Abstract

As one of the oldest distillates in the world, flavor compounds of Chinese Baijiu (Chinese liquor) were extremely complex. Propyl lactate was firstly detected by direct injection and gas chromatography-mass spectrometry (GC-MS) in 72 Chinese Baijius. The objectives were to detect the contents of propyl lactate and evaluate its contribution to the aroma of Chinese Baijiu based on odor activity values (OAVs). The levels of propyl lactate in these distillates were determined by internal standard method and selective ion monitoring (SIM), which ranged from 0.050 to 1.900 mg∙L−1 under investigation. Its detection threshold was determined by Three-Alternative Forced-Choice (3-AFC) and curve fitting (CF), which was 0.740 mg∙L−1 in 38% ethanol solution. The contribution of propyl lactate on the aroma of these distillate drinks was evaluated by their odor activity values (OAVs), which varied from 0.066 to 4.440. The OAVs of propyl lactate were found to exceed 1 in 13 Chinese Baijius, including 50° Jingzhi Guniang 5 years (4.440), 52° Jingzhi Guniang 10 years (3.024), Jingyanggang (2.568), Xianghe Ronghe Shaofang (2.313), and 1956 Laolang (1.431), which indicated that propyl lactate was one of odor-active components in these Chinese Baijius.

Keywords: Chinese Baijiu, propyl lactate, gas chromatography-mass spectrometry (GC-MS), threshold, odor activity values (OAVs)

1. Introduction

Chinese Baijiu (Chinese liquor) is one of the oldest distillates in the world, and it is the most popular spirits in China with the annual production of about 4 million metric tons. The general process for the production of Chinese Baijiu is as follows. At first, the grain raw materials, such as wheat, sorghum, corn, rice or glutinous rice, are cooked with steam. And then some saccharification and fermentation agents (“DaQu” or “XiaoQu”) are added into the cooked grain matrix. Finally, the liquors are distilled out with steam from the fermentation products after several months or years of fermentation [1]. The fresh distillates need to be aged for a long time in order to balance the flavors. The final commercialized products are blended with aged distillate drinks, fresh distillate drinks and water based on certain ratios according to different formulations of spirit drinks [2].

Flavor compounds of Chinese Baijiu are extremely complex due to different raw materials, various microorganisms and diverse procedures in different production regions, and a great number of compounds have been studied extensively [3,4,5,6], such as esters, alcohols, ketones, acids, and so on. Lactates have been reported to occur in Chinese liquors widely, such as methyl lactate [4], ethyl lactate [7], butyl lactate [8], hexyl lactate [9], isopropyl lactate [10], isobutyl lactate [4] and isoamyl lactate [4]. Lactates are recognized to be important flavor compounds in Chinese Baijiu [11]. Ethyl lactate and butyl lactate were detected in “Gujing” Baijiu during investigation carried out in our lab. In the meantime, lactic acid and propanol were also found in this distillate, which had been reported in other Chinese Baijius [12,13]. It is a little strange that propyl lactate has not been reported in Chinese Baijiu up to now. The same are other alcoholic beverages, except distilled Calvados [14] and Chinese rice wine [15]. Meanwhile, the odor properties of propyl lactate and its contribution to aroma of these spirits are also not known. We checked the newest edition (2011 edition) of NIST (National Institute of Standards and Technology) library and found that the mass spectrogram of propyl lactate was not included in this library. The occurrence of propyl lactate in Chinese Baijiu might be overlooked since the identification of volatile components was usually performed by searching NIST library. The objective of this work were (i) the detection of the occurrence of propyl lactate in 72 Chinese Baijius and (ii) the evaluation of its contribution to the aroma of Chinese Baijius based on odor activity values (OAVs).

