Abstract

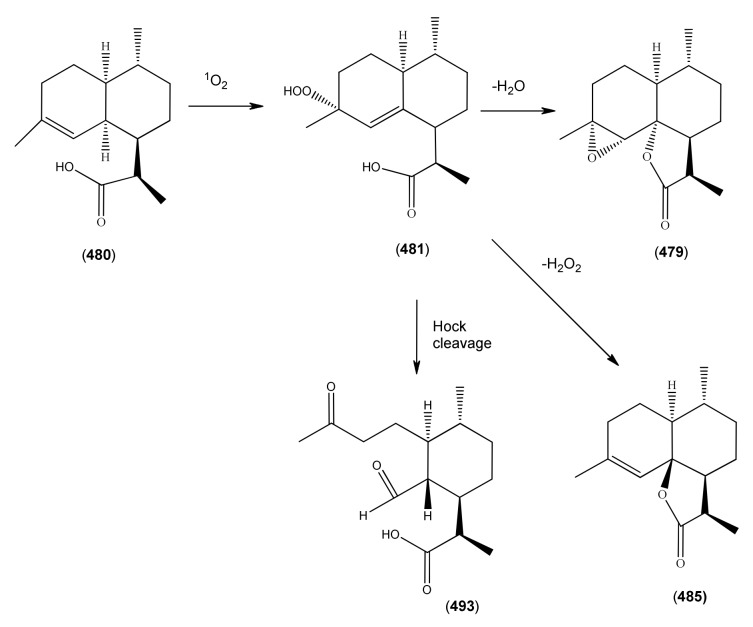

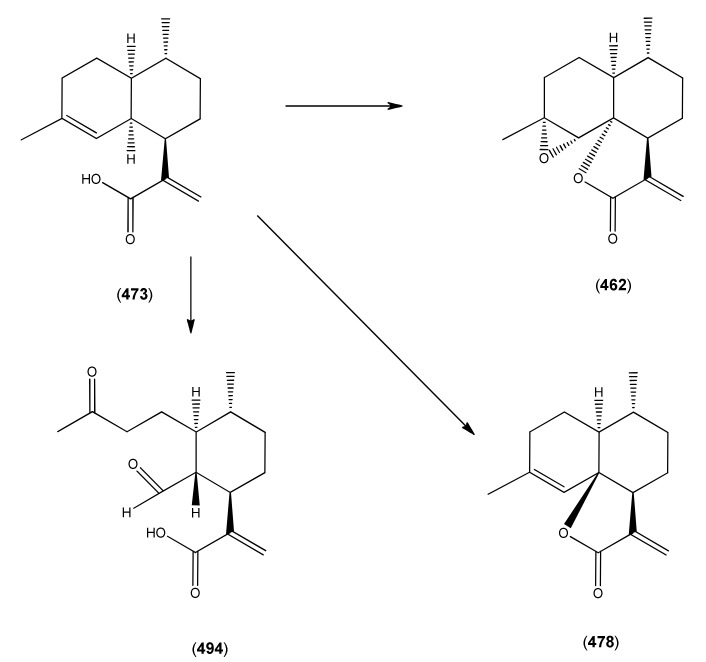

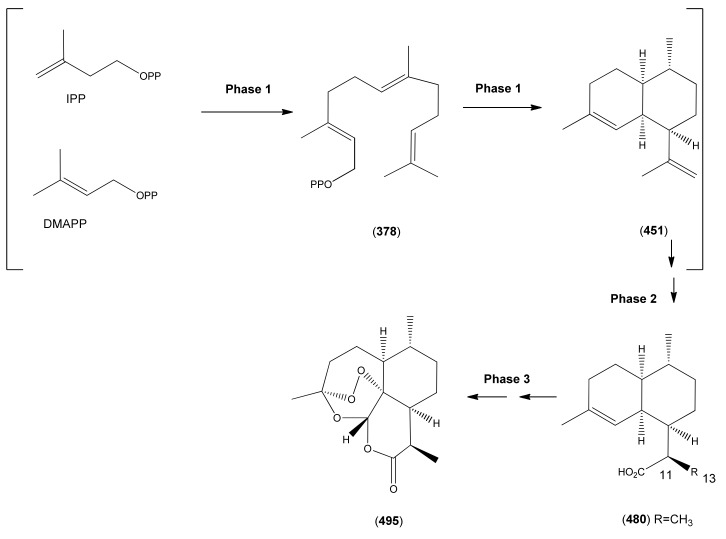

The Chinese medicinal plant Artemisia annua L. (Qinghao) is the only known source of the sesquiterpene artemisinin (Qinghaosu), which is used in the treatment of malaria. Artemisinin is a highly oxygenated sesquiterpene, containing a unique 1,2,4-trioxane ring structure, which is responsible for the antimalarial activity of this natural product. The phytochemistry of A. annua is dominated by both sesquiterpenoids and flavonoids, as is the case for many other plants in the Asteraceae family. However, A. annua is distinguished from the other members of the family both by the very large number of natural products which have been characterised to date (almost six hundred in total, including around fifty amorphane and cadinane sesquiterpenes), and by the highly oxygenated nature of many of the terpenoidal secondary metabolites. In addition, this species also contains an unusually large number of terpene allylic hydroperoxides and endoperoxides. This observation forms the basis of a proposal that the biogenesis of many of the highly oxygenated terpene metabolites from A. annua – including artemisinin itself – may proceed by spontaneous oxidation reactions of terpene precursors, which involve these highly reactive allyllic hydroperoxides as intermediates. Although several studies of the biosynthesis of artemisinin have been reported in the literature from the 1980s and early 1990s, the collective results from these studies were rather confusing because they implied that an unfeasibly large number of different sesquiterpenes could all function as direct precursors to artemisinin (and some of the experiments also appeared to contradict one another). As a result, the complete biosynthetic pathway to artemisinin could not be stated conclusively at the time. Fortunately, studies which have been published in the last decade are now providing a clearer picture of the biosynthetic pathways in A. annua. By synthesising some of the sesquiterpene natural products which have been proposed as biogenetic precursors to artemisinin in such a way that they incorporate a stable isotopic label, and then feeding these precursors to intact A. annua plants, it has now been possible to demonstrate that dihydroartemisinic acid is a late-stage precursor to artemisinin and that the closely related secondary metabolite, artemisinic acid, is not (this approach differs from all the previous studies, which used radio-isotopically labelled precursors that were fed to a plant homogenate or a cell-free preparation). Quite remarkably, feeding experiments with labeled dihydroartemisinic acid and artemisinic acid have resulted in incorporation of label into roughly half of all the amorphane and cadinane sesquiterpenes which were already known from phytochemical studies of A. annua. These findings strongly support the hypothesis that many of the highly oxygenated sesquiterpenoids from this species arise by oxidation reactions involving allylic hydroperoxides, which seem to be such a defining feature of the chemistry of A. annua. In the particular case of artemisinin, these in vivo results are also supported by in vitro studies, demonstrating explicitly that the biosynthesis of artemisinin proceeds via the tertiary allylic hydroperoxide, which is derived from oxidation of dihydroartemisinic acid. There is some evidence that the autoxidation of dihydroartemisinic acid to this tertiary allylic hydroperoxide is a non-enzymatic process within the plant, requiring only the presence of light; and, furthermore, that the series of spontaneous rearrangement reactions which then convert this allylic hydroperoxide to the 1,2,4-trioxane ring of artemisinin are also non-enzymatic in nature.

Keywords: artemisinin, dihydroartemisinic acid, sesquiterpene, biosynthesis, Artemisia annua, phytochemistry, oxidation, allylic hydroperoxide

- Introduction

-

1.1Malaria

-

1.2Artemisia annua (Qinghao)

-

1.3Artemisinin (Qinghaosu)

-

1.1

- The Phytochemistry of Artemisia annua L. (Qinghao)

-

2.1Aliphatic hydrocarbons, alcohols, aldehydes and acids

-

2.2Aromatic alcohols, ketones and acids

-

2.3Phenylpropanoids

-

2.4Flavonoids

-

2.5Monoterpenoids

-

2.5.1Regular acyclic monoterpenes

-

2.5.2Irregular acyclic monoterpenes

-

2.5.3Monocyclic monoterpenes

-

2.5.4Bicyclic monoterpenes

-

2.5.1

-

2.6Sesquiterpenoids

-

2.6.1Farnesane sesquiterpenes

-

2.6.2Monocyclic sesquiterpenes

-

2.6.3Bicyclic sesquiterpenes

-

2.6.4Tricyclic sesquiterpenes

-

2.6.1

-

2.7Higher terpenoids

-

2.7.1Diterpenes

-

2.7.2Triterpenes and sterols

-

2.7.1

-

2.8Nitrogen-containing natural products

-

2.1

- The Biosynthesis of artemisinin (Qinghaosu)

-

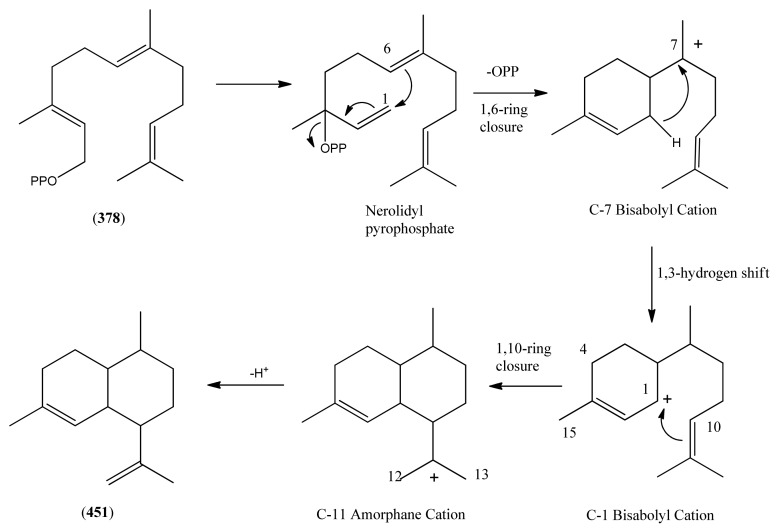

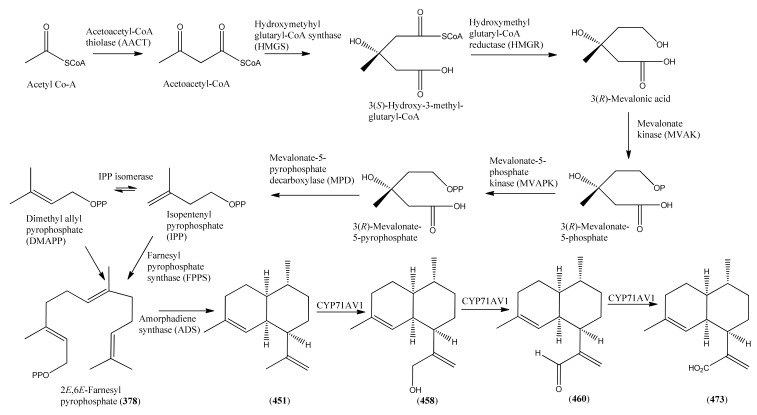

3.1Phase 1 (isopentenyl pyrophosphate to amorpha-4,11-diene)

-

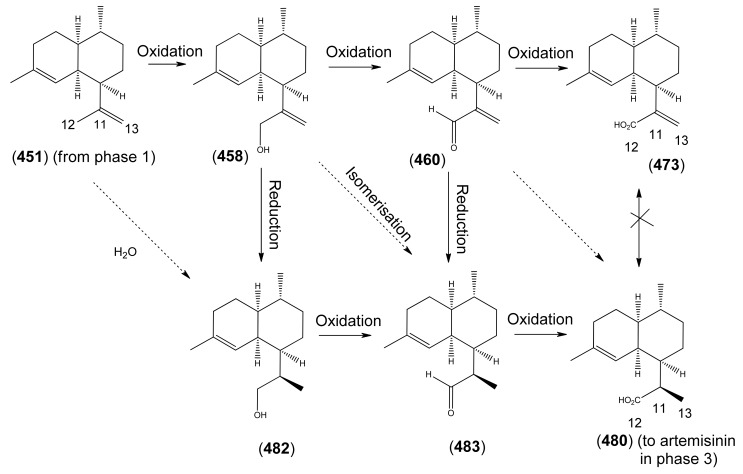

3.2Phase 2 (amorpha-4,11-diene to dihydroartemisinic acid)

-

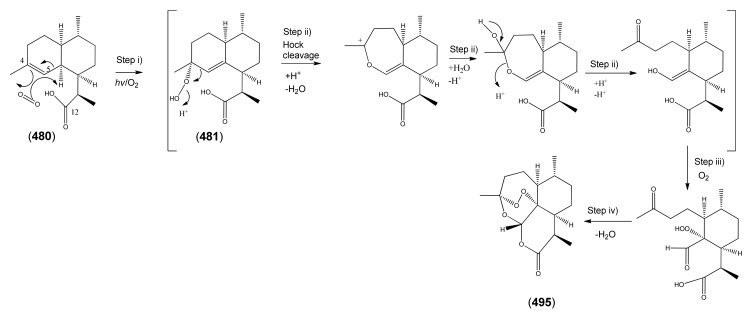

3.3Phase 3 (dihydroartemisinic acid to artemisinin)

-

3.1

- Strategies for the production of artemisinin from A. annua and derived systems

-

4.1Plant breeding programmes

-

4.2Plant tissue culture

-

4.3Endophytic fungi

-

4.4Genetic engineering

-

4.1

Acknowledgements

References

1. Introduction

1.1. Malaria

Malaria is an infectious disease which has affected human beings since the dawn of recorded history. By the middle of the last century, however, many felt that malaria was on the retreat and that one day it might even be vanquished. Two factors were primarily responsible for this perceived reduction in the severity of the malarial threat. Firstly, the Anopheles mosquito, which transmits the disease to humans, could at last be controlled by widespread application of the insecticide DDT. Secondly, the Plasmodium parasite, which causes malaria (four members of the genus infect humans: P. falciparum, P. vivax, P. malariae and P. ovale), could also be effectively be controlled by the use of synthetic analogues of quinine (itself also a natural product, obtained from the bark of the cinchona tree), such as chloroquine, which had been developed before World War II.

