Abstract

This study aimed to produce and characterize an oil in water (O/W) nanoemulsion containing Opuntia ficus-indica (L.) Mill hydroglycolic extract, as well as evaluate its preliminary and accelerated thermal stability and moisturizing efficacy. The formulations containing 0.5% of xanthan gum (FX) and 0.5% of xanthan gum and 1% of Opuntia ficus-indica MILL extract (FXE) were white, homogeneus and fluid in aspect. Both formulations were stable during preliminary and accelerated stability tests. FX and FXE presented a pH compatible to skin pH (4.5–6.0); droplet size varying from 92.2 to 233.6 nm; a polydispersion index (PDI) around 0.200 and a zeta potential from −26.71 to −47.01 mV. FXE was able to increase the water content of the stratum corneum for 5 h after application on the forearm. The O/W nanoemulsions containing 1% of Opuntia ficus-indica (L.) Mill extract presented suitable stability for at least for 60 days. Besides, this formulation was able to increase the water content of stratum corneum, showing its moisturizing efficacy.

Keywords: nanoemulsions, Opuntia ficus-indica, non-invasive methods, emulsions, formulation/stability, skin barrier

1. Introduction

Emulsions are a dispersion of an immiscible liquid into another stabilized by the presence of a third compound: the surfactant [1]. Among these formulations we can highlight a class of emulsions called nanoemulsions, characterized by their small particle size (50–500 nm) [2]. Nanoemulsions are thermodynamically unstable and kinetically stable systems [3]. The very small droplet size can reduce the occurrence of creaming, sedimentation and flocculation during storage. This happens due to the capacity of Brownian motion to reduce the force of gravity [4]. Ostwald ripening is the main instability process on nanoemulsions, because the small droplet size results in a higher driving force (Laplace pressure) [5,6]. The preparation method is very important for the formation and stability of nanoemulsions [7,8,9]. These systems can be prepared by high or low emulsification energy methods [10]. High-energy approaches utilize mechanical devices (microfluidizers, high pressure homogenizers or ultrasonic methods) that generate intense forces capable of forming very fine oil droplets. Low energy methods involve complex interfacial hydrodynamic phenomena and depend on the system composition properties [11].

Nanoemulsions are attractive systems for use in the cosmetics, pharmaceutical, food and other industries due to their low amount of surfactant, higher stability against coalescence, lack of toxicity or irritant characteristics, low viscosity, good appearance, and versatility of formulation as foams, creams, liquids and sprays [7,12]. Nanoemulsions are particularly useful systems for cosmetics because the small droplet size ensures a closer contact with the stratum corneum (SC), increasing the amount of active compound reaching the desired site of action. Besides, nanoemulsions can carry actives into the skin improving the skin layer penetration, thus enhancing efficacy [13].

The human skin has an important function providing a barrier between the internal contents of the organism and the external physical, chemical, and biological environment. This barrier protects against hazardous microorganisms, toxic chemicals, ultraviolet radiation and water loss [14].

Dry skin is a common problem among the population. Its main characteristic is a rough appearance and peeling, a phenomenon called xerosis. The barrier function and maintenance of the water content are dependent on the SC that provides mechanical protection and acts against water loss and the passage of external solutes. Changes in the stacking of corneocytes and delipidation are causes of cutaneous dryness leading to decreased skin flexibility and harming the skin’s protective barrier [15].

Moisturizers are one of the most important classes of cosmetic products due to their preventive action against xerosis and delaying of premature ageing and for their use to help dermatological therapies in a wide variety of skin disorders [16]. Moisturizers may act by an occlusive mechanism, impairing evaporation of skin moisture by forming an epicutaneous lipidic film that prevents water loss, as is the case with oils and lipids; or as humectants, i.e., glycerin, urea, sodium pyrrolidone carboxylic acid; which act by attracting water from the other layers of the epidermis to the stratum corneum [17]. Another two moisturizing mechanism are active hydration by rearranging the stratum corneum and aquaporin formation. The aquaporins are transmembrane proteins which form water channels and facilitate water flux through the cell plasma membrane thus being important to maintain a constant water content in viable epidermis [18,19].

Herbal products have gained increase popularity and the sales of herbal cosmetics are expanding nowadays [20]. Opuntia ficus-indica (L.) Mill is a plant that grows in arid areas. The semiarid region accounts for 12% of the extension of Brazil, where the Caatinga biome, an exclusively Brazilian bioma, prevails [21]. This plant has a huge socioeconomic importance to the semiarid region [22,23]. Its cladodes are mainly composed by water (80%–95%) and carbohydrates (3%–7%) [22]. Phenolic components (kaempherol and quercetin) and carbohydrates (galacturonic acid, glucose, rhamnose and arabinose) are some of the substances present in the chemical composition of Opuntia ficus-indica (L.) Mill and the cosmetic industry has interest in these substances as moisturizers and anti-aging products [24,25,26].

The aim this research was to produce and characterize an oil in water (O/W) nanoemulsion containing Opuntia ficus-indica (L.) Mill hydroglycolic extract, as well as evaluate its thermal stability and its moisturizing efficacy.

2. Results and Discussion

2.1. Nanoemulsion Formulations

Many variables are important when formulating a cosmetic product. The choice of emollients needs attention because their physico-chemical properties like molecular weight, chain length and polarity will affect sensorial properties like spreadability, final cosmetic sensorial properties and oleosity [27]. Caprylic/Capric Triglyceride, Ethylhexyl Palmitate and C12–15 Alkyl Benzoate were chosen due to their sensory and skin conditioning properties, and also for their dry and non-greasy touch.

The type of emulsion formed (W/O or O/W) is mainly dependent on the surfactant system used in the emulsification process, and the amount of each phase that could influence this process to form a nanoemulsion [28]. Nanoemulsions are formulations with high water content [29], so we tested formulations with water contents varying from 50% to 92%. Shakeel et al. [30] and Teo et al. [31] state that a high percentage of surfactant content may cause skin irritation. Sevcíková et al. [32] obtained nanoemulsions by varying the surfactant level between 3.0% to 5.0%, but they suggested that it is possible to obtain nanoemulsions using 1.5% to 10% of surfactant, what justifies the variation of surfactant concentration from 3% to 10% in our study [32].

All emulsions prepared were white, homogeneous and had a fluid aspect. With the aim of choosing the best formulation samples were submitted to centrifugation and high temperature exposure one day (24 h) after preparation of the nanoemulsions, as these are the most used stress situations to quickly evaluate the stability of an emulsion [33,34].

Emulsions were considered stable since no creaming, flocculation or phase separation were observed during the available time [35]. Samples F2, F3 and F4 showed some modification 24 h after preparation and phase separation happened five days later at 45 °C and 75% ± 5% relative humidity (RH). Samples F5, F6, F7 and F8 remained normal after 24 h, but showed some modifications after centrifugation and/or five days at 45 °C. After all tests, sample F1 showed a homogeneous and fluid aspect with a slightly bluish-white color, which can be caused by the Tyndall effect, typical of nanoemulsions, and was the only sample that showed no modifications.

The use of high molecular weight polymers, that are shear thinning (pseudoplastic) and give a very high viscosity at low shear rates, is one of most common procedures for reducing instability phenomena in the continuous phase [36]. Xanthan gum was thus added to the water phase to increase the stability of nanoemulsions and decrease the degree of nanoparticle aggregation [37]. The addition of xanthan gum to F1 (FX) resulted in a system presenting white color, homogeneous and with a fluid aspect, but presenting higher consistency.

The obtained extract presented a viscous and clear liquid appearance with a greenish-yellow color and characteristic odor as described by Dasmasceno [24]. FX (a formulation with 0.5% of Xanthan Gum) and FXE (a formulation with 0.5% of Xanthan Gum and 1% of Opuntia ficus-indica MILL extract) were submitted to preliminary and accelerated stability tests. The addition of extract to the aqueous phase did not change the macroscopic aspect of the formulations.