2. Results and Discussion

2.1. Identification of Propyl Lactate in Distillate Samples

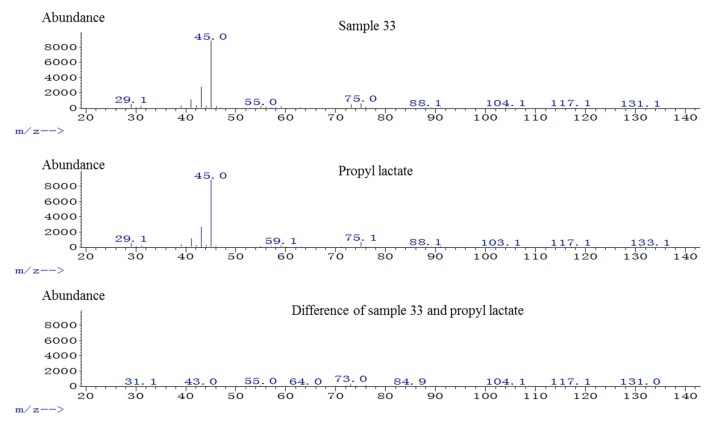

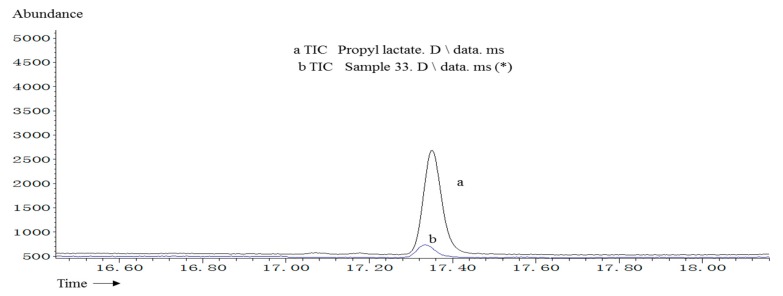

The mass spectra of an unknown compound shown at 17.4 min in sample 33 and propyl lactate standard were presented as Figure 1, and the differential spectrum of them was located at the bottom, which indicated the unknown compound shown at 17.4 min being matched with propyl lactate. The two magnified TICs of the unknown compound in sample 33 (a TIC) and propyl lactate standard (b TIC) at 17.4 min were shown in Figure 2. These two peaks were completely overlapped.

Figure 1.

TIC of propyl lactate in GC-MS. The mass spectra of an unknown compound shown at 17.4 min in sample 33 and propyl lactate standard are presented. The differential spectrum of them is located at the bottom.

Figure 2.

The magnifying TIC of sample 33 and propyl lactate at 17.4 min. The two magnified TICs are shown, one is the unknown compound in sample 33 (a TIC), and the other is propyl lactate standard (b TIC) at 17.4 min.

2.2. Quantitative Analysis of Propyl Lactate in Distillate Samples

The concentrations of propyl lactate were determined in these spirit drinks by the internal standard method with the selected ions monitoring mode of GC-MS. The LOD and the LOQ of the method were 0.025 mg∙L−1 and 0.050 mg∙L−1, respectively. The internal standard curve equations included three equations in different concentration ranges, including y = 4.4587x + 0.0112 (0.050 < y < 0.60), y = 1.9987x + 0.2673 (0.60 < y < 1.00) and y = 2.1972x + 0.0569 (1.00 < y < 4.50). The corresponding correlation coefficients (R2) were 0.9994, 0.9917 and 0.9993, respectively. The quantitative results of propyl lactate were shown in Table 1. The content of propyl lactate in other 10 Chinese Baijiu, numbered 73 to 82, were also included in Table 1, which our lab had reported before [16].

Table 1.

The concentrations of propyl lactate in 82 Chinese Baijiu samples (Detection threshold 0.740 mg∙L−1).

| No. | Sample Name (Alcohol % by Volume) | Manufacturer | Concentrations of Propyl Lactate (mg∙L−1) | OAV of Propyl Lactate |

|---|---|---|---|---|

| 1 | Guizhou Yuanjiang Chenniang 18 Years (52°) | Kweichow Moutai Co., Ltd. | 0.064 ± 0.003 | 0.086 |

| 2 | 1956 Laolang (53°) | Sichuan Langjiu Group Co., Ltd. | 1.059 ± 0.008 | 1.431 |

| 3 | Jiabin Lang (50°) | Sichuan Langjiu Group Co., Ltd. | 0.060 ± 0.002 | 0.081 |

| 4 | Xiaohutuxian (52°) | Guizhou Xingyi Yunfeng Co., Ltd. | a tr | - b |

| 5 | Tianzhilan (42°) | Jiangsu Yanghe Distillery Co., Ltd | tr | - b |

| 6 | Xiangquan (54°) | Jiugui Liquor Co., Ltd. | 0.068 ± 0.001 | 0.092 |

| 7 | Jinliufu Sixing (38°) | Wuliangye Group | 0.064 ± 0.001 | 0.086 |

| 8 | Jinliufu Hongsejingdian (38°) | Wuliangye Group | tr | - b |

| 9 | Shuanggou Daqu (38°) | Shuanggou Distillery | 0.091 ± 0.002 | 0.123 |

| 10 | Niulanshan Bainian (38°) | Shunxin Agriculture Ture | tr | - b |

| 11 | Jianzhuang Chenjiu (52°) | Wuliangye Group | tr | - b |

| 12 | Laishigang Chenniang 3 Years (53°) | Laishigang Group | 0.062 ± 0.001 | 0.084 |

