Abstract

Artificial Metals are polymeric semi-metallic composites obtained by combining thermosetting resins with atomized metal powders in order to achieve composite materials capable of reproducing metals, even in a rusty or corroded condition. These composites provide a solution for the reproduction of archaeological artefacts, sculptures, and ornaments for the purpose of conservation.

This work explores mechanical properties of three different resins bronze composites loaded with two different proportions of metal filler. The degree of conversion of the samples was measured by differential scanning calorimetry (DSC) and flexural tests were carried out to determine their mechanical performance. In addition, the samples were characterized by scanning electron microscopy (SEM) in order to determine the morphology of the samples at the microscale.

Keywords: Archaeology, Materials science

1. Introduction

Museums and other cultural institutions are concerned about the benefits of reproductions for the conservation of heritage artefacts, since these copies can substitute originals in temporary exhibitions to avoid loss and damage. New heritage and tourism models are using replicas as a way to find a sustainable path towards preservation (Cortell, 2016). While in the field of heritage metals conservation, the use of replicas is starting to arise due to the complexity of striking a balance between safeguarding and exhibiting historical metals, especially for many archaeological metallic artifacts, which are often in very poor condition (Pous, 2003). Since many institutions and local museums fail to provide even minimum guarantees for the preservation of some pieces, they instead opt for keeping them under controlled conditions, stored in museum vaults. Thus, the use of replicas has become not only necessary but desirable and provides a solution to keep the aforementioned balance between safeguarding and exhibiting. Nowadays, 3D scanning technologies and printing solutions are so precise that have matched the field of conservation, as powerful tools to record and reproduce heritage (Arbace et al., 2013; Scopigno et al., 2011).

In the field of stone sculpture conservation, mineral composites based on ceramic particles, are successfully being used since the 80's and 90's. The casting of artificial stones (mineral composites) arose and became very widespread since due to the need for solutions in the production of outdoor stone replicas to preserve stone sculptures in serious disrepair (Arciniegas et al., 2017; Bazán et al., 2014; Plano, 2003). According to the literature several mortars and mineral filled resins have been mechanically, morphologically, and chemically analysed (Kröner et al., 2016; Cerezo et al., 2014), but in the case of artificial metals there is still a lack of characterization studies in this field, even though their usage is growing.

Artificial metals are polymeric semi-metallic composites of thermosetting resins with atomized metal powders capable of reproducing any metal. Although these composites have been used in sculpture production (Brooks, 2005; Percy, 1962; Spenik, 1976), they are now finding use in heritage conservation (Herrero-Cortell, Mas-Barberá, Lastras-Pérez, Marcos-Martínez, & Culebras-Rubio). The use of artificial metals for reproduction purposes presents advantages such as weight reduction, cost reduction and faster production compared to metal foundry casting (Cortell et al., 2017) and electrochemical processes (La Niece et al., 2010). Furthermore, when compared with traditional lost wax foundry casting, artificial metals keep the scale and proportions avoiding shrinkage and deformations associated with thermal contraction that typically occurs when working with real metals, (Groover, 1997; Stefanescu et al., 1988).

Silicon elastomeric molds are frequently used for the reproduction process, because artificial metals, like artificial stones have to be cast or layered on surfaces. In fact molding is a common practice in the sculpture field (Brooks, 2005). Also, it is very common in heritage preservation as a way to record originals and to obtain copies, but restoration and conservation advocates for minimum contact with the original, in order to avoid stress induced damage. Conservators are concerned with the potential risk associated with moldmaking over the surface of an historical object, so there has been a move recently towards 3D printed models which is less severe on surfaces (Pieraccini et al., 2001).

Artificial metals can be cast or layered by controlling the amount of metal filler on the composite, while considering the kind of metal, and shape and size of the particles (M. H. Cortell et al., 2017; Herrero–Cortell et al., 2017). Usually, artificial metals can be cast at room temperature, without post-curing, and without sophisticated technology. Several resins can be used, but in this field epoxy and polyester are probably the most common, although others, such as vinylester can also be used for specific purposes, such as chemical resistance (Ratna, 2009).

