Abstract

Feed has been identified as a vector of transmission for porcine epidemic diarrhea virus (PEDV). The objective of this study was to determine if feed batch sequencing methods could minimize PEDV cross-contamination. Porcine epidemic diarrhea virus-free swine feed was manufactured to represent the negative control. A 50 kg feed batch was mixed in a pilot scale feed mill for 5 min, sampled, then discharged for 10 min into a bucket elevator and sampled again upon exit. Next, a pathogenic PEDV isolate was used to inoculate 49.5 kg of PEDV-free feed to form the positive control. The positive control was mixed, conveyed and sampled similar to the negative control. Subsequently, 4 sequence batches (sequence 1 to 4) were formed by adding a 50 kg batch of PEDV-negative feed to the mixer after the prior batch was mixed and conveyed; all sequences were mixed, conveyed, and sampled similar to the negative and positive control batches. None of the equipment was cleaned between batches within a replicate. This entire process was replicated 3 times with cleaning the feed mill between replicates. Feed was then analyzed for PEDV RNA by real-time reverse transcriptase semiquantitative polymerase chain reaction (rRT-PCR) as measured by cycle threshold (Ct) and for infectivity by bioassay. Sequence 1 feed had higher (P ˂ 0.05) rRT-PCR Ct values than the positive batch and sequence 2 feed had higher (P ˂ 0.05) Ct values than sequence 1, regardless of sampled location. Feed sampled from the mixer from sequence 2, 3, and 4 was rRT-PCR negative whereas feed sampled from the bucket elevator was rRT-PCR negative from sequence 3 and 4. Bioassay was conducted using 66 mixed sex 10-d-old pigs confirmed negative for PEDV allocated to 22 different rooms. Pigs were initially 10-d old. Control pigs remained PEDV negative for the study. All pigs from the mixer positive batch (9/9) and bucket elevator positive batch (3/3) were rRT-PCR positive on fecal swabs by the end of the study. One replicate of pigs from mixer sequence 1 was rRT-PCR positive (3/3) by 7 dpi. One replicate of mixer pigs from sequence 2 was rRT-PCR positive (3/3) by 7 dpi although no detectable PEDV RNA was found in the feed. The results demonstrate sequenced batches had reduced quantities of PEDV RNA although sequenced feed without detectible PEDV RNA by rRT-PCR can be infectious. Therefore, a sequencing protocol can reduce but not eliminate the risk of producing infectious PEDV carryover from the first sequenced batch of feed.

Keywords: bioassay, cross-contamination, feed, pig, porcine epidemic diarrhea virus, sequencing

INTRODUCTION

Porcine epidemic diarrhea virus (PEDV) profoundly affected the United States swine industry since its emergence in May 2013 (Huang et al., 2013; Madson et al., 2014). Outbreaks in the United States and Canada were suspected to be caused by consumption of PEDV-contaminated feed or feed ingredients (Pasick et al., 2014; Bowman et al., 2015a). Feed has since been confirmed as one of the many routes of PEDV-transmission, which has led to investigations into identifying ways to mitigate infectivity of contaminated diets or feed ingredients (Dee et al., 2014; Cochrane, 2015; Schumacher et al., 2016). Preliminary work from our previous studies suggested PEDV cross-contamination of feed may occur during feed manufacturing (Woodworth, 2015). However, infectivity of this batch-to-batch contamination was not established using bioassay. Due to the lack of additional data detailing PEDV cross-contamination during feed manufacturing, it is hypothesized that strategically sequencing batches during feed production may reduce the risk of PEDV cross-contamination. Therefore, the objective of this experiment was to determine if feed batch sequencing methods could minimize PEDV cross-contamination.

MATERIALS AND METHODS

The feed manufacturing portion of the experiments was approved by the Kansas State University Institutional Biosafety Committee and was conducted at the Kansas State University Cargill Feed Safety Research Center (FSRC; Manhattan, KS), a 3-story biosafety level 2 biocontainment laboratory containing pilot scale mixers, conveying equipment, and pellet mills. The experiment was replicated 3 times with decontamination before and after each replicate confirmed by the absence of PEDV RNA in the feed, equipment, and environment by real-time reverse transcriptase polymerase chain reaction (rRT-PCR) assay semi quantitatively measured by cycle threshold (Ct). Decontamination was done according to procedures outlined by Huss et al. (2017). Chemical decontamination was performed using a 2-step process using a 1:256 dilution of ammonium glutaraldehyde blend (Synergize; Preserve International, Reno, NV) and a 1:32 dilution of sodium hypochlorite solution. The facility was then heated to 60 °C for a minimum of 24 h and cooled to room temperature at which point the environmental surfaces were sampled using swabs (World Bioproducts, Mundelein, IL) moistened with phosphate-buffered saline (PBS; pH 7.4 1X, Life Technologies, Grand Island, NY) and verified devoid of PEDV genetic material to ensure efficacy of the disinfection procedures prior to initiation of the subsequent replicates. The efficacy of decontamination procedures was ensured using the environmental sampling technique outlined by Huss et al. (2017) with effective decontamination defined as no detectable PEDV genetic material via rRT-PCR. The pig bioassay portion of the experiments and experimental protocols were approved by the Iowa State University Institutional Animal Care and Use Committee and adhered to the ethical and humane use of animals for research. All animal work was conducted at the Iowa State University Veterinary Medical Research Institute (Ames, IA).

