Abstract

Rheological behaviour and certain quality attributes of the dough and bread prepared from the wheat–millet–Bambara flour (WMB) containing mixtures of emulsifiers and/or apple pectin were investigated. WMB was prepared by substituting wheat flour (WF) with 25% millet flour and 25% Bambara flour. Pectin (1.0–2.0 g) and emulsifiers namely sodium stearoyl lactylate (0.25–0.40 g), polysorbate 80 (0.50–0.80 g), and diacetyl tartaric acid ester of monoglycerides (0.10–0.25 g) mixed in different proportions were added to produce dough and bread. Mixolab was utilised to measure the rheological behaviour of dough and bread made from all mixes were analysed for physical characteristics, nutritional composition, and organoleptic properties. A significant increase in dough development time (emulsifier: 65% and pectin: 57.9%) and dough stability (emulsifier: 18.2% and pectin: 35.2%) were observed. Loaf volume, specific volume and proximate composition of the composite bread increased significantly relative to control. Protein content (33%), protein digestibility (85%) and certain essential amino acids (lysine: 54.6%; threonine: 36.4%) increased significantly in the WMB bread compared to the WF bread. Sensory evaluation revealed an above average acceptability for the composite bread samples. Emulsifiers and pectin used in the present study resulted in significant improvement in the dough rheology, as well as in the physical characteristics, the nutritional and sensory attributes of the WMB composite bread. The results of the present study confirm the potential for supplementation and fortification of wheat bread using flours from millet and Bambara sources.

Electronic supplementary material

The online version of this article (10.1007/s13197-018-3457-7) contains supplementary material, which is available to authorized users.

Keywords: Wheat–millet–Bambara flour, Composite flour, Rheological behaviour, Bambara groundnut, Mixolab, Emulsifiers, Pectin

Introduction

The problem of excessive dependence of the African nations on wheat importation led to a loss in foreign earnings and protein-energy malnutrition (PEM), which is one of the major challenges encountered by the continent in the production of staple foods (Temba et al. 2016). These problems are prevalent and, as suggested by FAO, may be reduced by the incorporation of indigenous protein food sources in staple foods such as bread (Noorfarahzilah et al. 2014). Baking with wheat (Triticum aestivum) alone does not provide the required amino acids in bread as wheat contains lysine in a limited amount only (Mubaiwa et al. 2017). Some traditional crops, e.g. Bambara groundnut (Vigna subterranea) and millet (Pennisetum glaucum), have been advocated as the potential crops for addressing food security challenges in the African countries (Temba et al. 2016). These crops are good sources of proteins and essential amino acids. Millet contains significant amounts of methionine (2.5%) (Saleh et al. 2013), an essential amino acid which is absent in wheat grains. Bambara grain is rich in lysine (6–8%) (Arise et al. 2016; Hillocks et al. 2012), and its protein content majorly consists of essential amino acids. Exploring the potential of Bambara and millet grains in bread production may reduce the incidence of PEM in the African populace. Substitution of wheat with millet and Bambara for bread production may also reduce the excessive dependence on wheat and thus, reduce the cost of wheat importation. There are some previous studies that have been successful in the supplementation and fortification of wheat with legumes and other food crops (Erukainure et al. 2016; Maktouf et al. 2016). The addition of non-gluten flours to wheat in a proportion greater than 20% in the composite flour formulations has been reported to produce bread with poor quality (Erukainure et al. 2016; Maktouf et al. 2016; Noorfarahzilah et al. 2014). As the levels of flours from other sources (legumes, cereals, and tuber flours) supplementing for wheat flour increase, the viscoelastic properties of the resulting dough are increasingly affected, leading to an adverse effect on the handling properties and the resultant quality of bread. Maktouf et al. (2016) evaluated the suitability of pearl millet in composite with wheat flour and observed that the composite at 5% level of addition of pearl millet produced bread with acceptable qualities close to wheat bread. Active surfactants, including emulsifiers and hydrocolloids such as apple pectin, and other technological aid materials have been successfully used to improve the rheological properties of dough prepared from composite or non-gluten flours. Emulsifiers such as sodium stearoyl lactylate (SSL), polysorbate 80 (PS 80) and diacetyl tartaric acid ester of monoglycerides (DATEM) exert the effects of dough strengthening, crumb softening, volume increase and crumb structure improvement on the wheat bread (Gómez et al. 2013). No single emulsifier has exhibited all the necessary properties required to produce a bread or baking product with all the acceptable characteristics (Sharma et al. 1990). Different emulsifiers result in the induction of different properties into the bread quality attributes; therefore, the emulsifiers are often combined in order to impart the desired quality parameters required for bread production (Gómez et al. 2013). Eduardo et al. (2014) observed that DATEM and SSL improved the specific volume and water absorption capacity of the dough and bread prepared from cassava, maize, and wheat composite. Composite bread produced from wheat and millet flour (50% of each) exhibited increased volume and a good crumb structure when emulsifiers were added (Schoenlechner et al. 2013). Pectin has also been observed to assist or help in retaining gas in the dough, increasing dough volume, retaining structure and slowing down the staling process in the bread (Kenijz and Sokol 2013). The composite flour of wheat, cassava, and maize produced bread that exhibited up to 13% increase in volume when pectin was added (Eduardo et al. 2013). Although the effects of emulsifiers and hydrocolloids on dough and bread quality have been studied, the information available on the combined effect of both emulsifiers (SSL, DATEM and PS 80) and pectin on the quality of the composite bread containing millet and Bambara groundnut flours is limited. Therefore, the aim of the present study was to investigate the rheological properties of the dough prepared from wheat, millet, and Bambara composite flour using the standard Chopin + protocol by Mixolab, following the addition of different levels of pectin and emulsifiers and also to investigate the quality of the resultant bread.

Materials and methods

Bambara groundnut (Vigna subterranea) seeds, wheat (Triticum aestivum) flour, and the other baking ingredients were purchased from a local market in Durban, South Africa. Pearl millet (Pennisetum glaucum) (the babala kind) was purchased from Agricol (Pty) Ltd. (Durban, South Africa). Emulsifiers were purchased from Hangzhou Union Biotechnology Co., Ltd. (Xihu District, Hangzhou, China). Apple pectin was purchased from Sigma-Aldrich (St. Louis, MO., USA).