Artificial metals not only can emulate a polished glossy finish, but also patinas and corrosion (Figs. 1 and 2) making them ideal for conservation purposes, since archaeological and historical metals use to have very rich patinas developed by the action of time and environmental factors. To achieve both results (burnished metal or patina finish) a very thin deposition of metal particles has to be layered on the inner of the mould. These particles will occur on the surface of the cast, saturating the proportion of metal in the outside of the composite, allowing the enhancement of the metal appearance of the composite and providing a significant amount of metal to develop a rich patina, if it is desired. Since artificial metals can be done with several metal fillers, the variety of colours, finishes and patinas is wide.

Fig. 1.

Different finishes of metal composites produced in this study based on vinylester resin for heritage cloning, by using a mould of a roman Augustus head. From left to right a patinated bronze; a burnished bronze and burnished iron.

Fig. 2.

Scheme which shows how colour and finishes used in this study are susceptible of changing depending on the choice of the process for a specific metal.

Many patinas contain very strong acids, like nitric acid, to help the metal develop the colour. Such substances can be harmful and can potentially damage the resins, reducing mechanical properties. Other formulas use direct fire or strong heaters to speed up the patina formation, that neither epoxy nor polyester resins are able to withstand. Thus, cold patinas, vat patinas and fume patinas have been successfully developed on artificial metal surfaces (Hughes and Rowe, 1982; Young, 2000) and shown in Fig. 3.

Fig. 3.

An artificial copper 80% wt based on epoxy resin used in this study as a decorative figurine. The vat patina has been developed with ammonia in a 48 hours cycle.

There is a lack of research on the characterisation of these artificial metals and the mechanical properties, which greatly influence performance, of these composite remain relatively unknown. Therefore, in this work we characterise three bronze composites based on epoxy, polyester, and vinylester utilising two bronze loadings (70% and 80%), which are typical loadings for layering and casting purposes (Herrero–Cortell et al., 2017). The main objective of this work is to perform a comparison of these thermosetting resins as a binder for bronze and iron fillers. Parameters such as: degree of conversion of monomeric species to growing chains and flexural properties are investigated. There is a direct relationship between these parameters and this is of importance as it relates to optimal performance in relation to subsequent artefact handling and restoration.

2. Experimental

2.1. Materials

Epoxy resin Araldite LY 554 curing agent HY 956 (Diethylenetriamine, Triethy lenetetramine and Propoxylated Triethylenetetramine) and Polyester resin S 1119 were purchased form CTS international, Vinylester resin 8470TX and Methyl ethyl ketone peroxide solution (36%) were provided by Glaspol composites S.L. Atomized non-deoxidized bronze particles of CuSn15 W75 (size 25–180 μm) were obtained from Pometon S.A.

2.2. Methods

Thermoset resin was poured into the reaction flask, then the curing agent was added in different proportions for each resin, 20 % wt of HY 956 for epoxy and 2 % wt of Methyl-ethyl-ketone peroxide solution for polyester S 1119 and Vinylester 8470TX. This mixture was filled with bronze particles (80 % and 70%). The resulting blend was mechanically stirred. Finally the dispersion was poured on a silicone mold in order to obtain the samples of 100 × 10 × 5 mm for mechanical characterisation. The samples were kept in the mould for 24 hours and after demoulding the samples were postcured at 313 K in a furnace for 48 hours.

3. Analysis

Scanning electron microscopy (SEM) has been used for morphological analysis of the samples. The images were obtained from Hitachi S-4800 microscope at an accelerating voltage of 20 kV and a working distance of 14 mm. The surfaces were vacuum coated with a thin gold-palladium alloy layer before testing.

In order to determine the degree of conversion (α) of each thermosetting resign differential scanning calorimetry measurements (DSC) were carried out on a Q-20 differential scanning calorimeter from TA Instruments calibrated with indium. The isothermal measurements were done at 298 K in order to know the verification time. To calculate the total heat of reaction two scans were carried out form −50 °C to 220 °C at 10 °C/min (see supplementary information). The degree of conversion, (α), was calculated according to the following equation:

where is the trace of isothermal DSC curves and is the total heat of reaction obtained from the dynamic curves.

Flexural tests was carried out using ASTM D-790 norm on a INSTRON model 5582. The sample dimensions were 100 × 10 × 5 mm and the experiments were repeated 6 times at a crosshead speed of 2 mm/min.