| 13 | Zhijiang Zhixin 5 Years (52°) | Zhijiang Group | 0.081 ± 0.002 | 0.109 |

| 14 | Jiannanchun (52°) | Sichuan Jiannanchun Jituan Co., Ltd. | tr | - b |

| 15 | Liulingzui 3 (52°) | Liulingzui Group | 0.100 ± 0.002 | 0.135 |

| 16 | Zhonghua Dukang K3 (50°) | Luoyang Dukang Holdings Limited Official Website | 0.052 ± 0.001 | 0.070 |

| 17 | Yangshao Caitaofang Jiuliang Miaopin (52°) | Yangshao Co., Ltd. | 0.553 ± 0.006 | 0.747 |

| 18 | Mianrou Dukang (50°) | Luoyang Dukang Holdings Limited Official Website | 0.065 ± 0.001 | 0.088 |

| 19 | Shamochun Shengshi (42°) | Neimenggu Dahekou Co., Ltd. | 0.064 ± 0.001 | 0.086 |

| 20 | Luzhou LaojiaoTouqu (52°) | Luzhou Laojiao Co., Ltd. | tr | - b |

| 21 | Luzhou Laojiao Chentouqu 8 Years (52°) | Luzhou Laojiao Co., Ltd. | tr | - b |

| 22 | Hetao Laojiao Jinzun (42°) | Hetao Liquor | tr | - b |

| 23 | Yingjia K6 (38°) | Yingjia Gongjiu Co., Ltd. | 0.075 ± 0.003 | 0.101 |

| 24 | Neimenggu Sorghum Blue Era (38°) | Neimenggu Dahekou Co., Ltd. | 0.068 ± 0.001 | 0.092 |

| 25 | Rouhe Shuanggou (42°) | Shuanggou Distillery | 0.059 ± 0.001 | 0.080 |

| 26 | Xinghuacun Baishun (45°) | Fenjiu Group | 0.094 ± 0.001 | 0.127 |

| 27 | Jingjiu Jixing (36°) | Wuliangye Group | 0.065 ± 0.002 | 0.088 |

| 28 | Guizhou Yuanjiang Zhenpin 9 Years (38°) | Guizhou Maotai Distillery Group Technology Development Company | 0.068 ± 0.002 | 0.092 |

| 29 | Guizhou DongcangYuanjiu 30 Years (38°) | Zhenpin Jiuye | 0.302 ± 0.010 | 0.408 |

| 30 | Xifeng Yucang (38°) | Xifeng Co., Ltd. | 0.056 ± 0.001 | 0.076 |

| 31 | Furuiwang (38°) | Furui Co., Ltd. | 0.079 ± 0.001c | 0.107 |

| 32 | Laobaifen Fengtan 15 Years (38°) | Fenjiu Group | 0.112 ± 0.001 | 0.151 |

| 33 | Honghuaci Erguotou (56°) | Sanhe Fucheng Co., Ltd. | 0.224 ± 0.042 | 0.303 |

| 34 | Jingdu Yujiu (42°) | Shuangqinghe Co., Ltd. | tr | - b |

| 35 | Zhoufuji Erguotou (42°) | Zhoufuji Co., Ltd. | tr | - b |

| 36 | Mendaolv (62°) | Ningheyuan Co., Ltd. | tr | - b |

| 37 | Weirenmin Fuwu (53°) | Guizhou Maotai Distillery Group | 0.130 ± 0.002 | 0.176 |

| 38 | Beijing Erguotou Qinghuaci (52°) | Jiuzhongjiu Co., Ltd. | 0.064 ± 0.002 | 0.086 |

| 39 | Zhougong Baisui (35°) | Huangjia Jingdu Co., Ltd. | 0.052 ± 0.003 | 0.070 |

| 40 | Tianshan Laobing (38°) | Tianshan Co., Ltd. | tr | - b |

| 41 | Beijing Erguotou I (56°) | Tongquanyong Co., Ltd. | tr | - b |

| 42 | Xianghe Ronghe Shaofang (53°) | Kweichow Moutai Co., Ltd. | 1.712 ± 0.023 | 2.313 |

| 43 | Dajinjiu (42°) | Dajin Co., Ltd. | tr | - b |

| 44 | Jingdu Heitan (42°) | Huangjia Jingdu Co., Ltd. | 0.066 ± 0.003 | 0.089 |

| 45 | Wuliang Yuanjiu (50°) | Yuqiao Co., Ltd. | 0.300 ± 0.054 | 0.405 |

| 46 | Guocuijiu (52°) | Luzhou Guocui Co., Ltd. | 0.052 ± 0.001 | 0.070 |

| 47 | Hongdu Tezhen 25 Years (50°) | Hongdu Co., Ltd. | tr | - b |

| 48 | Beijing Erguotou II (56°) | Shuangqinghe Co., Ltd. | 0.075 ± 0.006 | 0.101 |

