Abstract

Monitoring worker exposure to respirable crystalline silica in dusty environments is an important part of a proactive health and safety program. This is the case for surface copper mines in Arizona and New Mexico. The spatial and temporal variability of respirable dust and crystalline silica concentrations in those mines, coupled with the time lapse in obtaining crystalline silica analysis results from accredited laboratories, present a challenge for an effective exposure monitoring approach and the resulting intervention strategies. The National Institute for Occupational Safety and Health (NIOSH) is developing a novel approach to be used at a mine site for the quantification of crystalline silica in respirable dust samples collected with traditional sampling techniques. The non-destructive analysis is carried out using a portable Fourier transform infrared spectroscopy (FTIR) unit. In this study, respirable dust samples were collected over two visits to each of five copper mines, for a total of 10 data-sets. The silica in each respirable dust sample was estimated by analyzing the sample with the portable FTIR unit. The quality of the estimation was assessed using the results of the NIOSH 7500 method on the same samples. The confounding effect of other minerals present in the respirable dust in the mines was also assessed, and two quantification approaches were investigated to address it: a sector-specific and a mine-specific approach. The results showed that the sector-specific approach is not effective due to the high variability of relative composition of the minerals among mines. For this approach the combined average relative difference was −13% (−17.6%,−8.9% CI). When using the mine-specific quantification approach, the average relative difference was as low as 2.8% (−3.7%, 9.3% CI); however, this approach was still affected by the variable relative composition of the minerals in the dust in each mine. The use of a multivariate approach on the analysis of each sample was proposed as the next step to achieve consistent low relative differences. This study demonstrates the potential of using a portable FTIR for estimation of crystalline silica in respirable dust samples for in-field exposure monitoring.

Keywords: DoF-FTIR, field-based monitoring, mining, respirable crystalline silica

Introduction

Crystalline silica (hereafter also silica) is associated with many diseases:[1] silicosis,[2,3] chronic obstructive pulmonary disease (COPD),[4] and lung cancer.[5] Exposure to crystalline silica shows a correlation with renal disease.[1] Even short exposure duration to high levels of silica can lead to negative respiratory outcomes.[4] The incidence of respiratory health effects related to exposure to respirable crystalline silica (RCS) is poorly tracked in the U.S., and hospitalization remains the most cost-effective way to identify silicosis cases.[6,7] Based on the recognized potential hazard, the U.S. National Institute for Occupational Safety and Health (NIOSH) has recommended an exposure limit (REL) of 0.05 mg/m3 as a time-weighted average for up to 10 hr per day during a 40-hr week.[4]

The presence of RCS in the dust generated in metal mines is well known. Several studies in the past investigated the exposure of miners to crystalline silica containing respirable dust and the negative health effects.[8–13] The U.S. Mine Safety and Health Administration (MSHA) has established a permissible exposure limit (PEL) for respirable dust present in metal/nonmetal mines, which adjusts for the presence of RCS by lowering the PEL as the RCS content increases. Based on the formulaic approach, the resulting RCS PEL is 100 mg/m3. Watts et al.[14] analyzed the RCS concentration trends in U.S. metal and non-metal mining between 1993 and 2010. They found that while the measured levels are decreasing over time, the exposure potential still exists at levels above the MSHA PEL and especially the NIOSH REL.

The measurement and evaluation of workers’ RCS exposure is an important step toward reducing the risk of impaired health resulting from inhalation, as presented by the NIOSH Occupational Exposure Sampling Strategy Manual.[15] Exposure monitoring is conducted and management practices are implemented by operators of metal mines in the U.S. and globally as part of their health and safety programs. The monitoring relies on traditional industrial hygiene approaches and occasionally on the use of real-time respirable dust monitors.

Crystalline silica is just one of the constituents of the respirable dust present in most mining environments. A recent investigation[16] of respirable dust samples collected by MSHA in U.S. mining environments between 1997 and 2011 showed that the percentage of respirable crystalline silica (%RCS) in the dust is generally higher in metal and sand and gravel mines, with a small but significant increasing trend over time. The investigation stratified results according to sampling locations—underground, surface, and mill—and found a high variability of the silica content for samples in every location and commodity.

Another study investigated the variability of the crystalline silica content within a single mine dust bulk sample.[17] The silica content of different size ranges of dust samples from three metal mines was studied in a laboratory dust chamber. For all three dusts, it was found that the percent silica in dust is not constant for particles of different size ranges from 0.01–20 μm; notably this variability was also observed within the respirable range.

To improve the effectiveness of RCS exposure monitoring activities, NIOSH has been working to develop a new analytical technique to estimate RCS in respirable dust samples directly, at the mine and the end of the shift. This work is part of an effort to create technologies and methodologies that provide more accurate and timely monitoring of worker exposures to known respirable hazards. The technique is based on the use of portable Fourier transform infrared spectroscopy (FTIR) units for direct-on-filter (DoF) analysis of the dust sample.[18–20] Together with X-ray diffraction (XRD), FTIR is internationally recognized as one of the analytical techniques appropriate for quantification of RCS.[21–24] FTIR is already used by MSHA for samples collected in coal mines,[25] and the DoF approach is already used outside the U.S., but not with portable instrumentation.[22,26]

While the field-based estimation of RCS with portable FTIR can provide results comparable to the standard analysis—i.e., XRD analysis with NIOSH 7500—when no analytical confounders are present,[18] the negative effect of other minerals has been recognized as a necessary consideration.[27–29] Laboratory methods for RCS quantification uses the experience of analysts and, if needed, pre-treatment of the samples to address the presence of analytical cofounders. These tools will not be available if a portable FTIR is used by industrial hygienists in the field. For this reason, appropriate quantification models need to be designed. An important step is the understanding of the confounding minerals present in the respirable dust in different mines of the same commodity (for example, copper). If the mineral confounders in the respirable dust (and their relative content) in mines of the same sector are consistent, a sector-specific quantification approach could be created by using a large dataset from samples collected in mining operations of the same commodity. If instead the mineral confounders are consistent only mine by mine, mine-specific quantification approach should be investigated.

