Abstract

Ivermectin, a kind of valuable derivatives of Avermectin, is distinct from Avermectin due to the saturated bond at C22—C23 position. Combinatorial biosynthesis of Ivermectins based on Avermectins biosynthetic gene cluster (ave) has been achieved recently, while the establishment of an Ivermectin homogeneous component producing strain is challenging because of the limited compatibility between the native and heterologous polyketide synthase (PKS) domains. In this study, the PKS module 2 Dehydratase (DH)-Enoylreductase (ER)-Ketoreductase (KR) domain set of Meilingmycin, which is another naturally occurring homologue of Avermectin, was employed to substitute the DH-KR domains of Avermectins PKS module 2 to generate an Ivermectin biosynthetic gene cluster (ive). Ivermectins B1a and A1a were heterologously biosynthesized in a classic actinomyces host Streptomyces lividans. The Avermectin B1a high-producing strain S. avermitilis 3-115 was genetically engineered to give an artificial host cell and Ivermectin B1a single component was effectively produced with a production of 1.25 ± 0.14 g/L.

Keywords: Avermectin, Ivermectin, Meilingmycin, Domain swapping, Heterologo-us biosynthesis

1. Introduction

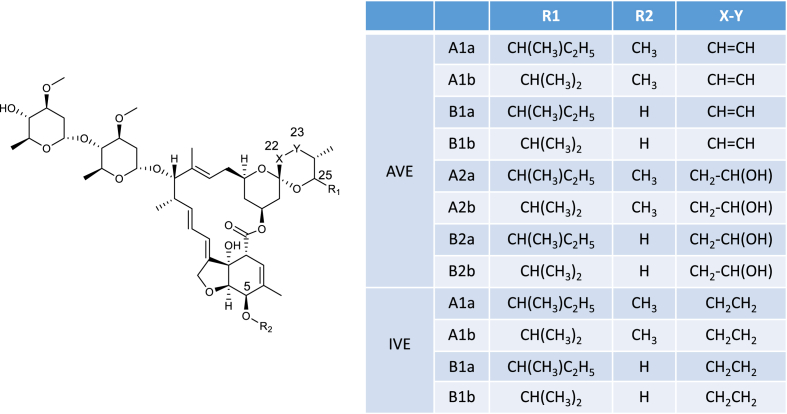

Ivermectin (IVE), one of the most remarkable derivatives of Avermectin (AVE), is a broad-spectrum antiparasitic agent (Fig. 1). It was widely used in the treatment of human onchocerciasis (river blindness), lymphatic filariasis (elephantiasis) and some parasitic skin diseases [[1], [2], [3]]. The antibacterial activity against Mycobacterium tuberculosis, including some drug-resistant clinical strains, was documented as well [4]. Traditionally, IVEs was chemically modified derivatives of AVE B1a/b in which the C22—C23 double bond was specifically hydrogenated by Wilkinson's catalyst [1]. Combinatorial biosynthesis and metabolic engineering provide attractive alternatives in industrial production of IVEs [5], since the chemical method suffers from high energy consumption, low efficiency and heavy metals pollution.

Fig. 1.

Chemical structure of Avermectins and Ivermectins.

