Graphical abstract

Keywords: Biogenic amines, Fermented sausages, HPLC, Decarboxylase enzymes

Highlights

-

•

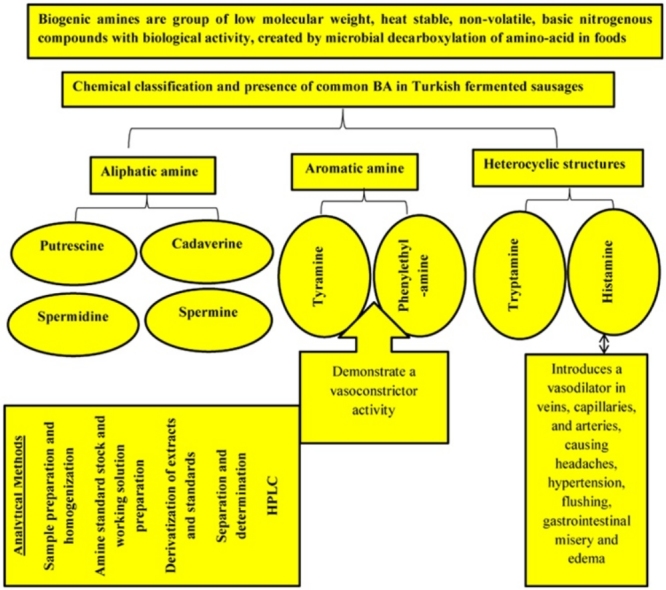

Biogenic amines (BAs) describe as a group of low molecular weight, heat stable, non-volatile, basic nitrogenous compounds with biological activity.

-

•

Biogenic amines are generated in foods as a result of free amino acid decarboxylation by bacterial enzymes.

-

•

HPLC method was moderately simple, sensitive, accurate, repeatable and reproducible for the determination of biogenic amine.

-

•

Biogenic amines, has been implicated as the causative agent in several outbreaks of food poisoning.

-

•

Histamine introduces a vasodilator in veins, capillaries, and arteries, causing headaches, hypertension, flushing, gastrointestinal misery and edema, tyramine and phenylethylamine demonstrate a vasoconstrictor activity.

Abstract

Biogenic amines, has been implicated as the causative agent in several outbreaks of food poisoning. Fermented food such as Turkish style fermented sausages can also contain biogenic amines, microorganisms possessing the enzymes decarboxylase, which converts amino acids to biogenic amines, are responsible for the formation of biogenic amines in fermented sausages. The purpose of this study was to determine the amount of biogenic amines in Turkish fermented sausage consumed in Van in Turkey, and to evaluate their concentrations in term of public health risks. High performance liquid chromatography method was used to the determination of 8 biogenic amines in 120 sausage samples collected from 10 different brands sold in the local markets of Van. The detection levels of biogenic amines in the samples was ranged from 0 to 129.375 mg/kg for tryptamine, from 0 to 65.625 mg/kg for 2-phenylethylamine, from 0 to 255.625 mg/kg for putrescine, from 0 to 1148.75 mg/kg for cadaverine, from 0 to 469.375 mg/kg for histamine, from 0 to 438.125 mg/kg for tyramine, from 0 to 554.375 mg/kg for spermidine, and from 0 to 614.375 mg/kg for spermine.

1. Introduction

Biogenic amines (BAs) describe as a group of low molecular weight, heat stable, non-volatile, basic nitrogenous compounds with biological activity [1,2]. The term biogenic amine defines decarboxylation products such as histamine, serotonin, tyramine, phenylethylamine, tryptamine, and also aliphatic polyamines [3]. Biogenic amines chiefly created by microbial decarboxylation of amino acid in foodstuffs, or by amination and transamination of aldehydes and ketones by amino acid transaminases [2,4]. Knowing the levels of histamine in foods is necessary to assess the health hazard arising from consumption of these products [5] and can be used as indicators for food quality markers [6,7]. They have been related to several outbreaks of food-borne intoxication in the world and are very important in public health concern due to their possible poisonous properties [2,8]. Biogenic amines investigated as a possible mutagenic precursor, since some amines may be nitrosated by react with nitrite and generate volatile nitrosamines which are carcinogenic and pose a potential health threat to humans [1,9]. Some strains of bacteria, for example, Escherichia, Enterobacter, Pseudomonas, Salmonella, Shigella, Clostridium perfringens, Streptococcus, Lactobacillus, and Leuconostoc are identified to be able of histamine creation [8,10] Much research has shown that biogenic amines in fermented foods has been implicated as the causative agent in several outbreaks of food poisoning. Canned tuna [11], tuna burger [12], and fermented meat products [13] contain excessive amounts of histamine. Henry [14] suggested that dry sausages should contain only 1–2 μg histamine/g, based on physiological muscle levels but sausages contaminated by undesirable microorganisms may easily reach histamine concentrations of 100 μg histamine/g or greater during the early stages of fermentation.

