ABSTRACT

The objective of this 2-yr study was to evaluate growing and finishing performance as well as carcass characteristics of spring-born steers backgrounded on 3 different systems, using feedstuffs readily available in the Midwest: 1) grazing corn residue and being supplemented with dried distillers plus solubles at 2.68 kg DM/steer 6 d/wk (RESIDUE), 2) grazing a late summer–planted oat–brassica forage mix (CCROP), or 3) being fed a corn silage–based diet in a drylot (DRYLOT). Steers (n = 715) were stratified by BW (278 kg ± 23 in yr 1 and 291 kg ± 91 in yr 2) and assigned to treatment and replicate (4 replications per treatment per yr). Steers assigned to DRYLOT were fed a corn silage–based diet for 54 d in yr 1 and 52 d in yr 2 before being transitioned to the finishing diet. Steers assigned to RESIDUE and those assigned to CCROP grazed 65 d in yr 1 and 66 d in yr 2 and then were fed a corn silage–based diet for 21 d in yr 1 and 33 d in yr 2 before being transitioned to the finishing diet. During backgrounding, the ADG (SEM 0.022) of steers assigned to DRYLOT (1.48 kg/d) was greater (P < 0.01) than that of steers assigned to both CCROP (1.05 kg/d) and RESIDUE (0.87 kg/d) and ADG of steers assigned to CCROP was greater (P < 0.01) than that of steers assigned to RESIDUE. At the start of the finishing period, BW of steers assigned to CCROP (381 kg) was greater (P < 0.01, SEM 2.5) than that of steers assigned to DRYLOT (361 kg) and RESIDUE (366 kg). The finishing period lasted 160 d for all treatments. Both 12th-rib fat (P = 0.89) and calculated yield grade (P = 0.39) did not differ among treatments. Finishing G:F of steers assigned to DRYLOT (0.162 kg/kg) was greater (P < 0.01, SEM 0.0015) than that of steers assigned to RESIDUE (0.153 kg/kg) and CCROP (0.153 kg/kg), which did not differ (P = 0.79). In yr 1, HCW of steers assigned to CCROP (402 kg) was greater (P < 0.01, SEM 2.1) than that of steers assigned to both RESIDUE (389 kg) and DRYLOT (391 kg), which did not differ (P = 0.40). This difference in HCW is most likely a result of differences in BW at the start of the finishing phase in yr 1. However in yr 2, HCW of steers assigned to CCROP (400 kg) and RESIDUE (397 kg) did not differ (P = 0.26, SEM 2.1) but were greater (P < 0.01) than that of steers assigned to DRYLOT (367 kg), despite the fact that steers assigned to RESIDUE entered the finishing phase at a lighter BW than steers assigned to CCROP. Marbling was greater (P = 0.01, SEM 3.9) for steers assigned to DRYLOT (429) than for steers assigned to RESIDUE (414), although steers assigned to CCROP (424) were not different (P ≥ 0.10) from steers assigned to DRYLOT or RESIDUE. When cost and price scenarios from the last 5 yr were conducted, no treatment appeared to be consistently superior in terms of cost of gain or net return. Therefore, all 3 systems appear to be viable options for producers.

Keywords: backgrounding steers, brassicas, carcass quality, corn residue, feedlot

INTRODUCTION

Different components of backgrounding management, such as diet type and ADG, have been found to impact subsequent finishing performance and carcass characteristics (Owens et al., 1995; McCurdy et al., 2010; Lancaster et al., 2014). Lesser growing phase ADG has been associated with increased finishing phase ADG (Lancaster et al., 2014) and finishing phase G:F (Reuter and Beck, 2013; Lancaster et al., 2014). However, backgrounding systems appear to have minimal effects, if any, on carcass quality if cattle are finished to equal 12th-rib fat (Reuter and Beck, 2013; Lancaster et al., 2014).

In the Midwest, there is significant opportunity to background fall-weaned calves in the winter using forages produced from cropland. Corn residue is an abundant forage resource that, with supplementation of protein and energy, can be used to background calves (Watson et al., 2015; Tibbitts et al., 2016). Additionally, corn silage is often grown near feedlots as a forage source for receiving and finishing diets. When corn silage is harvested in late summer, cool-season grasses and brassicas can be planted afterwards to provide fall/winter grazing. Late summer–planted oats and brassicas are highly digestible (Villalobos and Brummer, 2015; Coblentz and Cavadini, 2016), but little information regarding calf performance when grazing this resource is available.

Using these potentially readily available forage sources in the fall/winter may allow feedlots in the Midwest to purchase fall-weaned calves in excess of their drylot capacity and economically background them without negatively impacting finishing performance or carcass characteristics. The objectives of the current research were to evaluate the growing and subsequent finishing performance and carcass characteristics of backgrounded spring-born steers 1) grazing corn residue and being supplemented with dried distiller's grains plus solubles (DDGS); 2) grazing an oats, turnip, and radish mix planted after corn silage harvest; or 3) fed a corn silage–based diet in drylot.

MATERIAL AND METHODS

All animal use protocols were approved by the U.S. Meat Animal Research Center (USMARC) Animal Care and Use Committee.

Cattle

A 2-yr study was conducted at the USMARC near Clay Center, NE; 715 (355 in yr 1 and 360 in yr 2) spring-born MARC II composite (one-fourth each Gelbvieh, Simmental, Hereford, and Angus) steer calves in yr 1 and a combination of MARC II composite, MARC II crossed with MARC III composite (one-fourth Angus, Hereford, Red Poll, and Pinzgauer), and Angus crossed with MARC III composite steer calves in yr 2 were used. Steers were weaned in September and were fed a corn silage–based diet (Table 1) before being individually weighed in mid November to determine initial experimental BW. Throughout the experiment, BW were taken in the morning prior to feeding. Before each use, the scale was validated using a 453.6-kg certified weight and calibrated when the actual reading was >0.3% above or below the certified weight.

Table 1.

Composition of growing and finishing diet

| Item | Growing diet, DM basis, % | Finishing diet, DM basis, % |

|---|---|---|

| Ingredient | ||

| Dry rolled corn | – | 55.8 |

| Corn silage | 51.0 | 8.7 |

| Alfalfa hay | 25.0 | – |

| WDGS1 | 20.0 | 32.3 |

| Supplement2 | 4.0 | 3.2 |

| Analyzed composition | ||

| CP, % | 16.2 | 17.5 |

| NEm,3 Mcal/kg | 1.65 | 4.73 |

| NEg,3 Mcal/kg | 1.04 | 3.26 |

| NDF, % | 36.1 | 15.3 |

| Starch,% | 22.8 | 43.6 |

| Calcium, % | 0.85 | 0.68 |

| Phosphorus, % | 0.41 | 0.55 |

WDGS = wet distiller's grains plus solubles.

Supplement (Purina Animal Nutrition LLC, Gray Summit, MO) provided Rumensin at 31 g/t of diet DM.

Calculated using the] summative equation (Weiss et al., 1992).

Steers were stratified by genetic line and BW (278 kg ± 1.2 in yr 1 and 291 kg ± 4.8 in yr 2) and assigned to 1 of 3 treatments: 1) grazing corn residue and being supplemented with DDGS at 2.68 kg DM/steer 6 d/wk (RESIDUE), 2) grazing a late summer planted oat-brassica forage mix (CCROP) or 3) being fed a corn silage-based diet in drylot (DRYLOT) in a completely randomized design. Each treatment was replicated 4 times per year and contained 25 to 30 steers per replication.