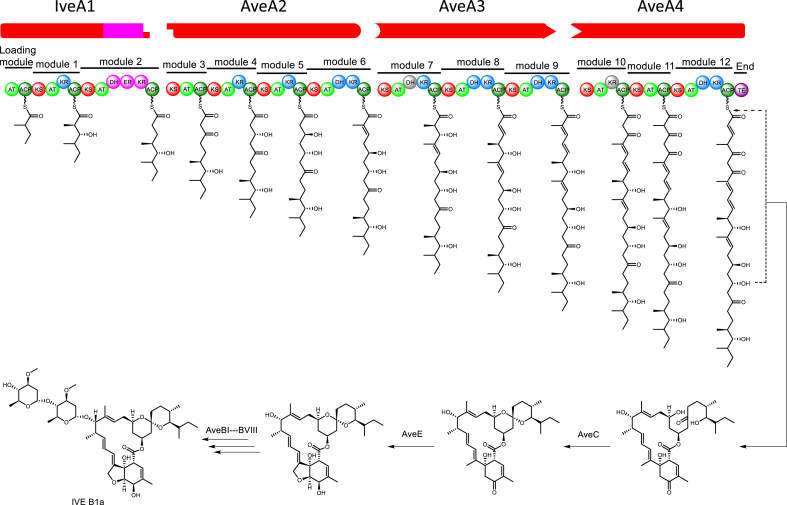

AVE biosynthetic gene cluster has been identified and the biosynthetic pathway was thoroughly elucidated [6,7]. The polyketide skeleton was assembled by four polyketide synthases (PKS) AveA1/A2/A3/A4 with one equal 2-methylbutyryl-CoA (or isobutyryl-CoA) as starter unit and 7 equal malonyl-CoA and 5 equal methylmalonyl-CoA as extending units. In the assembly line, beta-keto was selectively reduced by ketoreductase (KR) and dehydratase (DH) domains. It is wealthy to note that there is no enoylreductase (ER) domain in the AVE PKS. The PKS AveA1 loading module Acyl transferase domain (AveA1-LM-AT) was responsible for the selection of distinct starter units, which led to the divergence of C25 attached functional groups [6]. It was also proved that methyltransferase AveD determines the C5—O-methylation and bi-functional enzyme AveC involves in the spiroketal formation and optional dehydration at C22—C23 position [7].

Based on the AVE biosynthetic pathway, IVEs have been successfully produced by domain swapping, in which the DH-KR domain of AVEs PKS module 2 (DH2-KR2) was substituted by certain PKS reductase domains (as shown in Fig. 2), including Rapamycin DH13-ER13-KR13 [8], Pikromycin DH4-ER4-KR4 [9], Oligomycin DH3-ER3-KR3 [10] and Milbemycin DH2-ER2-KR2 [11]. Unfortunately, more than one IVE components were produced by the recombinant strains, and certain AVE components were produced as well. It is really challenging to extract the most active component IVE B1a from the mixture.

Fig. 2.

Combinatorial biosynthesis pathway of Ivermectins in S. avermitilis DQ03. Each polyketide skeleton was assembled by one equal 2-methylbutyryl-CoA (or isobutyryl-CoA) as starter units and 7 equal malonyl-CoA and 5 equal methylmalonyl-CoA as extending units. AT, acyltransferase; ACP, acyl carrier protein; KS, beta-ketoacyl synthase; DH, dehydratase; ER, enoylreductase; KR, ketoreductase; TE, thioesterase. The IveA1 DH-ER-KR domain set from Meilingmycin PKS module 2 was shown in magenta.

Meilingmycin (MEI) shares almost identical polyketide skeleton with AVE, while the C22—C23 is a saturated bond [12]. We have identified the MEI biosynthetic gene cluster and elucidated its biosynthetic pathway [13,14]. The MEI PKS MeiA1 showed 49% identities and 58% similarities with AveA1. It indicates that MEI DH2-ER2-KR2 is a competent candidate to substitute the AVE DH2-KR2 domains. We hence built a cell factory to produce IVE B1a single component effectively.

2. Materials and methods

2.1. Domain swapping by PCR targeting

To the first round of PCR targeting, a 3.1 kb MEI DH2-ER2-KR2 DNA fragment was amplified by PCR primer pair DQP01 F/R with the genomic DNA of Streptomyces nanchangensis NS3226 as template (See Table 1, Table 2). A Spectinomycin resistant gene aadA was amplified by PCR primer pair DQP02 F/R with plasmid pIJ778 as template [15]. Then, MEI DH2-ER2-KR2 fragment and aadA fragment were inserted into NdeI/EcoRI site of pUC18 to produce pWDZ255 with Hieff Clone™ Cloning Kit. The DH2-ER2-KR2-aadA DNA fragment was amplified with primer pair DQP03 F/R to give a 4.6 kb DNA fragment from plasmid pWDZ255 for PCR targeting (Fig. 3A). To the second round of PCR targeting, a 0.6 kb MEI KR2-ACP2 linker DNA fragment was amplified by primer pair DQP04 F/R, a 0.6 kb AVE ACP2 fragment amplified by PCR primer pair DQP05 F/R and a Spectinomycin resistant gene aadA amplified by PCR primer pair DQP06F/DQP02R were inserted into the NdeI/EcoRI site of pUC18 to produce pWDZ256. The linker-ACP2-aadA fragment was amplified with primer pair DQP07 F/R to give a 2.7 kb DNA fragment for PCR targeting (Fig. 3B). PCR targeting and aadA gene release were carried out according to the PCR targeting protocol [15].

Table 1.