Turkish fermented sausage (sucuk) is an old-style dry fermented sausage which is the most prevalent meat product in Turkey and is known in almost all Middle Eastern Countries and Europe [[15], [16], [17]]. Turkish style fermented dry sausage is very popular in Turkey. It is a traditional fermented dry sausage, mostly produced by traditional methods in small-scale enterprises by air drying. It is made from sheep or beef meat. Meat is mixed with tail fat, salt, sugar, dry garlic, spices and vegetable oil [7,15,17]. In manufacture lean meat and fat are ground through a 3 mm plate and the mixture stuffed into cattle small intestines. Traditionally they are hung for fermentation and dried at ambient temperature for 25 days [18].

The microbiological, physico-chemical characteristics of Turkish fermented sausages were studied by Sancak et al. [19], Gokmen et al. [20] and Sezer et al. [21]. In the microbiological analyses reported by Sancak et al. [1996] in Turkish fermented sausages consumed in Van showed the average value of the total colony, coliform, E. coli, fecal streptococci, staphylococci, coagulase positive staphylococci, Clostridium perfringens and yeast-mould were found to be 3.3 × 10 /gr., 5.2xl0 /gr., 6 × 10 /gr., 5.1 × 10 /gr., 6.7 × 10 /gr., l.9xl0 /gr., 1.7 × 10 /gr. and 7.3xl0 /gr. respectively. In the chemical and physical analyses, the average values of moisture, fat, salt, ash, and protein contents were found to be 38.57%, 36.13%, 4.12%, 3.99%, 16.43% respectively. The average values of pH and water activity (Aw) were found to be 5.50 and 0.91 respectively.

Sezer et al. [21] reported the presence of Escherichia coli in fermented sausages, neither Clostridium perfringens nor E. coli O157:H7 were identified in any of the fermented sausage samples. Also Listeria monocytogenes and Salmonella species was isolated in the fermented sausage samples. In the chemical and physical analyses, the maximum values of fat, ash, and salt contents were found to be 58%, 5.42%, and 3.15% respectively. The maximum value of pH was found in the range of 6.97. Gokmen et al. [20] reported the isolation and identification of Staphylococcaceae and Enterobacteriaceae species in Turkish sausage. In the chemical and physical analyses, the maximum values of humidity and salt contents were found in the following 44.26% and 3.79% respectively. The maximum values of pH and water activity (Aw) were found to be 5.20 and 0.78 respectively.

In many studies, the total number of aerobic microorganisms in fermented sausages is reported to be between 106 and 107 cfu/ g [22]. According to Turkish Standards Institute, TS-1070, pH value of Turkish sausage is between 4.7–5.4% and moisture content maximum is 40%, while the fat content can be up to 30% for the first grade, and up to 40% for the second grade. Protein concentration can be up to 20% for the first grade and up to 18% for the second grade [23].

This study was undertaken to determine the amount of biogenic amines in Turkish style fermented sausages since biogenic amines are important with regard to toxicological effects.

2. Materials and methods

2.1. Sample origin

In the present paper, 120 Turkish style dry fermented sausages belonging to ten different brands [Brands A, B, C, D, E, F, G, H, I, J] were obtained from retail stores in the Van area of Turkey, and analyzed for biogenic amines content. Twelve samples were collected from each brand. Samples were kept chilled until analysis. Assays were done on duplicate samples with the results being averaged.

2.2. Biogenic amines analysis

Sample preparation and biogenic amines analysis were done by using HPLC method as described by Eerola et al. [24].

2.3. Sample preparation and homogenization procedure

The samples of fermented sausages, whole sausage samples were sliced with a clean stainless steel knife. Some parts of the sausage samples (2 g of the sample) were randomly chosen and transferred into falcon plastic tubes then homogenized with a metallic staff homogenizer tools (T-25 digital Ultra-Turrax from IKA®-Works, Inc. Wilmington, NC 28405 USA) for about 2 min. The homogenization was done by adding 125 μl from internal standard (1.7-diaminoheptane) with 10 ml of 0.4 M perchloric acid (Merck Germany). In the next step the homogenate samples were centrifuged (3000 rpm for 10 min under 4 °C) by High-Speed Refrigerated Centrifuge (Hitachi Koki Co., Ltd. Japan) then the extraction solvents were transferred and filtered with filter paper (Schleicher and Schuell 589 Black ribbon Ø 70 mm) into a volumetric flask. The remain (supernatant) part again centrifuged with 10 ml perchloric acid and filtered into the same volumetric flask then complete to 25 ml with 0.4 M perchloric acid. An aliquot of 1 ml of the final extract was then used for analysis after derivatization while the remaining volume was stored at 4 °C for no more than one week.

2.4. Derivatization of standards and sample extracts

The dansylated derivatives of the amines were formed by adding 1 ml of extract or standard solution mixed with 200 μl of 2 N NaOH (Merck, Germany) and 300 μl of saturated NaHCO3 (Merck, Germany) solution and vortexed (Heidolph D-91126 Schwabach, Reax top, Germany), and 2 ml of dansyl-chloride solution 2 mg dansyl-chloride per ml in acetone (Sigma Chemical Co., USA) were added and solution and again vortexed. Fresh dansyl-chloride solutions were prepared each time just before use. After shaking, samples were left in the incubator at 40 °C for 45 min. After reaction time has passed, the residual dansyl-chloride was removed by addition of 100 μl of NH4OH 25% (v/v) then vortexed and wait 30 min at room temperature. The derivatization was completed upon addition ammonium acetate and acetonitrile mixture (1:1; v/v) and adjusted to 5 ml. Finally, the mixture was centrifuged (Hettich Zentrifugen, Werk Nr, Germany) at 3000 rpm for 5 min under 4 °C and the supernatant was filtered through 0.45 μm-pore-size filters (Millipore Co., USA).

