Abstract

Current floor space allowances were determined in research studies conducted 10 to 20 yr ago using pigs that were marketed at a BW of about 113 kg or less. Currently, pork producers are regularly marketing pigs that weigh over 128 kg. Given this precipitous increase in market weight, we conducted 2 experiments to determine if floor space allowances previously determined apply to pigs marketed at greater than 128 kg. Experiment 1 was conducted at 5 university research stations throughout the Upper Midwest region. In this experiment, we evaluated the growth performance, salivary cortisol concentrations, and lesion scores of pigs weighing between 27 and 138 kg provided 0.71, 0.80, 0.89, 0.98, or 1.07 m2/pig of floor space. Within each station, group size (range = 6 to 19 pigs) remained constant across floor space treatments but pen size was altered to achieve the desired space allocations. There were 14 replicate pens for each treatment. Overall, increasing floor space allowance increased final BW (linear, P = 0.04) and tended (linear, P < 0.06) to increase ADG and ADFI. There were no improvements in final BW or ADG beyond 0.89 m2/pig. The G:F was not influenced by increasing floor space allocation. Salivary cortisol concentrations and lesion scores were not affected by floor space allowances. Experiment 2 focused on floor space needs of pigs nearing market weight and was conducted at 4 research stations. Pigs weighing about 130 kg were assigned to pens that provided 0.71, 0.80, 0.89, 0.98, or 1.07 m2/pig of floor space. Group size ranged from 4 to 11 pigs per pen but was constant across floor space treatments within station. The study lasted 2 wk and there were 8 replicate pens per treatment. As floor space allowance increased, ADG (0.86, 0.95, 0.95, 1.10, and 1.06 kg; linear, P < 0.01), ADFI (3.03, 3.26, 3.22, 3.49, and 3.25 kg; quadratic, P < 0.05), and final BW (145.6, 145.7, 146.4, 148.3, and 147.9 kg; linear, P < 0.01) increased. Based on the results of these 2 experiments, pigs marketed at about 138 kg require at least 0.89 m2/pig to support optimal growth performance. However, heavier pigs (about 148 kg) at the end of the finishing period require 0.98 m2/pig.

Keywords: finishing pig, floor space, swine

INTRODUCTION

During the 1990s and early 2000s, the North Central Regional research committee on Swine Confinement Management and others conducted several studies to evaluate the impacts of various floor space allowances for growing–finishing pigs (NCR-89 Committee on Confinement Management of Swine, 1993; Gonyou and Stricklin, 1998; Brumm et al., 2001). These studies focused on pig performance and welfare when provided varying floor space allowance and marketed at about 113 kg BW or less. Using data generated in these studies, Gonyou et al. (2006) used the concepts of Petherick and Baxter (1981) to develop a mathematical equation that predicted floor space requirements for optimal pig performance based on BW. This equation determined that a pig weighing about 113 kg needed 0.79 m2 of floor space. Theoretically, this approach to determining floor space requirements should apply to a wide range of BW, but the equation was based on experiments that studied pigs to a final market weight of about 113 kg. The utility of this equation for pigs weighing greater than 113 kg has not been extensively studied.

Currently, pigs are marketed at much greater BW than were studied in earlier experiments on floor space. According to the USDA (2017), the average slaughter weight for market hogs was 128 kg in 2016. Anecdotal reports from industry sources (M. C. Brumm, Brumm Swine Consultancy, Inc., Mankato, MN, personal communication) indicate that many groups of pigs are marketed at an average weight of 136 kg or greater. So the primary objective of this investigation was to determine if the heavy market pigs (130+ kg) common in the U.S. swine industry today require more floor space than has been historically provided to lighter market pigs. We hypothesized that heavier pigs at marketing would require increased floor space than previously estimated to optimize growth performance and welfare of pigs. A secondary objective was to determine if the k values developed by Gonyou et al. (2006) still apply to pigs marketed at modern heavy weights.

MATERIALS AND METHODS

This project included 2 experiments. Experiment 1 was designed to determine the effects of floor space allowance on pigs from about 27 kg BW to marketing at an average pen weight of 134 kg or greater. Experiment 2 was designed to specifically study the effects of floor space allowance on growth performance of pigs weighing about 136 kg without any influences from earlier portions of the growing–finishing period. Experiment 1 was conducted at 5 cooperating stations (Table 1) under a common protocol. Due to problems with availability of pigs, Exp. 2 was conducted at 4 cooperating stations under a common protocol. Animal care and use procedures for these experiments were approved by the Institutional Animal Care and Use Committees at each respective participating university.

Table 1.

Participating stations1

| Station | No. ofreplicates | No. ofpigs/pen | Starting date | Duration ofexperiment, d |

|---|---|---|---|---|

| Exp. 1 | ||||

| Kansas | 6 | 6 or 7 | July 6, 2015 | 112 |

| Michigan | 2 | 11 | Dec. 19, 2015 | 114 |

| Minnesota | 2 | 19 | Mar. 11, 2016 | 126 |

| Missouri | 2 | 10 | Nov. 20, 2015, and Feb. 5, 2016 | 125 and 126 |

| Ohio | 2 | 11 | Dec. 23, 2015, and May 11, 2016 | 105 |

| Exp. 2 | ||||

| Kansas | 2 | 6 or 7 | Nov. 27, 2016 | 14 |

| Michigan | 2 | 11 | Sept. 30, 2016 | 14 |

| Minnesota | 2 | 8 | July 18, 2016 | 14 |

| Ohio | 2 | 4 or 5 | Apr. 13, 2016, and Aug. 31, 2016 | 14 |

Experiments were conducted at the following locations: Kansas State University, Manhattan; Michigan State University, East Lansing; University of Minnesota, West Central Research and Outreach Center, Morris; University of Missouri, Columbia; and The Ohio State University, Columbus.

