Abstract

We report here isolation and analysis of PCR amplified phbC gene from Pseudomonas spp. strain phbmbb15-B3. This strain was previously developed from mutations of landfill isolates and found to be an efficient Poly Hydroxy butyrate (PHB) producer. The fragment was cloned into pTZ57R/T cloning vector and then the gene has been sequenced and submitted to GenBank (Accession Number KT933807). The sequence results confirmed the clone to be phbC homologue and the ORF was 910 base pairs long and coded for 303 amino acids, which shared 92–99% amino acid sequence identity with the available bacterial sequences in Gene Bank. We could also predict the primary and secondary structural features of the expected phbC protein. Phylogenetic analysis also revealed its similarity with several pseudomonads. The results of the present study shall provide a stable foundation for further research on modeling studies of PHB synthase and developing PHB a commercial technology.

Electronic supplementary material

The online version of this article (10.1007/s12088-018-0767-4) contains supplementary material, which is available to authorized users.

Keywords: Pseudomonas, PHB synthase, Polyhydroxybutyrate, Cloning, Sequencing, In silico analysis, Ligand binding

Introduction

For cost effective Polyhydroxybutyrate (PHB) production, availability of an efficient bacterial strain and access to its genetic determinants is a prerequisite for its commercial exploitation. The Polyhydroxybutyrate (PHB), a kind of Polyhydroxyalkanoate (PHA) being biodegradable polymer [1–4], has thermoplastic properties similar to chemically synthesized polymers (polyethylene or polypropylene) and has great potential for industrial and medical applications [5–9]. PHB is commonly found in various bacterial genera such as Azotobacter, Bacillus Cupriavidus, Pseudomonas, Ralstonia, and Rhizobium [10–18]. Although certain bacterial species can accumulate PHA up to 80% of their cell biomass, however, the major issue is the high cost of production and downstream processing. To reduce the cost of PHB production, efforts are being directed to genetically engineer microbes, plants and use renewable resources as feed [19–26].

PHB is synthesized in three steps involving β-ketothiolase (phbA), acetoacetyl-CoA reductase (phbB), and PHB synthase (phbC). phbC is the most important gene in the pha operon for PHB production [27–29]. Different strategies have been found useful to make out PHB synthase genes involved in PHB biosynthesis. Primary structure of 44 different PHA synthases and their nucleotide sequences are available [30–32]. PHB biosynthesis genes were also cloned from two Pseudomonads [33]. These studies revealed the existence of diversity in these genes among bacteria. Here, we explored indigenous bacterial cultures for PHA production especially phbC genes of Pseudomonas involved in PHB synthesis.

Materials and Methods

Pseudomonas spp. phbmbb15-B3 strain with maximum PHB yield using fructose as a carbon source in combination with mustard cake and yeast extract as a nitrogen source was used here based on our previous study [33]. Strain (phbmbb15-B3) was used for cloning, sequencing and investigating its structural and functional characteristics using various bioinformatics tools.

Isolation of Genomic DNA and PCR Amplification

Genomic DNA from Pseudomonas spp. phbmbb15-B3 strain was isolated using CTAB method. Qualitative and quantitative estimation of DNA was done by using agarose gel electrophoresis using λ DNA marker. A total of nine different sets of gene specific primers were designed using diverse phbC sequences available in database to amplify phbC gene through the Primer Quest software of IDT-DNA Inc. US. All primer sequences and amplicon information are listed in Table S1. PCR reactions were performed using standard procedures using Biorad thermocycler. Electrophoresis on 1.2% agarose gel was carried out to resolve the amplified PCR products.

Cloning and Sequencing of phbC Gene

The desired fragment of phbC gene was excised and eluted from the gel using the MDI micro purification kit, India. The purified fragments were taken and ligated into the cloning vector pTZ57R/T using standard protocol. The correct recombinants were sent to ABI, Gurgaon for sequencing.