The focus of this study was to assess the DoF-FTIR technique for the estimation of crystalline silica in respirable dust samples collected in several open-pit copper mines in Arizona and New Mexico. As a first step, the study considered the RCS quantification model for the DoF-FTIR, with no adjustment for the presence of confounders.[18] Then the study investigated the use of a sector-specific and mine-specific quantification approach. The goal was not to establish the bias and precision of the DoF-FTIR technique in the estimation of crystalline silica for samples collected in this environment, but to quantify the discrepancy of the established quantification models—in terms of relative difference and standard deviation of the error—from the laboratory analysis. This is a necessary step to optimize the use of a portable FTIR unit for the estimation of crystalline silica in the field. A second objective was to investigate the relative crystalline silica content of the respirable dust present in copper mining environments.

Methodology

NIOSH collected respirable dust samples in different areas of five open-pit mines (M1–M5) in Arizona and New Mexico during two field surveys to each mine, for a total of 10 field surveys (S1–S10) between May 2015 and July 2016.

Sampling strategy

All respirable dust samples were collected as area samples. Sampling areas were selected with guidance from the industrial hygienist on site. The areas selected had a previously documented presence of respirable crystalline silica.

During each field survey, between 15 and 30 samples were collected. Each field survey included two sampling days with the exception of one mine (M4) where the samples were collected in a single day. Samples were collected with respirable dust aluminum cyclones (SKC Inc., Eighty Four, PA) calibrated at a flowrate of 2.5 lpm. The flowrate was verified with a Bios Defender 510 volumetric flow calibrator before and after each sampling event. Samples were collected on pre-weighed 37-mm PVC filters in three-piece styrene/acrylonitrile co-polymer cassettes. Sampling trains were spread throughout the identified areas. Collection times ranged from 4–6 hr.

Researchers also collected bulk samples of settled fine dust in the vicinity of each respirable dust sampler; bulk samples were stored in sealed containers for subsequent laboratory processing and analysis. Those bulk samples are considered to be a rough representation of the aggregate dust present in the atmosphere.

Analysis and data processing

After shipping to the NIOSH laboratories in Pittsburgh, the respirable dust samples were equilibrated, neutralized, and post-weighed in a controlled environment where they had previously been pre-weighed. The controlled environment is kept at 22 ± 0.7 °C and 50% ± 2% relative humidity. Gravimetric analysis of the samples was conducted on a microbalance (XP6, Mettler-Toledo, Columbus, OH) with a precision better than 5 μg; overall the gravimetric analysis had a limit of quantification LOQ 14 μg in a single weighing.[30] Laboratory and field blank filters were analyzed: blank filters had an average net gain of 5 μg, but this value was not used to correct the final mass determination for each sample.

The estimation of RCS using the portable FTIR unit followed the protocol described in a previous article.[18] The respirable dust samples on the filter media were analyzed with the instrument (FTIR Alpha, Bruker) in transmission mode. For two of the surveys, this estimation was done at the mine site at the end of the day. Only the center of the filter was analyzed, representing an analysis area 6 mm in diameter. The total RCS collected on the filter was estimated with a quantification approach developed using RCS standards.[18,31]

For the samples collected during the surveys S6–S10, the established protocol summarized in the paragraph above was used and referred hereafter as Approach 1. Two additional quantification approaches, sector-specific (Approach 2) and mine-specific (Approach 3), were employed to process the raw data extracted from the portable FTIR unit for these samples.

For Approach 2, the aggregated estimation data for the field surveys (S1–S5) were used together with the NIOSH 7500 results to create sector-specific copper mine quantification approaches. Portable FTIR results for each sample were regressed against the NIOSH 7500 (XRD) results for the same sample. An ordinary least squares regression was generated with the aggregated data (S1–S5) and the regression parameters used to adjust the quantification model of Approach 1 when applied to the DoF-FTIR data obtained for each sample collected in the surveys S6–S10.

For Approach 3, the estimation data for each field-survey (S1–S5) were used with the NIOSH 7500 results for each sample, independently, to create a mine-specific quantification approach. An ordinary least squares regression was generated with the data for each mine, and the regression parameters used to adjust the quantification model of Approach 1 when applied to the DoF-FTIR data obtained for each sample collected in the same mine during the surveys S6–S10.

When the DoF-FTIR estimation was completed, the sample filters were sent to an accredited laboratory (Bureau Veritas North America, Inc., Novi, MI) for the quantification of RCS with the NIOSH 7500 method. In order to conduct a valid comparison of the DoF-FTIR estimates and NIOSH 7500 results, the laboratory was asked to perform the analysis only on the filter, without recovering dust deposited on the wall of the cassettes. The results of the NIOSH 7500 analysis on each sample were used in comparison with the DoF-FTIR estimation. Two methods were used to compare the results on the same sample: the relative difference for each sample, and the standard error of the estimate for an entire set of data. For each sample, the relative difference was calculated as [(DoF-FTIR estimate—NIOSH 7500 value)/NIOSH 7500 value]. The relative difference values for samples collected during the same survey were then grouped together and descriptive statistical analysis was conducted. The standard error of the estimate was calculated for each survey as [(Sum(DoF-FTIR estimate—NIOSH 7500 value) ○ 2/(number of samples collected)] ○ (1/2).

In addition, the crystalline silica quantification data for each sample was combined with the gravimetric data relative to the same sample to calculate the %RCS.