Bacterial strains and plasmids used in this study.

| Strain or plasmid | Relevant phenotype and/or characteristics | Source or Reference |

|---|---|---|

| pWDZ255 | pUC18- meiDH2-ER2-KR2 + addA | This work |

| pWDZ256 | pUC18-meiKR2+aveACP + addA | This work |

| 14F9S | BAC recombinant, which harbors an ave cluster | [19] |

| pIJ778 | A plasmid harboring Spectinomycin resistant gene aadA | [15] |

| pWHU2009 | A plasmid harboring an ive cluster | This work |

| pWHU2010 | A plasmid harboring an ive cluster without aveD | This work |

| pWDZ307 | A plasmid for knockout of ave gene cluster in S. avermitilis 3-115 | This work |

| S. nanchangensis NS3226 | Wild-type strain, Meilingmycins producer | [12,13] |

| S. avermitilis 3-115 | Avermectins producer | [20] |

| S. lividans 1326 | Host for heterologous expression | CGMCC |

Table 2.

PCR primers used in this study.

| Primer name | Sequence (5′-3′) (homologous arm underlined) |

|---|---|

| DQP01F | actgagagtgcaccatagcggcggagcacccgctgatcgg |

| DQP01R | ggtcgacggatccccggaatctgctcccacagccccca |

| DQP02F | accggggcctggtcggatccattccggggatccgtcgacc |

| DQP02R | gctatgaccatgattacgaatttgtaggctggagctgctt |

| DQP03F | ctactggctcgaaagcacacagcccggtgccggcaacgtgtcagcagccggactcgacgcggcggagcacccgctgatcggcgccgcc |

| DQP03R | ccgggcgtgcagctgggcgccgttgtccgcaccaccggtagtggtggtgcgggtggtgcgtgtaggctggagctgcttcgaagttcct |

| DQP04F | tactgagagtgcaccatagctgcgagaggagctgaccgagc |

| DQP04R | ggtggtgcgggtggtgcgggatccgaccaggccccggtac |

| DQP05F | cggggcctggtcggatcccgcaccacccgcaccaccactacc |

| DQP05R | cgacggatccccggaattcaggacaggccgaggtcgttgtc |

| DQP06F | acgacctcggcctgtcctgaattccggggatccgtcgacc |

| DQP07F | gcgcgcccgccatctgctgctggtcggccgacgcggccccgacgccccgggcgccgaggagctgcgagaggagctgaccg |

| DQP07R | caattgcattcacgtcctagcagggcccagcggatacgggcggagtggcaggcgtccggttgtaggctggagctgcttcg |

| DQP08F | cttcatgccggtccgcccgaaggcgcgcagtgcgacgtccgtgacggcattccggggatccgtcgacc |

| DQP08R | cacgggccgccgggtcctggacgtcggctgcggttccggaaagccggcgtgtaggctggagctgcttc |

| DQP09F | cgacggccagtgccaagctttacgacaccgcggacatctggtg |

| DQP09R | gaaagccgacagctctgcgagtacgccggaatgatcgccg |

| DQP10F | gcgatcattccggcgtactcgcagagctgtcggctttcgt |

| DQP10R | tatgacatgattacgaattcctttacgaggttcttcccac |

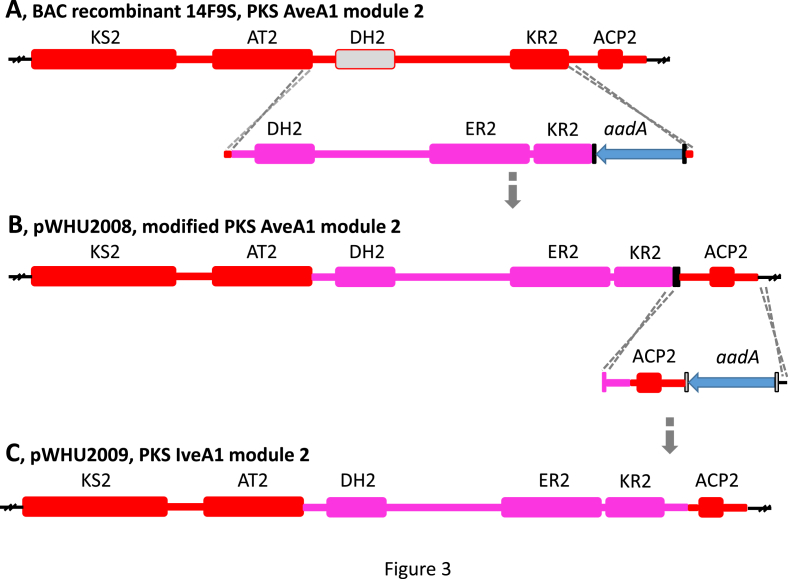

Fig. 3.