Virus and Virus Aliquot Transportation and Handling

PEDV virus isolation, propagation, and titration were performed as described elsewhere (Chen et al., 2014). The US PEDV prototype (strain cell culture isolate USA/IN19338/2013 cell passage 8) was used to inoculate feed in this study. The stock solution of PEDV contained 4.5 × 106 50% tissue culture infectious dose/mL (TCID50/mL). This isolate has been previously shown to be pathogenic in young pigs (Thomas et al., 2015). The virus was divided into 3, 500 mL aliquots and stored at −80 °C. One aliquot was used in each replication. In 1 of 3 replicates, a 500 mL aliquot was shipped frozen on dry ice from Iowa State University Veterinary Diagnostic Laboratory (ISU VDL) to the FSRC. The 500 mL aliquots were allowed to thaw overnight at 4 °C in the FSRC until used the following day for the experiment.

Swine Diet

A corn soybean meal-based diet was manufactured at the Kansas State University O.H. Kruse Feed Technology Innovation Center (Manhattan, KS) (Table 1). A subsample of the feed was obtained using a feed probe to sample from multiple bags of manufactured feed creating a composite sample that was confirmed PEDV negative by rRT-PCR prior to inoculation for each repetition.

Table 1.

Diet composition, as fed basis

| Ingredient, % | Composition |

|---|---|

| Corn | 79.30 |

| Soybean meal, 46.5% CP | 15.70 |

| Choice white grease | 1.00 |

| Calcium phosphate (monocalcium) | 1.40 |

| Limestone | 1.15 |

| Salt | 0.50 |

| L-Thr | 0.03 |

| Trace mineral premix1 | 0.15 |

| Sow add pack2 | 0.50 |

| Vitamin premix3 | 0.25 |

| Phytase4 | 0.02 |

| Total | 100.00 |

| Chemical analysis, %5 | |

| Dry matter | 91.4 |

| Crude protein | 17.1 |

| Crude fiber | 3.7 |

| Ca | 0.78 |

| P | 0.52 |

| Fat | 3.5 |

1Each kilogram of premix contains 73 g Fe, 73 g Zn, 22 g Mn, 11g Cu, 0.198 mg I, and 0.198 mg Se.

2Each kilogram of premix contains 4,409 IU vitamin E, 44 mg biotin, 992 mg pyridoxine, 331 mg folic acid, 110,229 mg choline, 40 mg chromium, 9,920 mg L-carnitine.

3Each kilogram of premix contains 4,409,171 IU vitamin A, 551,146 IU vitamin D3, 17,637 IU vitamin E, 1,764 mg menadione, 3,300 mg riboflavin, 11,023 mg d-pantothenic acid, 19,841 mg niacin, 15 mg vitamin B12.

4High Phos 2700 GT, DSM Nutritional Products, Parsippany, NJ.

5One sample was analyzed by Ward Laboratories Inc., Kearney, NE.

Negative Feed Batch

Fifty kilograms of swine diet were mixed in a 0.113 m3 electric paddle mixer (H. C. Davis Sons Manufacturing model# SS-L1; Bonner Springs, KS) that was previously validated to mix a 50 kg batch of feed with coefficient of variation (CV) less than 10%, as per standard mixing efficiency protocol (McCoy, 2005). The feed was mixed for 5 min before aseptically sampled. Clean disposable gloves were worn while using a disposable plastic cup to subsample 5 equally spaced locations within the mixer. The subsampled feed formed a 400 to 500 g sample which was placed in a closeable plastic specimen bag. Feed was then discharged at a rate of approximately 4.5 kg/min into the bucket elevator (Universal Industries, Cedar Falls, IA) which had a boot pit depth of 2.54 cm from the edge of the cup to the boot bottom and contained 74 buckets (each 114 cm3). Feed carried by the buckets then exited the bucket elevator through a downspout where an additional 400 to 500 g sample was collected directly into a plastic specimen bag once the feed stream began. Mixer and bucket elevator specimen bags were set on ice in a cooler until transported the same day for rRT-PCR analysis. Bagged feed samples were then temporarily stored at -20°C until discarded when no longer needed.

PEDV Inoculum and Positive Feed Batch

The PEDV inoculum premix was established by mixing a 500 mL aliquot of stock virus into a 4.5 kg batch of the swine diet using procedures established in a prior experiment (Schumacher et al., 2106). The PEDV inoculum premix (4.5 kg of feed + 500 mL of stock virus) was then added to 45 kg of swine diet to form the positive experimental batch and was mixed, discharged, sampled, and handled as described above.