By the 1960’s, however, malaria was back with a vengeance. The mosquitoes were developing resistance to DDT, which was soon to be banned in any case because of environmental concerns. The Plasmodium falciparum parasite, which is responsible for cerebral malaria, an often fatal complication, was also developing resistance to chloroquine. Thailand and South America were the first regions to be affected, but resistance to chloroquine soon spread to many other parts of the World. Nowadays, it is particularly serious in South East Asia. It was against this background of increasing resistance, and of the on-going wars in neighboring Cambodia and Vietnam, that the Chinese government began a major initiative to discover new antimalarials from plants used in Traditional Chinese Medicine (TCM).

1.2. Artemisia annua (Qinghao)

The herb “Qinghao” first appeared in a book entitled “Wu Shi Er Bing Fang” (Prescriptions for Fifty-Two Ailments) more than two thousand years ago. The earliest reported use for Qinghao was for the treatment of haemorroids; but “Zhou Hou Bei Ji Fang” (Handbook of Prescriptions for Emergency Treatment), written in 340 AD, describes the use of Qinghao as a treatment for fevers [1]. The first text in which Qinghao might specifically be identified as a remedy for malaria is “Ben Cao Gang Mu” (1596) in which the herb is described as “a treatment for hot and cold due to intermittent fever illness”. These old pharmacopeias describe preparations in which the leaves (collected in summer or spring) are pounded with a pestle and mortar in order to express the “juice”. This procedure was, perhaps, intended to improve the recovery of essential oils from trichomes on the leaf surface, in which the active principal, artemisinin, is now thought be contained.

It is not entirely clear whether “Qinghao” which is referred to in these ancient texts is solely Artemisia annua L. [2]; and it has sometimes been suggested that the term may also have been used synonomously for Artemisia apiacea Hance [1]. In the modern pharmacopeia of the People’s Republic of China, however, Qinghao is now officially listed as the aerial parts of A. annua L. [3] (5g dried herb/1L water is suggested for the preparation of a decoction). In the TCM system, A. annua is cool in nature (yin) and is therefore suitable for treating “heat” syndromes (yang), such as malaria; other applications described for this cooling herb, such as the relief of symptoms of febrile diseases, tidal fever, low grade fever and summer heat stroke, are also consistent with this classification.

1.3. Artemisinin (Qinghaosu)

As has been noted, after a brief respite lasting only a few decades, malaria was once again on the increase in the 1960s. In 1967, the Chinese government launched a program to discover new antimalarial drugs based on a systematic investigation of indigenous plants used in TCM.

When the Chinese scientists made infusions of A. annua with hot or boiling water, as described in the ancient texts, they observed no activity against mice infected with Plasmodium berghei (a rodent malarial parasite). However, thanks to the insight of Prof. Tu, cold ethereal extracts of A. annua were also tested and these did show encouraging activity, leading to the isolation of the active principle, artemisinin, in 1972 (the original reports of this new drug referred to “Qinghaosu”, meaning “principle from Qinghao” [4]). Nowadays, artemisinin is extracted from A. annua using diethyl ether, hexane, petroleum ether or even petrol as solvent [5].

At first sight, the lack of effectiveness for hot water extracts from A. annua appears to be at variance with the reports in the traditional pharmacopeias (in addition, we now know that artemisinin is virtually insoluble in water). One possible explanation is that the original recipes normally required that A. annua preparations be made in conjunction with other herbs (so-called “minister” or “guide” herbs). For example, in the herbal “Wen Bing Tiao Bian” (1798), an infusion of A. annua together with Amyda sinensis, Rehmannia glutinosa, Anemarrhena asphodeloides and Paeonia suffructicosa is described. It is quite possible that saponins, or other components from the latter three herbs which are capable of acting as detergents, might be able to assist the dissolution of artemisinin in water (cf. the suggestion in Section 2.4 that flavonoids, which are present both in A. annua and other herbs, may be able to potentiate the antimalarial effect of artemisinin in crude plant preparations).

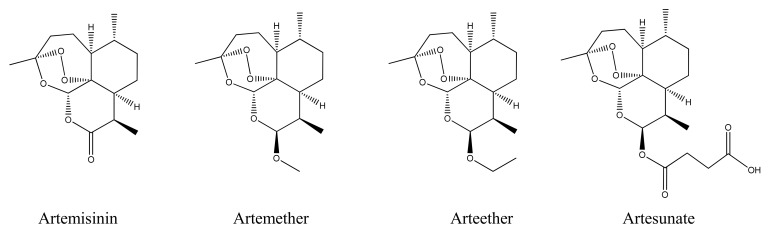

Clinical studies in the late 1970s with patients infected with P. vivax or P. falciparum demonstrated that artemisinin could kill the malarial parasite very quickly at the schizont stage of the parasite’s life cycle (i.e. while it infected the human red blood cell) and with no obvious side effects [6]. Most importantly, artemisinin was completely effective in the treatment of chloroquine-resistant Falciparum malaria [7]. The discovery of this new and potent antimalarial attracted the attention of the World Health Organization (WHO), which had the resources to develop artemisinin globally; and both A. annua and artemisinin soon became well known outside of China. However, the therapeutic value of artemisinin was limited by its low solubility in both oil and water, and this has lead to the development of semi-synthetic drugs with pharmacological properties superior to those of the parent [8]. The most important such derivatives are artemether, arteether and artesunate (Figure 1), which exhibit greater potency than artemisininin itself, as well as improved solubility, and favourable metabolic and hydrolytic stabilities. Formulations based on these drugs are now at the heart of the WHO’s global fight against malaria The entire world production of such semi-synthetic artemisinin derivatives is currently reliant on harvesting and extraction of artemisinin from A. annua plants, which is practiced on a multi-tonne scale in countries such as China and Vietnam.

Figure 1.

Artemisinin and its semi-synthetic derivatives, which are currently used in the treatment of malaria.

Malaria is now the most serious infectious disease in the World, with at least 300 million cases reported every year. It is estimated to be responsible for up to 2 million deaths annually - mainly amongst children - with more than half of the deaths occurring amongst the poorest 20% of the World’s population. The importance of artemisinin has been founded on a continuing lack of resistance almost three decades after its introduction – although, very recently, reports of the emergence of resistance have indeed begun to appear [7,8] This slow onset of resistance may be a consequence of the unique mechanism of action for this drug, which is associated with the unusual endoperoxide group. It is thought that artemisinin becomes activated when its endoperoxide group comes into contact with Fe(II) in free haem groups, which have been liberated by the parasite’s digestion of the haemoglobin contained in the red blood cell.

The appearance of resistance to artemisinin could be a devastating blow for many parts of South East Asia and Africa, where artemisinin-based drugs are currently the only effective treatment for malaria (resistance to the older generation of quinine-derived antimalarials having already become endemic to these regions). In an attempt to forestall the emergence of resistance, the WHO have been recommending that artemisnin should be taken in combination with another antimalarial drug – so-called Artemisinin Combination Therapy (ACT). This strategy is designed to slow the development of resistance, because during treatment with two drugs, the chance of a mutant emerging which is resistant to both is the product of the probabilities of resistance arising to either drug separately. It seems that, in the continuing absence of an effective malaria vaccine, the development of new antimalarial drugs – most likely derived from, or inspired by, artemisinin – will continue to be our primary weapon in the fight against malaria.

2. The Phytochemistry of Artemisia annua L. (Qinghao)

Artemisia annua Linn. (sweet wormwood; Chinese wormwood) is a member of the Asteraceae family of plants (formerly Compositae). It is a native of China, originally found in the steppes of Chahar and Suiyuan Provinces, but is now widespread in many parts of the World, and is cultivated in countries such as Vietnam, Thailand, Burma, Madagascar, Malaysia, USA, Brazil, Australia (Tasmania), Holland, Switzerland, France and Finland. Most phytochemical investigations of A. annua have employed the aerial parts (leaves and/or stems - sometimes also including the flowers) although one report has concentrated on the seeds [9]. The phytochemistry of A. annua is dominated by terpenoids (in particular sesquiterpene lactones), flavonoids, coumarins and other shikimate metabolites, as is the case for many other members of the genus Artemisia. The sesquiterpene, artemisinin, is however unique to A. annua – it has been searched for on several occasions in other species in the genus Artemisia, always without success [10,11]. The artemisinin content from A. annua is highly variable, ranging anywhere between 0.01% and 1%, depending on variety, and can even be as high as 1.4% in some cultivated strains.

There have been several reviews of the phytochemistry of A. annua [12,13,14,15]. In this section, an attempt has been made to provide a comprehensive review of the original phytochemical literature concerning A. annua up to 2009. Almost six hundred secondary metabolites are described, which have been divided into eight sections (Section 2.1, Section 2.2, Section 2.3, Section 2.4, Section 2.5, Section 2.6, Section 2.7 and Section 2.8) and further sub-divided into more than forty Tables. The grouping of these natural products from A. annua is based on the (largely biogenetic) classification adopted by a standard reference work, the Dictionary of Natural Products [16]. Thus, the structurally most simple group of metabolites – derivatives of aliphatic hydrocarbons (branched, unbranched, saturated or unsaturated) with varying levels of oxidation at C-1 (alcohol, aldehyde, ketone, acid or ester) - are described first in Section 2.1. The next major group to be covered in Section 2.2 comprises derivatives of simple aromatic hydrocarbons. The phenylpropanoids, in which a C3 substituent is attached to the aromatic unit (C6), form a biosynthetically distinct group of aromatic metabolites, which is described in Section 2.3. The flavonoids, which are biosynthetically derived from this same C6C3 precursor, constitute the second largest group of metabolites from A. annua, and are described separately in Section 2.4. By far the largest group of metabolites from A. annua is the terpenoids, which are biosynthetically derived from a branched isoprenoid unit (C5). They have been further subdivided into monoterpenoids (C10; i.e. 2 × C5); sesquiterpenoids (C15 ; i.e. 3 × C5); and higher terpenoids (which include both diterpenes (C20), triterpenes (C30) and sterols (C29). These large groupings are covered in Section 2.5, Section 2.6 and Section 2.7, respectively. Finally, a very small number of miscellaneous nitrogen-containing natural products appear in Section 2.8.

The essential oil of A. annua was first studied as long ago as 1917 [17,18]. Researchers have continued to analyse the volatile constituents of this essential oil over the past century, primarily utilising gas chromatography (GC) and the hyphenated analytical technique of gas chromatography-mass spectrometry (GC-MS) [19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35]. GC/GC-MS studies of the essential oil of A. annua have been reported from countries as diverse as France [36], Finland [37], Hungary [38], Romania [39], Kazakhstan [40], Iran [41,42], India [43,44,45], China [46,47,48,49,50] and Vietnam [51]. A detailed study of the essential oils from Chinese and Vietnamese varieties of A. annua demonstrated that the Chinese variety contained predominantly artemisia ketone, while the Vietnamese oil was dominated by camphor and germacrene D [21] (others have confirmed the absence of artemisia ketone from Vietnamese oil) [52]. Interestingly, this difference was also reflected in the artemisinin content of Chinese and Vietnamese plants at 0.17% and 1.0% dry weight, respectively. Others have reported a similar variation in essential oil content between varieties of A. annua [53,54] and have concurred that differences in the essential oil composition should be ascribed to the existence of chemotypes (or chemical races) in this species [43] (see also Section 4.1).

GC-MS studies are particularly suited to the analysis of the more volatile components of the plant metabolome, such as the monoterpenes (Section 2.5) and some of the unfunctionalized sesquiterpene hydrocarbons which are reported in Section 2.6. The identification of a metabolite by GC-MS generally requires that its retention time and mass spectrum be matched with that of a known standard, which is recorded in a database. Using this thechnique, it is therefore possible to make a very rapid analysis of a large number of compounds employing a relatively small amount of plant material. Many of the simple aliphatic and aromatic metabolites which are reported in Section 2.1 and Section 2.2 are actually comparatively minor components of the essential oil of A. annua, that have been identified solely on this basis. Although it is also possible to analyse more highly oxygenated sesquiterpenes, such as artemisinin and its biosynthetic precursors by GC-MS [55] (Section 2.6), these less volatile components are generally more easily isolated by liquid chromatography (LC) [15]. LC is definitely the technique of choice for the more non-volatile compounds of the extract of A. annua, which include flavonoids (Section 2.4), and many triterpenoids and sterols (Section 2.7). In the preparative mode, the LC techniques [56] of column chromatography and high performance liquid chromatography (HPLC) can provide sufficient material to allow for the subsequent structural elucidation of completely novel metabolites, when used in conjunction with techniques such as nuclear magnetic resonance (NMR) spectroscopy and X-ray crystallography. Most of the structures of the more highly oxygenated cadinane and amorphane sesquiterpenoids from A. annua which are reported in Section 2.6.3, were determined by this more powerful, but also more laborious approach. The majority of these components are unique to this species and several have turned out to be relevant to the biosynthesis of artemisinin.