Construction sketch of Ivermectins polyketide synthetase IveA1 by domain swapping. AT, acyltransferase; ACP, acyl carrier protein; KS, beta-ketoacyl synthase; DH, dehydratase; ER, enoylreductase; KR, ketoreductase. A, the first round of PCR targeting. Meilingmycin PKS module 2 DH2-ER2-KR2 encoding DNA was amplified by PCR and fused with Spectinomycin resistant gene aadA. Then, the DH2-ER2-KR2-aadA DNA fragment was employed to substitute the Avermectin PKS module 2 DH2-KR2 by PCR targeting, and the aadA gene was subsequently released by DNA recombination. B, the second round of PCR targeting. The MEI KR2-ACP2 linker DNA fragment and AVE ACP2 encoding DNA fragment were amplified by PCR, and then fused with aadA gene. The linker-ACP2-aadA DNA fragment was employed to substitute the scar-ACP2 region by PCR targeting, and the aadA gene was subsequently released to generate a scarless IveA1 encoding gene. Avermectin PKS domains are shown in red, Meilingmycin PKS domains are shown in magenta.

2.2. S. avermitilis 3-115 ave cluster knock-out

A 3.0 kb left arm DNA fragment for homologous recombination double crossover was amplified with Bacterial Artificial Chromosome (BAC) recombinant 14F9S as template and DQP09 F/R as primers, and a 3.0 kb right arm was amplified with DQP10 F/R as primers. The left and right arms were inserted into temperature sensitive plasmid pKC1139 to give pWHU2011. Then, pWHU2011 was transfer into S. avermitilis 3-115 (CGMCC No. 3229) by conjugation and the ave cluster deleted mutant strain S. avermitilis DQ02 was screened out according to the standard protocol [16].

2.3. Heterologous biosynthesis of IVE

The ive cluster harboring BAC plasmids were prepared by the alkaline lysis method [17], and transferred into E. coli ET12567/pUZ8002 by electroporation using a BioRad GenePulser II instrument, 200 Ω, 25 μF and 2,5 kV. Then the BAC plasmids were introduced into Streptomyces cells by conjugation between E. coli and Streptomyces [16]. Recombinant Streptomyces strains were cultured with production medium at 28 °C, 200 rpm for 10 days in 250 mL flasks. The fermentation medium contained (per liter) 140 g of corn starch, 0.1 g of α-amylase, 28 g of soy flour, 10 g of yeast extract, 0.022 g of Na2MoO4·2H2O, 0.0023 g of MnSO4·H2O, 0.25 g of (NH4)2SO4, 0.02 g of CoCl2, and 0.8 g of CaCO3. The medium pH was adjusted to 7.5 with NaOH [18].

2.4. HPLC-MS analysis of IVE

Streptomyces culture broth was ten times (v/v) diluted with methanol and then homogenized by ultrasonication at 40 KHz for 30 min. The precipitates were eliminated by centrifugation (12,000 g, 30 min) and the supernatants were further filtered by 0.22 μm filter. Samples were injected into a SHIMAZDU HPLC instrument equipped with a PDA detector (SPD-M20A). Chromatography was carried out on a Dikma C18 column (5 μm, 250 × 4.6 mm) with a mobile phase of solvent A: B = 88: 12 (solvent A, 0.1% formic acid in acetonitrile; solvent B, 0.1% formic acid), flow rate 1.0 mL/min. HPLC traces were recorded by monitoring the absorption at 245 nm. Mass spectrometric (MS) analysis was conducted on a LTQ-Orbitrap (Thermo Scientific) instrument with a positive mode as described previously [19]. The mass to charge scan range was from 200 to 2000. Data dependent tandem mass spectrometry method was employed and all of the top five ions of each san were fragmented by collision-induced dissociation at 35 eV.