Sequenced Feed Batches

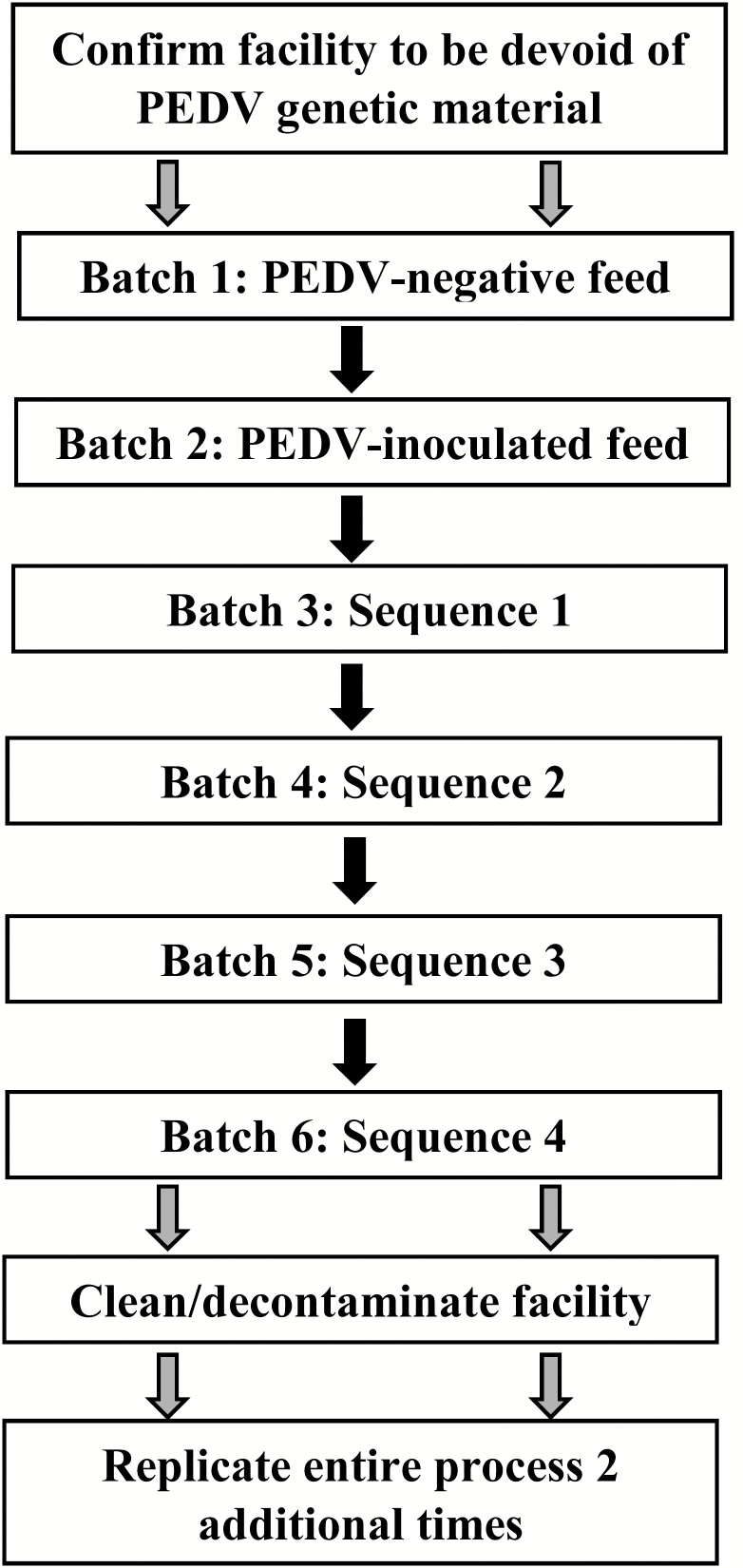

Following the positive feed batch, 4 subsequent 50 kg batches of PEDV-free swine diet were each mixed, discharged, and sampled as described for the negative control batch to form sequence feed batch 1, 2, 3, and 4 and were mixed, discharged, sampled, and handled as described in Figure 1. The equipment was not cleaned between any feed batches until completion of the replicate to mimic commercial feed manufacturing conditions. Equipment was cleaned and decontaminated between each replicate.

Figure 1.

Experimental design distinguishing feed batching order. All batches were mixed for 5 min. For each batch a sample was aseptically collected from the mixer, then feed was discharged from mixer into bucket elevator and a feed sample was collected from the bucket elevator during discharge. The entire process was replicated a total of 3 times.

Feed Sample Processing Procedures and Storage

Each mixer and bucket elevator sample were divided into 3 subsamples (100 g/sample) and then used to make a 20% suspension. Briefly, the 100 g sample was added to 400 mL of PBS (Life Technologies; pH, 7.4) in 500 mL bottles (Nalgene square bottles; Thermo Scientific, Waltham, MA); contents were thoroughly mixed and allowed to settle at 4 °C overnight. Aliquots were then collected without remixing the supernatant by using sterile serologic pipettes and pipette controller (Pipetboy; Integra Biosciences, Hudson, NH). A 4 mL aliquot of the feed suspension was evaluated by Kansas State University (KSU) using a PEDV spiked gene-based rRT-PCR assay as described below. Twenty milliliters of aliquots for bioassay were harvested from all batch samples and placed in sterile conical polypropylene centrifuge tubes (Tornado tubes; MidSci, St. Louis, MO). Bioassay aliquots were stored frozen at −80 °C until used for bioassay.

RNA Extraction and PEDV rRT-PCR

All feed samples were analyzed at Kansas State University Molecular Diagnostics Development Laboratory (Manhattan, KS) for the presence of PEDV RNA by rRT-PCR. Nucleic acids were extracted from a 50 µL sample of feed supernatant. Automated extraction was carried out on a KingFisher magnetic particle processor (Thermo Scientific) using a MagMAX-96 Viral RNA Isolation Kit (Life Technologies). All manufacturer’s instructions were followed, with the exception of a final elution volume of 60 µL. Each 96-well extraction run included an extraction positive control (PEDV stock virus) and an extraction negative control (1× PBS). An in-house-developed duplex rRT-PCR assay targeting the spike gene (S) of PEDV and host 18S rRNA (internal control) was used for the detection and quantification of PEDV. The 20 µL reaction mixture comprised 1× Path-ID Multiplex rRT-PCR buffer, 2 µL Path-ID Multiplex Enzyme Mix (Thermo Scientific), 500 nM of each of 3 PEDV primers and 2 18S primers and 62.5 nM of each probe (PEDV and 18S), and 4 µL of the extracted nucleic acid. Amplification was performed on the CFX96 Touch Real-Time PCR Detection System (Bio-Rad Laboratories, Hercules, CA). The thermal cycling parameters were: 10 min reverse transcription at 48 °C, 10 min of reverse transcriptase inactivation/initial denaturation at 95 °C followed by 45 cycles of 10 s at 95 °C and 40 s at 60 °C.

