Abstract

Adhatoda vasica Nees, belonging to family Acanthaceae, is a well-known medicinal plant. It is endorsed for its pyrroloquinazoline alkaloids and its derivatives, such as vasicine and vasicinone. Germinating A. vasica seeds is a tedious task; on that account, vegetative propagation is the preferred method for its multiplication. For rapid and large-scale multiplication, germplasm conservation as well as secondary metabolites production, in vitro culture of A. vasica was preferred over conventional propagation by several researchers; however, some major applications of this tissue culture technique are still awaiting to undergo extensive research. The present review, for the first time, illustrates all the major achievements associated with in vitro regeneration of A. vasica, reported till date and highlights the future prospects.

Keywords: Artificial seed, Medicinal plant, Organogenesis, Somatic embryogenesis, Vasicine, Vasicinone

Abbreviations: 2,4-D, 2,4-dichlorophenoxyacetic acid; AC, Activated charcoal; B5, B5 medium, or Gamborg’s medium; BA, N6-benzyladenine; GA3, gibberellin A3; IAA, indole-3-acetic acid; IBA, indole-3-butyric acid; Kn, Kinetin or 6-furfurylaminopurine; MS, Murashige and Skoog; NAA, α-napthalene acetic acid; PGR, plant growth regulator; SH, Schenk and Hildebrandt; TDZ, thidiazuron

1. Introduction

Ardusi (Adhatoda vasica Nees syn. Justicia adhatoda L.), a shrub with an unpleasant smell, is popularly known as Malabar nut or Vasaka (in Sanskrit) [1]. It is an important member of the Acanthaceae family. In Unani and Ayurveda, this shrub is highly treasured owing to its healing properties against asthma, cold, cough and tuberculosis [2]. It acts as antispasmodic and expectorant as well [3]. A. vasica leaf, shoot and root prevalently possess quinazoline alkaloids like vasicine and vasicinone [4], and a non-crystalline steroid (vasakin), along with several essential oils, fatty acids, glycosides, sterols, and other phenolic components [5]. Due to an immoderate exploitation of plant parts for the purpose of constant phytochemical extraction by pharmaceutical industries, the natural population of A. vasica is under threat. As a consequence, the ever-increasing demand for its plant-part-based secondary metabolites cannot be fulfilled. Seed germination rate of A. vasica is quite poor and clonal propagation is occasional as well [6], [7]. Owing to these drawbacks, tissue culture techniques i.e. direct and indirect organogenesis has been preferred [7], [8], [9], [10].

2. Distribution and description

A. vasica is widely spread over India (up to an altitude of 1300 m), few parts of Sri Lanka, Bhutan, Pakistan, Afghanistan, and is progressively introduced to other countries like China, Hong Kong, Taiwan, Cyprus, Ethiopia etc. It is also found throughout the tropical regions of Southeast Asia [11] and some parts of Germany and Sweden [12], as well. A. vasica is a typically evergreen shrub, perennial, and grows at a height of about 1.2–2.5 m; leaves are characteristically perfect, elliptic-lanceolate, borne on short petioles and leathery to touch. The leaves carry an unpleasant smell and have a bitter taste. Chloral hydrate preparations of leaves showed oval stomata encircled by two crescent-shaped cells at right angles to the ostiole [13]. The branching habit is opposite and ascending with white, purple or pink flowers. But when the flowers become dry, they turn dull brownish in color. White with yellow or red barred throats with large bracts are seen in the flowers. Fruit-capsules and seeds are globular in nature [1].

3. Pharmaceutical/therapeutic importance

Ardusi contains numerous bioactive compounds, for instance, vasicinol, 5-hydroxy vasicine, vasicine, vasicine glycoside, deoxyvasicine, vasicinone, adhavasicinone, vasicolinone, adhatodine, anisotine and vasnetine [14], [15], [16], [17]. Vasicine shows bronchodilatory activity under in vitro and in vivo condition, whilst, vasicinone exhibited its effectiveness towards bronchoconstriction in vivo. Simultaneous effect of these two alkaloids was preferably administered for bronchodilatory activity both under in vitro and in vivo. A combination of vasicine and vasicinone also showed a significant reduction in cardiac depressant effects. Vasicinone produced from the roots, prevents shrinkage of intestine and cardiac depression in guinea pigs, and transient hypotension in cats, thus displaying decent anticholinesterase activity [18]. Vasicine produces ambroxol and bromhexine that have a pH-dependent growth inhibitory influence on Mycobacterium tuberculosis, which suggests that it may play a significant part in the primary treatment of tuberculosis [19]. Both vasicine and vasicinone have sucrose inhibitory activity, signifying that they can be explored as natural antidiabetic agents [20]. It has been reported that vasicine and its derivatives are excreted through urine [21]. By way of intramuscular and intravenous administration, for the first 18 and 22 h, 55% of the excreted product was vasicine, whilst, on oral administration, it was 18% during the first 24 h. The leaves of A. vasica possess anti-ulcer activity, which was tested in rats. The ardusi leaves have the highest degree of anti-ulcer activity (80%) as detected in the ethanol induced ulceration model when compared to that of the actions of pylorus and aspirin [22]. The syrup made from A. vasica leaves improved symptoms of dyspepsia as well [23]. A. vasica extracts exhibited antimutagenic activity when cadmium-intoxicated mice was treated with the same, wherein, it showed marked decline in inhibition of lipid peroxidation and xanthine oxidase activity [24]. Swiss albino mice when exposed to Cobalt-60 radiation, was affected with radiation-induced ailment, displaying noticeable effects in histology of testis. This effect was significantly reduced when A. vasica plant extract was applied. This suggests that the ardusi plant extracts have radioprotective effects on testis [25].