Preparation and blending of flours

Bambara groundnut flour was prepared using the method described by Mubaiwa et al. (2017). The Bambara groundnut (cream coloured South African landrace) seeds were cleaned, sorted, and roasted in an oven at 50 °C for 5 h. The roasted nuts were coarse-milled and winnowed to in order to remove the hull. The dehulled seeds were then milled and sieved to obtain flour with a fine consistency. Millet flour was prepared using the millet flour production method described by Saleh et al. (2013). The millet grains were sprayed with tap water and shed-dried at room temperature (25 °C) for 30 min for conditioning. The grains were then coarse-milled and dried in an air oven at 60 °C to reach a moisture content of about 8%. The coarse grits were winnowed to remove hulls, milled and sieved to obtain flour with a fine consistency. The wheat, millet, and Bambara groundnut flours were sieved using a 250 µm mesh and were mixed in 50:25:25 ratio respectively. A Kenwood blender (BL380 model, Maraisburg, South Africa) was utilised to mix the flours to obtain a homogenous mixture. The composite flour obtained was subsequently packed into a labelled plastic container and stored at 4 °C until use.

Preparation of dough and bread samples

The ingredients used for bread preparation were: flour (200 g), margarine (10 g), sugar (8 g), salt (2 g), yeast (5 g), and water (100 mL for wheat bread and 110 mL for composite bread). Water was added in an amount that was in accordance with the water absorption capacity calculated for that particular flour using Mixolab. Composite bread was coded as WMB3–7 for the different levels of treatment with emulsifiers (SSL, DATEM and PS 80) and pectin. Emulsifiers and pectin were added in proportions within the acceptable limits of their addition to bakery products (FAO/WHO 2001). Pectin (1.0, 1.5, and 2.0 g) and/or the emulsifiers namely sodium stearoyl lactylate (SSL) (0.25–0.40 g), polysorbate 80(PS80) (0.50–0.80 g), and diacetyl tartaric acid ester of monoglycerides (DATEM) (0.10–0.25 g) were mixed and added to the composite flour in different proportions (1.0%, 1.3% and 1.6%). Nine bread samples were produced altogether, three samples were developed to evaluate treatment with emulsifiers (WMB3–5), three samples for the pectin treatment (WMB4–6) and one sample for evaluating treatment with both emulsifier and pectin (WMB7). Two samples, one with 100% wheat flour (WF) and the other with 100% millet flour (MF) served as controls. Bread samples were prepared in accordance with the method (straight dough method) described by Ceserani et al. (1995), with a few modifications. The dry and the wet ingredients were mixed separately in a stainless-steel bowl. A mixer (Kitchen Aid heavy duty–5K5SS model, Maraisburg, South Africa) was utilised to mix the dough for 5 min. The dough was left to rest for 10 min prior to kneading. The dough was then proofed at 35 °C for 90 min at 85% humidity and subsequently baked in a preheated oven at 200 °C for 25 min. The bread samples produced from 100% wheat flour and 100% millet flour (WF and MF) served as controls. Three batches of bread samples were produced for all the categories and the analyses were conducted 1 h following the bread preparation.

Mixolab analysis of dough

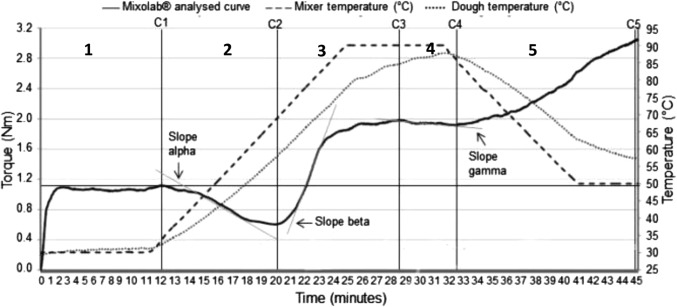

The rheological characteristics of dough were measured using the standard Chopin + protocol in accordance with the manufacturer’s manual. This protocol consisted of heating/cooling cycles with a constant mixing speed of 80 rpm and a constant water absorption level which was calculated using the Mixolab® software on the basis of the flour weight and moisture level (Erukainure et al. 2016). The amount of water used for dough mixing was also calculated using the Mixolab® software. The Mixolab equipment was used to analyse various rheological parameters of the composite flour dough including the dough development time (DDT), water absorption capacity (WAC), dough elasticity (DE), torque, and dough stability (Fig. 1).

Fig. 1.

Typical Mixolab curves comparing the rheological behaviours of dough. The description of a Mixolab curve/points obtained. The numbers indicate the different zones detected in the curve according to physical dough changes. C1—dough development time and stability, C2—protein weakening pattern, and dough elasticity, C3—maximum viscosity, C4—amylolysis pattern, C5—retrogradation. The behavior of Mixolab dough constitutes, where α: represents protein weakening speed under heat; β: represents starch gelatinization speed and γ: represents enzyme, degradation speed (1), dough development time (2), protein reduction during heating (3), starch gelatinization (4), amylase activity (5) and starch gelling due to cooling

Proximate composition

Bread samples were analysed for moisture content, crude protein content (Kjeldahl method), crude fat content (solvent extraction), and ash content (AOAC 2000). Carbohydrate content was determined by simple difference and the caloric value was calculated using the Atwater factors (4, 9, and 4 kilocalories for protein, fat, and carbohydrate, respectively).

Physical characteristics of bread loaves

Bread volume was determined using the rapeseed displacement method and the specific volume was calculated using the volume and weight data for the loaf (Hallén et al. 2004).