2.2. Preliminary Stability Tests

Stability tests are necessary due to their predictive capacity. For that, formulations are submitted to situations aimed to accelerate changes that may occur under market conditions. Results of stability tests are not absolute, but have a good probability of success [38].

Both formulations (FX and FXE) remained homogenous after 3000 rpm centrifugation, with a white color and macroscopic homogeneity, as shown in Table 1. The absence of phase separation is a positive factor in the stability evaluation, seeing that when phase separation occurs all characteristics of emulsions are affected [39]. Phase separation occurred at temperatures over 60 °C during thermal stress. This result shows the instability of these nanoemulsions on high temperatures. Komaiko and McClements [40] obtained nanoemulsions by spontaneous emulsification and by the phase inversion method, using non-ionic surfactants, and observed instability at high temperatures too, concluding that nanoemulsions produced by low energy methods and with these non-ionic surfactants are likely to be thermally sensitive due to the properties of the surfactants [40].

Table 1.

Results of preliminary stability tests of nanoemulsions with and without Opuntia ficus-indica (L.) Mill extract.

| Parameters | FX | FXE |

|---|---|---|

| After 24 h | ||

| Centrifugation | N | N |

| pH value | 5.62 ± 0.04 | 5.53 ± 0.02 |

| Electrical conductivity (µS/cm) | 676.0 ± 3.0 * | 689.4 ± 4.7 * |

| Droplet size (nm) | 142.6 ± 2.3 * | 139.1 ± 2.8 * |

| PDI | 0.26 ± 0.01 | 0.23 ± 0.01 |

| Zeta potential (mV) | −38.10 ± 1.69 * | −42.98 ± 0.88 |

| After TS | ||

| pH value | N/A | N/A |

| Electrical conductivity (µS/cm) | N/A | N/A |

| Droplet size (nm) | N/A | N/A |

| PDI | N/A | N/A |

| Zeta potential (mV) | N/A | N/A |

| After FDC | ||

| pH value | 5.55 ± 0.05 | 5.49 ± 0.01 |

| Electrical conductivity (µS/cm) | 457.7 ± 33.6 * | 510.7 ± 3.1 * |

| Droplet size (nm) | 160.6 ± 3.3 * | 148.8 ± 1.6 * |

| PDI | 0.21 ± 0.02 | 0.26 ± 0.01 |

| Zeta potential (mV) | −47.01 ± 1.64 * | −42.58 ± 0.99 |

Notes: FDC = Freeze-Defrost Cycles; TS = Thermal Stress; N = Normal; N/A = Not evaluated, PDI = Polidispersion Index; FX = Sample containing 0.5% Xanthan Gum; FXE = Sample containing to 0.5% Xantham Gum and 1% Opuntia ficus-indica extract. * p < 0.05 compared to the initial time.

After freeze-defrost cycles, nanoemulsions showed a homogeneous aspect. FX samples presented a pH value about 5.50 ± 0.05 and FXE 5.49 ± 0.01, which were not statistically different (p < 0.05) from the values measured before the cycles (Table 1). These pH values are suitable for skin care products, where values should be between 4.5–6.0 [41], therefore, these nanoemulsions were considered suitable for use.

Determination of electrical conductivity is the most common procedure to investigate phase inversion. When this process occurs on an O/W emulsion, the conductivity decreases strongly [36]. This parameter helps to identify the type of nanoemulsions because large conductivity values, like values obtained in our study, characterize O/W nanoemulsions [42]. Conductivity values decreased for both formulations, as described in Table 1. Bernardi et al. [43] observed conductivity changes in nanoemulsions but considered the samples stable due to the absence of signs of macroscopic destabilization of the systems. It is reported that it is difficult to assess the stability only using conductivity as there is no linear relation between this parameter and the instability process [43].

It is known that the smaller the droplet size is the better emulsion stability is. This happens because Brownian motion becomes more significant than the force of gravity [44,45]. Determination of particle size and zeta potential are the most common methods employed to assess the stability of nanoemulsions, because particle size interferes with flocculation and coalescence phenomena [7]. Particle size is an important parameter to define application and stability. The droplet size showed a slight increase after the end of the cycles (12th day) as demonstrated in Table 1, however, droplet radius remained below the 100 nm size that characterizes a nanoemulsion according to McClements [3].

A lower PDI value (near zero) indicates a monodisperse droplet population, whereas a PDI value closer to 1 (one) indicates a wide range of droplet sizes [46]. Despite the fact the droplet size slightly increased after this test, the PDI value remained around 0.2, indicating the homogeneity of the droplet population in both formulations.

A zeta potential value between |−25 mV| and |−30 mV| is already enough to create an energy barrier between the droplets thus avoiding coalescence [47]. Maruno and Rocha-Filho [48] found significant negative zeta potentials using nonionic surfactants, and associated this phenomenon with some chemical properties of the polyoxyethylene chains in the surfactants used [49]. The zeta potentials of the formulations prepared were above −30 mV before and after the test for both formulations, so the formulations were considered stable enough for the accelerated stability tests.

2.3. Accelerated Stability Tests

In the development of a cosmetic product, it is important to consider the appearance of the formulation, physical properties and stability [33,50]. At 25 °C and 45 °C, there was a statistically significant (p < 0.05) decrease of the pH value. According to Gallarate [51] this change could be associated with degradation of some oil phase components yielding free fatty acids (Table 2). Despite this statistically significant change of pH values, they remained in the ideal range of the skin (between 4.5–6.0) ensuring the stability of formulations, and this pH change did not modify their visual aspect. Bernardi et al. [43] observed a decrease of pH values of O/W nanoemulsions containing rice bran oil after storage at 40 ± 2 °C for 90 days and associated that fact to a probable hydrolysis process caused by temperature, but pH values also remained in an acceptable range for the skin in that study [43].

Table 2.

Results of accelerated stability tests of nanoemulsions with and without Opuntia ficus-indica (L.) Mill extract.

| FX | FXE | |||||||

|---|---|---|---|---|---|---|---|---|

| Initial 24 h | After 60 Days | Initial 24 h | After 60 Days | |||||

| 4 °C | 25 °C | 45 °C | 4 °C | 25 °C | 45 °C | |||

| Macroscopic characteristics | N | N | N | N | N | N | N | N |

| pH | 5.67 ± 0.03 | 5.68 ± 0.03 | 5.62 ± 0.03 * | 5.42 ± 0.02 * | 5.62 ± 0.02 | 5.63 ± 0.02 | 5.56 ± 0.02 * | 5.32 ± 0.21 * |

| Particle size (nm) | 126.3 ± 5.9 | 136.5 ± 10.8 | 185.9 ± 52.4 * | 117.9 ± 8.8 | 119.0 ± 7.4 | 121.6 ± 8.8 | 233.6 ± 30.1 * | 92.17 ± 6.1 * |

| PDI | 0.264 ± 0.030 | 0.231 ± 0.071 | 0.349 ± 0.052 | 0.260 ± 0.020 | 0.257 ± 0.038 | 0.251 ± 0.020 | 0.305 ± 0.126 | 0.228 ± 0.044 |

| Zeta potential (mV) | −28.60 ± 10.33 | −44.35 ± 4.07 * | −36.53 ± 12.94 | −43.28 ± 4.72 * | −26.71 ± 6.67 | −41.71 ± 4.55 * | −39.77 ± 5.99 * | −41.21 ± 6.02 * |

Notes: * p-valor < 0.05; N—Normal; PDI—Polydispersion index; FX is the formulation with 0.5% Xanthan Gum; FXE is the formulation with 0.5% Xanthan Gum and 1% of Opuntia ficus-indica L. Mill extract.

It is very important that nanoemulsions remain physically stable throughout their shelf life, and for that no or a minimal change in the particle size distribution is necessary [11]. The emulsion stability is closely related to the droplet size distribution. A large droplet size may enhance Ostwald ripening what makes droplet size increase and can lead to coalescence and creaming [50].

