Abstract

Background

Biosurfactants are surface-active agents produced by microorganisms that have higher efficiency and stability, lower toxicity and higher biocompatibility and biodegradability than chemical surfactants. Despite its properties and potential application in a wide range of environmental and industrial processes, biosurfactants are still not cost-competitive when compared to their synthetic counterparts. Cost effective technologies and renewable raw substrates as agro-industrial and regional waste from northeast of Brazil as cassava flour wastewater, supplemented with lactose and corn oil are mainly the chemically media for growing microorganism and in turn the production of the biosurfactant of quality. This study aimed to obtained biosurfactant by Serratia marcescens UCP 1549 containing cassava flour wastewater (CWW), by application of a full-factorial design, as sustainable practices in puts the production process in promising formulation medium. The characterization of the biomolecule was carried out, as well as the determination of its stability and toxicity for cabbage seeds. In addition, its ability to stimulate seed germination for agriculture application and oil spill bioremediation were investigated.

Results

Serratia marcescens showed higher reduction of surface tension (25.92 mN/m) in the new medium containing 0.2% lactose, 6% cassava flour wastewater and 5% corn waste oil, after 72 h of fermentation at 28 °C and 150 rpm. The substrate cassava flour wastewater showed a promising source of nutrients for biosurfactant production. The isolate biosurfactant exhibited a CMC of 1.5% (w/v) and showed an anionic and polymeric structure, confirmed by infrared spectra. The biomolecule demonstrated high stability under different temperatures, salinity and pH values and non-toxicity against to cabbage seeds. Thus, exploring biosurfactant their potential role in seeds germinations and the promotion and agricultural applications was investigated. In addition, the effectiveness of biosurfactant for removal burned motor oil adsorbed in sand was verified.

Conclusions

The use of medium containing CWW not only reduces the cost of process of biosurfactant production, but also the environmental pollution due to the inappropriate disposal of this residue. This fact, added to the high stability and non-toxicity of the biosurfactant produced by S. marcescens UCP 1549, confirms its high environmental compatibility, make it a sustainable biocompound that can be replace chemical surfactants in diverse industries. In addition, the effectiveness of biosurfactant for stimulate seed germination and removing burned motor oil from sand, suggests its suitability for agriculture and bioremediation applications.

Electronic supplementary material

The online version of this article (10.1186/s12934-018-1046-0) contains supplementary material, which is available to authorized users.

Keywords: Biosurfactant, Serratia marcescens, Cassava flour wastewater, Seed germination, Oil removing

Background

Surfactants are amphipathic molecules with hydrophobic (nonpolar) and hydrophilic (polar) moieties that reduce surface and interfacial tension between liquid. According to their origin, they can be classified as chemical surfactants (derived from petroleum) or biosurfactants (microbial origin) [1, 2].

Biosurfactants are secondary metabolites produced by various microorganisms (bacteria, yeasts and filamentous fungi), and they are classified according to their chemical composition and microbial origin. Producing microorganisms are distributed in various genres, mostly bacteria; some examples are Pseudomonas aeruginosa, Bacillus subtilis and Lactobacillus sp. [3, 4]. The major classes of biosurfactants include glycolipids, lipopeptides, phospholipids, fatty acids, lipoproteins and polymeric and particulates compounds [5, 6].

In recent decades, the interest in biosurfactants has increased due to their advantages over their synthetic counterparts, including better environmental compatibility, production from renewable waste substrates, maintaining activity at harsh environmental conditions, lower or no environmental toxicity. These properties makes feasible to utilize them for numerous environmental, food, pharmaceutical, medical, cleaning and other industrial application purposes [7–10].

However, widespread industrial applications of biosurfactants are quite limited, mainly due to cost-competitiveness. Chemical surfactants are still comparatively cheaper than biosurfactants [3, 11, 12]. However, the characteristics of the non-biodegradability, ability to accumulate and toxicity of some of the chemical petroleum based product to the environment suggest to find replacement surfactants to the chemically synthesized compounds with ecofriendly products as biosurfactant or bioemulsifier [10–12]. Therefore, different strategies are currently explored to improve biosurfactant production economics. Among them, the use of low-cost raw materials such as agro-industrial wastes is a sustainable alternative since the utilization of these residues contributes to the reduction of environmental pollution [6, 8, 13]. A characteristic wastewater from industrial cassava processing has a huge adverse impact on the environment by large amount of cyanogenic glucosides (linamarin and lotaustralin) is produced [14]. Brazil is one of the largest global producers of cassava (Manihot esculenta Crantz) liquid waste (“manipueira”) whose processing to produce flour and starch gives rise to about 250–300 L wastewater per ton of processed cassava, mainly composed of organic matter and nutrients [15, 16].

In addition, optimization of culture medium, growth conditions and process parameters by using statistical models can also significantly increase the yield and reduce the overall cost [17, 18].

Serratia marcescens, a facultative bacterium belonging to the Enterobacteriaceae family, produces biosurfactant such as serrawetins that present enormous potential of application in pharmaceutical industry [19, 20]. Over the last years, several studies have reported the production of biosurfactants by S. marcescens strains using a variety of hydrophilic and hydrophobic substrates [21–24]. However, researches focusing on the use of agro-industrial waste are still few and they have been carried out by our research group [8, 25]. In addition, the toxicity of this secondary metabolite has only been tested in mice [26], and considering its potential for environmental application, further studies are needed.

In this sense, this work aimed to the improved production of biosurfactant by S. marcescens UCP 1549 in low-cost fermentative medium containing cassava flour wastewater (CWW). The effect of the medium components was investigated by full factorial design (FFD) and the best condition was selected and used for kinetics of microbial growth and biosurfactant production. The isolation and characterization of biosurfactant were carried out, as well as studies of its stability, phytotocity and application in removal burned engine oil.

Results and discussion

Biosurfactant production

In this study, the production of biosurfactant by S. marcescens UCP 1549 was improved using the 23 FFD proposed in Table 1, in order to determine the relationship and influence between input and output variables on the process efficiency. The following response equation (Eq. 1) was used to correlate the dependent and independent variables:

| 1 |

where Y is the response variable or surface tension, b0 is a constant; b1, b2 and b3 are regression coefficients for the linear effects and b12, b13, b23 and b123 are interaction coefficients.

Table 1.

Variables levels used in the full-factorial design for biosurfactant production by Serratia marcescens UCP 1549

| Variables | Levels | ||

|---|---|---|---|

| Low (−1) | Central (0) | High (+1) | |

| Lactose (% m/v) | 0.2 | 0.6 | 1.0 |

| Cassava flour wastewater (% v/v) | 1.0 | 3.5 | 6.0 |

| Corn oil (% v/v) | 5 | 6.25 | 7.5 |

To analyze the mathematical models, adjustments to the points were made by nonlinear regression methods and Table 2 shows the experimental and predicted values of the model to obtain the lower surface tension.

Table 2.

Full-factorial design for the biosurfactant production by Serratia marcescens UCP 1549 after 72 h

| Assay | Lactose (%) | Cassava flour wastewater (%) | Corn oil (%) | Surface tension (mN/m) | |

|---|---|---|---|---|---|

| Experimental | Predicted | ||||

| 1 | − 1 | − 1 | − 1 | 29.33 | 28.77 |

| 2 | 1 | − 1 | − 1 | 42.29 | 41.73 |

| 3 | − 1 | 1 | − 1 | 25.92 | 25.36 |

| 4 | 1 | 1 | − 1 | 28.34 | 27.78 |

| 5 | − 1 | − 1 | 1 | 29.29 | 28.73 |

| 6 | 1 | − 1 | 1 | 34.63 | 34.07 |

| 7 | − 1 | 1 | 1 | 26.78 | 26.22 |

| 8 | 1 | 1 | 1 | 29.07 | 28.51 |

| 9 | 0 | 0 | 0 | 29.03 | 30.14 |

| 10 | 0 | 0 | 0 | 29.33 | 30.14 |

| 11 | 0 | 0 | 0 | 28.82 | 30.14 |

| 12 | 0 | 0 | 0 | 28.89 | 30.14 |

The regression coefficient values, standard deviation, texp and significance level are represented in Table 3. As can be seen all regression and interaction coefficients were significant, with confidence level 95% (p ≤ 0.05), determined by the analysis of variance (ANOVA).