All animal samples and stock virus were analyzed by Iowa State University Veterinary Diagnostic Laboratory (ISU VDL). Nucleic acids were extracted from initial stock virus (50 µL), bioassay inoculum (100 µL), and rectal swabs (100 µL) and eluted into 90 µL of elution buffer using a RNA/DNA kit (MagMAX Pathogen RNA/DNA Kit; Thermo Scientific) and a Kingfisher-96 magnetic particle processor following the manufacturer’s instructions. Samples were analyzed for PEDV using a previously described PEDV nucleocapsid (N) gene-based rRT-PCR assay (Thomas et al., 2015). Five microliters of RNA template were used in the rRT-PCR setup in a 25 µL reaction using a Path-ID Multiplex One-Step RT-PCR Kit (Thermo Scientific) and amplification reactions were conducted on an ABI 7500 Fast instrument (Thermo Scientific) following previously described procedures (Thomas et al., 2015).

Pig

To assess infectivity of batches, bioassay was performed following a previously established protocol (Thomas et al., 2015). A total of 66, 10-d-old pigs were purchased from a conventional breeding farm and delivered to the Iowa State University Laboratory Animal Resource facilities. All pigs were confirmed negative for PEDV, porcine delta coronavirus (PDCoV), transmissible gastroenteritis virus (TGEV), and porcine rotaviruses (groups A, B, and C) by virus-specific rRT-PCR on rectal swabs and were serologically negative for PEDV. Pigs were randomly divided into groups of 3 per room. Rooms had independent ventilation systems and solid flooring that was minimally rinsed to reduce PEDV aerosols. Pigs were fed liquid milk replacer (Esbilac; PetAg, Hampshire, IL) and a commercially pelleted diet (All Natural Starter 2; Heartland Co-op, Alleman, IA). The pelleted diet did not contain any animal protein with the exception of dried whey. The milk replacer and pelleted feed were not evaluated for the presence of PEDV genetic material. Previous studies using similar procedures and the same feed have resulted in no pigs which were inoculated with the negative control samples becoming positive for PEDV (Schumacher et al., 2016; Cochrane et al., 2017). Pigs had ad libitum access to feed and water at all times. After 2 d of acclimation, each pig was administered PBS feed suspension inoculum (as described above) by orogastric gavage using an 8-gauge French catheter [0 dpi (day postinoculation)]. Rectal swabs were collected daily but analyzed on -2, 0, 2, 4, 6, and 7 dpi (with remaining swabs saved if additional analysis was required) from all pigs at ISU VDL for PEDV RNA by rRT-PCR. All pigs were euthanized at 7 dpi for necropsy by i.v. overdose of pentobarbital sodium solution (Fatal-Plus; Vortech Pharmaceuticals Ltd, Dearborn, MI). An aliquot of fresh cecal contents for PEDV rRT-PCR was sent to the Iowa State University Veterinary Diagnostic Laboratory (Ames, IA).

Bioassay Study Design

A total of 16 rooms (3 pigs per room) were assigned to the batches sampled from the mixer (1 negative control room and 15 challenge rooms). Each pig from the mixer negative control room was orogavaged with a 10 mL aliquot of inoculum created from the negative control feed collected from the mixer during each of replicate 1, 2, and 3, thus each negative pig represented 1 of 3 replicates. Each pig from the mixer challenge rooms (positive, sequence 1 to sequence 4) was given a 10 mL aliquot of inoculum from the same replicate, thus 1 room represented the combination of 1 batch within replicate. A total of 6 rooms (3 pigs per room) were assigned to the bucket elevator negative, positive, sequence 1 to sequence 4 (1 negative control and 5 challenge rooms) batches. Pigs were given a 30 mL aliquot that combined 3, 10 mL aliquots derived from 1 batch from 1 replicate. Thus, each pig represented 1 of 3 replicates per batch and 1 room represented each batch.

Statistical Analysis

Data were analyzed using the GLIMMIX procedure in SAS (SAS Inst. Inc., Cary, NC) as a completely randomized design to determine the main effects of batch, location (mixer vs. bucket elevator), and their interaction on PEDV Ct values with feed sample as the unit of analysis. Samples considered negative by rRT-PCR were evaluated as a value of 45 (thermocycler parameter was set at 45 cycles to minimize false negatives) in the statistical model. SEM were calculated and reported as pooled SEM values due to uneven sample size in the mixer bioassay. Results for treatment criteria were considered significant at P ≤ 0.05.

RESULTS

Detection of PEDV RNA in Feed

As expected, no PEDV RNA was detected by rRT-PCR when the negative control batch was sampled from the mixer or conveyer (Table 2). After the positive feed batch was manufactured, all samples from the mixer and conveyer had detectible PEDV RNA (mean Ct = 31.7 and 30.9, respectively). From the mixer after sequence 1, fewer samples (7/9) had detectible PEDV RNA and the mean Ct increased (Ct = 39.6; P ˂ 0.05) compared to the positive feed batch; however, no samples produced detectible PEDV RNA after sequence 2, 3, or 4. For the samples collected from the bucket elevator, after sequence 1 there were fewer samples with detectible PEDV genetic material (7/9) and the samples resulted in an increase in the mean feed Ct (Ct = 39.4; P ˂ 0.05) as compared to the positive batch. Unlike mixer feed from sequence 2, PEDV genetic material was detected in 2 of 9 bucket elevator feed samples from sequence 2 and again the mean Ct increased (Ct = 43.7; P ˂ 0.05) as compared to sequence 1. Like the mixer, no bucket elevator feed samples had detectible RNA after sequence 3 and 4. The main effect of batch (P = 0.001) had an effect on feed Ct values whereas the main effect of location and interaction of location by batch was unaffected (P = 0.18 and P = 0.72, respectively).