4. In vitro regeneration

Conventionally, A. vasica is propagated through seed or nodal cuttings. Nevertheless, the frequency of propagation is limited since the seed setting is insufficient; seed germination is poor and clonal propagation via stem cuttings is exclusively season-dependent [7], [8]. As an alternative to the conventional methods, in vitro propagation through plant cell, tissue and organ culture becomes a proficient technique for accelerated production of propagules in large-scale, exploring the variability among the propagules, and, to induce new attributes of commercial importance, as well as to develop novel variant via genetic transformation [26], [27]. There are several in vitro techniques that have been applied for direct and indirect regeneration in A. vasica till date. It is now quite essential to compare the reported in vitro techniques and classify them based on their efficacy, in order to select the suitable need-based protocol [28], [29], [30]. Accordingly, in this review, we’ve compared the reported methods of micropropagation in A. vasica, for instance direct organogenesis via multiple shoot culture and indirect organogenesis mediated by callus culture, along with some improved technologies like artificial seed development and in vitro production of secondary metabolites.

4.1. Explant selection

Appropriate selection and collection of explants is the first and foremost step for a successful in vitro regeneration study. Even though A. vasica is a perennial shrub and collection of explants can be done round the year; the most active growth stage was considered to retain the regeneration ability of collected explants. Preferable time of explant collection for in vitro regeneration is considered to be between November and March [8], [31], based on certain aspects like ontogenetic or physiological age and position (certain part of the plant, from where explants are collected) or size of explants. A number of explants, such as whole leaf, leaf disc, petiole, shoot tip, nodal segment, axillary meristems and root have been utilized for initiation of in vitro direct or indirect regeneration of A. vasica that has been summarized in Table 1. Among these explants, the sole use of nodal segments from field-grown plants was the most prevalent in majority of the reports [8], [9], [10], [32], [33], [34]. Additionally, when the regeneration efficiency of nodal segments was compared with other explants like shoot tip [35], [36], [37], the nodal segment explants displayed better response based on multiple shoot initiation and subsequent proliferation. Similar trend was also observed in case of indirect regeneration, where the nodal segment explants induced higher frequency of callogenesis in comparison to shoot tip, petioles, and leaf disc explants [38]. To induce cell culture and to obtain maximum cell biomass, Singh et al. [39], unconventionally used root segment explants and attained significant results. On the other hand, Madhukar et al. [40] used leaf explants to develop cell suspension culture via friable callus induction from leaf explants. Even after considering the superior morphogenetic competence of nodal segment explants, leaf explants was preferred for induction and subsequent regeneration of callus [7], [31], [41], [42], [43], [44]. In couple of the instances, the specific age of the explant source (mother plant) was mentioned either as 2–3 years old plant [35] or 6–7 year old flowering plant [8]; however in majority of the reports the age and stage of mother plants were not mentioned, which is considered to be a major factor during explant selection.

Table 1.

Factors involved and their influence on micropropagation of Adhatoda vasica (arranged in chronological order).

| Explant | Surface sterilization | Culture medium composition | Culture condition | Regeneration response | Acclimatization | Reference |

|---|---|---|---|---|---|---|

| Leaf (in vitro) | 0.1% HgCl2 for 5 min → 4 interim rinse with sterile water | MS + 1.0 mg/1 BA + 0.1 mg/1 NAA | 25 ± 1 °C temp, 60% RH, 16 h photoperiod, with an irradiance of 3000 lux | Maximum number of shoots with optimum callus growth | Regenerated plantlets were acclimatized in soil | [49] |

| PGR-free MS | Rooting | |||||

| Nodal segment | 1% Savlon 10 min → 80% ethanol for 30 sec → 0.1% HgCl2 for 7–10 min → 4–5 interim rinse with sterile water | MS + 0.5 mg/l BA + 0.1 mg/l NAA | 26 ± 1 °C temp, 60% RH, 16 h photoperiod, with an irradiance of 2000–3000 lux | Maximum 10.5 shoots of 4 cm and 2.8 of leaves/ shoot | 80% survival on garden soil, sand and compost (2:1:1) | [32] |

| PGR-free MS | 100% rooting, 3.5 roots/shoot with 4 cm length in 15 days | |||||

| Leaf | Not mentioned | B5 + 1 mg/l 2,4-D | Not mentioned | Callus induction | Wasn’t carried out | [41] |

| B5 + 0.1 mg/l Kn | Shoot regeneration | |||||

| Shoot tip | 2–3 drops teepol for 5–10 min → 0.01% HgCl2 for 7–18 min → thorough rinse with sterile water | MS + 0.5 mg/l BA + 15% CM | 25 ± 1 °C temp, unspecified RH, 16 h photoperiod, with an irradiance of 3000 lux | 4.3 shoots per explant with 5 leaves 3.2 nodes/shoot | 85% plants were acclimatized in sterilized sand and soil mixture (3:1) | [47] |

| PGR-free MS | 9.33 roots per shoot with 0.6 cm length | |||||

| Leaf | 5 drops Tween 80 for 5 min → 0.1% HgCl2 for 5 min → 3 rinse with sterile water | MS + 21.5 μM NAA + 19.7 μM IBA + 9.3 μM Kn | 25 ± 2 °C temp, unspecified RH, 16 h photoperiod, with an irradiance of 30 μE/m2/s PPFD | 76% callus with precocious roots | Wasn’t carried out | [42] |