The settled bulk dust samples collected during each survey were processed and analyzed for mineral content. Each sample was dried and re-aerosolized in a small dust chamber at the NIOSH laboratory and a single respirable dust sample was collected, using a high-volume respirable sampler, GK2.69 (MESA, Lake Wood, CO) at a flowrate of 4.2 lpm. Several studies[32,33] verified that the use of this sampler provides an accurate respirable dust sample. The resulting sample was sent to an external laboratory (H&M Analytical Services, Cream Ridge, NJ) for mineral phase identification (including relative abundance of each mineral) via X-ray diffraction and Rietveld refinement.[34]

Results and discussion

A synopsis of the results generated from the NIOSH 7500 analysis on each sample and grouped by field survey set is presented in Table 1. The number of samples with a measured RCS mass above the LOQ of the analysis is variable set by set. The sets S6, S7, S8, S9, and S10 represent the second field survey at the mines M1, M2, M3, M4, and M5, respectively. The LOQ varied survey by survey and within the same survey sample by sample—this variability was the effect of the NIOSH7500 analysis conducted on samples where interfering matrix compounds were identified.

Table 1.

Summary of the information generated by the NIOSH 7500 method analysis on samples collected during the 10 surveys.

| S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 | S10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| N (samples> LOQ) | 21 | 28 | 13 | 13 | 30 | 25 | 22 | 23 | 12 | 26 |

| Min (μg) | 25 | 400 | 63 | 95 | 45 | 35 | 46 | 25 | 160 | 34 |

| Max (μg) | 490 | 1,800 | 390 | 410 | 3,100 | 690 | 580 | 880 | 840 | 1,300 |

| LOQ (μg) | 17 | 17,34,51,100 | 17,34 | 22 | 19 | 34 | 17 | 17 | 17,34,85 | 17 |

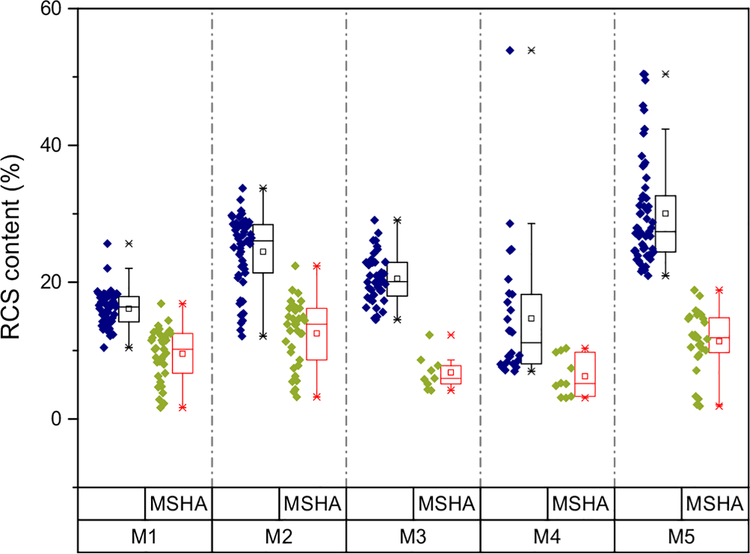

The NIOSH 7500 results were used to calculate the %RCS relative to respirable dust for the samples collected in each mine. The values for the samples collected in each mine during both surveys were grouped and compared with historic data for the same mine generated by MSHA during exposure compliance sampling. To compare datasets of similar size, data were retrieved from the MSHA database for the years 2008–2013. The comparison is displayed in a box plot (Figure 1). While the mine-by-mine trend is similar, the silica content of the samples collected for this study is consistently higher than the silica content of the samples collected by MSHA over the 5-year period. This outcome was unexpected and the different constraints for the two datasets might provide some clarification, as follows. The samples for this study were collected in areas with a known presence of crystalline silica where workers’ exposure was a concern. This is similar to how MSHA collects exposure samples, even if samples from different areas might be considered. The collection period and concentration levels for the samples in the two datasets could be different. MSHA collected samples intermittently over 5 years, whereas the samples in this study were collected over a few days during two visits at the same mine. Temporal variability might be the cause of the difference, even though the MSHA data did not present any substantial temporal trend (not shown) for any mine. Finally, MSHA collects personal samples while this study collected area samples. It is possible that workers spend only a portion of their time in areas where the %RCS in the dust is high, and the %RCS could be affected by control technologies, such as water spray, while workers are present in one area. What is evident is that the variability of the %RCS in the dust present in a single mine is very high.

Figure 1.

Respirable crystalline silica (RCS) content (%) in the respirable dust samples collected during the 10 surveys and grouped by mine. For each mine, data relative to the silica content of MSHA respirable dust samples collected between 2008 and 2013 are reported.

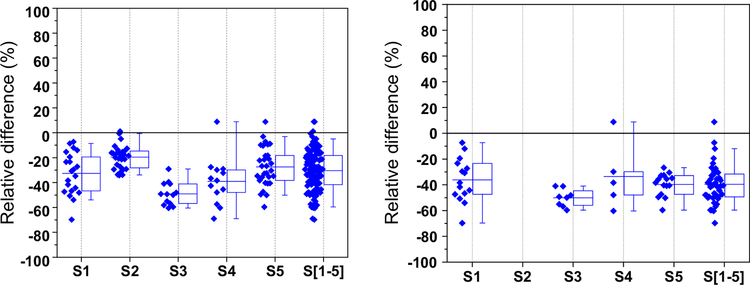

The second phase of the data analysis focused on comparing the DoF-FTIR silica estimation generated using portable FTIR to the NIOSH 7500 analysis results. Because the DoF-FTIR analysis is nondestructive, both analyses were conducted on the same samples. The comparison of the samples collected during the first survey to the five mines (S1–S5) are presented in Figure 2 as relative difference. Figure 2a shows the entire data-set while Figure 2b shows only the samples with more than 200 μg silica (as reported by NIOSH 7500). The value of 200 μg of silica mass was selected as a threshold between medium and high amounts of RCS that can be collected on a filter media using a respirable sampler. The findings are presented mine-by-mine and then grouped as a single set S[1–5]. The line in each box represents the mean value of the relative difference for the samples considered; the range of each box represents the 25–75% percentile of the relative difference, while the whiskers display the 5–95% percentile.

Figure 2.

