Abstract

Four solvents (isopropanol (IPA), n-butyl alcohol (NBA), n-amyl alcohol (NAA), and n-hexyl alcohol (NHA)) were investigated to prepare CH3NH3I (methylammonium iodide, MAI) solutions to transform PbI2 film into CH3NH3PbI3 (MAPbI3) film. It was found that the morphology of the perovskite MAPbI3 film was not only affected by the chain of the solvent molecule, but also by the concentration of MAI. The use of solvents with a long alkyl chain (NAA and NHA) allowed the MAPbI3 to grow via an in situ transformation step, which easily made the perovskite films compact, but with a high surface roughness due to the growth of unexpected nanorods/nanoplates. The solvent with a short alkyl chain (IPA) led to the dissolution−crystallization growth mechanism, resulting in rapid generation of perovskite films with a number of pinholes. A high-quality (compact, smooth, pinhole-free) perovskite film was obtained with NBA and an optimized MAI concentration of 8 mg/mL. The corresponding perovskite solar cells achieved a maximum power conversion efficiency (PCE) of 16.66% and average PCE of 14.76% (for 40 cells).

Keywords: solvent, compact, smooth, perovskite solar cells

1. Introduction

Organic-inorganic lead halide perovskite solar cells have attracted intensive attention due to the remarkable progress in power conversion efficiency (PCE), increasing rapidly to over 22% in a few years [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18]. The PCEs of perovskite solar cells with various architectures (mesoporous or planar heterojunction structures) are strongly dependent on the morphology of the perovskite film [19,20,21,22,23,24,25,26]. The growth mechanism relating to the chemical reaction kinetics significantly influences the perovskite polymorph [27]. There are several fabrication methods of perovskite films, including two-step deposition techniques [6,7], one-step solution spin-coating [8,28,29], and vacuum-evaporation deposition [9,30]. Among them, the two-step solution-process deposition technique is an easy method to obtain cells with excellent photovoltaic performance in a reproducible way [6,7].

In a typical two-step sequential solution process, PbI2 film is first deposited on a TiO2-coated substrate by spin-coating with a dimethylformamide (DMF) solution of PbI2, and is subsequently transformed into a perovskite CH3NH3PbI3 (methylammonium lead iodide, MAPbI3) film through exposure to a CH3NH3I (methylammonium iodide, MAI) solution in isopropanol (IPA) [6,7]. However, this two-step solution method often results in poor grain structure, incomplete surface coverage, and high surface roughness [19,20,21,22,23,25], which limits the further improvement of photovoltaic performance of perovskite solar cells. In a previous investigation, it was proposed that the perovskite grain morphology was governed by its growth mechanism. The growth mechanism is in line with a competing relation between an in situ transformation and dissolution-crystallization mechanism, which is determined by the rate and amount of PbI2 dissolving in the MAI solution [27]. It was confirmed that the MAI concentration significantly affects the solubility of PbI2 in the MAI solution and the morphology of perovskite grains. When the MAPbI3 crystals grow based on the in situ transformation mechanism, the formed MAPbI3 grains will maintain parallel geometries to PbI2. On the other hand, in the dissolution–crystallization mechanism, the large amount of dissolved PbI2 results in the rapid generation rate of perovskite grains, the collapse of lead backbones, and the occurrence of tetragonal-shaped MAPbI3 [27]. Hence, perovskite films forming in different solutions might display diverse morphologies. Unfortunately, the role of the solvent on the MAPbI3 film formation has been neglected. Thus, it is essential to systematically probe the relationship between the chemical properties of the solvent and the perovskite crystal growth mechanism.

Herein, besides commonly used IPA, n-butyl alcohol (NBA), n-amyl alcohol (NAA), and n-hexyl alcohol (NHA) (the corresponding molecular formula are shown in Figure S1 in Supporting Information) were also selected as solvents to prepare MAI solutions to transform PbI2 into MAPbI3. From IPA to NHA, the polarity of the solvents decreases with the increasing length of the molecule chain. Considering that PbI2 is a polar molecule, its solubility is oppositely correlated with the length of the alkyl chain of the solvent molecule in the MAI solution. Therefore, the effect of the length of the alkyl chain of the solvents on the perovskite film morphology could be investigated systemically.

In this work, it was found that the morphology of the perovskite MAPbI3 film was significantly affected by the alkyl chain of the solvent (i.e., solvent polarity) and the MAI concentration. On one hand, the coverage and compactness of the perovskite film was improved through the use of a solvent with a longer alkyl chain of MAI. This may be attributed to the slow chemical reaction rate of PbI2 and MAI, resulting from the low polarity of the solvent with a longer alkyl chain. On the other hand, the long-alkyl-chain solvent may also generate unexpected nanorods/nanoplates on the film surface that increase the roughness of the perovskite film, which is negatively related to the photovoltaic performance of the perovskite solar cell. In a word, both the high concentration of MAI and long reaction time facilitated PbI2 to form PbI3- or PbI42-, which also led to large crystal MAPbI3 nanorods/nanoplates growing on the surface with long loading time [27,31]. The best-quality (highly compact, pinhole-free, and smooth) perovskite films were fabricated with an optimized MAI concentration of 8 mg/mL and using NBA as solvent. The resulting perovskite solar cell based on this film achieved a maximum PCE of 16.66% and average PCE of 14.76% (for 40 cells).