Amino acid composition and protein digestibility of bread

The total amino acid content of the bread was determined by using Ultra Performance Liquid Chromatography (UPLC) with UV or fluorescence detection following the derivatisation with 6-aminoquinolyl-N-hydroxysuccinimidyl carbamate (AQC). The amino acids were measured either as free amino acids in solution or following the hydrolysis of proteins using the standard 6 M HCl acid digestion. Amino acid separation and detection were performed using the UPLC fitted with a photodiode array (PDA) detector. Exactly 1 µL of the digested sample was injected into the mobile phase which carried the derivatised amino acids into a Waters UltraTag C18 column (2.1 mm × 50 mm × 1.7 µm) maintained at 60 °C. MassLynx software was used to acquire and to manage the data. The total amino acid content values were expressed in gramme per 100 g of the sample (g/g) (Grobbelaar et al. 2014). In vitro protein digestibility (IVPD) was performed using the method described by Ayo et al. (2007), with a few modifications. Pepsin from porcine gastric mucosa supplied by Sigma-Aldrich (St. Louis, MO. USA) was used for digestion. The sample (0.2 g) was taken into a flask and 1.5 mg pepsin was added to it along with 35 mL of 0.1 M phosphate buffer (pH 2.0). The mixture was then incubated at 37 °C for 2 h in a continuously shaking water bath. The digestion was terminated by adding 2 mL of 2 M NaOH and the solution was then centrifuged at 4000 rpm at 40 °C for 24 min. The supernatant was discarded and the residue was washed twice with 15 mL of 0.1 M phosphate buffer (pH 7.0), followed by centrifugation as performed earlier. The residue was washed again and filtered and dried in an oven at 80 °C for 2 h. The undigested nitrogen (N) was analysed using the micro-Kjeldahl method, and the digestible nitrogen was calculated as follows;

Sensory evaluation

Sensory analyses were conducted 1 h subsequent to the baking, and the samples were presented in 3-digit-coded white disposable cups. The bread samples were evaluated by a 40-person panel constituted from the staff and students of Durban University of Technology, Durban, South Africa. In order to describe the level of liking by the panellists, the nine-point hedonic scale (1 = extremely disliked, 9 = extremely liked) was used (1 = extremely dislike, 9 = extremely liked) (Kilcast and Subramaniam 2000).

Statistical analysis

All analyses were performed in triplicate. Data were analysed using the analysis of variance (ANOVA) and the means were compared using Fisher’s least significant difference (LSD) test (p < 0.05).

Results and discussion

Mixolab rheological behaviour of composite dough

The addition of Bambara and millet flours each at the level of 25% significantly increased (p < 0.05) the water absorption capacity (WAC) of the dough prepared from the resulting composite flour (Table 1). The dough prepared from the flour treated with 1.5% pectin (WMB5) registered the highest WAC compared to the other composite dough samples. Previous research work has also reported that cryoprotectants such as pectin are able to improve the water holding capacity of dough (Kenijz and Sokol 2013). Emulsifier-treated dough (ETD) resulted in a significant decrease (p < 0.05) in the WAC of the composite dough (Table 2), similar to what was revealed in a previous study by Gómez et al. (2013) where they observed that the addition of SSL and PS 80 significantly decreased the WAC of dough with an increase in the level of emulsifiers added. Both the time required for dough development and the dough stability was prolonged by the addition of emulsifiers (WMB1–3), and the effect was not significantly different (p > 0.05) among the different levels of emulsifier additions used in this study, however, a significant difference (p < 0.05) was observed in comparison to both WF and MF. A similar effect was observed with pectin treatment (WMB4–6). Overall, the addition of emulsifiers at 1.3% (WMB1) significantly increased (p < 0.05) the DDT. This observation suggested that the composite flour used in the present study may withstand long mixing times without weakening. This may have been a result of the protein–protein networks formed by the emulsifiers with the wheat, millet and Bambara proteins (Gómez et al. 2013). The stability time, which is a measure of dough strength, was increased significantly (p < 0.05) for both ETD and pectin-treated dough (PTD), although it was more prolonged in PTD. This behaviour might have occurred because of the ability of hydrocolloids to form an interface between dough and water, thereby increasing the dough strength and bread volume (Correa et al. 2012). MF dough exhibited the lowest rheological properties despite the addition of both emulsifiers and pectin at the highest levels. This may be attributed to the absence of gluten and the occurrence of irregular gelatinisation of starch molecules present in the millet grain (Obilana 2003).

Table 1.

Mixolab parameters of composite dough rheology

| Parameters | WF | MF | WMB1 | WMB2 | WMB3 | WMB4 | WMB5 | WMB6 | WMB7 |

|---|---|---|---|---|---|---|---|---|---|

| Torque (NM) | 3.9f ± 0.09 | 3.03e ± 0.05 | 1.91bcd ± 0.37 | 2.24cd ± 0.09 | 2.42d ± 0.03 | 1.8bc ± 0 | 2.04bcd ± 0.45 | 1.63b ± 0.37 | 2.38d ± 0.05 |

| *WAC (%) | 43.80c ± 0.6 | 0a | 21.46b ± 0.01 | 21.17b ± 0.52 | 21.17b ± 0.01 | 40.15c ± 0 | 44.52c ± 4.91 | 40.17c ± 0.03 | 40.14c ± 0.07 |

| *DDT (Min) | 1.69b ± 0.08 | 0.75a ± 0.11 | 4.89e ± 0.26 | 4.73e ± 0.09 | 4.28de ± 0.1 | 3.38c ± 0.01 | 4.01d ± 0.59 | 3.77c ± 0.1 | 3.35c ± 0.74 |

| Stability (Min) | 4.75b ± 0.38 | 2.61a ± 0.24 | 5.52bc ± 0.48 | 5.81bc ± 0.52 | 5.14bc ± 0.94 | 5.54bc ± 0.27 | 5.34bc ± 0.69 | 6.22c ± 0.31 | 7.33d ± 0.52 |

| *DE (NM) | 0.15c ± 0.01 | 0.07a ± 0.01 | 0.07a ± 0.01 | 0.07a ± 0.01 | 0.08ab ± 0.01 | 0.1ab ± 0.02 | 0.11b ± 0.05 | 0.09ab ± 0.01 | 0.1ab ± 0.04 |

*DDT, dough development time (Min); WAC, water absorption capacity (%); DE, dough elasticity (N m); WF, wheat flour bread (100%); MF, millet flour bread (100%); WF, wheat flour bread (100%); MF, millet flour bread (100%); WMB1–3, wheat, millet and Bambara breads with emulsifiers treatment at 1%, 1.3%, and 1.6% levels; WMB4–7, wheat, millet and Bambara breads with pectin treatment at 1%, 1.5% and 2% levels

The values in the same row with different letters are significantly different at p < 0.05 using Fisher’s least significant difference (LSD) test

Table 2.