Relative difference (%) chart presenting the comparison result between the DoF-FTIR technique and the NIOSH 7500 method. Relative difference data are reported for each single survey S1–S5 and grouped as S[1–5]. (Left) complete set of data; (right) data with an amount of silica lower than 200 μg.

The DoF-FTIR technique consistently underestimates the amount of silica in the samples. The average relative differences are summarized in Table 2. The average relative difference varies survey by survey, ranging from −49% to −19.6%, and when the datasets are combined this value is −30.5% - confidence interval, alpha = 0.05 (CI95) = (−33.8%, −27.2%). The calculated average relative differences for samples with less than 200 μg were comparable with the differences calculated for the complete datasets.

Table 2.

Summary of the results of the comparison between the DoF-FTIR technique and the NIOSH 7500 method for the surveys S1–S5.

| Entire set of samples | Samples below 200 μg | |||||

|---|---|---|---|---|---|---|

| N | Standard error of the estimate (μg) | Average relative difference | N | Standard error of the estimate (μg) | Average relative difference | |

| S1 | 21 | 55 | −32.70% | 15 | 34 | −36.2% |

| S2 | 28 | 204 | −19.60% | |||

| S3 | 13 | 98 | −49% | 8 | 46 | −50.1% |

| S4 | 13 | 118.5 | −39.10% | 5 | 50.4 | −33.5% |

| S5 | 30 | 140.5 | −27.40% | 15 | 34.1 | −39.7% |

| S[1–5] | 105 | 142.5 | −30.50% | 43 | 39.8 | −39.6% |

The standard error of the estimate was used as a secondary means of comparison of the two analytical techniques. The standard error associated with the use of the DoF-FTIR method ranged from 54–200 μg for the different datasets and was 142 mg when the datasets were combined. When only samples with less than 200 μg of RCS were considered in the analysis, the standard error of the estimate was lower—between 34 and 50 μg.

As described in the Methodology section, for the samples collected during the surveys S6–S10, three different quantification approaches were used to estimate silica from the raw data generated by the portable FTIR. The comparison of the results of the two analytical techniques was conducted independently on each set of data from each estimation approach, while the results of the NIOSH 7500 method were always used as a reference. The findings of the comparison are presented in Table 3 as average relative difference and standard error of the estimate. A separate analysis was conducted for the entire dataset and for the samples with a NIOSH 7500 reported RCS amount less than 200 μg. The findings are presented survey by survey and then grouped as a single set S[6–10]. In the same table, the coefficient of determination (R2) for each ordinary least square regression is reported: the R2 values for Approach 2 are all the same because they refer to the sector-specific quantification approach. The R2 values for Approach 3 are specific for each mine and they are indicative of the correlation between the DoF-FTIR results and the NIOSH7500 method for each set S1–S5.

Table 3.

Summary of the results of the comparison between the DoF-FTIR technique and the NIOSH 7500 method for the surveys S6–S10. The confidence level CI(95) is indicated together with the average relative difference values.

| Approach | R2 | Entire set of samples | Samples below 200 μg | |||||

|---|---|---|---|---|---|---|---|---|

| N | Standard error of the estimate (ug) | Average relative difference | N | Standard error of the estimate (ug) | Average relative difference | |||