Table 3.

Estimated regression coefficients and corresponding texp and significance levels for the surface tension

| Coefficient | Value | Standard deviation | t exp | p |

|---|---|---|---|---|

| b 0 | 30.1433 | 0.0652 | 462.2643 | 0.0000 |

| b 1 | 2.8763 | 0.0799 | 36.0147 | 0.0001 |

| b 2 | − 3.1786 | 0.0799 | − 39.8025 | 0.0000 |

| b 3 | − 0.7638 | 0.0799 | − 9.5632 | 0.0024 |

| b 12 | − 1.6988 | 0.0799 | − 21.2708 | 0.0002 |

| b 13 | − 0.9688 | 0.0799 | − 12.1301 | 0.0012 |

| b 23 | 1.1613 | 0.0799 | 14.5405 | 0.0007 |

| b 123 | 0.9363 | 0.0799 | 11.7232 | 0.0013 |

The application of response surface methodology (RSM), offers, on the basis of parameter estimation (Table 3), the following empirical relationship (Eq. 2) between the surface tension (Y) and independent variables studied.

| 2 |

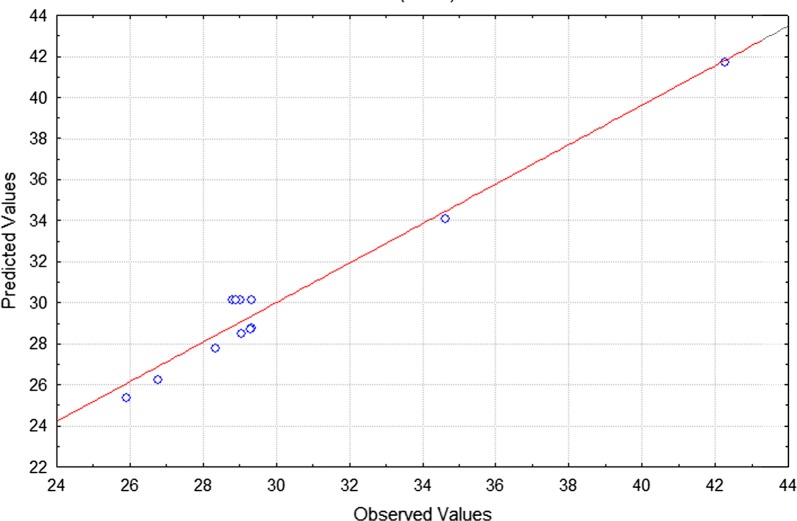

The predicted versus the actual plot for surface tension determined by the model equation demonstrated that observed values were distributed near the straight line (Fig. 1), which indicates that such values were close to the predicted values. The ANOVA showed that the regression model had a high coefficient of determination (R2 = 0.963), indicating that 96.3% of the variation in the process efficiency was explained by the independent variables and that only 3.7% was not explained by the model. Reproducibility of the experimental data was confirmed by the low pure error (0.051) and value of the adjusted determination coefficient (Adj. R2 = 0.897). Hence, the model proved to be suitable for the prediction of biosurfactant production under the experimental conditions.

Fig. 1.

Observed values versus predicted values by model for the answer surface tension

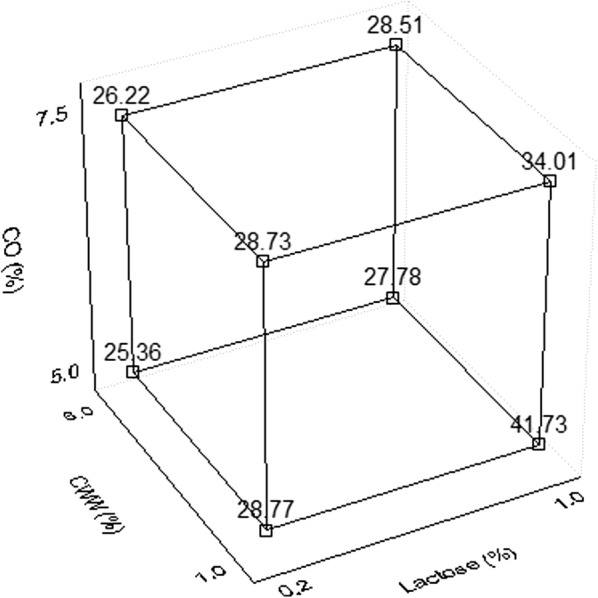

The reduction in surface tension is commonly used as a primary criterion for selecting biosurfactant-producing microorganisms [2, 27, 28]. In this study, surface tension was used as response variable, and the effects of independent variables (lactose, CWW and CO concentrations) as well as the interactions of them, were analyzed by estimated effects represented in Table 3 and Fig. 2. It can be concluded that although the three variables were significant, the increase of all of them led to increment of surface tension. However, the increment of CWW and diminution of CO and lactose allowed the lower value of surface tension, as verified in Table 2, in condition 3 of the FFD.

Fig. 2.

Cubic plot of the surface tension values estimated from the full-factorial design of Table 2

Previously, Araújo et al. [25] used the same substrates and FFD for the production of biosurfactant by S. marcescens UCP 1549, but in static conditions, and they found the best results in condition 8, with reduction on surface tension to 30.60 mN/m. Highest tensioactive activity detected in current study in flasks with agitation can be linked to the physiological function of the biosurfactants. It has been suggested that their production can increase the solubility of hydrophobic substrates in water and, consequently, facilitate the transport of nutrients to microorganisms [3, 29]. Therefore, the shear stress caused by agitation can induce larger biosurfactant excretion since the contact between the organic phase drops, dispersed in water, and the microorganisms becomes more difficult [30]. In addition, several researchers have indicated that an increase in agitation speed favored the production of biosurfactant, since that it influences the mass transfer efficiency of both oxygen molecules and medium components [31, 32].

In other hand, it was ratified the suitability of CWW as low-cost substrate for biosurfactant production. Commonly, it is used as nitrogen source, because it has a high presence of nitrogen in its composition [8, 25, 33, 34] (see Additional file 1: Table S1). Earlier, Ferraz et al. [33] showed the ability of the biosurfactant produced by S. marcescens to reduce water surface tension of 72–28 mN/m using CWW as substrate. Similarly, this residue was used for biosurfactant production by Bacillus sp. and results showed a reduction in surface tension of 59–26 mN/m [34]. The use of CWW can contribute considerably to the diminution of cost production of biosurfactants, since it is estimated that raw materials represent 30% of the total costs of bioprocess [1, 13, 35].

Growth kinetics and biosurfactant production

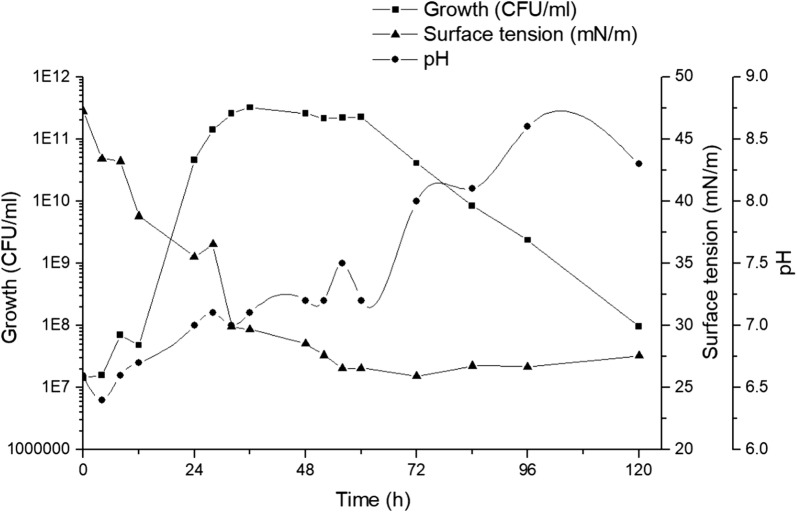

After the selection of the medium with higher reduction of surface tension, the microbial growth kinetics and biosurfactant production were monitored during 120 h. Figure 3 shows the production kinetics of biosurfactant produced by S. marcescens UCP 1549 in medium containing 0.2% lactose, 6% CWW and 5% CO.

Fig. 3.