| 49 | Beijing Fangzhuang Erguotou (52°) | Fangzhuang Co., Ltd. | tr | - b |

| 50 | Laobeijing Erguotou (41°) | Duxing Co., Ltd. | tr | - b |

| 51 | Sichuan Sorghumjiu I (40°) | Yaoquan Laojiao Co., Ltd. | tr | - b |

| 52 | Guantoushan (40°) | Guantoushan Co., Ltd. | 0.093 ± 0.001 | 0.126 |

| 53 | Mengguwang (44°) | Mengguwang Co., Ltd. | 0.090 ± 0.002 | 0.122 |

| 54 | Caoyuan Andaqing (62.8°) | Andaqing Co., Ltd. | 0.100 ± 0.004 | 0.135 |

| 55 | Luchun (52°) | Luzhou Laojiao Co., Ltd. | tr | - b |

| 56 | Yujingfang Shaojiu (38°) | Yujingfang Shaojiu Group | 0.058 ± 0.002 | 0.078 |

| 57 | Sichuan Sorghum II (42°) | Culiangfang Co., Ltd. | tr | - b |

| 58 | Xianli Jianguo 60 Years (50°) | MaotaiJiucheng Co., Ltd. | tr | - b |

| 59 | Longfeng (38°) | Longfeng Co., Ltd. | tr | - b |

| 60 | Caoyuan Liema (62°) | Menggudao Co., Ltd. | tr | - b |

| 61 | Shuijing Kongdong (52°) | Liuhuchun Co., Ltd. | 0.066 ± 0.001 | 0.089 |

| 62 | Gubei Chunliang (42°) | Gubeichun Co., Ltd. | 0.050 ± 0.001 | 0.066 |

| 63 | Banmasuo Chenniao 3 Years (65°) | Muniu Co., Ltd. | 0.074 ± 0.001 | 0.100 |

| 64 | Heitudi (38°) | Hecheng Co., Ltd. | tr | - b |

| 65 | Hengshui Laobaigan (39°) | Hengshui Laobaigan Co., Ltd. | 0.149 ± 0.005 | 0.201 |

| 66 | Bancheng Laojiu (42°) | Qianlongzui Co., Ltd. | 0.075 ± 0.001 | 0.101 |

| 67 | Jingyanggang (38°) | Jingyanggang Co., Ltd. | 1.900 ± 0.002 | 2.568 |

| 68 | 65667 Troops Tegong T99B (38°) | Beimao Co., Ltd. | 0.250 ± 0.002 | 0.338 |

| 69 | Huanghelong Laoliangfang (52°) | Huanghelong Group | 0.100 ± 0.001 | 0.135 |

| 70 | Guojiao 1573 (52°) | Luzhou Laojiao Co., Ltd. | tr | - b |

| 71 | Mengzhilan M6 (40.8°) | Jiangsu Yanghe Distillery Co., Ltd | 0.176 ± 0.006 | 0.238 |

| 72 | Kouzijiao Zhencang 20 Years (41°) | Kouzi Yjiuye | 0.052 ± 0.002 | 0.070 |

| 73 | Moutai (53°) c | Kweichow Moutai Co., Ltd. | 0.851 ± 0.001 c | 1.150 |

| 74 | Xifeng (55°) c | Xifeng Co., Ltd. | 0.818 ± 0.011 c | 1.105 |

| 75 | Guojing 1# (65°) c | Shandong Bandaojing Co., Ltd. | 1.008 ± 0.018 c | 1.362 |

| 76 | Gujing Yuanjiang (65°) c | Anhui Gujing Group Co., Ltd. | 2.237 ± 0.022 c | 3.023 |

| 77 | Jinshiyuan Yuanjiang (59°) c | Jiangsu King’s Luck Brewery Joint-Stock Co., Ltd. | 0.932 ± 0.024 c | 1.259 |

| 78 | Jinshiyuan (53°) c | Jiangsu King’s Luck Brewery Joint-Stock Co., Ltd. | 0.810 ± 0.017 c | 1.095 |

| 79 | Jingzhi Guniang10 Years (52°) c | Shandong Jingzhi Liquor Co., Ltd. | 3.024 ± 0.025 c | 4.086 |