In Silico Analysis of phbC Gene

phbC Gene Structure and Protein Sequence Analysis

Position of coding region of phbC gene sequence was marked through FGenesh software (http://linux1.softberry.com/berry.phtml?topic=fgenesh&group=programs&subgroup=gfind). The phbC gene sequence was translated using Expasy tool and the resulting protein sequence was used as a query in BLASTp analysis at NCBI to retrieve its similar sequences. Primary structural analysis of phbC protein sequence was performed using ProtParam tool (http://web.expasy.org/protparam/; whereas secondary structural analysis was performed through Sopma (npsapbil.ibcp.fr/cgibinnpsa_automat.pl?page=/NPSA/npsa_sopma.html) tool. PFP tool was used to perform phbC protein functional analysis. Furthermore, CCD analysis was done to identify the conserved domains in phbC protien (http://www.ncbi.nlm.gov/structure/cdd/wrpsb.cgi).

Phylogenetic Study

Phylogenetic analysis using amino acid sequence of phbC protein and its related sequences available in the database was performed with the help of MEGA6 software [34]. Un-rooted phylogenetic tree was constructed using Neighbour-Joining Method that uses distant matrix with a bootstrap of 1000 iterations.

phbC Protein Structure Analysis

3D structures of phbC gene was generated using its amino acid sequence employing Swiss-Model [35] and Phyre server and the generated models were further justified through Structure Analysis and Verification Server (SAVES) that uses both geometric and energy minimization method (http://nihserver.mbi.ucla.edu/SAVES) employing VERIFY3D [36] and ERRAT [37]. programs and Swiss-Model server using structure assessment tool. Energy calculations were done using ANOLEA (Atomic Empirical Mean Force Potential) [38] and Ramachandra plot analysis using (Phi/Psi) RAMPAGE program was carried out to evaluate the backbone of both the models [39]. Ligand binding site analysis for phbC gene was performed using software 3DLigandSite (http://www.sbg.bio.ic.ac.uk/3dligandsite) [40].