Kinetic profiles of growth, surface tension and pH of Serratia marcescens UCP 1549. The strain was grown in medium containing 0.2% lactose, 6% CWW and 5% CO during 120 h at 150 rpm and 28 °C

As can be observed, the exponential phase of microorganism occurred in the first 24 h, after a very short phase of adaptation to physico-chemical composition of medium. Simultaneously, the surface tension began to decrease, indicating that the new substrates promote the biosynthesis of essential compounds to the microbial growth and the production of biomolecules with surface active properties. The start of growth stationary phase occurred at 36 h when the value of surface tension was lower to 30 mN/m. Similar profile was observed when S. marcescens UCP 1549 was grown in LB medium (see Additional file 1: Figure S1). However, the maximum production of biosurfactant was detected at 72 h, with lower value of surface tension (25.9 mN/m).

According to the literature, the bacterial biosurfactants are more effective in reduce surface tension. Particularly, the bacterium Pseudomonas aeruginosa have been the most studied microorganism to produce potent biosurfactant, with the ability to reduce surface tension to values around 28–27 mN/m [36–38]. However, lastly other microorganisms have been explored in this sense, such as S. marcescens strains [21–26]. Pruthi and Cameotra [39] obtained a reduction of 68–27 mN/m in mineral medium containing 2% glucose by S. marcescens. Recently, Rosas-Galván et al. [24] informed a reduction to 26.5 mN/m of biosurfactant produced by S. marcescens SM3.

Stability of biosurfactant

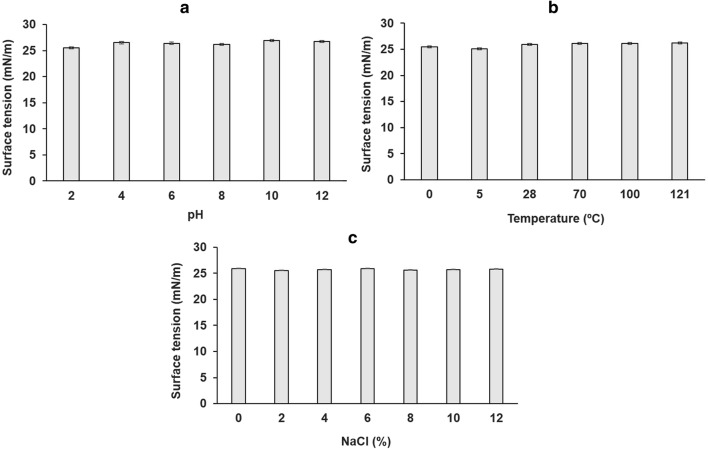

The suitability of biosurfactants for application in diverse industrial areas depends on its stability against extreme or varying conditions of temperature, pH and salinity. The suitability of biosurfactants for application in diverse industrial areas depends on its stability against extreme or varying conditions of temperature, pH and salinity [40]. Figure 4 illustrates the effects of temperature, pH and NaCl concentration on the surface tension of the biosurfactant produced by S. marcescens UCP 1549.

Fig. 4.

Stability of surface tension of biosurfactant produced by Serratia marcescens UCP 1549. Influence of pH (a), temperature (b) and sodium chloride concentrations (c) on surface tension of biosurfactant produced by S. marcescens UCP 1549 after 72 h of fermentation

The results showed that the surface tension remained practically uniform (25.1–26.8 mN/m) at all conditions tested, evidencing the stability of the biosurfactant produced by S. marcescens UCP 1549 against extreme values of pH, temperature and NaCl concentration. Previously, these parameters had no appreciable effects on the activity of the biosurfactant produced by S. marcescens UCP 1549 in CWW and waste soybean oil [8]. Similarly, biosurfactants produced by other S. marcescens strains have indicated stability in a wide range of pH, temperature and salinity [22, 26], make them potential candidates for environmental or industrial processes in extreme conditions [3, 41].

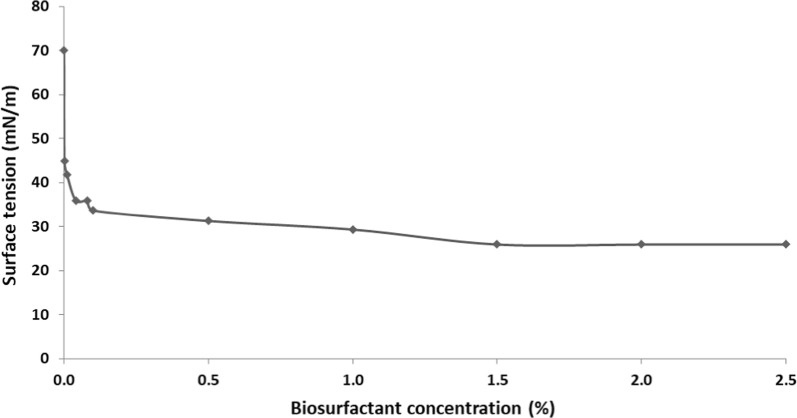

CMC of biosurfactant

The critical micelle concentration (CMC) is an important physiochemical parameter used to evaluate biosurfactant activity, which indicates the minimum concentration of biosurfactant necessary to achieve the lowest stable surface tension [37, 42]. Efficient surfactants have low CMC values, i.e., less surfactant is required to decrease surface tension [13, 43]. As shown in Fig. 5, biosurfactant produced by S. marcescens UCP 1549 exhibited a CMC of 1.5%, with surface tension of 25.92 mN/m.

Fig. 5.

Critical micelle concentration of the biosurfactant produced by Serratia marcescens UCP 1549. Surface tension versus concentration of isolated biosurfactant produced by S. marcescens UCP 1549 after 72 h of fermentation

This CMC was higher compared to others biosurfactants produced by S. marcescens strains but the reduction of surface tension was noticeably greater for biosurfactant produced by S. marcescens UCP 1549. Anyanwu et al. [26] reported the production of biosurfactant by S. marcescens NSK-1, which exhibited a CMC of 29 mg/L (0.03%) and reducing the surface tension of distilled water from 72 to 38 mN/m. Previously, S. marcescens UCP 1549 exhibited CMC of 2.5% with surface tension of 33.8 mN/m [44].

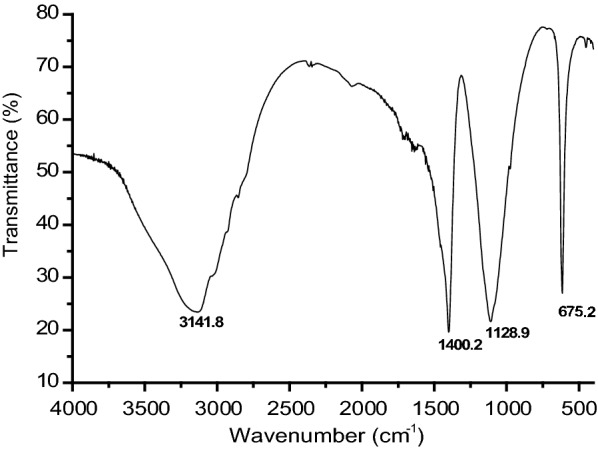

Characterization of biosurfactant

The biosurfactant produced by S. marcescens UCP 1549 was isolated and appeared as a light brown precipitated soluble in water. The chemical composition analyses revealed the presence of 43% lipids, 32% proteins and 11% carbohydrates, suggesting its polymeric nature.

Biosurfactants are generally macromolecules and it is not easy to determine their chemical structure, especially when they are produced from industrial wastes. However, the determination of the structural formula of these compounds is fundamental to study and better understand their properties, as well as to propose the most appropriate field of its application [3, 45]. Fourier transform infrared (FT-IR) is a powerful tool that has been extensively used to study the different forms of biosurfactants [2, 13, 46–48]. Partially purified biosurfactant produced by S. marcescens UCP 1549 was subjected to FT-IR and the spectra is shown in Fig. 6.

Fig. 6.

Fourier transform-infrared (FT-IR) spectra of the biosurfactant produced by Serratia marcescens UCP 1549

The FT-IR spectrum showed a significant absorbance peak at 3141 cm−1 ranging from 2700 to 3700 cm−1. This feature typically is attributed to the presence of carbon and amino groups and caused due to stretching vibrations of C–H and N–H bonds, present in the peptide moiety. A sharp band at 1400.2 cm−1 correspond to C–H stretching mode, suggesting the presence of aliphatic chain of fatty acids, whereas the absorption peak, located at 1128.9 cm−1 showed the presence of ester carbonyl groups (–CO bond), indicating the ester linkage between the polysaccharides-forming monomers. At last a sharp peak at 675.2 cm−1 represented –CH bending of alkenes [49, 50].