2.5. Chromatographic conditions

Two solvent reservoirs containing (A) ammonium acetate and (B) acetonitrile were used to separate all the amines with an HPLC elution program. The gradient–elution system was 0.1 M ammonium acetate as solvent A and acetonitrile as solvent B. The gradient–elution program was started at 50% solvent B and ended at 90% solvent B in 25 min. The system was equilibrated for 10 min before next analysis. The flow rate 1.0 ml/min and the column temperature was 40 °C. A 20 μl sample was injected onto the column. The quantitative determinations were carried out by an internal standard (1.7-diaminoheptane) method, using peak heights.

2.6. Statistical analysis of data

In the statistical analysis of the data obtained in this study, SAS 9.4, a software package was used. In order to assess significant differences between brands means, we performed ANOVA based on the Duncan multiple comparison tests. A p-value of 0.05 or less (P < 0.05) was considered statistically significant [25]. The results of statistical analysis are shown as mean values ± standard error, mg/kg wet weight in (Table 1).

Table 1.

Results of biogenic amine levels found in fermented sausage samples (mean ± Standard error, mg/kg wet weight).

| Bran | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| N | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| TRY | 20.00±11.08 a,b | 40.88±9.40 a | 25.54±6.94 a,b | 22.78±6.18 a,b | 37.39±10.49 a | 33.36±4.4 a,b | 11.1±2.25 b | 16.63±3.2 a,b | 35.72±9.36 a | 19.82±4.43 a,b |

| PHE | 2.473±1.20 b | 2.329±1.26 b | 7.588±2.43 b | 2.622±1.15 b | 4.297±1.69 b | 5.530±2.46 b | 7.746±2.06 b | 37.75±6.38 a | 4.376±2.9 b | 2.207±0.86 b |

| PUT | 24.602±5.71 a | 2.318±0.83 b | 6.570±1.95 b | 4.278±1.87 b | 1.008±1.65 b | 1.050±0.38 b | 1.073±0.51 b | 5.093±1.41 b | 1.278±0.51 b | 1.168±0.48 b |

| CAD | 320.0±114.45 b | 203.5±97.043 b,c | 162.1±61.78 b,c | 72.2±47.4 c | 211.8±55.33 b,c | 23.8±4.98 c | 630.6±88.57 a | 681.2±113.6 a | 41.4±30.12 c | 148.0±52.04 b,c |

| HIS | 99.88±36.83 b | 41.50±20.59 b,c | 5.18±1.87 c | 13.68±5.9 b,c | 68.89±26.39 b,c | 0.87±0.59 c | 343.91±48.19 a | 280.26±42.8 a | 23.29±15.86 b,c | 43.91±27.3 b,c |

| TYR | 160.67±45.15 b | 95.78±36.57 b,c | 118.55±34.02 b,c | 69.42±28.53 b,c | 162.40±19.55 b | 63.61±5.12 c | 273.91±33.8 a | 265.37±40.4 a | 53.50±17.65 c | 56.26±15.65 c |

| SPD | 34.41±10.62 b,c | 68.71±3.26 a | 54.05±7.32 a,b | 40.66±7.15 b,c | 53.41±7.7 a,b | 52.43±5.64 a,b | 19.38±8.39 c,d | 23.84±7.48 c,d | 26.64±8.09 c,d | 13.24±6.005 d |

| SPM | 7.55±1.33 b | 19.96±7.34 b | 10.28±3.96 b | 2.74±1.04 b | 3.85±0.69 b | 6.05±1.2 b | 38.28±10.29 a | 16.17±7.01 b | 17.7±7.4 b | 19.06±6.23 b |

*Bran; brands, N; number of samples examined.

*Biogenic amine concentrations in (mg/kg) were TRY (tryptamine), PHE (2-phenylethylamine), PUT (putrescine), CAD (cadaverine), HIS (histamine), TYR (tyramine), SPD (spermidine), and SPM (spermine).

*a – d Means with the same letter are not significantly different (P˃0.05). *a – d Means with different letter are statistically significant P˂0.05).

3. Results and discussion

Table 1 shows the biogenic amines contents of the Turkish style dry-sausages of different brands obtained from Van retail markets. As seen from the Table 1 there are statistically significant differences (P < 0.05) in the contents of biogenic amines in fermented sausage samples. Differentiation in the biogenic amines concentrations of sausages could be due to the hygienic quality of raw material, manufacturing practices, the specific bacteria, ripening period and the type of culture. The biogenic amines concentration may be used as a quality index for this kind of meat product. Handling of raw materials and production technology for fermented sausages are relatively primitive in Turkey. These results indicate that the natural fermentation process used for dry sausages can result in the accumulation of high biogenic amines levels. The brand specific variation suggests that different environmental conditions have some effect on histamine content.