2. Experimental Section

2.1. Materials

Methylamine (33 wt% in absolute ethanol), hydroiodic acid (57 wt% in water, 99.99%), and Li-bis(trifluoromethanesulfonyl) imide (Li-TFSI) were purchased from Sigma-Aldrich (St. Louis, MO, USA). 4-tert-butylpyridine (TBP) was purchased from Aladdin (Shanghai, China). Acetonitrile (99.8%), chlorobenzene (99.9%), dimethylformamide (DMF) (99.9%), PbI2 (99.999%), IPA, NBA, NAA, and NHA were purchased from Alfa Aesar (Ward Hill, MA, USA). 2,2’,7,7’-tetrakis-(N,N-di-p-methoxyphenylamine)-9,9’-spirobifluorene (spiro-OMeTAD) (≥99.0%) was purchased from Shenzhen Feiming Science and Technology Co., Ltd. (Shenzhen, China).

2.2. MAI Preparation

A solution was prepared by reacting methylamine (27.8 mL, 33 wt% in absolute ethanol) with hydroiodic acid (30 mL, 57 wt% in water) at 0 °C for 2 h. Subsequently, a precipitate was obtained through rotary evaporation of the solution at 60–70 °C. The as-prepared product was washed with diethyl ether and ethanol, and then dried in a vacuum oven at 60 °C overnight.

2.3. Devices Fabrication

A TiO2 compact layer was prepared on fluorine-doped tin oxide glass (FTO) by spin-coating a sol-gel solution at 5000 rpm for 30 s and sintering at 500 °C for 30 min. The sol-gel solution consisted of 18 ml ethanol, 1.8 mL tetrabutyl titanate, and 0.38 mL diethanolamine. Subsequently, the TiO2 microstructure film was fabricated by spin-coating with dispersion (Deysol HR TiO2/ethanol 1:5 wt) and heated at 500 °C for 30 min.

Next, 60 μL of 1.0 M PbI2 solution in DMF was dropped on the TiO2-coated FTO substrate, and the substrate was then spun at 4000 rpm for 25 s. The as-prepared PbI2 film was heated at 70 °C for 10 min, and then naturally cooled to room temperature. Subsequently, 150 μL MAI solution was used to fully covered the PbI2 film. After a certain loading time (1–3 min), PbI2 was transformed into MAPbI3, and the solution was then dried by spinning. The MAPbI3 film was heated at 100 °C for 30 min. When the MAPbI3 film cooled down to room temperature, 30 μL of hole-transport materials (HTM) solution was spun on the film at 3000–4000 rpm for 45 s. The HTM solution was prepared by dissolving 68 mM spiro-OMeTAD, 26 mM Li-TFSI, and 55 mM TBP in acetonitrile and chlorobenzene (v/v = 1:10). The above processes were operated in an Ar glove box. Finally, a back-contact electrode (120 nm silver film) was evaporated on HTM layer. In this work, the active area of a cell was 0.09 cm2. A series of solar cells were prepared by tuning the solvents and concentration of MAI in different MAI solution. The solvent sorts are IPA, NBA, NAA and NHA; the concentrations of MAI in the four-selected solvents range from 6 to 12 mg/mL.

2.4. Characterization

The crystallographic phases of the as-prepared products were determined by powder X-ray diffraction (XRD) (Rigaku Ultima III, Tokyo, Japan) using Cu-Ka radiation (λ = 0.154178 nm) with a scan rate of 10 °/min at 40 kV and 40 mA. The morphologies of the films were examined with a field emission scanning electron microscope (FE-SEM) (JEOL, Tokyo, Japan, JSM-6700F with an accelerating voltage of 5 kV). Atomic force microscope (AFM) analysis was performed on a MFP3D microscope (Asylum Research, MFP-3D-SA, Santa Barbara, CA, USA). The absorption properties of films were investigated by ultraviolet-visible (UV-vis) spectrometer (Shimadzu UV-2550, Kyoto, Japan) and all the data were corrected by deducting the baseline value of the TiO2-coated FTO substrate. Photocurrent density-voltage (I-V) measurements were carried out with a Keithley (Johnston, OH, USA) 236 source measurement unit under AM 1.5 illumination cast with an Oriel 92251A-1000 sunlight simulator (Irvine, CA, USA) calibrated with the standard reference of a Newport 91150 silicon solar cell. The external quantum efficiency (EQE) spectra were measured under monochromatic irradiation with a xenon lamp and a monochromator. Photoluminescence (PL) spectrum was obtained with a 532 nm pulsed laser as excition source at a frequency of 9.743 MHz.