Diets and Animal Care

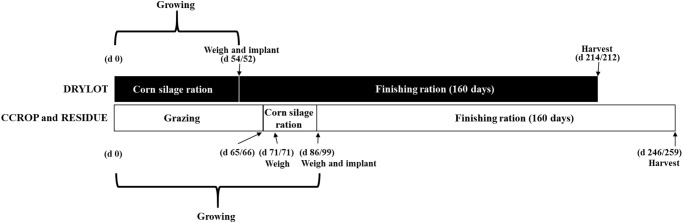

Steers assigned to the DRYLOT treatment were placed in 4 soil-surfaced feedlot pens with 30 steers per pen in both years. Pens were approximately 15.4 by 61 m with a concrete apron extending 4.7 m from the bunk and 15.1 m of bunk space available. Steers assigned to DRYLOT were backgrounded on a corn silage–based diet (Table 1) for 54 d in yr 1 and 52 d in yr 2, to meet a targeted BW of 363 kg at the end of the growing period (Fig. 1). Once steers reached 363 kg, they were weighed, implanted with Revalor-XS (200 mg trenbolone acetate and 40 mg estradiol 17β; Merck Animal Health, DeSoto, KS), and transitioned to the finishing diet (Table 1) over a 15-d period in both years and then fed the finishing diet for 144 d in yr 1 and 146 d in yr 2.

Figure 1.

Study timeline, day of trial indicated in parentheses, with yr 1 represented first and yr 2 represented second. Steers were assigned to 1 of 3 treatments 1) grazing corn residue and being supplemented with dried distillers plus solubles at 2.68 kg DM/steer 6 d/wk (RESIDUE), 2) grazing a late summer planted oat-brassica forage mix (CCROP) or 3) being fed a corn silage-based diet in drylot (DRYLOT). Steers assigned to DRYLOT were fed a corn silage-based diet for 54 d in yr 1 and 52 d in yr 2 before being implanted and transitioned to the finishing diet (top bar). Steers assigned to RESIDUE and those assigned CCROP grazed 65 d in yr 1 and 66 d in yr 2 and then were fed a corn silage-based diet for 21 d in yr 1 and 33 d yr 2 before being implanted and transitioned to the finishing diet (bottom bar). The finishing period lasted 160 days for all treatments in both years.

Steers assigned to CCROP were placed in an irrigated field that was seeded with 94 kg/ha of oat, 2.2 kg/ha of daikon radish, and 1.7 kg/ha of purple top turnips after corn silage harvest. Nitrogen was split-applied using the pivot with 54 kg N/ha total applied in yr 1 and 45.7 kg N/ha total applied in yr 2. Initial forage yield before turning steers out to graze was 3,756 ± 256 and 5,144 ± 506 kg/ha (DM basis) in yr 1 and yr 2, respectively. Steers were stocked at a rate 1,538 ± 37 kg DM/steer in yr 1 and 1,984 ± 108 kg DM/steer in yr 2. On a DM basis, the potentially grazeable forage was 57% oats, 22% turnip top, 5% turnip root, 13% radish top, and 3% radish root. In yr 1, the field was divided into 12.5-ha quarters, and the number of steers per quarter varied according to the amount of forage available, resulting in 25, 30, 30, and 30 steers per quarter. In yr 2, the field was divided into 14.2-, 13.8-, 14.6-, and 10.2-ha quarters based on the forage yield and stocked with 30 steers per quarter. The grazing period lasted 65 d in yr 1 and 66 d in yr 2, and steers were removed from grazing when the CCROP biomass appeared limiting (1,445 ± 104 kg DM/ha in yr 1 and 1,401 ± 499 kg DM/ha in yr 2).

Steers assigned to RESIDUE were placed in a harvested, irrigated corn field that was divided into 4 quarters with 12.5 ha per quarter in yr 1 and 9.4 ha per quarter in yr 2. In both years, each quarter was stocked with 30 steers and steers were supplemented 6 d a week with 2.68 kg DM/steer of DDGS, with limestone added at 2% on a DM basis. The grazing period for RESIDUE was the same as that for CCROP each year.

Both RESIDUE and CCROP steers were given access to a free-choice mineral containing 1,323 g monensin/t (Vigortone Ag Products, Brookville, OH) during the grazing period. At the end of the grazing period, each group of steers from both the CCROP treatment and the RESIDUE treatment was placed into a separate soil-surfaced feedlot pens (8 pens/4 replications per treatment), and steers were fed the same corn silage–based ration that DRYLOT steers had previously received (Table 1). After 6 d in yr 1 and 5 d in yr 2, BW were collected for the RESIDUE and CCROP steers (Fig. 1). These BW were taken to correct final grazing BW and ADG for potential differences in gut fill. The gain of the steers during the 5- or 6-d period was calculated using the gains of the DRYLOT steers and was subtracted to calculate the ADG during the grazing period. Steers continued to be fed the corn silage–based ration for an additional 15 d in yr 1 and 28 d in yr 2 (Fig. 1) in an effort to allow steers to reach a targeted BW of approximately 363 kg. Then, they were implanted with Revalor-XS (200 mg trenbolone acetate and 40 mg estradiol 17β; Merck Animal Health) and transitioned to the finishing diet (Table 1) over a 13- (yr 1) and 5-d (yr 2) period and then fed the finishing diet for 145 d in yr 1 and 154 in yr 2.

Feed bunks were visually evaluated each day of the experiment at approximately 0630 h to determine the quantity of feed to offer each pen. Bunk management readings were conducted so that less than 0.15 kg feed per steer remained in the bunk at the time of evaluation. Steers were fed once daily at approximately 0730 h. Wet distiller's grains plus solubles used in the experiment was delivered weekly from a single source and stored on a concrete pad. Changes in DM of wet distiller's grains plus solubles were monitored by collecting and drying samples weekly as well as every time a new load was delivered and after rain events.

On the day of harvest, HCW and harvest order were recorded. After a 36-h chill, LM area, 12th-rib fat thickness, and marbling score were determined by USMARC personnel using the VBG2000 beef grading camera (E + V Technology GmBH & Co. KG, Oraineburg, Germany; Shackelford et al., 2003). Yield grade was calculated [2.5 + (6.35 × 12th-rib fat) + (0.2 × 2.5[KPH]) + (0.0017 × HCW) − (2.06 × LM area)] for each individual steer and then averaged within pen (USDA, 1997). The common dressing percent of steers in the present study of 62% was multiplied by HCW to calculate carcass-adjusted final BW, which was used to calculate carcass-adjusted ADG and G:F.

Economic Analysis

Each treatment was evaluated in terms of cost of gain (COG) and net returns using the average cost of the previous 5 yr for feed, fertilizer, seed, and cattle prices. Additionally, costs and prices from the highest feed price year in the last 5 yr (2012) and the lowest feed price year (2016) were used to evaluate COG and net returns. Feed prices were based on United States Department of Agriculture Economic Research Service Feed Grains Database Yearbook Tables (USDA-ERS, 2017). Fertilizer prices were obtained from Index Mundi (Barrientos and Soria, 2017). Oat and brassica seed prices were obtained from Green Cover Seed (Bladen, NE; K. Berns, personal communication). These variable costs and prices are shown in Table 2.