Result and Discussion

Amplification, Cloning and DNA Sequencing of the phbC Gene

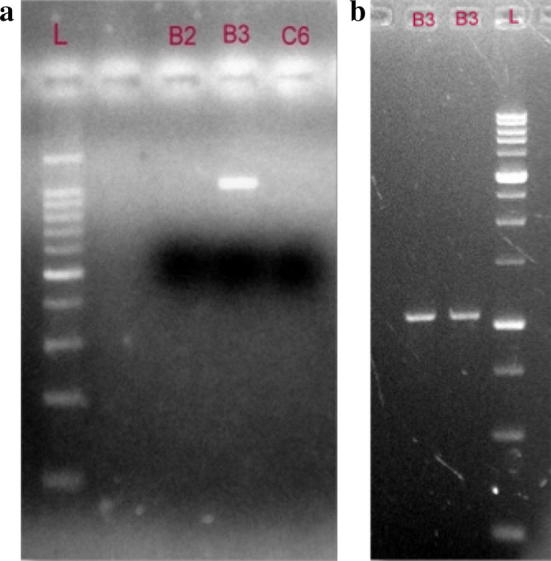

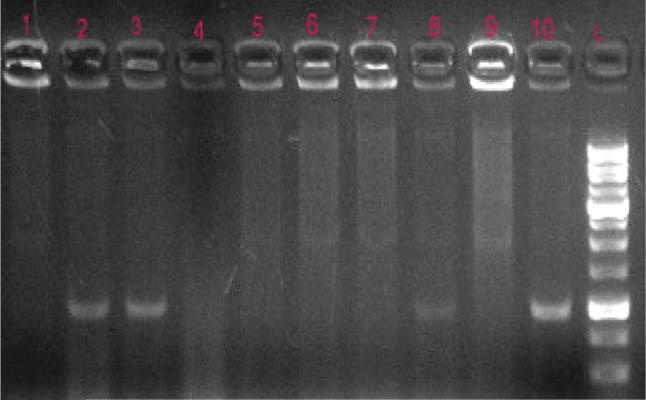

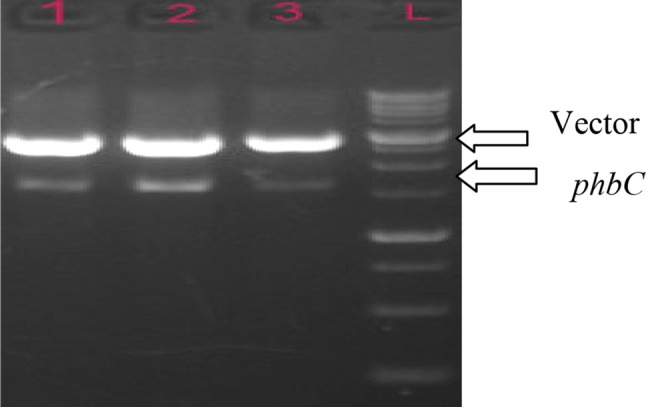

The phbC gene was amplified from the genomic DNA using a specific primer pair (F-ATCCCGATGCCCTGAAATG; R-TGCTTGCTGGTGGGTTAAT) (Table S1) and a fragment of approximately 1000 bp was obtained (Fig. 1). The amplified product was purified and cloned into pTZ57R/T cloning vector prior to transformation into E. coli DH5α cells. Luria–bertani (LB) agar plates comprising X-gal/IPTG and ampicillin were used to check the cloned target sequence (Fig. 2) and was further confirmed by colony PCR (Fig. 3) and restriction enzyme (EcoRI and BamHI) digestion (Fig. 4) prior to sequencing. After sequencing, the sequence has been submitted to GenBank (Accession Number KT933807).

Fig. 1.

a Gel showing PCR amplification by Primer psdPHB15 specific for phbC gene in strain Pseudomonas phbmbb15-B3. b Gel showing DNA fragments resolved for elution and to be cloned later

Fig. 2.

Transformed colonies of E. coli with psdPHB15 amplified fragment of phbCgene

Fig. 3.

Colony PCR of transformants for authentication of cloned product

Fig. 4.

Restriction enzyme digestion of recombinant plasmid vector authentication of cloned product

In Silico Analysis of phbC Gene and Protein Sequence

Cloning and DNA sequencing results indicated that the open reading frame (ORF) of phbC gene consisted of 910 bp and was found to be GC rich (58.24%). The translated phbC protein sequence consisted of 303 amino acids. CDD analysis showed that the phbC protein has two domins: the first one belongs to phaC_N superfamily (2–50 aa) and the second is abhydrolase_1_catalytic domain (55–293). Protparam tool computed molecular weight, theoretical pI, instability index, aliphatic index, grand average of hydropathicity (GRAVY) and extinction coefficient at 280 nm of phbC protein sequence to be 34.151 KD, 6.35, 39.05, 101.39, − 0.048 and 57,870 (assuming all pairs of cysteine residues form cystines) − 58245 (assuming all pairs of cysteine residues are reduced) M−1 cm−1, respectively. Moreover, number of negatively charged residues (29) was found to be higher than the positively charged residues (26). Further, SOPMA tool predicted that the translated protein sequence had 31.02% alpha helix, 23.76% extended strand, 8.58% beta turn and 36.63% random coil in phbC sequence. Kyte-Doolittle hydrophobicity analysis predicted that phbC protein is hydrophobic in nature which is evident from its graph where regions of the protein below the 0.0 line are hydrophilic whereas regions above the 0.0 line are hydrophobic in nature. It was found through PFP tool that molecular function of this protein is related with transferase activity in the cytoplasm and this protein is mainly involved in polyhydroxybutyrate biosynthetic process. Similar results were shown by Edkie and prasad [41] in which they studied the regulatory functions of bacillus PHB synthase.