4. Results and discussion

Preliminary experiments have shown that the best proportion of metal for resin is between 65% and 85% of metal in total weight. Less than 65 % of metal produces a bad finish due to the lack of metal particles at the surface, while more than 85 % of metal produces a thick viscous putty that causes problems with mixing, saturation of mesh, bad handling, and poor mechanical performance due to the lack of resin (Herrero–Cortell et al., 2017).

As a result two weight proportions were set for each working method: 70% of metal for casting, and 80 % of metal for layering purposes.

Fig. 4 shows the degree of conversion as a function of time for each thermosetting resin used in the present study at room temperature. The results indicate higher values of degree of conversion for vinylester resin (0.5) then polyester resin (0.3) and the lowest values were obtained for epoxy resin (0.2). These values indicate that at room temperature all the thermosetting resins are not fully cured. It is possible to increase α by accelerating the curing process at higher temperatures but the limitations of the sculpture methodologies coupled with usual facilities available in the sculpture workshops restrict the experiment to room temperature conditions. Thus, vinylester resins seem to be a good polymer binder for this proposes since the degree conversion is more or less acceptable at room temperature.

Fig. 4.

Degree of conversion of Epoxy, Polyesther and Vinylesther resins calculated at room temperature.

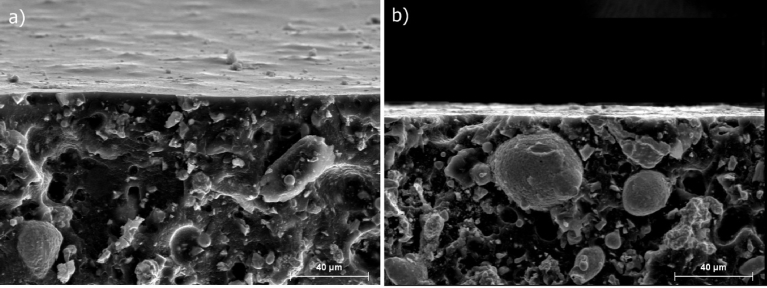

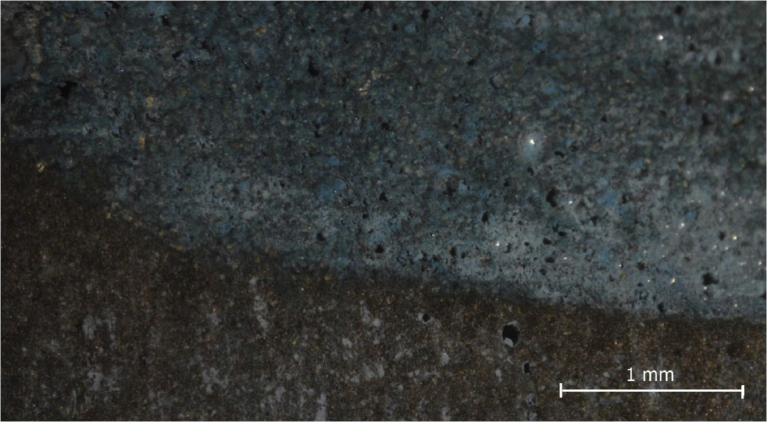

The cross section of the samples was studied using SEM. Fig. 5 (a) and (b) show the cross section of the sample synthetized using polyester resin and 70% bronze. A homogenous distribution of the metallic particles are clearly observed within the polymer. However, the metallic appearance is only observed after burnishing the surface of the sample. This process removes part of the polymer from the surface leaving the bonze particles at the solid-air interface as shown in Fig. 5. Their appearance was metallic and is indistinguishable from the original made by melt Bronze. In addition, this method allows the possibility to use acid or basic solutions to stimulate the degradation process that happens during the passage of time as it can be observed in Fig. 6 for an epoxy/bronze sample treated with ammonia solution (15 M).

Fig. 5.

SEM images of the cross section of the polyester resin with 70 % of Bronze (a) before and (b) after burnish.

Fig. 6.

A sample of epoxy resin with 80 % bronze. The sample has been polished and then patinated with ammonia during 12 (brown) and 24 hours (blue).