Table 2.

Variable inputs used for economic analysis of backgrounding treatments

| Item | Average (2012 to 2016) | 2012 | 2016 |

|---|---|---|---|

| Growing diet, $/t1 | 169 | 256 | 127 |

| Finishing diet, $/t | 197 | 325 | 143 |

| Distiller's grain supplement, $/t | 184 | 285 | 123 |

| Fertilizer, $/t of N | 647 | 899 | 442 |

| Oat–brassica seed, $/ha | 72 | 71 | 59 |

| Initial calf value, $/kg BW | 2.83 | 3.17 | 4.07 |

| End growing, $/kg BW | 3.43 | 3.17 | 3.30 |

| Hot carcass, $/kg | 4.71 | 4.10 | 4.34 |

All economical analysis was conducted on a US dollar basis

Cost calculations for grazing in the RESIDUE and CCROP treatments included the mineral, grazing resource, transportation, fencing, and yardage. Yardage was charged at a constant US$0.20/d for RESIDUE and $0.10/d for CCROP. Fencing was assumed to be temporary 2-wire electric fence at a cost of $10.87/ha. Transportation costs assumed $2.64 per loaded kilometer for 64 km for 60 steers at a cost of $2.83/steer. Free choice mineral was charged at $0.07/d. The grazing resource cost for the RESIDUE treatment included $37/ha for corn residue rental and the DDGS supplement cost based on USDA-ERS price data (Table 2; USDA-ERS, 2017). The grazing resource cost for the CCROP treatment covered the cost of establishing the oat–brassicas stand. This included the cost of seed (Table 2), fertilizer cost (Table 2), and custom rate drilling expenses at $37/ha. Cost calculations for growing and finishing phases including diet costs (Table 2) and yardage charged at a constant $0.43/d.

Net returns to management were calculated using cattle prices from 2012 through 2016 (Table 2) obtained from the Livestock Marketing Information Center using the Weighted Average Summary for Nebraska Combined Auctions and Monthly Weighted Averages for Nebraska Direct Slaughter (LMIC, unpublished data). Interest was charged for the term of ownership on the beginning animal value at 0.0137%.

Lab Analysis

Diet samples were collected from the bunks daily (200 g, as-fed basis, from each treatment) and composited by diet type within week and stored at −20°C. Multiple (2 to 3) grab samples were collected from each bunk. After the experiment, the weekly samples were thawed and composited to form monthly samples. Composited monthly samples were analyzed for DM, CP, ADF, NDF, ether extract, and starch at a commercial laboratory (Dairyland Laboratories, Inc., Arcadia, WI). Dry matter intake was calculated by multiplying the as-fed feed delivered by the weekly DM percentage of each treatment group.

Biomass and quality samples were collected from the CCROP treatment prior to the start of grazing. For biomass determination, 4 random 0.37-m2 areas were sampled in each replicate. The turnips and radishes within this area were pulled up so that grazeable root biomass could be included and oats were clipped at ground level. The samples were separated by species, with the brassica leaves being separated from the root. The samples were dried in paper bags, in a 60°C forced-air oven (model LBB2-21-1; Despatch, Minneapolis, MN), until a constant weight was obtained (AOAC, 1965; method 935.29). Forage quality samples were taken on the same date as the biomass samples. Each species (oats, radish, and turnip) were collected at random within each replicate and put into separate bags according to species type. They were kept in a portable cooler with ice for transport to the laboratory. Once at the lab, brassicas were separated into leaf and root, and samples were stored frozen. Samples were then freeze-dried (Virtis Freezemobile 25ES; Life Scientific, Inc., St. Louis, MO) and ground through a 1-mm screen using a Wiley mill (Thomas Scientific, Swedesboro, NJ). Freeze-dried samples were analyzed for corrected DM (100°C), OM, CP, ADF, and in vitro OM disappearance (IVOMD).

Organic matter was determined by placing samples in a muffle furnace for 6 h at 600°C (AOAC, 1999; method 4.1.10). Crude protein analyses were determined using a combustion chamber (TruSpec N Determinator; LECO Corporation, St. Joseph, MO; AOAC, 1999; method 990.03). Acid detergent fiber analysis was conducted according to the Van Soest et al. (1991) method using an Ankom 200 fiber analyzer (ANKOM Technology Corp., Macedon, NY). In vitro OM disappearance was determined after a 48-h incubation period using the method described by Tilley and Terry (1963), modified by adding urea to the McDougall's buffer (McDougall, 1948) at a rate of 1 g urea/L buffer solution, to ensure adequate RDP was available for microbes in the rumen fluid (Weiss, 1994). Samples from yr 1 were analyzed separately from those from yr 2. Blanks were included in both incubation runs to adjust for any feed particles that might have come from the inoculum.

Statistical Analysis

Data were analyzed using the MIXED procedure of SAS 9.3 (SAS Inst. Inc., Cary, NC) with replicate (pen or grazing paddock) as the experimental unit. The model for growth performance data (BW, ADG, DMI, and G:F) and carcass characteristics (HCW, LM area, 12th-rib fat, marbling score, and USDA yield grade) included the fixed effects of backgrounding treatment, year, and interaction between year and backgrounding treatment. The model for COG and net return included the fixed effects of backgrounding treatment, and year was considered random. For all analysis, effects were considered significant at P-value ≤ 0.05, with tendencies declared at P-values between 0.05 and 0.10.

RESULTS

Grazing Period Gains

When comparing RESIDUE and CCROP during the grazing period, there was no year × backgrounding treatment interaction (P ≥ 0.60) for final grazing BW or ADG. There was a treatment effect (P < 0.01) for grazing ADG, with steers grazing CCROP having greater (P < 0.01) ADG than steers grazing RESIDUE (Table 3). There was an effect of year (P < 0.01) on ADG, with greater (P < 0.01) ADG observed in yr 1 than in yr 2 (0.82 ± 0.029 and 0.35 ± 0.029 kg/d, respectively).

Table 3.

Two-year growing performance of steers grazing corn residue and being supplemented with dried distillers plus solubles at 2.68 kg DM/steer 6 d/wk (RESIDUE), grazing a late summer planted oat-brassica forage mix (CCROP) or being fed a corn silage-based diet in drylot (DRYLOT)

| Item | RESIDUE | CCROP | DRYLOT | SEM1 | P-value2 |

|---|---|---|---|---|---|

| Initial BW, kg | 286 | 285 | 283 | 1.3 | 0.13 |

| Grazing, d | 66 | 66 | – | – | – |

| Grazing ADG, kg | 0.45b | 0.72a | – | 0.028 | <0.01 |

| Final grazing BW, kg | 315b | 331a | – | 1.8 | <0.01 |

| Growing diet, d | 27 | 27 | 53 | – | – |

| Growing diet ADG, kg | 1.92a | 1.88a | 1.48b | 0.087 | <0.01 |

| Growing diet DMI, kg | 7.5b | 7.8b | 8.3a | 0.11 | <0.01 |

| Total growing, d | 93 | 93 | 53 | – | – |

| Total growing ADG, kg | 0.87c | 1.05b | 1.48a | 0.022 | <0.01 |

| Final growing BW, kg | 366b | 381a | 361b | 1.8 | <0.01 |

Means within a row with different superscripts differ (P ≤ 0.05).

Standard error of the least squares mean (n = 8 pens/mean).