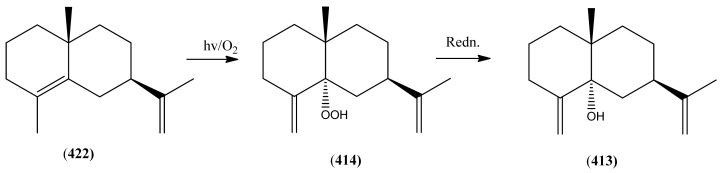

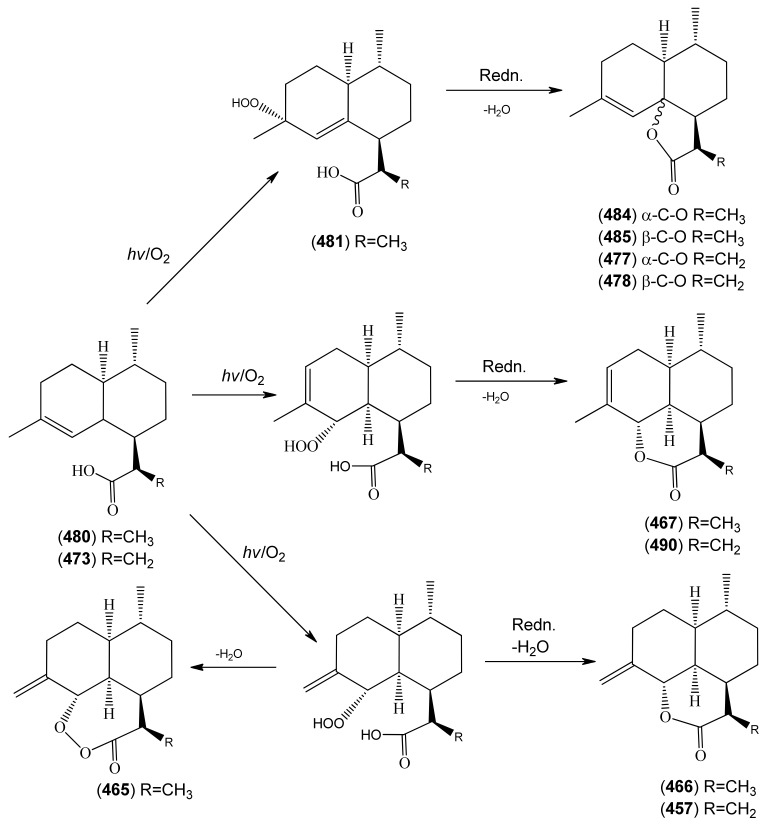

The highly oxygenated nature of many of the terpenoid metabolites from A. annua has been stressed throughout this review, because of its perceived relevance to the biosynthesis of artemisinin. In particular, the reader’s attention has been drawn to the unusually wide diversity of terpenoid allylic hydroperoxides and endoperoxides which have been recorded from this species. It is suggested that several of these peroxides result from the reaction of molecular oxygen with the tri-substituted double bond of an appropriate (and frequently abundant) mono- sesqui- or diterpene precursor. Thus, allylic hydroperoxides are found for monoterpenes (264 and 265; Section 2.5.1), sesquiterpenes (414 and 481; Section 2.6.3) and diterpenes (553; Section 2.7.1), all of which might be derived from abundant hydrocarbon precursors; in addition to one monoterpene endoperoxide (329; Section 2.5.3) and three sesquiterpene endoperoxides (465, 495 and 497; Section 2.6.3). These reactive hydroperoxides might then be responsible for the formation of a large number of the highly-oxygenated terpenes reported from A. annua.

Finally, it has recently been proposed that the the yin-yang nature of Chinese herbal medicine might equate to antioxidation-oxidation in modern parlance [57]. If this is true, then the wide-ranging antioxidant properties associated with the various terpenoidal components from A. annua (i.e. their propensity to undergo spontaneous autoxidation) would be entirely consistent with its classification as a cooling herb in the TCM system.

2.1. Aliphatic Hydrocarbons, Alcohols, Aldehydes and Acids

All possible saturated unbranched hydrocarbons between C16 [hexadecane; (5)] and C26 [hexacosane; (14)] have now been reported from GC-MS studies of A. annua (Table 1).

Table 1.

Saturated Unbranched Hydrocarbons.

| Structure | Name | CAS Number | References |

|---|---|---|---|

| CH3(CH2)3CH3 | Pentane (1) | [109-66-0] | [58] |

| CH3(CH2)4CH3 | Hexane (2) | [110-54-3] | [22] |

| CH3(CH2)10CH3 | Dodecane (3) | [112-40-3] | [24] |

| CH3(CH2)11CH3 | Tridecane (4) | [629-50-5] | [24] |

| CH3(CH2)14CH3 | Hexadecane (5) | [544-76-3] | [24] |

| CH3(CH2)15CH3 | Heptadecane (6) | [629-78-7] | [27] |

| CH3(CH2)16CH3 | Octadecane (7) | [593-45-3] | [32,43] |

| CH3(CH2)17CH3 | Nonadecane (8) | [629-92-5] | [27,32,43] |

| CH3(CH2)18CH3 | Eicosane (9) | [112-95-8] | [32,43] |

| CH3(CH2)19CH3 | Heneicosane (10) | [629-94-7] | [32,34] |

| CH3(CH2)21CH3 | Tricosane (11) | [638-67-5] | [32] |

| CH3(CH2)22CH3 | Tetracosane (12) | [646-31-1] | [32] |

| CH3(CH2)23CH3 | Pentacosane (13) | [629-99-2] | [32] |

| CH3(CH2)24CH3 | Hexacosane (14) | [630-01-3] | [32] |

| CH3(CH2)27CH3 | Nonocosane (15) | [630-03-5] | [58] |

| CH3(CH2)32CH3 | Tetratriacontane (16) | [14167-59-0] | [59] |

The saturated fatty acids listed in Table 3 are likely to be the biogenetic parents of the saturated hydrocarbons, alcohols, aldehydes and ketones which appear in Table 1 and Table 2. Saturated fatty acids have been obtained from A. annua as a continuous series between C12 [dodecanoic acid; (36)] and C20 [eicosanoic acid; (48)]. Hexadecanoic acid (41; C16) and octadecanoic acid (45; C18) are the most dominant saturated lipids from A. annua (Table 3), while oleic acid (80) (C18) is the most abundant unsaturated fatty acid (Table 5).

Table 3.

Saturated Unbranched Carboxylic Acids and Esters.

| Structure | Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|---|

| CH3CH2OCHO | Ethyl formate (31) | [109-94-4] | [50] | |

| CH3CH2CO2CH2CH3 | Propanoic acid, ethyl ester (32) | Ethyl propionate | [105-37-3] | [50] |

| CH3(CH2)3CO2H | Pentanoic acid (33) | Valeric acid | [109-52-4] | [24] |

| CH3(CH2)3CO2C(CH3)3 | Pentanoic acid, tert-butyl ester (34) | Pentanoic acid, 1,1-dimethylethyl ester | [23361-78-6] | [50] |

| CH3(CH2)8CO2H | Decanoic acid (35) | Capric acid | [334-48-5] | [63, 64] |

| CH3(CH2)10CO2H | Dodecanoic acid (36) | Lauric acid | [143-07-7] | [63, 64] |

| CH3(CH2)10CO2CH2CH3 | Dodecanoic acid, ethyl ester (37) | Ethyl laurate | [106-33-2] | [24] |

| CH3(CH2)11CO2H | Tridecanoic acid (38) | [638-53-9] | [63] | |

| CH3(CH2)12CO2H | Tetradecanoic acid (39) | Myristic acid | [544-63-8] | [23, 63, 64] |

| CH3(CH2)13CO2H | Pentadecanoic acid (40) | [1002-84-2] | [63] | |

| CH3(CH2)14CO2H | Hexadecanoic acid (41) | Palmitic acid | [57-10-3] | [20, 23, 24, 27, 32, 43, 63, 64, 65] |

| CH3(CH2)14CO2CH3 | Hexadecanoic acid, methyl ester (42) | Methyl hexadecanoate Methyl palmitate | [112-39-0] | [27] |

| CH3(CH2)14CO2CH2CH3 | Hexadecanoic acid, ethyl ester (43) | Ethyl palmitate | [628-97-7] | [24] |

| CH3(CH2)15CO2H | Heptadecanoic acid (44) | Margaric acid | [506-12-7] | [63] |

| CH3(CH2)16CO2H | Octadecanoic acid (45) | Stearic acid | [57-11-4] | [27, 43, 63, 64] |

| CH3(CH2)16CO2CH3 | Octadecanoic acid, methyl ester (46) | Methyl octadecanoate Methyl stearate |

[112-61-8] | [27] |

| CH3(CH2)17CO2H | Nonadecanoic acid (47) | [646-30-0] | [20] | |

| CH3(CH2)18CO2H | Eicosanoic acid (48) | Arachidic acid | [506-30-9] | [64] |

| CH3(CH2)20CO2H | Docosanoic acid (49) | Behenic acid | [112-85-6] | [64] |

| CH3(CH2)22CO2H | Tetracosanoic acid (50) | Lignoceric acid | [557-59-5] | [64] |

| CH3(CH2)28CO2(CH2)30CH3 | Hentriacontanyl triacontanoate (51) | Triacontanoic acid hentriacontyl ester |

[135729-36-1] | [59, 62] |

Table 2.

Saturated Unbranched Alcohols, Aldehydes and Ketones.

| Structure | Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|---|

| Alcohols | ||||

| CH3(CH2)3CH2OH | 1-Pentanol (17) | Pentyl alcohol | [71-41-0] | [24] |

| CH3(CH2)4CH2OH | n-Hexanol (18) | [111-27-3] | [22, 32, 43] | |

| CH3(CH2)4CH2O-(C=O)CH2CH(CH3)2 | n-Hexyl isovalerate (19) | 3-Methylbutyric acid hexyl ester | [10032-13-0] | [32, 43] |

| CH3(CH2)4CH2O-(C=O)C(CH3)=CHCH3 | n-Hexyl tiglate (20) | (2E)- 2-Butenoic acid, 2-methyl-, hexyl ester | [16930-96-4] | [32, 43] |

| CH3(CH2)6CH2OH | 1-Octanol (21) | Caprylic alcohol | [111-87-5] | [24] |

| CH3(CH2)7CH2OH | n-Nonyl alcohol (22) | 1-Nonanol | [143-08-8] | [24] |

| CH3(CH2)26CH2OH | Octacosanol (23) | [557-61-9] | [59, 60, 61] | |

| CH3(CH2)27CH2OH | Nonacosanol (24) | [6624-76-6] | [59, 62] | |

| Aldehydes and Ketones | ||||

| CH3COCH3 | Acetone (25) | 2-Propanone | [67-64-1] | [24] |

| CH3(CH2)2CHO | Butanal (26) | Butyraldehyde | [50] | |

| CH3(CH2)4CHO | Hexanal (27) | Caproic aldehyde | [66-25-1] | [23] |

| CH3CO(CH2)4CH3 | 2-Heptanone (28) | Methyl pentyl ketone | [110-43-0] | [45] |

| CH3(CH2)6CHO | Octanal (29) | Capric aldehyde | [124-13-0] | [32] |

| CH3(CH2)11CHO | Tridecanal (30) | Tridecyl aldehyde | [10486-19-8] | [24] |

Table 5.

Unbranched Alkenic Ketones, Aldehydes, Carboxylic acids and Esters.

| Structure | Name | Alternative ame(s) | CAS Number | References |

|---|---|---|---|---|

| Ketones and aldehydes | ||||

| H2C=CHCH2CH2CHO | 4-Pentenal (71) | [2100-17-6] | [50] | |

| CH3(CH2)2CH=CHCHO | 2-Hexenal (72) | Leaf aldehyde | [505-57-7] [6728-26-3] | [24, 31, 43] |

| CH3(CH2)3CH=CHCHO | 2-Heptenal (73) | [2463-63-0] | [24] | |

| CH3(CH2)5CH=CHCHO | (Z)-2-Nonenal (74) | [60784-31-8] | [50] | |

| CH3(CH2)3CH=CHCH=CHCHO | (2E,4E)- Nonadienal (75) | [5910-87-2] | [19] | |

| CH3(CH2)4CH=CHCOCH3 | 3-Nonen-2-one (76) | [14309-57-0] | [24] | |

| CH3(CH2)6CH=CHCHO | 2-Decenal (77) | [3913-71-1] | [24] | |

| CH3(CH2)4CH=CHCH=CHCHO | 2,4-Decadienal (78) | [2363-88-4] | [24] | |

| H2C=CH(CH2)8CHO | 10-Undecenal (79) | [112-45-8] | [24] | |

| Carboxylic acids and esters | ||||

| CH3(CH2)7CH=CH(CH2)7CO2H | Oleic acid (80) | (Z)-9-Octadecanoic acid | [112-80-1] [27104-13-8] | [28, 63, 64] |

| CH3(CH2)7CH=CH(CH2)7CO2CH3 | Methyl 9-octadecenoate (81) | Methyl elaidate | [2462-84-2] | [24] |

| CH3(CH2)7CH=CH(CH2)7CO2CH2CH(OH)CH2OH | 9-Octadecenoic acid, 2,3-dihydroxypropyl ester (82) | [251983-54-7] | [24] | |

| CH3(CH2)4CH=CHCH2CH=CH(CH2)7CO2H | Linoleic acid (83) | (Z,Z)-9,12-Octadecadienoic acid | [60-33-3] [27213-43-0] [28984-77-2] | [20, 63] |

| CH3CH2CH=CHCH2CH=CHCH2CH=CH(CH2)7CO2H | α-Linolenic acid (84) | (Z,Z,Z)-9,12,15-Octadecatrien-oic acid | [463-40-1] | [20, 63] |

Table 4.

Unbranched Alkenic Hydrocarbons and Alcohols.

| Structure | Name | Alternative Name(s) |

CAS Number | References |

|---|---|---|---|---|

| Hydrocarbons | ||||

| CH2=CHCH=CHCH3 | 1,3-Pentadiene (52) | 1-Methyl-1,3-butadiene | [504-60-9] | [50] |

| CH3CH=CHCH=CHCH3 | trans,trans-2,4-Hexadiene (53) | [5194-51-4] | [50] | |

| H2C=CHCH=CHCH=CHCH3 | trans,trans-1,3,5-Heptatriene (54) | [17679-93-5] | [50] | |

| H2C=CH(CH2)4CH=CH2 | 1,7-Octadiene (55) | [3710-30-3] | [50] | |

| H2C=CH(CH2)2CH=CH(CH2)2CH=CH2 | trans-1,5,9-Decatriene (56) | [39139-91-8] | [50] | |

| Alcohols | ||||

| CH2=CHCH2CH(OH)CH3 | 4-Pentene-2-ol (57) | 1-Penten-4-ol | [625-31-0] | [25] |

| CH2=CH(CH2)3O-(C=O)CH2CH3 | 4-Penten-1-ol, propionate (58) | 4-Pentenyl propionate | [30563-30-5] | [43] |

| CH3(CH2)2CH=CHCH2OH | (E)-2-Hexenol (59) | 2-Hexen-1-ol | [928-95-0] | [45] |

| CH3CH2CH=CHCH2CH2OH | (E)-3-Hexen-1-ol (60) | [928-97-2] | [19] | |

| CH3CH2CH=CHCH2CH2OH | (Z)-3-Hexen-1-ol (61) | Phyllol | [928-96-1] | [22, 32, 43] |

| CH3CH2CH=CHCH2CH2O-(C=O)CH3 | (E)-3-Hexen-1-ol, acetate (62) | [3681-82-1] | [19] | |

| CH3CH2CH=CHCH2CH2O-(C=O)CH2CH3 | (Z)-3-Hexenyl propanoate (63) | [33467-74-2] | [20] | |

| CH3CH2CH=CHCH2CH2O-(C=O)CH2CH2CH3 | 3-Hexenyl butanoate (64) | [2142-93-0] | [23] | |

| CH3CH2CH=CHCH2CH2O-(C=O)(CH2)4CH3 | 3-Hexenyl hexanoate (65) | [84434-19-5] | [24] | |

| CH3CH2CH=CHCH2CH2O-(C=O)CH2CH(CH3)2 | (Z)-3-Hexenyl isovalerate (66) | [35154-45-1] | [32] | |

| CH3CH2CH=CHCH2CH2O-(C=O)C(CH3)=CHCH3 | (Z)-3-Hexenyl tiglate (67) | [67883-79-8] | [43] | |

| H2C=CHCH(OH)(CH2)3CH3 | 1-Hepten-3-ol (68) | [4938-52-7] | [24] | |

| H2C=CHCH(OH)(CH2)4CH3 | 1-Octen-3-ol (69) | [3391-86-4] | [31,32,43] | |

| H2C=CH(CH2)7CH2OH | 9-Decen-1-ol (70) | [13019-22-2] | [32, 43] | |

Table 6.