2.5. Quantification of IVE B1a by HPLC

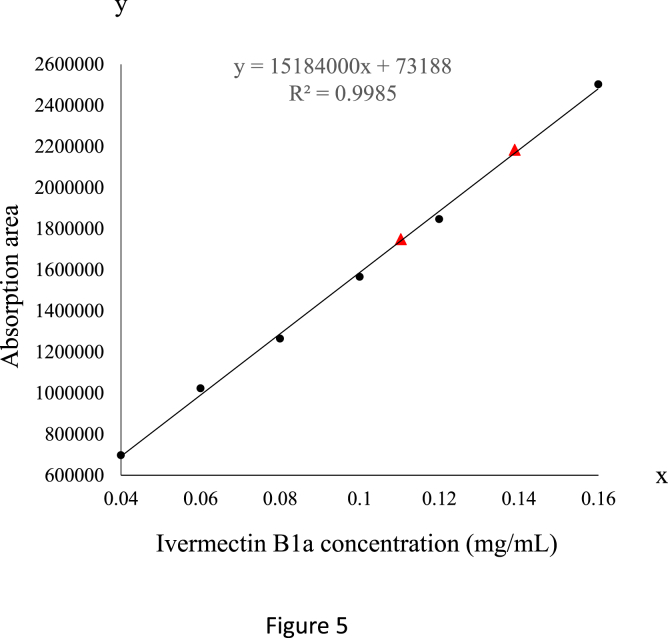

IVE B1a standard solution with a final concentration of 2 mg/mL was prepared as stock and diluted to 0.04, 0.06, 0.08, 0.10, 0.12, 0.14, 0.16 mg/mL, respectively. The absorption area of standard solution at 245 nm was measured and the standard curve was obtained as y = 15184000x + 73188, R2 = 0.9985. According to the standard curve and the absorption area of individual samples, IVE B1a yield of recombinant Streptomyces strains was measured. Data were collected from two independent experiments.

3. Results

3.1. Construction of IVE biosynthetic gene cluster ive

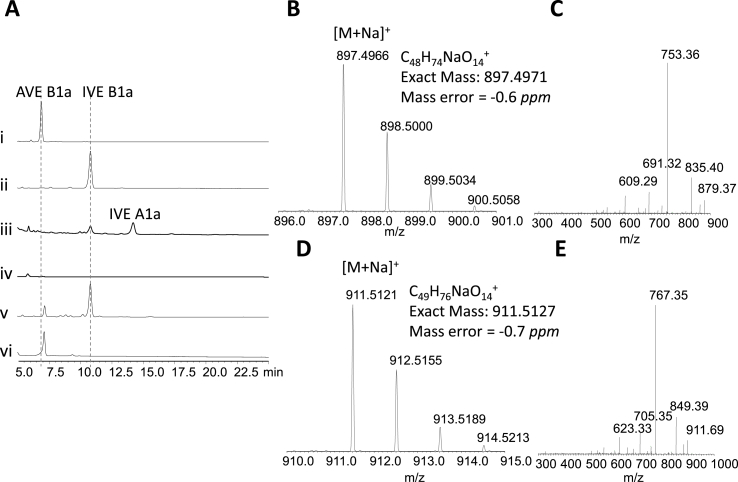

MEI DH2-ER2-KR2 was employed for domain swapping as shown in Fig. 3. Benefit from the successful hetero-expression of AVE biosynthetic gene cluster ave, PCR targeting was carried out on BAC recombinant 14F9S, which harbors an ave cluster [19]. After the first round of PCR targeting, recombinant plasmid pWHU2008 which harbors an AVE/MEI hybrid biosynthetic gene cluster was generated. Unfortunately, neither AVE nor IVE was detected from the recombinant strains when pWHU2008 was introduced into diverse host cells, including S. albus J1074, S. lividans 1326 and S. coelicolor M145. It might be attributed to the non-compatibility between MEI DH2-ER2-KR2 and AVE PKS domains since the PCR targeting manipulation introduced a scar DNA fragment of 81 bp (encoding 27 amino acids, the black rectangular box of Fig. 3B) in module 2 immediately following the KR2 encoding sequence. So, a second round of PCR targeting was carried out based on pWHU2008 to give pWHU2009. The 81 bp DNA scar was shifted to the down-stream of aveA1 gene. We got a scar-free AVE/MEI hybrid PKS, which was defined as IveA1 here (Fig. 3C). The pWHU2009 was introduced into S. lividans 1326 to generate recombinant strain DQ01. The methanol extracted sample of S. lividans DQ01 was 50 times concentrated prior to the HPLC analysis due to a low production. IVE components B1a and A1a were detected and the B1a production was ∼1.26 mg/L in flask. None of the AVE component was detected any more (Fig. 4). It means that the planted MEI DH2-ER2-KR2 worked well with AVE PKS domains and all of the C22—C23 bonds were saturated thoroughly. The modified ave cluster was defined as IVE biosynthetic gene cluster ive in this work.

Fig. 4.

Metabolite profiles of recombinant strains constructed in this study. A, HPLC traces of cell extracts. i) AVE B1a standards; ii) IVE B1a standards; iii) S. lividans DQ01; iv) S. lividans 1326; v) S. avermitilis DQ03; vi) S. avermitilis DQ02.B, high resolution mass spectrum of IVE B1a. C, MS/MS spectrum of IVE B1a.[M – disaccharide + Na]+ = 609.29; [M – H2O – CO2 – monosaccharide + Na]+ = 691.32; [M – monosaccharide + Na]+ = 753.36; [M – H2O – CO2 + Na]+ = 835.40; [M – H2O + Na]+ = 879.37. D, high resolution mass spectrum of IVE A1a. E, MS/MS spectrum of IVE A1a. [M – disaccharide + Na]+ = 623.33; [M – H2O – CO2 – monosaccharide + Na]+ = 705.35; [M – monosaccharide + Na]+ = 767.35; [M – H2O – CO2 + Na]+ = 849.39.