Values for Mixolab curve (C1–C5) and the behavior of dough constitutes of wheat–millet–Bambara composite dough

| Parameters | Samples | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| WF | MF | WMB1 | WMB2 | WMB3 | WMB4 | WMB5 | WMB6 | WMB7 | |

| C1 | 6.26c ± 0.50 | 2.56a ± 0.24 | 5.71b ± 0.24 | 5.47b ± 0.09 | 5.55b ± 0.18 | 5.58b ± 0.24 | 5.67b ± 0.07 | 6.65c ± 0.07 | 6.91d ± 0.32 |

| C2 | 18.41a ± 0.21 | 20.57a ± 0.47 | 20.01cd ± 0.88 | 18.7ab ± 0.14 | 18.77ab ± 0.08 | 18.59a ± 0.05 | 18.36a ± 0.93 | 19.18abc ± 0.88 | 19.87bcd ± 1.04 |

| C3 | 23.80b ± 0.29 | 0.0a | 23.0b ± 0.0 | 23.64b ± 0.57 | 23.0b ± 0.0 | 23.98b ± 0.09 | 23.87b ± 0.34 | 25.54c ± 2.23 | 23.0b ± 0.0 |

| C4 | 26.96b ± 0.12 | 0.0a | 30.0bc ± 0.0 | 27.03b ± 2.58 | 30.0bc ± 0.0 | 28.36b ± 0.40 | 26.23b ± 2.11 | 33.35c ± 5.17 | 30.0bc ± 0.0 |

| C5 | 45.01a ± 0.01 | 45.02a ± 0.0 | 45.02a ± 0.0 | 45.02a ± 0.0 | 45.02a ± 0.0 | 45.01a ± 0.01 | 45.01a ± 0.01 | 45.02a ± 0.0 | 45.01a ± 0.01 |

| α | − 0.09c ± 0.06 | − 0.07ab ± 0.02 | − 0.07ab ± 0.03 | − 0.07ab ± 0.02 | − 0.03b ± 0.02 | − 0.10a ± 0.02 | − 0.07ab ± 0.03 | − 0.11a ± 0.02 | − 0.75ab ± 0.03 |

| β | 0.18e ± 0.11 | 0.0abcd | 0.10cde ± 0.13 | 0.0abcd ± 0.06 | 0.08bcde ± 0.01 | − 0.05a ± 0.02 | − 0.04ab ± 0.02 | − 0.03abc ± 0.02 | 0.11c ± 0.06 |

| γ | − 0.05a ± 0.01 | 0.0ab | 0.10bc ± 0.13 | 0.00ab ± 0.06 | 0.08bc ± 0.01 | − 0.05a ± 0.02 | − 0.04a ± 0.02 | − 0.03a ± 0.02 | 0.11c ± 0.06 |

WF, wheat flour bread (100%); MF, millet flour bread (100%); WMB1–3, wheat, millet and Bambara breads with emulsifiers treatment at 1%, 1.3%, and 1.6% levels; WMB4–7, wheat, millet and Bambara breads with pectin treatment at 1%, 1.5% and 2% levels; C1, dough development time and stability; C2, protein weakening pattern, dough elasticity; C3, maximum viscosity; C4, amylolysis pattern; C5, retrogradation. Mixolab dough constituents behaviour. α: represents protein weakening speed under heat; β: represents starch gelatinization speed and γ: represents enzyme degradation speed

The values in the same row with different letters are significantly different at p < 0.05 using Fisher’s least significant difference (LSD) test

The Mixolab graph has different phases (C1–C5) of measurement, each phase measuring different rheological parameters of the flour (Table 1; Fig. 1). C1 was the highest point on the curve and it recorded the dough development time and dough stability time. It also measured protein behaviour in the dough (Table 2). The dough stability increased from 4.75 min for the control (WF) to 5.81 min and 7.33 min for ETD and PTD, respectively. The findings of the present study supported the previous study where a combination of SSL, DATEM, and PS80 produced high dough stability when the proofing time was prolonged (Gómez et al. 2013). The longer stability time that was observed could also be attributed to the strength of the Bambara flour protein molecules which are soluble and absorb water easily (Erukainure et al. 2016). The protein weakening pattern value (C2) increased significantly (p < 0.05) for ETB (WMB1) and PTB (WMB6) in comparison to the control. The increased protein-weakening pattern value demonstrated a good protein pattern present in the composite dough (Table 2). According to Collar et al. (2007), a good protein exhibits stability during the process of heating, although it becomes weakened, reduced, and breaks down eventually when the heating time is prolonged. The weakening of proteins was further proven by the α slopes of the Mixolab graph, which indicated the protein weakening speeds for the doughs influenced by heat (Pastukhov and Dogan 2014) (Table 2).

No significant difference (p < 0.05) was observed in the viscosity of the dough (C3) with the increase in temperature for all the composite dough samples and the control (WF), with the only exception of PTD at 2% level of treatment, for which the viscosity increased relative to the control. The dough weakened as the mixing temperature increased, suggesting that gelatinisation of starch particles reduced as the mixing continued. This could explain the reduction in β slope values for the composite dough in comparison to control (Table 2). The highest point on the Mixolab graph, C3 indicated maximum viscosity and was attributed to quick rupture of the starch granules, leading to lower pasting temperatures and higher paste consistency (Pastukhov and Dogan 2014). The increased dough temperature together with water produced from the denaturation of proteins (C2) caused the starch granules to swell and burst, thereby inducing an increase in the dough consistency for all the composite dough samples (Aprodu et al. 2010).

At the peak of the Mixolab curve (C4), a significant increase (p < 0.05) was observed in the dough consistency for EPTD (WMB7) in comparison to control, as indicated by the γ slope in Table 2. This implied that there was a significant increase in the level of activities of the amylose and amylopectin molecules constituting the starch of the composite bread sample and that this increase was greater than that observed in the control WF. At treatment levels of 1.6% and 2% in both ETD (WMB3) and PTD (WMB6), a higher level of gelatinisation was observed in comparison to WF. This signified a steady increase in the amylase index for both ETD and PTD as the treatment levels increased (Table 2). This implied that the increased concentrations of both pectin and the emulsifiers reduced the ability of starch to withstand amylolysis, thereby causing a lower rate of staling in the composite bread (Erukainure et al. 2016).