Multiple Sequence Alignment

The sequences showing 97% minimum coverage, 92% minimum identity and zero e-value to phbC protein sequence were retrieved and it was found that phbC showed maximum similarly to sequences from P. extremaustralis, P. pseudoalcaligenes, P. aeruginosa, P. salinarum and P. oleovorans (Table S2). Sequence analysis of the phbC protein indicated that the amplified phbC protein sequence is of partial length.

Phylogenetic Analysis

Based on amino acid sequences, a phylogenetic tree (Fig. S1) was constructed which has two major clusters, where all the sequences except Pseudomonas sequence from RIT-PI-q 17 formed a first cluster. The first cluster was again divided into two sub-clusters. Our phbC protein sequence showed similarly to sequences from P. salinarum, P. USM4-55, P. alcaligenes, P. extremaustralis and P. oleovorans but formed an out group. Phylogenetic analysis of Pseudomonas spp. phbmbb15-B3 is in agreement with the analysis of Pseudomonas spp LDC-5 studied by Sujata et al. [42].

3D Structure Analysis of phbC Protein

SWISS-MODEL Server and PHYRE2 server were used to carry out comparative homology modeling of the protein sequences. 3D models of the aligned protein sequences were generated from the rigid bodies through SWISS MODEL. The 3D structures so generated were verified through Phyer2 server, automated fold identification server for protein structure and function prediction through homology modeling. The alignment transformation to a 3D model was performed using SWISS-MODEL and PHYRE2. Both the programs differ in the way in which the sequences are aligned to build the 3D model [43].

Ligand Binding Site Analysis

The ligand binding analysis identified one-fourteen clusters for the binding of N-acetyl glucosamine (NAG) but the cluster having maximum ligands was selected for the prediction of ligand binding in the target sequence. Serine, proline, glutamate and leucine were identified as ligand binding amino acid residues at 41, 42, 43, 204, 205 and 206 (last three positions for leucine) positions respectively. Structural properties as well as catalytic mechanism by predicting the three-dimensional (3D) model of the Type II Pseudomonas sp. USM 4–55 PHA synthase 1 also studied by Wahab et al. [44].

In conclusion, PhbC gene was PCR isolated from Pseudomonas, it was cloned and sequenced. Analysis of the sequence was performed and attempts were made to predict the three-dimensional structure of PHB synthase. Homology based approaches (SWISS-MODEL and Phyre2) were used to for structure analysis. Verify3D and ANOLEA were used to verify the 3D models. Additionally, to check whether all amino acids lie in the favorable regions Ramachandran plot analysis was carried out Z-score and 3D–1D score were used for validation and verification which showed that SWISS-MODEL is of good and acceptable quality and was found to be better than Phyre 2. To use 3PHB-copolymer industrially, it has been recommended to pick up the enzymatic activities of genes involved in biosynthesis operon of bioplastic producing microorganism. Structure analysis and modeling based design is one of the major strategies to engineer the enzyme activities. In several studies, enhanced expression of either PhaC by itself has been reported to increase P(3HB) production. It is on the microbial level where the tools of genetic engineering can be most readily applied. Characterization of these genes homologues involved in production of bioplastic will help scientists in modification of recombinants as per requirements of substrate specificity and expression of genes.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Compliance with Ethical Standards

Conflict of interest

The authors declare that they have no conflict of interest.