Experiment 1

At about 27 kg BW, pigs were blocked by weight and assigned to pens, and pens were randomly assigned within weight block to floor space treatments. Floor space treatments were 0.71, 0.80, 0.89, 0.98, and 1.07 m2/pig. Floor space allowances were determined based on a study by Gonyou et al. (2006). Assuming a final pig weight of 136 kg and a k value of 0.0336, the floor space allowance of 0.89 m2/pig was determined. Two floor space allowances greater and less than the predicted value were selected to evaluate pigs' response to floor space across a range of presumed crowded and spacious space allowances. A variance of ±0.02 m2/pig in floor space allowance was permitted to accommodate differences in gating and flooring designs across stations. Floor space allowances did not include space occupied by the feeder. Floor space treatments were imposed from initiation of the study until the average weight of pigs in the pen reached at least 134 kg. Each pen group remained intact until the end of the experiment. No pigs were removed for marketing until after the experiment ended. Floor space treatments were achieved by adjusting pen size for a constant group size across all treatments. Group size varied across participating stations but was constant across treatments within a replicate at each station.

Standard management protocols observed at each participating station were followed throughout this experiment. Pigs had ad libitum access to dry feed in meal form and water throughout the entire experiment. Feeding programs (diet formulations, number of phases, and phase breaks) were determined by each station and were standardized across floor space treatments with the stipulation that nutrient requirement estimates described by the NRC (2012) were satisfied. All stations used diets based on corn, soybean meal, and, in some cases, dried distillers grains with solubles. Ractopamine was not fed at any point in the experiment. At each station, pigs were housed in mechanically ventilated barns on totally slatted floors or on partially slatted floors with equal slat and solid proportions across treatments (Ohio station). Linear feeder trough space ranged from 9.7 cm to 4.8 cm/pig across stations but was consistent across floor space treatments within each station. The experiment ended when the average BW of pigs across pens reached 134 kg or greater. If a pig died or was removed for welfare reasons, pen size was adjusted to maintain the appropriate floor space allowance but feeder space was not adjusted.

Pigs were individually weighed and feed disappearance was measured on a pen basis every 14 d throughout the experiment. From these data, ADG, ADFI, and G:F were calculated. The CV for live weight within pens was calculated at the beginning and end of the experiment. By suspending cotton ropes in 2 pens per treatment at each station, saliva samples were collected on 3 separate days throughout the experiment: when the average weight of pigs assigned to the experiment was about 80 kg, 2 wk before the final weight, and the week of final weight. After pigs chewed on the ropes, saliva was harvested and frozen for subsequent analysis according to the procedures described by Prickett et al. (2008). Saliva samples were analyzed for free cortisol concentration by Salimetrics, Inc. (State College, PA) using an enzyme immunoassay kit (Salimetrics, 2017). During periods of normal barn activities, animal care staff watched for signs of estrus at stations that included gilts in the study and recorded incidence of estrus. Incidence of mortality and morbidity were recorded throughout the experiment. Incidence of lameness was recorded subjectively every 14 d using the following scale: 1 = normal walking, 2 = slight lameness and may have an arched back, 3 = obvious limping but able to keep up with pen mates when the group is walking, 4 = not able to keep up with pen mates due to lameness, and 5 = can barely walk. Lesion scores as defined by Li and Gonyou (2013) were recorded for all pigs during the last week of the study according to the following scale: 1 = no cut, swelling, or previous wounds have healed; 2 = minor cut, slight swelling, or presence of scabs; and 3 = major cut, remarkable swelling, or open wounds. Lesion scores were recorded only at Minnesota and Ohio.

Each station provided data from at least 2 replications for each treatment. Data were tested for normality using the UNIVARIATE procedure of SAS (SAS Inst. Inc., Cary, NC). Because data were not normally distributed, the GLIMMIX procedure of SAS was used to analyze performance data. The statistical models included the fixed effects of floor space treatments, with station included as a random effect. Repeated measures analysis was used for analysis of growth performance and salivary cortisol data.

Experiment 2

Pigs weighing about 130 kg were selected for this experiment and randomly assigned to pens. Group size was constant across treatments within station but was not the same as in Exp. 1. Except for the Ohio station, pigs used in Exp. 1 were not used in this experiment. At the Ohio station, 45 pigs from Exp. 1 with BW closest to 136 kg were selected for use in Exp. 2. Pigs were assigned to pens so that pigs from at least 3 floor space allowances in Exp. 1 were represented in each pen during Exp. 2. All pigs were allowed 7 d to reestablish their social hierarchy in pens that provided 1.07 m2 of floor space per pig. At the end of the acclimation period, pen size was adjusted to the preassigned treatment that provided 0.71, 0.80, 0.89, 0.98, or 1.07 m2 of floor space per pig. Pigs were individually weighed at the start of the experiment and 14 d later at the end of the experiment. Feed disappearance was measured on a pen basis when the experiment was terminated. From these data, ADG, ADFI, and G:F were calculated. Mortality, morbidity, and incidence of lameness were recorded as described for Exp. 1. Four stations contributed data from 2 replicate pens for each floor space treatment. Similar to Exp. 1, the UNIVARIATE procedure of SAS was used to test normality of data and the GLIMMIX procedure of SAS was used to analyze growth performance data. The statistical model included the fixed effect of floor space allowance and station as a random effect.