| Petiole | MS + 4.5 μM 2,4-D + 2.3 μM Kn | 62% callus with precocious somatic embryos | ||||

| Nodal segment | 0.1% HgCl2 for 5 min → 4–5 rinse with sterile water; or, 0.1% HgCl2 for 5 min → Geneticin treatment → 4–5 interim rinse with sterile water | MS + 10 mg/l BA | 25 ± 2 °C temp, 80% RH, 16 h photoperiod, with an irradiance of 100 μmol/m2/s PPFD | 7.75 shoots/explant in 4 weeks | Successfully acclimatized for 3 weeks in soilrite with liquid ½ MS nutrient spraying | [8] |

| MS + 1 mg/l BA + 1 mg/l Kn | 30 shoots/explant in 6 weeks | |||||

| MS + 0.1 mg/l IBA | 90% rooting | |||||

| Shoot tip, Nodal segment | 1% Savlon (w/v) and 2 drops Tween 80 for 20 min → unspecified HgCl2 for 5 min | MS + 2 mg/l BA + 0.2 mg/l NAA | 25 ± 2 °C temp, unspecified RH, 16 h photoperiod, with an irradiance of 3000 lux | 90% of explants produced 7 shoots/explant with 4.9 cm length in 28 days | 80% plantlets were acclimatized in garden soil + cow dung + sand (1:1:1) | [35] |

| MS + 1 mg/l IBA | 80% rooting with 3–4 roots/shoot of 3 cm length were recorded in 28 days | |||||

| Leaf, Petiole, Nodal segment | Unspecified | MS + 10.7 µM NAA + 2.2 µM BA | Unspecified | 90% repeatability to induce callus with 7 day callus induction | Wasn’t carried out | [53] |

| Leaf | 0.1% HgCl2 for 5 min → 3 rinse with sterile water | MS + 1.5 ppm 2,4-D + 1.5 ppm IAA + 1.5 ppm Kn + 1.5 ppm BA | 24 ± 2 °C temp, unspecified RH, 16 h photoperiod, with an irradiance of 3000 lux | 75% callus induction and proliferation with 18.16 g fresh weight | Wasn’t carried out | [43] |

| Nodal segment, Shoot tip, Petioles, Leaf disc | 0.1% HgCl2 for 5 min → thorough rinse with sterile water | MS + 2.0 mg/l BA + 0.5 mg/l NAA | Unspecified | Maximum callus induction from nodal segments | Rooted plantlets were acclimatized in a mixture of sandy soil and FYM (1:1) | [38] |

| MS + 2.0 mg/l 2,4-D, 0.5 mg/l Kn and 0.5 mg/l GA3 | Embryogenic callus proliferation | |||||

| ½ MS + 0.5 mg/l IBA + 0.2 g/l AC | Rooting | |||||

| Shoot tip | Unspecified | MS + 22.20 µm BA | Unspecified | High frequency and maximum number of multiple shoots | The rooted plantlets were hardened and established at 50–60% | [50] |

| PGR-free MS | High frequency of rooting | |||||

| Axillary meristems, Leaf, Nodal segment | 0.1% HgCl2 for 2 min → thorough rinse with sterile water | MS + 1 mg/l BA + 1 mg/l GA3 | 25 ± 2 °C temp, unspecified RH, 10 h photoperiod, with unspecified irradiance | High frequency shoot multiplication | Wasn’t carried out | [36] |

| MS + 1 mg/l Kn + 2 mg/l 2,4-D 1 mg/l BA + 0.1 mg/l Pic | Callus initiation within 5 days, both friable and green calli | |||||

| Nodal segment | 0.2% HgCl2 for unspecified duration → 4–5 interim rinse with sterile water | MS + 15% (v/v) CW + 5 mg/l BA | 25 ± 2 °C temp, unspecified RH, 16 h photoperiod, with unspecified irradiance | 14 shoots with 3 cm long in 8 weeks | 80% plants were acclimatized under laboratory conditions → transferred to pots filled with sterilized soil: sand mixture (1:3) | [33] |

| MS + 1 mg/l IBA | Rooting (unspecified) | |||||

| Nodal segment | Unspecified HgCl2 + Tween-20 for 5 min → thorough rinse with sterile water | MS + 1.0 mg/l BA + 0.05 mg/l NAA | 24 ± 2 °C temp, unspecified RH, 16 h photoperiod, with an irradiance of 2000–2500 lux | 10 shoots/explant within 4 weeks with maximum elongation | Wasn’t carried out | [9] |

| MS + 0.5 IBA | Rooting with root length 3.5–4 cm after 3 weeks | |||||

| MS + 0.05 mg/l NAA + 0.1 mg/l BA + 0.1 mg/l Kn | Dark green, compact and hard callus | |||||

| Leaf | Unspecified | MS + 1 mg/l 2,4-D + 0.5 mg/l Kn | 27 ± 2 °C temp, unspecified RH, 16 h photoperiod, with unspecified irradiance | 70% callusing from leaf explants after 4 weeks | Wasn’t carried out | [7] |

| Petiole | MS + 1 mg/l 2,4-D + 1 mg/l Kn | 45% callusing from petiole explants after 4 weeks | ||||

| Friable calli | MS (liquid) + 1 mg/l 2,4-D + 0.5 mg/l Kn | Rotary shaker at 120 ± 5 rpm | Cell suspension culture | |||