Branched Aliphatic Hydrocarbons and Alcohols.

| Structure | Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|---|

| Hydrocarbons | ||||

| CH3(CH2)8CH(CH3)CH2CH2CH(CH3)2 | Tetradecane, 2,5-dimethyl- (85) | [56292-69-4] | [24] | |

| (CH3)2CH(CH2)26CH(CH3)2 | Triacontane, 2,29-dimethyl- (86) | 2,29-Dimethyltriacontane | [135729-37-2] | [62] |

| (CH3)2CHC(CH3)3 | 2,2,3-Trimethylbutane (87) | [464-06-2] | [50] | |

| CH3(CH2)3CH(CH3)(CH2)7CH3 | Tridecane, 5-methyl- (88) | 5-Methyltridecane | [25117-31-1] | [24] |

| Alcohols | ||||

| (CH3)2CHCH2CH2O-(C=O)CH3 | 3-Methyl-1-butanol, acetate (89) | Isoamyl acetate | [123-92-2] | [43] |

| (CH3)2CHCH2O-(C=O)CH2CH3 | 2-methylpropylpropionate (90) | Isobutyl propionate | [540-42-1] | [50] |

| (CH3)2C(OH)(CH2)2CH3 | 2-Methyl-2-pentanol (91) | [590-36-3] | [25] | |

| (CH3)2C(OH)(CH2)3CH3 | 2-Methyl-2-hexanol (92) | [625-23-0] | [24] | |

| (CH3)2CH(CH2)3CH2OH | 5-Methyl-1-hexanol (93) | 1-Hexanol, 5-methyl- | [627-98-5] | [24] |

| Aldehydes and Ketones | ||||

| (CH3)2CHCH2CHO | 3-Methylbutanal (94) | Isovaleraldehyde | [590-86-3] | [24] |

| CH3CH2CH(CH3)CH2CHO | 3-Methylpentanal (95) | [15877-57-3] | [20] | |

| (CH3)2CHCH2COCH3 | 4-Methyl-2-pentanone (96) | Isobutyl methyl ketone | [108-10-1] | [24] |

| (C6H5)CH2CH(CHO)(CH2)5CH3 | 2-Benzyloctanal (97) | Benzenepropanal, α-hexyl- | [161403-65-2] | [24] |

| (CH3)2CH(CH2)5C=O(CH2)14CH2OH | 8-Tricosanone, 23-hydroxy-2-methyl- (98) | [135729-35-0] | [59, 62] | |

Table 7.

Branched Aliphatic Carboxylic Acids, Esters and Anhydrides.

| Structure | Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|---|

| CH3CH2CH(CH3)CO2H | 2-Methylbutanoic acid (99) | [868-57-5] | [22] | |

| CH3CH2CH(CH3)CO2CH2CH3 | 2-Methyl butanoic acid, ethyl ester (100) | Ethyl 2-methylbutyrate | [7452-79-1] | [22, 32] |

| (CH3CH2CH(CH3)CO2)O | 2-Methylbutanoic acid anhydride (101) | 2-Methylbutyryl anhydride | [1519-23-9] | [50] |

| CH3CH2CH(CH3)CO2(CH2)4CH3 | Amyl 2-methylbutyrate (102) | Pentyl 2-methylbutanoate | [68039-26-9] | [43] |

| CH3CH2CH(CH3)CO2CH2CH(CH3)CH2CH3 | 2-Methyl-butanoic acid, 2-methylbutyl ester (103) | 2-Methylbutyl 2-methylbutyrate | [2445-78-5] | [31] |

| (CH3)2CHCH2CO2CH2CH3 | 3-Methylbutanoic acid, ethyl ester (104) | Ethyl 3-methylbutanoate Ethyl isovalerate |

[108-64-5] | [23] |

| (CH3)2CHCH2CO2(CH2)3CH3 | 3-Methylbutanoic acid, butyl ester (105) | Butyl-3-methylbutanoate | [109-19-3] | [25] |

| (CH3)2CHCH2CO2CH2CH2C(=CH2)CH3 | 3-Methylbutanoic acid, 3-methyl-3-butenyl ester (106) | 3-Methyl-3-butenyl 3-methylbutyrate | [54410-94-5] | [20] |

| CH3CH2CH(CH2CH3)CO2CH3 | 2-Ethylbutanoic acid, methyl ester (107) | 2-Methyl-ethylbutanoate | [816-11-5] | [25] |

Table 8.

Branched Alkenic Hydrocarbons and Aldehydes.

| Structure | Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|---|

| Hydrocarbons | ||||

| H2C=CHC(CH3)3 | 3,3-Dimethyl-1-butene (108) | tert-Butylethylene | [558-37-2] | [20] |

| H2C=CHCH(CH3)2 | 2,4-Dimethyl-2-pentene (109) | [625-65-0] | [24] | |

| CH3CH=CHCH(CH3)CH2CH3 | trans-4-Methyl-2-hexene (110) | [3683-22-5] | [20] | |

| Aldehydes | ||||

| CH3(CH2)4CH=CH(CHO)(CH2)3CH3 | 2-Butyl-2-octenal (111) | [13019-16-4] | [24] | |

| (CH3)2C=CHCH=CH(C=O)CH3 | 6-Methyl-3,5-heptadien-2-one (112) | [16647-04-4] | [66] | |

Artemisia annua contains relatively few polyacetylenes by comparison with other members of the genus Artemisia (and also as compared to other members of the Asteraceae family). The only two such compounds to be reported to date are ponticaepoxide (121) and annuadiepoxide (122), which have been isolated from both leaves [67] and seeds [9] of A. annua.

Table 9.

Acetylenic Hydrocarbons.

| Structure | Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|---|

| CH3C≡CCH2OMe | 1-Methoxy-2-butyne (113) | [2768-41-4] | [50] | |

| H2C=CH(CH2)3C≡CH | 1-Hepten-6-yne (114) | [65939-59-5] | [50] | |

| CH3O(C=O)C≡C(CH2)5CH3 | 2-Nonynoic cid, methyl ester (115) | Methyl 2-nonynoate | [111-80-8] | [50] |

| CH3(CH2)9C≡CH | 1-Dodecyne (116) | Decylacetylene | [765-03-7] | [23] |

| CH3C≡C(CH2)8CH2OH | 10-Dodecyn-1-ol (117) | [69221-99-4] | [23] | |

| (CH3)2CHC≡CCH=CHCH(CH3)2 | 3-Octen-5-yne, 2,7-dimethyl- (118) | [91400-77-0] | [50] | |

| CH3(CH2)6CH=CHC≡CH3 | 3-Undecen-1-yne (119) | [74744-32-4] [91250-91-8] | [23] | |

| (C6H5)CH2C≡C-C≡C-CH3 | Capillene (120) | 2,4-Hexadiynylbenzene | [520-74-1] | [30] |

| Ponticaepoxide (121) | 2-Ethenyl-3-(1-nonen-3,5,7-triynyl)oxirane 2-(1-Nonen-3,5,7-triynyl)-3-vinyloxirane 3,4-Epoxy-1,5-tridecadiene-7,9,11-triyne |

[3562-36-5] | [9, 67] | |

| Annuadiepoxide (122) | 1,3,5-Tridecatriene-7,9,11-triyne (E,E), 3,4:5,6-diepoxide 3,4:5,6-Diepoxy-1-tridecene-7,9,11-triyne |

[139122-80-8] | [9, 67] |

Table 10.

Cyclic Hydrocarbons.

| Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|

| 1,1’-Bicyclopropyl, 2,2’-dimethyl (123) | [1975-84-6] | [23] | |

| Bicyclo[2.2.2]octa-2,5-diene, 1,2,3,6-tetramethyl- (124) | [62338-43-6] | [20] | |

| 3,5-Cycloheptadienone (125) | [1121-65-9] | [28] | |

| Cyclooctane, 1,4-dipropyl- (126) | [251983-53-6] | [24] | |

| Cyclopropane, (1-methyl-1,2-propadien-1-yl)- (127) | 3-Cyclopropyl-1,2-butadiene | [51549-86-1] | [50] |

| Cyclopropene, 3-ethenyl-3-methyl-(128) | 3-Methyl-3-vinylcyclopropene | [71153-30-5] | |

| 1,1-Dicyclopropylethylene (129) | Cyclopropane, 1,1’-ethenylidenebis- | [822-93-5] | [50] |

| Hexylcyclohexane (130) | [4292-75-5] | [20] | |

| Jasmone (131) | 3-Methyl-2-(2-pentenyl)-2-cyclopenten-1-one | [488-10-8] | [22, 32, 43] |

| Methyl cyclopentane (132) | [96-37-7] | [22] |

Table 11.

Furans.

2.2. Aromatic Alcohols, Ketones and Acids

The simple aromatic compounds described in Table 12, Table 13 and Table 14 form a relatively small group of natural products from A. annua. Metabolites in this section are probably biosynthesised by both the polyketide and shikimate pathways (some simple aromatics which are derived from the terpenoid pathway are discussed separately in Section 2.5.3).

Table 12.

Simple Phenols and Benzylic Alcohols.

| Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|

| Anisole (138) | Phenyl methyl ether | [100-66-3] | [48] |

| Benzyl isovalerate (139) | 3-Methylbutanoic acid, benzyl ester | [103-38-8] | [22, 23, 25, 32, 43] |

| Benzyl 2-methyl butyrate (140) | 2-Methylbutanoic acid, benzyl ester | [56423-40-6] | [41] |

| Benzyl phenylacetate (141) | Benzeneacetic acid, phenylmethyl ester | [102-16-9] | [50] |

| Benzyl valerate (142) | Benzyl pentanoate | [10361-39-4] | [19, 23] |

| 5-Nonadecylresorcinol-3-O-methyl ether (143) | Phenol 3-methoxy-5-nonadecyl | [68] |

Table 13.

Simple Aryl Ketones.

| Name | Alternative Name(s) | CAS number | References |

|---|---|---|---|

| 2’,4’,6’-Trihydroxyacetophenone 2’,4’-dimethyl ether (144) | 2-Hydroxy-4,6-dimethoxyacetophenone | [68] | |

| 2’,4’,6’-Trihydroxyacetophenone 2’-methyl ether (145) | 2’,4’-dihydroxy-6’-methoxyacetophenone | [3602-54-8] | [68, 69] |

| 2’,4’,6’-Trihydroxyacetophenone 2’-methyl ether 4’-O-β-D-glucopyranosde (146) | Annphenone | [61775-18-6] | [70] |

| 2’,4’,6’-Trihydroxyacetophenone 4’-methyl ether 2-O-β-D-glucopyranoside (147) | Domesticoside | [24587-97-1] | [15] |

Table 14.

Simple Benzoic Acids and their Homologues.

| Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|

| Benzoic acid (148) | [65-85-0] | [9, 24] | |

| Salicylic acid (149) | 2-Hydroxybenzoic acid | [69-72-7] | [15] |

| Methyl salicylate (150) | Methyl-2-hydroxybenzoate | [119-36-8] | [27, 32] |

| 2-Hydroxybenzoic acid, 3-methylbutyl ester (151) | Isoamyl salicylate | [87-20-7] | [24] |

| 3,4-Dihydroxybenzoic acid (152) | Benzoic acid, 3,4-dihydroxy- Protocatechuic acid |

[99-50-3] | [71] |

| Protocatechuic acid 4-glucoside (153) | Benzoic acid, 4-(β-D-glucosyloxy)-3-hydroxy- | [7361-59-3] | [71] |

| Phenylacetic acid (154) | [103-82-2] | [24] | |

| Phenylpropanoic acid (155) | [9] | ||

| Benzenepropanoic acid, 3-cyanophenyl ester (156) | [40123-39-5] | [50] |

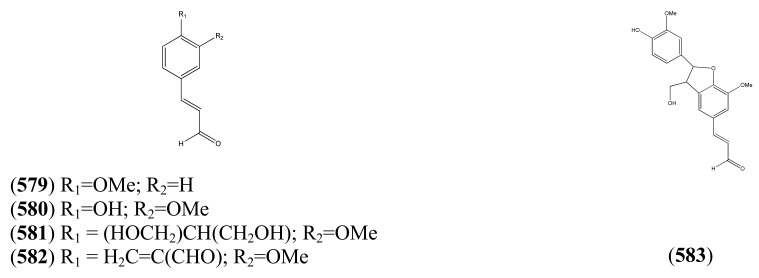

2.3. Phenylpropanoids

The phenylpropanoids, all of which contain a C3 substituent fused to a benzene ring (C6), are produced by the shikimate pathway, which is unique to plants. Most of the simple phenylpropanoids reported in Table 15 were described from GC-MS studies. Compounds 166-182 (Table 16), which are esters formed by various combinations of ferulic and cinnamic acid with the four hydroxyl groups of quinic acid, were isolated from a single HPLC-MS study [71]. Some of the coumarins reported in Table 17 have also been obtained from undifferentiated tissue cultures (callus and suspension) of A. annua (see Section 4.2). The structures of both of the 2,2-dihydroxychromene natural products 190 and 191, which appear in Table 17, are questionable on thermodynamic grounds - one might expect both to lose a molecule of water thereby forming a more highly conjugated coumarin.

Table 15.