Although the natural fermentation process used in the preparation of these sausages probably did not involve growth of any major biogenic amines - producing bacteria, the lack of quality control in their production [26] and the use of natural fermentation makes selection of desirable organisms difficult.

No standards or guidelines exist for the allowable concentrations of biogenic amines in fermented sausages. Determination of the exact toxicity threshold of biogenic amines in individuals is extremely difficult, since the toxic dose is strongly dependent on the efficiency of the detoxification mechanisms of each individual. Although the toxicity of biogenic amines to man is a controversial subject, ingestion of from 70 to 1000 mg histamine will usually cause clinical symptoms intoxication [14]. The FDA has established a hazard action concentration for histamine in tuna fish of 50 mg of histamine/100 g [27]. Moreover, it must be noted that smaller amounts of biogenic amines may cause poisoning particularly if the person is vulnerable, because of the inhibition of the biogenic amines detoxification mechanism in the body due to reasons such as personal predisposition, gastrointestinal diseases, the use of certain medicines and alcohol intake, and the existence of other amines [26,28].

Phenylethylamine and tryptamine could be viewed as minor amines happening in fermented sausage. Their aggregation appears to be subject to the event of a high substance of tyramine connected with some lactic acid bacteria or coagulase-negative staphylococci [29]. The dominant amine found in Turkish fermented sausage in this study in most sampling analyzed was cadaverine, while tryptamine is highest BA detected in dry-fermented sausage as reported by Ikonić et al. [30]. Other than this, tyramine reported as the most copious amine identified in sausages as presented by Bover-Cid et al. [31] and Komprda et al. [32].

As expected, the total BA level was enormously variable, this wide variability of BAs was observed in the distribution of BAs, for instance, in CAD the levels ranged from 0 to 1147.75 mg/kg of sample. This variability was within the same and different group fermented sausages, which could be attributed to differences in the manufacturing practices, raw materials, poor hygienic conditions, temperature storage, ripening time and specific bacteria. The substance of these biogenic amines can be utilized as a concoction pointer of crude material and/or produce rehearse cleanliness since their amassing is connected with the action of the contaminant microorganisms.

The records informed by numerous authors established the vital role played by the raw material quality, for example, Şenoz et al. [18] found TRY, HIS and TYR in the range of (25–619 mg/kg, 6.72-362.2 mg/kg and 208.6-1173 mg/kg, respectively), in Turkish sausage, Ikonić [30] found PHE in the range of (18.7–81.4 mg/kg) and PUT in the range of (31.3 mg/kg), in traditional dry-fermented sausage, Erkmen and Bozkurt [34] found TRY in the range of 46.53 mg/kg, and PUT from not detected to 383.17 mg/kg in factory sucuks, De Mey et al. [35] found TRY from 4.4 to 7.0 mg/kg in the mean of 5.6 mg/kg in Dry sausage, Coloretti et al. [36] found TRY in the range of 5.52 mg/kg in fermented sausage, Papavergou [37] found TRY from 0 to 60.53 mg/kg in the mean of 14.27 mg/kg, PHE, TYR in the range of 0-56.40 mg/kg, 164.95 mg/kg, respectively, in fermented sausage, Mokhtar et al. [38] found TRY in the range of 4.09 mg/kg in fermented sausage, Tasic et al. [39] found TRY and HIS in the range of 47.6 mg/kg and 16.1 mg/kg, respectively, in traditional dry fermented sausage, Lu et al. [40] found PHE, CAD, HIS, SPD and SPM in the range of (60.96 mg/kg, 24.54–178.03 mg/kg, 90.56 mg/kg, 22.03 mg/kg and 7.12 mg/kg, respectively) in traditional Chinese smoked horsemeat sausages, Blagojevic et al. [42] found PUT, CAD and TYR in the range of (50.9 mg/kg, 33 mg/kg and 24.8 mg/kg, respectively) in fermented sausage, Domínguez et al. [43] found PUT, HIS, SPD and SPM in the range of (3.27 mg/kg, 4.12 mg/kg, 11.75 mg/kg and 24.1 mg/kg, respectively) inDry-cured foal sausage, Bozkurt and Erkmen [15], Coloretti et al. [36] and Stojanović [45] found HIS in the range of (0.85–378.29 mg/kg, 94.78 mg/kg and 98.3 mg/kg, respectively) in fermented sausage. Though, extra variables (for example pH, water activity, temperature, redox potential, oxygen supply, nature of the food, manufacturing practices, preservatives, NaCl, and additives, etc.) may have a significant effect on the formation of biogenic amine in fermented sausage [33].

Shalaby [9] suggested amounts of BAs (tyramine 100–800 mg/kg, histamine 50–100 mg/kg, phenylethylamine <30 mg/kg) as parameters for evaluation of good manufacture practices (GMPs). It is expected that 2–10 mg histamine for every day per individual is perfect with people. A toxicological sum differs from 70 to 1000 mg, as indicated by the powerlessness of a person to this substance. It is further expected that an admission of 100 mg histamine will normally bring out harming side effects. Little is thought about the toxicological measurements of other biogenic amines. About 8.33% (10 samples) of all fermented sausage samples had higher phenylethylamine concentration than 30 mg/kg.