| Leaf | Few drops Tween 80 for 15–20 min → 0.1% HgCl2 for 3–4 min | MS + 6 mg/l IAA + 6 mg/l Kn | 25 ± 2 °C temp, 55–6-% RH, 16 h photoperiod, with an irradiance of 2000 lux | Induction and proliferation of friable calli | Wasn’t carried out | [44] |

| Nodal segment | MS + 3 mg/l IBA + 3 mg/l BA | Induction and proliferation of friable calli | ||||

| Root | MS + 3 mg/l IBA + 6 mg/l BA | Induction and proliferation of friable calli | ||||

| Friable calli | PGR-free MS (liquid) | Rotary shaker at 120 rpm | Cell suspension culture | |||

| Shoot tip, Nodal segment | 1% Dettol for 10 min → 0.1% HgCl2 1–4 min → thorough rinse with sterile water | MS + 2 mg/l BA + 0.5 mg/l NAA + 0.5 mg/l TDZ | 25 ± 2 °C temp, unspecified RH, 16 h photoperiod, with an irradiance of 1000 lux | 100% of explants produced 23.3 shoots/explant in 28 days | 98.2% plantlets were acclimatized in garden soil + sand + vermicompost (1:1:1) in 28 days | [37] |

| MS + 0.1 IBA | 5.8 roots/shoot with 2.5 cm root length in 17 days | |||||

| Petiole | 0.1% HgCl2 for 5 min → 5 interim rinse for 10 min with sterile water | MS + 0.25 mg/l TDZ + 0.25 mg/l NAA | 25 °C temp, unspecified RH, 16 h photoperiod, with an irradiance of 35 μmol/m2/s PPFD | 100% callus induction, 90.6% regeneration with 8.10 shoots per callus | 90% were acclimatized in garden soil within 12 weeks | [31] |

| SH + 0.5 mg/l IBA | 75% rooting with 9–10 roots/ shoot | |||||

| Root | 0.1% HgCl2 for 1–1.5 min → 3 rinse with sterile water | MS + 3.5 mg/l NAA + 1.25 mg/l BA | 25 ± 1 °C temp, unspecified RH, 16 h photoperiod, with an irradiance of 3000 lux | Induction and proliferation of friable calli | Wasn’t carried out | [54] |

| Leaf | 1% Bavistine® solution for 10 min → 1% Savlon 10 min → 70% ethanol for 30 sec → 0.1% HgCl2 for 3 min → 5–7 interim rinse with sterile water | MS + 1 ppm 2,4‑D + 1 ppm BA + 1 ppm IAA | 25 ± 1 °C temp, 70% RH, 16 h photoperiod, with an irradiance of 2000–3000 lux | Profuse growth of soft creamy colored calli | Wasn’t carried out | [40] |

| MS (liquid) + KNO3 + NaCl | Rotary shaker at 120 rpm | Cell suspension culture | ||||

| Nodal segment | 70% alcohol for 1 min → 0.1% HgCl2 (w/v) for 5 min → 4–5 interim rinse with sterile water | MS + 10.0 mg/l BA | 25 ± 2 °C temp, unspecified RH, 12 h photoperiod, with unspecified irradiance | 93.33% explants produced 10.6 shoots with 5.2 cm length | 80% plantlets were acclimatized in garden soil and compost (2:1) | [34] |

| MS + 0.05 mg/l IAA + 0.05 mg/l NAA + 1.0 mg/l BA | 100% induction of light green callus in 14 days | |||||

| MS + 10 mg/l BA | Callus mediated shoot regeneration | |||||

| MS + 1 mg/l IBA | Rooting | |||||

| Nodal segment | 3% (v/v) H2O2 for 2 min → 95% (v/v) ethanol for 1 min → 3 interim rinse with sterile water | MS + 1.1 mg/l BA | 25 ± 1 °C temp, a 16 h photoperiod, with an irradiance of 60 μmol/m2/s PPFD | Shoot initiation in 6 days, 7.4 shoots of 7.2 cm length, 2.8 of leaves/ shoot | Initially in soil and sand (1:1; v/ v) for 4 weeks recording a survival rate of 95%. Finally, plantlets were established in sand, soil and farmyard manure (1:1:1; v/v) for another 4 weeks | [10] |

| MS + 1 mg/l IBA + 0.25 mg/l NAA | 94% rooting, 8.4 roots/shoot with 5.6 cm length | |||||

| MS + 1 mg/l 2,4-D | 46% callus induction that subsequently induced 60 roots per callus, devoid of adventitious shoots | |||||

| Root segment | 0.1% HgCl2 (w/v) for 5 min → 3 interim rinse with sterile water | MS + 1 mg/l 2,4-D + 4 mg/l BA | 25 ± 2 °C temp, 60% RH, unspecified photoperiod, 8 days on rotary shaker (120 rpm) | Cell culture, maximum cell biomass (47.43 g/flask) was achieved | Wasn’t carried out | [39] |

2,4-D 2,4-dichlorophenoxyacetic acid; AC activated charcoal; B5 B5 medium, or Gamborg’s medium [52]; BA N6-benzyladenine; CM coconut milk; CW coconut water; GA3 gibberellin A3; IAA indole-3-acetic acid; IBA indole-3-butyric acid; Kn kinetin or 6-furfurylaminopurine; MS Murashige and Skoog medium [48]; NAA α-napthalene acetic acid; PGR plant growth regulator; Pic piclorum; SH Schenk and Hildebrandt [55]; TDZ thidiazuron.