3. Results and Discussion

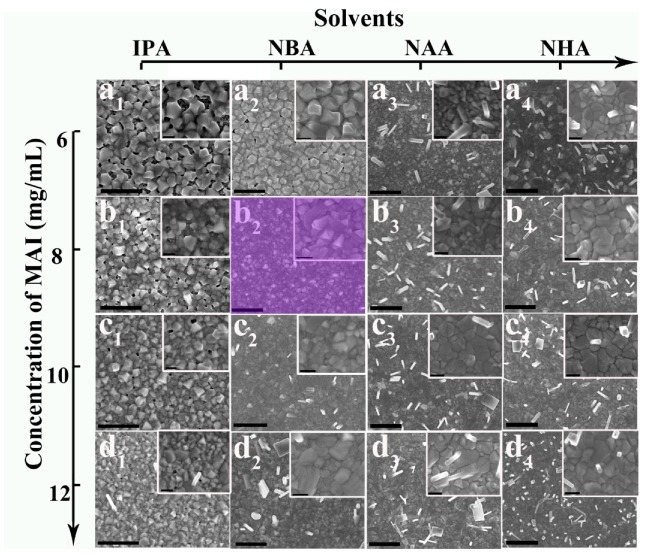

Figure 1a1–a4 shows the morphologies of various perovskite films prepared using different solvents with the same MAI concentration of 6 mg/mL. As the solvent changes from IPA to NHA accompanying with the alkyl chain increasing, the perovskite films become pinhole-free and compact. The presence of the pinholes may result in subsequently coated HTM solutions to deleteriously infiltrate into the perovskite absorber layer. It increased the recombination of electron and hole due to the large contact area between HTM and perovskite [13]. Furthermore, for NAA and NHA solvents, some nanorods/nanoplates were observed to grow on the film surface, which will be detrimental to the performance of the perovskite solar cell. The presence of the nanorods/nanoplates requires thick HTM layers to cover the perovskite in order to eliminate the short-circuiting [22]. Thus, the thick HTM layer may result in lower short-circuit photocurrent density (Jsc) and fill factor (FF) due to the low conductivity of the HTM.

Figure 1.

Field emission scanning electron microscope (FE-SEM) images of CH3NH3PbI3 (MAPbI3) films obtained from 6–12 mg/mL CH3NH3I (MAI) in (a1–d1) isopropanol (IPA), (a2–d2) n-butyl alcohol (NBA), (a3–d3) n-amyl alcohol (NAA), and (a4–d4) n-hexyl alcohol (NHA). The scale bars of a1–d4 are 1 μm, and those of inserts are 200 nm.

Through careful observation of the film (inserts of Figure 1a1–a4), the perovskite grains were found to gradually transit from nanocuboids to an unspecific shape without any corners. The morphology change trend indicated different growth mechanisms of perovskite grains between the four used solvents. For the in situ transformation mechanism, the resulting perovskite grains should keep parallel geometries to PbI2 due to the preservation of the inorganic lead framework. For the dissolution-crystallization mechanism, grains would be reconstructed into a tetragonal shape because of the tetragonal phase MAPbI3 [27]. In order to clearly reveal the effect of the solvent molecule, we specifically explored the growth mechanisms of the perovskite grains in IPA and NHA solutions. Two series of films were fabricated through exposing PbI2 films to the 6 mg/mL MAI in IPA or NHA with a loading time of 0–3 min. Note that the 0 min loading time signifies that the film was quickly dried through spinning as soon as the PbI2 film was covered with the MAI solution. X-ray diffraction (XRD) patterns (Figure S2) and ultraviolet-visible (UV-vis) absorption spectra (Figure S3) were performed to trace the reaction process of the PbI2 film with MAI in IPA and NHA. In the case of IPA, only the film prepared with a 0-min loading time shows a PbI2 diffraction peak, whereas no PbI2 peak was observed in the other films with longer loading times (Figure S2a). This demonstrates that the reaction of PbI2 and MAI can be finished in 1 min in IPA. The smaller differences between the UV-vis absorption spectra of those films with loading times of 1–3 min for IPA also demonstrate that the PbI2 film was totally transformed into the MAPbI3 film in 1 min (Figure S3a). The dissolution-crystallization mechanism is responsible for the fast reaction [18]. The PbI2 peak intensity of the film in NHA was gradually decreased with increasing loading time, and totally disappeared at 3 min (Figure S2b). This means that the formation of the PbI2 residue-free perovskite film took 3 min of loading time. The UV-vis absorption spectra of those films showed that the absorption obviously increased at 2 min, and differences decreased between 2 and 3 min in NHA (Figure S3b), which indicated that the formation of MAPbI3 film was completed in 2–3 min. The slower rate of perovskite film generation provides evidence for the in situ transformation mechanism in NHA [27]. In addition, long reaction times (2–3 min) would make a certain amount of PbI2 dissolve in NHA, resulting in the formation of perovskite nanorods/nanoplates.

The corresponding FE-SEM images of the resulting films are presented in Figure S4. For IPA, the number of perovskite nanocuboids increased with loading time from 0 min (Figure S4a) to 1 min (Figure S4b), and the interconnection between nanocuboids became closer. The morphologies of films with 2 min (Figure S4c) and 3 min loading (Figure S4d) are not obviously different from that of 1 min loading, and the films still have incomplete coverage. The final tetragon-shaped morphology (Figure S4a–d) implies the collapse of the lead backbone occurred in the IPA solution with the present 6 mg/mL MAI. This indicates that the growing MAPbI3 crystals followed a dissolution-crystallization step. Notably, the randomly stacked nanocuboids might be responsible for difficulties in obtaining pinhole-free and full-coverage perovskite films from IPA solutions.