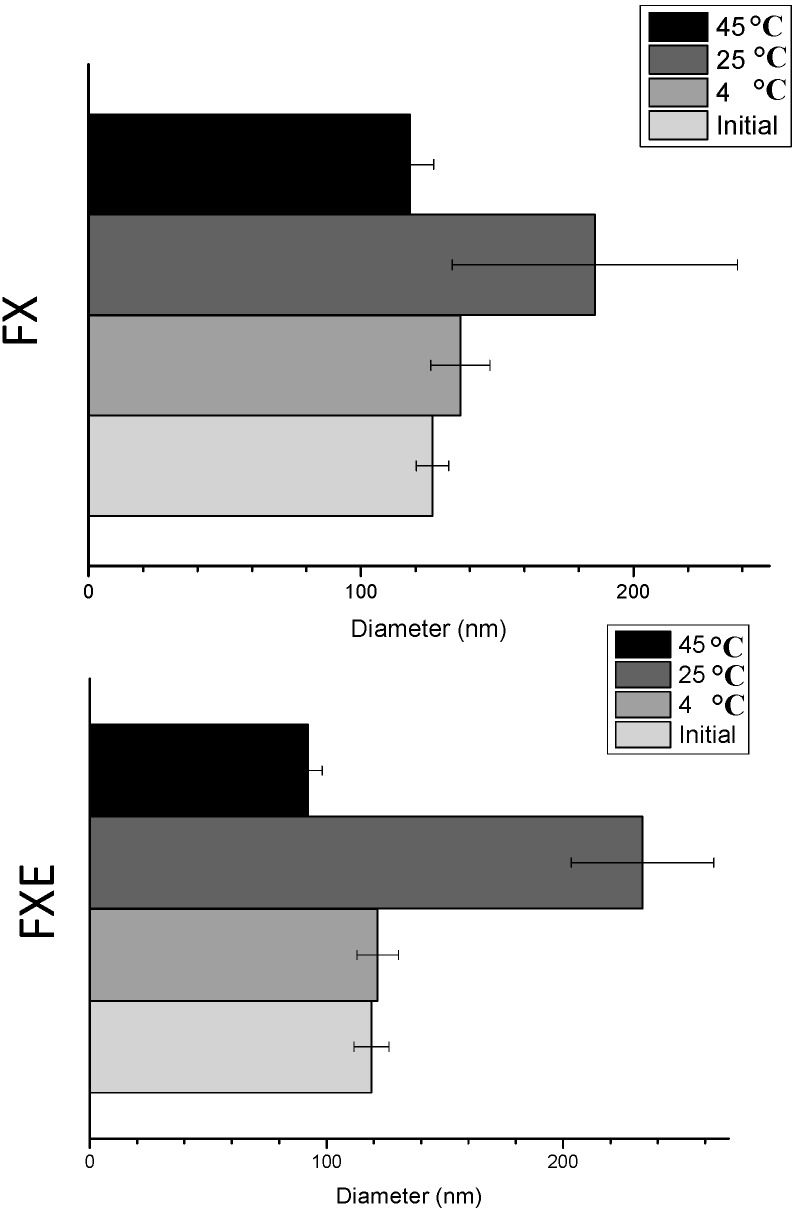

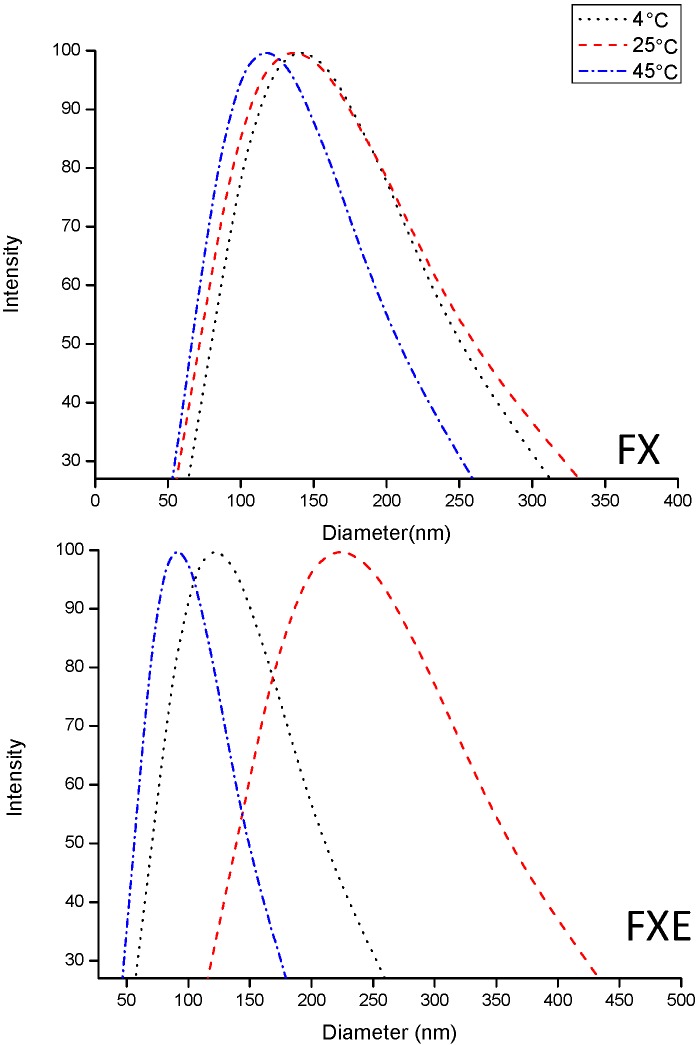

The relation between storage temperature and emulsion stability is well known. Samples stored at 4 °C maintained the same droplet size until the end of 60 days (Table 2, Figure 1). Ševčíková et al. [28] also reported better results for samples stored at 4 °C at which minimal particle size changes happen, compared to samples stored at higher temperatures [28]. Samples stored at 45 °C (except FX) and 25 °C showed significant changes in particle size after 60 days (Figure 1 and Figure 2). Despite these changes, the nanoemulsions did not show any macroscopic instability processes and their particle size remained in the nanoscale range, taking into account that the droplet size range of nanoemulsions is 100–500 nm [4]. Like in our study, Ševčíková et al. [32] produced stable nanoemulsions in which an increase in droplet size from 140 nm (25th day) to 250 nm (28th day) at 25 °C storage temperature was observed.

Figure 1.

Droplet size graphic of accelerated stability tests of nanoemulsions with and without Opuntia ficus-indica (L.) Mill extract.

Figure 2.

Dynamic Light Scattering (DLS) size distribution of stable samples (FX and FXE) after 60 days.

PDI values varied from 0.228 to 0.349 showing no statistically significant (p < 0.05) difference (Table 2). Changes in particle size but not in PDI also happened in other studies as found by Saberi, Fang and McClements [6].