Table 2.

Effect of batch sequencing feed on porcine epidemic diarrhea virus (PEDV) cross-contamination1

| Item | Negative | Positive | Sequence 1 | Sequence 2 | Sequence 3 | Sequence 4 |

|---|---|---|---|---|---|---|

| Feed, Detectable RNA/Total2 | ||||||

| Mixer | 0/9 | 9/9 | 7/9 | 0/9 | 0/9 | 0/9 |

| Bucket elevator | 0/9 | 9/9 | 7/9 | 2/9 | 0/9 | 0/9 |

| Feed, Ct3 | ||||||

| Mixer | 45.0a | 31.7c | 39.6b | 45.0a | 45.0a | 45.0a |

| Bucket elevator | 45.0a | 30.9c | 39.4b | 43.7a | 45.0a | 45.0a |

a,b,cMeans with different superscripts differ (P ˂ 0.05).

1Tissue culture fluid containing 4.5 × 106 TCID50/mL of PEDV was inoculated into 49.5 kg of PEDV-negative feed to form the positive batch. For each negative, positive and sequence batch, feed was mixed for 5 min and sampled, then discharged for 10 min into the bucket elevator and sampled upon exit. Equipment was not cleaned between batches; however, was decontaminated between replicates. Sequences were formed by sequentially adding 50 kg of PEDV-negative feed to the mixer after the prior batch was processed. This process was replicated 3 times and analyzed by real-time reverse transcriptase polymerase chain reaction for the presence of PEDV RNA.

2Count of samples with detectible PEDV RNA (Ct ˂45)/number of samples analyzed.

3Mean cycle threshold (Ct) value of samples. A value of 45.0 was used for samples with no detectible PEDV RNA. For feed Ct analysis: Main effect of location P = 0.18. Main effect of batch P = 0.001. Location × Batch P = 0.72 and pooled SEM = 0.52.

PEDV Bioassay of Feed Obtained from the Mixer and Bucket elevator

Fecal virus shedding from pigs challenged with feed batches is summarized in Table 3. All pigs used in the mixer bioassay were rRT-PCR negative on rectal swabs collected before inoculation and at 0 dpi. Additionally, all pigs from the mixer negative control batch remained rRT-PCR negative on rectal swabs throughout the study and in cecum contents at 7 dpi. All pigs from the mixer positive batch were rRT-PCR positive on rectal swabs at 2 dpi and continued to shed virus to the end of the study (7 dpi). One pig from a sequence 1 room was PEDV rRT-PCR positive at 2 dpi; by 4 dpi, 3 of 3 pigs in this room had detectible PEDV RNA on fecal swabs and continued to shed virus to the end of the study. Although none of the feed from mixer sequence 2 had detectible PEDV RNA, 1 pig was rRT-PCR positive on rectal swab at 2 dpi and by 4 dpi, 3 of 3 pigs from this batch room were PEDV rRT-PCR positive on fecal swabs and remained positive to termination of the study. None of the pigs from mixer sequence 3 and sequence 4 shed virus on rectal swabs throughout the study nor had detectible PEDV RNA in cecum contents at 7 dpi.

Table 3.

Pig bioassay results from manufactured and batch sequenced porcine epidemic diarrhea virus (PEDV) inoculated feed collected from mixing and conveying equipment1

| Fecal swabs2 | ||||||

|---|---|---|---|---|---|---|

| Item | 0 dpi | 2 dpi | 4 dpi | 6 dpi | 7 dpi | 7 dpi Cecum content |

| Feed from mixer, Positive pigs/Total3 | ||||||

| Negative | 0/3 | 0/3 | 0/3 | 0/3 | 0/3 | 0/3 |

| Positive | 0/9 | 9/9 | 9/9 | 9/9 | 9/9 | 9/9 |

| Sequence 1 | 0/9 | 1/9 | 3/9 | 3/9 | 3/9 | 3/9 |

| Sequence 2 | 0/9 | 1/9 | 3/9 | 3/9 | 3/9 | 3/9 |

| Sequence 3 | 0/9 | 0/9 | 0/9 | 0/9 | 0/9 | 0/9 |

| Sequence 4 | 0/9 | 0/9 | 0/9 | 0/9 | 0/9 | 0/9 |

| Feed from bucket elevator, Positive pigs/Total | ||||||

| Negative | 0/3 | 0/3 | 0/3 | 0/3 | 0/3 | 0/3 |

| Positive | 0/3 | 1/3 | 1/3 | 3/3 | 3/3 | 3/3 |

| Sequence 1 | 0/3 | 0/3 | 0/3 | 0/3 | 0/3 | 0/3 |

| Sequence 2 | 0/3 | 0/3 | 0/3 | 0/3 | 0/3 | 0/3 |

| Sequence 3 | 0/3 | 0/3 | 0/3 | 0/3 | 0/3 | 0/3 |

| Sequence 4 | 0/3 | 0/3 | 0/3 | 0/3 | 0/3 | 0/3 |

1Tissue culture fluid containing 4.5 × 106 TCID50/mL of PEDV was inoculated into 49.5 kg of PEDV-negative feed to form the positive batch. For each negative, positive and sequence batch, feed was mixed for 5 min and sampled, then discharged for 10 min into the bucket elevator and sampled upon exit. Equipment was not cleaned between batches; however, was decontaminated between replicates. Sequences were formed by sequentially adding 50 kg of PEDV-negative feed to the mixer after the prior batch was processed. This process was replicated 3 times. For bioassay, pigs were initially 10 d old. Feed from the mixer was inoculated into pigs in 3 rooms with 3 pigs per room for the positive feed and sequences. One room with 3 pigs were inoculated with negative feed. Each pig in the negative control room was inoculated from each replicate. The same process as used for the feed from the bucket elevator so there was 1 room with each pig inoculated with feed from each replicate.