For NHA, with 0 min loading time, the film was found to be already full-covered but the grains did not interconnect closely (Figure S4e). The interconnection became increasingly closer with the extension of loading time, and the perovskite films finally became very compact (Figure S4f–h). The applied PbI2 films consisted of unspecific-shaped particles (Figure S5), and the subsequent perovskite grains of the full-covered films were still unspecific-shaped rather than tetragonal. This indicated the dominant growth mechanism was in situ transformation in the NHA solution with the present 6 mg/mL MAI [27]. With the in situ transformation, the MAPbI3 grains grow up in situ to fill the void between the pristine PbI2 particles (Figure S5), resulting in the film easily becoming compact and complete. However, perovskite nanorods grow upon the surface with loading times of 2 min or longer. The reason is that PbI2 is partly soluble in the MAI solution by forming a Pb complex (PbI3− or PbI42−), and the dissolving Pb complex increases with longer loading times so that large and tetragon-shaped MAPbI3 crystals grow on the surfaces of underlying film via the recrystallization step [27,31], i.e.,

Therefore, the in situ transformation mechanism occurred in NHA solution, whereas the dissolution-crystallization mechanism appeared in the IPA solution. It could be concluded that the molecules with a longer alkyl chain gave rise to slower chemical reaction rates. The results might be ascribed to the polarity of NHA being lower than that of IPA due to the different alkyl-chain lengths. Given that PbI2 is a polar molecule, it easily dissolves in the IPA solution, and then forms nanocuboids of MAPbI3. For NHA, the in situ transformation mechanism might bear responsibility for the formation of full-covered film, as the grain gradually grows in situ and maintains the inorganic lead framework (unspecific-shaped PbI2 particles). In other words, the coverage and compactness of the perovskite film could be easily achieved by using a longer-alkyl-chain solvent (i.e., low polar solvent) for MAI.

The morphology of the perovskite MAPbI3 film does not only depend on solvent polarity but also on the MAI concentration. Therefore, the relationship between the concentration of MAI and quality (e.g., compactness and smoothness) of the MAPbI3 film was also studied. The surface morphologies of the various MAPbI3 films obtained from different concentrations of MAI are described in Figure 1 and summarized in Table 1. The obtained perovskite films could be classified into three basic types: (1) incomplete-covered film, (2) compact film roughed with nanorods/nanoplates, and (3) compact and smooth film. All the perovskite films were proved to be PbI2-free by XRD patterns (Figure S6). For IPA, the resulting MAPbI3 films were incomplete-covered (Figure 1a1–d1). With increasing MAI concentrations, the coverage of the perovskite film increased, but the size of the perovskite grains decreased. These findings are in agreement with the literature [1,27]. No perovskite nanorods grew on the surface of films except sporadically on the film obtained from the 12 mg/mL MAI in IPA. For NBA, the perovskite grains growing in 6 mg/mL MAI were observed to still be nanocuboids (Figure 1a2). Although the perovskite film contained a number of pinholes, its coverage was better than that with the IPA solution. The film prepared with 8 mg/mL MAI in NBA became very compact, and no obvious perovskite nanorods were observed (Figure 1b2). Thus, this pinhole-free film was quite smooth. Since the high-quality film consisted of perovskite grains with tetragonal and unspecific morphologies, both dissolution–crystallization and in situ transformation mechanisms worked together with 8 mg/mL MAI in NBA. Perovskite nanorods or nanoplates began to form on the surfaces of two films obtained from 10 and 12 mg/mL MAI in NBA (Figure 1c2,d2). Figure 1a3–d4 shows that the surfaces of all compact films prepared with 6–12 mg/mL in NAA or NHA also contained nanorods or nanoplates. These nanorods/nanoplates grew on the compact film surface through CH3NH3− reacting with the Pb complex (PbI3– or PbI4–) in solutions of MAI, increasing the surface roughness. Figure S7 shows the corresponding atomic force microscope (AFM) images and root mean squares (RMS) of three perovskite films respectively obtained from 6, 8, and 10 mg/mL MAI in NBA, which represented incomplete-covered film, smooth and compact film, and compact film roughed with nanorods/nanoplates, respectively. With the film changing from incomplete to compact, the RMS decreased due to the disappearance of pinholes. Figure S7c indicates that the increase of the RMS originates from the height of nanorods/nanoplates over the compact film surface.

Table 1.