Simple Phenylpropanoids.

| Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|

| p-Allylanisole (157) | 1-Methoxy-4-(2-propenyl)benzene | [140-67-0] | [29, 72, 73] |

| Anethole (158) | 1-Methoxy-4-(1-propenyl)benzene | [4180-23-8] | [32, 43, 50] |

| 3-Allyl-6-methoxyphenol (159) | 4-Allyl-2-hydroxyl-1-methoxybenzene | [501-19-9] | [48] |

| Eugenol (160) | 2-Methoxy-4-(2-propenyl)phenol | [97-53-0] | [19, 32, 41, 43, 74] |

| Methyl eugenol (161) | 1,2-Dimethoxy-4-(2-propenyl)benzene | [93-15-2] | [43, 48] |

| Eugenyl isovalerate (162) | 2-Methoxy-4-(2-propenyl)phenol 3-methylbutanoyl | [61114-24-7] | [34] |

| 2-Methoxy-3-(2-propenyl)phenol (163) | [1941-12-4] | [23] |

Table 16.

Cinnamyl, Caffeoyl and Ferruloyl esters.

| Name | Alternative Name(s) | CAS Number | Refs |

|---|---|---|---|

| Methyl cinnamate (164) | 3-phenyl-2-propenoic acid methyl ester | [103-26-4] | [24] |

| Benzyl cinnamate (165) | 3-Phenyl-2-propenoic acid benzyl ester | [103-41-3] | [24] |

| Chlorogenic acid (166) | 3-(3,4-Dihydroxycinnamoyl)quinic acid | [327-97-9] | [71] |

| Cyclohexanecarboxylic acid, 1,3,4-trihydroxy-5-[[3-(4-hydroxy-3-methoxyphenyl)-1-oxo-2-propenyl]oxy]-, (167) | [53905-80-9] | [71] | |

| Cyclohexanecarboxylic acid, 3-[[3-(3,4-dihydroxyphenyl)-1-oxo-2-propenyl]oxy]-1,4,5-trihydroxy-, (168) | [342811-68-1] | [71] | |

| Isochlorogenic acid B (169) | 3,4-Di-O-caffeoylquinic acid | [4534-61-3] | [71] |

| 3-Caffeoyl-4-feruloylquinic acid (170) | 4-O-Feruloyl-5-O-caffeoylquinic acid | [125132-81-2] | [71] |

| 3,4-Diferuoylquinic acid (171) | [342811-70-5] | [71] | |

| Isochlorogenic acid A (172) | 3,5-bis-(3,4-Dihydroxycinnamoyl)quinic acid) | [2450-53-5] | [71] |

| 3-Caffeoyl-5-feruloylquinic acid (173) | [478156-24-0] | [71] | |

| 3-Feruloyl-5-caffeoylquinic acid (174) | [1039007-73-2] | [71] | |

| 3,5-Diferuoylquinic acid (175) | [333753-65-4] | [71] | |

| Isochlorogenic acid C (176) | 4,5-Di-O-caffeoylquinic acid | [57378-72-0] | [71] |

| 4-Caffeoyl-5-feruloylquinic acid (177) | [478156-25-1] | [71] | |

| 4-Feruloyl-5-caffeoylquinic acid (178) | [882535-14-0] | [71] | |

| 4,5-Diferuoylquinic acid (179) | [342811-69-2] | [71] | |

| Cyclohexanecarboxylic acid, 3-[[3-(3,4-dihydroxyphenyl)-1-oxo-2-propenyl]oxy]-4,5-dihydroxy-1-[[3-(4-hydroxy-3-methoxyphenyl)-1-oxo-2-propenyl]oxy]-, (180) | [865095-58-5] | [71] | |

| 1-Caffeoyl-5-feruoylquinic acid (181) | [865095-57-4] | [71] | |

| Cyclohexanecarboxylic acid, 3,4,5-tris[[3-(3,4-dihydroxy phenyl)-1-oxo-2-propenyl]oxy]-1-hydroxy-(182) | [437611-66-0] | [71] |

Table 17.

Coumarins (2H-1-Benzopyran-2-one, 9CI).

| Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|

| Coumarin (183) | 2H-1-Benzopyran-2-one | [91-64-5] | [56, 65, 68, 75, 76, 77, 79, 80] |

| Scopoletin (184) | 7-Hydroxy-6-methoxycoumarin 7-Hydroxy-6-methoxy-2H-1-benzopyran-2-one |

[92-61-5] | [77, 79, 80, 79, 80, 81, 82, 83, 84, 85, 86, 87] |

| Scoparone (185) | 6,7-Dimethoxycoumarin 6,7-Dimethoxy-2H-1-benzopyran-2-one |

[120-08-1] | [69, 88, 89] |

| Scopolin (186) | Scopoletin-O-β-D-glucopyranoside 7-Hydroxy-6-methoxycoumarin-O-β-D-glucopyranoside |

[531-44-2] | [15, 71, 79, 89, 90] |

| Isofraxidin (187) | 6,8-Dimethoxy-7-hydroxy coumarin | [486-21-5] | [79, 86, 87, 89] |

| Tomentin (188) | 5,6,7-Trihydroxy-2H-1-benzopyran-2-one 6,7-dimethyl ether | [28449-62-9] | [89] |

| 6,7-Dimethoxydihydrocoumarin (189) | 2H-1-Benzopyran-2-one,3,4 3,4-Dihydro-6,7-dimethoxy-coumarin | [56680-28-5] | [88] |

| 2,2,6-Trihydroxychromene (190) | 2H-1-Benzopyran-2,2,6-triol | [161585-88-2] | [89] |

| 2,2-Dihydroxy-6-methoxy-2H-1-benzopyran (191) | 6-Methoxy-2H-1-benzopyran-2,2-diol 2H-1-Benzopyran-2,2,6-triol 6-methyl ether |

[161585-87-1] | [89] |

2.4. Flavonoids

A. annua L. is a rich source of flavonoids, as are many other members of the Asteraceae family. It has been suggested that some of the more abundant methoxylated flavonoids from A. annua may potentiate the antimalarial activity of artemisinin in crude extracts of this plant. These flavones include: casticin (227), artemetin (228) [91], chrysosplenol D (225) and chrysoplenetin (226) [92] (interstingly, the latter two flavonoids are also reported to potentiate the activity of berberine and norfloxacin against a resistant strain of Staphylococcus aureus). Perhaps for this reason, phytochemical studies have sometimes sought to determine the distribution of bioactive flavonoids (such as chrysoplenetin (226), casticin (227), eupatin (232) and artemetin (228)) in conjunction with that of artemisinin [93].

The flavonoids are produced from the cyclization of a C15 chalcone precursor, which is in turn derived from malonyl coenzyme A and p-coumaryl coenzyme A (see Section 2.3). A biogenetic classification has been adopted in this section. Thus, this large group of flavonoids has been further sub-divided into flavonones (Table 18), which are produced directly by cyclization of this precursor; and flavonols (3-hydroxy-2-phenyl-4H-1-benzopyran-4-ones), which have undergone subsequent oxygenation at the 3-position (Table 19, Table 20, Table 21 and Table 22). The flavonols have been further grouped into tetrahydroxyflavonols in Table 19 [many are related to kaempferol (203)]; pentahydroxyflavonols in Table 20 [many are based on quercetin (207)]; hexahydroxyflavonols, based on quercetagetin (221) in Table 21; and miscellaneous hexahydroxyflavonols (Table 22).

Table 18.

Flavones (2-Phenyl-4H-1-benzopyran-4-one).

| Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|

| Apigenin (192) | 4’,5,7-Trihydroxyflavone 5,7-Dihydroxy-2-(4-hydroxyphenyl)-4H-1-benzopyran-4-one |

[520-36-5] | [71, 89] |

| Luteolin tetrahydroxyflavones | |||

| Luteolin (193) | 3’,4’,5,7-Tetrahydroxyflavone 2-(3,4-Dihydroxyphenyl)-5,7,-dihydroxy-4H-1-benzopyran-4-one |

[491-70-3] | [84, 89] |

| Luteolin-7-methyl ether (194) | 3’,4’,5-Trihydroxy-7-methoxyflavone 2-(3,4-Dihydroxyphenyl)-5-hydroxy-7-methoxy-4H-1-benzopyran-4-one |

[20243-59-8] | [89] |

| Glucoluteolin (195) | 3,4’,5,7-Tetrahydroxyflavone-7-O-β-D-glucopyranoside Luteolin 7-glucoside |

[5373-11-5] | [84, 89] |

| Chrysoeriol (196) | 4’,5,7-Trihydroxy-3’-methoxyflavone 5,7-Dihydroxy-2-(4-hydroxy-3-methoxyphenyl)-4H-1-benzopyran-4-one |

[491-71-4] | [76, 94] |

| Other tetrahydroxyflavones | |||

| Cirsimaritin (197) | 4’,5-Dihydroxy-6,7-dimethoxyflavone 5-Hydroxy-2-(4-hydroxyphenyl)-6,7-dimethoxy-4H-1-benzopyran-4-one |

[6601-62-3] | [76, 94] |

| Pentahydroxyflavones | |||

| Cirsiliol (198) | 3’,4’,5,6,7-Pentahydroxyflavone 6,7-dimethyl ether 3’,4’,5-Trihydroxy-6,7-dimethoxyflavone |

[34334-69-5] | [76, 94] |

| Eupatorin (199) | 6-Methoxy luteolin 7,4’-dimethyl ether 3’,5-Dihydroxy-4’,6,7-trimethoxyflavone 5-Hydroxy-2-(3-hydroxy-4-methoxyphenyl)-6,7-dimethoxy-4H-1-benzopyran-4-one |

[855-96-9] | [76, 94, 95] |

| 5-Hydroxy-3’,4’,6,7-tetramethoxyflavone (200) | 3’,4’,5,6,7-Pentahydroxyflavone 3’,4’,6,7-tetra methyl ether | [21763-80-4] | [96] |

| 4H-1-Benzopyran-4-one, 2-(2,4-dihydroxyphenyl)-5-hydroxy-6,7-dimethoxy- (201) | [101909-51-7] | [76] | |

| Hexahydroxyflavones | |||

| 2,4’,5’-Trihydroxy-5’6,7-trimethoxyflavone (202) | [94] | ||

Table 19.

Tetrahydroxy Flavonols.

| Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|

| Kaempferols | |||

| Kaempferol (203) | 3,4’,5,7-Tetrahydroxyflavone 3,5,7-Trihydroxy-2-(4-hydroxyphenyl)-4H-1-benzopyran-4-one 4’,5,7-Trihydroxyflavonol |

[520-18-3] | [84, 89] |

| Kaempferol-3-O-glucoside (204) | Astragalin 3-O-β-D-Glucopyranosyloxy-4’,5,7-trihydroxyflavone |

[480-10-4] | [84, 89] |

| Rhamnocitrin (205) | 3,4’,5-Trihydroxy-7-methoxyflavone 3,5-Dihydroxy-2-(4-hydroxyphenyl)-7-methoxy-4H-1-benzopyran-4-one 4’,5-Dihydroxy-7-methoxyflavonol |

[569-92-6] | [76, 94] |

| Other Tetrahydroxyflavonols | |||

| 4H-1-Benzopyran-4-one, 3-hydroxy-6,7-dimethoxy-2-(4-methoxyphenyl)- (206) | [77184-81-7] | [71] | |

Table 20.

Pentahydroxy Flavonols.

| Name | Alternative Name(s) | CAS Number | Refs |

|---|---|---|---|

| Quercetin | |||

| Quercetin (207) | 3,3’,4’,5,7-Pentahydroxyflavone 2-(3,4-Dihydroxyphenyl)-3,5,7-trihydroxy-4H-1-benzopyran-4-one 3’,4’,5,7-Tetrahydroxyflavonol |

[117-39-5] | [84] |

| Quercetin 3-methyl ether (208) | 3’,4’,5,7-Tetrahydroxy-3-methoxyflavone 2-(3,4-Dihydroxyphenyl)-5,7-dihydroxy-3-methoxy-4H-1-benzopyran-4-one |

[1486-70-0] | [76, 94] |

| Isoquercitrin (209) | Quercetin-3-glucofuranoside 2-(3,4-Dihydroxyphenyl)-3-(β-D-glucopyranosyloxy)-5,7-dihydroxy-4H-1-benzopyran-4-one 3-Glucopyranosyloxy-3’,4’,5,7-tetrahydroxyflavoneQuercetin-3-glucopyranoside |

[21637-25-2] [482-35-9] | [71, 89] |

| Quercetin 3-rutinoside (210) | [153-18-4] | [84] | |

| Isorhamnetin 3-glucoside (211) | 3-Glucopyranosyloxy-4’,5,7-trihydroxy-3’-methoxyflavone | [5041-82-7] | [71] |

| Rhamnetin (212) | 3,3’,4’,5-Tetrahydroxy-7-methoxyflavone 2-(3,4-Dihydroxyphenyl)-3,5-dihydroxy-7-methoxy-4H-1-benzopyran-4-one 3’,4’5-Trihydroxy-7-methoxyflavonol |

[90-19-7] | [76, 94] |

| Quercimeritrin (213) | 7-O-β-D-glucopyranosyloxy-3,3’,4’,5-tetrahydroxyflavone Quercetin 7-glucoside |

[491-50-9] | [89] |

| Isorhamnetin (214) | 3,4’,5,7-Tetrahydroxy-3’-methoxyflavone 3,5,7-Trihydroxy-2-(4-hydroxy-3-methoxyphenyl)-4H-1-benzopyran-4-one 4’,5,7-Trihydroxy-3’-methoxyflavonol Quercetin 3’-methyl ether |

[480-19-3] | [89] |

| Quercetin 3’-glucoside (215) | 3,3,’4’,5,7-Pentahydroxyflavone 3’-O-β-D-glucopyranoside | [19254-30-9] | [84, 89] |

| Tamarixetin (216) | 3,3’,5,7-Tetrahydroxy-4’-methoxyflavone 3,5,7-Trihydroxy-2-(3-hydroxy-4-methoxyphenyl)-4H-1-benzopyran-4-one 3’,5,7-Trihydroxy-4’-methoxyflavonol |

[603-61-2] | [76, 94] |

| Other pentahydroxyflavonols | |||

| Eupalitin (217) | 3,4’,5-Trihydroxy-6,7-dimethoxyflavone 3,5-Dihydroxy-2-(4-hydroxyphenyl)-6,7-dimethoxy-4H-1-benzopyran-4-one 4’,5-Dihydroxy-6,7-dimethoxyflavonol |

[29536-41-2] | [96] |

| Penduletin (218) | 3,4’,5,6,7-Pentahydroxyflavone 3,6,7-trimethyl ether 4’,5-Dihydroxy-3,6,7-trimethoxyflavone |

[569-80-2] | [76, 94, 97] |

| 3,4’,5,6,7-Pentahydroxyflavone 3,4’,6,7-tetramethyl ether (219) | 5-Hydroxy-3,4’,6,7-tetramethoxyflavone | [14787-34-9] | [61, 75, 78, 97] |

| Mikanin (220) | 3,4’,5,6,7-Pentahydroxyflavone 4’,6,7-trimethyl ether 3,5-Dihydroxy-4’,6,7-trimethoxyflavone |

[4324-53-2] | [71] |

Table 21.