2Fecal swabs and cecum contents were analyzed for presence of PEDV RNA by real-time reverse transcriptase polymerase chain reaction on 0, 2, 4, 6, and 7 d postinoculation (dpi) and necropsied at d 7 when cecum contents and tissues were collected.

3Count of pigs shedding detectible PEDV RNA/number of pigs analyzed.

As expected, all pigs from the negative bucket elevator batch were rRT-PCR negative on rectal swabs collected before inoculation and for the duration of the study. One pig from the positive bucket elevator batch was rRT-PCR positive on rectal swab at 2 dpi and by 4 dpi, 3 of 3 pigs from this room had rRT-PCR positive rectal swabs and shed virus to the end of the study and in 7 dpi cecum contents. Although most of the feed (7/9) from bucket elevator sequence 1 was rRT-PCR positive, none of the pigs shed PEDV during the study. Additionally, some of the feed (2/9) from bucket elevator sequence 2 was rRT-PCR positive and again none of the pigs had detectible PEDV RNA on fecal swabs during the study. None of the pigs from bucket elevator feed sequence 3 and 4 shed PEDV on fecal swabs nor had detectible PEDV in cecum contents at 7 dpi.

DISCUSSION

The potential for PEDV contamination in feed manufacturing facilities is a concern since research has confirmed feed and feed ingredients as vectors for PEDV transmission (Dee et al., 2014; Pasick et al., 2014). Since little is known about viral cross-contamination during animal feed production, the objective of this experiment was to determine the efficacy of feed batch sequencing as a method of reducing PEDV cross-contamination when manufacturing feed using a pilot scale mixer and conveying equipment. The virus isolate used in this study had been previously demonstrated to be pathogenic causing disease in neonatal pigs when cell culture fluid was inoculated into the pigs (Thomas et al., 2015). Again, we have demonstrated virulence of this isolate through feed where all pigs challenged with positive feed in the mixer and bucket elevator bioassay exhibited signs of infectivity by 7 dpi.

The results clearly demonstrate that cross- contamination in the feed manufacturing process is possible as indicated by feed collected from the first sequence that was infective. To our knowledge, this is the first experiment that demonstrates cross-contamination across batches in a feed mill by a viral pathogen as demonstrated by bioassay. Although cross-contamination occurred, feed batch sequencing did reduce the amount of detectible PEDV RNA in feed after sequencing 2 batches of swine diet following the positive batch. Thus, sequencing virally contaminated feed appears to be similar to sequencing medicated feed in effort to reduce carryover. Sequencing a batch of medicated-free feed has been shown to reduce significant drug carryover in medicated feed manufacturing (Herrman et al., 1995; Martinez-Kawas, 2008) and has been adopted by the Food and Drug Administration (FDA) as an approved clean-out procedure for manufacturing medicated feed (FDA, 1976). Similar to medicated feed, the amount of PEDV detectible RNA in knowingly contaminated feed from our study decreased after sequencing and therefore appears to potentially mitigate cross-contamination during feed manufacturing.

Another finding from this study is that cross-contamination seems to occur at different locations during feed manufacturing. Manufacturing equipment was not cleaned nor disinfected between batches during feed mixing and conveying to mimic the feed manufacturing process in a commercial mill. Even after 2 sequences, detectible PEDV RNA persisted in feed from the bucket elevator whereas no PEDV RNA was detected in feed from the mixer. This observation could be due to cross-contamination that occurred within the boot of the bucket elevator. Buckets within the bucket elevator are designed to pick up their load from the boot—which is dead space or pit area—that fills with feed at the bottom foot pulley. This space is filled with previously discharged product, thus charging the boot. In commercial settings, manual clean-out of the boot is not done on a regular basis (Tilley, 2013) due to time constraints, difficult accessibility, messiness, and was seemingly unnecessary prior to this research. Therefore, the boot can create a potential source of cross-contamination as batches of feed are manufactured. Another source for persistent PEDV detection in conveyed feed could have originated from contaminated equipment surfaces following PEDV positive feed production. In a complementary study to the current experiment, we monitored the rapid widespread contamination that ensued after production of a PEDV-contaminated batch of feed and demonstrated swabs collected from the plastic bucket elevator buckets and rubber belt remained rRT-PCR positive during feed sequencing (Schumacher et al., 2017). An additional source of cross-contamination is possibly from the mixer. Although the mixer was empty and clean between discharges by commercial feed manufacturing standards, some feed (approximately 1.4 kg via preliminary data) always remained at the bottom of the mixer. Therefore, it is possible for cross-contamination of feed to occur at multiple sites during feed manufacturing.