| S6 | 1 | 24 | 83 | −33.0% [−39.4%; −26.5%] | 11 | 27 | −37.9% [−47.0%; −28.7%] | |

| 2 | 0.96 | 63 | −19.6% [−27.3%; −11.8%] | 19 | −25.4% [−36.4%; −14.4%] | |||

| 3 | 0.94 | 63 | −11.1% [−19.7%; −2.6%] | 15 | −17.6% [−29.7%; −5.4%] | |||

| S7 | 1 | 22 | 24 | −11.4% [−18.8%; −4.1%] | 14 | 22 | −20.4% [−28.3%; −12.4%] | |

| 2 | 0.96 | 66 | 6.3% [−2.5%; 15.1%] | 16 | −4.4% [−13.9%; 5.1%] | |||

| 3 | 0.79 | 60 | 7.9% [−0.9%; 16.9%] | 16 | −2.9% [−12.6%; 6.7%] | |||

| S8 | 1 | 23 | 47 | −21.1% [−28.6%; −13.7%] | 9 | 16 | −34.7% [−44.1%; −25.3%] | |

| 2 | 0.96 | 80.3 | −5.3% [−14.3%; 3.6%] | 11 | −21.6% [−33.2%; −9.9%] | |||

| 3 | 0.89 | 306 | 48.8% [34.7%; 62.9%] | 27 | 23.3% [6.1%; 40.5%] | |||

| S9 | 1 | 12 | 143 | −54.2% [−59.8%; −48.6%] | 5 | 103 | −57.2% [−60.6%; −53.8%] | |

| 2 | 0.96 | 110 | −45.1% [−51.1%; −38.3%] | 72 | −48.6% [−52.7%; −44.5%] | |||

| 3 | 0.38 | 72 | −18.9% [−28.9%; −9.0%] | 46 | −24.2% [−30.2%; −18.2%] | |||

| S10 | 1 | 26 | 90 | −30.5% [−35.1%; −25.9%] | 15 | 49 | −39.4% [−45.3%; −33.4%] | |

| 2 | 0.96 | 37 | −16.6% [−22.1%; −11.2%] | 27 | −27.2% [−34.1%; −20.4%] | |||

| 3 | 0.97 | 52 | −21.1% [−26.2%; −15.9%] | 37 | −31.1% [−37.9%; −24.4%] | |||

| S[6–10] | 1 | 98 | 68 | −29.5% [−33.2%; −25.8%] | 50 | 43 | −33.8% [−38.2%; −29.4%] | |

| 2 | 0.96 | 70 | −13.2% [−17.6%; −8.9%] | 32 | −21.2% [−26.6%; −15.9%] | |||

| 3 | 155 | 2.8% [−3.8%; 9.4%] | 25 | −9.5% [−16.7%; −2.4%] | ||||

For every single dataset, the unadjusted estimation was obtained using the calibration with pure silica samples.[18] In this case, the relative differences range from −54% to −11%, similar to what was found with the surveys S1–S5, using the same estimation approach. When the sets were combined S[6–10], the average relative difference was −28.6% (CI95) (−32.3%,−24.9%). The sector-specific approach (Approach 2) and mine-specific approach (Approach 3) improved the relative difference for each single dataset. While the effect is not consistent across datasets, the use of the mine-specific estimation approach induces a more pronounced improvement in the estimation than the one obtained with the sector-specific approach. For the datasets S7 and S8, the mine-specific approach induces the DoFFTIR technique to overestimate the RCS in the samples compared to the NIOSH 7500 method. When the data-sets are combined S[6–10], the average relative differences are −12.9% (CI95)= (−17.3%, −8.6%) 2.8% (CI95) = (−3.8%, 9.4%) if Approach 2 and Approach 3 are used, respectively. For the samples with less than 200 μg in the combined dataset S[6–10], the average relative differences are −20.8% (CI95) = (−26.3%, −15.4%) and −9.5% (CI95) = (−16.7%,−2.4%) when Approach 2 and Approach 3 are used, respectively.

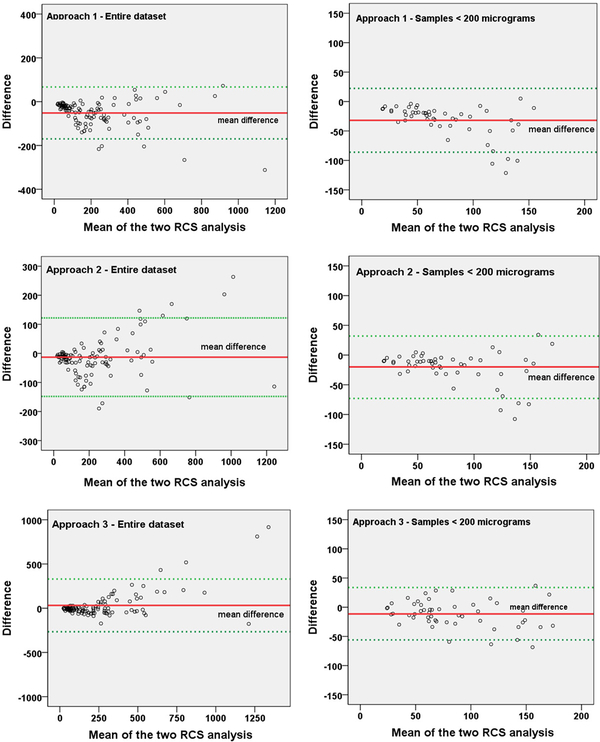

Table 3 indicates that the relative difference between the DoF-FTIR estimation and NIOSH 7500 is not constant but varies on average mine-by-mine and more specifically sample-by-sample. Using the NIOSH 7500 method as the reference, this indicates that the quality of the DoF-FTIR silica estimation is not consistent. To exclude variability in the performance of the portable instrumentation, silica-containing respirable dust samples are used as performance standards in the analytical protocol. The standards are analyzed each day prior to analysis of any respirable dust samples, including when the portable instrumentation is used the mine site. Comparing the results obtained for the standards with historic data provides reassurance that the analytical process is performing as expected,[18] thus, it is possible to exclude the idea that factors such as humidity, transportation, or other conditions could have affected the analysis. Instead, the trend shown in Figure 3 and the data in Table 3 seems to indicate that something specific mine to mine could be the cause.

Figure 3.

Bland-Altman plots for the DoF-FTIR technique and the NIOSH7500 methods for combined set S[6–10]. (Top) plots relative to the results obtained with Approach 1; (center) plots relative to the results obtained with Approach 2; (bottom) plots relative to the results obtained with Approach 3.

The data in Table 3 provide evidence that the use of Approach 2 and Approach 3 induces an improvement in the RCS estimation generated by the DoFFTIR technique. Compared to the unadjusted Approach 1, the sector-specific and mine-specific approaches take advantage of previous results generated from samples collected in other copper mines in Arizona and New Mexico, or in the same mine, respectively. The improvement induced by the use of Approach 2 may be due to the presence of similar FTIR mineral confounders in the dust of each mine. The larger improvement induced by the use of Approach 3 might indicate that differences in the dust of each mine are less substantial. This is evident, for example, for the samples of the S8 and S9 surveys. For the samples in the dataset S9, this improvement seems to minimize the relative difference, while the use of Approach 3 on the S8 samples induces the opposite effect, which is the overestimation of RCS compared to the NIOSH 7500 results. This specific outcome could be explained by changes in the dust in the mine between surveys, indicating that respirable dust can be different, not only mine-by-mine but also sample-by-sample with the same mine.

The results of the standard error of the estimate analysis (Table 3) seem to corroborate the idea of sample-by-sample variability. The use of Approach 2 and Approach 3 does not consistently reduce the standard error of estimate value for a single dataset. The reduction is present for the S6, S9, and S10 samples, but no trend is evident. Approach 3 induces an increment in the standard error of the estimate for S8 samples from 47 μg to 306 μg, while the same approach reduces the standard error of the estimate for S9 samples from 143 μg to 72 μg. When the datasets are combined, the use of Approach 2 seems not to affect the standard error of the estimate, while Approach 3 increases it from 68 μg to 155 μg. It is important to consider that both Approach 2 and 3 are applied uniformly on the entire dataset for the samples collected in each survey. The approaches do not consider the specificity of each single sample, and this limit is highlighted by the standard error of the estimate.