The histamine contents of the different groups were significantly different (P < 0.05) from each other. Histamine concentrations ranged from 0 to 469.375 mg/kg, in fermented sausage samples in this study. Whereas tyramine is the amine in higher concentration (372 mg/kg) followed by histamine (165 mg/kg) in “Salamini italiani alla cacciatora PDO’’ was detected by Coïson et al. [44].

Histamine is the amine most contemplated as to its toxicological impacts. An intake of 5–10 mg of histamine can be considered as abandoning to some delicate individuals, 10 mg is considered as a middle of as far as possible, 100 mg affect a medium poisonous quality and 1000 mg is very lethal [48,49]. Some different scientists Eerola et al. [50] and Gardini et al. [51] recommended taking after intoxication points of confinement of histamine, 8–40 mg causes slight intoxication, 40-100 mg middle of the road injuring and more than 100 mg can bring about concentrated poisoning.

Nout [52] called attention to the allowable greatest of histamine and tyramine substance for foods from 50 to 100 mg/kg 100 to 800 mg/kg, respectively. About 26.66% (32 tests) and 22.5% (27 tests) of fermented sausages had higher histamine fixation than 100 and 200 mg/kg, respectively (Table 1). Variation in histamine concentrations of fermented sausages could be because of the clean nature of crude materials, producing practices, and the presence of the particular microorganisms.

Tyramine and putrescine were found from (0 to 438.125 and 0–255.625 mg/kg), respectively. The results obtained in this study are close to the lower mentioned limits, 100-800 mg of TYR [53]. Tyramine is the most abundant BA in fermented sausage as reported by Bozkurt and Erkmen [15], Bover-Cid et al. [6] and Latorre-Moratalla et al. [46]. Tyramine levels was found from not detected to a maximum of 411 mg/kg which is the most abundant BA in fermented sausage followed by putrescine as testified by Latorre-Moratalla et al. [46]. In another study related to fermented sausage, essential amines were putrescine (more than 400 mg/kg), followed by tyramine (250 mg/kg) [41]. While cadaverine was the predominant biogenic amine 1387 mg/kg in Egyptian fermented sausage [47]. Cadaverine generally found in higher concentrations which are ranged in the mean of (23.8 to 681.2 mg/kg) in this study followed by histamine (0.87 to 343.91 mg/kg) and tyramine (53.50 to 273.91 mg/kg). Putrescine concentrations were lower and exceeded 200 mg/kg of about 1.66% (2 samples) of fermented sausage samples examined.

The spermidine and spermine amounts in this work had a variable (P < 0.05) changes among the same groups and between two different groups of fermented sausages (Table 1). This distinction in variability most likely reflects the naturally occurring spermine in meat and extensive environmental effects (pH, temperature) on bacterial amine generation [6].

A total of 100–200 mg/kg is regarded as an acceptable level for BA [52]. Spermidine and spermine concentrations were lower and exceeded 200 mg/kg of about 1.66 (2 samples) and 3.33% (4 samples), respectively, and this value was proposed as a possible indicator of hygienic conditions and good manufacturing practices in sausage production. Til et al. [55] and Naila et al. [56] reported oral toxicity levels for putrescine (2000 mg/kg), cadaverine (2000 mg/kg), tryptamine (2000 mg/kg), spermine (600 mg/kg), and spermidine (600 mg/kg). Til et al. [55] reported a single iv administration of tyramine to rats (0.01–0.3 mg/kg body weight) induced a disease-related increase in systolic and diastolic blood pressure (hypertension).

The danger limit of different BA in people is variable since it, for the most part, relies on upon components connected with the utilizers. Healthy people with a powerful detoxifying component (the ordinary action of mono-amine oxidase) have a generally safe of wellbeing inconveniences while ingesting TYR with sustenance’s. Other than this, measurements as low as 6 mg or 50–100 mg of TYR can bring about hypertensive manifestations to patients treated with established MAOI medications [46]. Be that as it may, more consideration is vital for the direction of histamine in sustenance [27].

There were significant increases in the concentrations of cadaverine, histamine, and tyramine in fermented sausages and these amines reach high value compared to other BAs in this study. However, consumption of fermented sausages should be limited especially for individuals undergoing MAOI drug therapy. Various measures have been taken with the aim of inhibiting or reducing production of biogenic amines during the manufacture of raw-cured sausages, such as improved sanitary conditions in production plants, the use of starter cultures formed by lactic acid bacteria with acidifying capacity, and the use of certain preservatives [54].

Turkish fermented sausages contained biogenic amines for histamine not more than 500 mg/kg and not more than 800 mg/kg for tyramine. The maximum histamine and tyramine detection levels were respectively less than those of the regulation and recommendation.

4. Conclusion

It is concluded that the histamine levels obtained from the study were not important from a public health viewpoint but these levels may be a potential risk according to susceptible individuals. However, handling of raw materials and production technology for fermented sausages is relatively primitive in Turkey. For this reason, must be developed methods for preventing formation of biogenic amines that aim at eliminating the decarboxylating microbes in fermented sausages, the use of high-quality raw materials, amine negative starter cultures and processing conditions which favour growth of the starter strains.

Transparency document

The Transparency document associated with this article can be found in the online version.