Morphologies of CH3NH3PbI3 (MAPbI3) films obtained from 6–12 mg/mL CH3NH3I (MAI) in four-selected solvents.

| Solvents | Isopropanol (IPA) | n-butyl Alcohol (NBA) | n-amyl Alcohol (NAA) | n-hexyl Alcohol (NHA) | |

|---|---|---|---|---|---|

| Conentration | |||||

| 6 (mg/mL) | Incomplete-covered | Incomplete-covered | compact with nanorods | compact with nanorods | |

| 8 (mg/mL) | Incomplete-covered | compact | compact with nanorods | compact with nanorods | |

| 10 (mg/mL) | Incomplete-covered | compact with nanorods | compact with nanorods and nanoplates | compact with nanorods and nanoplates | |

| 12 (mg/mL) | Incomplete-covered | compact with nanorods and nanoplates | compact with nanorods and nanoplates | compact with nanorods and nanoplates | |

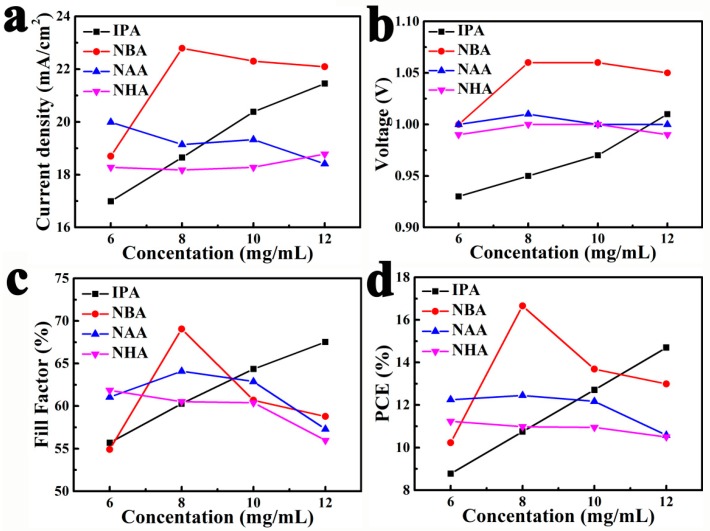

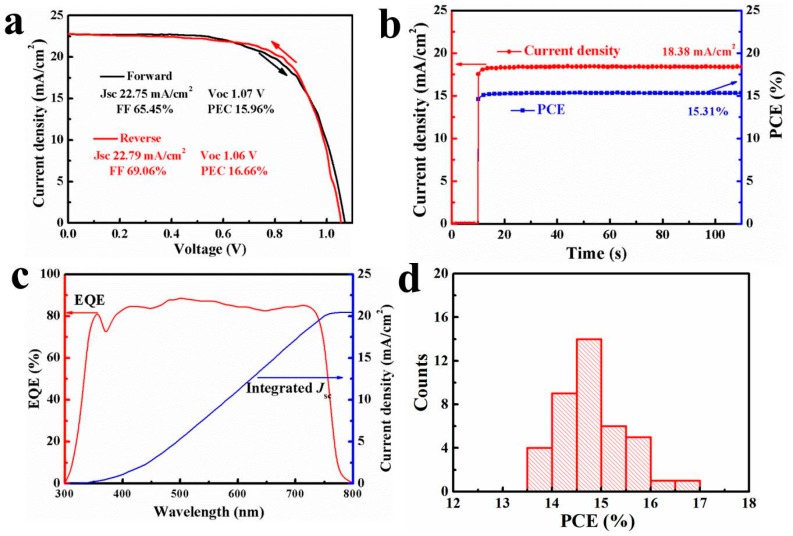

A series of perovskite solar cells were assembled to study the photovoltaic performance of those PbI2 residue-free perovskite films. Figure 2 performs the photovoltaic parameters of the corresponding devices as functions of the MAI concentrations and solvent sorts. Those photovoltaic parameters were obtained from photocurrent density-voltage (I-V) measurements under reverse scan. On one hand, the perovskite solar cells obtained from 6–8 mg/mL MAI in IPA suffered lower Jsc (16–18 mA/cm2) and open-circuit voltage (Voc, 0.93–0.95 V) due to serious recombination. The reason for this is that HTM infiltrated into the incomplete-covered films through the pinholes (Figure 1a1,b1), which increased the contact area between HTM and perovskite. The higher Jsc (20–21 mA/cm2) and Voc (0.97–1.01 V) of the films from 10–12 mg/mL MAI in IPA resulted from the improvement of perovskite film coverage (Figure 1c1,d1). On the other hand, unsatisfactory and slightly different PCEs (range 10–12%) were achieved by those cells obtained from NAA and NHA solutions, resulting from lower Jsc (17–19 mA/cm2) and fill factor (FF, 54–64%). This might be explained by the fact that thick HTM layers were required to completely cover the compact perovskite films with dense nanorods/nanoplates (Figure 1c2–d4 and Figure S7c), which increased the series resistance of devices. A solar cell obtained from an NBA solution of 8 mg/mL MAI (Figure 1b2) achieved promising Jsc (22.79 mA/cm2), Voc (1.06 V), FF (69%), and PCE (16.66%), which is ascribed to the compact and smooth perovskite film without pinholes or nanorods/nanoplates. In addition, it is well known that perovskite solar cells often show an unusual hysteresis in the I-V curves. All perovskite solar cells were measured with both reverse and forward scan directions to estimate their photovoltaic performance. The corresponding detailed parameters and I-V cures are presented in Figure 3a and Supporting Information (Figures S8–S11). Figure 3a shows the I-V curves and detailed parameters of the best-performing solar cell. The reverse scan curve shows the highest PCE (16.66%) and the forward scan curve indicates that the same cell achieved a PCE of 15.96%. The small difference between the two PCEs implies less hysteresis in the device prepared with 8 mg/mL MAI in NBA. In order to further study the performance of the cell under work conditions, the photocurrent density was measured at 0.833 V for 110 s. The stabilized photocurrent density was 18.38 mA/cm2, and a stable high PCE of 15.31% was obtained (Figure 3b). This stable power output efficiency suggests the possibility to prepare efficient and stable perovskite solar cells with 8 mg/mL MAI in NBA.