Year × treatment interactions were not significant (P ≥ 0.07).

Growing Period Performance

Steer growth performance for all 3 treatments during the growing period is presented in Table 3. The growing period was targeted to end when steers reached 364 kg BW and includes the grazing period plus the subsequent feeding of the corn silage–based diet for CCROP and RESIDUE. There was no year × backgrounding treatment interaction (P = 0.88) for ADG while steers consumed the growing diet. The ADG of steers assigned to RESIDUE and CCROP did not differ (P = 0.79) but was greater (P < 0.01) than that of steers assigned to DRYLOT. However, there was a tendency for year × backgrounding treatment interaction (P = 0.07) for DMI of the grower diet. In yr 1, DMI of steers assigned to CCROP (8.13 ± 0.16 kg/d) and RESIDUE (8.32 ± kg/d) did not differ (P = 0.40) but DMI of steers assigned to RESIDUE tended (P = 0.06) to be less than that of steers assigned to DRYLOT (8.58 ± 0.16 kg/d) and DMI of steers assigned to CCROP did not differ (P = 0.25) from that of steers assigned to DRYLOT. In yr 2, DMI of steers assigned to CCROP (6.86 ± 0.16 kg/d) and RESIDUE (7.23 ± 0.16 kg/d) did not differ (P = 0.11) but both were less (P < 0.01) than steers assigned to DRYLOT (8.04 ± 0.16 kg/d).

There was no year × backgrounding treatment interaction (P ≥ 0.17) for total growing ADG or final growing BW. There was a year effect (P < 0.01) on growing period ADG, with steers in yr 1 having greater (P < 0.01) ADG than steers during yr 2. There was also a treatment effect (P < 0.01) on growing period ADG, with DRYLOT steers having the greatest (P < 0.01) ADG, RESIDUE steers having the least (P < 0.01), and CCROP steers being intermediate, differing (P < 0.01) from both DRYLOT and RESIDUE steers (Table 3). Average daily gain of the DRYLOT steers during the backgrounding phase was used to estimate how many days RESIDUE and CCROP steers needed to be fed the corn silage–based diet to reach 364 kg. However, the days needed to reach the target BW was overestimated, as there was a treatment effect (P < 0.01) for final growing period BW, with CCROP steers having a greater (P < 0.01) final growing period BW than both RESIDUE and DRYLOT steers, and RESIDUE steers tending to be greater (P = 0.06) than DRYLOT steers (Table 3).

Finishing Performance

There was a year × backgrounding treatment interaction (P < 0.01) for carcass-adjusted ADG and final BW (Table 4). In yr 1, there was no difference (P > 0.30) in carcass-adjusted ADG among treatments during finishing, resulting in the initial finishing BW ranking to be maintained throughout finishing, with carcass-adjusted final BW in yr 1 being greater (P < 0.01) for CCROP steers than for DRYLOT and RESIDUE steers, which did not differ (P = 0.40). In yr 2, the lesser ADG for RESIDUE and CCROP steers during the growing phase resulted in compensatory gain during the finishing phase, with finishing ADG not differing (P = 0.12) between RESIDUE and CCROP steers but being greater (P < 0.01) than that of DRYLOT steers. This resulted in a change from the initial finishing BW ranking, with carcass-adjusted final BW not differing (P = 0.26) between CCROP and RESIDUE steers but both being greater (P < 0.01) than that of DRYLOT steers.

Table 4.

Two-year finishing (160 d period) performance of steers backgrounded by either grazing corn residue and being supplemented with dried distillers plus solubles at 2.68 kg DM/steer 6 d/wk (RESIDUE), grazing a late summer planted oat-brassica forage mix (CCROP) or being fed a corn silage-based diet in drylot (DRYLOT)

| Treatments | P-value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Year 1 | Year 2 | |||||||||

| Item | RESIDUE | CCROP | DRYLOT | RESIDUE | CCROP | DRYLOT | SEM1 | Year | Treatment | Year × treatment2 |

| Initial finishing BW, kg | 365b | 381a | 365b | 367b | 381a | 357c | 2.5 | 0.43 | <0.01 | 0.18 |

| Final live BW,3 kg | 608b | 625a | 614b | 616a | 622a | 570b | 4.0 | <0.01 | <0.01 | <0.01 |

| Final BW,4 kg | 627b | 648a | 631b | 640a | 645a | 593b | 3.4 | <0.01 | <0.01 | <0.01 |

| Daily DMI, kg | 10.2a | 10.3a | 9.6b | 10.9a | 10.7a | 9.0b | 0.13 | 0.12 | <0.01 | <0.01 |

| ADG,4 kg | 1.64 | 1.67 | 1.67 | 1.71a | 1.66a | 1.47b | 0.022 | 0.01 | <0.01 | <0.01 |

| G:F,4 kg/kg | 0.161b | 0.162b | 0.174a | 0.157ab | 0.155b | 0.162a | 0.0021 | <0.01 | <0.01 | 0.28 |

Means within item and year with different superscripts differ (P ≤ 0.05).

Standard error of the least squares mean (n = 4 replications/year).

Year × background treatment interaction.

BW were taken prior to feeding on the day they were hauled to the packing plant, with a calculated 4% shrink.

Carcass-adjusted final BW, ADG, and G:F using a common dressing percent of 62%.

There was a year × background treatment interaction (P < 0.01) for DMI. However, DMI of RESIDUE and CCROP steers within both years did not differ (P = 0.40) and were greater (P < 0.01) than that of DRYLOT steers. There was no year × background treatment interaction (P = 0.28) for G:F but there was a significant effect of treatment (P < 0.01, SEM 0.0015), with G:F of DRYLOT steers (0.162 kg/kg) being greater (P < 0.01) than that of RESIDUE (0.153 kg/kg) and CCROP (0.153 kg/kg) steers, which did not differ (P = 0.79). There was a year effect (P < 0.01) on G:F, with yr 1 having greater (P < 0.01) feed efficiency than yr 2 (0.159 and 0.152 kg/kg, respectively; SEM 0.0012).

Carcass Characteristics

Carcass data are summarized in Table 5. Neither 12th-rib fat nor marbling score had a year × background treatment interaction (P ≥ 0.24). There was no difference (P = 0.89) among treatments for 12th-rib fat. However, there was a tendency for a year effect (P = 0.06), with 12th-rib fat thickness tending to be less (P = 0.06) in yr 1 than in yr 2. Marbling score had a treatment effect (P = 0.04), as marbling score of DRYLOT steers (429) was greater (P = 0.01) and that of CCROP steers (424) tended to be greater (P = 0.10) than that of RESIDUE steers (414), with those of DRYLOT and CCROP steers not differing (P = 0.30). Like rib fat, marbling score had a year effect (P < 0.01) and was less (P < 0.01) in yr 1 than in yr 2, which is logical given the higher proportion of British genetics in yr 2.

Table 5.