Quecetagetin (Hexahydroxy) Flavonols.

| Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|

| Quercetagetin 3-methyl ether (221) | 3’,4’,5,6,7-Pentahydroxy-3-methoxyflavone 2-(3,4-Dihydroxyphenyl)-5,6,7-trihydroxy-3-methoxy-4H-1-benzopyran-4-one |

[64190-88-1] | [89] |

| Axillarin (222) | Quercetagetin 3,6-dimethyl ether 3’,4’,5,7-Tetrahydroxy-3,6-dimethoxyflavone 2-(3,4-Dihydroxyphenyl)-5,7-dihydroxy-3,6-dimethoxy-4H-1-benzopyran-4-one |

[5188-73-8] | [76, 84] |

| Quercetagetin-3,4’-dimethyl ether (223) | 3’,5,6,7-Tetrahydroxy-3,4’-dimethoxyflavone 3,3’,4’,5,6,7-Hexahydroflavone 3,4’-di-methyl ether |

[59171-34-5] | [76] |

| Bonanzin (224) | 5,7-Dihydroxy-3,3’,4’,6-tetramethoxyflavone 2-(3,4-Dimethoxyphenyl)-5,7-dihydroxy-3,6-dimethoxy-4H-1-benzopran-4-one |

[35688-42-7] | [96] |

| Chrysosplenol D (225) | 2-(3,4-Dihydroxyphenyl)-5-hydroxy-3,6,7-trimethoxy-4H-1-benzopyran-4-one | [14965-20-9] | [15, 76, 84, 92, 94, 95, 98] |

| Chrysosplenetin (226) | Chrysosplenol B 5,4’-Dihydroxy-3,6,7,3’-tetramethoxyflavone 5-Hydroxy-2-(4-hydroxy-3-methoxyphenyl)-3,6,7-trimethoxy-4H-1-benzopyran-4-one |

[603-56-5] | [15, 76, 80, 84, 91, 92, 95, 96, 99, 100, 101] |

| Casticin (227) | Quercetagetin 6,3,7,4’-tetramethyl ether 3’,5-Dihydroxy-3,4’,6,7-tetramethoxyflavone 5-Hydroxy-2-(3-hydroxy-4-methoxyphenyl)-3,6,7-trimethoxy-4H-benzopyran-4-one |

[479-91-4] | [76, 84, 91, 94, 95, 98, 99, 100, 103] |

| Artemetin (228) | 5-Hydroxy-3,6,7,3’,4’-Pentamethoxyflavone 2-(3,4,-Dimethoxyphenyl)-5-hydroxy-3,6,7-trimethoxy-4H-1-benzopyran-4-one |

[479-90-3] | [15, 75, 77, 78, 80, 94, 95, 96, 98, 100, 105, 106] |

| Patuletin-3-O-glucoside (229) | Quercetagetin 6-methyl ether 3-O-glucoside 6-Methoxykaempferol -3-O-glucoside |

[19833-27-3] | [84] |

| Patuletin (230) | 3,3’,4’,5,7-Pentahydroxy-6-methoxyflavone 2-(3,4-Dihydroxyphenyl)-3,5,7-trihydroxy-6-methoxy-4H-1-benzopyran-4-one 3’,4’,5,7-Tetrahydroxy-6-methoxyflavonol |

[519-96-0] | [84] |

| Cirsilineol (231) | 3’,4’,5,6,7-Pentahydroxyflavone 3’,6,7-tri methyl ether 4’,5-Dihydroxy-3’,6,7-trimethoxyflavone |

[41365-32-6] | [76, 94, 95, 98] |

| Eupatin (232) | 3,3’,5-Trihydroxy-4’,6,7-trimethoxyflavone 3,5-Dihydroxy-2-(3-hydroxy-4-methoxyphenyl)-6,7-dimethoxy-4H-1-benzopyran-4-one 3’,5-Dihyhdroxy-4’,6,7-trimethoxyflavonol Quercetagetin 4’,6,7-trimethyl ether |

[19587-65-6] | [61, 77, 98] |

| Quercetagetin-6,7,3’,4’-tetramethylether (233) | 3,5-Dihydroxy-3’,4’,6,7-tetramethoxyflavone 3,3’,4’,5,6,7-Hexahydroflavone 3’,4’,6,7-tetra methyl ether |

[57296-14-7] | [61, 71, 77, 105, 107] |

| Quercetagetin 4’-methyl ether (234) | 3,3’,4’,5,6,7-Hexahydroxyflavone 4’-methyl ether 3,3’,5,6,7-Pentahydroxy-4’-methoxyflavone 3’,5,6,7-Tetrahydroxy-4’-methoxyflavonol |

[161585-86-0] | [89] |

Table 22.

Other Hexahydroxy Flavonols.

| Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|

| 4H-1-Benzopyran-4-one 5-hydroxy-2-(2-hydroxy-3,4-di-methoxyphenyl)-3,7-dimethoxy (235) | [1186306-45-5] | [15] | |

| 4H-1-Benzopyran-4-one, 2-(3,5-dihydroxy-4-methoxy-phenyl)-3-(β-D-glucopyranosyloxy)-5,7-dihydroxy- (236) | [230283-37-1] | [71] | |

| Mearnsetin (237) | 3,3’,5,5’,7-Pentahydroxy-4’-methoxy-flavone 2-(3,5-Dihydroxyphenyl-4-methoxy-phenol)-3,5,7-trihydroxy-4H-1-benzopyran-4-one 3’,5’,5’,7-Tetrahydroxy-4’-methoxy-flavonol |

[16805-10-0] | [71] |

| Chrysosplenol E (238) | 2’,3,4’,5,5’,7-Hexahydroxyflavone 3,4’,5’,7-tetramethyl ether 2’,5-Dihydroxy-3,4’,5’,7-tetramethoxy-flavone |

[23289-81-8] | [80] |

| 5,3’-Dihydroxy, 3,6,7,5’-tetramethoxyflavone (239) | [99] | ||

| 3’,5,7,8-Tetrahydroxy-3,4’-dimethoxyflavone (240) | 3,3’,4’,5,7,8-Hexahydroxyflavone 3,4’-di-ethyl ether | [123563-74-6] | [76, 94] |

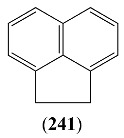

The miscellaneous polycyclic aromatic natural product acenaphthylene, 1,2,4,5-tetrahydro- ([54271-92-0]) (241) is also reported from A. annua [34].

2.5. Monoterpenoids

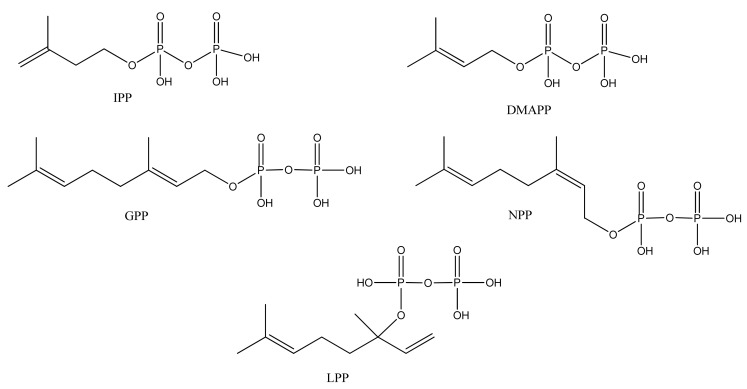

Monoterpenoids generally contain ten carbons (C10) and are the principal components of the essential oil of A. annua obtained by steam distillation (or other techniques that are selective for more volatile natural products). It is widely believed that monoterpenes are located in the glandular trichomes – small structures, which are loosely attached to the surfaces of the leaves and flowers [108]. The regular acyclic monoterpenes which are described in Section 2.5.1 consist of an eight-carbon chain, which is often functionalized at the 1-position, with methyl substituents at the 3- and 7-positions (Table 23). They are formed by ionization of the pyrophosphate group in one of the C10 precursors: geranyl pyrophosphate (GPP), neryl pyrophosphate (NPP) or linalyl pyrophosphate (LPP) (Figure 2) [these monoterpene precursors are, in turn, formed from the “head-to-tail” condensation of a “starter” molecule of dimetylallypyrophosphate (DMAPP) with a “chain extender” of isopentenyl pyrophosphate (IPP) (both C5)]. A. annua is also a rich source of irregular acyclic monoterpenoids (Section 2.5.2), which are derived from the “head-to-middle” condensation of two C5 precursors.

Table 23.

Regular Acyclic Monoterpenoids (2,6-Dimethyloctane, 9CI, 8CI).

| Name | Alternative Name(s) | CAS number | References |

|---|---|---|---|

| Citronellol (242) | 3,7-Dimethyl-6-octen-1-ol | [106-22-9] | [24] |

| Citronellal (243) | 3,7-Dimethyl-6-octenal | [106-23-0] | [28] |

| Geraniol (244) | (E)-3,7-Dimethyl-2,6-octadien-1-ol | [106-24-1] | [22] |

| Geranyl acetate (245) | (E)-3,7-Dimethyl-2,6-octadien-1-ol acetate | [105-87-3] | [23, 51] |

| 3,7-Dimethyl-2,6-octadienyl, isobutyric acid, ester (246) | (E)-Isobutyric acid, 3,7-dimethyl-2,6-octadienyl ester | [1188-06-3] | [50] |

| 2,6-Octadien-1-ol, 2,6-dimethyl-8-[(tetrahydro-2H-pyran-2-yl)oxy]- (247) | [80444-67-3] | [23] | |

| Nerol (248) | (Z)-3,7-Dimethyl-2,6-octadien-1-ol | [106-25-2] | [23, 58] |

| Neryl acetate (249) | (Z)-3,7-Dimethyl-2,6-octadien-1-ol acetate | [141-12-8] | [45] |

| Linalool (250) | 3,7-Dimethyl-1,6-octadien-3-ol | [78-70-6] | [19, 28, 31, 32, 45, 51, 74, 111] |

| Linalyl acetate (251) | 3,7-Dimethyl-1,6-octadien-3-ol acetate | [115-95-7] | [32, 43] |

| 3,7-Octadien-2-ol, 2,6-dimethyl- (252) | [62911-76-6] | [23] | |

| Myrcenol (253) | 2-Methyl-6-methylene-7-octen-2-ol | [543-39-5] | [30] |

| Myrcene (254) | 7-Methyl-3-methylene-1,6-octadiene | [123-35-3] | [19, 23, 29, 32, 33, 34, 43, 56, 50, 51, 73, 112, 113] |

| Ipsdienol (255) | 2-Methyl-6-methylene-2,7-octadien-4-ol | [35628-00-3] | [28] |

| allo-Ocimene (256) | 2,6-Dimethyl-2,4,6-octatriene | [673-84-7] | [22] |

| trans-α-Ocimene (257) | 3,7-Dimethyl-1,3,7-Octatriene | [27400-72-2] [3779-61-1] | [22, 32, 111] |

| (E)- 3,7-Dimethyl-1,3,6-octatriene (258) | [3779-61-1] | [43] | |

| (Z)-3,7-Dimethyl-1,3,6-octatriene (259) | [3338-55-4] | [32, 43] | |

| 2,6-Dimethyl-3,5,7-octatrien-2-ol (260) | [103272-78-2] | [23] | |

| 3,7-Dimethyl-1,5,7-octatrien-3-ol (261) | [29957-43-5] | [48] | |

| 2,6-Dimethyl-1,5,7-octatrien-3-ol (262) | [29414-56-0] | [23] | |

| 3,7-Octadien-2-ol, 2-methyl-6-methylene (263) | [22459-09-2] | [31] | |

| β-myrcene hydroperoxide (264) | 2-Methyl-6-methylene-3,7-octadiene-2-ol (E), 2-hydroperoxide | [9, 114] | |

| α- myrcene hydroperoxide (265) | 2-Methyl-6-methylene-1,7-octadiene, 3-hydro-peroxide | [9, 114] | |

| 1,6-Octadien-4-one, 7-methyl-3-methylene- (266) | [1079223-79-2] | [43] | |

| 1,7-Octadien-3-one, 2-methyl-6-methylene- (267) | 2-Methyl-6-methylene-1,7-octadien-3-one | [41702-60-7] | [20] |

| cis-Epoxyocimene (268) | 3,7-Dimethyl-1,3,6-Octatriene 6R,7-epoxide | [255832-06-5] | |

| 2,6-Dimethyl-1,3,5,7-octatetraene (269) | [90973-78-7] | [50] | |

| Perillene (270) | 3-(4-Methyl-3-pentenyl)furan | [539-52-6] | [23, 43] |

| 1,10-Oxy-α-myrcene hydroxide (271) | [9] | ||

| 1,10-Oxy-β-myrcene hydroxide (272) | [9] |

Figure 2.

Structures of isopentenyl pyrophosphate (IPP), dimethylallyl pyrophosphate (DMAPP), geranyl pyrophosphate (GPP), neryl pyrophosphate (NPP) and linaloyl pyrophosphate (LPP) which are all possible precursors to monoterpenes from A.annua.

The “regular” acyclic monoterpenoid precursors can then undergo further intramolecular reactions to yield monocyclic monoterpenes (Section 2.5.3). The largest group of such monocyclic monoterpenes in A. annua is the p-menthane series (Table 25), which incorporate a single six-membered ring. Further cyclization produces bicyclic monoterpenes (Section 2.5.4), which may contain an additional five-membered ring (e.g., camphanes in Table 26); or a four-membered ring (pinanes, Table 27); or a three-membered ring (thujanes, Table 28). Studies with 14C-labeled LPP have shown that in A. annua this precursor is converted to cyclised monoterpenes such as 1,8-cineole (326) and α-pinene (347) with greater efficiency than the alternative precusors, NPP and GPP [109].