In both experiments, pen nested within station served as the experimental unit in all analyses. Mean separations were achieved using linear and quadratic orthogonal contrasts. Significant differences among means were declared when P < 0.05 and trends were declared when P < 0.10. All reported means are least squares means.

RESULTS AND DISCUSSION

Experiment 1

As expected, there were differences in most response variables among stations (Table 2). However, with few exceptions, there were no station × floor space treatment interactions. This lack of station × treatment interactions suggests that the effects of floor space were consistent across stations.

Table 2.

Pig performance over the entire growing–finishing period at each participating station (Exp. 1)

| Trait | Kansas | Michigan | Minnesota | Missouri | Ohio | SE | Station effect (P-value) |

|---|---|---|---|---|---|---|---|

| No. of pens | 30 | 10 | 10 | 10 | 10 | – | |

| BW, kg | |||||||

| Initial | 38.4 | 21.8 | 25.2 | 23.9 | 24.7 | 0.39 | <0.001 |

| Final | 135.0 | 140.6 | 139.3 | 144.6 | 134.2 | 1.09 | <0.001 |

| Within pen CV, % | |||||||

| Initial | 9.88 | 3.85 | 4.37 | 1.81 | 5.13 | 0.74 | <0.001 |

| Final | 6.69 | 7.18 | 6.21 | 9.33 | 7.32 | 0.57 | <0.008 |

| ADG, kg | 0.93 | 1.05 | 0.92 | 0.96 | 1.04 | 0.01 | <0.001 |

| ADFI, kg | 2.48 | 2.36 | 2.57 | 2.40 | 2.76 | 0.04 | <0.001 |

| G:F | 0.374 | 0.444 | 0.358 | 0.401 | 0.378 | 0.005 | <0.001 |

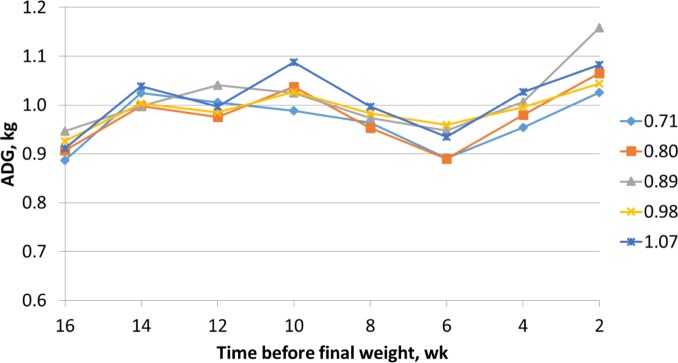

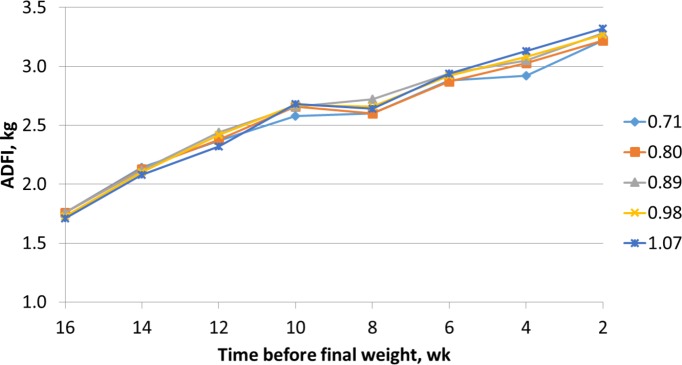

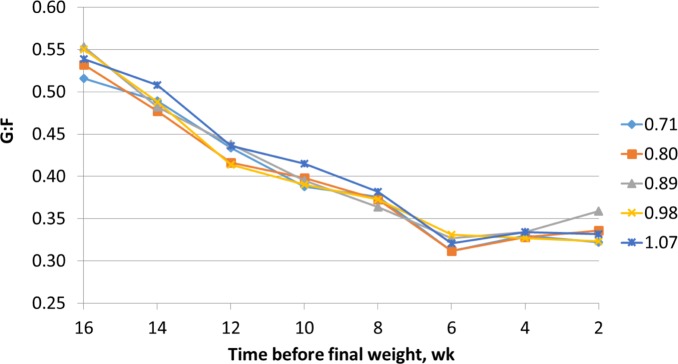

Initial BW of pigs was not different across floor space allowances; however, increasing floor space allowance increased final BW (linear, P = 0.04) and tended to increase ADG (linear, P = 0.06) and ADFI (linear, P = 0.06; Table 3). Gain efficiency was not influenced by increasing floor space allowance. Initial and final CV were not different across the floor space allowances studied in this experiment. The duration of this experiment ranged from 112 to 126 d across participating stations. Data presented in Table 3 represent average pig performance over the entire experimental period. To understand the performance responses of pigs to floor space allowances over time, we evaluated growth performance over the last 16 wk of the experiment. During this period, there were no significant effects of floor space allowance on ADG, ADFI or G:F (Fig. 1, 2, and 3, respectively).