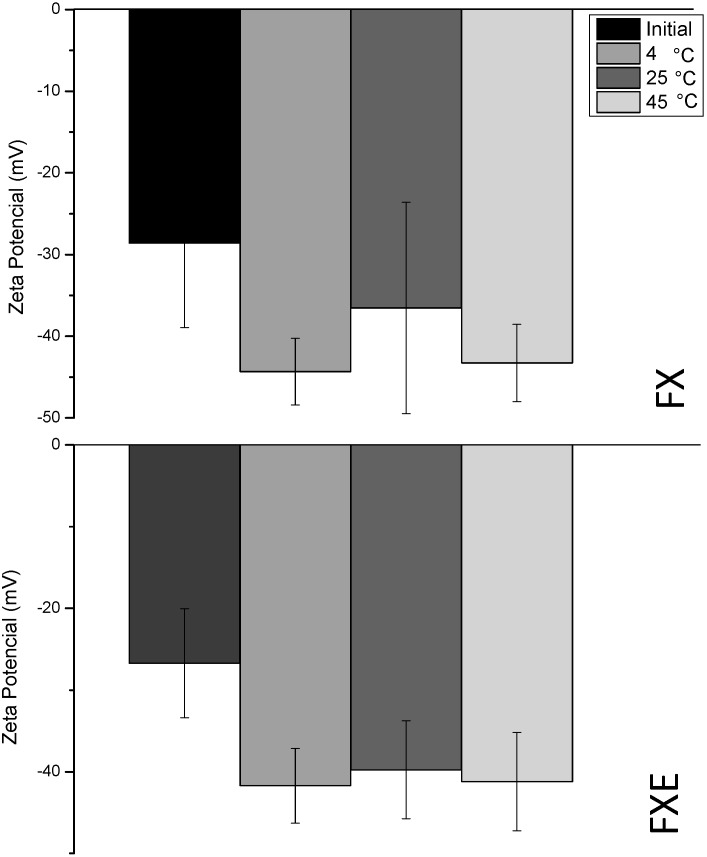

Zeta potential values were |−26.7 mV| and |−28.6 mV| for FX and FXE in the initial measurement, respectively (Table 2, Figure 3). During the storage, zeta potential increased, in modulus, with the accommodation and stabilization of the system. After 60 days this parameter was close to |−40 mV| which indicates good physical stability of the dispersed systems, because high zeta potential values ensure repulsion of droplets [36,52]. Bazylińska et al. [53] observed zeta potential values to range between |−42 mV| and |+47 mV| in anionic and cationic kinetically stable nanoemulsions and attributed that stability to these high values of zeta potential, because this parameter is responsible for the stability of colloidal dispersions and indicates the degree of repulsion between similarly charged particles in the dispersion. Decreases in zeta values are related to a greater flocculation tendency, which was not the case of the nanoemulsions in this study [49].

Figure 3.

Zeta potential graphic of accelerated stability tests of nanoemulsions with and without Opuntia ficus-indica (L.) Mill extract.

The FX and FXE samples were considered stable because they remained inside acceptable parameters, what means inside the nanoscale droplet size range and macroscopically stable.

2.4. Evaluation of in Vivo Moisturizing Properties

Moisturizing products are evaluated by the increase of water content in the stratum corneum and by the decrease in TEWL. SC hydration measurements are widely employed to verify the moisturizing effects of topical products [54]. The measurement of skin hydration using the Corneometer® CM 825 (Courage & Khazaka Electronic GmbH, Köln, Germany) is based on the capacitance effect. The dry SC is a dielectric medium and its dielectric properties change with changes in moisture content [55].

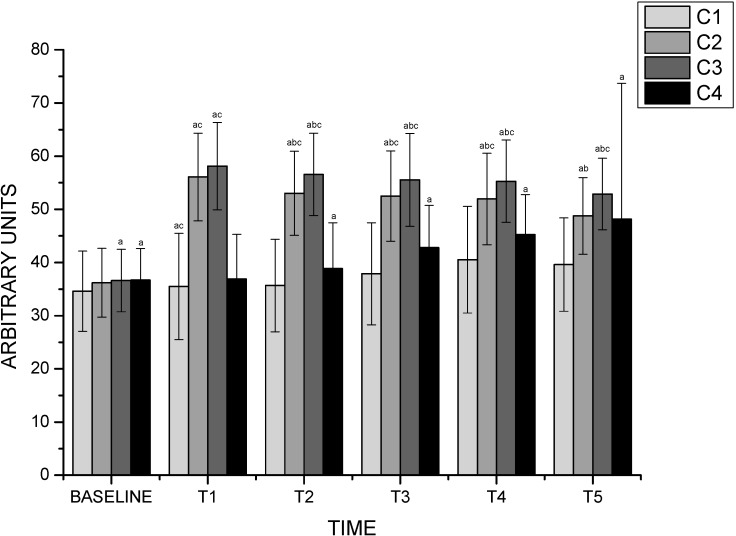

A moisturizer product prevents SC dehydration when the environmental humidity reaches very low values. When the water content is adequate, the skin maintains its barrier function, flexibility and healthy appearance [54]. At the beginning of analysis (basal), the mean volunteer hydration was under 40 arbitrary units. This profile is related to a dry skin according to the standard scale of this equipment [55]. Our results show a statistically significant increase (p < 0.05) of skin hydration after the application of our formulation on the skin and this effect lasted for 5 h (Figure 4).

Figure 4.

Water content values of the stratum corneum measured by Corneometer® CM 825 before and after 1, 2, 3, 4 and 5 h application of formulations.

Notes: a = p-value < 0.05 for ANOVA + Tukey post-test vs. negative control. b = p-value < 0.05 for ANOVA + Tukey post-test vs. C2 and C3. c = p-value < 0.05 for ANOVA + Tukey post-test vs. positive control. C1—Negative control; C2—vehicle; C3—Vehicle + 1% Opuntia ficus-indica L. Mill extract; and C4—Positive control (commercial moisturizer). T1—After one hour; T2—After two hours; T3—After three hours; T4—After four hours; T5—After five hours.

After product application, we can observe a significant statistically difference (p < 0.05) between the FX and FXE formulations after the second hour, proving the moisturizer potential of Opuntia ficus-indica (L.) Mill extract. Some reports in the literature show that carbohydrate derivatives exert a moisturizing effect, so we can affirm that Opuntia ficus-indica (L.) Mill extract has a moisturizing effect due to its large amount of carbohydrates (galacturonic acid, glucose, rhamnose and arabinose) [25,56]. Dal’belo et al. [17] studied formulations containing or not different amounts of aloe vera extract. In this study a significant difference between all formulations containing the extract was observed compared to vehicle formulation after 2 and 3 h after application, proving the extract’s moisturizing effect and not only the effect of the vehicle [17].

Nanotechnological products show some improvement on their characteristics when compared to other products. Damasceno [24] observed a moisturizing tendency in conventional emulsions containing Opuntia ficus-indica (L.) Mill extract. The use of nanoemulsions in our study allowed the observation of a better moisturizing effect performance when compared to conventional emulsions with the same extract added. According to Morganti [13] this could be associated with the better properties of nanoemulsions due to the small droplet size that facilitates uniform deposition on the skin and more permeability through the skin layers [13]. Besides, a commercial moisturizer was used as a positive control in this study. This parameter allow verifying the course of the experiment because the commercial moisturizer showed a statistically significant result for hydration of the stratum corneum after the second hour and maintained this moisturizing effect for at least 5 h after application.

We noted no statistically significant alteration of TEWL and barrier function compared with basal measurements, meaning that transepidermal water loss did not decrease (Table 3). However, our formulations were able to maintain the water loss under 10 g/mm2·h for all volunteers, which characterizes very healthy skin as directed by Courage-Khazaka [55]. Thus, our formulation was able to maintain skin health. Experimental formulations with 1% tetraisopalmitoyl ascorbic acid (IPAA) were developed by Maia-Campos et al. [57] and showed a similar profile. There was a significant increase of stratum corneum water content but the skin barrier function was not altered [57].

Table 3.

Transepidermal water loss values before and 1, 2, 3, 4 and 5 h after application of formulations.

| C1 | C2 | C3 | C4 | |

|---|---|---|---|---|

| BASAL | 6.06 ± 1.71 | 6.40 ± 1.60 | 6.91 ± 1.09 | 9.06 ± 2.24 |

| T1 | 6.47 ± 1.70 | 6.49 ±1.88 | 7.57 ± 1.67 | 8.13 ± 1.78 |

| T2 | 6.95 ± 2.21 | 6.74 ± 1.34 | 6.66 ± 1.88 | 7.66 ± 2.04 |

| T3 | 7.10 ± 1.47 | 6.87 ± 1.36 | 7.48 ± 1.60 | 8.31 ± 2.34 |

| T4 | 7.00 ± 1.80 | 7.15 ± 1.53 | 6.85 ± 1.85 | 7.74 ± 2.06 |

| T5 | 7.37 ± 2.36 | 7.16 ± 2.21 | 7.55 ± 2.32 | 8.38 ± 2.57 |

Notes: C1—Negative control; C2—vehicle; C3—Vehicle + 1% Opuntia ficus-indica L. Mill extract; and C4—Positive control (commercial moisturizer). T1—After one hour; T2—After two hours; T3—After three hours; T4—After four hours; T5—After five hours. TEWL in g/mm2·h.