The source of carbon and nitrogen used in the biosurfactant production is considered one of the most important parameters that influences in biosurfactant composition. In this work, S. marcescens UCP 1549 was able to use lactose and corn oil, probably as carbon source because they are carbohydrates and fatty acids respectively, proving the ability of microorganisms to utilize some carbohydrates and oils as carbon source in the induction of production of secondary metabolites [3, 51]. Cassava flour wastewater was used as nitrogen source, because it has a high presence of nitrogen in its composition [34, 52]. Studies show that to obtain high production of biopolymer, one should better define the relationship between sources of carbon and nitrogen in the medium. The balanced medium can contain ten times more carbon than nitrogen ensuring high protein content, while a ratio greater than 50:1 promotes the accumulation of extracellular secondary metabolites [1].

In other hand, the zeta potential determines the ionic charge of the particle, which serves to predict and control the stability of colloidal suspensions and emulsions. Higher values of zeta potential indicate good stability of the suspension, due to the repulsion between hydrophilic particles, according to the literature [53, 54]. According to the analyses using a Zeta Potential Meta 3.0+, the biosurfactant produced by S. marcescens showed an anionic character (Pz = − 20.13 mV). Other biosurfactants produced by Serratia sp. also display an anionic character [39, 55, 56]. The most commercially used surfactants are anionic, with extensive application in household cleaners and cosmetics [13, 57].

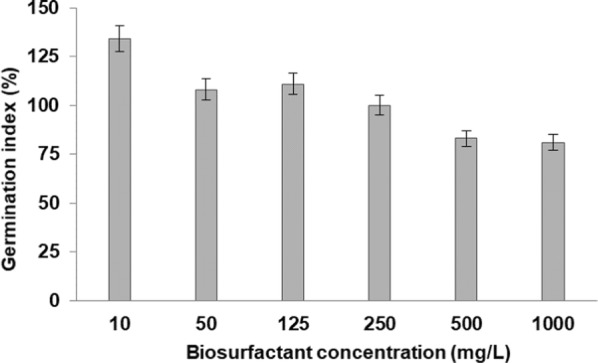

Phytotoxicity of biosurfactant

The use of plants in toxicity tests offers several advantages, among them low maintenance cost and rapid results, with a special benefit assessment of the potential eco-toxic compounds in terrestrial environments [58, 59]. In this study, the germination index (GI), which combines measures of relative seed germination and relative root elongation [2, 43, 60], has been used to evaluate the toxicity of the biosurfactant on cabbage (B. oleracea), and the results are represented in Fig. 7.

Fig. 7.

Phytotoxicity of biosurfactant produced by Serratia marcescens UCP 1549 on seeds of cabbage (Brassica oleracea)

Considering that a GI value of 80% has been used as an indicator of the disappearance of phytotoxicity [51, 62], the results obtained here indicated that the biosurfactant solutions tested did not show inhibitory effects on seed germination and root elongation of cabbage, after 5 days of incubation. GI of 134,108, 111, 100, 83 and 81 were found for biosurfactant solutions of 10, 50, 125, 250, 500 and 1000 mg/L, respectively. Similar results were observed by Silva et al. [60] who investigated the phytotoxic potential of biosurfactant from P. aeruginosa UCP 0992 cultivated in glycerol and found that the compound was innocuous with regard to cabbage. Recently, biosurfactant produced by Streptomyces sp. DPUA1559 in mineral medium containing 1% residual frying soybean oil not display inhibitory effects for seeds of cabbage, at concentrations of 1, 5 and 50 mg/mL [2]. Several researches have reported the phytotoxicity studies of biosurfactants [47, 63–65], but to our knowledge this is the first report regarding toxicity of biosurfactant from S. marcescens.

Interestingly, in this study it was possible to observe the presence of secondary roots and leaves on cabbage seeds, for all the biosurfactant solutions tested, suggesting that the biosurfactant produced by S. marcescens UCP 1549 showed a positive effect on the germination and growth of seeds. Rubio-Ribeaux et al. [47], Krawczyńska et al. [66], and Alsohim et al. [67] reported similar findings, when detected the positive effect of biosurfactants in seedling development. According to Kerbauy [68], the process of germination begins when the seed coat allows the entrance of water in the seed, which activates metabolism and leads to growth of the embryonic axis. For this process to take place, it is necessary that wrapping embryonic tissues be permeable to water. In this sense, biosurfactants, due to their amphipathic structure, probably acted on external wrapping tissue, increasing the permeability of seeds and thereby facilitating germination, as reported by Hameed et al. [69] for surfactants. This property, combined with the high environmental compatibility of these microbial molecules, can lead to the effective application of biosurfactant from S. marcescens UCP 1549 in agriculture, reducing the use of agrochemical [70].

Application of biosurfactant in removal of burned motor oil from contaminated sand

Biosurfactants can emulsify hydrocarbons enhancing their water solubility, decreasing surface tension and increasing the displacement of oil substances from soil particles [3, 6, 8, 54]. Results described in the literature show that the biosurfactants produced by strains of P. aeruginosa removed 49–54% of crude oil adsorbed in sand [71], whereas Silva et al. [60] demonstrated high removal rates (above 85%) of diesel oil from sand samples, but less than 20% when petroleum was tested. In this study, the crude biosurfactant produced by S. marcescens UCP 1549 was able to remove 94% of motor oil contained in sand, while the distilled water (control) removed only 63% (Fig. 8) (Additional file 1: Table S2). Similarly, Nalini and Parthasarathi [55] showed the recovery of 92% of used engine oil adsorbed in sand by biosurfactant from S. rubidae.

Fig. 8.

Application of biosurfactant produced by Serratia marcescens UCP 1549 in removal of burned motor oil from contaminated sand. Beach sand artificially contaminated with burned motor oil: without treatment (a) and after treatment with distilled water (b) and biosurfactant produced by S. marcescens UCP 1549 (c)

The effectiveness of biosurfactants produced by others S. marcescens strains in oil recovery was previously tested. Anyanwu et al. [26] informed 60% and 51% removal of engine oil and kerosene, respectively, of biosurfactant from S. marcescens NSK-1. Biosurfactant of S. marcescens UEO15 revealed recoveries of 78% and 59% of crude oil and kerosene, as compared to 10% and 25% obtained by distilled water, respectively [23]. In our previous work, the crude biosurfactant produced by S. marcescens UCP 1549, in medium containing only agro-industrial residues, exhibited removing of 88.27% and 73.70% of burned motor oil adsorbed in beach sand and mangrove sediments, respectively [8]. Thus, results obtained here confirmed the considerable potential of these biosurfactants for be applied in bioremediation processes of oil-polluted environments.

Conclusions

The present study demonstrated the effectiveness of using low-cost medium containing CCW for the production of biosurfactant by S. marcescens UCP 1549. The feasibility of utilization of agro-industrial wastes in combination with the application of a full-factorial design proved to be efficient strategies to obtain low-cost biosurfactant and becomes viable its industrial-scale production. The polymeric and non-toxic biomolecule exhibited not only its excellent properties to reduce surface tension, but also its high stability at wide range of pH, temperature and NaCl concentrations. In addition, it showed higher potential for breaking the dormancy in cabbage seeds and removing burned motor oil from beach sand, suggesting its application in agriculture and environmental processes.

Methods

Microorganism

Serratia marcescens UCP 1549, originally isolated and identified by Araujo et al. [25] was kindly provided by the Culture Collection of the Catholic University of Pernambuco, Recife, Brazil, registered in the World Federation for Culture Collection (WFCC). The bacterium was maintained in Luria-Bertani (LB) solid medium (tryptone 10 g/L, yeast extract 5 g/L, NaCl 10 g/L and agar 15 g/L) at 5 °C. Stored cultures were transferred first to LB medium and incubated for 18 h at 28 °C. Then, two colonies were transferred to 50 mL of LB broth and incubated at 28 °C and 150 rpm in an orbital shaker. Once the optical density at 600 nm reached 0.8–1.0, this culture was used as inoculum.