Table 3.

Effects of floor space allowance on pig performance over the entire growing–finishing period (Exp. 1)

| Floor space allowances, m2/pig | Significance (P-value)1 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Trait | 0.71 | 0.80 | 0.89 | 0.98 | 1.07 | SE | Trt | Linear | Quadratic |

| No. of pens | 14 | 14 | 14 | 14 | 14 | – | |||

| BW, kg | |||||||||

| Initial | 26.7 | 26.8 | 26.7 | 26.9 | 27.0 | 0.40 | 0.98 | 0.59 | 0.90 |

| Final | 137.5 | 136.7 | 140.3 | 139.0 | 140.2 | 1.12 | 0.10 | 0.04 | 0.79 |

| Within pen CV, % | |||||||||

| Initial | 4.85 | 5.14 | 5.06 | 5.17 | 4.82 | 0.75 | 0.99 | 0.98 | 0.71 |

| Final | 7.46 | 6.45 | 7.19 | 7.74 | 7.91 | 0.58 | 0.44 | 0.24 | 0.33 |

| ADG, kg | 0.97 | 0.96 | 0.99 | 0.98 | 0.99 | 0.01 | 0.14 | 0.06 | 0.93 |

| ADFI, kg | 2.48 | 2.49 | 2.52 | 2.52 | 2.57 | 0.033 | 0.38 | 0.06 | 0.67 |

| G:F2 | 0.393 | 0.386 | 0.396 | 0.391 | 0.389 | 0.004 | 0.57 | 0.73 | 0.77 |

Trt = floor space treatment effects; Linear represents the linear effects of floor space treatments; Quadratic represents the quadratic effects of floor space treatments.

Station × treatment interaction (P = 0.047).

Figure 1.

Average daily gain of pigs provided different floor space allowances during the last 16 wk of the experiment (Exp. 1; time effect, P < 0.01; station effect, P < 0.01; SE 0.84).

Figure 2.

Average daily feed intake of pigs provided different floor space allowances during the last 16 wk of the experiment (Exp. 1; time effect, P < 0.01; station effect, P < 0.01; SE 0.16).

Figure 3.

Gain:feed ratio of pigs provided different floor space allowances during the last 16 wk of the experiment (Exp. 1; time effect, P < 0.01; station effect, P < 0.01; SE 0.01).

Saliva samples were collected from pigs to determine cortisol concentration in saliva as a reliable, noninvasive indicator of chronic stress in pigs (Parrott et al., 1989; Parrott and Misson, 1989). The first sample was collected when pigs weighed about 80 kg because pigs at this weight assigned to all treatments presumably had sufficient floor space according to the equation of Gonyou et al. (2006). This sample served as an initial assessment of baseline salivary cortisol. Subsequent samples were collected 2 wk before the end of the experiment and in the final week of the experiment when pigs should have experienced varying levels of crowding and presumably different degrees of stress. There were no differences in initial salivary cortisol concentrations across floor space treatments (Table 4). Similarly, there were no differences in salivary cortisol among floor space allowances 2 and 1 wk before the final weight, when pigs should have experienced the greatest differences in crowding among treatments. Also noteworthy, there was not a noticeable increase in salivary cortisol the last 2 wk of the experiment that one might expect as pigs become more crowded with increasing BW. Likewise, Anil et al. (2007) found no effect of floor space allocations ranging from 0.64 to 0.88 m2 for pigs weighing up to 116 kg on salivary cortisol concentrations. However, unlike the current experiment, Anil et al. (2007) reported a significant decline in salivary cortisol concentration as pigs approached market weight regardless of floor space allowance. The response of salivary cortisol to floor space restrictions is mixed. Some researchers report an inverse relationship between baseline salivary cortisol and floor space allocation (Hemsworth et al., 1986; Barnett et al., 1992) whereas others report no relationship (Meunier-Salaun et al., 1987; Pearce and Paterson, 1993).

Table 4.

Effect of floor space allowance on salivary cortisol concentration (µg/dL) of pigs (Exp. 1)

| Floor space allowances, m2/pig | Significance (P-value)1 | |||||||

|---|---|---|---|---|---|---|---|---|

| Sampling time | 0.71 | 0.80 | 0.89 | 0.98 | 1.07 | SE | Linear2 | Quadratic2 |

| No. of pens | 10 | 10 | 10 | 10 | 10 | |||

| Initial3 | 0.194 | 0.228 | 0.183 | 0.195 | 0.212 | 0.009 | 0.98 | 0.78 |

| 2 wk before final weight | 0.211 | 0.241 | 0.255 | 0.215 | 0.211 | 0.011 | 0.76 | 0.20 |

| 1 wk before final weight | 0.216 | 0.165 | 0.211 | 0.169 | 0.203 | 0.009 | 0.73 | 0.29 |

P-values for the statistical model were effect of floor space treatments (P = 0.77), effect of sampling time (P = 0.07), effect of station (P = 0.002), and interaction of station and floor space treatments (P = 0.22).