| 80 | Jingzhi Guniang 5 Years (50°) c | Shandong Jingzhi Liquor Co., Ltd. | 3.286 ± 0.060 c | 4.440 |

| 81 | Wuyue Duzun (52°) c | Taishan Liuor Group Co., Ltd. | 0.788 ± 0.006 c | 1.065 |

| 82 | Jiuchao Chenxiang (42°) c | Shandong Lanling Meijiu Co., Ltd. | 0.910 ± 0.014 c | 1.230 |

a tr: The concentrations of propyl lactate were between 0.025 mg∙L−1 and 0.050 mg∙L−1; b No OAVs because of the concentrations of propyl lactate was much less than LOQ; c the concentrations of propyl lactate were from the reported article [16].

As shown in Table 1, propyl lactate did occur in all Chinese Baijius under investigation, though the concentrations in some distillate drinks were between 0.050 mg∙L−1 (LOQ) and 0.025 mg∙L−1 (LOD). The top 5 distillate samples were Jingzhi Guniang 5 years (50°) (3.286 mg∙L−1), Jingzhi Guniang 10 years (52°) (3.024 mg∙L−1), Gujing Yuanjiang (65°) (2.237 mg∙L−1), “Jingyanggang” (38°) (1.900 mg∙L−1), and “Xianghe Ronghe Shaofang” (53°) (1.712 mg∙L−1).

2.3. Detection Threshold of Propyl Lactate and OAV Analysis

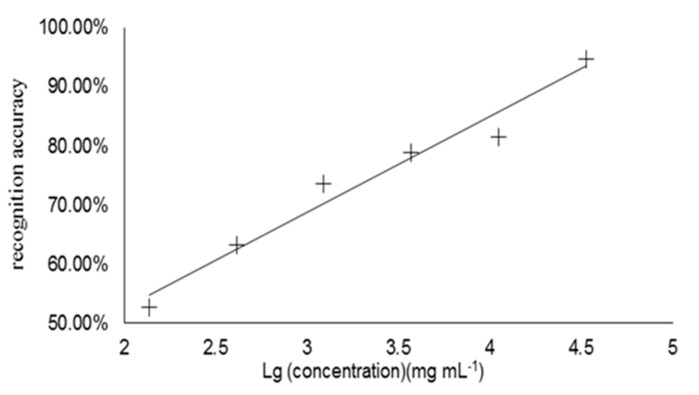

The determination of detection threshold of propyl lactate was conducted by the statistical analyses and the Curve Fitting, and the result was shown in Figure 3.

Figure 3.

Scatter diagram by CF for determination of propyl lactate detection threshold. The X-axis represents the concentration of propyl lactate to the base 10 logarithm (X = LogA) and Y-axis is the correct recognition ratio, which is the ratio of the correct recognition numbers in total recognition numbers.

The calibration curve equation was y = 0.1623x + 0.6877, and the correlation coefficient R2 = 0.9663. The threshold was the corresponding X value (0.740 mg∙L−1) when Y = 66.67% [17].

2.4. Discussion

The unknown compound shown at 17.4 min in sample 33 was identified to be propyl lactate based on the comparison of mass spectra and retention time with the standard. Propyl lactate was also discovered in all other samples under investigation by the same method.

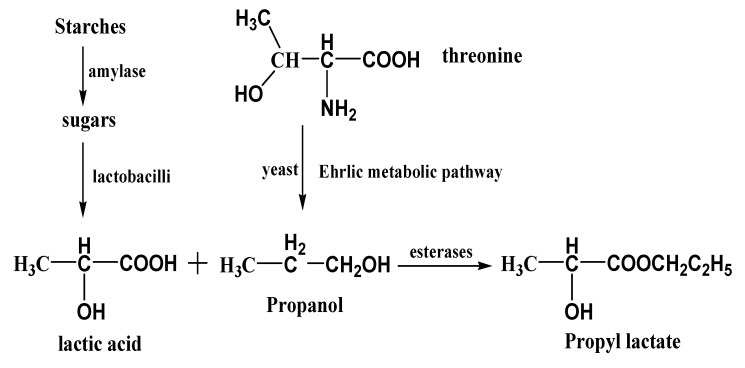

Propyl lactate was possibly formed through the esterification of lactic acid with propanol, both of which have been reported during the fermentation. There were a great number of lactobacilli during the fermentation process of Chinese spirit drinks, which could convert sugars to lactic acid [18,19]. Higher alcohols could be formed during the fermentation under aerobic condition from sugar or under anaerobic conditions from amino acids [20] since the raw materials, sorghum, rice, sticky rice, wheat and corn, were rich sources of amino acids. Propanol can be produced from threonine by yeast via the Ehrlich metabolic pathway [21]. Small amounts of propanol could also be formed by yeast through reduction of propanal. The esterification of lactic acid with propanol could be taken place directly or catalyzed by esterases during the fermentation and aging process of Chinese liquor production [20]. The esterases might be from yeasts, molds, or bacteria, which existed in “Daqu” or “Xiaoqu” [21]. Fan [22] also reported that the “Daqu” had high esterase activities. The main formation process of propyl lactate was as Figure 4.