References

- 1.Kalia VC. Microbes: factories for bioproducts. In: Kalia VC, editor. Microbial factories. New Delhi: Springer India; 2015. pp. 1–5. [Google Scholar]

- 2.Reddy CSK, Ghai R, Kalia VC. Polyhydroxyalkanoates: an overview. Bioresour Technol. 2003;87:137–146. doi: 10.1016/S0960-8524(02)00212-2. [DOI] [PubMed] [Google Scholar]

- 3.Kumar P, Patel SKS, Lee JK, Kalia VC. Extending the limits of Bacillus for novel biotechnological applications. Biotechnol Adv. 2013;31:1543–1561. doi: 10.1016/j.biotechadv.2013.08.007. [DOI] [PubMed] [Google Scholar]

- 4.Kumar P, Mehariya S, Ray S, Mishra A, Kalia VC. Biotechnology in aid of biodiesel industry effluent (glycerol): biofuels and bioplastics. In: Kalia VC, editor. Microbial factories. New Delhi: Springer; 2015. pp. 105–119. [Google Scholar]

- 5.Cheng GQ, Wu Q. The application of polyhydroxyalkanoates as tissue engineering materials. Biomaterials. 2005;26:6565–6578. doi: 10.1016/j.biomaterials.2005.04.036. [DOI] [PubMed] [Google Scholar]

- 6.Ray S, Kalia VC. Co-metabolism of substrates by Bacillus thuringiensis regulates polyhydroxyalkanoates co-polymer compositions. Bioresour Technol. 2017;224:743–747. doi: 10.1016/j.biortech.2016.11.089. [DOI] [PubMed] [Google Scholar]

- 7.Ray S, Kalia VC. Microbial cometabolism and polyhydroxyalkanoate co-polymers. Indian J Microbiol. 2017;57:39–47. doi: 10.1007/s12088-016-0622-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Ray S, Kalia VC. Biomedical applications of polyhydroxyalkanoates. Indian J Microbiol. 2017;57:261–269. doi: 10.1007/s12088-017-0651-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Singh M, Kumar P, Ray S, Kalia VC. Challenges and opportunities for the customizing polyhydroxyalkanoates. Indian J Microbiol. 2015;55:235–249. doi: 10.1007/s12088-015-0528-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Kalia VC, Chauhan A, Bhattacharyya G. Genomic databases yield novel bioplastic producers. Nat Biotechnol. 2003;21:845–846. doi: 10.1038/nbt0803-845. [DOI] [PubMed] [Google Scholar]

- 11.Kumar U, Sharma A, Sikka VK. Maximization of poly-β-hydroxybutyrate production by rhizo-bacteria using ecofriendly agri-byproducts. SPJPBS. 2009;27:35–37. [Google Scholar]

- 12.Singh M, Patel SKS, Kalia VC. Bacillus subtilis as potential producer for polyhydroxyalkanoates. Microb Cell Fact. 2009;8:38. doi: 10.1186/1475-2859-8-38. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Kumar T, Singh M, Purohit HJ, Kalia VC. Potential of Bacillus sp. to produce polyhydroxybutyrate from biowaste. J Appl Microbiol. 2009;106:2017–2023. doi: 10.1111/j.1365-2672.2009.04160.x. [DOI] [PubMed] [Google Scholar]

- 14.Kumar P, Singh M, Mehariya S, Patel SKS, Lee JK, Kalia VC. Ecobiotechnological approach for exploiting the abilities of Bacillus to produce co-polymer of polyhydroxyalkanoate. Indian J Microbiol. 2014;54:151–157. doi: 10.1007/s12088-014-0457-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Kumar P, Ray S, Patel SKS, Lee JK, Kalia VC. Bioconversion of crude glycerol to polyhydroxyalkanoate by Bacillus thuringiensis under non-limiting nitrogen conditions. Int J Biol Macromol. 2015;78:9–16. doi: 10.1016/j.ijbiomac.2015.03.046. [DOI] [PubMed] [Google Scholar]

- 16.Singh M, Kumar P, Patel SKS, Kalia VC. Production of polyhydroxyalkanoate co-polymer by Bacillus thuringiensis. Indian J Microbiol. 2013;53:77–83. doi: 10.1007/s12088-012-0294-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Bhubalan K, Lee WH, Loo CY, Yamamoto T, Tsuge T, Doi Y, Sudesh K. Controlled biosynthesis and characterization of poly(3-hydroxybutyrate-co-3-hydroxyvalerate-co-3-hydroxyhexanoate) from mixtures of palm kernel oil and 3HV-precursors. Polym Degrad Stab. 2008;93:17–23. doi: 10.1016/j.polymdegradstab.2007.11.004. [DOI] [Google Scholar]