Carcass characteristics of steers backgrounded by either grazing corn residue and being supplemented with dried distillers plus solubles at 2.68 kg DM/steer 6 d/wk (RESIDUE), grazing a late summer planted oat-brassica forage mix (CCROP) or being fed a corn silage-based diet in drylot (DRYLOT)

| Treatments | P-value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Year 1 | Year 2 | |||||||||

| Item | RESIDUE | CCROP | DRYLOT | RESIDUE | CCROP | DRYLOT | SEM1 | Year | Treatment | Year × treatment2 |

| HCW, kg | 389b | 402a | 391b | 397a | 400a | 367b | 2.14 | <0.01 | <0.01 | <0.01 |

| 12th-rib fat, cm | 1.48 | 1.55 | 1.54 | 1.68 | 1.57 | 1.58 | 0.053 | 0.06 | 0.89 | 0.24 |

| LM area, cm2 | 85.2a | 85.0a | 82.7b | 86.3a | 87.3a | 80.1b | 0.71 | <0.44 | <0.01 | 0.02 |

| Calculated YG3 | 3.29b | 3.48a | 3.49a | 3.54 | 3.42 | 3.52 | 0.065 | 0.20 | 0.39 | 0.08 |

| Marbling score4 | 402 | 419 | 423 | 426 | 428 | 435 | 5.5 | <0.01 | 0.04 | 0.35 |

| Percent Choice | 44 | 59 | 56 | 58 | 57 | 63 | 3.4 | <0.03 | 0.04 | 0.11 |

Means within a row and year with different superscripts differ (P ≤ 0.05).

Standard error of the least squares mean (n = 4 replications/year).

Year × background treatment interaction.

YG = yield grade.

Marbling score: 400 = Slight00; 450 = Slight50; 500 = Small00

There was a year × background treatment interaction (P ≤ 0.02) for HCW and LM area. In yr 1, HCW of CCROP steers was greater (P < 0.01) than that of both RESIDUE and DRYLOT steers, which did not differ (P = 0.40). This difference in HCW is most likely a result of differences in BW at the start of the finishing phase in yr 1. However in yr 2, HCW of CCROP and RESIDUE steers did not differ (P = 0.26) but were greater (P < 0.01) than that of DRYLOT steers, despite the fact that RESIDUE steers entered the finishing phase at a lighter BW than CCROP steers. There was a year effect (P < 0.01) as HCW across all treatments were greater (P < 0.01) in yr 1 than in yr 2. The LM area of RESIDUE and CCROP steers within both years did not differ (P = 0.40) but was greater (P < 0.01) than that of DRYLOT steers.

There was a tendency for a year × background treatment interaction (P = 0.08) for calculated yield grade (YG). In yr 1, calculated YG of CCROP and DRYLOT steers did not differ (P = 0.91) but were greater (P < 0.05) than that of RESIDUE steers. However, in yr 2, calculated YG was not different (P ≥ 0.22) among all 3 treatments.

Cost of Gain

Cost per kilogram gained is shown in Table 6. During the growing period, COG tended (P = 0.08) to differ among treatments when average prices for the past 5 yr were used. The growing COG for DRYLOT and CCROP did not differ (P = 0.56), but that of RESIDUE tended (P = 0.10) to be greater than that of CCROP and was (P = 0.03) greater than that of DRYLOT. When prices from the year (2012) with the highest feed costs in the last 5 yr were used, growing COG of DRYLOT and RESIDUE did not differ (P = 0.88) but were greater (P < 0.01) than that of CCROP. When prices from the year (2016) with the lowest feed costs were used, growing COG of DRYLOT tended (P = 0.07) to be less than that of CCROP and was less (P < 0.01) than that of RESIDUE, with those of CCROP and RESIDUE not differing (P = 0.18).

Table 6.

Cost of gain (COG) and net return of steers backgrounded by either grazing corn residue and being supplemented with dried distillers plus solubles at 2.68 kg DM/steer 6 d/wk (RESIDUE), grazing a late summer planted oat-brassica forage mix (CCROP) or being fed a corn silage-based diet in drylot (DRYLOT)

| Item | RESIDUE | CCROP | DRYLOT | SEM | P-value |

|---|---|---|---|---|---|

| Growing COG, $/kg1 | |||||

| Average (2012–2016) | 1.44 | 1.37 | 1.35 | 0.16 | 0.08 |

| High feed (2012) | 1.85a | 1.61b | 1.84a | 0.21 | <0.01 |

| Low feed (2016) | 1.22a | 1.17ab | 1.11b | 0.14 | 0.01 |

| Finishing COG, $/kg | |||||

| Average (2012–2016) | 1.64a | 1.65a | 1.59b | 0.039 | 0.04 |

| High feed (2012) | 2.48a | 2.49a | 2.39b | 0.06 | 0.01 |

| Low feed (2016) | 1.29 | 1.30 | 1.26 | 0.031 | 0.11 |

| Total COG, $/kg | |||||

| Average (2012–2016) | 1.59a | 1.57a | 1.53b | 0.073 | <0.01 |

| High feed (2012) | 2.32b | 2.25a | 2.25a | 0.11 | <0.01 |

| Low feed (2016) | 1.27a | 1.26a | 1.22b | 0.058 | <0.02 |

| Growing net return, $/steer | |||||

| Average (2012–2016) | 5b | 46a | 33a | 29.2 | <0.01 |

| High feed (2012) | 118b | 141a | 100c | 29.5 | <0.01 |

| Low feed (2016) | −75c | −35a | −59b | 34.8 | <0.01 |

| Finished net return, $/steer | |||||

| Average (2012–2016) | 151 | 181 | 157 | 49.4 | 0.06 |

| High feed (2012) | −109b | −76a | −80a | 44.6 | <0.01 |

| Low feed (2016) | 45 | 73 | 49 | 48.0 | 0.06 |

Means within a row and year with different superscripts differ (P ≤ 0.05).

All economical analysis was conducted on a US dollar basis

Due to the greater DMI of CCROP and RESIDUE in the finishing phase, the COG during finishing of CCROP and RESIDUE were greater (P < 0.04) than that of DRYLOT, when both the 5-yr average prices and when the highest feed price year (2012) was used. When prices from the lowest feed price year (2016) were evaluated, there were no differences (P = 0.11) among treatments.

When the 5-yr average prices and prices from the lowest feed price year (2016) were used to evaluate total COG, DRYLOT had a lesser (P ≤ 0.02) COG than both CCROP and RESIDUE, which did not differ (P ≥ 0.23). However, when prices from the high feed cost year (2012) were used, DRYLOT did not differ (P = 0.82) from CCROP and both were lesser (P < 0.01) than RESIDUE.

Net Return

When 5-yr average prices were used, net returns of DRYLOT and CCROP did not differ (P = 0.15) but were greater (P < 0.01) than that of RESIDUE at the end of the growing phase. When the high feed price year was used, the net returns of CCROP were greatest (P < 0.01), and that of RESIDUE was greater (P = 0.01) than that of DRYLOT at the end of the growing phase. When prices from the lowest feed price year (2016) were used, net returns of CCROP and DRYLOT did not differ (P = 0.15) but were greater (P < 0.01) than that of RESIDUE.

When the 5-yr average prices were used, there was a tendency (P = 0.06) for a difference in net returns among treatments at the end of the finishing phase. Net returns of DRYLOT and RESIDUE did not differ (P = 0.58), but that of CCROP was greater (P = 0.02) than that of RESIDUE and tended (P = 0.07) to be greater than that of DRYLOT. When the high feed price year (2012) was used, net returns of DRYLOT and CCROP did not differ (P = 0.68) but were greater (P < 0.01) than that of RESIDUE. When lowest feed price year (2016) was used, there was a tendency (P = 0.06) for an effect of treatment, with net returns of DRYLOT and RESIDUE not differing (P = 0.71) but that of CCROP being greater (P = 0.02) than that of RESIDUE and tending (P = 0.06) to be greater than that of DRYLOT.