Dal’Belo et al. [17] noted that formulations supplemented with freeze-dried aloe vera extract significantly increased the water content of the stratum corneum but did not change the TEWL when compared with the vehicle, like in our study [17]. This was related to the composition of freeze-dried aloe vera extract that presented a rich hygroscopic mono- and polysaccharides content and the amino acids histidine, arginine, threonine, serine, glycine and alanine, that have a humectant mechanism of action. Like freeze-dried aloe vera extract, Opuntia ficus-indica (L.) Mill extract has no occlusive properties but can increase the retention of water on the skin surface, thus we can hypothesize that formulations containing Opuntia ficus-indica (L.) Mill extract could act by a humectant mechanism and not by an occlusion mechanism [19].

Gaspar et al. [56] evaluated the moisturizer efficacy of formulations containing Saccharomyces cerevisiae extract and vitamins and found similar results. Even though the formulation caused an increase in stratum corneum hydration, no changes were observed in the TEWL leading to the conclusion that this formulation also has a moisturizing effect due to a humectant mechanism [56].

Damasceno [24], observed a decrease in TEWL up to four hours after application of a gel-cream containing the same concentration of Opuntia fícus-indica hydroglycolic extract indicating an occlusive effect of these formulations. This proves that the vehicle could influence the moisturizing process mechanism due to the differences in system characteristics between a gel-cream and a nanoemulsion coupled to the presence of a polymer that could make the formulation more occlusive, justifying the decrease on TEWL with the gel-cream used by Damasceno and no decrease using our studied nanoemulsions.

3. Experimental Section

3.1. Materials

The surfactants used were Polysorbate 80 (HLB = 15) and Sorbitan Oleate (HLB = 4.5) (Croda do Brasil Ltda., Campinas, SP, Brazil). The oil phase was composed of Capric/Caprilic Triglycerides, Ethylhexyl Palmitate, C12–15 Alkyl Benzoate (Croda do Brasil Ltda., Campinas, SP, Brazil), Paraffinum Liquidum (Êxodo Científica, Hortolândia, SP, Brazil), Phenoxyethanol (and) Caprylyl Glycol (Ashland Inc., São Paulo, SP, Brazil) and BHT (Galena Química e Farmacêutica, Campinas, SP, São Paulo, Brazil). The water phase was composed by Disodium EDTA (DEG Importação de Produtos Químicos, Sorocaba, SP, Brazil); Xanthan Gum (CP Kelco Brasil, Limeira, SP, Brazil) and distilled water.

3.2. Preparation of Opuntia ficus-indica (L.) Mill Extract

The cladodes of Opuntia ficus-indica were supplied by the Agricultural Research Corporation of Rio Grande do Norte, Brazil (5°17'27.71''S, 36°16'27.63''W). A voucher specimen was deposited at the Herbarium of the Federal University of Rio Grande do Norte under number UFRN-16600. The hydroglycolic extract was obtained from fresh cladodes. A 20:80 (w/w) water/propylene glycol mixture was used as extraction vehicle. To perform the extraction a 1:3 (w/w) plant-solvent ratio was used. The cladodes were washed with distilled water, cut into small pieces and macerated for 12 h. Subsequently, the resultant mixture was percolated under a flow of 2 mL/min to obtain the extract [24].

3.3. Preparation and Formulations

The oil and water phases were heated separately to 75 ± 2 °C. The oil phase was added to the aqueous phase, followed by agitation at 11.000 rpm (IKA, Ultra Turrax Mod. T18 basic, Staufen, Germany) during five minutes. Samples were placed in an ice bath under mechanical agitation (IKA, mod. Digital RW 20, Staufen, Germany) at 500 rpm during 2 min [49]. The Opuntia ficus-indica (L.) Mill hydroglycolic extract was added and the system was stirred for 2 min (Table 4).

Table 4.

Nanoemulsion compositions (%, w/w).

| COMPONENTS | F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | FX | FXE |

|---|---|---|---|---|---|---|---|---|---|---|

| BHT | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Caprylic/Capric Triglyceride | 2.0 | 4.0 | 8.0 | 1.0 | 1.0 | 2.0 | 3.0 | 1.0 | 2.0 | 2.0 |

| Ethylhexyl Palmitate | 2.0 | 4.0 | 8.0 | 1.0 | 1.0 | 2.0 | 3.0 | 1.0 | 2.0 | 2.0 |

| C12–15 Alkyl Benzoate | 1.0 | 2.0 | 4.0 | 0.5 | 0.5 | 1.0 | 1.5 | 0.5 | 1.0 | 1.0 |

| Paraffinum Liquidum | 5.0 | 10.0 | 20.0 | 2.5 | 2.5 | 5.0 | 7.5 | 2.5 | 5.0 | 5.0 |

| Phenoxyethanol (and) Caprylic Glycol | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Sorbitan Oleate | 4.7 | 4.7 | 4.7 | 4.7 | 2.4 | 2.4 | 2.4 | 1.4 | 4.7 | 4.7 |

| Polysorbate 80 | 5.3 | 5.3 | 5.3 | 5.3 | 2.6 | 2.6 | 2.6 | 1.6 | 5.3 | 5.3 |

| Disodium EDTA | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Xanthan Gum | --- | --- | --- | --- | --- | --- | --- | --- | 0.5 | 0.5 |

| Opuntia ficus-indica (L.) Mill extract | --- | --- | --- | --- | --- | --- | --- | --- | --- | 1.0 |

| Distilled Water | 78.8 | 68.8 | 48.8 | 83.8 | 88.8 | 83.8 | 78.8 | 90.8 | 78.3 | 77.3 |

Notes: FX = Sample added to 0.5% Xanthan Gum; FXE = Sample added to 0.5% Xanthan Gum and 1% Opuntia ficus-indica extract.

The Hydrophilic Lipophilic Balance (HLB) required by the oil phase was theoretically calculated according to the values provided by manufactures of oil phase compounds. Different samples of emulsions were prepared varying the surfactant, oil and water amounts, as detailed on Table 4.

Emulsions were evaluated macroscopically 24 h after formation, centrifuged at 3000 rpm (Fanen, mod. 206 BL, Guarulhos, SP, Brazil) during thirty minutes and samples were stored at 45 ± 2 °C and 75% ± 5% RH (Nova Etica, mod. 520-CLDTS 150, Vargem Grande Paulista, SP, Brazil) for 5 days. Stable formulation (F1) was added to Xantham Gum 0.5% and Opuntia ficus-indica (L.) Mill extract 1% was added into it (FXE) or not (FX) (Table 4).

3.4. Preliminary Stability Tests

Centrifugation test: centrifugation was performed on 24 h-old preparations at 3000 rpm (Fanen, mod. 206 BL, Guarulhos, SP, Brazil) for 30 min at room temperature [48]. The appearance, homogeneity and organoleptic characteristics were evaluated by macroscopic analyses [48].

Thermal stress: emulsions were submitted to a heated thermostatic bath (Logen Scientific, mod. LSBMLS 2006-2, São Paulo, SP, Brazil) set for the temperature range of 40 to 80 °C, with temperature increase at intervals of 5 °C, and holding at each temperature for 30 min. The organoleptic characteristics, pH value determination and electrical conductivity measures were obtained to evaluate the formulations before and at the end at 80 °C, after the natural cooling of the samples at room temperature (25 ± 2 °C) [33].

Freeze-defrost cycles: samples were subjected to 4 ± 2 °C/24 h (Consul, Facilite Frost free 300 L, Joiville, SC, Brazil) and then 45 ± 2 °C/24 h and 75% ± 5% RH (Nova Etica, mod. 520-CLDTS 150, Vargem Grande Paulista, SP, Brazil), thus completing a cycle [33].