- 18.Kumar P, Mehariya S, Ray S, Mishra A, Kalia VC. Biodiesel industry waste: a potential source of bioenergy and biopolymers. Indian J Microbiol. 2015;55:1–7. doi: 10.1007/s12088-014-0509-1. [DOI] [Google Scholar]

- 19.Suriyamongkol P, Weselake R, Narine S, Moloney M, Shah S. Biotechnological approaches for the production of polyhydroxyalkanoates in microorganisms and plants: a review. Biotechnol Adv. 2007;25:148–175. doi: 10.1016/j.biotechadv.2006.11.007. [DOI] [PubMed] [Google Scholar]

- 20.Yunus AMM, Parveez GKA, Ho CL. Transgenic plants producing polyhydroxyalkanoates. Asian Pac J Mol Biol Biotechnol. 2008;16:1–10. [Google Scholar]

- 21.Ray S, Kalia VC. Biological significance of degradation of polyhydroxyalkanoates. In: Kumar P, Kalia VC, editors. Microbial applications. Cham: SpringerNature; 2017. pp. 125–139. [Google Scholar]

- 22.Tsuge T. Metabolic improvements and use of inexpensive carbon sources in microbial production of polyhydroxyalkanoates. J Biosci Bioeng. 2002;6:579–584. doi: 10.1016/S1389-1723(02)80198-0. [DOI] [PubMed] [Google Scholar]

- 23.Kumar P, Ray S, Kalia VC. Production of co-polymers of Polyhydroxyalkanoate by regulating the hydrolysis of biowastes. Bioresour Technol. 2016;200:413–419. doi: 10.1016/j.biortech.2015.10.045. [DOI] [PubMed] [Google Scholar]

- 24.Patel SKS, Singh M, Kumar P, Purohit HJ, Kalia VC. Exploitation of defined bacterial cultures for production of hydrogen and polyhydroxybutyrate from pea-shells. Biomass Bioenergy. 2012;36:218–225. doi: 10.1016/j.biombioe.2011.10.027. [DOI] [Google Scholar]

- 25.Patel SKS, Lee JK, Kalia VC. Integrative approach for producing hydrogen and Polyhydroxyalkanoate from mixed wastes of biological origin. Indian J Microbial. 2016;56:293–300. doi: 10.1007/s12088-016-0595-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Porwal S, Kumar T, Lal S, Rani A, Kumar S, Cheema S, Purohit HJ, Sharma R, Patel SKS, Kalia VC. Hydrogen and polyhydroxybutyrate producing abilities of microbes from diverse habitats by dark fermentative process. Bioresour Technol. 2008;99:5444–5451. doi: 10.1016/j.biortech.2007.11.011. [DOI] [PubMed] [Google Scholar]

- 27.Kalia VC, Lal S, Cheema S. Insight into the phylogeny of polyhydroxyalkanoate biosynthesis: horizontal gene transfer. Gene. 2007;389:19–26. doi: 10.1016/j.gene.2006.09.010. [DOI] [PubMed] [Google Scholar]

- 28.Lal S, Cheema S, Kalia VC. Phylogeny vs genome reshuffling: horizontal gene transfer. Indian J Microbial. 2008;48:228–242. doi: 10.1007/s12088-008-0034-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Ray S, Sharma R, Kalia VC. Co-utilization of crude glycerol and biowastes for producing polyhydroxyalkanoates. Indian J Microbiol. 2018;58:33–38. doi: 10.1007/s12088-017-0702-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Slater SC, Voige WH, Dennis DE. Cloning and expression in E. coli of Alcaligens eutrophus H16 polyhydroxybutyrate (PHB) biosynthetic pathway. J Bacteriol. 1988;170:4431–4436. doi: 10.1128/jb.170.10.4431-4436.1988. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Peoples OP, Sinskey AJ. Poly β-hydroxybutyrate (PHB) biosynthesis in Alcaligens eutrophus H16. Identification and characterization of PHB polymerasegene (PhbC) J Biol Chem. 1989;264:1. [PubMed] [Google Scholar]