DISCUSSION

Variation between Years

The ADG of steers during the growing period was greater in yr 1 than in yr 2 for all treatments, which is most likely a result of weather differences between the years. Interestingly, differences among treatments within year were consistent, with DRYLOT steers having 0.415 kg/d greater gain than CCROP steers, which had 0.185 kg/d greater gain than RESIDUE steers. The year differences observed for growing phase ADG is most likely due to the fewer number of precipitation incidents during the growing period in yr 1 than in yr 2. According to data compiled by The Weather Company, LLC (2016), in Hastings, NE (29 km northwest), temperature was slightly cooler in November (−6.0°C average minimum and 8.7°C average maximum) and December (−5.3°C average minimum and 3.3°C average maximum) in yr 1 than in November (0.67°C average minimum and 12.1°C average maximum) and December (−4.2°C average minimum and 5.4°C average maximum) of yr 2. However, in yr 1, there was very little precipitation (0.58 cm in November and 1.37 cm in December) and only 1 event of freezing rain, whereas in yr 2, there was more precipitation (5.16 cm in November and 5.54 cm in December), with 6 events of freezing rain and 1 event of ice pellets. The increased number of precipitation events in yr 2 may have increased maintenance energy requirements, because steers would have needed to use more energy to maintain body temperature, due to reduced external insulation as a result of damp hair coats (NASEM, 2016).

Expected Grazing Performance

Expected performance of steers grazing oat–brassica forage is challenging to assess because of the lack of published research. The digestibility of late summer–planted oats and brassicas in this study was quite high (89 and 83% IVOMD with 19 and 26% ADF for yr 1 and 2, respectively) and the CP content, although variable, was also high, ranging from 25% in yr 1 to 16% in yr 2. These values are consistent with previously observed values for summer-planted oats and brassicas (Koch et al., 2002; Villalobos and Brummer, 2015; Coblentz and Cavadini, 2016). The ADG of steers grazing CCROP in the present study ranged from 1.15 kg/d in yr 1 to 0.49 kg/d in yr 2. Smart and Pruitt (2006) reported similarly high quality forage for rye (21% ADF and 18% CP) and turnips (13 and 12% ADF and 24 and 14% CP for tops and roots, respectively) when planted in late July near Brookings, SD. Heifers grazing a mix of turnips and rye (reported to consist mainly of turnips) during October and November had an ADG of 0.56 kg/d and those grazing a monoculture of rye gained 0.72 kg/d (Smart and Pruitt, 2006). Steers grazing an oats monoculture (78.9% IVOMD, 25.6% ADF, and 18% CP) near Mead, NE (approximately 160 km northeast of Clay Center, NE), during a similar time period (November and December) as grazing occurred in yr 2 of the present study had an ADG of 0.59 kg/d (Ulmer et al., 2017). Therefore, the lower gains in yr 2 are within the range that has been previously reported, but gains in yr 1 were much greater than previous reports. More studies are needed to obtain better estimates of the expected rate and potential variability of gain when grazing calves on these summer-planted cool-season annuals in the winter.

Corn residue is abundantly available in the Midwest for grazing by beef cattle. In Nebraska alone, 4 million ha of corn grain were planted in 2016 (USDA-NASS, 2016). This opportunity especially holds true for farmer–feeders that manage a combination of farm ground and cattle. The corn grain yield from the fields in this study averaged 14 t/ha in yr 1 and 13 t/ha in yr 2. Harvest index [dry grain weight/(dry grain weight + dry residue weight)] can range from 0.45 (low yielding situations; approximately 6 t grain/ha) to 0.62 (high yielding situations; approximately 16 t grain/ha; Gallagher and Baumes, 2012). Assuming a harvest index of 0.58, the total amount of corn residue available would have been 10 t/ha in yr 1 and 9.4 t/ha in yr 2. Given the stocking rates used, there would have been approximately 4 (yr 1) and 3 t (yr 2) of total corn residue available per steer. Assuming a corn residue intake of 3.92 kg DM∙steer−1∙d−1 (Gustad et al., 2006), the steers would have consumed only 6.1 and 8.7% of the total corn residue available in yr 1 and yr 2, respectively. Assuming that 39% of the total corn residue available is leaf and husk (Watson et al., 2015), then the steers would have consumed only 16% of the leaf and husk available in yr 1 and 22% in yr 2. Therefore, although corn residue hectares were decreased in yr 2, sufficient forage would have been available throughout the grazing period in both years.

Solely grazing corn residue will not meet the maintenance requirements of growing calves let alone allow for gains. Metabolizable protein is generally the first limiting nutrient of growing calves grazing corn residue, although to achieve moderate or high rates of gain, supplemental energy is also needed (Fernandez-Rivera and Klopfenstein, 1989; Tibbitts et al., 2016). Distiller's grains are high in CP (31%), with the majority of the CP being RUP (68% of CP), and, therefore, is a good source of MP. Distiller's grains are also a good source of energy because they contain more net energy than corn grain (NASEM, 2016). Based on a pooled analysis of 3 trials in which steers grazed corn residue and were supplemented with distiller's grains at amounts ranging from 0.68 to 3.0 kg/steer over a 3-yr period (Welchons and MacDonald, 2017), the gains of RESIDUE steers would have been predicted to be 0.74 kg/d. The ADG of RESIDUE steers in yr 1 (0.69 kg/d) appears to fit this model. However, the ADG (0.20 kg/d) of RESIDUE steers in yr 2 was only one-third of what would have been predicted using this model.

Growing and Finishing Performance

Previous studies have suggested that growing phase ADG is negatively correlated with finishing phase ADG and G:F (Reuter and Beck, 2013; Lancaster et al., 2014). Gains of RESIDUE and CCROP steers during the time that they received the growing diet after grazing were greater and DMI was generally lower than that of DRYLOT steers (despite the fact that their average BW while receiving this diet was greater), suggesting that there was some compensatory gain experienced by these steers during this period.

However, increased finishing ADG was observed for only RESIDUE and CCROP steers compared with DRYLOT steers in yr 2. In yr 1, no difference in finishing ADG was observed among treatments. It is unclear why a greater finishing phase ADG was observed only in yr 2, because the relative difference in growing phase ADG among treatments was similar among years. However, yr 1 growing period gains of all treatments were greater than those in yr 2.

In contrast, finishing DMI was greater in both years (6 and 20% in yr 1 and 2, respectively) and G:F was lesser (4 and 7% in yr 1 and 2, respectively) for the 2 grazing treatments (CCROP and RESIDUE) when compared with DRYLOT. The study design was intended to evaluate the effect of the 3 backgrounding treatments when steers were placed in the finishing phase at the same BW. However, in both years, feedlot placement BW was greatest for CCROP steers, whereas RESIDUE and DRYLOT steers did not differ in yr 1 and feedlot placement BW of RESIDUE steers was greater than that of DRYLOT steers in yr 2. Increased feedlot placement BW has been shown to be correlated with an increase in finishing DMI and lesser G:F (Reuter and Beck, 2013; Lancaster et al., 2014). However, the differences in feedlot placement BW were relatively small, with the greatest difference being 24 kg between CCROP and DRYLOT steers in yr 2. Given that RESIDUE and DRYLOT steer placement weight and final BW did not differ in yr 1, this does not completely explain the DMI and G:F differences observed.