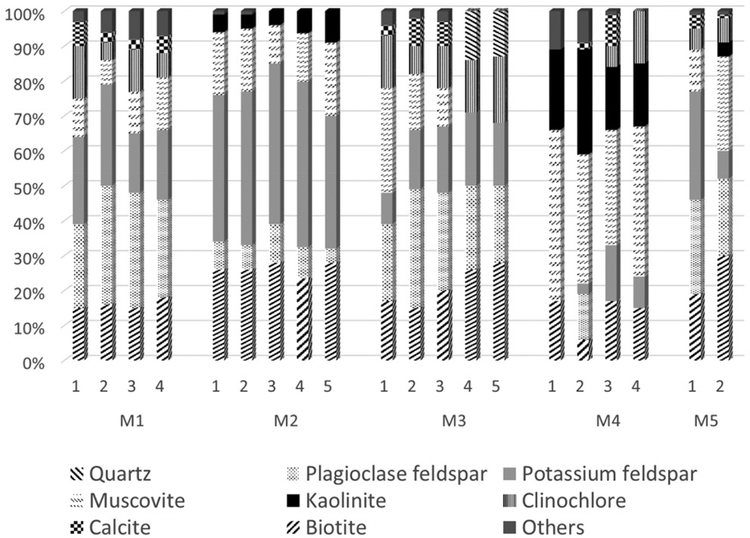

To investigate the effect of RCS loading on the performance of the three quantification approaches, a series of Bland-Altman charts were created for the combined sets S[6–10] (Figure 3). A stand-alone chart for each approach was created for the entire data set and for the samples with less than 200 μg of RCS. The plots relative to the entire sets indicate that the difference between the methods is heteroscedastic because higher values for both signs, positive and negative, are found for larger amount of RCS. This phenomenon is less pronounced for the samples with less than 200 μg of RCS but still present for the results from Approach 1 and Approach 3. Independent information was obtained from the mineral analysis of the respirable dust contained in the settled fine dust samples collected during each survey at the five mine operations. The results of the mineral analysis are summarized in the Figure 4. For each mine, two to five samples were analyzed. Crystalline silica (as quartz) was found in every sample. Cristobalite or tridymite were not present in any sample. In addition to quartz, the most abundant families of minerals have been listed in the stack chart. The family of plagioclase feldspar minerals—including albite, anorthite, andenise, and oligoclase—was very abundant, found in high levels in the respirable dust of four mines. Potassium feldspars, including microcline and orthoclase, were also generally present. The dust collected in the mine (M4) relative to the surveys S4 and S9 showed a different pattern, with high levels of muscovite and kaolinite. Muscovite was also present in samples from the other four mines.

Figure 4.

Variability in mineral composition of respirable dust present in multiple samples from each of the five mines.

The relative content for each mineral or family of minerals was found to be variable in the respirable dust in each mine. The minerals in the dust collected in M1, M2, and M4 were found to be quite consistent. The same was not true for the dust samples collected in M3 considering that high levels of muscovite were found only in three samples out of five. This information is indicative of the variability of the mineral content in the dust in the areas of the mines where the respirable dust samples were collected. For this reason, it is possible to hypothesize that a similar variability was present in those samples.

The information illustrated in Figure 4, combined with the results on the quality of the RCS estimations by the DoF-FTIR technique using the three quantification approaches, leads to three findings. First, the respirable dust present in copper mines in Arizona and New Mexico is composed of crystalline silica and several other minerals. While commonalities can be found for minerals present in the respirable dust in each mine, the relative content of each mineral is highly variable. Second, the DoF-FTIR technique generally underestimates the RCS content in respirable dust samples collected in this study. The quality of the estimation is also variable, and on average is different for samples collected in different mines. Third, the use of sector-specific and especially mine-specific quantification approaches can improve the quality of the RCS estimation performed by the DoF-technique. This improvement is consistent neither across nor within datasets and indicates that each sample might have specific characteristics that affect the DoFFTIR estimation.

We have evidence that each respirable dust sample can have a unique mineral composition, different from other samples collected during the same survey or other surveys. These differences do affect the estimation as theorized in previous studies[28,29] confirming the assumption of the presence of other minerals (including confounders for silica, as discussed above) in the respirable dust in the surveyed mines, The first research question in the Methodology section posed the possibility of creating a sector-specific quantification approach to address the presence of common mineral confounders for the silica estimation. From the findings in Table 3 and Figure 4, it is clear that a sector-specific quantification approach does not address the presence of significant minerals sufficiently to overcome the confounding effect. Similar minerals were found in the respirable dust of the five mines, and data currently processed for other studies indicate that these minerals can uniquely characterize dust in copper mines. Unfortunately, the relative content for each mineral present in the dust of the five mines is too variable to be addressed by a sector-specific quantification approach. The second research question focused on the possibility of creating a mine-specific quantification approach. This approach showed more promising results, as evident from the overall and mine-specific lower average relative difference. The relative content of the minerals detected in the dust of each mine is variable, but the range is more limited than for the entire sector.

The future adoption of the mine-specific silica quantification approach, in conjunction with the use of the portable FTIR at the mine site, might require an active role by the industrial hygienist involved in the monitoring activity. As the DoF-FTIR analysis is a non-destructive technique, it is conceivable that, periodically, a subset of the samples collected by the hygienist could be sent to an accredited laboratory for standard analysis. Those results could then be used to verify the quality of the estimation generated by the portable FTIR and to establish the mine-specific quantification approach presented in this article.

While a mine-specific quantification model might be a possible approach to address the mineral confounders present in the respirable dust of one of the mines, this approach has also evident limitations due to the variability of minerals in the respirable dust of a single mine. In order to achieve a lower relative difference and standard error of the estimate for estimation of crystalline silica using the DoF-FTIR approach, the relative quantities of minerals in each sample needs to be taken into account. This can be done by designing a quantification approach that identifies the presence of all the minerals in the FTIR spectrum, is trained to address the effect of each mineral, and as a result provides an improved estimation of crystalline silica. This approach, using principal component analysis and partial least square modeling, has been adopted successfully for the use of DoF-FTIR analysis for respirable dust samples collected in coal mines.[27] In those environments, the only recognized mineral confounder is kaolinite. For respirable dust samples collected in non-coal mines, such as copper mines, it is evident that the number of minerals is much higher. Because of the co-presence of multiple minerals with silica in the respirable dust, a multivariate analysis of the FTIR spectrum might be needed. This suggests the development of a quantification model that needs to be trained using calibration standards composed of minerals present in the mine’s respirable dust. The information summarized in Figure 4 can be used for the selection of the minerals and to define the range of minerals content in the calibration standards. The creation of calibration standards and the development and training of the quantification models are the next steps of the NIOSH initiative.