Table 25.

p-Menthane Monoterpenoids, 8CI (1-Methyl-4-(1-methylethyl)cyclohexane, 9CI).

| Name | Alternative Name(s) | CAS number | References |

|---|---|---|---|

| p-Menth-3-ene (287) | [500-00-5] | [50] | |

| p-Mentha-2,4-diene (288) | [586-68-5] | [25] | |

| α-Phellandrene (289) | p-Mentha-1,5-diene | [99-83-2] | [32] |

| β-Phellandrene (290) | p-Mentha-1(7),2-diene | [555-10-2] | [22, 25, 45] |

| α-Terpinene (291) | p-Menthan-1,3-diene | [99-86-5] | [19, 32, 40, 41, 45, 66, 74] |

| γ-Terpinene (292) | p-Menthan-1,4,diene | [99-85-4] | [19, 28, 32, 40, 41, 43, 66] |

| Terpinolene (293) | p-Mentha-1,4(8)-diene | [586-62-9] | [32, 43] |

| Limonene (294) | p-Mentha-1,8-diene | [138-86-3] [5989-27-5] |

[24, 31, 34, 43, 45, 50, 66, 111] |

| p-Cymene (295) | 1-Methyl-4-isopropyl benzene | [99-87-6] | [19, 24, 25, 28, 29, 32, 34, 38, 40, 43, 45, 48, 73, 74] |

| Cuminic alcohol (296) |

p-Mentha-1,3,5-trien-7-ol 4-Isopropenylbenzyl alcohol |

[536-60-7] | [51] |

| Cuminal (297) | Cuminaldehyde p-Menthan-1,3,5-trien-1-al 4-Isopropylbenzaldehyde |

[122-03-2] | [23, 25, 32, 43, 45] |

| Carvacrol (298) | p-Mentha-1,3,5-trien-2-ol | [499-75-2] | [31, 32, 43] |

| Thymol (299) |

p-Cymen-3-ol p-Mentha-1,3,5-trien-3-ol |

[89-83-8] | [19, 32, 43] |

| p-Cymen-8-ol (300) | 2-(4-Methylphenyl)-2-propanol | [1197-01-9] | [19, 25, 32] |

| Menthol (301) | p-Menthan-3-ol | [89-78-1] | [23, 25, 30, 60, 111] |

| β-Terpineol (302) | p-Menth-8-en-1-ol | [7299-41-4] | [43] |

| cis-p-Menth-2-en-1-ol (303) | [29803-81-4] | [19, 45] | |

| trans-p-Menth-2-en-1-ol (304) | [29803-82-5] | [19, 45] | |

| p-Menth-2,8-dien-1-ol (305) | 1-Methyl-4-(1-methylethyl)-2-cyclohexen-1-ol | [3886-78-0] | [32] |

| trans-Carveol (306) | p-Mentha-1,8-dien-6-ol, trans- | [1197-07-5] | [19, 25, 41, 43, 45] |

| cis-Carveol (307) | p-Mentha-1,8-dien-6-ol, cis- | [1197-06-4] | [19, 41, 43] |

| trans-Carvyl acetate (308) | p-Mentha-6,8-dien-2-ol, acetate, trans- | [1134-95-8] | [19, 31] |

| cis-Carvyl acetate (309) | p-Mentha-6,8-dien-2-ol, acetate, cis- | [1205-42-1] | [19] |

| Carvone (310) | p-Mentha-1,8-dien-6-one | [99-49-0] | [19, 24, 25, 28,32, 43] |

| p-Mentha-1(7),5-dien-2-ol (311) | [30681-15-3] | [43] | |

| p-Mentha-1(7),8-dien-2-ol (312) | [35907-10-9] | [51] | |

| p-Menth-1-en-5-ol (313) | [55708-42-4] | [22] | |

| p-Mentha-1,4(8)-dien-3-ol (314) | [6753-08-8] | [32] | |

| 3-Cyclohexene-1-methanol 2-hydroxy-α,α,4-trimethyl-, 1-acetate (315) | [138913-54-9] | [25] | |

| Iso-menthone (316) | p-Menthan-3-one | [491-07-6] | [45] |

| Piperitone (317) | p-Menth-1-en-3-one | [89-81-6] | [24] |

| Terpinen-4-ol (318) | p-Menth-1-en-4-ol | [562-74-3] | [19, 30, 31, 32, 34, 41, 43, 45, 51, 66] |

| 4-Terpinyl acetate (319) | p-Menth-1-en-4-ol acetate | [4821-04-9] | [34] |

| Phellandral (320) | p-Menth-1-en-7-al | [21391-98-0] | [23] |

| Perillaldehyde (321) | p-Mentha-1,8-dien-7-al | [2111-75-3] | [45] |

| α-Terpineol (322) | l-α-Terpineol p-Menth-1-en-8-ol |

[98-55-5] [10482-56-1] |

[19, 22, 23, 28, 32, 40, 43, 45, 74] |

| δ-Terpineol (323) | p-Menthen-1(7)-en-8-ol | [7299-42-5] | [19] |

| Limonene-1,2-epoxide (324) | Limonene oxide 1,2-Epoxy-p-menth-8-ene |

[1195-92-2] | [23, 51] |

| 1,4-Cineole (325) | 1,4-Epoxy-p-menthane | [470-67-7] | [112] |

| 1,8-Cineole (326) | Eucalyptol 1,8-Epoxy-p-menthane |

[470-82-6] | [19, 22, 23, 24, 25, 28, 29, 32, 33, 34, 36, 37, 38, 40, 41, 43, 45, 48, 49, 50, 51, 53, 66, 72, 73, 74, 112, 113] |

| 2,3-Dihydro-1,8-cineole (327) | 1,8-Epoxy-p-menth-2-ene | [92760-25-3] | [19, 32, 41, 43] |

| 2-α-Hydroxy-1,8-cineole (328) | [60761-00-4] | [113] | |

| Ascaridole (329) | 1,4-Epidioxy-p-menth-2-ene | [512-85-6] | [28] |

| 2-Cyclohexen-1-one, 2-methyl-5-(1-methylcyclopropyl)- (330) | [26541-44-6] | [43] |

Table 26.

Camphane Monoterpenoids (1,7,7-Trimethylbicyclo-[2.2.1]heptane, 9CI).

| Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|

| Borneol (334) | [464-43-7] [507-70-0] [124-76-5] |

[19, 25, 30, 31, 34, 40, 41, 43, 45, 72, 73, 111, 112] | |

| Bornyl acetate (335) | [76-49-3] [92618-89-8] |

[25, 31, 40, 45] | |

| Borneol isobutyrate (336) | [24717-86-0] | [45] | |

| Bornyl valerate (337) | Bornyl pentanoate | [7549-41-9] | [31] |

| 2-Butenoic acid, 3-methyl-(1S,2R,4S)-1,7,7-trimethylbicyclo[2.2.1]hept-2-yl ester (338) | [91404-82-9] | [31] | |

| Cyclopentanecarboxylic acid, 3-methylene-, 1,7,7-trimethylbicyclo-[2.2.1]hept-2-yl ester (339) | [74793-59-2] | [31] | |

| Isobornyl acetate (340) | 2-Bornanol acetate | [125-12-2] | [19] |

| Camphor (341) | 1,7,7-Trimethylbicyclo[2.2.1] heptan-2-one |

[76-22-2] [464-48-2] |

[19, 23, 25, 26, 29, 32, 34, 36, 37, 38, 40, 41, 42, 43, 44, 45, 48, 49, 51, 53, 66, 72, 73, 74, 112, 113] |

| endo-Dehydronorborneol (342) | Bicyclo[2.2.1]hept-5-en-2-ol | [694-97-3] | [23] |

Table 27.

Pinane Monoterpenoids (2,6,6-Trimethylbicyclo[3.1.1]heptane, 9CI).

| Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|

| α-Pinene (347) | 2,6,6-Trimethylbicyclo[3.1.1]hept-2-ene | [80-56-8] [7785-26-4] [7785-70-8] |

[19, 22, 25, 28, 29, 32, 33, 34, 36, 37, 38, 40, 41, 42, 43, 44, 45, 50, 51, 66, 73, 74, 112, 113, 120, 132] |

| Verbenyl acetate (348) | Verbenol acetate 2-Pinen-4-ol, acetate |

[33522-69-9] | [23] |

| trans-Chrysanthenol (349) | [38043-83-3] | [43] | |

| cis-Chrysanthenyl acetate (350) | [67999-48-8] | [19] | |

| Myrtenol (351) | 2-Pinen-10-ol | [515-00-4] [564-94-3] |

[19, 23, 32, 41, 43, 66] |

| (-)-Myrtenyl acetate (352) | (-)-O-Acetylmyrtenol | [36203-31-3] | [23] |

| Verbenone (353) | 2-Pinen-4-one | [80-57-9] | [19, 25, 34, 43, 45] |

| Chrysanthenone (354) | 2-Pinen-6-one | [473-06-3] | [32, 43, 66] |

| Myrtenal (355) | 2-Pinen-10-al | [23727-16-4] | [66] |

| β-Pinene (356) | 6,6-Dimethyl-2-methylenebicyclo[3.1.1]-heptane | [127-91-3] [1330-16-1] |

[19, 22, 23, 25, 26, 27, 28, 32, 33, 34, 36, 38, 40, 43, 45, 51, 66, 73, 74, 112, 113, 120, 132] |

| (-)-trans-Pinocarveol (357) | 2(10)-Pinen-3-ol | [547-61-5] [3917-59-7] |

[19, 23, 25, 32, 33, 40, 43] |

| cis-Pinocarveol (358) | Isopinocarveol 2(10)-Pinen-3-ol, cis- |

[6712-79-4] [5947-36-4] |

[30, 43] |

| Pinocarvyl acetate (359) | 2(10)-Pinen-3-ol, acetate | [1078-95-1] | [30] |

| Pinocarvone (360) | 2(10)-Pinen-3-one | [30460-92-5] [19890-00-7] |

[19, 23, 25, 28, 30, 32, 33, 42, 43, 45, 66] |

| 3-Pinanol (361) | 2,6,6-Trimethylbicyclo[3.1.1]heptan-3-ol | [25465-95-6] | [30] |

| β-Pinene oxide (362) | 2,10-Epoxypinane | [6931-54-0] | [19] |

| Bicyclo[3.1.1]heptan-3-one, 2,6,6-trimethyl-4-methylene- (363) | [62594-31-4] | [30] |

Table 28.

Thujane Monoterpenoids (4-Methyl-1-(1-methylethyl)-bicyclo[3.1.0]hexane, 9CI).

| Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|

| α-Thujene (366) | 3-Thujene 2-Methyl-5-(1-methylethyl)bicyclo[3.1.0]hex-2-ene |

[2867-05-2] | [28, 34, 41, 43, 45, 66] |

| 3-Thujen-2-ol (367) | Bicyclo[3.1.0]hex-3-en-2-ol, 4-methyl-1-(1-methylethyl) | [3310-03-0] | [25] |

| 3-Thujen-10-al (368) | [57129-54-1] | [50] | |

| (-)-α-Thujone (369) | [546-80-5] | [45, 66, 111] | |

| Sabinene (370) | 4(10)-Thujene Bicyclo[3.1.0]hexane,4-methylene-1-(1-methylethyl)- |

[2009-00-9] [3387-41-5] [204524-73-2] |

[19, 23, 31, 32, 34, 40, 41, 43, 45, 51, 66, 74, 113] |

| Sabinol (371) | 4(10)-Thujen-3-ol | [471-16-9] | [32, 43] |

| trans-Sabinyl acetate (372) | Bicyclo[3.1.0]hexan-3-ol, 4-methylene-1-(1-methylethyl)-, 3-acetate | [139757-62-3] [3536-54-7] |

[43] |

| β-Sabinene hydrate (373) | 4-Thujanol | [546-79-2] [15537-55-0] [17699-16-0] |

[19, 25, 32, 34,41, 43, 45] |

| Sabina ketone (374) | Didehydrosabina ketone Bicyclo[3.1.0]hexan-2-one, 5-(1-methylethyl)-, 5-Isopropyl- bicyclo[3.1.0]hexan-2-one |

[513-20-2] [110716-99-9] [147043-52-5] |

[19, 43] |

2.5.1. Regular Acyclic Monoterpenes

A cDNA for (3R)-linalool synthase, which converts GPP to (3R)-linalool (250) by ionization of the pyrophosphate group, has been described recently from A. annua [110]. Most of the regular acyclic monoterpenes reported in Table 23 can be derived by further functional group modifications (dehydration, reduction or oxidation) of linalool (250) or its isomers, geraniol (244) and nerol (248).