Linear or quadratic effects of floor space treatments within sampling time.

Sample collected when pigs weighed about 80 kg.

Gross measures of pig health were not substantially affected by floor space allowance (Table 5). The incidence of pigs that were removed from the experiment for welfare reasons, dead pigs, and pigs with skin lesions or lameness were not different across floor space treatments. Similarly, the number of days pigs required injectable therapy was not influenced by floor space allowance. Interestingly, there was a tendency for greater numbers of pigs to die in the lowest and highest floor space allocations. Other researchers (Turner et al., 2000; Anil et al., 2007) have reported an inverse relationship between floor space allowance and incidence of skin lesions and injury. Anil et al. (2007) reported increased injury scores for pigs housed at 0.64 m2 of floor space compared with those provided greater than 0.8 m2, probably as a result of the greater incidence of aggressive interactions among crowded pen mates observed in their experiment. This result suggests the welfare of crowded pigs was compromised but they did not report incidence of morbidity or mortality. Similar to our findings, other researchers reported that floor space allowance had no significant influence on morbidity or mortality of finishing pigs (Flohr et al., 2016). No station recorded any incidence of tail biting or other behavioral vices. Because of the heavy market weight in this experiment, we observed gilts for signs of estrus. Animal caretakers across all stations recorded only rare incidence of behavioral estrus. In general, floor space allowances studied in this experiment did not compromise the criteria used to evaluate welfare of pigs.

Table 5.

Effect of floor space allowance on pig morbidity, mortality, incidence of lameness, and lesion scores (Exp. 1)

| Floor space allowances, m2/pig | |||||||

|---|---|---|---|---|---|---|---|

| Trait | 0.71 | 0.80 | 0.89 | 0.98 | 1.07 | χ2 | Significance(P-value) |

| Morbidity and mortality | |||||||

| No. of pigs | 144 | 144 | 144 | 144 | 138 | – | |

| No. of pigs removed | 3 | 4 | 3 | 2 | 2 | 0.94 | <0.95 |

| No. of dead pigs | 6 | 2 | 0 | 1 | 4 | 9.17 | <0.07 |

| No. of days pigs treated1 | 31 | 22 | 21 | 16 | 39 | 44.5 | <0.29 |

| No. of pigs with lameness score > 12 | 5 | 3 | 5 | 3 | 3 | 1.23 | <0.90 |

| Lesions | |||||||

| No. of pigs observed | 30 | 30 | 30 | 30 | 30 | – | |

| No. of pigs with lesions3 | 28 | 15 | 19 | 18 | 19 | 45.8 | <0.13 |

| Average lesion score4 | 1.62 | 1.38 | 1.44 | 1.44 | 1.44 | – | <0.15 |

Number of days pigs required injectable therapy due to ill health.

Lameness data for last week before final weight. Lameness scoring system was 1 = normal walking, 2 = slight lameness and may have an arched back, 3 = obviously limping but able to keep up with pen mates when group is walking, 4 = not able to keep up with pen mates due to lameness, and 5 = can barely walk.

Number of pigs with at least 1 lesion observed at some time during the experiment. A single pig could be counted more than once if fresh lesions appeared. Only data from 30 pigs per treatment in Ohio and Minnesota are included.

Lesion scoring system was 1 = no cut, swelling, or previous wounds have healed; 2 = minor cut (cut does not go through the skin), slight swelling (skin is red with inflammation), presence of scabs; and 3 = major cut (cuts through the skin), remarkable swelling, or open wounds. Floor space treatment was not significant (P < 0.15; SE 0.147)

Based on the growth performance and pig welfare data collected in Exp. 1, a clearly optimal floor space recommendation is not apparent. The equation of Gonyou et al. (2006) estimates that 138-kg pigs require 0.91 m2 of floor space; therefore, the present study provided 2 treatments below and 2 treatments above the predicted requirement. Our data are clear that pigs in the present study did not respond to floor space allowances greater than the predicted need of 0.91 m2 with improved growth performance or welfare. Similar to our findings, Brumm and NCR-89 Committee on Management of Swine (1996) found that 0.84 to 0.93 m2 of floor space maximized growth performance of 136-kg barrows with no notable improvement in performance above 1.0 m2. Likewise, performance and welfare of pigs in the present experiment did not significantly deteriorate as floor space allowances declined to 0.80 and 0.71 m2.

The lack of detrimental effects of restricted floor space allowances might be explained by the extended period during which pigs were not crowded in this experiment. The most restrictive floor space allowance (0.71 m2/pig) would be sufficient to accommodate a pig weighing 95 kg according to Gonyou et al. (2006). Theoretically, no pig would have experienced crowding until they reached a BW of 95 kg. So for the first 68 kg of BW gain, pigs assigned to the 0.71 m2 treatment would not have been crowded. This represents 61% of the total gain (138 kg final weight − 27 kg beginning weight) achieved by pigs in the experiment. The acceptable growth performance during this relatively long period with no crowding could have diluted any negative effects of crowding on growth performance near the end of the experiment. We anticipated this phenomenon would occur, which was the motivation to design and conduct Exp. 2. In fact, Gonyou et al. (2006) recommended such an experiment to evaluate the specific floor space needs of heavy pigs not confounded by earlier growth performance.