Conclusions

This study presents the results of using a direct-on-filter FTIR analysis for the estimation of respirable crystalline silica in dust samples collected in five copper mines in Arizona and New Mexico during 10 field surveys. The direct-on-filter analysis was conducted using a commercially available portable FTIR that can be used at the mine site for RCS monitoring. The standard NIOSH 7500 method was also used to analyze the same samples.

The results produced the following findings:

The %RCS in the dust of the five mines was found to be variable. Several other minerals were found in the respirable dust of the five mines. While the minerals found were similar, suggesting the possibility of identifying a set of specific mineral characteristics of copper mines in this region, their relative content was extremely variable between mines and within each mine.

Without a sector-specific or mine-specific approach, the DoF-FTIR analysis on average underestimated the amount of silica present in the respirable dust samples collected in the five mines. When combining the results from the five mines, the underestimation is in the range of −30%.

The adoption of sector-specific and mine-specific quantification approaches was tested. The high variability of mineral confounders between mines was identified as the cause for the inefficacy of the sector-specific quantification approach. Considering the limited range of mineral content in the dust of a specific mine, the mine-specific approach showed to be more effective in the silica estimation generated by the DoF-FTIR technique. Specifically, the use of the sector-specific quantification approach was effective in reducing the underestimation to an average of −13% when the results of the five mines are combined. On the other hand, the use of the mine-specific quantification approach induced an average relative difference of 2.8%.

Mine-specific quantification was proposed as a feasible approach to generate field-based silica estimation results from the analysis of respirable dust samples with a portable FTIR. The mine-specific quantification approach can be developed in a single mine to induce low average relative difference for the results compared to the standard analysis.

A quantification approach that considers the mineral composition of each sample was indicated as the necessary further step to improve the estimation of silica in each respirable dust sample analyzed with the DoF-FTIR technique.

As explained in the introduction, the DoF-FTIR technique is essential for the idea of using a portable FTIR unit for estimation of crystalline silica in respirable dust samples for future in-field exposure monitoring. This work contributes to the development of the field-based respirable crystalline silica monitoring approach and more generally to the NIOSH Mining program outcome aimed at the idea of mine operators adopting technologies and methodologies that provide more accurate and timely monitoring of worker exposures to known respirable hazards.

Acknowledgments

The authors would like to thank: Dr. Eric Lutz and Dr. Arthur Miller (SMRD, NIOSH, Spokane) for their support in the early stages of the study; Dr. Steve Schatzel (PMRD, NIOSH, Pittsburgh) and Dr. Steve Mercurio (H&M analytics) for the very productive conversations on mineralogy; and William Archer (PMRD, NIOSH, Pittsburgh) for the support in the Pittsburgh laboratory.

Footnotes

Publisher's Disclaimer: Disclaimer

Mention of any company or product does not constitute an endorsement by the National Institute for Occupational Safety and Health (NIOSH). The findings and conclusions in this article are those of the authors and do not necessarily represent the views of NIOSH.

Color versions of one or more of the figures in the article can be found online at www.tandfonline.com/uoeh.

References

- [1].Steenland K: One agent, many diseases: Exposure-response data and comparative risks of different outcomes following silica exposure. Am. J. Industr. Med 48(1):16–23 (2005). [DOI] [PubMed] [Google Scholar]

- [2].Bang KM, Mazurek JM, Wood JM, White GE, Hendricks SA, and Weston A, et al. : Silicosis mortality trends and new exposures to respirable crystalline silica - United States, 2001–2010. MMWR Morb Mortal Wkly Rep. 64(5):117–120 (2015). [PMC free article] [PubMed] [Google Scholar]

- [3].Leung CC, Yu ITS, and Chen WH: Silicosis. Lancet 379(9830):2008–2018 (2012). [DOI] [PubMed] [Google Scholar]

- [4].NIOSH: NIOSH hazard review: Health effects of occupational exposure to respirable crystalline silica. Publication No. 2002–129. Cincinnati, OH: National Institute for Occupational Safety and Health; (2002). [Google Scholar]

- [5].Steenland K, and Ward E: Silica: A lung carcinogen. CA Cancer J. Clin 64(1):63–69 (2014). [DOI] [PubMed] [Google Scholar]

- [6].Schleiff PL, Mazurek JM, Reilly MJ, et al. : Surveillance for silicosis — Michigan and New Jersey, 2003–2011. MMWR Morb Mortal Wkly Rep. 63:73–78 (2016). Available from https://www.cdc.gov/mmwr/volumes/63/wr/mm6355a7.htm#contribAff. [DOI] [PubMed] [Google Scholar]

- [7].Rosenman KD: What is the most cost-effective way to identify silica problem worksites?. Am. J. Industr. Med 35(4):434–435 (1999). [DOI] [PubMed] [Google Scholar]

- [8].Steenland K, and Brown D: Silicosis among gold miners: Exposure-response analyses and risk assessment. Am. J. Publ. Health 85(10):1372–1377 (1995). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [9].Steenland K, and Sanderson W: Lung cancer among industrial sand workers exposed to crystalline silica. Am. J. Epidemiol 153(7):695–703 (2001). [DOI] [PubMed] [Google Scholar]

- [10].Attfield MD, and Costello J: Quantitative exposure-response for silica dust and lung cancer in Vermont granite workers. Am. J. Industr. Med 45(2):129–138 (2004). [DOI] [PubMed] [Google Scholar]