McCurdy et al. (2010) indicated that growing phase management may influence finishing phase G:F. They reported that finishing G:F was 20% greater for steers grown on a sorghum silage diet fed ad libitum and steers limit-fed a high-concentrate diet than for steers grazing winter wheat pasture. All 3 treatments did not differ in growing phase ADG (1.14 kg/d), feedlot placement age, or feedlot placement BW (376 kg). McCurdy et al. (2010) suggested that stress due to shipping steers from wheat pasture to the feedlot and adapting them to the pen, bunk, and water could have caused the observed decrease in G:F for the steers grazing wheat. These results are very similar to the finishing G:F differences in the present study, in which grazing steers during the growing phase had a lesser finishing G:F than steers consuming a corn silage–based ration in pens. In the present study, both RESIDUE and CCROP steers were hauled from the drylot to their fields and then were trailed by horse from the field to the drylot pens (approximately 2.72 km for RESIDUE steers and 6.35 km for CCROP steers in yr 1 and 3.50 km for RESIDUE steers and 4.34 km for CCROP steers in yr 2).

Carcass Characteristics

In the present study, 12th-rib back fat did not differ among treatments. However, RESIDUE steers had a slight reduction in marbling. The majority of studies evaluating the effects of backgrounding systems on marbling score have found no impact if cattle are slaughtered at a similar 12th-rib fat thickness (Lancaster et al., 2014). Regression models created by Reuter and Beck (2013) and Lancaster et al. (2014) also indicated that growing phase ADG was not correlated with marbling score. However, when McCurdy et al. (2010) compared backgrounding steers by grazing winter wheat pasture, feeding a sorghum silage diet, or limit feed a high-concentrate diet, steers that grazed winter wheat during the growing period had a slight reduction in marbling score (409) compared with steers that had been fed the sorghum silage diet and those limit-fed a concentrate diet (449 and 423, respectively) during the growing period, despite the fact that 12th-rib fat thickness at harvest did not differ among treatments. Again, McCurdy et al. (2010) suggested that stress due to shipping of the steers grazing wheat pasture could have caused the observed decrease in marbling score, because stress causes an elevation in catecholamine hormone, which causes lipolysis (Pethick and Dunshea, 1996; Pethick et al., 2004). In the present study, however, both CCROP and RESIDUE steers were similarly treated in terms of movement to and from the fields. The RESIDUE steers did, however, have to learn how to graze corn residue. The concept of learned grazing behavior for calves grazing corn residue was demonstrated by Summers et al. (2014), when they observed that heifer calves that previously grazed corn residue prior to breeding had greater ADG (0.41 kg/d) after breeding while grazing corn residue than heifers developed in a drylot or heifers developed on winter range and grazing corn residue after breeding (0.30 and 0.34 kg/d, respectively). They concluded that heifers learned which plant parts to select for when developed on corn residue, which allowed them to more quickly adapt to grazing corn residue as pregnant heifers compared with pregnant heifers developed either on winter range or in the drylot. Calves in the present study had not grazed corn residue prior to starting the trial, and it could have taken them some time to adjust to grazing this forage source (learning which plant parts to select). This may have resulted in a period of time in which energy intake was not sufficient to maintain similar amounts of intramuscular fat deposition as those on the other treatments.

Steers on both of the grazing treatments had a greater HCW and LM area than DRYLOT steers. Feedlot placement BW may partially explain the greater HCW of the steers on the grazing treatments. Lancaster et al. (2014) indicated that calves entering the feedlot at a greater BW were likely to have a greater HCW at harvest and that HCW has a strong positive relationship (R2 = 0.86) with LM area.

Economics

No treatment appeared to be consistently superior in terms of COG or net returns, although RESIDUE never had the lowest COG or highest net return of any of the treatments. Growing COG of CCROP and DRYLOT were comparable, with CCROP having an advantage in the high feed cost year and DRYLOT having a slight advantage in the low feed cost year. The growing COG of RESIDUE did not differ from that of DRYLOT in the high feed cost year and from that of CCROP in the low feed cost year. Both CCROP and RESIDUE had greater finishing COG than DRYLOT due to greater DMI and lesser G:F. However, due to the greater HCW, net returns of CCROP were as good as or better than those of DRYLOT, with those of RESIDUE being equal to (when 5-yr average or low feed cost year was analyzed) or less than (when high feed cost year was analyzed) those of DRYLOT.

It should also be noted that this analysis attributed all of the establishment cost for the fall oat brassica forage to the CCROP treatment. Given that this system provides cover on corn silage ground, there may be additional conservation benefits to be gained from this practice. Those benefits are beyond the scope of the present paper, but one could expect them to cast the CCROP treatment in an even more favorable light. The analysis of the RESIDUE treatment included $37/ha for corn residue rental. In a recent survey of Nebraska farmers, 24% allowed grazing of residue for free and 59% charged between $2.5 and $37/ha (Cox et al., 2017); therefore, the fee charged in this analysis is on the higher end of what is currently reported and some operations may incur a significantly lower cost to use this forage resource. If they were not charged a fee to use this resource, then the cost would have been reduced by $13 per steer.

In conclusion, weather can have a large impact on the expected rate of growth when backgrounding calves over the winter in the Midwest. Grazing steers on corn residue and supplementing with 0.86% BW of distiller's grains or grazing an oats–brassica forage mix during a short backgrounding period did increase finishing DMI and decrease G:F compared with feeding a corn silage–based diet during the backgrounding period. Marbling of steers grazing corn residue and supplemented with distiller's grains was lesser than that of those grazing the oat–brassica forage mix and those fed the corn silage–based ration. However, according to the results from this study, these grazing systems can be used without causing noteworthy detrimental effects on carcass characteristics. Therefore, all 3 systems appear to be viable options for feedlots, especially when considering the use of CCROP or RESIDUE to stage spring-born fall-weaned calves for later entry into the feedlot, thereby allowing them to buy more calves during the period when calf prices are seasonally low.

LITERATURE CITED

- AOAC 1999. Official method of analysis. 16th ed.AOAC Int., Arlington, VA. [Google Scholar]

- Association of Official Analytical Chemists (AOAC) 1965. Official methods of analysis. 10th ed.AOAC, Washington, DC. [Google Scholar]

- Barrientos M., Soria C. Mundi index. Commodity prices, urea. 2017http://www.indexmundi.com/commodities/?commodity=urea&months=120. (Accessed 1 September 2017.). [Google Scholar]

- Coblentz W. K., Cavadini J. S. 2016. Effects of seeding rate on the dry matter yield and nutritive value of fall-grown oat. Crop Forage Turfgrass Manage. 2. doi: 10.2134/cftm2016.0004 [DOI] [Google Scholar]

- Cox J. L., Ulmer K. M., Rakkar M., Franzen-Castle L., Blanco-Canqui H., Drewnoski M. E., MacDonald J. C., Rasby R. J. 2017. Perceptions of crop consultants and crop producers on grazing corn residue in Nebraska. J. Ext. 55: 5RIB2 https://joe.org/joe/2017october/rb2.php. [Google Scholar]

- Fernandez-Rivera S., Klopfenstein T. J. 1989. Yield and quality components of corn crop residues and utilization of these residues by grazing cattle. J. Anim. Sci. 67:597–605. doi: 10.2527/jas1989.672597x [DOI] [PubMed] [Google Scholar]