4.2. Surface sterilization

The most crucial step for establishment of any in vitro culture is sterilization of explants that are to be inoculated in the media, since there persists a high chance of microbial contamination in the plant materials, collected from fields [45]. There are three key parameters of surface sterilization: the category of disinfectant, their levels and duration of exposure. These parameters should be standardized in such a way that the sterilization would eradicate the contaminants without disturbing the regeneration ability of the explants. In majority of the instances, these three parameters depend upon the nature of explant tissue; softer or juvenile tissue requires an exposure of lower levels of disinfectants for a briefer time span in comparison to mature and hard tissues [29], [46]. As noted in the published literatures (Table 1), the surface sterilization of A. vasica was done by the way of exposing the explants to 1% (v/v) Savlon for 10 min, 80% (v/v) ethanol for 30 sec and 0.1% (w/v) HgCl2 for 7–10 min with 3–5 interim rinse with sterile water (Table 1). However, in many of the reports it was found that prior to ethanol or HgCl2 exposure, the explants were usually treated with 2–3 drops Teepol for 5–10 min [47] or 2 drops Tween-80 for 15–20 min [35], [44] or Tween-20 for 5 min [9] or 1% (v/v) Dettol for 10 min [37] as an alternative to Savlon solution. There are few other reports that used several other alternative surface sterilants. For example, Madhukar et al. [40] used 1% (w/v) Bavistine® solution for 10 min prior to the treatment with Savlon, ethanol and HgCl2. Use of 3% (v/v) H2O2 treatment for 2 min, before HgCl2 exposure was reported by Panigrahi et al. [10]. In a unique approach, Abhyankar and Reddy [8] used Geneticin solution after treating with HgCl2 to make the explants free from any contamination.

4.3. Multiple shoot formation

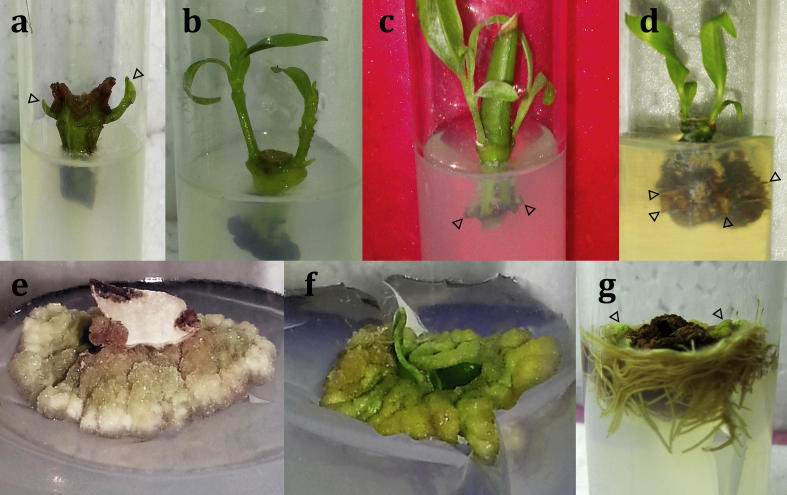

Following the collection, surface sterilization and preparation, the explants undergo processing for optimization of in vitro regeneration protocol via standardization of type and formulation of basal media, vitamins, carbohydrates, levels of solidifying agent, pH and plant growth regulators (PGRs). Influence of these factors on micropropagation of A. vasica has been summarized in Table 1. For multiple shoot initiation and subsequent proliferation (Fig. 1a and b), full strength Murashige and Skoog [48] (MS) medium was the only choice as found in all the published reports on A. vasica. Supplementation of PGRs in MS medium significantly varied, as displayed by the reports on shoot multiplication. In several reports, combination of cytokinin and auxin were preferred. For instance, 0.5–2 mg/l N6-benzyladenine (BA) was used as cytokinin in combination with 0.05–0.2 mg/l α-napthalene acetic acid (NAA), which was used as auxin [9], [32], [35], [49]. As an additional cytokinin source, 1 mg/l 6-furfurylaminopurine (Kinetin or Kn) was used along with equal concentration of BA for shoot multiplication [8]. Similarly, Roja et al. [36] used 1 mg/l supplementation of gibberellin A3 (GA3) with 1 mg/l BA to enhance the shoot multiplication frequency of A. vasica. Later on, Lone et al. [37] added 0.5 mg/l NAA and 0.5 mg/l thidiazuron (TDZ) with 2 mg/l BA to improve the regeneration efficiency of BA; wherein, 100% of explants produced the maximum (23.3) shoots/explant in 28 days. However, in contrast, there are several reports on the sole use of BA for initiation of high frequency multiple shoots, wherein very high concentrations of 10 mg/l [8], [34] or 22.20 µm [50] BA were used. As an outcome, 93.33% explants produced ∼11 shoots/explant, each 5.2 cm in length. Exceptionally, a very low level (1.1 mg/l) of BA alone induced multiple shoots in 6 days of culture and eventually produced 7.4 shoots of 7.2 cm length with 2.8 of leaves/shoot [10].

Fig. 1.

Micropropagation of Adhatoda vasica: (a) Direct shoot initiation (arrows) from nodal segment explant after one week of inoculation in MS medium with 1.1 mg/l BA, (b) elongation and proliferation of initiated shoots at 10 days of culture, (c) multiple shoot proliferation and root initiation (arrows) in MS medium with 1 mg/l IBA and 0.25 mg/l NAA, (d) in vitro rooting in clump after 14 days of inoculation (arrows), (e) induction of friable calli in MS medium with 3 mg/l 2,4-D, (f) induction of organogenic calli in MS medium with 0.5 mg/l 2,4-D, (g) indirect rooting and shoot bud (arrows) initiation after 21 days. [Photographs are not in scale].