Substrates

The substrates used for production of biosurfactant was lactose (Merck), cassava flour wastewater (CWW), kindly supplied by the cassava processing plant located in the municipality of Carnaíba, Pernambuco, Brazil, and corn oil (CO), bough in a local supermarket.

Biosurfactant production

Biosurfactant production was carried out in 250 mL Erlenmeyer flasks with 100 mL of production medium containing lactose, CWW and CO, according to a full-factorial design (FFD) (“Factorial design” section). The media were adjusted to pH 7.0 and autoclaved at 121 °C for 15 min. Then, they were inoculated at 1% and incubated for 72 h at 28 °C, under orbital agitation (150 rpm).

Factorial design

In this study, a 23 FFD with 8 assays and 4 replicates at the central point was applied to investigate the effects of each independent variables (lactose, CWW and CO concentrations), as well as the interactions between them, on surface tension as response variable. Table 1 shows the levels studied and the decoded matrix of FFD.

The data obtained from the experiments were subjected to statistical analysis by Statistica® software, version 8.0 (StatSoft Inc., USA) and the significance of the results was tested at p < 0.05 level.

Determination of surface tension

The surface tension was determined on cell-free metabolic liquid obtained by centrifuging (12,000×g for 20 min) and filtration of culture media. Analyses were performed at 25 °C in a Sigma 70 tensiometer (KSV Instruments Ltd., Finland), using the Du Nouy ring method [72]. Milli-Q water with surface tension of 72 mN/m was used to calibrate the tensiometer.

Growth kinetics and biosurfactant production

To determine the growth kinetics, samples were collected every 4 h during the first 12 h, then every 12 h until 120 h of fermentation. Microbial growth was evaluated by “pour plate” technique, inoculating aliquots of 0.1 mL of each sample on Petri plates containing medium LB and incubating at 28 °C for 24 h. Then, each plate was subjected to counting of viable colonies and growth was expressed in CFU/mL. Samples were also subjected to determination of pH and surface tension.

Studies of biosurfactant stability

Studies of stability of biosurfactant were carried out using 25 mL of cell-free metabolic liquid at different temperatures (0, 5, 28, 70, 100 and 121 °C), for 1 h, and cooled to room temperature, after which the surface tension was measured. The effect of pH on surface tension was evaluated after adjustment of the metabolic liquid pH to 2, 4, 6, 8, 10 and 12 with 2 M HCl or NaOH. The effect of NaCl concentrations (2, 4, 6, 8, 10 and 12%, w/v) on the activity of the biosurfactant were also determined [8].

Isolation of biosurfactant

The biosurfactant produced by S. marcescens UCP 1549 after 72 h of fermentation was isolated from cell-free metabolic liquid obtained by centrifuging (12,000×g for 20 min) the culture. The metabolic liquid was subjected to precipitation by adding ammonium sulfate [(NH4)2SO4] salts to achieve 65% of saturation and incubated overnight at 4 °C. Then, it was centrifuged at 15,000×g for 15 min and the cell-free metabolic liquid was collected and again centrifuged at 5000×g for 15 min [73]. The supernatant obtained was discarded and the crude biosurfactant was subjected to dialysis with deionized water for 24 h, with exchanges every 4 h to remove the salt adhered to the sample. The precipitate was collected, lyophilized and used for analysis [54].

Determination of CMC of biosurfactant

The critical micelle concentration (CMC) of biosurfactant isolated after 72 h of cultivation was determined in aqueous solution. The surface tension was measured on an automatic tensiometer (model Sigma 70 KSV Ltd., Finland) using a platinum-iridium ring. The sample of the isolated biosurfactant was diluted at different concentrations, starting with a minimum concentration of 0.001 mg/mL, until up to reaching a constant value of surface tension. The CMC was seen to have produced a surface tension of a constant value. The value of CMC was obtained by plotting surface tension against percentage concentration of biosurfactant (%) [54].

Characterization of biosurfactant

Chemical composition

The carbohydrate content of the isolated biosurfactant was determined by the method of phenol–sulphuric acid using d-glucose as a standard [74]. The lipids were extracted with chloroform (1:1) three times, after separate the organic phase with the solvent system chloroform/methanol (1:2), the organic phase rotatory evaporator and then weigh the flask, the difference is the amount of lipids [75]. Protein concentrations were evaluated using the kit of total proteins Labtest Diagnostica S.A. (Brazil) for colorimetric determination of total proteins by Biuret reagent.

Zeta potential

The electrokinetic of potential zeta was analyzed in the Zeta Meter instrument using 100 mg of biosurfactant in 5 mL of an aqueous solution of KCl, with the corresponding ionic strength at 0.001 M [54].

Gel chromatography

Elution was performed using the PD10 column (Sephadex G25) column XK 16/40 GE Healthcare. Initially, the column was equilibrated with 25 mL of distilled water and then applied 2 mL of sample containing high concentrations of salt. After the entry of the sample, the elution of the biopolymer was made with distilled water.

Fourier transform infrared spectroscopy (FT-IR)

The identification of functional groups in the isolated biosurfactant was carried out by Fourier-transform infrared spectroscopy (FTIR) on Bruker IFS 66 spectrometer, using KBr pellets. The spectrum was generated in the wavelength range of 4000–400 cm−1.

Determination of biosurfactant phytotoxicity

The phytotoxicity of the biosurfactant was evaluated in seeds of cabbage (Brassica oleracea) according to Tiquia et al. [61]. The biosurfactant isolated was tested at concentrations of 10, 50, 125, 250, 500 and 1000 mg/L. 5 mL of each biosurfactant solution were inoculated into Petri plates containing ten disinfected seeds under sterilized Whatman no. 1 filter paper. The plates were incubated for 120 h at room temperature in the dark. The tests were performed in triplicate and it was used distillated water for the control test [76]. Phytotoxicity of biosurfactant was determined by seed germination, root elongation (≥ 5 mm) and germination index (GI, a factor of relative seed germination and relative root elongation), according to the following equations:

Application of biosurfactant in removal of hydrophobic pollutant in sand

Biosurfactant suitability for removing hydrophobic pollutants was determined using artificially contaminated sand containing 5% burned motor oil. Twenty-gram samples of contaminated sand were transferred to 250 Erlenmeyer flask and submitted to the following treatments: (A) addition of 50 mL of distilled water (control), (B) addition of 50 mL of cell-free metabolic liquid and (C) addition of 50 mL of aqueous solution of the isolated biosurfactant at concentration of 1000 mg/L. The flasks were subjected to 150 rpm for 48 h at 28 °C and then, centrifuged at 5000×g for 20 min for separation of the washing solution and sand sediment. The amount of oil remaining in the sand was gravimetrically determined by hexane [8, 77].

Additional file

Additional file 1: Table S1. Average of chemical composition of cassava wastewater. Table S2. Application of biosurfactant produced by Serratia marcescens UCP 1549 in removal of burned motor oil from contaminated marine soil. Figure S1. Growth profile of Serratia marcescens UCP 1549 on Luria Bertani (LB) medium, during 144 h at 28 °C and 150 rpm.

Authors’ contributions

HWCA carried out the experiments, analyzed the data and drafted the manuscript. RFSA assisted in the performing of experiments and discussion of results. DMR and DRR assisted in statistical analysis and discussion of results and writing the manuscript. CAAS participated in the design of the study and coordination. GMCT conceived and supervised the study and reviewed the final manuscript. All authors read and approved the final manuscript.

Acknowledgements

The authors are grateful to State University of Paraiba (UEPB) for teaching qualification, and to Nucleus of Research in Environmental Sciences and Biotechnology (NPCIAMB), Catholic University of Pernambuco, Pernambuco, Brazil, for the use of laboratories.

Competing interests

The authors declare that they have no competing interests.

Availability of data and materials

The datasets supporting the conclusions of this article are included within the article.

Consent for publication

Not applicable.

Ethics approval and consent to participate

Not applicable.