The organoleptic characteristics, pH value determination, electrical conductivity measures, droplet size, PDI and zeta potential were evaluated before and after preliminary stability tests [33,49].

pH value determination: 1.0 g of nanoemulsion and 9.0 g of distilled water were placed in a test tube and homogenized. The pH value (Hanna Instruments, mod. HI 21, Tamboré, SP, Brazil Brazil) was determined by inserting the electrode directly into the aqueous dilution 1:10 (w/w) of the sample [33].

Electrical conductivity determination: electrical conductivity measures (Logen Scientific, mod. CD-300-K1) were evaluated at a temperature of 25 ± 2 °C by inserting the electrode directly into the sample [33].

Determination of particle size and zeta potential: The mean particle size and zeta potential of nanoemulsions were measured by Dynamic Light Scattering (DLS) and phase analysis light scattering, respectively (Brookhaven ZetaPALS, Holtsville, NY, USA). The formulations were diluted with distilled water by 200-fold before the measurement [58].

3.5. Accelerated Stability Tests

The samples considered stable by preliminary tests were stored under different conditions: 4 ± 2 °C (Consul, Facilite Frost free 300 L, Joinville, SC, Brazil); 25 ± 2 °C (room temperature), and 45 ± 2 °C and 75% ± 5% RH (Nova Etica, mod. 520-CLDTS 150, Vargem Grande Paulista, SP, Brazil). The samples were maintained under these conditions for 60 days. The macroscopic analyses (appearance, homogeneity and organoleptic characteristics), pH value determinations, droplet size, PDI and zeta potential were evaluated at different time intervals (24 h after preparation of formulations and on 7th, 30th and 60th days) [48,49].

3.6. Evaluation of Mosturizing Eficacy in Vivo

This study was approved by the Research Ethics Committee of the University of Cuiabá (2012-041). A total of 18 volunteers with a range of ages from 20 to 65 years old, with no history of previous skin disease were included in this study after having given their written informed consent. This study was designed as a one-sided blind, placebo-controlled study. The volunteers were instructed not to use any cosmetic products for two weeks before and on the day of the experiment, except cleaning products like soap [57,59]. Prior to all measurements, volunteers were left in the room for at least 30 min in order to allow full skin adaptation to the room’s temperature (21 ± 2 °C) and relative humidity (60% ± 5%) [57,59].

Four sites (9 cm2 each) on the volunteers’ forearm skin were chosen (C1 to C4): one (C1) serving as the control where only measurements were taken, and the others (C2 to C4), where different formulations were applied. C2 had FX formulation (vehicle), C3 had the formulation containing 1.0% of Opuntia ficus-indica hydroglycolic extract—FXE, and a commercial moisturizer was used as positive control in C4. All formulations were applied to the surface of the skin at a dose of 2 mg/cm2 with a light massage of approximately 10 s [57,59].

Stratum corneum moisture content was determined by noninvasive biometrical measurements using a skin capacitance meter (Corneometer® CM 825-Courage & Khazaka Electronic GmbH, Köln, Germany) whereas transepidermal water loss was determined by an evaporimeter (Tewameter® TM 300-Courage & Khazaka Electronic GmbH, Köln, Germany). TEWL values were registered for 2 min following a 30 s period of equilibration of the probe on the skin. The baseline measurements (control area—region which received no formulation) of skin hydration were taken after at least 30 min of acclimatization under standard climatic conditions. Skin capacitance and TEWL were determined before, and at 1, 2, 3, 4 and 5 h after a single application of the formulations to areas C2-C4 and to the control field without formulation (C1). For skin capacitance measurement, nine readings were taken in each field. For TEWL evaluation, one reading in each field was taken [57,59].

4. Conclusions

The interest and investment in the cosmetic area concerning the advent of nanotechnology has motivated this study that contributes to the field of moisturizing cosmetics by producing a stable nanoemulsified system, that can improve the performance of cosmetic products when compared to conventional techniques and emulsified products. Beyond that, the study collaborated with the cosmetic market trends that look for products with vegetal raw materials and contributed to produce a cosmetic containing a regional Brazilian Caatinga biome product thus adding value to this region’s vegetation. The O/W nanoemulsion containing 1% of Opuntia ficus-indica (L.) Mill hydroglycolic extract could increase water content in the stratum corneum for 5 h and showed a significant difference when compared to vehicle formulation (FX). The high moisturizing capacity of FXE was probably related to the chemical composition of Opuntia ficus-indica (L.) Mill which is rich in carbohydrates (galacturonic acid, glucose, rhamnose and arabinose), suggesting a humectant mechanism. Overall, these results indicate that the produced oil-in-water nanoemulsion was stable and had moisturizing efficacy, proving to be a product with potential in the cosmetic area.

Acknowledgments

The authors are grateful to Croda of Brazil Ltda., CP Kelco Brasil and Lubrizol of Brazil Ltda. for the donation of sample materials. The authors also would like to thank the Laboratório de Sistemas Dispersos (LASID-UFRN), Laboratório de Tecnologia e Biotecnologia Farmacêutica (TECBIOFAR-UFRN) and Núcleo de Ensino e Pesquisa em Petróleo e Gás (NUPEG-UFRN). This work was supported by Federal University of Rio Grande do Norte (UFRN) and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) and by grants from CAPEs and UFRN.

Author Contributions

RCAR was the student who carried out the laboratory work, analyzed the data and drafted the paper. SMAGB contributed with the laboratory work. EAO and PARF contributed with the analysis of the data and the critical reading of the manuscript. LMV was the supervisor of the nanoemulsions study and contributed to critical reading of the manuscript. MF was the principal scientific supervisor of the study. He designed the study, supervised the laboratory work and contributed to critical reading of the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

Footnotes

Sample Availability: Samples of the nanoemulsions are available from the authors.

References

- 1.Breuer M.M. Cosmetics emulsions. In: Becher P., editor. Encyclopedia of Emulsions Technology. Volume 2. Marcel Dekker; New York, NY, USA: 1985. pp. 385–424. [Google Scholar]

- 2.Izquierdo P., Esquena J., Tadros T.F., Dederen C., Garcia M.J., Azemar N., Solans C. Formation and stability of nano-emulsions prepared using the phase inversion temperature method. Langmuir. 2001;18:26–30. doi: 10.1021/la010808c. [DOI] [Google Scholar]

- 3.Mcclements D.J. Nanoemulsions versus microemulsions: Terminology, differences and similarities. Soft Matter. 2012;8:1719–1729. doi: 10.1039/c2sm06903b. [DOI] [Google Scholar]

- 4.Kabri T.-H., Arab-Tehrany E., Belhaj N., Linder M. Physico-chemical characterization of nano-emulsions in cosmetic matrix enriched on omega-3. J. Nanobiotechnol. 2011;9:41. doi: 10.1186/1477-3155-9-41. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Chebil A., Desbrières J., Nouvel C., Six J.-L., Durand A. Ostwald ripening of nanoemulsions stopped by combined interfacial adsorptions of molecular and macromolecular nonionic stabilizers. Colloids Surf. A Physicochem. Eng. Asp. 2013;425:24–30. doi: 10.1016/j.colsurfa.2013.02.028. [DOI] [Google Scholar]

- 6.Saberi A.H., Fang Y., McClements D.J. Fabrication of vitamin E-enriched nanoemulsions: Factors affecting particle size using spontaneous emulsification. J. Colloid Interface Sci. 2013;391:95–102. doi: 10.1016/j.jcis.2012.08.069. [DOI] [PubMed] [Google Scholar]

- 7.Gianeti M.D., Wagemaker T.A.L., Seixas V.C., Maia Campos P.M.B.G. The use of nanotechnology in cosmetic formulations: The influence of vehicle in the vitamin a skin penetration. Curr. Nanosci. 2011;8:526–534. doi: 10.2174/157341312801784375. [DOI] [Google Scholar]

- 8.Adjonu R., Doran G., Torley P., Agboola S. Whey protein peptides as components of nanoemulsions: A review of emulsifying and biological functionalities. J. Food Eng. 2014;122:15–27. doi: 10.1016/j.jfoodeng.2013.08.034. [DOI] [Google Scholar]