Source: Original and unpublished photographs from the experiments, carried out by the authors.

4.4. Callus induction and regeneration

Similar to the multiple shoot regeneration, MS medium was the preferred choice for callus induction and its subsequent regeneration too. The only exception was reported by Anand and Bansal [51], who used Gamborg's medium (B5) [52] as a basal media instead of MS medium to induce callus from leaf explants with a supplementation of 1 mg/l 2,4-D. Apart from the basal medium, types and concentrations of PGRs played the most significant role during indirect organogenesis of A. vasica. In many instances, either equivalent amounts of auxin/cytokinin or variable auxin/cytokinin ratio efficiently induced high frequency of friable calli (Fig. 1e) or organogenic calli (Fig. 1f) (Table 1). For example, an equal amount of (1 mg/l) 2,4-D and Kn combination resulted 45% callusing from petiole explants within 4 weeks of inoculation [7]. Rashmi et al. [44] testified induction and proliferation of friable calli in MS medium with 6 mg/l IAA and 6 mg/l Kn from leaf explants, and in 3 mg/l indole-3-butyric acid (IBA) and 3 mg/l BA from nodal segment explants. A comparable result was reported by Mandal and Laxminarayana [31], who obtained 100% callus induction in MS medium supplemented with 0.25 mg/l each of NAA and TDZ. On the account of higher auxin/cytokinin ratio, Dinesh and Parameswaran [53] reported 90% callus induction within 7 days of inoculation on MS medium fortified with 10.7 µM NAA plus 2.2 µM BA. Analogous trend was detected by Bhambhani et al. [7], who reported as high as 70% callusing within 4 weeks of inoculation of leaf explants in MS medium plus 1 mg/l 2,4-D and 0.5 mg/l Kn. Later, Singh and Sharma [54] achieved high frequency of friable calli in MS medium fortified with 3.5 mg/l NAA and 1.25 mg/l BA. A completely opposite trend was also displayed in the report of Sil and Ghosh [38], who obtained maximum callus induction from nodal segments on MS medium accompanied with 2 mg/l BA plus 0.5 mg/l NAA, a higher cytokinin/auxin ratio. An interesting study conducted by Maurya and Singh [43] exhibited the use of dual auxin/cytokinin combination, unique of its kind, in the form of an amalgamation of 1.5 ppm 2,4-D, 1.5 ppm IAA, 1.5 ppm Kn, and 1.5 ppm BA in MS medium that induced as high as 75% callus with 18.16 g fresh weight. As an exceptional result, the sole use of auxin in the form of 1 mg/l 2,4-D to induce 46% calli from nodal segment explants, that successively induced 60 roots per callus, without adventitious shoots, was reported by Panigrahi et al. [10]. Hence, from this above result, we, the authors came to this projection that large-scale in vitro roots could be achieved from callus, suppressing shoot regeneration simultaneously (Fig. 1g). Earlier, Jayapaul et al. [42] observed similar results of callus induction (76%) with precocious root formation in MS medium but only after addition of 21.5 μM NAA, 19.7 μM IBA and 9.3 μM Kn. The same authors also reported the only occurrence of somatic embryogenesis (though precocious in nature) following 62% callus induction in MS medium supplemented with 4.5 μM 2,4-D and 2.3 μM Kn. Nevertheless, somatic embryogenesis in A. vasica is yet to be studied.

4.5. Root formation

The final phase of in vitro regeneration is the rooting of multiple shoots, following which ex vitro acclimatization and establishment of plantlets in external environment is achieved that completes any micropropagation protocol. For in vitro rooting of A. vasica (Fig. 1c and d), use of MS medium as a basal medium was mentioned in majority of the reports (Table 1). The only exception, was the use of Schenk and Hildebrandt [55] (SH) medium by Mandal and Laxminarayana [31], who observed 75% rooting with 9–10 roots/ shoot in SH medium fortified with 0.5 mg/l IBA. Even though in A. vasica, auxins are the preferred PGRs for in vitro rooting of shoots, PGR-free MS medium also proved its root regeneration potential in several instances. According to Amin et al. [49] PGR-free MS medium performed better than MS media supplemented with 0.1–0.5 mg/1 of either NAA or IBA for in vitro root induction of A. vasica microcuttings. Following this trend, 100% rooting with 3.5 roots/shoot of 4 cm length in 15 days was testified by Azad et al. [32] in MS medium, devoid of any PGR. Nath and Buragohain [47] obtained as many as 9.33 roots per shoot of 0.6 cm length in PGR-free MS medium and a comparable result was reported by Tejavathi et al. [50] as well. Apart from PGR-free MS medium, the most frequently used auxin was IBA. The minimum level of IBA supplementation was 0.1 mg/l that initiated 90% rooting [8] or a high frequency rooting with 5.8 roots/shoot of 2.5 cm length in 17 days of inoculation [37]. An increase in IBA level to 0.5 mg/l resulted in initiation of longer roots (3.5–4 cm) after 3 weeks of culture [9]. However, two-times higher concentration of IBA (1 mg/l) resulted in delayed (28 days) and lesser frequency (80%) of rooting with fewer (3–4) and shorter (3 cm) roots/shoot [35]. Similar outcome was also evident in the observation of Bimal and Shahnawaz [33], and Khan et al. [34] as well. Supplementation of a lower concentration of NAA (0.25 mg/l) with 1 mg/l IBA was reported to overcome such drawback and initiated as high as 94% rooting with 8.4 roots/shoot of 5.6 cm in length [10]. In addition to auxins (IBA in particular), use of activated charcoal (AC) was reported to enhance in vitro rooting of A. vasica [38]. According to Gantait and Mandal [56] supplementation of AC offers additional advantage by eliminating light and providing a reasonable physical environment for the rhizosphere and helps in rooting. Nevertheless, such inductive effect of AC was not tested in successive reports in A. vasica till date.