Funding

The study was supported by National Council for Scientific and Technological Development (CNPq), Coordination for the Improvement of Higher Level Education Personnel Fellowship (CAPES), Foundation for the Support of Science and Technology of the State of Pernambuco (FACEPE), Brazil.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Hélvia W. C. Araújo, Email: hwcasullo@ig.com.br

Rosileide F. S. Andrade, Email: rosileide_fontenele@yahoo.com.br

Dayana Montero-Rodríguez, Email: dayanamontero87@gmail.com.

Daylin Rubio-Ribeaux, Email: drubioribeaux@gmail.com.

Carlos A. Alves da Silva, Email: carlos.alves@unicap.br

Galba M. Campos-Takaki, Phone: +55-81-21194044, Email: galba_takaki@yahoo.com.br

References

- 1.Brumano LP, Soler MF, Silva SS. Recent advances in sustainable production and application of biosurfactants in Brazil and Latin America. Ind Biotechnol. 2016 doi: 10.1089/ind.2015.0027. [DOI] [Google Scholar]

- 2.Santos APP, Silva MDS, Costa EVL, Rufino RD, Santos VA, Ramos CS, Sarubbo LA, Porto AFL. Production and characterization of a biosurfactant produced by Streptomyces sp. DPUA 1559 isolated from lichens of the Amazon region. Braz J Med Biol Res. 2018 doi: 10.1590/1414-431x20176657. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Santos DKF, Rufino RD, Luna JM, Santos VA, Sarubbo LA. Biosurfactants: multifunctional biomolecules of the 21st century. Int J Mol Sci. 2016 doi: 10.3390/ijms17030401. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Perfumo A, Rudden M, Marchant R, Banat IM. Biodiversity of biosurfactants and roles in enhancing the (bio) availability of hydrophobic substrates. In: Krell T, editor. Cellular ecophysiology of microbe: hydrocarbon and lipid interactions. Handbook of hydrocarbon and lipid microbiology. Springer: Cham; 2018. pp. 75–103. [Google Scholar]

- 5.Shekhar S, Sundaramanickam A, Balasubramanian T. Biosurfactant producing microbes and their potential applications: a review. Crit Rev Environ Sci Technol. 2015 doi: 10.1080/10643389.2014.955631. [DOI] [Google Scholar]

- 6.Geetha SJ, Banat IM, Joshi SJ. Biosurfactants: production and potential applications in microbial enhanced oil recovery (MEOR) Biocatal Agric Biotechnol. 2018 doi: 10.1016/j.bcab.2018.01.010. [DOI] [Google Scholar]

- 7.Banat IM, Franzetti A, Gandolfi I, Bestetti G, Martinotti MG, Fracchia L, Smyth TJ, Marchant R. Microbial biosurfactants production, applications and future potential. Appl Microbiol Biotechnol. 2010 doi: 10.1007/s00253-010-2589-0. [DOI] [PubMed] [Google Scholar]

- 8.Montero-Rodríguez D, Andrade RF, Ribeiro DLR, Rubio-Ribeaux D, Lima RA, Araújo HW, Campos-Takaki GM. Bioremediation of petroleum derivative using biosurfactant produced by Serratia marcescens UCP/WFCC 1549 in low-cost medium. Int J Curr Microbiol Appl Sci. 2015;4:550–562. [Google Scholar]

- 9.Mujumdar S, Bashetti S, Pardeshi S, Thombre RS. Industrial applications of biosurfactants. In: Thangadurai D, Sangeetha J, editors. Industrial biotechnology: sustainable production and bioresource utilization. Boca Raton: CRC Press; 2017. pp. 61–90. [Google Scholar]

- 10.Nitschke M, Silva SSE. Recent food applications of microbial surfactants. Crit Rev Food Sci Nutr. 2018 doi: 10.1080/10408398.2016.1208635. [DOI] [PubMed] [Google Scholar]

- 11.Marchant R, Banat IM. Biosurfactants: a sustainable replacement for chemical surfactants? Biotechnol Lett. 2012 doi: 10.1007/s10529-012-0956-x. [DOI] [PubMed] [Google Scholar]

- 12.Montero-Rodríguez D, Andrade RFS, Rubio-Ribeaux D, Silva TAL, Silva GKB, Araújo HWC, Campos-Takaki GM. Suitability of wheat bran as promising substrate for coproduction of prodigiosin and biosurfactant by Serratia marcescens UCP/WFCC 1549. In: Méndez-Vilas A, editor. Exploring microorganisms: recent advances in applied microbiology. Badajoz: BrownWalker Press; 2018. pp. 149–153. [Google Scholar]

- 13.Lima RA, Andrade RF, Rodríguez DM, Araujo HW, et al. Production and characterization of biosurfactant isolated from Candida glabrata using renewable substrates. Afr J Microbiol Res. 2017 doi: 10.5897/AJMR2016.8341. [DOI] [Google Scholar]

- 14.Fukushima AR, Nicoletti MA, Rodrigues AJ, Pressutti C, Almeida J, Brandão T, Ito RK, Leoni LAB, De Souza Spinosa H. Cassava flour: quantification of cyanide content. Food Nutr Sci. 2016;7:592–599. doi: 10.4236/fns.2016.77060. [DOI] [Google Scholar]

- 15.Food and Agriculture Organization (FAO). An assessment of the impact of cassava production and processing on the environment and biodiversity. FAO, Rome, Italy. 2001. http://www.fao.org/fileadmin/templates/biodiversity_paia/PAR-FAO-book_lr.pdf. Accessed 24 Nov 2018.

- 16.Damasceno S, Cereda MP, Pastore GM, Oliveira JG. Production of volatile compounds by Geotrichum fragrans using cassava wastewater as substrate. Process Biochem. 2016;39:411–414. doi: 10.1016/S0032-9592(03)00097-9. [DOI] [Google Scholar]

- 17.Santos DK, Brandão YB, Rufino RD, Luna JM, Salgueiro AA, Santos VA, Sarubbo LA. Optimization of cultural conditions for biosurfactant production from Candida lipolytica. Biocatal Agric Biotechnol. 2014 doi: 10.1016/j.bcab.2014.02.004. [DOI] [Google Scholar]

- 18.Almeida DG, Soares da Silva RCF, Luna JM, Rufino RD, Santos VA, Sarubbo LA. Response surface methodology for optimizing the production of biosurfactant by Candida tropicalis on industrial waste substrates. Front Microbiol. 2017 doi: 10.3389/fmicb.2017.00157. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Matsuyama T, Tanikawa T, Nakagawa Y. Serrawettins and other surfactants produced by Serratia. In: Soberón-Chávez G, editor. Biosurfactants. Springer: Berlin; 2011. pp. 93–120. [Google Scholar]

- 20.Su C, Xiang Z, Liu Y, Zhao X, Sun Y, Li Z, Li L, Chang F, Chen T, Wen X, Zhou Y, Zhao F. Analysis of the genomic sequences and metabolites of Serratia surfactantfaciens sp. nov. YD25 T that simultaneously produces prodigiosin and serrawettin W2. BMC Genomics. 2016 doi: 10.1186/s12864-016-3171-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Bidlan R, Deepthi N, Rastogi NK, Manonmani HK. Optimized production of biosurfactant by Serratia marcescens DT-1P. Res J Microbiol. 2007 doi: 10.3923/jm.2007.705.716. [DOI] [Google Scholar]

- 22.Ibrahim ML, Ijah UJJ, Manga SB, Bilbis LS, Umar S. Production and partial characterization of biosurfactant produced by crude oil degrading bacteria. Int Biodeterior Biodegrad. 2013 doi: 10.1016/j.ibiod.2012.11.012. [DOI] [Google Scholar]

- 23.Elemba OM, Ijah UJJ, Chibunna M. Isolation, characterization and MEOR ability of the biosurfactant produced from Serratia marcescens UEO15. Glob J Adv Res. 2010;2:962–974. [Google Scholar]

- 24.Rosas-Galván NS, Martínez-Morales F, Marquina-Bahena S, Tinoco-Valencia R, Serrano-Carreón L, Bertrand B, León-Rodríguez R, Guzmán-Aparicio J, Alvaréz-Berber L, Trejo-Hernández MR. Improved production, purification and characterization of biosurfactants produced by Serratia marcescens SM3 and its isogenic SMRG-5 strain. Biotechnol Appl Biochem. 2018 doi: 10.1002/bab.1652. [DOI] [PubMed] [Google Scholar]