Concerns of PEDV cross-contamination raise questions about how to eliminate the pathogen from contaminated feed production facilities. Undesired microorganisms are quite difficult to remove once introduced; therefore, enhanced protocols for feed mill housekeeping could be critical to prevent cross-contamination (Cochrane et al., 2016). However, housekeeping in general can be difficult for some systems for a variety of reasons such as additional labor, constant accumulation of dust and debris, and lack of downtime to perform cleaning protocols. Additionally, wet disinfection is not ideal for feed mills since mainly dry ingredients are used and because most of the equipment has limited accessibility needed for chemical cleaning (Huss et al., 2015). Instead, feed production facilities must rely on physical cleaning and good manufacturing procedures to prevent spread of microorganisms; however, these methods have been proven to increase contamination (Huss et al., 2015). Even with chemical disinfectant, PEDV genetic material has proven difficult to eliminate in the FSRC (Huss et al., 2017). In other studies, and in our own preliminary data, RNA can still be detectable by rRT-PCR following disinfection treatment (Bowman et al., 2015b). Therefore, perhaps more enhanced measures are needed for cleaning and decontamination if a feed mill becomes contaminated with PEDV.

In the current study, infectivity of feed was assessed by bioassay. The concerning results are the demonstration that rRT-PCR negative samples from sequence 2 were infectious in a swine bioassay. These results parallel previous studies where infected tissue homogenates titrated beyond detection limits of rRT-PCR (i.e., rRT-PCR negative) were positive by bioassay (Goyal, 2014) and a serial dilution of PEDV cell culture fluid titrated beyond detection limits of rRT-PCR was infective in neonatal pigs (Thomas et al., 2015). This demonstrates that in some situations, bioassay is more sensitive at detecting PEDV relative to rRT-PCR.

Results of the current study demonstrate that feed batch sequencing appears to reduce the magnitude of infectivity when evaluated using swine bioassay. For example, in the mixer bioassay, only 1 pig from sequence 1 and 1 pig from sequence 2 became infected by 2 dpi in contrast to the mixer positive control where 9 of 9 pigs were infected by 2 dpi. This is likely due to the lower amount of virus in sequenced batches that can induce an infection. Similarly, in another study that used serial PEDV tissue culture dilutions to determine the minimum infectious dose, only 1 neonatal pig became infected at the lowest serial titration as compared to all pigs that became infected when challenged with higher PEDV concentrations (Thomas et al., 2015). Therefore, it seems sequencing decreased the magnitude of infectivity similarly seen with minimum infectious dose studies (Thomas et al., 2015; Schumacher et al., 2016).

Since the sequencing protocol did not eliminate the risk of producing infectious feed after the first sequence, this suggests that other strategies in addition to sequencing may be needed in the feed processing chain. Such strategies may include thermal or chemical mitigation to further decrease the risk of PEDV transmission (Cochrane, 2015; Cochrane et al, 2017). This may be especially true considering the stage of pig production sequenced feed is fed. For example, high health herds from nucleus farms, boar studs, or breeding stock multiplication units are critical to swine production. Porcine epidemic diarrhea infection in these herds would disrupt swine production and have devastating economic impact. Thus, sequencing alone may not provide enough hazard mitigation for these swine herds since the magnitude of the risk of infection increases when feeding larger populations (Davies et al., 2015). Further research by our group is underway investigating additional PEDV mitigation methods during feed manufacturing.

In conclusion, we confirmed the hypothesis that batch-to-batch carryover of PEDV-infected feed can result in subsequent cross-contamination of infectious PEDV in feed. The results of the present study suggest that a sequencing protocol can be used as a risk-reduction but not risk-elimination procedure for infectious PEDV carryover from the first sequenced batch. Manufacturing feed with a high possibility of contamination prior to manufacturing diets for at-risk animal populations (i.e., early nursery pigs or lactating sows) should be avoided to reduce exposure to infectious PEDV carryover. Concerning findings from this study revealed that sequenced rRT-PCR-negative feed was infectious. Additional research is needed to define ways to further minimize the risk of viral pathogen contamination during feed manufacturing.

Footnotes

Contribution no. 18-505-J from the Kansas Agriculture Experiment Station, Manhattan, KS 66506-0210. Financial support for this research was provided by the National Pork Checkoff Award number 14–273.

LITERATURE CITED

- Bowman A. S., Krogwold R. A., Price T., Davis M., and Moeller S. J.. 2015a. Investigating the introduction of porcine epidemic diarrhea virus into an Ohio swine operation. BMC Vet. Res. 11:38. doi: 10.1186/s12917-015-0348-2 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bowman A. S., Nolting J. M., Nelson S. W., Bliss N., Stull J. W., Wang Q., and Premanandan C.. 2015b. Effects of disinfection on the molecular detection of porcine epidemic diarrhea virus. Vet. Microbiol. 179:213–218. doi: 10.1016/j.vetmic.2015.05.027 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen Q., Li G., Stasko J., Thomas J. T., Stensland W. R., and Pillatzki A. E.. 2014. Isolation and characterization of porcine epidemic diarrhea viruses associated with the 2013 disease outbreak among swine in the United States. J. Clin. Microbiol. 52:234–243. doi: 10.1128/jcm.02820-13 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cochrane R. A. 2015. Chemical mitigation of microbial pathogens in animal feed and ingredients. MS Thesis. Kansas State Univ, Manhattan. [Google Scholar]

- Cochrane R. A., Dritz S. S., Woodworth J. C., Stark C. R., Huss A. R., Cano J. P., Thompson R. W., Fahrenholz A. C., and Jones C. K.. 2016. Feed mill biosecurity plans: a systematic approach to prevent biological pathogens in swine feed. J Swine Health Prod. 24:154–164. Available from https://www.aasv.org/shap/issues/v24n3/v24n3p154.pdf [Google Scholar]

- Cochrane R. A., Schumacher L. L., Dritz S. S., Woodworth J. C., Huss A. R., Stark C. R., DeRouchey J. M., Tokach M. D., Goodband R. D., Bia J., et al. 2017. Effect of pelleting on survival of porcine epidemic diarrhea virus-contaminated feed. J. Anim. Sci. 95:1170–1178. doi: 10.2527/jas.2016.0961 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Davies P., Sampedro F., Snider T., Bueno I., Bergeron J., and Urriola P.. 2015. Risk assessment of feed ingredients of porcine origin as vehicles for transmission of porcine epidemic diarrhea virus (PEDV) Available from http://research.pork.org/FileLibrary/ResearchDocuments/14-164-DAVIES-UofMN.pdf. (Accessed February 12, 2015).

