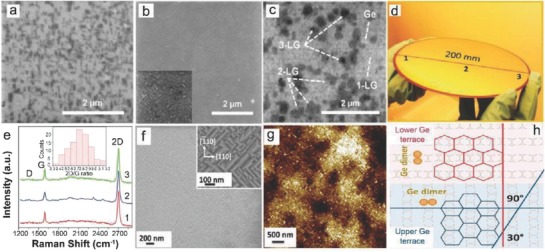

As discussed earlier that Ge possesses higher catalytic ability, very low carbon solubility, and high diffusivity even at its melting point as as compared to Si. Thus, immiscible Ge‐C system under equilibrium conditions dictates graphene growth on Ge via self‐limiting and surface‐mediated process instead of precipitation process as observed for metals with high carbon solubility. Wang et al. reported the direct growth of single‐layered graphene on Ge substrate via APCVD, and it was a large‐area and uniformly deposited high‐quality graphene.18 Generally, the amount of hydrocarbon gas and H2 determines the number of grown graphene layers, as H2 balances the production of reactive hydrocarbon radicals and etching of graphitic carbon during a CVD process. Therefore, the optimized graphene growth was carried out with H2:CH4 = 50:0.1 sccm at 910 °C for 100 min to obtain single‐layered graphene. Figure 15 a shows the Raman spectrum of the as‐grown graphene with very weak intensity of the D band, which indicated that the grown graphene film was of high quality similar to exfoliated graphene.114 The symmetric 2D peak with a FWHM of ≈30 cm−1 (inset Figure 15a) was well fitted by a single Lorentzian curve, which confirmed the growth of single‐layered graphene.115 Raman mapping of the 2D to G peak intensity ratio over a 15 µm × 15 µm area with a spot size of 1 µm and a step size of 1 µm was carried out, which revealed that the I 2D/I G ratio was quite uniform over the region studied (Figure 15b). The I 2D/I G was in the range of 1–1.5, which confirmed the complete SLG coverage.116 The AFM micrograph of the transferred graphene film from Ge onto 300 nm SiO2/Si substrate with a uniform height of 1.1 nm (Figure 15c) also confirmed that the graphene film was single‐layered.117 The single‐layer and single‐crystalline nature of the grown graphene was also confirmed by TEM and SAED analyses as shown in Figure 15d. Furthermore, it was also observed from the Raman spectra (Figure 15e) that the D peak disappeared gradually as the growth time reached to 100 min. Similar results were obtained for the samples grown for 120 min or longer durations, which indicated that the growth on Ge was self‐limited. Figure 15f–i shows the investigation of graphene domains expansion by the color‐coded intensity mapping of the 2D peak over an area of 15 × 15 µm2 with a spot size of 1 µm and step size of 1 µm. The green and the dark regions correspond to graphene domains and bare Ge surface, respectively. Initially, the size of the graphene domains was relatively small and there were a large number of edge defects related to the domains of graphene, which led to the remarkable D peak in the Raman spectra. As the growth time reached to 100 min, the graphene domains grew in 2D islands due to excess carbon atoms, and finally merged together to form a continuous film (Figure 15j). The constituents in the Ge–C alloy were immiscible under equilibrium in the bulk according to equilibrium phase diagram of the Ge–C system and resembled to the Cu–C system, which is known to be mutually immiscible in the solid and liquid states.118 Moreover, the properties of the graphene films grown on Ge were the same irrespective of fast or slow cooling process. As the carbon solubility in bulk Ge (<0.1 atm %) is negligible, therefore a self‐limiting and surface‐mediated growth process was observed similar to Cu‐catalyzed growth of graphene.

Figure 15.

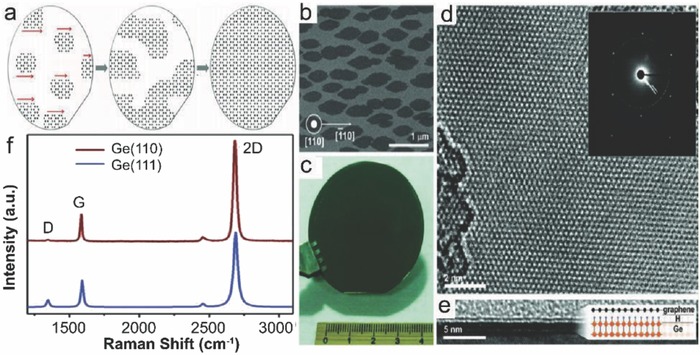

Large‐scale uniform growth of monolayered graphene films on Ge substrate. a) Raman spectrum of graphene on Ge substrate. The inset shows the FWHM and the Lorentzian fitting of 2D peak. b) 2D Raman mapping of the I 2D/I G peak intensity ratio obtained from the graphene deposited on Ge (15 µm × 15 µm region with the step size of 1 µm). c) Contact‐mode AFM image of a graphene film transferred on SiO2 showing the monolayered feature and wrinkles. d) TEM image and SAED pattern revealing the high crystalline quality of the graphene and HR‐TEM image showing that the graphene is monolayered. The scale bar in the HR‐TEM image is 3 nm. Characterization of graphene grown on Ge substrates for different durations and illustration of graphene growth evolution. e) Raman spectra of graphene films deposited on Ge under optimal conditions for different time. f–i) Color‐coded Raman mapping of the 2D peak intensity images of graphene as a function of deposition time. The green features are graphene domains and the dark regions represent the bare Ge surface. The scale bar is 2 µm. j) Schematic illustration of evolution of the graphene films on Ge for different deposition time. Reproduced with permission.18 Copyright 2013, Springer Nature.