3.2. Producing of IVE B1a single component

To get rid of the IVE A1a component, the ive cluster was modified further. As we known, AVE A1a was formed with AVE B1a as substrates under the catalysis of methyltransferase AveD. We suspect that the formation of IVE A1a is similar to that of AVE A1a. So, pWHU2009 aveD gene was removed by PCR targeting to give pWHU2010. To build a host cell for the effective biosynthesis of IVE B1a, we focused our attention on an AVE industrial strain, S. avermitilis 3-115. It is an AVEs high-producing strain developed by traditional improvement programs with a yield of 4167 mg/L, in which the ‘a’ serial component is the predominant one [20]. Homologous recombination double crossover directed gene knock out was employed for ave cluster deletion. The ave cluster deleted mutant was selected out and defined as S. avermitilis DQ02 here. HPLC-MS analysis results showed that S. avermitilis DQ02 did not produce any detectable AVEs (Fig. 4 Avi). Then, pWHU2010 was introduced into S. avermitilis DQ02 to generate recombinant strain DQ03. Based on the HPLC profiles, there was only one component showed identical retention time with IVE B1a standard was detected from DQ03 cell extracts (Fig. 4v). It was further validated by high resolution MS (Fig. 4B). Neutral losses of H2O, CO2, monosaccharide and disaccharide were observed in tandem MS (Fig. 4C), which accord well with the documented mass spectrum of IVE B1a [21]. It means that this component is IVE B1a indeed. Trace amount of IVE B1b was detected in the high resolution mass spectra, but it was not detected by HPLC analysis. IVE A1a component was not detected anymore. It means that IVE B1a is the predominant component of S. avermitilis DQ03 products. In the quantification experiment, the absorption area of DQ03 cell extract samples was 1748735 and 2183664 (Fig. 5, data from two independent experiments). According to the standard curve of y = 15184000x + 73188 (y, absorption area; x, IVE B1a concentration), the IVE B1a yield was 1.25 ± 0.14 g/L. IVE B1b component could not be quantified by the method described here because of the really low concentration, just like it could not be detected by HPLC analysis. Certain methods with higher sensitivity should be established to measure the ratio of major component B1a to minor component B1b in the total output of strain DQ03. This is our ongoing investigation.

Fig. 5.

Quantification of IVE B1a by HPLC analysis. The standard curve of Ivermectin B1a is y = 15184000x + 73188, R2 = 0.9985. The absorption area of DQ03 cell extract samples was 1748735 and 2183664 for two independent experiments, represented by triangles.

4. Discussions

Recently, numerous combinatorial biosynthesis attempts have been carried out to produce unnatural natural products. Identification of AVE biosynthetic gene cluster and dissection of AVE biosynthetic pathway conferred a paradigm for combinatorial biosynthesis study. Several star compounds have been produced successfully, including IVE [[8], [9], [10], [11]], Doramectin and Milbemycin [[22], [23], [24]]. Replacement of AVE DH2-KR2 with Rapamycin DH13-ER13-KR13, Pikromycin DH4-ER4-KR4 or Oligomycin DH3-ER3-KR3 led to the producing of IVE, but the production is low [[7], [8], [9]]. Substitution of AVE DH2-KR2 by Milbemycin DH2-ER2-KR2 gave a high production of IVE B1a up to 3450 ± 65 μg/mL, while AVE B1a and B2a were produced simultaneously. We developed a S. avermitilis strain DQ03 to produce IVE B1a single component with a production of 1.25 ± 0.14 g/L in flask.

In theory, the ratio of AVE “a” and “b” serial components is determined by the start units provided to the PKS assembly line, which is 2-methylbutoryl-CoA for “a” and 2-isobutoryl-CoA for “b”. Both of them are branched chain amino acid catabolites catalyzed by branched chain 2-oxoacid dehydrogenase (BCDH) complex with isoleucine and valine as substrate, respectively [25,26]. Since AVE ‘a’ serial components are the main component of S. avermitilis 3-115, the flux must be redirected for 2-methylbutoryl-CoA formation. So, it is reasonable to observe that IVE B1a is the predominant component of S. avermitilis DQ03 products.