- Dee S., Clement T., Schelkopf A., Nerem J., Knudsen D., Christopher-Hennings J., and Nelson E.. 2014. An evaluation of contaminated complete feed as a vehicle for porcine epidemic diarrhea virus infection of naive pigs following consumption via natural feeding behavior: proof of concept. BMC Vet. Res. 10:176. doi: 10.1186/s12917-014-0176-9 [DOI] [PMC free article] [PubMed] [Google Scholar]

- FDA, Department of Health and Human Services.. 1976. Current good manufacturing practice for medicated feeds. 21 C.F.R. part 225.65. Fed. Regist. 41:52618 [Google Scholar]

- Goyal S. 2014. Environmental stability of PED (porcine epidemic diarrhea virus) Available from http://www.pork.org/wp-content/uploads/2014/05/goyal-13-215-main.pdf. (Accessed December 15, 2014).

- Herrman T., Behnke K., and Loughin T.. 1995. Mixing and clean-out properties of sulfamethazine and carbadox in swine feed. J Swine Health and Prod. 3:127–131. [Google Scholar]

- Huang Y. W., Dickerman A. W., Piñeyro P., Li L., Fang L., Kiehne R., Opriessnig T., and Meng X. J.. 2013. Origin, evolution, and genotyping of emergent porcine epidemic diarrhea virus strains in the United States. Mbio 4:e00737–e00713. doi: 10.1128/mBio.00737-13 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Huss A. R., Cochrane R. A., Deliephan A., Stark C. R., and Jones C. K.. 2015. Evaluation of a biological pathogen decontamination protocol for animal feed mills. J. Food Prot. 78:1682–1688. doi: 10.4315/0362-028X.JFP-15-052 [DOI] [PubMed] [Google Scholar]

- Huss A. R., Schumacher L. L., Cochrane R. A., Poulsen E., Bai J., Woodworth J. C., Dritz S. S., Stark C. R., and Jones C. K.. 2017. Elimination of porcine epidemic diarrhea virus in an animal feed manufacturing facility. Plos One 12:e0169612. doi: 10.1371/journal.pone.0169612 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Madson D. M., Magstadt D. R., Arruda P. H., Hoang H., Sun D., Bower L. P., Bhandari M., Burrough E. R., Gauger P. C., Pillatzki A. E., et al. 2014. Pathogenesis of porcine epidemic diarrhea virus isolate (US/Iowa/18984/2013) in 3-week-old weaned pigs. Vet. Microbiol. 174:60–68. doi: 10.1016/j.vetmic.2014.09.002 [DOI] [PubMed] [Google Scholar]

- Martinez-Kawas A. 2008. Evaluating flushing procedures to prevent drug carryover during medicated feed manufacturing. MS Thesis. Kansas State Univ, Manhattan. [Google Scholar]

- McCoy R. A. 2005. Mixer testing. In: Schofield E. K., editor, Feed manufacturing technology V. American Feed Industry Association, Arlington, VA: p. 620–622. [Google Scholar]

- Pasick J., Berhane Y., Ojkic D., Maxie G., Embury-Hyatt C., Swekla K., Handel K., Fairles J., and Alexandersen S.. 2014. Investigation into the role of potentially contaminated feed as a source of the first-detected outbreaks of porcine epidemic diarrhea in Canada. Transbound. Emerg. Dis. 61:397–410. doi: 10.1111/tbed.12269 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schumacher L. L., Huss A. R., Cochrane R. A., Stark C. R., Woodworth J. C., Bai J., Poulsen E. G., Chen Q., Main R. G., Zhang J., et al. 2017. Characterizing the rapid spread of porcine epidemic diarrhea virus (PEDV) through an animal food manufacturing facility. Plos One 12:e0187309. doi: 10.1371/journal.pone.0187309 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schumacher L. L., Woodworth J. C., Jones C. K., Chen Q., Zhang J., Gauger P. C., Stark C. R., Main R. G., Hesse R. A., Tokach M. D., et al. 2016. Evaluation of the minimum infectious dose of porcine epidemic diarrhea virus in virus-inoculated feed. Am. J. Vet. Res. 77:1108–1113. doi: 10.2460/ajvr.77.10.1108 [DOI] [PubMed] [Google Scholar]

- Thomas J. T., Chen Q., Gauger P. C., Giménez-Lirola L. G., Sinha A., Harmon K. M., Madson D. M., Burrough E. R., Magstadt D. R., Salzbrenner H. M., et al. 2015. Effect of porcine epidemic diarrhea virus infectious doses on infection outcomes in naïve conventional neonatal and weaned pigs. Plos One 10:e0139266. doi: 10.1371/journal.pone.0139266 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tilley D. R. 2013. Incidence and spread of insects from bucket elevator leg boots. PhD Dissertation. Kansas State Univ, Manhattan. [Google Scholar]

- Woodworth J. C. 2015. Determining the impact of conditioning time and temperature in pelleted diets on porcine epidemic diarrhea virus (PEDV) survivability in complete swine diets Available from http://research.pork.org/FileLibrary/ResearchDocuments/14-159-WOODWORTH-KSt.pdf. (Accessed May 22, 2018).