Acknowledgment

The authors acknowledge financial support from the Presidency of Scientific Research Projects (BAP, Project No.: 2015-SBE-YL316), and the Yüzüncü Yıl University, Distance Education Center Directorate for English assistance (YÜSEM).

Footnotes

Summarised from master thesis.

References

- 1.Önal A. A review: current analytical methods for the determination of biogenic amines in foods. Food Chem. 2007;103(4):1475–1486. [Google Scholar]

- 2.Stadnik J., Dolatowski Z.J. Biogenic amines in meat and fermented meat products. Acta. Sci. Pol. Technol. Aliment. 2010;9(3):251–263. [Google Scholar]

- 3.Righetti L., Tassoni A., Bagni N. Polyamines content in plant derived food: a comparison between soybean and Jerusalem artichoke. Food Chem. 2008;111:852–856. [Google Scholar]

- 4.Kim M., Jae-Mah J., Hwang H. Biogenic amine formation and bacterial contribution in fish, squid and shellfish. Food Chem. 2009;116:87–95. doi: 10.1016/j.foodchem.2012.06.091. [DOI] [PubMed] [Google Scholar]

- 5.Vale S., Gloria M.B.A. Determination of biogenic amines in cheese. J. A.O.A.C. Int. 1997;60:651–657. [PubMed] [Google Scholar]

- 6.Bover-Cid S., Schoppen S., Izquierdo-Pulido M., Vidal-Carou M. Relationship between biogenic amine contents and the size of dry fermented sausages. Meat Sci. 1999;51(4):305–311. doi: 10.1016/s0309-1740(98)00120-x. [DOI] [PubMed] [Google Scholar]

- 7.Ekici K.R., Sekeroglu Y.C., Sancak T., Noyan A note on histamine levels in Turkish style fermented sausages. Meat Sci. 2004;68(1):123–125. doi: 10.1016/j.meatsci.2004.02.013. [DOI] [PubMed] [Google Scholar]

- 8.Santos M., Draisci H., Giannetti R., Boria L., Lucentini L., Palleschi L., Cavalli S. Amino acid decarboxylase capability of microorganisms isolated in Spanish fermented meat products. Int. J. Food Microbiol. 1998;39(3):227–230. doi: 10.1016/s0168-1605(97)00129-3. [DOI] [PubMed] [Google Scholar]

- 9.Shalaby A. Significance of biogenic amines to food safety and human health. Food Res. Int. 1996;29(7):675–690. [Google Scholar]

- 10.Edwards S.T., Sandine W.E. Public health significance of amines in cheese. J. Dairy. Sci. 1981;64:2431–2438. [Google Scholar]

- 11.Merson M.H., Baine W.B., Gangarosa E.J., Swanson R.C. Scombroid fish poisoning. Outbreak traced to commercially canned tuna fish. J. Am. Med. Assoc. 1974;228:1268–1269. doi: 10.1001/jama.228.10.1268. [DOI] [PubMed] [Google Scholar]

- 12.Becker K., Southwick K., Reardon J., Berg R., MacCormack J.N. Histamine poisoning associated with eating tuna burgers. J. Am. Med. Assoc. 2001;285(10):1327–1330. doi: 10.1001/jama.285.10.1327. [DOI] [PubMed] [Google Scholar]

- 13.Rice S.L., Eitenmiller R.R., Koehler P.E. Histamine and tyramine content of meat products. J. Milk Food Technol. 1975;38:256–258. [Google Scholar]

- 14.Henry M. Dosage biologique de l'histamine dans les aliments. Ann. Fals. Eexp. Chim. 1960;53:24–33. [Google Scholar]

- 15.Bozkurt H., Erkmen O. Effects of starter cultures and additives on the quality of Turkish style sausage (sucuk. Meat Sci. 2002;61(2):149–156. doi: 10.1016/s0309-1740(01)00176-0. [DOI] [PubMed] [Google Scholar]

- 16.Gençcelep H., Kaban G., Kaya M. Effects of starter cultures and nitrite levels on formation of biogenic amines in sucuk. Meat Sci. 2007;77(3):424–430. doi: 10.1016/j.meatsci.2007.04.018. [DOI] [PubMed] [Google Scholar]

- 17.Kurt Ş., Zorba Ö. Biogenic amine formation in Turkish dry fermented sausage (sucuk) as affected by nisin and nitrite. J. Sci. Food Agric. 2010;90(15):2669–2674. doi: 10.1002/jsfa.4138. [DOI] [PubMed] [Google Scholar]

- 18.Şenoz B., Işikli N., Coksoyler N. Biogenic amines in Turkish sausages (Sucuks) J. Food Sci. 2000;65(5):764–767. [Google Scholar]

- 19.Sancak Y.C., Kayaardı S., Sagun E., Isleyici O., Sancak H. Studies on the physical. Chemical, microbiological and organoleptical properties of the Turkish fermented sausages consumed in Van. YYU Vet Fak Derg. 1996;7(1-2):67–73. [Google Scholar]

- 20.Gokmen M., Kara R., Akkaya L., Gok V. Identification of Enterobacteriaceae and Staphylococcaceae at Turkish sucuk. Eurasian J. Vet. Sci. 2013;29(4):192–197. [Google Scholar]