Experiment 2

The primary objective of Exp. 2 was to focus on the floor space requirements of pigs weighing 138 kg, not confounded by earlier space allocation or growth performance. Significant station effects were observed for all measured traits except G:F (Table 6). But there were no significant interactions between station and floor space treatments observed.

Table 6.

Performance of pigs 2 wk before marketing at each participating station (Exp. 2)

| Trait | Kansas | Michigan | Minnesota | Ohio | SE | Station effect (P-value) |

|---|---|---|---|---|---|---|

| No. of pens | 10 | 10 | 10 | 10 | – | |

| BW, kg | ||||||

| Initial | 122.8 | 134.8 | 134.2 | 140.2 | 0.89 | <0.001 |

| Final | 137.4 | 150.4 | 145.7 | 153.7 | 0.57 | <0.001 |

| ADG, kg | 1.04 | 1.11 | 0.82 | 0.96 | 0.04 | <0.001 |

| ADFI, kg | 3.67 | –1 | 2.88 | 3.20 | 0.05 | <0.001 |

| G:F | 0.283 | –1 | 0.285 | 0.300 | 0.01 | <0.55 |

Feed intake data was lost.

The initial BW of pigs was not different across floor space treatments, but we observed a linear increase (P < 0.01) in final BW at the end of the 2-wk period with increasing floor space allowance (Table 7). Similarly, increasing floor space allowance elicited a linear increase (P < 0.01) in the ADG and G:F of pigs. A quadratic increase (P < 0.05) in ADFI was observed as floor space allowance increased, with maximal feed intake occurring at 0.98 m2/pig. Brumm and NCR-89 Committee on Management of Swine (1996) also observed that ADFI responded in a quadratic manner to increasing floor space allowance. Results of Exp. 2 suggest that the optimal floor space allowance for pigs weighing about 148 kg at marketing is 0.98 m2/pig. We are aware of only 1 report in which floor space allowance for pigs weighing up to 136 kg was studied (Brumm, and NCR-89 Committee on Management of Swine 1996). These authors concluded that optimal performance of barrows marketed at 136 kg was achieved when pigs were provided 0.84 to 1.0 m2 of floor space.

Table 7.

Effects of floor space allowance on performance of pigs 2 wk before marketing (Exp. 2)

| Floor space allowances, m2/pig | Significance (P-value)1 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Trait | 0.71 | 0.80 | 0.89 | 0.98 | 1.07 | SE | Trt | Linear | Quadratic |

| No. of pens | 8 | 8 | 8 | 8 | 8 | – | |||

| BW, kg | |||||||||

| Initial | 133.6 | 132.5 | 133.1 | 132.8 | 133.0 | 0.71 | 0.87 | 0.71 | 0.57 |

| Final | 145.6 | 145.7 | 146.4 | 148.3 | 147.9 | 0.64 | 0.02 | 0.002 | 0.99 |

| ADG, kg | 0.86 | 0.95 | 0.95 | 1.10 | 1.06 | 0.04 | 0.003 | 0.001 | 0.48 |

| ADFI,2 kg | 3.03 | 3.26 | 3.22 | 3.49 | 3.25 | 0.06 | 0.002 | 0.003 | 0.014 |

| G:F2 | 0.264 | 0.278 | 0.283 | 0.304 | 0.317 | 0.015 | 0.17 | 0.02 | 0.80 |

Trt = floor space treatment effects; Linear represents the linear effects of floor space treatments; Quadratic represents the quadratic effects of floor space treatments.

Means represent 6 pens for each floor space treatment.

Group size ranged from 6 to 19 pigs per pen in Exp. 1 and 4 to 11 pigs per pen in Exp. 2, which is smaller than group sizes typical of commercial conditions. In a regression analysis of 20 experiments encompassing group sizes of 3 to 100 pigs, Turner et al. (2003) found a linear decline in ADG of growing pigs (31 to 68 kg BW) but no effect of group size on ADG of finishing pigs. Group size had no discernable effect on ADFI of growing or finishing pigs. Similarly, Schmolke et al. (2003) reported no effect of group sizes ranging from 10 to 80 pigs per pen on growth performance of growing–finishing pigs. More importantly, Street and Gonyou (2008) determined that the negative effects of reduced floor space allocations on growth performance were of similar magnitude for pigs housed in groups of 18 compared with groups of 108. Consequently, we believe results of the experiments reported herein are applicable to commercial conditions where larger group sizes are common.

In Exp. 2, the floor space needs of heavy market pigs could be studied isolated from the diluting effects of the early growth period that were present in Exp. 1. Results of Exp. 2 indicate that 0.98 m2/pig optimized growth performance of pigs between the weights of 133 and 148 kg. Assuming an average BW during this 2-wk period of 140 kg, one can calculate floor space allowance estimates using k values from Gonyou et al. (2006). To optimize ADG, Gonyou et al. (2006) suggested k values that ranged from 0.0317 to 0.0348, which would predict floor space needs of 0.86 to 0.94 m2 for a 140-kg pig. These floor space allowances are 88 to 96% of the optimal floor space allowance observed in Exp. 2. To optimize ADFI, Gonyou et al. (2006) suggested k values of 0.0335 to 0.0358, which would predict floor space allocations of 0.90 to 0.97 m2 for a 140-kg pig. These floor space allowances are 92 to 99% of the optimal floor space allowance for a 140-kg pig (0.98 m2) determined in Exp. 2. Therefore, results of the present experiment agree with the suggestions of Potter et al. (2010) and Flohr et al. (2016) that the k values proposed by Gonyou et al. (2006) may underestimate floor space needs of heavy market pigs but that the underestimate is slight when considering the results presented herein.