- [11].Chen W, Yang J, Chen J, and Bruch J: Exposures to silica mixed dust and cohort mortality study in tin mines: Exposure-response analysis and risk assessment of lung cancer. Am. J. Industr. Med 49(2):67–76 (2006). [DOI] [PubMed] [Google Scholar]

- [12].Verma DK, Rajhans GS, Malik OP, and des Tombe K: Respirable dust and respirable silica exposure in Ontario gold mines. J. Occup. Environ. Hyg 11(2):111–116 (2014). [DOI] [PubMed] [Google Scholar]

- [13].Park RM, and Chen W: Silicosis exposure-response in a cohort of tin miners comparing alternate exposure metrics. Am. J. Industr. Med 56(3):267–275 (2013). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [14].Watts WF, Huynh TB, and Ramachandran G: Quartz concentration trends in metal and nonmetal mining. J. Occup. Environ. Hyg 9(12):720–732 (2012). [DOI] [PubMed] [Google Scholar]

- [15].NIOSH: Occupational Exposure Sampling Strategy Manual. 1977.

- [16].Cauda E, Joy G, Miller A, and Mischler S: Analysis of the silica percent in airborne respirable mine dust samples from U.S. operations ASTM STP1565 on Symposium on Silica and Associated Respirable Mineral Particles. October 25–26, 2012, Atlanta, GA: (2013). [Google Scholar]

- [17].Chubb L, and Cauda E: Characterizing particle size distributions of crystalline silica in gold mine dust. Aerosol Air Qual. Res 17(1):24–33 (2017). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [18].Cauda E, Miller A, and Drake P: Promoting early exposure monitoring for respirable crystalline silica: Taking the laboratory to the mine site. J. Occup. Environ. Hyg 13(3):D39–D45 (2016). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [19].Miller AL, Drake PL, Murphy NC, Noll JD, and Volkwein JC: Evaluating portable infrared spectrometers for measuring the silica content of coal dust. J. Environ. Monitor (2012). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [20].Cauda E, Drake P, Lee T, and Pretorius C: High-volume samplers for the assessment of silica content in metal mine dust via direct-on-filter analysis In 10th International Mine Ventilation Congress, IMVC2014; South Africa, 2013. [Google Scholar]

- [21].Bhaskar R, Li JL, and Xu LJ: A comparative study of particle size dependency of IR and XRD methods for quartz analysis. Am. Industr. Hyg. Assoc. J 55(7):605–609 (1994). [DOI] [PubMed] [Google Scholar]

- [22].Kauffer E, Masson A, Moulut JC, Lecaque T, and Protois JC: Comparison of direct (X-ray diffraction and infrared spectrophotometry) and indirect (infrared spectrophotometry) methods for the analysis of alpha-quartz in airborne dusts. Ann. Occup. Hyg 49(8):661–671 (2005). [DOI] [PubMed] [Google Scholar]

- [23].Kauffer E, Moulut JC, Masson A, Protois JC, and Grzebyk M: Comparison by X-ray diffraction and infrared spectroscopy of two samples of alpha quartz with the NIST SRM 1878a alpha quartz. Ann. Occup. Hyg 46(4):409–421 (2002). [DOI] [PubMed] [Google Scholar]

- [24].Stacey P, Kauffer E, Moulut JC, Dion C, et al. : An international comparison of the crystallinity of calibration materials for the analysis of respirable alpha-quartz using X-ray diffraction and a comparison with results from the infrared KBr disc method. Ann. Occup. Hyg 53(6):639–649 (2009). [DOI] [PubMed] [Google Scholar]

- [25].Mine Safety Health Administration (MSHA): Infrared determination of quartz in respirable coal mine dust - Method No. MSHA P7. U.S. Dept. of Labor-MSHA-Pittsburgh Safety and Health Technology Center; (2008). [Google Scholar]

- [26].HSE - Health and Safety Executive: MDHS 101 -Crystalline silica in respirable airborne dusts direct-on-filter analyses by infrared spectroscopy and X-ray diffraction. 2005.

- [27].Miller A, Weakley AT, Griffiths PR, Cauda EG, and Bayman S: Direct-on-filter α-quartz estimation in respirable coal mine dust by transmission FT-IR spectrometry and partial least-squares regression. Appl. Spectrosc 9:1–11 (2016). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [28].Weakley A, Miller AL, Griffiths PR, and Bayman SJ: Quantifying silica in filter-deposited mine dusts using infrared spectra and partial least squares regression. Analyt. Bioanalyt. Chem 1–10 (2014). [DOI] [PubMed] [Google Scholar]

- [29].Ojima J: Determining of crystalline silica in respirable dust samples by infrared spectrophotometry in the presence of interferences. J. Occup. Health 45(2):94–103 (2003). [DOI] [PubMed] [Google Scholar]

- [30].Page SJ, and Volkwein JC: A revised conversion factor relating respirable dust concentrations measured by 10 mm Dorr-Oliver nylon cyclones operated at 1.7 and 2.0 L min-1. J. Environ. Monitor 11(3):684–689 (2009). [DOI] [PubMed] [Google Scholar]

- [31].Miller AL, Drake PL, Murphy NC, Cauda EG, LeBouf RF, and Markevicius G: Deposition uniformity of coal dust on filters and its effect on the accuracy of FTIR analyses for silica. Aerosol Sci. Technol 47(7):724–733 (2013). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [32].Lee T, Kim SW, Chisholm WP, Slaven J, and Harper M: Performance of high flow rate samplers for respirable particle collection. Ann. Occup. Hyg 54(6):697–709 (2010). [DOI] [PMC free article] [PubMed] [Google Scholar]

- [33].Cauda E, Drake P, Lee T, and Pretorius C: High-volume samplers for the assessment of respirable silica content in metal mine dust via direct-on-filter analysis In 10th International Mine Ventilation Congress. Sun City, South Africa, 2014. [Google Scholar]

- [34].Rietveld HM: A profile refinement method for nuclear and magnetic structures. J. Appl. Crystallogr (2):65–71 (1969). [Google Scholar]