The high C5 value indicated the greater susceptibility of bread to retrogradation and therefore a shorter shelf-life (Dhaka et al. 2012) (Fig. 1). The addition of emulsifiers and pectin did not significantly increase (p < 0.05) the retrogradation time of the composite dough (Table 2). The retrogradation time of the composite flour doughs did not exhibit a significant difference (p < 0.05) in comparison to WF. However, the emulsifier concentration at 1.6% (WMB3) resulted in the highest retrogradation level close to that of control (Fig 2) (online resource). This finding implied that the shelf-life of the composite bread and WF could be similar. The Mixolab equipment was unable to generate a regular dough profile for the millet flour dough due to the irregular gelling nature of this flour and the absence of gluten (Tables 1 and 2). The online appendix (Fig 2) shows the effect of inclusion of millet and Bambara flours on functional properties of wheat composite dough.

Proximate composition of composite bread

The protein content in the composite bread increased significantly (p < 0.05) from 10 to 14% with the addition of Bambara and millet flours (Table 3). Moisture content in the composite bread also increased (14–20%) significantly (p < 0.05) in comparison to the control (WF). High moisture content is observed commonly with the composite flour bread (Temba et al. 2016). Flours high in starch and protein have been demonstrated to possess a high physical affinity for water resulting in the formation of protein and starch gels (Kaur et al. 2018). The increase in the moisture levels could also be due to the addictive effects of legume proteins from the Bambara flour, as 70–90% of the proteins in this flour is soluble in water (Hallén et al. 2004). In the present study, as the levels of emulsifiers and pectin (added separately) increased, a significant decrease was observed in the moisture content, and a similar effect was observed in the composite bread treated with both emulsifiers and pectin (WMB7). The addition of pectin in the bread system has also been linked to high bonding among the free water molecules present in the flour. High water bonding might be associated with interactions between water and the hydroxyl, carbonyl or amine groups of the added pectin polysaccharides and flour proteins (Sivam et al. 2011). The fat content in the composite bread was also increased significantly (p < 0.05), probably due to a relatively high-fat content in both millet and Bambara groundnut flours (Table 3).

Table 3.

Characteristics of wheat–millet–Bambara composite bread

| Samples | Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Moisture (%) | Ash (%) | Protein (%) | Fat (%) | *CHO (%) | Energy (%) | Volume (cm3) | Weight (g) | *SPV (cm3/g) | *PD (%) | |

| WF | 14.78a ± 0.39 | 2.68c ± 0.23 | 10.01a ± 0.25 | 1.64a ± 0.03 | 70.88f ± 0.62 | 328.37abc ± 15.4 | 851.67g ± 2.89 | 314.1g ± 0.44 | 2.71h ± 0.01 | 64.9a ± 3.2 |

| MF | 19.45e ± 0.68 | 3.22e ± 0.11 | 10.91b ± 0.04 | 4.39b ± 0.05 | 62.02e ± 0.81 | 320.33a ± 16.1 | 427.33a ± 2.52 | 302.19f ± 0.1 | 1.42b ± 0.01 | 69.97ab ± 3.5 |

| WMB1 | 20.22f ± 0.09 | 1.7ab ± 0.39 | 14.72cd ± 0.37 | 5.41c ± 0.12 | 57.94abc ± 0.74 | 324.42ab ± 26.47 | 550d ± 5 | 298.9e ± 0.1 | 1.83d ± 0.01 | 85.12b ± 2.3 |

| WMB2 | 19.6ef ± 0.25 | 1.88b ± 0.22 | 14.86cd ± 0.16 | 6.42d ± 0.07 | 57.24a ± 0.12 | 346.15abcd ± 1.49 | 616.67f ± 15.28 | 297.7d ± 0.36 | 2.07f ± 0.05 | 81.67b ± 7.2 |

| WMB3 | 18.03cd ± 0.17 | 1.83ab ± 0.24 | 14.88cd ± 0.1 | 6.43d ± 0.06 | 58.82c ± 0.24 | 337.7abcd ± 25.99 | 620f ± 18.03 | 243.53a ± 0.27 | 2.55g ± 0.07 | 78.42ab ± 5.57 |

| WMB4 | 19.68ef ± 0.59 | 1.49ab ± 0.18 | 14.77cd ± 0.13 | 6.65de ± 0.04 | 57.41ab ± 0.8 | 348.57bcd ± 2.48 | 476.67b ± 7.64 | 292.8b ± 0.27 | 1.63c ± 0.03 | 77.82ab ± 1.85 |

| WMB5 | 18.64d ± 0.23 | 1.47a ± 0.18 | 14.59c ± 0.06 | 6.96ef ± 0.47 | 58.34bc ± 0.53 | 354.41cd ± 1.63 | 485bc ± 5 | 385.03h ± 0.15 | 1.26a ± 0.01 | 77.58ab ± 1.3 |

| WMB6 | 17.83c ± 0.07 | 1.87b ± 0.15 | 14.96d ± 0.08 | 6.49d ± 0.08 | 58.84c ± 0.49 | 353.62cd ± 2.35 | 500c ± 10 | 387.63i ± 0.55 | 1.29a ± 0.02 | 75.31ab ± 4.64 |

| WMB7 | 16.48b ± 0.23 | 1.51ab ± 0.17 | 14.89cd ± 0.06 | 14.89cd ± 0.06 | 60.22d ± 0.3 | 364.22d ± 1.23 | 573.33e ± 7.64 | 295.83c ± 1 | 1.94e ± 0.04 | 79.31ab ± 4.9 |

*WF, wheat flour bread (100%); MF, millet flour bread (100%); WMB1–3, emulsifiers treatment at 1%, 1.3%, and 1.6% levels; WMB4–7, pectin treatment at 1%, 1.5% and 2% levels. *Carbohydrate calculated by difference. *SPV, specific volume; PD, protein digestibility

The values in the same row with different letters are significantly different at p < 0.05 using the Fisher’s least significant difference (LSD) test

Physical characteristics of composite bread

The loaf volume of composite bread increased significantly (p < 0.05) with an increase in the level of emulsifiers and pectin added to the composite bread (Table 3). Overall, the emulsifier treated bread (ETB) exhibited a significant volume increase of 45.6% and the pectin treated bread (PTB) exhibited an increase of 17.42% in the loaf volume, despite the gluten content in the composite flour being reduced to 50%. This ascertained the ability of the emulsifiers and pectin to influence volume increase in bread (Correa et al. 2012; Gómez et al. 2013). However, WF registered the highest volume among all the bread samples. The appendix image (Fig. 3) (online resource) depicts the composite bread samples 1 h subsequent to leaving the oven.