Within a reasonable range, increasing stocking density increases the total kilograms of live weight produced from fixed building assets, which increases net revenue (Powell and Brumm, 1992) or income over feed and facility costs (Flohr et al., 2016) for producers. Crowding finishing pigs can reduce growth performance of individual pigs (Exp. 2; Moser et al., 1985; NCR-89 Committee on Confinement Management of Swine, 1993; Brumm and NCR-89 Committee on Management of Swine,, 1996) and compromise welfare of finishing pigs (Anil et al., 2007). These negative effects of reduced floor space can be substantially mitigated by removing a portion of the heaviest pigs as pens become most crowded. This practice is commonly known as “topping” pens. Removing the heaviest pigs in a pen improves growth performance of remaining pigs (DeDecker et al., 2005; Flohr et al., 2016) likely due to greater access to resources such as floor space and feeder space, greater water access, and favorable alterations of the social dynamics within the pen. For instance in Exp. 2, removing 25% of the heaviest pigs in pens assigned to the most restrictive floor space allowance (0.71 m2) would increase floor space for the remaining pigs to 0.94 m2/pig, which is very close to the floor space allowance that optimized pig performance. DeDecker et al. (2005) removed 25% of the heaviest pigs from pens 19 d before the end of the experiment and found a 20% improvement in ADG and an 11% improvement in ADFI of the remaining pigs in the pen. Removing 50% of the heaviest pigs in the pen did not further improve pig performance. So providing adequate floor space allocation in the early and middle portion of the growing–finishing period and then removing 25% of the pigs in the pen in the late portion of the finishing period can mitigate negative effects of floor space restrictions close to marketing.

In conclusion, pigs marketed at 138 kg BW optimize growth performance when provided 0.89 to 0.98 m2 of floor space per pig. However, the negative effects of low space allocations were mostly observed in heavy pigs. Therefore, the use of a pig removal strategy near the end of the finishing period may be an effective strategy to diminish the negative effects of crowding when pigs are near market weight.

Footnotes

This project represents work of the NCERA-219 Committee on Swine Production Management to Enhance Animal Welfare.

LITERATURE CITED

- Anil L., Anil S. S., Deen J. 2007. Effects of allometric space allowance and weight group composition on grower-finisher pigs. Can. J. Anim. Sci. 87:139–151. doi: 10.4141/A06-051 [DOI] [Google Scholar]

- Barnett J. L., Hemsworth P. H., Cronin G. M., Newman E. A., McCallum T. H., Chilton D. 1992. Effects of pen size, partial stalls and method of feeding on welfare-related behavioural and physiological responses of group-housed pigs. Appl. Anim. Behav. Sci. 34:207–220. doi: 10.1016/S0168-1591(05)80116-9 [DOI] [Google Scholar]

- Brumm M. C., NCR-89 Committee on Management of Swine 1996. Effect of space allowance on barrow performance to 136 kilograms body weight. J. Anim. Sci. 74:745–749. doi: 10.2527/1996.744745x [DOI] [PubMed] [Google Scholar]

- Brumm M. C., Ellis M., Johnston L. J., Rozeboom D. W., Zimmerman D. R. 2001. Interaction of swine nursery and grow-finish space allocations on performance. J. Anim. Sci. 79:1967–1972. doi: 10.2527/2001.7981967x [DOI] [PubMed] [Google Scholar]

- DeDecker J. M., Ellis M., Wolter B. F., Corrigan B. P., Curtis S. E., Parr E. N., Webel D. M. 2005. Effects of proportion of pigs removed from a group and subsequent floor space on growth performance of finishing pigs. J. Anim. Sci. 83:449–454. doi: 10.2527/2005.832449x [DOI] [PubMed] [Google Scholar]

- Flohr J. R., Tokach M. D., DeRouchey J. M., Woodworth J. C., Goodband R. D., Dritz S. S. 2016. Evaluating the removal of pigs from a group and subsequent floor space allowance on the growth performance of heavy-weight finishing pigs. J. Anim. Sci. 94:4388–4400. doi: 10.2527/jas.2016-0407 [DOI] [PubMed] [Google Scholar]

- Gonyou H. W., Brumm M. C., Bush E., Deen J., Edwards S. A., Fangman T., McGlone J. J., Meunier-Salaun M., Morrison R. B., Spoolder H., Sundberg P. L., Johnson A. K. 2006. Application of broken-line analysis to assess floor space requirements of nursery and grower-finisher pigs expressed on an allometric basis. J. Anim. Sci. 84:229–235. doi: 10.2527/2006.841229x [DOI] [PubMed] [Google Scholar]

- Gonyou H. W., Stricklin W. R. 1998. Effects of floor area allowance and group size on the productivity of growing/finishing pigs. J. Anim. Sci. 76:1326–1330. doi: 10.2527/1998.7651326x [DOI] [PubMed] [Google Scholar]