Benefit from the successful hetero-expression of ave cluster, we tailored ave by domain swapping and gene deletion to generate an ive cluster. IVE was biosynthesized in a heterologous host strain for the first time. Based on the ive cluster harboring plasmids, the PKS assembly line could be tailored smoothly to establish an AVE derivatives library. It circumvented the labor-intensive and time-consuming process of Actinomyces genetic manipulation and paved the way for industrial production of IVE B1a.

Conflicts of interest

Authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Acknowledgments

This work was financially supported by the Ministry of Science and Technology of China (“973” Program 2013CB734003) and the National Science Foundation of China (31670030).

Footnotes

Peer review under responsibility of KeAi Communications Co., Ltd.

Supplementary data to this article can be found online at https://doi.org/10.1016/j.synbio.2018.12.003.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- 1.Chabala J.C., Mrozik H., Tolman R.L., Eskola P., Lusi A., Peterson L.H. Ivermectin, a new broad-spectrum antiparasitic agent. J Med Chem. 1980;23:1134–1136. doi: 10.1021/jm00184a014. [DOI] [PubMed] [Google Scholar]

- 2.Campbell W.C., Fisher M.H., Stapley E.O., Albers-Schonberg G., Jacob T.A. Ivermectin: a potent new antiparasitic agent. Science. 1983;221:823–828. doi: 10.1126/science.6308762. [DOI] [PubMed] [Google Scholar]

- 3.Omura S., Crump A. Ivermectin: panacea for resource-poor communities? Trends Parasitol. 2014;30:445–455. doi: 10.1016/j.pt.2014.07.005. [DOI] [PubMed] [Google Scholar]

- 4.Lim L.E., Vilcheze C., Ng C., Jacobs W.R., Jr., Ramon-Garcia S., Thompson C.J. Anthelmintic avermectins kill Mycobacterium tuberculosis, including multidrug-resistant clinical strains. Antimicrob Agents Chemother. 2013;57:1040–1046. doi: 10.1128/AAC.01696-12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Zhuo Y., Zhang T., Wang Q., Cruz-Morales P., Zhang B., Liu M. Synthetic biology of avermectin for production improvement and structure diversification. Biotechnol J. 2014;9:316–325. doi: 10.1002/biot.201200383. [DOI] [PubMed] [Google Scholar]

- 6.Ikeda H., Nonomiya T., Usami M., Ohta T., Omura S. Organization of the biosynthetic gene cluster for the polyketide anthelmintic macrolide avermectin in Streptomyces avermitilis. Proc Natl Acad Sci U S A. 1999;96:9509–9514. doi: 10.1073/pnas.96.17.9509. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Sun P., Zhao Q., Yu F., Zhang H., Wu Z., Wang Y. Spiroketal formation and modification in avermectin biosynthesis involves a dual activity of AveC. J Am Chem Soc. 2013;135:1540–1548. doi: 10.1021/ja311339u. [DOI] [PubMed] [Google Scholar]

- 8.Gaisser S., Kellenberger L., Kaja A.L., Weston A.J., Lill R.E., Wirtz G. Direct production of ivermectin-like drugs after domain exchange in the avermectin polyketide synthase of Streptomyces avermitilis ATCC31272. Org Biomol Chem. 2003;1:2840–2847. doi: 10.1039/b304022d. [DOI] [PubMed] [Google Scholar]

- 9.Zhang X., Chen Z., Li M., Wen Y., Song Y., Li J. Construction of ivermectin producer by domain swaps of avermectin polyketide synthase in Streptomyces avermitilis. Appl Microbiol Biotechnol. 2006;72:986–994. doi: 10.1007/s00253-006-0361-2. [DOI] [PubMed] [Google Scholar]

- 10.Li M., Chen Z., Lin X., Zhang X., Song Y., Wen Y. Engineering of avermectin biosynthetic genes to improve production of ivermectin in Streptomyces avermitilis. Bioorg Med Chem Lett. 2008;18:5359–5363. doi: 10.1016/j.bmcl.2008.09.061. [DOI] [PubMed] [Google Scholar]

- 11.Zhang J., Yan Y.J., An J., Huang S.X., Wang X.J., Xiang W.S. Designed biosynthesis of 25-methyl and 25-ethyl ivermectin with enhanced insecticidal activity by domain swap of avermectin polyketide synthase. Microb Cell Factories. 2015;14:152. doi: 10.1186/s12934-015-0337-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Sun Y., Zhou X., Liu J., Bao K., Zhang G., Tu G. ‘Streptomyces nanchangensis’, a producer of the insecticidal polyether antibiotic nanchangmycin and the antiparasitic macrolide meilingmycin, contains multiple polyketide gene clusters. Microbiol (Read Engl) 2002;148:361–371. doi: 10.1099/00221287-148-2-361. [DOI] [PubMed] [Google Scholar]