- 21.Sezer C., Aksoy A., Celebi O., Deprem T., Ogun M., Bilge Oral N., Vatansever L., Guven A. Evaluation of the quality characteristics of fermented sausages and sausage-like products sold in Kars. Eurasian J. Vet. Sci. 2013;29(3):143–149. [Google Scholar]

- 22.Nazlı B. Researches on the ripening of Turkish fermented sausage using a local starter culture combination. Turk. J. Vet. Anim. Sci. 1998;22:393–397. [Google Scholar]

- 23.Anonymous . Turkish Standards Institute; Ministries, Ankara: 2012. Turkish Sausage TS1070. [Google Scholar]

- 24.Eerola S., Hinkkanen R., Lindfors E., Hirvi T. Liquid chromatographic determination of biogenic amines in dry sausages. J. AOAC. Int. 1993;76(3):575–577. [PubMed] [Google Scholar]

- 25.SAS . SAS, Inst. Inc.; Cary, N.C. USA: 2014. SAS/ STAT Software: Hangen and Enhanced, Version 9.4. [Google Scholar]

- 26.Bodmer S., Imark C., Kneubühl M. Biogenic amines in foods: Histamine and food processing. Inflam. Res. 1999;48(6):296–300. doi: 10.1007/s000110050463. [DOI] [PubMed] [Google Scholar]

- 27.Stratton J., Hutkins R., Taylor S. Biogenic amines in cheese and other fermented foods: a review. J. Food Prot. 1991;54(6):460–470. doi: 10.4315/0362-028X-54.6.460. [DOI] [PubMed] [Google Scholar]

- 28.Joosten H.M.L.J., Van-Boekel M.A.J.S. Condition allowing the formation of biogenic amines in cheese. A study of the kinetics of histamine formation in an infected Gouda cheese. Neth.Milk. Dairy. J. 1988;42:3–24. [Google Scholar]

- 29.Pereira C.I., Barreto-Crespo M.T., San Romão M.V. Evidence for proteolytic activity and biogenic amines production in Lactobacillus curvatus and L. homohiochii. Int. J. Food Microbiol. 2001;68:211–216. doi: 10.1016/s0168-1605(01)00534-7. [DOI] [PubMed] [Google Scholar]

- 30.Ikonić P., Tasić T., Petrović L., Škaljac S., Jokanović M., Mandić A., Ikonić B. Proteolysis and biogenic amines formation during the ripening of Petrovská klobása, traditional dry-fermented sausage from Northern Serbia. Food Cont. 2013;30(1):69–75. [Google Scholar]

- 31.Bover-Cid S., Izquierdo-Pulido M., Carmen Vidal-Carou M. Changes in biogenic amine and polyamine contents in slightly fermented sausages manufactured with and without sugar. Meat Sci. 2001;57(2):215–221. doi: 10.1016/s0309-1740(00)00096-6. [DOI] [PubMed] [Google Scholar]

- 32.Komprda T., Smela D., Pechova P., Kalhotka L., Stencl J., Klejdus B. Effect of starter culture, spice mix and storage time and temperature on biogenic amine content of dry fermented sausages. Meat Sci. 2004;67(4):607–616. doi: 10.1016/j.meatsci.2004.01.003. [DOI] [PubMed] [Google Scholar]

- 33.Suzzi G., Gardini F. Biogenic amines in dry fermented sausages: a review. Int. J. Food Microbiol. 2003;88(1):41–54. doi: 10.1016/s0168-1605(03)00080-1. [DOI] [PubMed] [Google Scholar]

- 34.Erkmen O., Bozkurt H. Quality characteristics of retailed sucuk (Turkish dry fermented sausage. Food Technol. Biotechnol. 2004;42(1):63–69. [Google Scholar]

- 35.De Mey E., De Klerck K., De Maere H., Dewulf L., Derdelinckx G., Peeters M.C., Fraeye I., Heyden Y.V., Paelinck H. The occurrence of N-nitrosamines, residual nitrite and biogenic amines in commercial dry fermented sausages and evaluation of their occasional relation. Meat Sci. 2014;96(2):821–828. doi: 10.1016/j.meatsci.2013.09.010. [DOI] [PubMed] [Google Scholar]

- 36.Coloretti F., Tabanelli G., Chiavari C., Lanciotti R., Grazia L., Gardini F., Montanari C. Effect of wine addition on microbiological characteristics, volatile molecule profiles and biogenic amine contents in fermented sausages. Meat Sci. 2014;96(3):1395–1402. doi: 10.1016/j.meatsci.2013.11.027. [DOI] [PubMed] [Google Scholar]

- 37.Papavergou E. Biogenic amine levels in dry fermented sausages produced and sold in Greece. Procedia Food Sci. 2011;1:1126–1131. [Google Scholar]

- 38.Mokhtar S., Mostafa G., Taha R., Eldeep G. Effect of different starter cultures on the biogenic amines production as a critical control point in fresh fermented sausages. Eur. Food Res. Technol. 2012;235(3):527–535. [Google Scholar]