Figure 4.

The pathway of propyl lactate formation by esterase catalyzation.

The odor activity values (OAV) equaled to the ratio of the concentration of propyl lactate and its detection threshold value. If a compound has an OAV > 1.0, then it would contribute to the flavor of a product [23]. The OAVs of propyl lactate in 82 Chinese Baijius were listed in Table 1. There were 13 distillate samples with the OAVs of propyl lactate higher than 1, including 50° Jingzhi Guniang 5 years (4.440), 52° Jingzhi Guniang 10 years (3.024), 38° Jingyanggang (2.568), 53° Xianghe Ronghe Shaofang (2.313), and so on, whereas other 69 liquor samples with the OAVs lower than 1. Propyl lactate had a grape-like fruity, milk and ester odor [17]. The results indicated that propyl lactate was one of odor-active components of these 13 Chinese Baijius. Whether propyl lactate was a key odor compound or not based on more experiments and proofs, which we would be to study next.

3. Experimental Section

3.1. Chemicals

Chemicals and standards were GC grade with a high purity (>99.0%).The water was boiling for at least 0.5 h and redistilled twice before use. Methyl lactate (PubChem CID: 11040), used as internal standard (IS), and propyl lactate (PubChem CID: 92821) were obtained from Tokyo Chemical Industry CO., Ltd. (Shanghai, China). Absolute ethanol (PubChem CID: 702) was obtained from Merck (Darmstadt, Germany).

3.2. Spirit Drink Samples

A total of 72 spirit drinks, shown as Table 1, were obtained from different factories in China, or supermarkets, such as Wal-Mart and Carrefour in Beijing, China.

3.3. Qualitative and Quantitative Analysis by GC-MS

1.0 µL of Chinese spirit drinks was injected and analyzed by GC-MS with the full scan mode, and the occurrence of propyl lactate was confirmed by comparing its retention time and mass spectrum with the standards.

The concentrations of propyl lactate in these distillates were determined by the internal standard method with the selected ions monitoring mode of GC-MS. At first, a series of the standard solutions, such as 5.000 mg∙L−1, 2.500 mg∙L−1, 1.250 mg∙L−1, 0.625 mg∙L−1, 0.313 mg∙L−1, 0.156 mg∙L−1, 0.078 mg∙L−1, 0.039 mg∙L−1 and 0.020 mg∙L−1, were prepared with absolute ethanol and analyzed by GC-MS. Then 1.0 mL of each distillate drink sample with 10.0 µL of methyl lactate solution (100.000 mg∙L−1) were placed in 72 tightly closed sample vials, numbered 1 to 72, for GC-MS analysis. Finally, the concentrations of propyl lactate were calculated by the software of GC-MS. The conditions of GC-MS (6890A-5975C, Agilent technologies Co., Ltd., Beijing, China) were as follows.

GC conditions: DB-FFAP capillary column (30 m × 0.25 mm, 0.25 μm film thickness, Santa Clara, CA, USA); carrier gas, helium, 99.9995%; flow rate, 1.0 mL∙min−1; The oven temperature was programmed at 50 °C for 2 min, then raised to 100 °C at 6 °C∙min−1, then raised to 170 °C at 3 °C∙min−1 for 2 min, and then raised to 200 °C at 10 °C∙min−1 for 2 min, and finally raised to 230 °C at 15 °C∙min−1 for 5 min; inlet temperature, 250 °C; transfer line temperature, 250 °C; injection volume, 1 µL; split ratio, 20:1.

MS conditions: electron ionization source, 70 eV; ion source and quadruple temperatures, 230 °C and 150 °C, respectively; The monitored ions and other parameters of selected-ion-monitoring (SIM) mode were listed in Table 2.

Table 2.