5. Acclimatization

Success of micropropagation eventually relies on efficient transfer and adaptation of in vitro regenerated plantlets in ex vitro autotrophic environmental conditions with maximum survival [45]. During acclimatization, plantlets that are multiplied under in vitro condition are exposed to a suitable growing condition that either assists them to grow rapidly or to extirpate them considering incompetent for ex vitro environment. The incompetency is determined based on the inability of the in vitro regenerated plantlets to control water loss and heterotrophic means of sustenance. That is why the relocation of in vitro regenerated plants to ex vitro environment necessitates specified states (controlled humidity, light intensity and temperature) for the effective acclimatization in field or in greenhouse [28]. The simplest substrate used for acclimatization of in vitro regenerated plantlets of A. vasica was garden soil in which 90% survival of plantlets was recorded within 12 weeks of transfer [31]. The next successful and yet simple substrate was the mixture of sand and soil. Nath and Buragohain [47] reported acclimatization of 85% plants in sterilized sand and soil mixture (3:1); in the similar medium, Bimal and Shahnawaz [33] successfully acclimatized 80% plants following their primary acclimatization under laboratory conditions. The effectiveness of soil and sand (1:1; v/ v) mixture during primary acclimatization was also proved by Panigrahi et al. [10], who recorded a survival rate of 95% within 4 weeks of transfer. Later on, they established plantlets in sand, soil and farmyard manure (1:1:1; v/v) for another 4 weeks for secondary acclimatization. Inclusion of common compost, vermicompost or farmyard manure enhanced the rate of acclimatization and increased the survival rate. According to Gantait et al. [57], compost and farmyard manure plays a major role in retention of moisture of the substrate apart from nutrient supply. It has already been established in several reports that retention of high humidity is a key component for high frequency acclimatization. Based on this fact, Azad et al. [32] reported 80% post-acclimatization survival on garden soil, sand and compost (2:1:1). A comparable success rate (acclimatization of 80% plantlets) was also observed by Khalekuzzaman et al. [35] in garden soil, sand and cow dung (1:1:1). Later, a much higher survival of 98.2% plantlets was achieved in garden soil, sand and vermicompost (1:1:1) in 4 weeks of transfer (Lone et al. 2013). In an exclusive experiment, Abhyankar and Reddy [8] used soil rite as a substrate and intermittently sprayed liquid ½ MS nutrient, which ensured a very high frequency of survival rate within 3 weeks of acclimatization.

6. Secondary metabolite production

The production of secondary metabolites can be fulfilled in a more sustainable approach via in vitro organogenesis as compared to that from in vivo or wild plant population [58]. All the parts of A. vasica plant have medicinal values [21]. The production of pyrroloquinazoline alkaloids has been reported in A. vasica; vasicine and vasicinone being the significant ones among them all. The first report of vasicine production from the leaf-derived callus culture of A. vasica was published by Jayapaul et al. [42]. They observed that the accumulation of vasicine was practically more in leaf-derived callus induced in MS media, fortified with NAA and BA. Later on, the high-performance liquid chromatography study of various extracts of A. vasica revealed the presence of higher levels of vasicine than that of vasicinone. Particularly, the water extracts of this plant contained more vasicine, i.e., 5.98% dry weight, whereas, the amount of vasicinone was 5.2%. Other extracts, like methanolic and petroleum ether extracts contained 2.8% and 0.187% vasicine in dry weight basis, respectively [36]. Bhambani et al. [7] successfully enhanced the production of vasicine in A. vasica by introducing elicitors in the cell culture. Elicitors such as chitosan, yeast extract, sodium salicylate, ascorbic acid, and methyl jasmonate (MeJ) were employed. This resulted in higher yield of vasicine (0.45 and 0.39%, based on dry weight) that was higher (3.7 and 3.2-fold) in comparison to the control cultures; when inoculated with 0.121% (20 µM MeJ) and 50 mg/l yeast extracts. Furthermore, Rashmi et al. [44] observed that vasicine production was higher under in vitro (callus- 5.15 mg/ml and leaf suspension culture 4.09 mg/l) conditions in A. vasica. Similar trends was observed by Madhukar et al. [40], when they assessed the callus culture of A. vasica via ultra-performance liquid chromatography/quadrupole-time-of-flight mass-spectrometry (UPLC/Q‑TOF‑MS), wherein, 123.3% increase in vasicine content was observed, compared to control plantlets. However, only a single report was documented, concerning the production of vasicinone, both from in vivo and in vitro plant parts of A. vasica [59]. In that report, the maximum vasicinone content (6.402% of dry weight) was obtained from in vitro leaf, followed by in vitro shoot (2.007% of dry weight), making way for simultaneous production of vasicinone more efficiently.