Amino acid composition and protein digestibility of bread

A significant increase (p < 0.05) was observed in the lysine content, from 0.15 g in the WF bread to 0.33 g in the composite bread (Table 4). As the level of emulsifiers increased, a significant decrease (p < 0.05) in the level of lysine was observed. Emulsifiers have been demonstrated to form complexes and networks with gluten proteins in order to exert their dough strengthening effect (Forssell et al. 1998), which might have caused the reduction in the lysine content. Increased levels of complex gelatinisation of protein and starch in the presence of Bambara and millet proteins have been reported earlier (Stampfli and Nersten 1995). The reverse trend was observed for PTB, which exhibited a significant increase (p < 0.05) in the lysine content with an increase in pectin level. This indicated that the addition of pectin may have improved the bioavailability of the essential amino acids in the composite bread. Threonine and lysine increased significantly (p < 0.05) in the emulsifier and pectin treated bread (EPTB) (WMB7). This demonstrated that the addition of both emulsifiers and pectin may not have affected the bioavailability of the amino acids in the composite bread (Table 4). A significant increase (p < 0.05) was observed in the IVPD for the composite bread (Table 3). ETB and PTB exhibited an average IVPD of 81% and 76% respectively, which was higher than that for the control (67%). This may have occurred because of the inclusion of Bambara and millet grains which contain proteins that are highly digestible in vitro (Ayo et al. 2007). ETB (WMB1–3) registered the best IVPD at a lower level of addition (1.3%). As the level of emulsifiers increased, the in vitro digestibility reduced, which was in line with the trend observed with lysine and threonine (Table 4). A similar trend was observed for PTB (WMB4–6). The IVPD of EPTB (WMB7) was higher than that of PTB (WMB4–6) (Table 3). Generally, in the present study, the addition of emulsifiers and pectin significantly increased (p < 0.05) the protein digestibility of the composite bread in comparison to the WF bread.

Table 4.

Amino acids composition of composite flour bread (g/100 g)

| Parameters (g/100 g) | Samples | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| WF | MF | WMB1 | WMB2 | WMB3 | WMB4 | WMB5 | WMB6 | WMB7 | |

| Histidine | 0.31a ± 0.11 | 0.31a ± 0.06 | 0.24a ± 0.17 | 0.5b ± 0.73 | 0.47b ± 0.01 | 0.46b ± 0.07 | 0.26a ± 0.05 | 0.44b ± 0.04 | 0.46b ± 0 |

| Serine | 0.51b ± 0.36 | 0.36a ± 0.11 | 0.53bc ± 0 | 0.7d ± 0.16 | 0.67bcd ± 0.54 | 0.54bc ± 0 | 0.57bcd ± 0 | 0.6bcd ± 0.03 | 0.56bcd ± 0.03 |

| Arginine | 0.37a ± 0.28 | 0.39a ± 0.17 | 0.73b ± 0.06 | 0.9bc ± 0.1 | 0.74b ± 0.03 | 0.83bc ± 0.01 | 0.87de ± 0.03 | 0.74b ± 0.18 | 0.98c ± 0.32 |

| Glycine | 0.62b ± 0.01 | 0.47d ± 0.1 | 0.72bcd ± 0.34 | 0.85e ± 0.72 | 0.67bc ± 0.21 | 0.73cd ± 0 | 0.78de ± 0.03 | 0.74b ± 0.86 | 0.79de ± 0.32 |

| Asparagine | 0.76a ± 0.34 | 0.78ab ± 0.15 | 1.26c ± 0.1 | 0.99abc ± 0.17 | 1.06abc ± 0 | 1.22c ± 0.05 | 1.2c ± 0.21 | 1.09bc ± 0.18 | 1.18c ± 0.11 |

| Glutamine | 4.42c ± 0.56 | 1.69a ± 0.25 | 3.66b ± 0.15 | 3.12b ± 0.3 | 3.28b ± 0.52 | 3.52b ± 0.16 | 3.52b ± 0.6 | 3.35b ± 0.29 | 3.47b ± 0.4 |

| Threonine | 0.42a ± 0.37 | 0.43a ± 0.05 | 0.53ab ± 0.04 | 0.66b ± 0.18 | 0.64b ± 0.08 | 0.49ab ± 0 | 0.55ab ± 0.01 | 0.55ab ± 0.1 | 0.63b ± 0.02 |

| Alanine | 0.47a ± 0 | 0.69b ± 0.09 | 0.68b ± 0.01 | 0.61ab ± 0.15 | 0.63ab ± 0.04 | 0.67b ± 0.04 | 0.66b ± 0.07 | 0.58ab ± 0.05 | 0.68b ± 0.07 |

| Proline | 1.71d ± 0.01 | 0.73a ± 0.1 | 1.32bc ± 0.05 | 1.38bc ± 0.12 | 1.33bc ± 0.06 | 1.41c ± 0.05 | 1.29bc ± 0.06 | 1.37bc ± 0.18 | 1.19b ± 0 |

| Lysine | 0.15abc ± 0.03 | 0.09a ± 0.01 | 0.33d ± 0.04 | 0.13ab ± 0.01 | 0.29d ± 0.08 | 0.09a ± 0.01 | 0.25cd ± 0.09 | 0.23bcd ± 0.06 | 0.3d ± 0.02 |

| Valine | 0.59a ± 0.05 | 0.57a ± 0.07 | 0.77c ± 0 | 0.75bc ± 0.13 | 0.78c ± 0.04 | 0.75bc ± 0.02 | 0.76bc ± 0.05 | 0.74bc ± 0.11 | 0.8c ± 0.1 |

| Isoleucine | 0.57b ± 0.02 | 0.42a ± 0.03 | 0.63b ± 0 | 0.64b ± 0.08 | 0.64b ± 0.04 | 0.63b ± 0.02 | 0.64b ± 0.04 | 0.63b ± 0.08 | 0.67b ± 0.07 |

| Leucine | 0.98ab ± 0.03 | 0.94a ± 0.07 | 1.17abc ± 0.01 | 1.15abc ± 1.13 | 1.19bc ± 0.05 | 1.16abc ± 0.08 | 1.15abc ± 0.07 | 1.14abc ± 0.17 | 1.23c ± 0.14 |

| Phenylalanine | 0.62ab ± 0.14 | 0.51ab ± 0.46 | 0.97ab ± 1.18 | 1.76b ± 0.07 | 0.11a ± 0.01 | 0.1a ± 0.02 | 0.56ab ± 1.3 | 1.01ab ± 0.87 | 1.12ab ± 1.17 |