The monitored ions and other parameters.

| Compound | Mode | Mass List or Range |

|---|---|---|

| Methyl lactate | Full Scan | 50–500 |

| SIM | 45, 75, 89,105 | |

| Propyl lactate | Full Scan | 50–500 |

| SIM | 45, 75, 117 |

3.4. Determination of the Detection Threshold of Propyl Lactate

3-AFC test was recommended as the national standard method for determination of Chinese Baijiu flavors thresholds by GB/T 22366-2008 [16], which is a general guidance for measuring odor, flavor and taste detection threshold, because of its higher efficiency and accuracy. Meanwhile, CF method was adopted as threshold calculation method, which was recommended by ASTM E1432-2004 Standard Practice. So 3-AFC and CF were selected to determine the detection threshold of propyl lactate in Chinese spirit drinks.

Most concentrations of alcohol in the distillate samples under investigation were 38 vol% or nearby, so 38% ethanol solution was used as the benchmark. A series of propyl lactate solutions were prepared for sensory evaluation with 38% ethanol solution, such as 0.137 mg∙L−1 (A1), 0.412 mg∙L−1 (A2), 1.235 mg∙L−1 (A3), 3.704 mg∙L−1 (A4), 11.111 mg∙L−1 (A5) and 33.333 mg∙L−1 (A6).

There were eighteen samples for sensory evaluation, which were equally divided into six groups. All these samples were placed in 10 mL tulip-like glass wine cups. Two samples of each group were the control samples and the remaining one had different concentration of propyl lactate in it. Each sample was marked in a random four-digit number. A group of 30 untrained and normal olfaction assessors were invited to determine propyl lactate detection threshold. All samples were assessed at room temperature. For each test, the assessors needed to pick out the one which was “very different from the references”, and wrote down the number. Each test was replicated 3 times, so that 90 responses were obtained for each testing concentration. Then the Curve Fitting (CF) was conducted by the statistical analyses, and the curve was drawn. When Y = 66.7%, the corresponding X value was the detection threshold value of propyl lactate.

4. Conclusions

In summary, this work reported the occurrence of propyl lactate in 72 Chinese Baijius for the first time. The concentration of propyl lactate ranged from 0.050 to 1.900 mg∙L−1 in 72 Chinese Baijius. The detection threshold of propyl lactate in 38% ethanol solution was 0.740 mg∙L−1. Based on OAV analysis in this research, propyl lactate had much contribution to the aroma of 13 Chinese Baijius , including 50° Jingzhi Guniang 5 years (4.440), 52° Jingzhi Guniang 10 years (3.024), Jingyanggang (2.568), Xianghe Ronghe Shaofang (2.313), and 1956 Laolang (1.431).

Acknowledgements

The financial supports from National Natural Science Foundation of China (31471665 and 31301466) and National Natural Science Foundation of Beijing (KZ201410011015) are gratefully acknowledged.

Author Contributions

Conceived and designed the experiments: B.S., F.Z. and M.H. Performed the experiments: J.W. (mostly), Y.Z., X.S. and J.S. Analyzed the data: J.W. Wrote the paper: J.W. and M.H.

Conflicts of Interest

The authors declare no conflict of interest. The founding sponsors had no role in the design of the study, in the collection, analyses, or interpretation of data, in the writing of the manuscript, and in the decision to publish the results.

Footnotes

Sample Availability: Samples of the compounds are available from the authors.

References

- 1.Yu Q.W. Chuantong Baijiu Niangzao Jishu. China Light Industry Press; Beijing, China: 2013. pp. 17–19. [Google Scholar]

- 2.Fan W.L., Shen H.Y., Xu Y. Quantification of volatile compounds in Chinese soy sauce aroma type liquor by stir bar sorptive extraction and gas chromatography-mass spectrometry. J. Sci. Food Agric. 2011;91:1187–1198. doi: 10.1002/jsfa.4294. [DOI] [PubMed] [Google Scholar]

- 3.Zhu S.K., Lu X., Ji K.L., Guo K.L., Li Y.L., Wu C.Y., Xu G.W. Characterization of flavor compounds in Chinese liquor Moutai by comprehensive two-dimensional gas chromatography/time-of-flight mass spectrometry. Anal. Chim. Acta. 2007;597:340–348. doi: 10.1016/j.aca.2007.07.007. [DOI] [PubMed] [Google Scholar]

- 4.Fan W.L., Xu Y. Identification of volatile compounds of Fenjiu and Langjiu by liquid-liquid extraction coupled with normal phase liquid chromatography (part one) Liquor -Mak. Sci. Technol. 2013;3:17–27. [Google Scholar]

- 5.Liao Y.H., Zhao S., Zhang Y.B., Zhang X., Tong R.N., Xu M. Analysis of flavor substances in Erguotou wine by LLE, SDE, SPME and GC-MS combined with Kovats retention indices. J. Chin. Inst. Food Sci. Technol. 2014;14:220–228. [Google Scholar]