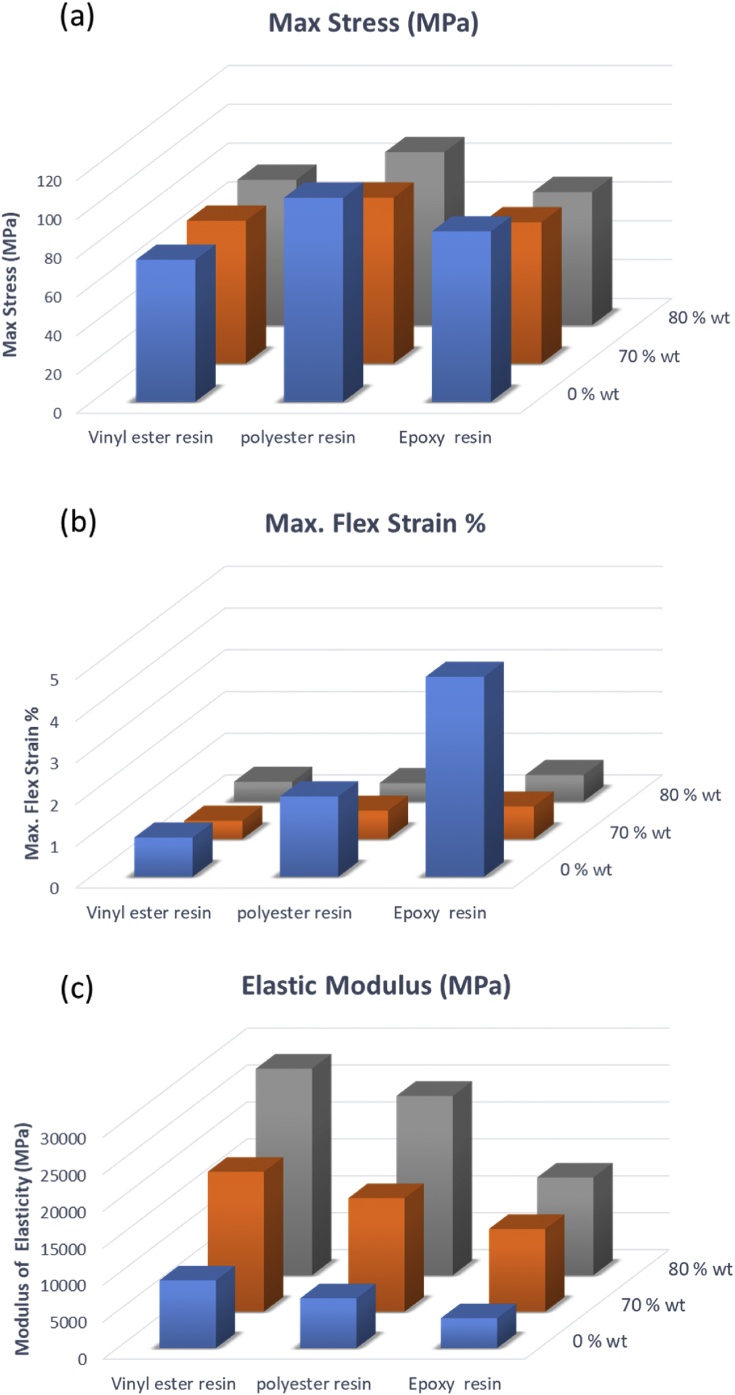

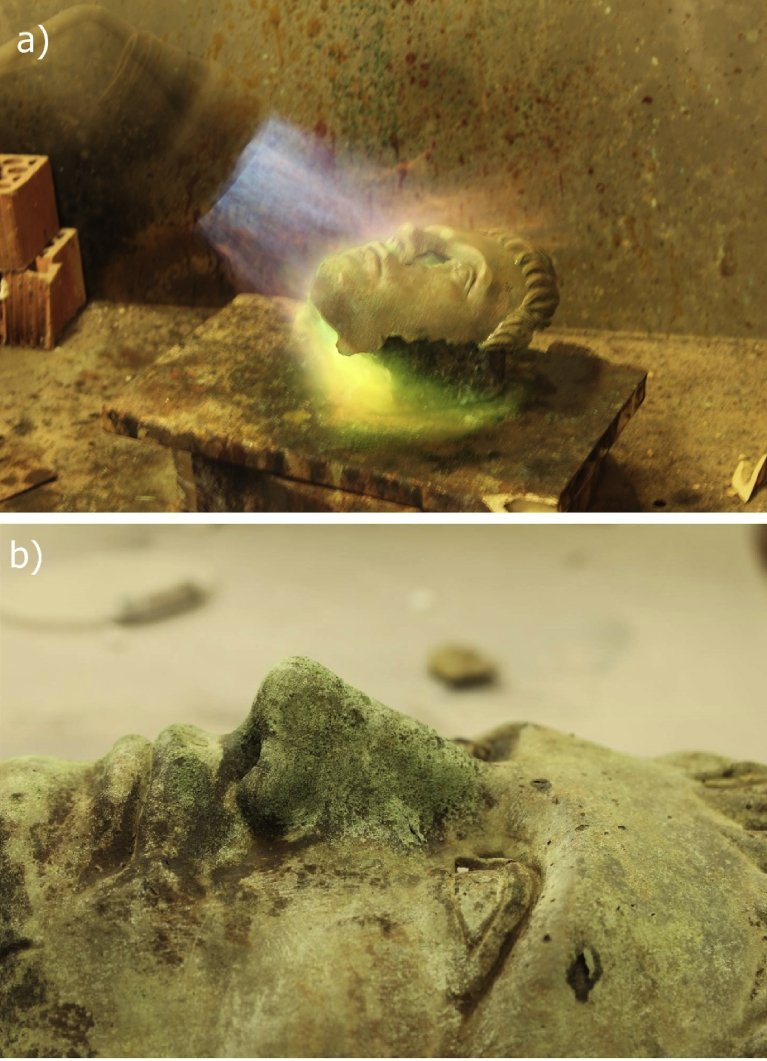

Fig. 7 shows the mechanical properties of samples prepared using each resin with a different content of bronze particles (additional information about flexural properties is shown in the supplementary information file). The values of maximum stress (Fig. 3a) remain in the same order with the addition of the bronze particles. For the case of the vinylester resin values around 73 MPa were obtained keeping the same values with the addition of 70 % and 80 % of bronze particles. The maximum stress for the samples prepared using a polyester resin decreased from 100 MPa to 85 MPa with the addition of bronze particles. The same effect has been observed for the case of the samples prepared using the epoxy resin decreasing the maximum stress from 87 MPa to 73 and 69 MPa with the addition of 70 % and 80 % of particles respectively. In terms of strain the resins show a clearly different behavior as can be observed in Fig. 7b. Without bronze particles the epoxy resin achieved strain values around 4.8 % before break, clearly higher compared to polyester and vinylester resin (1.9 and 0.9 % respectively) that difference can be explained due to low degree of conversion of the epoxy resin. However, with the addition of bronze particles the strain values before brake is reduced to values between 0.5 and 0.7 %. The elastic modulus (Fig. 7c) increased one order of magnitude with the particle content suggesting a stiffening effect of the polymer binder (Douglas et al., 2016a; Douglas et al., 2016b; Guadagno et al., 2017, Guadagno et al., 2014; Nohales et al., 2013). The elastic modulus varies in the following order vinylester >polyster>epoxy resins. This trend is related to the different structure of each material. Looking at the mechanical properties and the degree of conversion, metallic composites based on vinylester resins are more suitable for archaeological and artistic metal heritage cloning, especially if a patina finish is desired, like the one shown in Fig. 8.

Fig. 7.

Maximum Stress (a), Maximum flex strain (b) and modulus of elasticity (c) of the three resins for each average of bronze filler.

Fig. 8.

a) A complex copper patina developed on the surface of a bronze vinylester composite (80 % bronze) by using several strong chemicals and a torch. b) Detail of the patina as it develops.

5. Conclusions

Artificial metals are being studied as useful tools in the reproduction and casting of metal replicas, in order to preserve some endangered original pieces, and also to repair those damaged during the aging process. Thus, in the field of conservation these kind of materials are of utmost importance.