- Hemsworth P. H., Barnett J. L., Hansen C., Winfield C. G. 1986. Effects of social environment on welfare status and sexual behaviour of female pigs. II. Effects of space allowance. Appl. Anim. Behav. Sci. 16:259–267. doi: 10.1016/0168-1591(86)90118-8 [DOI] [Google Scholar]

- Li Y. Z., Gonyou H. W. 2013. Comparison of management options for sows kept in pens with electronic feeding stations. Can. J. Anim. Sci. 93:445–452. doi: 10.4141/cjas2013-044 [DOI] [Google Scholar]

- Meunier-Salaun M. C., Vantrimponte M. N., Raab A., Dantzer R. 1987. Effect of floor area restriction upon performance, behavior and physiology of growing-finishing pigs. J. Anim. Sci. 64:1371–1377. doi: 10.2527/jas1987.6451371x [DOI] [PubMed] [Google Scholar]

- Moser R. L., Cornelius S. G., Pettigrew J. E., Jr, Hanke H. E., Hagen C. D. 1985. Response of growing-finishing pigs to decreasing floor space allowance and(or) Virginiamycin in diet. J. Anim. Sci. 61:337–342. doi: 10.2527/jas1985.612337x [DOI] [PubMed] [Google Scholar]

- NCR-89 Committee on Confinement Management of Swine 1993. Space requirements of barrows and gilts penned together from 54 to 113 kilograms. J. Anim. Sci. 71:1088–1091. doi: 10.2527/1993.7151088x [DOI] [PubMed] [Google Scholar]

- NRC 2012. Nutrient requirements of swine. 11th rev. ed Natl. Acad. Press, Washington, DC. [Google Scholar]

- Parrott R. F., Misson B. H. 1989. Changes in pig salivary cortisol in response to transport simulation, food and water deprivation, and mixing. Br. Vet. J. 145:501–505. doi: 10.1016/0007-1935(89)90110-3 [DOI] [PubMed] [Google Scholar]

- Parrott R. F., Misson B. H., Baldwin B. A. 1989. Salivary cortisol in pigs following adrenocorticotrophic hormone stimulation: Comparison with plasma levels. Br. Vet. J. 145:362–366. doi: 10.1016/0007-1935(89)90034-1 [DOI] [PubMed] [Google Scholar]

- Pearce G. P., Paterson A. M. 1993. The effect of space restriction and provision of toys during rearing on the behavior, productivity and physiology of male pigs. Appl. Anim. Behav. Sci. 36:11–28. doi: 10.1016/0168-1591(93)90095-7 [DOI] [Google Scholar]

- Petherick J. C., Baxter S. H. 1981. Modelling the static spatial requirement of livestock. In: Modelling, design and evaluation of agricultural buildings. Scott. Farm Build. Investig. Unit. Bucksburn, Aberdeen, UK: p. 75–82. [Google Scholar]

- Potter M. L., Dritz S. S., Tokach M. D., DeRouchey J. M., Goodband R. D., Nelssen J. L. 2010. Effects of increasing stocking density on finishing pig performance. Kansas Swine Ind. Day Rep. Prog. No. 1038. Kansas State Univ. Agric. Exp. Sta, Manhattan, KS: p. 216–222. [Google Scholar]

- Powell T. A., Brumm M. C. 1992. Economics of space allocation for grower-finisher hogs. J. Farm Mngs. Rural Appr. 56:67–72. [Google Scholar]

- Prickett J. R., Kim W., Simer R., Yoon K., Zimmerman J. 2008. Oral-fluid samples for surveillance of commercial growing pigs for porcine reproductive and respiratory syndrome virus and porcine circovirus type 2 infections. J. Swine Prod. Health 16:86–91. [Google Scholar]

- Salimetrics 2017. Expanded range high sensitivity salivary cortisol enzyme immunoassay kit. https://www.salimetrics.com/assets/documents/1-3002n.pdf. (Accessed May 4, 2017.)

- Schmolke S. A., Li Y. Z., Gonyou H. W. 2003. Effect of group size on performance of growing-finishing pigs. J. Anim. Sci. 81:874–878. doi: 10.2527/2003.814874x [DOI] [PubMed] [Google Scholar]

- Street B. R., Gonyou H. W. 2008. Effects of housing finishing pigs in two group sizes and at two floor space allocations on production, health, behavior, and physiological variables. J. Anim. Sci. 86:982–991. doi: 10.2527/jas.2007-0449 [DOI] [PubMed] [Google Scholar]

- Turner S. P., Allcroft D. J., Edwards S. A. 2003. Housing pigs in large social groups: A review of implications for performance and other economic traits. Livest. Prod. Sci. 82:39–51. doi: 10.1016/S0301-6226(03)00008-3 [DOI] [Google Scholar]

- Turner S. P., Ewen M., Rooke J. A., Edwards S. A. 2000. The effect of space allowance on performance, aggression and immune competence of growing pigs housed on straw deep-litter at different group sizes. Livest. Prod. Sci. 66:47–55. doi: 10.1016/S0301-6226(00)00159-7 [DOI] [Google Scholar]

- USDA 2017. National statistics for hogs. https://quickstats.nass.usda.gov/results/1951BC4F-B1BB-3412-8BCB-D4CAF19978C5?pivot = short_desc. (Accessed May 3, 2017.)