- Gallagher P. W., Baumes H. 2012. Biomass supply from corn residues: Estimates and critical review of procedures. USDA agricultural economics report no. 847. ARS-USDA, Washington, DC. [Google Scholar]

- Gustad K. H., Klopfenstein T. J., Erickson G. E., VanderPol K. J., MacDonald J. C., Greenquist M. A. 2006. Dried distillers grains supplementation of calves grazing corn residue. In: Nebraska beef cattle rep. MP 88. The Board of Regents of the University of Nebraska, Lincoln, NE: p. 36–37. [Google Scholar]

- Koch D. W., Kercher C., Jones R. 2002. Fall and winter grazing of brassicas – A value-added opportunity for lamb producers. J. Sheep Goat Res. 17:1–13. [Google Scholar]

- Lancaster P. A., Krehbiel C. R., Horn G. W. 2014. A meta-analysis of effects of nutrition and management during the stocker and backgrounding phase on subsequent finishing performance and carcass characteristics. Prof. Anim. Sci. 30:602–612. [Google Scholar]

- McCurdy M. P., Horn G. W., Wagner J. J., Lancaster P. A., Krehbiel C. R. 2010. Effects of winter growing programs on subsequent feedlot performance, carcass characteristics, body composition, and energy requirements of beef steers. J. Anim. Sci. 88:1564–1576. doi: 10.2527/jas.2009-2289 [DOI] [PubMed] [Google Scholar]

- McDougall E. I. 1948. Studies on ruminant saliva. I. The composition and output of sheep's saliva. Biochem. J. 43:99–109. doi: 10.1042/bj0430099 [DOI] [PMC free article] [PubMed] [Google Scholar]

- National Academics of Sciences, Engineering, and Medicine (NASEM) 2016. Nutrient requirements of beef cattle. 8th rev. ed.Natl. Acad. Press, Washington, DC. [Google Scholar]

- Owens F. N., Gill D. R., Secrist D. S., Coleman S. W. 1995. Review of some aspects of growth and development of feedlot cattle. J. Anim. Sci. 73:3152–3172. doi: 10.2527/1995.73103152x [DOI] [PubMed] [Google Scholar]

- Pethick D. W., Dunshea F. R. 1996. The partitioning of fat in farm animals. Proc. Nutr. Soc. Aust. 20:3–13. [Google Scholar]

- Pethick D. W., Harper G. S., Oddy V. H. 2004. Growth, development and nutritional manipulation of marbling in cattle: A review. Aust. J. Exp. Agric. 44:705–715. doi: 10.1071/EA02165 [DOI] [Google Scholar]

- Reuter R. R., Beck P. A. 2013. Southern section interdisciplinary beef cattle symposium: Carryover effects of stocker cattle systems on feedlot performance and carcass characteristics. J. Anim. Sci. 91:508–515. doi: 10.2527/jas.2012-5527 [DOI] [PubMed] [Google Scholar]

- Shackelford S. D., Wheeler T. L., Koohmaraie M. 2003. On-line prediction of yield grade, longissimus muscle area, preliminary yield grade, adjusted preliminary yield grade, and marbling score using the MARC beef carcass image analysis system. J. Anim. Sci. 81:150–155. doi: 10.2527/2003.811150x [DOI] [PubMed] [Google Scholar]

- Smart A. J., Pruitt R. J. 2006. Rye and turnips to extend the grazing season for weaned calves. In: South Dakota State beef report 2006-11. South Dakota State University, Brookings, SD: p. 48–51. [Google Scholar]

- Summers A. F., Weber S. P., Lardner H. A., Funston R. N. 2014. Effect of beef heifer development system on average daily gain, reproduction, and adaptation to corn residue during first pregnancy. J. Anim. Sci. 92:2620–2629. doi: 10.2527/jas.2013-7225 [DOI] [PubMed] [Google Scholar]

- Tibbitts B. T., MacDonald J. C., Funston R. N., Welchons C. A., Bondurant R. G., Hilscher F. H. 2016. Effects of supplementing energy and protein sources on performance of steers grazing irrigated corn residue. In: Nebraska beef cattle rep. MP103. The Board of Regents of the Univ. of Nebraska, Lincoln, NE: p. 31–32. [Google Scholar]

- Tilley J. M. A., Terry R. A. 1963. A two-stage technique for the in vitro digestion of forage crops. J. Br. Grassl. Soc. 18:104–111. doi: 10.1111/j.1365-2494.1963.tb00335.x [DOI] [Google Scholar]

- Ulmer K. M., Bondurant R. G., Gramkow J. L., Drewnoski M. E., MacDonald J. C. 2017. Nutrient content of summer-planted oats after corn harvest and grazing performance. In: Nebraska beef cattle rep. MP104. The Board of Regents of the Univ. of Nebraska, Lincoln, NE: p. 43–45. [Google Scholar]

- USDA 1997. United States standards for grades of carcass beef. Agric. Mark. Serv., USDA, Washington, DC. [Google Scholar]

- USDA National Agriculture Statistics Service (USDA-NASS) Corn, grain acres harvested. 2016 http://quickstats.nass.usda.gov/?long_desc_LIKE=corn&x=42&y=11. (Accessed 2 June 2016.)

- USDA Economic Research Service (USDA-ERS) 2017. Feed grains: Yearbook tables. https://www.ers.usda.gov/data-products/feed-grains-database/feed-grains-yearbook-tables. (Accessed 1 September 2017.)

- Van Soest P. J., Robertson J. B., Lewis B. A. 1991. Methods of dietary fiber, neutral detergent fiber, and non-starch polysaccharides in relation to animal nutrition. J. Dairy Sci. 74:3583–3597. [DOI] [PubMed] [Google Scholar]

- Villalobos L. A., Brummer J. E. 2015. Forage brassicas stockpiled for fall grazing: Yield and nutritive value. Crop Forage Turfgrass Manage. 1. [Google Scholar]

- Watson A. K., MacDonald J. C., Erickson G. E., Kononoff P. J., Klopfenstein T. J. 2015. Forages and pastures symposium: Optimizing the use of fibrous residues in beef and dairy diets. J. Anim. Sci. 93:2616–2625. doi: 10.2527/jas.2014-8780 [DOI] [PubMed] [Google Scholar]

- The Weather Company, LLC 2016. Weather history. Hastings, NE: https://www.wunderground.com/history/airport/KHSI/DailyHistory.html. (Accessed 29 November 2016.) [Google Scholar]

- Weiss W. P. 1994. Estimation of digestibility of forages by laboratory methods. In: Fahey G. C., Jr editor, Forage quality, evaluation, and utilization. Am. Soc. Agron., Crop Sci. Soc. Am., Soil Sci. Soc. Am., Madison, WI: p. 644–681. [Google Scholar]

- Weiss W. P., Conrad H. R., St-Pierre N. R. 1992. A theoretically-based model for predicting total digestible nutrient values of forages and concentrates. Anim. Feed Sci. Technol. 39:95–110. doi: 10.1016/0377-8401(92)90034-4 [DOI] [Google Scholar]

- Welchons C. A., MacDonald J. C. 2017. Pooled gain analysis of steers grazing corn residue and supplemented with distillers grains. In: Nebraska beef cattle rep. MP104. Univ. of Nebraska, Lincoln, NE: p. 34–35. [Google Scholar]