- 9.Mason T.G., Wilking J.N., Meleson K., Chang C.B., Graves S.M. Nanoemulsions: Formation, structure and physical properties. J. Phys. Condens. Matter. 2006;18:635–666. doi: 10.1088/0953-8984/18/41/R01. [DOI] [Google Scholar]

- 10.Abbas S., Bashari M., Akhtar W., Li W.W., Zhang X. Process optimization of ultrasound-assisted curcumin nanoemulsions stabilized by OSA-modified starch. Ultrason. Sonochem. 2014;21:1265–1274. doi: 10.1016/j.ultsonch.2013.12.017. [DOI] [PubMed] [Google Scholar]

- 11.Piorkowski D., Mcclements D.J. Beverage emulsions: Recent developments in formulation, production, and applications. Food Hydrocoll. 2013;42:5–41. doi: 10.1016/j.foodhyd.2013.07.009. [DOI] [Google Scholar]

- 12.Peshkovsky A.S., Peshkovsky S.L., Bystryak S. Scalable high-power ultrasonic technology for the production of translucent nanoemulsions. Chem. Eng. Process. 2013;69:77–82. doi: 10.1016/j.cep.2013.02.010. [DOI] [Google Scholar]

- 13.Morganti P. Use and potential of nanotechnology in cosmetic dermatology. Clin. Cosmet. Investig. Dermatol. CCID. 2010;3:5–13. doi: 10.2147/CCID.S4506. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Mancini A.J. Skin. Pediatrics. 2004;113:1114–1119. [PubMed] [Google Scholar]

- 15.Barco D., Giménez-Arnau A. Xerosis: Una disfunción de la barrera epidérmica. Actas Dermo-Sifiliogr. 2008;99:671–682. doi: 10.1016/S0001-7310(08)76171-4. [DOI] [PubMed] [Google Scholar]

- 16.Capitani R.D., Mercúrio D.G., Camargo Júnior F.B., Maia Campos P.M.B.G. Stability and clinical efficacy of moisturizing cosmetics formulations containing vitamins C and E. Biomed. Biopharm. Res. 2012;9:215–224. [Google Scholar]

- 17.Dal’Belo S.E., Rigo Gaspar L., Maia Campos P.M.B.G. Moisturizing effect of cosmetic formulations containing Aloe vera extract in different concentrations assessed by skin bioengineering techniques. Skin Res. Technol. 2006;12:241–246. doi: 10.1111/j.0909-752X.2006.00155.x. [DOI] [PubMed] [Google Scholar]

- 18.Bonté F. Skin moisturization mechanisms: New data. Ann. Pharm. Fr. 2011;69:135–141. doi: 10.1016/j.pharma.2011.01.004. [DOI] [PubMed] [Google Scholar]

- 19.Ribeiro C. Cosmetologia Aplicada a Dermoestética. 2nd ed. Pharmabook; São Paulo, SP, Brasil: 2010. [Google Scholar]

- 20.Lee D.-H., Seo E.-S., Hong J.-T., Lee G.-T., You Y.-K., Lee K.-K., Jo G.-W., Kim N.-K. The efficacy and safety of proposed herbal moisturizing cream for dry skin and itch relief: A randomized, doubled-blind, placebo-controlled treial-study protocol. BMC Complement. Altern. Med. 2013;13:330. doi: 10.1186/1472-6882-13-330. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Pinheiro E.A.R., Costa C.A.G., de Araújo J.C. Effective root depth of the Caatinga biome. J. Arid Environ. 2013;89:1–4. doi: 10.1016/j.jaridenv.2012.10.003. [DOI] [Google Scholar]

- 22.Ginestra G., Parker M.L., Bennett R.N., Robertson J., Mandalari G., Narbad A., Lo Curto R.B., Bisignano G., Faulds C.B., Waldron K.W. Anatomical, chemical, and biochemical characterization of cladodes from prickly pear [Opuntia ficus-indica (L.) Mill.] J. Agric. Food Chem. 2009;57:10323–10330. doi: 10.1021/jf9022096. [DOI] [PubMed] [Google Scholar]

- 23.Souza A.E.F., Nascimento L.C., Araújo E., Lopes E.B., Souto F.M. Ocorrência e identificação dos agentes etiológicos de doenças em Palma Forrageira (Opuntia ficus-indica Mill.) no Semi-Árido paraibano. Biotemas. 2010;23:11–20. [Google Scholar]

- 24.Damasceno G.A.B. Master Thesis. Universidade Federal do Rio Grande do Norte; Natal, RN, Brazil: Mar 28, 2014. Obtenção de Extratos da Opuntia ficus-indica (L.) Mill e suas Aplicações em Formulações Cosméticas: Avaliação in vivo do Sensorial e da Eficácia Hidratante. [Google Scholar]

- 25.Habibi Y., Heyraud A., Mahrouz M., Vignon M.R. Structural features of pectic polysaccharides from the skin of Opuntia ficus-indica prickly pear fruits. Carbohydr. Res. 2004;339:1119–11127. doi: 10.1016/j.carres.2004.02.005. [DOI] [PubMed] [Google Scholar]

- 26.Zhong X.-K., Jin X., Lai F.-Y., Lin Q.-S., Jiang J.-G. Chemical analysis and antioxidant activities in vitro of polysaccharide extracted from Opuntia ficus-indica Mill cultivated in China. Carbohydr. Polym. 2010;82:722–727. doi: 10.1016/j.carbpol.2010.05.042. [DOI] [Google Scholar]

- 27.Kamershwarl V., Mistry N.D. Propriedades sensoriais dos emolientes. Cosmet. Toilet. 2001;13:52–59. [Google Scholar]

- 28.Ševčíková P., Vltavská P., Kašpárková V., Krejčí J. Formation, Characterization and Stability of Nanoemulsions Prepared by Phase Inversion. In: Demiralp M., Bojkovic Z., Repanovici A., editors. Proceedings of the 13th WSEAS International Conference on Mathematical and Computational Methods in Science and Engineering; Catania, Sicily, Italy. 3 November 2011; Zografou, Athens, Greece: World Scientific and Engineering Academy and Society (WSEAS); 2011. [Google Scholar]

- 29.Anton N., Vandamme T. Nano-emulsions and micro-emulsions: clarifications of the critical differences. Pharm. Res. 2011;28:978–985. doi: 10.1007/s11095-010-0309-1. [DOI] [PubMed] [Google Scholar]

- 30.Shakeel F., Ramadan W. Transdermal delivery of anticancer drug caffeine from water-in-oilnanoemulsions. Colloids Surf. B Biointerfaces. 2010;75:356–362. doi: 10.1016/j.colsurfb.2009.09.010. [DOI] [PubMed] [Google Scholar]

- 31.Teo B., Basri M., Zakaria M., Salleh A., Rahman R., Rahman M. A potential tocopherol acetate loaded palm oil esters-in-water nanoemulsions for nanocosmeceuticals. J. Nanobiotechnol. 2010;8:4. doi: 10.1186/1477-3155-8-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Sevcíková P., Kaspárková V., Vltavská P., Krejcí J. On the preparation and characterization of nanoemulsions produced by phase inversion emulsification. Colloids Surf. A Physicochem. Eng. Asp. 2012;410:130–135. doi: 10.1016/j.colsurfa.2012.06.031. [DOI] [Google Scholar]

- 33.Lima C.G., Vilela A.F.G., Silva A.A.S., Piannovski A.R., Silva K.K., Carvalho V.F.M., de Musis C.R., Machado S.R.P., Ferrari M. Desenvolvimento e avaliação da estabilidade física de emulsões O/A contendo óleo de babaçu (Orbignya oleifera) Rev. Bras. Farm. 2008;89:239–245. [Google Scholar]

- 34.Rieger M.M. Teste de estabilidade para macroemulsões. Cosmet. Toilet. 1996;8:47–53. [Google Scholar]