- 39.Tasic T., Ikonic P., Jokanovic M., Mandic A., Tomovic V., Sojic B., Skaljac S. Content of vasoactive amines in Sremski Kulen and Sremska Kobasica traditional dry fermented sausages from Vojvodina. Procedia Food Sci. 2015;5:282–284. [Google Scholar]

- 40.Lu S., Ji H., Wang Q., Li B., Li K., Xu C., Jiang C. The effects of starter cultures and plant extracts on the biogenic amine accumulation in traditional Chinese smoked horsemeat sausages. Food Cont. 2015;50:869–875. [Google Scholar]

- 41.Ayhan K., Kolsarici N., Özkan G. The effects of a starter culture on the formation of biogenic amines in Turkish soudjoucks. Meat Sci. 1999;53(3):183–188. doi: 10.1016/s0309-1740(99)00046-7. [DOI] [PubMed] [Google Scholar]

- 42.Blagojevic B., Antic D., Adzic B., Tasic T., Ikonic P., Buncic S. Decontamination of incoming beef trimmings with hot lactic acid solution to improve microbial safety of resulting dry fermented sausages – a pilot study. Food Cont. 2015;54:144–149. [Google Scholar]

- 43.Domínguez R., Munekata P., Agregán R., Lorenzo J. Effect of commercial starter cultures on free amino acid, biogenic amine and free fatty acid contents in dry-cured foal sausage. LWT Food Sci. Technol. 2016;71:47–53. [Google Scholar]

- 44.Coïsson J.D., Cerutti C., Travaglia F., Arlorio M. Production of biogenic amines in “Salamini Italiani Alla Cacciatora PDO. Meat Sci. 2004;67(2):343–349. doi: 10.1016/j.meatsci.2003.11.007. [DOI] [PubMed] [Google Scholar]

- 45.Stojanović Z., Švarc-Gajić J. A simple and rapid method for histamine determination in fermented sausages by mediated chronopotentiometry. Food Cont. 2011;22(12):2013–2019. [Google Scholar]

- 46.Latorre-Moratalla M.L., Veciana-Nogués T., Bover-Cid S., Garriga M., Aymerich T., Zanardi E., Ianieri A., Fraqueza M.J., Patarata L., Drosinos E.H., Lauková A., Talon R., Vidal-Carou M.C. Biogenic amines in traditional fermented sausages produced in selected European countries. Food Chem. 2008;107(2):912–921. [Google Scholar]

- 47.Rabie M., Elsaidy S., el-Badawy A., Siliha H., Malcata F. Biogenic amine contents in selected Egyptian fermented foods as determined by ion-exchange chromatography. J. Food Prot. 2011;74(4):681–685. doi: 10.4315/0362-028X.JFP-10-257. [DOI] [PubMed] [Google Scholar]

- 48.Santos M. Biogenic amines: their importance in foods. Int. J. Food Microbiol. 1996;29(2-3):213–231. doi: 10.1016/0168-1605(95)00032-1. [DOI] [PubMed] [Google Scholar]

- 49.Karovičová J., Kohajdová Z. Review: biogenic amines in food. Chem. Pap. 2005;59(1):70–79. [Google Scholar]

- 50.Eerola S., Sagués A., Lilleberg L., Aalto H. Biogenic amines in dry sausages during shelf-life storage. Z. Lebensm. Unters. Forsch. A. 1997;205(5):351–355. [Google Scholar]

- 51.Gardini F., Martuscelli M., Caruso M., Galgano F., Crudele M., Favati F., Guerzonia M.E., Suzzi G. Effects of pH, temperature and NaCl concentration on the growth kinetics, proteolytic activity and biogenic amine production of Enterococcus faecalis. Int. J. Food Microbiol. 2001;64(1-2):105–117. doi: 10.1016/s0168-1605(00)00445-1. [DOI] [PubMed] [Google Scholar]

- 52.Nout M. Fermented foods and food safety. Food Res. Int. 1994;27(3):291–298. [Google Scholar]

- 53.Hernández-Jover T., Izquierdo-Pulido M., Veciana-Nogués M., Mariné-Font A., Vidal-Carou M. Effect of starter cultures on biogenic amine formation during fermented sausage production. J. Food Prot. 1997;60(7):825–830. doi: 10.4315/0362-028X-60.7.825. [DOI] [PubMed] [Google Scholar]

- 54.Bermúdez R., Lorenzo J., Fonseca S., Franco I., Carballo J. Strains of Staphylococcus and Bacillus isolated from traditional sausages as producers of biogenic amines. Front. Microbiol. 2012;3:1–6. doi: 10.3389/fmicb.2012.00151. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 55.Naila A., Flint S., Fletcher G., Bremer P., Meerdink G. Biogenic amines and potential histamine – forming bacteria in Rihaakuru (a cooked fish paste) Food Chem. 2011;128:479–484. doi: 10.1016/j.foodchem.2011.03.057. [DOI] [PubMed] [Google Scholar]

- 56.Til H.P., Falke H.E., Prinsen M.K., Willems M.I. Acute and subacute toxicity of tyramine, spermidine, spermine, putrescine and cadaverine in rats. Food Chem. Toxicol. 1997;35:337–348. doi: 10.1016/s0278-6915(97)00121-x. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.