- 6.Zheng Y., Zhao J.W., Zhang F.G., Huang M.Q., Sun B.G., Zheng F.P., Sun J.Y. Analysis of volatile compounds of Bandaojing sesame-flavor liquor. Food Sci. 2014;35:60–65. [Google Scholar]

- 7.Peng Q., Tian R.G., Chen F.R., Li B.B., Gao H.G. Discrimination of producing area of Chinese Tongshan kaoliang spirit using electronic nose sensing characteristics combined with the chemometrics methods. Food Chem. 2015;178:301–305. doi: 10.1016/j.foodchem.2015.01.023. [DOI] [PubMed] [Google Scholar]

- 8.Zhu S.L., Gao C.Q., Cui G.Y. Analysis of trace compositions of Meilanchun sesame-flavor Liquor. Liquor -Mak. Sci. Technol. 2012;6:106–110. [Google Scholar]

- 9.Fan W.L., Xu Y. Determination of volatile compounds of fermented-grains in the solid phase fermentation by HS-SPME coupled with GC-MS. Liquor Mak. 2008;35:94–98. [Google Scholar]

- 10.Wu Z.Z., Fan Z.Y., Zuo G.Y., Wang H.C. GC-MS direct analysis of qualitative and quantitative sampling of liqour. Liquor Mak. 2009;36:88–90. [Google Scholar]

- 11.Fan W.L., Xu Y. Flavor Chemistry of Alcoholic Beverage. China Light Industry Press; Beijing, China: 2014. pp. 117–121. [Google Scholar]

- 12.Guo W.J., Lu J.C. Research on characteristic flavoring components of Gujinggong liquor. Liquor -Mak. Sci. Technol. 2001;5:83–85. [Google Scholar]

- 13.Feng J.Q., Yan Z.M., Wei X.J. Detection and analysis of the trace components in Shedian wine by gas chromatography-mass spectrometry. J. Henan Inst. Sci. Technol. 2011;39:23–26. [Google Scholar]

- 14.Ledauphin J., Saint-Clair J.-F., Lablanquie O., Hugues G., Nicole F., Elisabeth G., Daniel B. Identification of trace volatile compounds in freshly distilled calvados and cognac using preparative separations coupled with gas chromatography-mass spectrometry. J. Agric. Food Chem. 2004;52:5124–5134. doi: 10.1021/jf040052y. [DOI] [PubMed] [Google Scholar]

- 15.Luan J. Research on the flavor in rice wine. China Brew. 2002;6:21–24. [Google Scholar]

- 16.Wu J.H., Li A.J., Huang M.H., Zheng F.P., Sun J.Y., Sun B.G. Research and discovery of propyl lactate in Chinese liquor. J. Chin. Inst. Food Sci. Technol. 2015;15:194–200. [Google Scholar]

- 17.National Standard of the People’s Republic of China . Sensory Analysis-Methodology-General Guidance for Measuring Odour, Flavour and Taste Detection Thresholds by a Three-Alternative Forced-Choice (3-AFC) Procedure. China Standards Press; Beijing, China: 2008. GB/T 22366-2008. [Google Scholar]

- 18.Li W.Q. Relationship between Luzhou flavor liquor, lactic acid bacteria, lactic acid and ethyl lactate. Liquor Mak. 2010;37:90–94. [Google Scholar]

- 19.Cai X.Y. Flavor compounds analysis of Chinese liquor by direct-injection technique using capillary GC: An overview. Liquor Mak. 2004;3:7–10. [Google Scholar]

- 20.Fan W.L., Qian C.M. Identification of aroma compounds in Chinese “Yanghe Daqu” liquor by normal phase chromatography fractionation followed by gas chromatography/olfactometry. Flavour Fragr. J. 2006;21:333–342. doi: 10.1002/ffj.1621. [DOI] [Google Scholar]

- 21.Liu Y.P., Huang M.Q., Zheng F.P., Chen H.T., Sun B.G. Recent advances in extraction and analysis of volatile flavor compounds in Chinese liquor. Food Sci. 2010;31:437–441. [Google Scholar]

- 22.wang Y, Fan W.L., Xu Y., Diao Y.Q., Lu H.Z. Study on the determination method about the esterifying enzymes from DaQu of Chinese strong flavour liquor making. Liquor Mak. 2003;30:18–21. [Google Scholar]

- 23.Antalick G, Perello M.C., Revel D.G. Development, validation and application of a specific method for the quantitative determination of wine esters by headspace-solid-phase microextraction-gas chromatography-mass spectrometry. Food Chem. 2010;121:1236–1245. [Google Scholar]