Although all three resins have successful results as metal composite binders there are some critical points that must be considered when a resin is chosen for sculpture reproductions or archaeological replicas of metallics. Epoxy composites often display problems with curing, and post curing tends not to be an option considered by sculptors, artists and restorers, because of the large size of many reproductions. Furthermore, artists tend to work without considering the post-curing process which, though is common in industrial applications, is not so common in sculptors workshops for obvious limitations of resources. This lack of post-curing processes makes epoxy composites easily deformable but also harder to break. Epoxies are not recommended for outdoor purposes because epoxy composites suffer with aging and get damaged by weathering conditions.

Polyester composites are perfectly suited to artistic applications due to its mechanical characteristics. They can be employed in order to obtain successful metal finishes, thought they do not suppose a good solution if a patina is considered as a finish, because this kind of treatments involves the usage of chemicals and acids, and factors which are direct responsible of polyester degradation.

Vinylester composites offer good mechanical results, presenting a middle performance between epoxy and polyester, and they are especially resistant to chemical conditions. They are a good solution for metal reproductions if a patina finish is considered, due to their capability to withstand temperature and chemical attack.

All three resins are suitable for casting and layering, but some limitations must be considered for each of them, thus, the selection of a resin for bronze composites must take into account parameters like size, weight, location, and production risks associated with the reproduction.

Declarations

Author contribution statement

Mario Culebras, Miquel Herrero-Cortell, Clara Gómez, Xavier Mas-Barberà, Andrés Cantarero, Maurice N. Collins: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

The authors wish to thank Dr Montserralt Lastras-Pérez, from Instituto de Conservación y Restauración del Patrimonio, and Dr Carmen Marcos-Martínez from Instituto de Química Molecular Aplicada, of the Universitat Politècnica de València (UPV). The authors also wish to thank Mr. Joan Navarra, and Pometon España, for metal powder samples and technical advice.

Appendix A. Supplementary data

The following is the supplementary data related to this article:

References

- Arbace L., Sonnino E., Callieri M., Dellepiane M., Fabbri M., Idelson A.I., Scopigno R. Innovative uses of 3D digital technologies to assist the restoration of a fragmented terracotta statue. J. Cult. Herit. 2013;14(4):332–345. [Google Scholar]

- Arciniegas A., Martinez L., Briand A., Prieto S., Serfaty S., Wilkie-Chancellier N. Experimental ultrasonic characterization of polyester-based materials for cultural heritage applications. Ultrasonics. 2017;81:127–134. doi: 10.1016/j.ultras.2017.06.011. [DOI] [PubMed] [Google Scholar]

- Bazán M.M., Kröner S., Mas-Barberà X., Mastroiacovo T., Medda G. Chromatic properties study of mortars with organic binder used in the reproduction of outdoor artworks. Sci. Technol. Cult. Herit. 2014:163. [Google Scholar]

- Brooks N. Crowood; 2005. Mouldmaking and Casting. [Google Scholar]

- Cerezo A., Mas-Barber X., Kröner S. CeROArt. Conservation, Exposition, Restauration d'Objets d'Art. Association CeROArt asbl; 2014. Study of the mechanical properties of mortars based on organic binders used in the reproduction of outdoor artworks. [Google Scholar]

- Cortell M.A.H. RdM. Revista de Museología: Publicación científica al servicio de la comunidad museológica (67) 2016. Arsgeminis pro ars. Las copias y reproducciones patrimoniales: usos, tendencias, percepción, y repercusión social; pp. 11–20. [Google Scholar]

- Cortell M.H., Barberá J.M., Martínez C.M., Pérez M.L., Rubio M.C. Museum reproduction of metallic archaeological artefacts: from lost wax casting techniques to artificial metals. Ge-conservación/conservação. 2017;(12):31–44. http://hdl.handle.net/10459.1/62337 [Google Scholar]

- Douglas P., Albadarin A.B., Sajjia M., Mangwandi C., Kuhs M., Collins M.N., Walker G.M. Effect of poly ethylene glycol on the mechanical and thermal properties of bioactive poly (ε-caprolactone) melt extrudates for pharmaceutical applications. Int. J. Pharm. 2016;500(1–2):179–186. doi: 10.1016/j.ijpharm.2016.01.036. [DOI] [PubMed] [Google Scholar]