Figure 2.

Detail parameters and power conversion efficiencies (PCEs) of the cells prepared by using MAPbI3 films obtained from 6–12 mg/mL MAI in IPA, NBA, NAA, or NHA.

Figure 3.

(a) Density-voltage (I–V) cures of the best-performing cell, the voltage scan rate is 50 mV/s (b) Photocurrent density and PCE as a function of time for the same cell under 0.833 V, (c) External quantum efficiency (EQE) spectrum of the best-performing cell, (d) Histograms of PCEs measured for 40 cells prepared by using 8 mg/mL MAI in NBA.

To check the Jsc of the best-performing cell, the external quantum efficiency (EQE) was measured (Figure 3c). The Jsc can be predicted by integrating the EQE spectrum with the incident photo flux density distribution using Equation (1),

| Integrated JSC = ʃ qF(λF(λ)EQ)dλ | (1) |

where q is the electron charge and F(λ) is the incident photon flux density (AM 1.5, ASTM G173) at wavelength λ. The integrated Jsc of the cell was 20.46 mA/cm2, which is close to the value obtained from the I–V measurement (Figure 3a). To investigate the reproducibility of the performance of cells fabricated using 8 mg/mL MAI in NBA, 40 individual devices were measured to obtain the corresponding PCEs. Statistical analysis of these PCEs showed an average value of 14.76% with a small standard deviation of 0.67% for all 40 cells (Figure 3d).

4. Conclusions

It was demonstrated that the solvent significantly affects the growth mechanism of perovskite grains. The morphology of perovskite films was controlled by manipulating the solvent polarity and concentration of MAI solutions. The use of solvents with long alkyl-chain molecule (i.e., low polarity solvent) allowed the MAPbI3 to grow via an in situ transformation step, which easily made the perovskite films compact, but increased the surface roughness due to the growth of unexpected nanorods/nanoplates. Using the solvent with a short alkyl chain (i.e., high polarity solvent) led to the dissolution-crystallization growth mechanism, resulting in rapidly generation of perovskite films with smooth surface, but with a number of pinholes. The best quality (highly compact, pinhole-free, and smooth) perovskite films were fabricated with an optimized MAI concentration of 8 mg/mL and NBA as the solvent, where both growth mechanisms worked together. The corresponding perovskite solar cell achieved a promising PCE of 16.66% and average PCE of 14.76% (for 40 cells). The present work may give some clues to other groups to further investigate the mechanisms of perovskite grain growth and prepare high-quality perovskite film through simple methods.

Supplementary Materials

Supplementary materials are available online at http://www.mdpi.com/2079-4991/8/11/897/s1.

Author Contributions

L.C. performed the experiments and wrote the paper. H.Z. carried out UV-vis spectrometer measurements. J.Z. and Y.Z. contributed the idea of the paper and analyzed the experimental results. All authors read and agreed to the final version for publication.

Funding

This research was funded by National Natural Science Foundation of China (No. 51802029), Scientific Research Fund of Hunan Provincial Education Department (No. 17B028), Natural Science Foundation of Hunan Province, China (No. 2017JJ3343) and the Initial Founding of Scientific Research for The Introduction of Talents of Changsha University (No. SF1606). Project of Changsha bureau of science and technology (No. k1705062). NSF of Jiangsu Province (Nos. BK20160412 and BK20130425).

Conflicts of Interest

The authors declare no conflict of interest.

References

- 1.Green M.A., Ho-Baillie A., Snaith H.J. The emergence of perovskite solar cells. Nat. Photonics. 2014;8:506. doi: 10.1038/nphoton.2014.134. [DOI] [Google Scholar]

- 2.Zhou H., Chen Q., Li G., Luo S., Song T.-B., Duan H.-S., Hong Z., You J., Liu Y., Yang Y. Interface engineering of highly efficient perovskite solar cells. Science. 2014;345:542. doi: 10.1126/science.1254050. [DOI] [PubMed] [Google Scholar]

- 3.Yang W.S., Noh J.H., Jeon N.J., Kim Y.C., Ryu S., Seo J., Seok S.I. High-performance photovoltaic perovskite layers fabricated through intramolecular exchange. Science. 2015;348:1234. doi: 10.1126/science.aaa9272. [DOI] [PubMed] [Google Scholar]