- 13.Sun Y., Zhou X., Tu G., Deng Z. Identification of a gene cluster encoding meilingmycin biosynthesis among multiple polyketide synthase contigs isolated from Streptomyces nanchangensis NS3226. Arch Microbiol. 2003;180:101–107. doi: 10.1007/s00203-003-0564-1. [DOI] [PubMed] [Google Scholar]

- 14.He Y., Sun Y., Liu T., Zhou X., Bai L., Deng Z. Cloning of separate meilingmycin biosynthesis gene clusters by use of acyltransferase-ketoreductase didomain PCR amplification. Appl Environ Microbiol. 2010;76:3283–3292. doi: 10.1128/AEM.02262-09. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Gust B. PCR targeting system in Streptomyces coelicolor. 2018;A3(2) [Google Scholar]

- 16.Kieser T., Buttner M.J., Chater K.F., Hopwood D.A. John Innes Foundation; Norwich, United Kingdom: 2000. Practical Streptomyces genetics. [Google Scholar]

- 17.Sambrook J, Fritsch F, Maniatis T. Molecular cloning : a laboratory manual. third ed..

- 18.Gao H., Liu M., Zhou X., Liu J., Zhuo Y., Gou Z. Identification of avermectin-high-producing strains by high-throughput screening methods. Appl Microbiol Biotechnol. 2010;85:1219–1225. doi: 10.1007/s00253-009-2345-5. [DOI] [PubMed] [Google Scholar]

- 19.Deng Q., Zhou L., Luo M., Deng Z., Zhao C. Heterologous expression of Avermectins biosynthetic gene cluster by construction of a Bacterial Artificial Chromosome library of the producers. Synth Syst Biotechnol. 2017;2:59–64. doi: 10.1016/j.synbio.2017.03.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Zhuo Y., Zhang W., Chen D., Gao H., Tao J., Liu M. Reverse biological engineering of hrdB to enhance the production of avermectins in an industrial strain of Streptomyces avermitilis. Proc Natl Acad Sci U S A. 2010;107:11250–11254. doi: 10.1073/pnas.1006085107. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Gianelli L., Mellerio G.G., Siviero E., Rossi A., Cabri W., Sogli L. Mass spectrometry of avermectins: structural determination of two new derivatives of Ivermectin B(1a) Rapid Commun Mass Spectrom. 2000;14(14):1260–1265. doi: 10.1002/1097-0231(20000730)14:14<1260::AID-RCM20>3.0.CO;2-#. [DOI] [PubMed] [Google Scholar]

- 22.Cropp T.A., Wilson D.J., Reynolds K.A. Identification of a cyclohexylcarbonyl CoA biosynthetic gene cluster and application in the production of doramectin. Nat Biotechnol. 2000;18:980–983. doi: 10.1038/79479. [DOI] [PubMed] [Google Scholar]

- 23.Wang J.B., Pan H.X., Tang G.L. Production of doramectin by rational engineering of the avermectin biosynthetic pathway. Bioorg Med Chem Lett. 2011;21:3320–3323. doi: 10.1016/j.bmcl.2011.04.008. [DOI] [PubMed] [Google Scholar]

- 24.Kim M.S., Cho W.J., Song M.C., Park S.W., Kim K., Kim E. Engineered biosynthesis of milbemycins in the avermectin high-producing strain Streptomyces avermitilis. Microb Cell Factories. 2017;16:9. doi: 10.1186/s12934-017-0626-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Denoya C.D., Fedechko R.W., Hafner E.W., McArthur H.A., Morgenstern M.R., Skinner D.D. A second branched-chain alpha-keto acid dehydrogenase gene cluster (bkdFGH) from Streptomyces avermitilis: its relationship to avermectin biosynthesis and the construction of a bkdF mutant suitable for the production of novel antiparasitic avermectins. J Bacteriol. 1995;177:3504–3511. doi: 10.1128/jb.177.12.3504-3511.1995. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Skinner D.D., Morgenstern M.R., Fedechko R.W., Denoya C.D. Cloning and sequencing of a cluster of genes encoding branched-chain alpha-keto acid dehydrogenase from Streptomyces avermitilis and the production of a functional E1 [alpha beta] component in Escherichia coli. J Bacteriol. 1995;177:183–190. doi: 10.1128/jb.177.1.183-190.1995. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.