- Douglas P., Kuhs M., Sajjia M., Khraisheh M., Walker G., Collins M.N., Albadarin A.B. Bioactive PCL matrices with a range of structural & rheological properties. React. Funct. Polym. 2016;101:54–62. [Google Scholar]

- Groover M.P. Pearson Educación; 1997. Fundamentos de manufactura moderna: materiales, procesos y sistemas. [Google Scholar]

- Guadagno L., Raimondo M., Vittoria V., Vertuccio L., Naddeo C., Russo S. Development of epoxy mixtures for application in aeronautics and aerospace. RSC Adv. 2014;4(30):15474–15488. [Google Scholar]

- Guadagno L., Naddeo C., Raimondo M., Barra G., Vertuccio L., Russo S. Influence of carbon nanoparticles/epoxy matrix interaction on mechanical, electrical and transport properties of structural advanced materials. Nanotechnology. 2017;28(9) doi: 10.1088/1361-6528/aa583d. [DOI] [PubMed] [Google Scholar]

- Herrero-Cortell, M., Mas-Barberá, X., Lastras-Pérez, M., Marcos-Martínez, C., & Culebras-Rubio, M. El ‘bronce artificial’en la reproducción de objetos arqueológicos, escultóricos y ornamentales. Una solución para la conservación preventiva y la divulgación del patrimonio metálico. METALESPAÑA 2015. Actas del II Congreso de Conservación y Restauración del Patrimonio Metálic, 139-148.

- Herrero–Cortell M., Rubio M.C., Mas–Barberà X. Metales artificiales en aplicaciones escultóricas: matrices termoestables y cargas metálicas. Revista Iberoamerica de Polímeros Volumen. 2017;18:1. [Google Scholar]

- Hughes R., Rowe M. The Crafts Council; 1982. The Colouring, Bronzing and Patination of Metals, a Manual for the fine Metal Worker and Sculptor. [Google Scholar]

- Kröner S., Alcaide B.M., Mas-Barberà X. Influence of substrate pore size distribution, poultice type, and application technique on the desalination of medium-porous stones. Stud. Conserv. 2016;61(5):286–296. [Google Scholar]

- La Niece S., Röhrs S., McLeod B. British Museum; 2010. The Heritage of ‘Maître Alpais’: an International and Interdisciplinary Examination of Medieval Limoges Enamel and Associated Objects. [Google Scholar]

- Nohales A., López D., Culebras M., Gómez C.M. Rheological study of gel phenomena during epoxide network formation in the presence of sepiolite. Polym. Int. 2013;62(3):397–405. [Google Scholar]

- Percy H. 1962. New Materials in Sculpture; p. 66. [Google Scholar]

- Pieraccini M., Guidi G., Atzeni C. 3D digitizing of cultural heritage. J. Cult. Herit. 2001;2(1):63–70. [Google Scholar]

- Plano A.N. Actas de los XIII Cursos Monográficos sobre el Patrimonio Histórico (Reinosa, julio-agosto 2002) Universidad de Cantabria; 2003. Las reproducciones de esculturas: del mármol a los materiales imitadores; pp. 77–88. [Google Scholar]

- Pous A.M. Actas de los XIII Cursos Monográficos sobre el Patrimonio Histórico (Reinosa, julio-agosto 2002) Universidad de Cantabria; 2003. Copias y reproducciones de piezas arqueológicas: resumen histórico y función en los museos; pp. 31–40. [Google Scholar]

- Ratna D. ISmithers Shawbury; UK: 2009. Handbook of Thermoset Resins. [Google Scholar]

- Scopigno R., Callieri M., Cignoni P., Corsini M., Dellepiane M., Ponchio F., Ranzuglia G. 3D models for cultural heritage: beyond plain visualization. Computer. 2011;44(7):48–55. [Google Scholar]

- Spenik R. Stobart Davies; 1976. Successful Cold-casting and Mould Making. [Google Scholar]

- Stefanescu D., Davis J., Destefani J. ASM International; 1988. p. 937. (Metals Handbook, Vol. 15--Casting). [Google Scholar]

- Young R.D. Sculpt-Nouveau; 2000. Contemporary Patination. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.