- 4.Mei A., Li X., Liu L., Ku Z., Liu T., Rong Y., Xu M., Hu M., Chen J., Yang Y., et al. A hole-conductor–free, fully printable mesoscopic perovskite solar cell with high stability. Science. 2014;345:295. doi: 10.1126/science.1254763. [DOI] [PubMed] [Google Scholar]

- 5.Jeon N.J., Noh J.H., Yang W.S., Kim Y.C., Ryu S., Seo J., Seok S.I. Compositional engineering of perovskite materials for high-performance solar cells. Nature. 2015;517:476. doi: 10.1038/nature14133. [DOI] [PubMed] [Google Scholar]

- 6.Im J.-H., Jang I.-H., Pellet N., Grätzel M., Park N.-G. Growth of CH3NH3PbI3 cuboids with controlled size for high-efficiency perovskite solar cells. Nat. Nanotechnol. 2014;9:927. doi: 10.1038/nnano.2014.181. [DOI] [PubMed] [Google Scholar]

- 7.Burschka J., Pellet N., Moon S.-J., Humphry-Baker R., Gao P., Nazeeruddin M.K., Grätzel M. Sequential deposition as a route to high-performance perovskite-sensitized solar cells. Nature. 2013;499:316. doi: 10.1038/nature12340. [DOI] [PubMed] [Google Scholar]

- 8.Saliba M., Matsui T., Seo J.-Y., Domanski K., Correa-Baena J.-P., Nazeeruddin M.K., Zakeeruddin S.M., Tress W., Abate A., Hagfeldt A., et al. Cesium-containing triple cation perovskite solar cells: improved stability, reproducibility and high efficiency. Energy Environ. Sci. 2016;9:1989–1997. doi: 10.1039/C5EE03874J. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Yang W.S., Park B.-W., Jung E.H., Jeon N.J., Kim Y.C., Lee D.U., Shin S.S., Seo J., Kim E.K., Noh J.H., et al. Iodide management in formamidinium-lead-halide-based perovskite layers for efficient solar cells. Science. 2017;356:1376. doi: 10.1126/science.aan2301. [DOI] [PubMed] [Google Scholar]

- 10.Kim Y.Y., Park E.Y., Yang T.-Y., Noh J.H., Shin T.J., Jeon N.J., Seo J. Fast two-step deposition of perovskite via mediator extraction treatment for large-area, high-performance perovskite solar cells. J. Mater. Chem. A. 2018;6:12447–12454. doi: 10.1039/C8TA02868K. [DOI] [Google Scholar]

- 11.Shabdan E., Hanford B., Ilyassov B., Dikhanbayev K., Nuraje N. Multifunctional Nanocomposites for Energy and Environmental Applications. Volume 1. John Wiley & Sons, Inc.; Hoboken, NJ, USA: 2018. Perovskite Solar Cell; pp. 91–111. [DOI] [Google Scholar]

- 12.Tsai H., Asadpour R., Blancon J.-C., Stoumpos C.C., Durand O., Strzalka J.W., Chen B., Verduzco R., Ajayan P.M., Tretiak S., et al. Light-induced lattice expansion leads to high-efficiency perovskite solar cells. Science. 2018;360:67. doi: 10.1126/science.aap8671. [DOI] [PubMed] [Google Scholar]

- 13.Zhang Y., Kim S.-G., Lee D.-K., Park N.-G. CH3NH3PbI3 and HC(NH2)2PbI3 Powders Synthesized from Low-Grade PbI2: Single Precursor for High-Efficiency Perovskite Solar Cells. ChemSusChem. 2018;11:1813–1823. doi: 10.1002/cssc.201800610. [DOI] [PubMed] [Google Scholar]

- 14.Bai Y., Meng X., Yang S. Interface Engineering for Highly Efficient and Stable Planar p-i-n Perovskite Solar Cells. Adv. Energy Mater. 2017;8:1701883. doi: 10.1002/aenm.201701883. [DOI] [Google Scholar]

- 15.Luo D., Yang W., Wang Z., Sadhanala A., Hu Q., Su R., Shivanna R., Trindade G.F., Watts J.F., Xu Z., et al. Enhanced photovoltage for inverted planar heterojunction perovskite solar cells. Science. 2018;360:1442. doi: 10.1126/science.aap9282. [DOI] [PubMed] [Google Scholar]

- 16.Rajagopal A., Yao K., Jen A.K.Y. Toward Perovskite Solar Cell Commercialization: A Perspective and Research Roadmap Based on Interfacial Engineering. Adv. Mater. 2018;30:1800455. doi: 10.1002/adma.201800455. [DOI] [PubMed] [Google Scholar]

- 17.Singh T., Miyasaka T. Stabilizing the Efficiency Beyond 20% with a Mixed Cation Perovskite Solar Cell Fabricated in Ambient Air under Controlled Humidity. Adv. Energy Mater. 2017;8:1700677. doi: 10.1002/aenm.201700677. [DOI] [Google Scholar]

- 18.Turren-Cruz S.-H., Saliba M., Mayer M.T., Juárez-Santiesteban H., Mathew X., Nienhaus L., Tress W., Erodici M.P., Sher M.-J., Bawendi M.G., et al. Enhanced charge carrier mobility and lifetime suppress hysteresis and improve efficiency in planar perovskite solar cells. Energy Environ. Sci. 2018;11:78–86. doi: 10.1039/C7EE02901B. [DOI] [Google Scholar]