- 25.Araujo HWC, Andrade RFS, Montero-Rodriguez DM, Santos VP, Maia PCVS, Costa Filho CFB, et al. Biochemical and molecular identification of newly isolated pigmented bacterium and improved production of biosurfactant. Afr J Microbiol Res. 2017 doi: 10.5897/ajmr2016.8340. [DOI] [Google Scholar]

- 26.Anyanwu CU, Obi SKC, Okolo BN. Lipopeptide biosurfactant production by Serratia marcescens NSK-1 strain isolated from petroleum-contaminated soil. J Appl Sci Res. 2011;7:79–87. [Google Scholar]

- 27.Youssef NH, Duncan KE, Nagle DP, Savage KN, Knapp RM, McInerney MJ. Comparison of methods to detect biosurfactant production by diverse microorganisms. J Microbiol Methods. 2004 doi: 10.1016/j.mimet.2003.11.001. [DOI] [PubMed] [Google Scholar]

- 28.Acioly LML, Silveira ABD, Anjos MN, Silva GKB, Leite MV, Okada K, Campos-Takaki GM. Biosurfactant production by Mucor circinelloides using apple peel, vegetable oil and corn steep liquor as substrate. In: Mendez-Vilas A, editor. Microbes in applied research: current advances and challenges. Badajoz: BrownWalker Press; 2012. pp. 344–347. [Google Scholar]

- 29.Karlapudi AP, Venkateswarulu TC, Tammineedi J, Kanumuri L, Ravuru BK, ramu Dirisala V, Kodali VP. Role of biosurfactants in bioremediation of oil pollution—a review. Petroleum. 2018 doi: 10.1016/j.petlm.2018.03.007. [DOI] [Google Scholar]

- 30.Elkhawaga MA. Optimization and characterization of biosurfactant from Streptomyces griseoplanus NRRL-ISP 5009 (MS 1) J Appl Microbiol. 2018 doi: 10.1111/jam.13665. [DOI] [PubMed] [Google Scholar]

- 31.Amaral PFF, da Silva JM, Lehocky M, Barros-Timmons AMV, Coelho MAZ, Marrucho IM, Coutinho JAP. Production and characterization of a bioemulsifier from Yarrowia lipolytica. Process Biochem. 2006 doi: 10.1016/j.procbio.2006.03.029. [DOI] [Google Scholar]

- 32.Fontes GC, Amaral PF, Nele M, Coelho MA. Factorial design to optimize biosurfactant production by Yarrowia lipolytica. J Biomed Biotechnol. 2010 doi: 10.1155/2010/821306. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Ferraz C, Araújo AA, Pastore GM. The influence of vegetable oils on biosurfactant production by Serratia marcescens. Appl Biochem Biotechnol. 2002;98:841–847. doi: 10.1385/ABAB:98-100:1-9:841. [DOI] [PubMed] [Google Scholar]

- 34.Nitschke M, Pastore GM. Biosurfactant production by Bacillus subtilis using cassava processing effluent. Appl Biochem Biotechnol. 2004;112:163–172. doi: 10.1385/ABAB:112:3:163. [DOI] [PubMed] [Google Scholar]

- 35.Magalhães ERB, Silva FL, Dos Sousa MADSB, DosSantos ES. Use of different agroindustrial waste and produced water for biosurfactant production. Biosci Biotechnol Res. 2018 doi: 10.13005/bbra/2604. [DOI] [Google Scholar]

- 36.Sekhon Randhawa KK, Rahman PK. Rhamnolipid biosurfactants—past, present, and future scenario of global market. Front Microbiol. 2014 doi: 10.3389/fmicb.2014.00454. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Varjani SJ, Upasani VN. Critical review on biosurfactant analysis, purification and characterization using rhamnolipid as a model biosurfactant. Bioresour Technol. 2017 doi: 10.1016/j.biortech.2017.02.047. [DOI] [PubMed] [Google Scholar]

- 38.Liu G, Zhong H, Yang X, Liu Y, Shao B, Liu Z. Advances in applications of rhamnolipids biosurfactant in environmental remediation: a review. Biotechnol Bioeng. 2018 doi: 10.1002/bit.26517. [DOI] [PubMed] [Google Scholar]

- 39.Pruthi V, Cameotra SS. Novel sucrose lipid produced by Serratia marcescens and its application in enhanced oil recovery. J Surfactants Deterg. 2000;3(4):533–537. doi: 10.1007/s11743-000-0153-9. [DOI] [Google Scholar]

- 40.Jain RM, Mody K, Joshi N, Mishra A, Jha B. Effect of unconventional carbon sources on biosurfactant production and its application in bioremediation. Int J Biol Macromol. 2013 doi: 10.1016/j.ijbiomac.2013.08.030. [DOI] [PubMed] [Google Scholar]

- 41.Perfumo A, Banat IM, Marchant R. Going green and cold: biosurfactants from low-temperature environments to biotechnology applications. Trends Biotechnol. 2018 doi: 10.1016/j.tibtech.2017.10.016. [DOI] [PubMed] [Google Scholar]

- 42.Liu J, Chen Y, Xu R, Jia Y. Screening and evaluation of biosurfactant-producing strains isolated from oilfield wastewater. Indian J Microbiol. 2013;53:168–174. doi: 10.1007/s12088-013-0379-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43.Rufino RD, Moura de Luna J, de Campos Takaki GM, Asfora Sarubbo L. Characterization and properties of the biosurfactant produced by Candida lipolytica UCP 0988. Electron J Biotechnol. 2014;17(1):6. doi: 10.1016/j.ejbt.2013.12.006. [DOI] [Google Scholar]

- 44.Alves TS, Salgado JP, Andrade RFS, Montero-Rodríguez D, Ferreira WB, Almeida MM, Araújo HWC. Production and evaluation of biosurfactant by Serratia marcescens UCP 1549 using industrial wastes. Br Biotechnol J. 2014;4:708. doi: 10.9734/BBJ/2014/9774. [DOI] [Google Scholar]

- 45.Mouafo TH, Mbawala A, Ndjouenkeu R. Effect of different carbon sources on biosurfactants’ production by three strains of Lactobacillus spp. Biomed Res Int. 2018 doi: 10.1155/2018/5034783. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46.Antoniou E, Fodelianakis S, Korkakaki E, Kalogerakis N. Biosurfactant production from marine hydrocarbon-degrading consortia and pure bacterial strains using crude oil as carbon source. Front Microbiol. 2015 doi: 10.3389/fmicb.2015.00274. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Rubio-Ribeaux D, Andrade RFS, da Silva GS, de Holanda RA, Pele MA, et al. Promising biosurfactant produced by a new Candida tropicalis UCP 1613 strain using substrates from renewable-resources. Afr J Microbiol Res. 2017 doi: 10.5897/AJMR2017.8486. [DOI] [Google Scholar]

- 48.Pele MA, Montero-Rodriguez D, Rubio-Ribeaux D, Souza AF, Luna MA, et al. Development and improved selected markers to biosurfactant and bioemulsifier production by Rhizopus strains isolated from Caatinga soil. Afr J Biotechnol. 2018 doi: 10.5897/AJB2017.16230. [DOI] [Google Scholar]

- 49.Gautam G, Mishra V, Verma P, Pandey AK, Negi S. A cost effective strategy for production of bio-surfactant from locally isolated Penicillium chrysogenum SNP5 and its applications. J Bioprocess Biotech. 2014;4(6):1. doi: 10.4172/2155-9821.1000177. [DOI] [Google Scholar]

- 50.Zhang J, Xue Q, Gao H, Lai H, Wang P. Production of lipopeptide biosurfactants by Bacillus atrophaeus 5-2a and their potential use in microbial enhanced oil recovery. Microb Cell Fact. 2016 doi: 10.1186/s12934-016-0574-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Abouseoud M, Maach R, Amrane A. Biosurfactants production from olive oil by Pseudomonas fluorescens. In: Méndez-Vilas A, editor. Communicating current research and educational topics and trends in applied microbiology. Badajoz: FORMATEX; 2007. pp. 340–347. [Google Scholar]

- 52.Nitschke M, Pastore GM. Cassava flour wastewater as a substrate for biosurfactant production. Appl Biochem Biotechnol. 2003;106:295–302. doi: 10.1385/ABAB:106:1-3:295. [DOI] [PubMed] [Google Scholar]