- 32.Zhang G, Hang XM, Phillip G, Kwok-Ping H, Chen GQ. PCR cloning of type II polyhydroxyalaanoate biosynthesis genes from two Pseudomonads. FEMS Microbiol Lett. 2001;198:165–170. doi: 10.1111/j.1574-6968.2001.tb10637.x. [DOI] [PubMed] [Google Scholar]

- 33.Jangra M, Sikka VK. Expeditious and ecofriendly production of poly-β-hydroxy butyrate in bacteria grown on renewable agribyproducts. Int J Recent Sci Res. 2015;9:6400–6404. [Google Scholar]

- 34.Tamura K, Peterson D, Peterson N, Stecher G, Nei M, Kumar S. MEGA5: molecular evolutionary genetics analysis using maximum likelihood, evolutionary distance, and maximum parsimony methods. Mol Biol Evol. 2011;28:2731–2739. doi: 10.1093/molbev/msr121. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Bordoli L, Kiefer F, Arnold K, Benkert P, Battey J, Schwede T. Protein structure homology modeling using SWISS-MODEL workspace. Nat Protoc. 2009;4:1. doi: 10.1038/nprot.2008.197. [DOI] [PubMed] [Google Scholar]

- 36.Eisenberg D, Luthy R, Bowie JU. VERIFY3D: assessment of protein models with three-dimensional profiles. Methods Enzymol. 1997;277:396–404. doi: 10.1016/S0076-6879(97)77022-8. [DOI] [PubMed] [Google Scholar]

- 37.Colovos C, Yeates TO. Verification of protein structures: patterns of non-bonded atomic interactions. Protein Sci. 1993;2:1511–1519. doi: 10.1002/pro.5560020916. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Melo F, Feytmans E. Assessing protein structures with non-local atomic interaction energy. J Mol Biol. 1998;2775:1141–1152. doi: 10.1006/jmbi.1998.1665. [DOI] [PubMed] [Google Scholar]

- 39.Lovell SC, Davis IW, Arendall WB, de Bakker PI, Word JM, Prisant MG, Richardson JS, Richardson DC. Structure validation by Calpha geometry: phi, psi and Cbeta deviation. Proteins. 2002;50:437–450. doi: 10.1002/prot.10286. [DOI] [PubMed] [Google Scholar]

- 40.Wass MN, Kelley LA, Sternberg MJ. 3D LigandSite: predicting ligand-binding sites using similar structures. Nucl Acids Res. 2010;38:469–473. doi: 10.1093/nar/gkq406. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Edkie NG, Prasad DH. Bacillus PHA synthase C gene showed regulatory functions: an in silico analysis. Biotechnology. 2014;13:143–151. doi: 10.3923/biotech.2014.143.151. [DOI] [Google Scholar]

- 42.Sujata K, Shenbagarathai R, Mahalakshmi A. Analysis of PCR for PHB production in indigenous Pseudomonas sp. LDC-5. Indian J Biotechnol. 2005;4:323–335. [Google Scholar]

- 43.Jain R, Tiwari A. Acetoacetyl-CoA reductases in Cupriavidus necator. J Mater Environ Sci. 2015;6:686–692. [Google Scholar]

- 44.Wahab HA, Khairudin NBA, Samian, Najimudin N. Sequence analysis and structure prediction of type II Pseudomonas sp. USM 4–55 PHA synthase and an insight into its catalytic mechanism. BMC Struct Biol. 2006;6:23. doi: 10.1186/1472-6807-6-23. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.