- 19.Zhang T., Yang M., Zhao Y., Zhu K. Controllable Sequential Deposition of Planar CH3NH3PbI3 Perovskite Films via Adjustable Volume Expansion. Nano Lett. 2015;15:3959–3963. doi: 10.1021/acs.nanolett.5b00843. [DOI] [PubMed] [Google Scholar]

- 20.Wu C.-G., Chiang C.-H., Tseng Z.-L., Nazeeruddin M.K., Hagfeldt A., Grätzel M. High efficiency stable inverted perovskite solar cells without current hysteresis. Energy Environ Sci. 2015;8:2725–2733. doi: 10.1039/C5EE00645G. [DOI] [Google Scholar]

- 21.Li W., Fan J., Li J., Mai Y., Wang L. Controllable Grain Morphology of Perovskite Absorber Film by Molecular Self-Assembly toward Efficient Solar Cell Exceeding 17% J. Am. Chem. Soc. 2015;137:10399–10405. doi: 10.1021/jacs.5b06444. [DOI] [PubMed] [Google Scholar]

- 22.Li G., Ching K.L., Ho J.Y.L., Wong M., Kwok H.-S. Identifying the Optimum Morphology in High-Performance Perovskite Solar Cells. Adv. Energy Mater. 2015;5:1401775. doi: 10.1002/aenm.201401775. [DOI] [Google Scholar]

- 23.Zhang H., Mao J., He H., Zhang D., Zhu H.L., Xie F., Wong K.S., Grätzel M., Choy W.C.H. A Smooth CH3NH3PbI3 Film via a New Approach for Forming the PbI2 Nanostructure Together with Strategically High CH3NH3I Concentration for High Efficient Planar-Heterojunction Solar Cells. Adv. Energy Mater. 2015;5:1501354. doi: 10.1002/aenm.201501354. [DOI] [Google Scholar]

- 24.Eperon G.E., Burlakov V.M., Docampo P., Goriely A., Snaith H.J. Morphological Control for High Performance, Solution-Processed Planar Heterojunction Perovskite Solar Cells. Adv. Funct. Mater. 2013;24:151–157. doi: 10.1002/adfm.201302090. [DOI] [Google Scholar]

- 25.Wu Y., Islam A., Yang X., Qin C., Liu J., Zhang K., Peng W., Han L. Retarding the crystallization of PbI2 for highly reproducible planar-structured perovskite solar cells via sequential deposition. Energy Environ. Sci. 2014;7:2934–2938. doi: 10.1039/C4EE01624F. [DOI] [Google Scholar]

- 26.Zhao Y., Zhu K. Solution Chemistry Engineering toward High-Efficiency Perovskite Solar Cells. J. Phys. Chem. Lett. 2014;5:4175–4186. doi: 10.1021/jz501983v. [DOI] [PubMed] [Google Scholar]

- 27.Yang S., Zheng Y.C., Hou Y., Chen X., Chen Y., Wang Y., Zhao H., Yang H.G. Formation Mechanism of Freestanding CH3NH3PbI3 Functional Crystals: In Situ Transformation vs. Dissolution-Crystallization. Chem. Mater. 2014;26:6705–6710. doi: 10.1021/cm5028817. [DOI] [Google Scholar]

- 28.Xiao M., Huang F., Huang W., Dkhissi Y., Zhu Y., Etheridge J., Gray-Weale A., Bach U., Cheng Y.-B., Spiccia L. A Fast Deposition-Crystallization Procedure for Highly Efficient Lead Iodide Perovskite Thin-Film Solar Cells. Angew. Chem. Int. Ed. 2014;53:9898–9903. doi: 10.1002/anie.201405334. [DOI] [PubMed] [Google Scholar]

- 29.Ahn N., Son D.-Y., Jang I.-H., Kang S.M., Choi M., Park N.-G. Highly Reproducible Perovskite Solar Cells with Average Efficiency of 18.3% and Best Efficiency of 19.7% Fabricated via Lewis Base Adduct of Lead(II) Iodide. J. Am. Chem. Soc. 2015;137:8696–8699. doi: 10.1021/jacs.5b04930. [DOI] [PubMed] [Google Scholar]

- 30.Chen C.-W., Kang H.-W., Hsiao S.-Y., Yang P.-F., Chiang K.-M., Lin H.-W. Efficient and Uniform Planar-Type Perovskite Solar Cells by Simple Sequential Vacuum Deposition. Adv. Mater. 2014;26:6647–6652. doi: 10.1002/adma.201402461. [DOI] [PubMed] [Google Scholar]

- 31.Zheng E., Wang X.-F., Song J., Yan L., Tian W., Miyasaka T. PbI2-Based Dipping-Controlled Material Conversion for Compact Layer Free Perovskite Solar Cells. ACS Appl. Mater. Int. 2015;7:18156–18162. doi: 10.1021/acsami.5b05787. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.