*WMB1–7, wheat, millet and Bambara bread with different concentrations of emulsifiers and pectin; MF, 100% millet flour; WF, 100% wheat flour

The values in the same row with different letters are significantly different at p < 0.05 using the Fisher’s least significant difference (LSD) test

Sensory analysis of composite bread

The results of the present study demonstrated a significantly high (p < 0.05) overall acceptability score for PTB at a concentration of 2% (WMB6) in comparison to the control (Table 5). The addition of emulsifiers and pectin significantly improved the overall acceptability score for the composite bread. Millet bread exhibited the lowest score for all the attributes evaluated. In terms of colour, all the bread samples scored above the acceptable level i.e. 5, with the only exception of millet bread. The results demonstrated that all the composite bread samples (WMB1–7) were significantly different (p < 0.05) in taste (level 4) in comparison to WF. This could have occurred due to consumer familiarity with wheat bread, introducing bias in the panellist ratings (Erukainure et al. 2016). In all the attributes subjected to scoring, all the composite bread samples were adjudged acceptable as most of them scored above five, which is considered the minimum acceptable score on the 9-point hedonic scale.

Table 5.

Sensory evaluation of wheat–millet–Bambara composite bread

| Samples | Parameters | ||||

|---|---|---|---|---|---|

| Colour | Texture | Taste | Aroma | Acceptability | |

| WF | 7.38c ± 1.35 | 7.35c ± 1.33 | 6.75e ± 1.92 | 6.33d ± 1.98 | 7.03c ± 1.49 |

| MF | 4.28a ± 2.48 | 3.65a ± 2.27 | 3.13a ± 2.22 | 4.18a ± 2.4 | 4.58a ± 2.52 |

| WBM1 | 5.2b ± 2.17 | 5.55cd ± 2.17 | 4.33bc ± 2.41 | 4.35ab ± 2.5 | 6.45ab ± 2.38 |

| WBM2 | 5.73b ± 1.91 | 5.83d ± 1.71 | 5.38d ± 1.84 | 4.73abc ± 2.01 | 6.78b ± 1.87 |

| WBM3 | 5.08ab1.93 | 5.4cd ± 1.99 | 5.03cd ± 1.99 | 5.38bcd ± 2.02 | 6.78b ± 2.03 |

| WBM4 | 5.65b ± 1.99 | 4.43ab ± 2.04 | 3.95ab ± 2.03 | 5.03abc ± 2.04 | 6.88b ± 1.73 |

| WBM5 | 5.58b ± 1.95 | 4.63bc ± 1.88 | 4.45bcd ± 1.92 | 5.73cd ± 2.44 | 6.7b ± 1.92 |

| WBM6 | 5.53b ± 2.1 | 4.25ab ± 2.1 | 3.85ab ± 2.03 | 5.15abc ± 2.27 | 7.13ab ± 2.03 |

| WBM7 | 5.59b ± 2.1 | 5.15bc ± 2.35 | 4.38bcd ± 2.33 | 5.1abc ± 2.35 | 6.9b ± 2.26 |

WMB1–7, wheat, millet and Bambara bread with the different levels of emulsifiers and pectin treatment, MF, 100% millet flour; WF, 100% wheat flour

The values in the same column with different letters are significantly different at p < 0.05 using the Fisher’s least significant difference (LSD) test

Conclusion

Wheat, pearl millet, and Bambara groundnut (South African landrace) were used to constitute the composite flour for bread production. The addition of pectin at a level of 1.5% improved dough stability while the overall acceptability was the highest for composite bread at 2% pectin addition. Composite bread treated with emulsifiers at a level of 1.3% resulted in the highest increase in lysine content. The addition of mixtures of emulsifiers (SSL, DATEM and PS 80) at 1.6% increased the dough development time as well as the specific volume. The significant increase in the protein content in the composite bread produced may contribute to ameliorating the problem of protein-energy malnutrition. Therefore, the ratio of composite flour and levels of pectin and emulsifiers proposed in this study would be useful in the preparation of various bakery snacks and wheat flour-based products and in the enhancement of the use of underutilized pearl millet and Bambara groundnut.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

This work was based on the research supported in part by the National Research Foundation NRF) of South Africa for the grant, Unique Grant No. 93977 and ARC-DUT-UFS broadening the food base grant.

References

- AOAC (2000) Approved methods of the american association of cereal chemists 10th edition: method 56-81B

- Aprodu I, Banu I, Stoenescu G, Ionescu V. Effect of the industrial milling process on the rheological behavior of different types of wheat flour. St Cerc St CICBIA. 2010;11:429–437. [Google Scholar]

- Arise AK, Amonsou EO, Ijabadeniyi OA (2016) Composition and functional bioactive properties of bambara groundnut protein and hydrolysates. Thesis, Durban University of Technology

- Ayo J, Ayo V, Nkama I, Adewori R. Physiochemical, in-vitro digestibility and organoleptic evaluation of “acha” wheat biscuit supplemented with soybean flour. Niger Food J. 2007;25:77–89. [Google Scholar]

- Ceserani V, Kinton R, Foskett D. Practical cookery. London: Hodder and Stonghton; 1995. [Google Scholar]

- Collar C, Bollain C, Rosell C. Rheological behaviour of formulated bread doughs during mixing and heating. Food Sci Technol Int. 2007;13:99–107. doi: 10.1177/1082013207078341. [DOI] [Google Scholar]