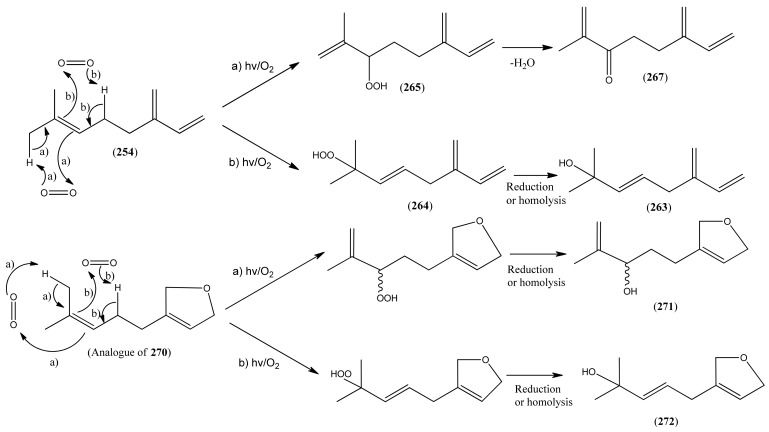

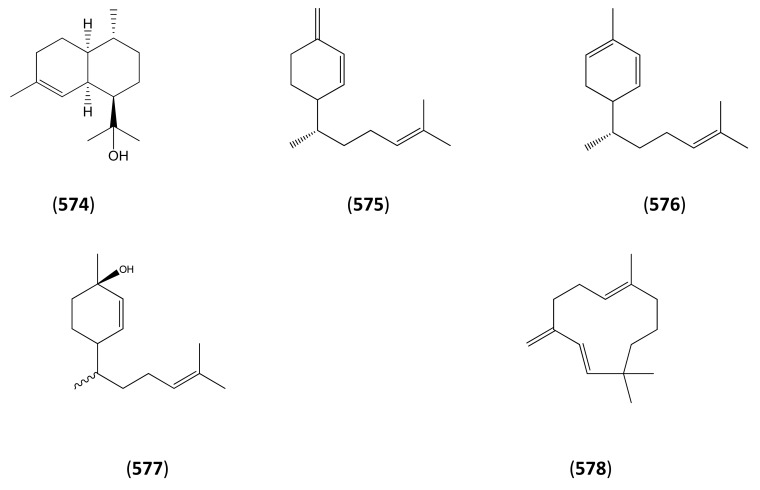

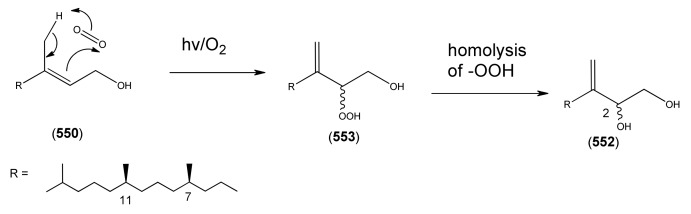

Myrcene (254) is the most abundant regular acyclic monoterpene from A. annua, and can account for up to 5% of the essential oil [22,33,43]. The secondary and tertiary allylic hydroperoxides, α- and β-myrcene hydroperoxide (265 and 264), have been isolated from A. annua on more than one occasion [9,114], and are possibly formed by an “ene”-type reaction of molecular oxygen with the tri-substituted double bond in myrcene (254), occurring in the presence of light and a photosensitizer (i.e. singlet oxygen, 1O2), as is shown in Scheme 1. Further known reactions of these allylic hydroperoxides might account for the formation of other highly oxygenated myrcene monoterpenoids from A. annua, such as compounds 267 and 263 (Scheme 1). This propensity towards spontaneous autoxidation has also been suggested for several other terpenoidal hydroperoxides from A. annua, and it is repeatedly stressed in this review because of its perceived relvance to the biosynthesis of artemisinin (Section 3.3). Compounds 271 and 272 are also derivatives of myrcene, in which oxidation at C-1 and C-10 has produced a 1,4-dihydrofuran functionality, rarely found in natural products. It has been proposed that the biogenesis of the secondary and teriary allylic hydroxide functionality in this pair of compounds might also be explained by similar autoxidation reactions of a putatative monoterpene precursor (closely related to perillene (270)), which also proceeds via a pair of secondary and tertiary allylic hydroperoxide intermediates [9], as is shown in Scheme 1.

Scheme 1.

Postulated biosynthesis of allylic hydroperoxides: α-myrcene hydroperoxide (265) and β-myrcene hydroperoxide (264) via spontaneous autoxidation reactions at the tri-substituted bond of the precursor myrcene (254). Further reactions of such allylic hydroperoxides would account for the biogenesis of oxygenated monoterpenes such as (267), (263), (271) and (272).

2.5.2. Irregular Acyclic Monoterpenes

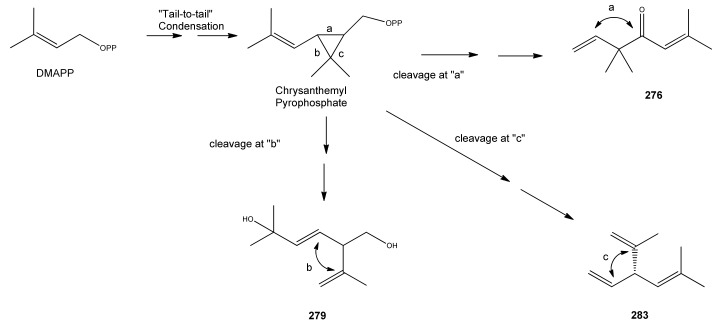

Phytochemists were interested in A. annua before the discovery of artemisinin because it is a rich source of unusual irregular acyclic monoterpenoids, such as artemisia ketone (276) [115,116,117,118,119,120], which is the major constituent of the essential oil in some varieties of A. annua [29,37,42,73], and can account for up to 50% of the total [22,25,33,43,45,53]. It is often found in conjunction with smaller amounts of artemisia alcohol (273) [22,33,38,121]. Artemisia ketone (276) is formed by a non-standard “head-to-middle” condensation of DMAPP [104,122,123,124,125,126], which is thought to proceed as shown in Scheme 2 via chrysanthemyl pyrophosphate, an intermediate containing a three-membered ring. The mechanism for the formation of this unusual intermediate [127], is believed to mimic the formation of presqualene, another naturally-occuring cyclopropane, which is involved in the biosynthesis of the triterpene precursor, squalene (see Section 2.7.2) [128]. Two other classes of irregular cyclic monoterpenoids, the lavandulanes 279)–281 and the santolinanes 282 and 283, are also known from A. annua. The formation of all three skeletons has been explained in terms of different cleavage reactions occurring at each of the three carbon-carbon bonds in the cyclopropyl ring of the common precursor, chysanthemyl pyrophosphate (Scheme 2) [126].

Scheme 2.

Formation of the irregular artemisyl, lavandulyl and santolinyl skeletons in A. annua by “head-to-middle” condensation of a DMAPP (C5) precursor and subsequent carbon-carbon cleavage reactions of the resulting intermediate, chryanthemyl pyrophosphate.

Table 24.

Irregular Acyclic Monoterpenoids.

| Name | Alternative Name(s) | CAS Number | References |

|---|---|---|---|

| Artemisanes | |||

| Artemisia alcohol (273) | 3,3,6-Trimethyl-1,5-heptadien-4-ol | [29887-38-5] [27644-04-8] [77363-66-7] |

[19, 23, 29, 33, 38, 40, 43, 45, 48, 51, 66, 73, 121] |

| Artemisyl acetate (274) | Artemisia alcohol acetate 3,3,6-Trimethyl-1,5-heptadien-4-ol acetate |

[3465-88-1] [29887-38-5] |

[25, 40, 43, 45, 72, 112, 113] |

| (E)-2-Butenoic acid, 2-methyl-, 2,2-dimethyl-1-(2-methyl-1-propenyl)-3-butenyl ester (275) | [62594-30-3] | [30] | |

| Artemisia ketone (276) | 3,3,6-Trimethyl-1,5-heptadien-4-one | [546-49-6] | [19, 21, 22, 23, 24, 26, 29, 31, 33, 36, 38, 40, 41, 42, 43, 44, 45, 49, 53, 66, 72, 73, 112, 113, 121] |

| Yomogi alcohol (277) | 2,5,5-Trimethyl-3,6-heptadien-2-ol | [26127-98-0] | [19, 32, 38, 45] |

| Artemisiatriene (278) | 2,5,5-Trimethyl-1,3,6-heptatriene | [29548-02-5] | [23] |

| Lavandulanes | |||

| trans-5-Hydroxy-2-isopropenyl-5-methylhex-3-en-1-ol (279) | 3-Hexene-1,5-diol, 5-methyl-2-(1-methyl-ethenyl)- | [403797-33-1] | [129] |

| 4-Hydroxy-2-isopropenyl-5-methylene-hexan-1-ol (280) | [9] | ||

| Lavandulyl acetate (281) | 5-Methyl-2-(1-methylethenyl)-4-hex-en-1-ol | [20777-39-3] | [19] |

| Santolinanes | |||

| Santolina alcohol (282) | 3-Ethenyl-2,5-dimethyl-4-hexen-2-ol | [35671-15-9] | [19, 32, 43] |

| Santolinatriene (283) | 3-Ethenyl-2,5-dimethyl-1,4-hexadiene | [70005-95-7] [2153-66-4] |

[23, 25, 43, 45, 50] |

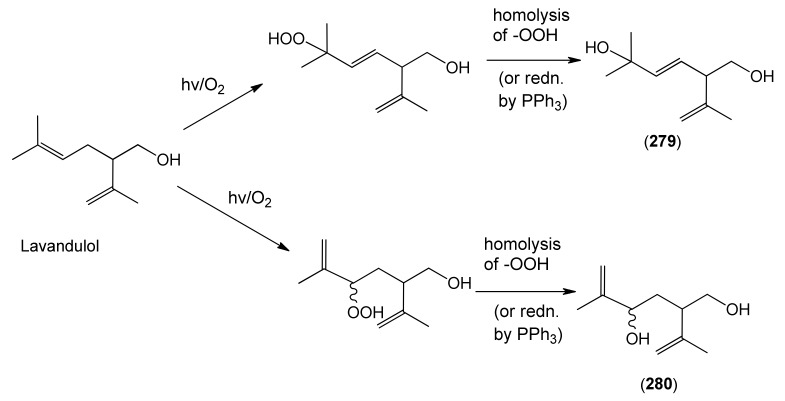

Both the lavandulane tertiary allylic alcohol 279 and its secondary allylic alcohol analogue 280 have been proposed to be derived from the precursor, lavandulol, by spontaneous autoxidation reactions which yield allylic hydroperoxide intermediates as shown in Scheme 3 [129]. This suggestion was supported by a biomimetic synthesis, in which photooxygenation of racemic lavandulol yielded both of the hydroperoxide intermediates expected from the reaction of singlet oxygen with the tri-substituted double bond in this precursor. Reduction of the tertiary allylic hydroperoxide product then resulted in a tertiary allylic alcohol identical with the natural product 279.

Scheme 3.

Proposed formation of lavandulanes 279 and 280 by spontaneous autoxidation reactions.

2.5.3. Monocyclic Monoterpenes

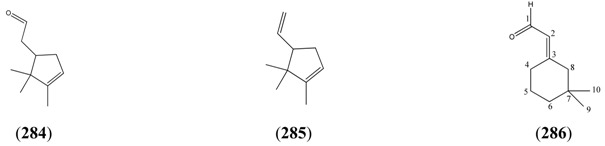

Two unusual cyclopentane monoterpeneoids, α-campholenal ([4501-58-0]) (284) [19] and cyclopentene, 4-ethenyl-1,5,5-trimethyl- ([1727-69-1]) (285) [23] are reported from A. annua. Both are probably derived from cleavage reactions of the corresponding bicyclic monoterpenoids (see Section 2.5.4). 2-Ochtoden-1-al [26532-25-2] (286) [25] is another unusual six-membered monoterpene, belonging to the ochtodane class of monoterpenoids (3-ethyl-1,1-dimethylcyclohexane, 9CI). The vast majority of monocyclic monoterpenes from A. annua, however, are p-menthanes (Table 25), incorporating a six-membered ring, which is formed directly by cyclization of an LPP/NPP precursor.

1,8-Cineole (326) is the most abundant p-menthane monoterpene from A. annua [22,29,40,42,43,45,73], accounting for as much as 10-30% of the essential oil [25,28,33,34,41,53]. 1,8-Cineole is sometimes accompanied by significant quantities of p-cymene (295) [28,34] and α-terpineol (322) [28], which could be derived from opening of the ether linkage in 1,8-cineole (326).

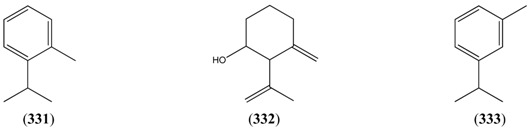

Only two o-menthanes: o-cymene (1-isopropyl-2-methylbenzene [527-84-4] [25155-15-1]) (331) [41] and o-mentha-1(7),8-dien-3-ol ([15358-81-3]) (332) [23]; and one m-menthane: m-cymene (β-cymene; 1-methyl-3-(1-methylethyl)benzene [535-77-3]) (333) [31] are reported from A. annua. These unusual skeletons presumably arise by migration of a methyl group in the corresponding p-menthane precursor (i.e. 331 and 333 are perhaps derived from 295).

2.5.4. Bicyclic Monoterpenes

Further cyclization of the carbocation which produces the p-menthane skeleton results in bicyclic monoterpenes. In the camphane monoterpenes listed in Table 26, the second cyclization has produced an additional five-membered ring. The most abundant member of this class of monoterpenoids is camphor (341) [25,29,37,45], which can account for up to 10-30% of the essential oil [19,22,41,42]. Borneol (334) [46,73] and bornyl acetate (335) [29] are sometimes reported together with camphor (351) as significant constituents of the essential oil.

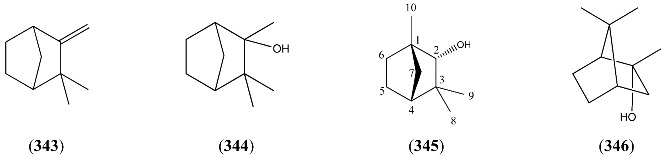

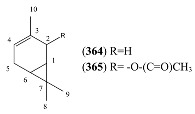

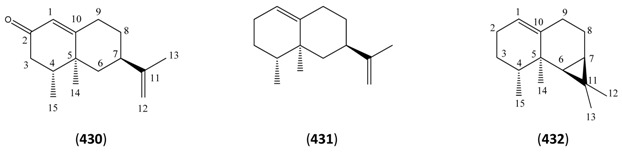

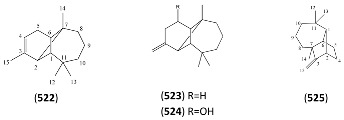

Other miscellaneous bicyclic monoterpenoids which contain both 5- and 6-membered rings are: camphene (2,2-dimethyl-3-methylenebicyclo[2.2.1]heptane [79-92-5]) (343) [19,23,25,26,28,29,31,32, 34,36,37,40,41,43,45,51,73,74,130]; camphene hydrate ([465-31-6]) (344) [19]; fenchol (fenchyl alcohol; 1,3,3-trimetylbicyclo[2.2.1]heptan-2-ol [1632-73-1]) (345) [66]; and trans-pinene hydrate (2-norbornanol, 2,7,7-trimethyl-, endo-; bicyclo[2.2.1]heptan-2-ol, 2,7,7-trimethyl-, endo-; [3247-40-3]) (346) [25]. Camphene (343) has been obtained as both its (+)- and (-)-enantiomeric forms [37].

In the pinane monoterpenes (Table 27), the second cyclization of the C10 p-menthane precursor has produced an additional four-membered ring. α-Pinene (347) [40,42,43] is the most abundant pinane monoterpene from A. annua (up to 10%) [33], and sometimes co-occurrs with significant amounts of either β-pinene (356) [101] or pinocarvone (360) [42]. A β-pinene synthase, which converts GPP to both (-)-α-pinene (347) and (-)-β-pinene (356), has recently been described from A. annua [131]. α-Pinene (347) is known in both its (+)- and (-)-enantiomeric forms from this species [37].