- 35.Oliveira E.C.V., Boock K.P., Maruno M., Rocha-Filho P.A. Accelerated stability and moisturizing capacity of emulsions presenting lamellar gel phase obtained from brazilian natural raw material. J. Dispers. Sci. Technol. 2011;32:1135–1139. doi: 10.1080/01932691.2010.498234. [DOI] [Google Scholar]

- 36.Junyaprasert V.B., Teeranachaideekul V., Souto E.B., Boonme P., Müller R.H. Q10-loaded NLC versus nanoemulsions: Stability, rheology and in vitro skin permeation. Int. J. Pharm. 2009;377:207–214. doi: 10.1016/j.ijpharm.2009.05.020. [DOI] [PubMed] [Google Scholar]

- 37.Tadros T., Izquierdo P., Esquena J., Solans C. Formation and stability of nanoemulsions. Adv. Colloid Interface Sci. 2004;108:303–318. doi: 10.1016/j.cis.2003.10.023. [DOI] [PubMed] [Google Scholar]

- 38.Agência Nacional de Vigilância Sanitária—Anvisa . Guia de Estabilidade de Produtos Cosméticos. Volume 1 Anvisa; Brasília, DF, Brazil: 2005. [Google Scholar]

- 39.Casteli V.C., Mendonça C.C., Maia Campos P.M.B.G., Ferrari M., Machado S.R.P. Desenvolvimento e estudos de estabilidade preliminares de emulsoes O/A contendo Cetoconazol 2,0% Acta Sci. Health Sci. (UEM) 2008;30:121–128. [Google Scholar]

- 40.Komaiko J., McClements D.J. Optimization of isothermal low-energy nanoemulsion formation: Hydrocarbon oil, non-ionic surfactant, and water systems. J. Colloid Interface Sci. 2014;425:59–66. doi: 10.1016/j.jcis.2014.03.035. [DOI] [PubMed] [Google Scholar]

- 41.Brooks G., Idson B. Skin lipids. Int. J. Cosmet. Sci. 1991;13:103–113. doi: 10.1111/j.1467-2494.1991.tb00553.x. [DOI] [PubMed] [Google Scholar]

- 42.Jiang J., Mei Z., Xu J., Sun D. Effect of inorganic electrolytes on the formation and the stability of water-in-oil (W/O) emulsions. Colloids Surf. A Physicochem. Eng. Asp. 2013;429:82–90. doi: 10.1016/j.colsurfa.2013.03.039. [DOI] [Google Scholar]

- 43.Bernardi D., Pereira T., Maciel N., Bortoloto J., Viera G., Oliveira G., Rocha-Filho P.A. Formation and stability of oil-in-water nanoemulsions containing rice bran oil: In vitro and in vivo assessments. J. Nanobiotechnol. 2011;9:44. doi: 10.1186/1477-3155-9-44. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Kong M., Park H.J. Stability investigation of hyaluronic acid based nanoemulsion and its potential as transdermal carrier. Carbohydr. Polym. 2011;83:1303–1310. doi: 10.1016/j.carbpol.2010.09.041. [DOI] [Google Scholar]

- 45.Wiącek A., Chibowski E. Zeta potential, effective diameter and multimodal size distribution in oil/water emulsion. Colloids Surf. A Physicochem. Eng. Asp. 1999;159:253–261. doi: 10.1016/S0927-7757(99)00281-2. [DOI] [Google Scholar]

- 46.Tang S.Y., Manickam S., Wei T.K., Nashiru B. Formulation development and optimization of a novel Cremophore EL-based nanoemulsion using ultrasound cavitation. Ultrason. Sonochem. 2012;19:330–345. doi: 10.1016/j.ultsonch.2011.07.001. [DOI] [PubMed] [Google Scholar]

- 47.Shanmugam A., Ashokkumar M. Ultrasonic preparation of stable flax seed oil emulsions in dairy systems—Physicochemical characterization. Food Hydrocoll. 2014;39:151–162. doi: 10.1016/j.foodhyd.2014.01.006. [DOI] [Google Scholar]

- 48.Ferrari M., Rocha-filho P.A. Multiple emulsions containing amazon oil: Açaí oil (Euterpe oleracea) Rev. Bras. Farmacogn. 2011;21:737–743. doi: 10.1590/S0102-695X2011005000093. [DOI] [Google Scholar]

- 49.Maruno M., Rocha-Filho P.A. O/W nanoemulsion after 15 years of preparation: A suitable vehicle for pharmaceutical and cosmetic applications. J. Dispers. Sci. Technol. 2010;31:17–22. doi: 10.1080/01932690903123775. [DOI] [Google Scholar]

- 50.Moulai Mostefa N., Hadj Sadok A., Sabri N., Hadji A. Determination of optimal cream formulation from long-term stability investigation using a surface response modelling. Int. J. Cosmet. Sci. 2006;28:211–218. doi: 10.1111/j.1467-2494.2006.00305.x. [DOI] [PubMed] [Google Scholar]

- 51.Gallarate M., Chirio D., Bussano R., Peira E., Battaglia L., Baratta F., Trotta M. Development of O/W nanoemulsions for ophthalmic administration of timolol. Int. J. Pharm. 2013;440:126–134. doi: 10.1016/j.ijpharm.2012.10.015. [DOI] [PubMed] [Google Scholar]

- 52.Pund S., Borade G., Rasve G. Improvement of anti-inflammatory and anti-angiogenic activity of berberine by novel rapid dissolving nanoemulsifying technique. Phytomedicine. 2014;21:307–314. doi: 10.1016/j.phymed.2013.09.013. [DOI] [PubMed] [Google Scholar]

- 53.Bazylińska U., Kulbacka J., Wilk K.A. Dicephalic ionic surfactants in fabrication of biocompatible nanoemulsions: Factors influencing droplet size and stability. Colloids Surf. A Physicochem. Eng. Asp. 2014;460:312–320. doi: 10.1016/j.colsurfa.2013.12.042. [DOI] [Google Scholar]

- 54.Leite e Silva V.R., Schulman M.A., Ferelli C., Gimenis J.M., Ruas G.W., Baby A.R., Velasco M.V.R., Taqueda M.E., Kaneko T.M. Hydrating effects of moisturizer active compounds incorporated into hydrogels: In vivo assessment and comparison between devices. J. Cosmet. Dermatol. 2009;8:32–39. doi: 10.1111/j.1473-2165.2009.00421.x. [DOI] [PubMed] [Google Scholar]

- 55.Courage Khazaka. [(accessed on 1 August 2014)]. Available online: http://courage-khazaka.de/index.php/en/products/scientific.

- 56.Gaspar L.R., Camargo F.B., Jr., Gianeti M.D., Maia Campos P.M.B.G. Evaluation of dermatological effects of cosmetic formulations containing Saccharomyces cerevisiae extract and vitamins. Food Chem. Toxicol. 2008;46:3493–3500. doi: 10.1016/j.fct.2008.08.028. [DOI] [PubMed] [Google Scholar]

- 57.Maia Campos P.M.B.G., Gianeti M.D., Camargo F.B., Jr., Gaspar L.R. Application of tetra-isopalmitoyl ascorbic acid in cosmetic formulations: Stability studies and in vivo efficacy. Eur. J. Pharm. Biopharm. 2012;82:580–586. doi: 10.1016/j.ejpb.2012.08.009. [DOI] [PubMed] [Google Scholar]

- 58.Silva A.L., Alexandrino F., Verissimo L.M., Agnez-Lima L.F., Egito L.C.M., de Oliveira A.G., Do Egito E.S.T. Physical factors affecting plasmid DNA compaction in stearylamine-containing nanoemulsions intended for gene delivery. Pharmaceuticals. 2012;5:643–654. doi: 10.3390/ph5060643. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 59.Faria W.C.S., Damasceno G.A.B., Ferrari M. Moisturizing effect of a cosmetic formulation containing pequi oil (Caryocar brasiliense) from the Brazilian cerrado biome. Braz. J. Pharm. Sci. 2014;50:131–136. doi: 10.1590/S1984-82502011000100013. [DOI] [Google Scholar]