- Correa MJ, Pérez GT, Ferrero C. Pectins as breadmaking additives: effect on dough rheology and bread quality. Food Bioprocess Technol. 2012;5:2889–2898. doi: 10.1007/s11947-011-0631-6. [DOI] [Google Scholar]

- Dhaka V, Gulia N, Khatkar B. Application of mixolab to assess the bread making quality of wheat varieties. Open Access Sci Rep. 2012;1:1–8. [Google Scholar]

- Eduardo M, Svanberg U, Oliveira J, Ahrné L. Effect of cassava flour characteristics on properties of cassava–wheat–maize composite bread types. Int J Food Sci. 2013;2013:1–10. doi: 10.1155/2013/305407. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Eduardo M, Svanberg U, Ahrné L. Effect of hydrocolloids and emulsifiers on baking quality of composite cassava–maize–wheat breads. Int J Food Sci. 2014;2014:1–9. doi: 10.1155/2014/479630. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Erukainure OL, Okafor JN, Ogunji A, Ukazu H, Okafor EN, Eboagwu IL. Bambara–wheat composite flour: rheological behavior of dough and functionality in bread. Food Sci Nutr. 2016;4:852–857. doi: 10.1002/fsn3.356. [DOI] [PMC free article] [PubMed] [Google Scholar]

- FAO, WHO J . Compendium of food additive specifications: addendum 9. Rome: Food & Agriculture Org; 2001. [Google Scholar]

- Forssell P, Shamekh S, Härkönen H, Poutanen K. Effects of native and enzymatically hydrolysed soya and oat lecithins in starch phase transitions and bread baking. J Sci Food Agric. 1998;76:31–38. doi: 10.1002/(SICI)1097-0010(199801)76:1<31::AID-JSFA915>3.0.CO;2-2. [DOI] [Google Scholar]

- Gómez AV, Buchner D, Tadini CC, Añón MC, Puppo MC. Emulsifiers: effects on quality of fibre-enriched wheat bread. Food Bioprocess Technol. 2013;6:1228–1239. doi: 10.1007/s11947-011-0772-7. [DOI] [Google Scholar]

- Grobbelaar MC, Makunga NP, Stander MA, Kossmann J, Hills PN. Effect of strigolactones and auxins on growth and metabolite content of Sutherlandia frutescens (L.) R. Br. micro plants in vitro. PCTOC. 2014;117:401–409. doi: 10.1007/s11240-014-0449-9. [DOI] [Google Scholar]

- Hallén E, İbanoğlu Ş, Ainsworth P. Effect of fermented/germinated cowpea flour addition on the rheological and baking properties of wheat flour. J Food Eng. 2004;63:177–184. doi: 10.1016/S0260-8774(03)00298-X. [DOI] [Google Scholar]

- Hillocks R, Bennett C, Mponda O. Bambara nut: a review of utilisation, market potential and crop improvement. Afr Crop Sci J. 2012;20:1–16. [Google Scholar]

- Kaur P, Singh N, Pal P, Kaur A. Traditional and improved paddy varieties: composition, protein, pasting and gluten free chapati making properties. Cereal Chem. 2018 [Google Scholar]

- Kenijz N, Sokol N. Pectic substances and their functional role in bread-making from frozen semi-finished products. Eur Online J Nat Soc Sci. 2013;2:253–256. [Google Scholar]

- Kilcast D, Subramaniam P. The stability and shelf-life of food. Cambridge: CRC Press; 2000. [Google Scholar]

- Maktouf S, Jeddou KB, Moulis C, Hajji H, Remaud-Simeon M, Ellouz-Ghorbel R. Evaluation of dough rheological properties and bread texture of pearl millet–wheat flour mix. J Food Sci Technol. 2016;53:2061–2066. doi: 10.1007/s13197-015-2065-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mubaiwa J, Fogliano V, Chidewe C, Linnemann AR. Hard-to-cook phenomenon in Bambara groundnut (Vigna subterranea (L.) Verdc.) processing: options to improve its role in providing food security. Food Rev Int. 2017;33:167–194. doi: 10.1080/87559129.2016.1149864. [DOI] [Google Scholar]

- Noorfarahzilah M, Lee JS, Sharifudin M, Mohd Fadzelly A, Hasmadi M. Applications of composite flour in development of food products. Int Food Res J. 2014;21:2061–2074. [Google Scholar]

- Obilana A. Overview: importance of millets in Africa. World (All Cultivated Millet Species) 2003;38(28):38. [Google Scholar]

- Pastukhov A, Dogan H. Studying of mixing speed and temperature impacts on rheological properties of wheat flour dough using Mixolab. Agronomy Res. 2014;12:779–786. [Google Scholar]

- Saleh AS, Zhang Q, Chen J, Shen Q. Millet grains: nutritional quality, processing, and potential health benefits. Comp Rev Food Sci Food Saf. 2013;12:281–295. doi: 10.1111/1541-4337.12012. [DOI] [Google Scholar]

- Schoenlechner R, Szatmari M, Bagdi A, Tömösközi S. Optimisation of bread quality produced from wheat and proso millet (Panicum miliaceum L.) by adding emulsifiers, transglutaminase and xylanase. LWT Food Sci Technol. 2013;51:361–366. doi: 10.1016/j.lwt.2012.10.020. [DOI] [Google Scholar]

- Sharma G, Madhura C, Arya S. Interaction of plastic films with foods. II, Effect of polyethylene and polypropylene films on the stability of vegetable oils. J Food Sci Technol. 1990;27:328–331. [Google Scholar]

- Sivam AS, Sun-Waterhouse D, Waterhouse GI, Quek S, Perera CO. Physicochemical properties of bread dough and finished bread with added pectin fiber and phenolic antioxidants. J Food Sci. 2011;76:H97–H107. doi: 10.1111/j.1750-3841.2011.02086.x. [DOI] [PubMed] [Google Scholar]

- Stampfli L, Nersten B. Emulsifiers in bread making. Food Chem. 1995;52:353–360. doi: 10.1016/0308-8146(95)93281-U. [DOI] [Google Scholar]

- Temba MC, Njobeh PB, Adebo OA, Olugbile AO, Kayitesi E. The role of compositing cereals with legumes to alleviate protein energy malnutrition in Africa. Int J Food Sci Technol. 2016;51:543–554. doi: 10.1111/ijfs.13035. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.