- 53.Satpute SK, Banpurkar AG, Dhakephalkar PK, Banat IM, Chopade BA. Methods for investigating biosurfactants and bioemulsifiers: a review. Crit Rev Biotechnol. 2010;30:127–144. doi: 10.3109/07388550903427280. [DOI] [PubMed] [Google Scholar]

- 54.Silva NRA, Luna MAC, Santiago ALCMA, Franco LO, Silva KJB, de Souza PM, Okada K, Albuquerque CDC, Silva CAA, Campos-Takaki GM. Biosurfactant-and-bioemulsifier produced by a promising Cunninghamella echinulata isolated from Caatinga soil in the northeast of Brazil. Int J Mol Sci. 2014;15:15377–15395. doi: 10.3390/ijms150915377. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 55.Nalini S, Parthasarathi R. Biosurfactant production by Serratia rubidaea SNAU02 isolated from hydrocarbon contaminated soil and its physico-chemical characterization. Bioresour Technol. 2013 doi: 10.1016/j.biortech.2013.08.041. [DOI] [PubMed] [Google Scholar]

- 56.Nalini S, Parthasarathi R. Production and characterization of rhamnolipids produced by Serratia rubidaea SNAU02 under solid-state fermentation and its application as biocontrol agent. Bioresour Technol. 2014 doi: 10.1016/j.biortech.2014.09.051. [DOI] [PubMed] [Google Scholar]

- 57.Karray F, Mezghani M, Mhiri N, Djelassi B, Sayadi S. Scaledown studies of membrane bioreactor degrading anionic surfactants wastewater: isolation of new anionic-surfactant degrading bacteria. Int Biodeterior Biodegrad. 2016;2016:114. doi: 10.1016/j.ibiod.2016.05.020. [DOI] [Google Scholar]

- 58.Farré K, Barceló D. Toxicity testing of wastewater and sewage sludge by biosensors, bioassays and chemical analysis. Trends Anal Chem. 2003 doi: 10.1016/S0165-9936(03)00504-1. [DOI] [Google Scholar]

- 59.Priac A, Badot PM, Crini G. Treated wastewater phytotoxicity assessment using Lactuca sativa: focus on germination and root elongation test parameters. C R Biol. 2017 doi: 10.1016/j.crvi.2017.01.002. [DOI] [PubMed] [Google Scholar]

- 60.Silva SNRL, Farias CBB, Rufino RD, Luna JM, Sarubbo LA. Glycerol as subtrate for the production of biosurfactant by Pseudomonas aeruginosa UCP 0992. Colloids Surf B Biointerfaces. 2010 doi: 10.1016/j.colsurfb.2010.03.050. [DOI] [PubMed] [Google Scholar]

- 61.Tiquia SM, Tam NFY, Hodgkiss IJ. Effects of composting on phytotoxicity of spent pig-manure sawdust litter. Environ Pollut. 1996;93(3):249–256. doi: 10.1016/S0269-7491(96)00052-8. [DOI] [PubMed] [Google Scholar]

- 62.Tiquia SM. Reduction of compost phytotoxicity during the process of decomposition. Chemosphere. 2010 doi: 10.1016/j.chemosphere.2010.02.040. [DOI] [PubMed] [Google Scholar]

- 63.Luna JM, Rufino RD, Porto ALF, Sarubbo LS. Assessment of toxicity of a biosurfactant from Candida sphaerica UCP 0995 cultivated with industrial residues in a bioreactor. Electron J Biotechnol. 2013 doi: 10.2225/vol16-issue4-fulltext-4. [DOI] [Google Scholar]

- 64.Chandankere R, Yao J, Cai M, Masakorala K, Jain AK, Choi MM. Properties and characterization of biosurfactant in crude oil biodegradation by bacterium Bacillus methylotrophicus USTBa. Fuel. 2014 doi: 10.1016/j.fuel.2014.01.023. [DOI] [Google Scholar]

- 65.Bouassida M, Ghazala I, Ellouze-Chaabouni S, Ghribi D. Improved biosurfactant production by Bacillus subtilis SPB1 mutant obtained by random mutagenesis and its application in enhanced oil recovery in a sand system. J Microbiol Biotechnol. 2018 doi: 10.4014/jmb.1701.01033. [DOI] [PubMed] [Google Scholar]

- 66.Krawczyńska M, Kołwzan B, Rybak J, Gediga K, Shcheglova NS. The influence of biopreparation on seed germination and growth. Pol J Environ Stud. 2012;21:175–180. [Google Scholar]

- 67.Alsohim AS, Taylor TB, Barrett GA, Gallie J, Zhang X, Altamirano-Junqueira AE, Rainey PB, Jackson RW. The biosurfactant viscosin produced by Pseudomonas fluorescens SBW25 aids spreading motility and plant growth promotion. Environ Microbiol. 2014 doi: 10.1111/1462-2920.12469. [DOI] [PubMed] [Google Scholar]

- 68.Kerbauy GB. Fisiologia vegetal. 2. Rio de Janeiro: Guanabara Koogan Ltd.; 2008. pp. 389–406. [Google Scholar]

- 69.Hameed A, Ahmed MZ, Gulzar S, Khan MA. Effect of surfactants in ameliorating seed germination of Suaeda fruticosa under saline conditions. Pak J Bot. 2009;41:2639–2644. [Google Scholar]

- 70.Nalini S, Parthasarathi R. Optimization of rhamnolipid biosurfactant production from Serratia rubidaea SNAU02 under solid-state fermentation and its biocontrol efficacy against Fusarium wilt of eggplant. Ann Agrar Sci. 2018 doi: 10.1016/j.aasci.2017.11.002. [DOI] [Google Scholar]

- 71.Bordoloi NK, Konwar BK. Microbial surfactant-enhanced mineral oil recovery under laboratory conditions. Colloids Surf B Biointerfaces. 2008 doi: 10.1016/j.colsurfb.2007.11.006. [DOI] [PubMed] [Google Scholar]

- 72.Kuyukina MS, Ivshina IB, Philp JC, Christofi N, Dunbar SA, Ritchkova MI. Recovery of Rhodococcus biosurfactants using methyl tertiary-butyl ether extraction. J Microbiol Methods. 2001 doi: 10.1016/S0167-7012(01)00259-7. [DOI] [PubMed] [Google Scholar]

- 73.Shah MUH, Sivapragasam M, Moniruzzaman M, Yusup SB. A comparison of recovery methods of rhamnolipids produced by Pseudomonas aeruginosa. Procedia Eng. 2016 doi: 10.1016/j.proeng.2016.06.538. [DOI] [Google Scholar]

- 74.Dubois M, Gilles K, Hamilton J, Rebers P, Smith F. Colorimetric method for determination of sugars and related substances. Anal Chem. 1956 doi: 10.1021/ac60111a017. [DOI] [PubMed] [Google Scholar]

- 75.Manocha MS, San-Blas G, Centeno S. Lipid composition of Paracoccidioides brasiliensis: possible correlation with virulence of different strains. J Gen Microbiol. 1980 doi: 10.1099/00221287-117-1-147. [DOI] [PubMed] [Google Scholar]

- 76.e Silva NMPR, Rufino RD, Luna JM, Santos VA, Sarubbo LA. Screening of Pseudomonas species for biosurfactant production using low-cost substrates. Biocatal Agric Biotechnol. 2014 doi: 10.1016/j.bcab.2013.09.005. [DOI] [Google Scholar]

- 77.Santos DK, Rufino RD, Luna JM, Santos VA, Salgueiro AA. Sarubbo LA synthesis and evaluation of biosurfactant produced by Candida lipolytica using animal fat and corn steep liquor. J Petrol Sci Eng. 2013 doi: 10.1016/j.petrol.2013.03.028. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Additional file 1: Table S1. Average of chemical composition of cassava wastewater. Table S2. Application of biosurfactant produced by Serratia marcescens UCP 1549 in removal of burned motor oil from contaminated marine soil. Figure S1. Growth profile of Serratia marcescens UCP 1549 on Luria Bertani (LB) medium, during 144 h at 28 °C and 150 rpm.

Data Availability Statement

The datasets supporting the conclusions of this article are included within the article.