Table 3.

Synthetic results of mechanochemical CuAAC a.

| Entry | Alkyne | Azide | Product | Yield b % (Conv. c) |

|---|---|---|---|---|

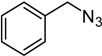

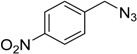

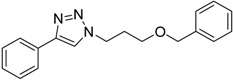

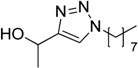

| 1 d | 2a |

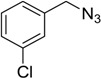

1b |

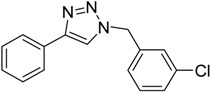

3b |

98 (>99) |

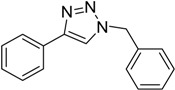

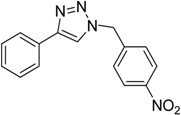

| 2 d | 2a |

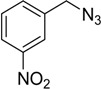

1c |

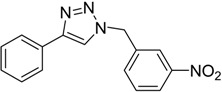

3c |

97 (>99) |

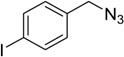

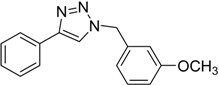

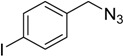

| 3 | 2a |

1d |

3d |

95 (>99) |

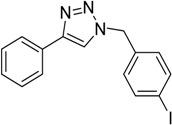

| 4 d | 2a |

1e |

3e |

91 (95) |

| 4 d | 2a |

1f |

3f |

94 (97) |

| 5 d | 2a |

1g |

3g |

97 (>99) |

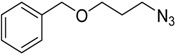

| 6 | 2a |

1h |

3h |

90 (92) |

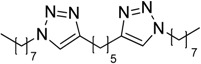

| 7 d |

2b |

1i |

3i |

98 (>99) |

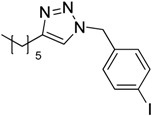

| 8 |

2c |

1a |

3j |

92 (96) |

| 9 |

2d |

1a |

3k |

88 (91) |

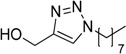

| 10 e |

2e |

1a |

3l |

98 (>99) |

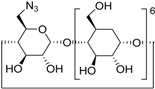

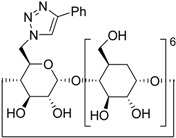

| 11 f | 2a |

1j |

3m |

81 |

a: Reaction conditions: azide 1 (1 mmol), alkyne 2 (1 mmol), Cu powder (1 mmol), 5 min, 650 rpm; stainless steel jar (50 mL), 1500 small balls and 48 medium balls; b: Isolated yield, compound purity proved by 1H-NMR and 13C-NMR (see Supporting Info); c: Determined by GC-MS; d: Reaction time 10 min; e: Excess 1a (2 mmol); f: Reaction condition: 0.1 mmol 1j (6-monoazido-β-CD) (0.1 mmol), 2a (0.5 mmol), Cu powder (0.1 mmol), 30 min.