7. Artificial seed production

Artificial seed production is considered to be a multifaceted technology that has become quite popular among researchers, working on in vitro propagation and short/long-term conservation of threatened or endangered medicinal plant germplasms [60], [61]. This technology is most suitable for storage or exchange of precious plant germplasms, since it encapsulates very small size of plant tissue or organ without disturbing the natural population. In this course, explants like apical or axillary shoot bud, nodal segment or somatic embryo etc. are drenched in sodium alginate solution and the aliquots with explants are dropped in calcium chloride solution to form the spherical artificial seeds. There are multiple examples of medicinal plants for which this technology has become indispensible where the propagation, storage and exchange of plant materials is concerned [62], [63], [64]. However, such a convenient technology has not been potentially used in A. vasica yet. There is a lone report of Anand and Bansal [41] who developed artificial seeds of A. vasica. They encapsulated the in vitro shoot buds in hydrogel (4% sodium alginate) with 1.1% (w/v) hydrated calcium chloride solution. The hydrogel was dissolved either in distilled water B5 medium alone/with 4.65 μM Kn or B5 medium with 4.65 μM Kn plus 50 mg/l Phloroglucinol. They observed that encapsulated shoot buds (artificial seeds) retained their maximum morphogenetic competence when prepared with and inoculated on B5 medium, 4.65 μM Kn plus 50 mg/l Phloroglucinol. The artificial seeds registered maximum germination frequency of 66.28% and developed into complete plantlets within four weeks of inoculation. However, assessments on variable levels of sodium alginate, calcium chloride and germination medium are yet to be explored significantly. Additionally, no report on storage potential and post-storage phytochemical/molecular analysis exists that might have generated useful information on A. vasica.

8. Outlook

Several facets of in vitro regeneration like explant selection, surface sterilization, multiple shoot culture, callus culture and in vitro rooting of A. vasica has been discussed aptly in this review. Interestingly, no researchers reported clonal fidelity analysis of regenerated plantlets, which is considered to be an integral part of a successful micropropagation protocol. Progress on in vitro intervention for its secondary metabolite production as well as artificial seed production has been highlighted as well. There are several other key and advanced applications based on in vitro regeneration that are yet not attempted in this plant. Even though encapsulation of in vitro plant parts have immense utility for short-term storage or germplasm exchange and encapsulation-based cryopreservation, no such attempt has yet been made so far. Furthermore, a survey of the available literature found no information on genetic transformation on A. vasica as well. Techniques of protoplast fusion as well as incorporation of desired genes via protoplast transformation could have been aptly used to enhance the quality and quantity of secondary metabolites. However, as this area of genetic transformation has not been touched as of now, there is ample scope for the introduction of Agrobacterium-mediated transformation of root cultures to produce more quinzolline alkaloids. This appraisal provides sufficient briefing about the insides of in vitro culture, which would aid the future Adhatoda researchers for further advanced study.

Authors’ contribution

Both the authors contributed equally in conceiving the idea of the review, surveying of the literature and drafting of manuscript. Both the authors scrutinized, corrected and approved the final version of the manuscript prior to its submission.

Funding

This research did not obtain any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Peer review under responsibility of National Research Center, Egypt.

Contributor Information

Saikat Gantait, Email: saikatgantait@yahoo.com.

Jitendriya Panigrahi, Email: jitenp2001@gmail.com.

References

- 1.Patel V.K., Venkata-Krishna-Bhatt H. Indian J. Med. Sci. 1984;38:70–72. [PubMed] [Google Scholar]

- 2.Sharma M.P., Ahmad J., Hussain A., Khan S. Int. J. Pharmacogn. 1992;30:129–134. [Google Scholar]

- 3.Karthikeyan A., Shanthi V., Nagasathya A. Int. J. Green Pharm. 2009;3:78–80. [Google Scholar]

- 4.K.R. Kritikar, B.D. Basu, Indian Medicinal Plants, second ed., vol. II, Publ. Lalit Mohan Basu, Allahabad, 1994, pp. 870–872.

- 5.The Wealth of India, Vol. A, NISCAIR, Council of Scientific and Industrial Research, New Delhi, 2003, pp. 76–79.

- 6.Mathew A.S., Patel K.N., Shah B.K. Indian J. Nat. Prod. 1998;14:11–16. [Google Scholar]

- 7.Bhambhani S., Karwasara V.S., Dixit V.K., Banerjee S. Acta Physiol. Plant. 2012;34:1571–1578. [Google Scholar]

- 8.Abhyankar G., Reddy V.D. Indian J. Exp. Biol. 2007;45:268–271. [PubMed] [Google Scholar]

- 9.Murali R.S.S., Basavaraju R. Med. Plant. 2012;4:138–142. [Google Scholar]

- 10.Panigrahi J., Gantait S., Patel I.C. Natl. Acad. Sci. Lett. 2017;40:319–324. [Google Scholar]

- 11.Chakraborty A., Brantner A.H. Phytother. Res. 2001;15:532–534. doi: 10.1002/ptr.737. [DOI] [PubMed] [Google Scholar]

- 12.Hossain M.T., Hoq M.O. Asian J. Med. Biol. Res. 2016;2:156–163. [Google Scholar]

- 13.Kumar M., Dandapat S., Kumar A., Sinha M.P. Acad. J. Plant Sci. 2013;6:103–108. [Google Scholar]

- 14.Dhankhar S., Kaur R., Ruhil S., Balhara M., Dhankar S., Chhillar A.K. Afr. J. Plant Sci. 2011;5:620–627. [Google Scholar]

- 15.Tafazul M., Badkhane Y., Raghuvwanshi D., Shabir K.L., Yadav A., Sharma A.S., Ajit K. Indo Am. J. Pharma. Res. 2013;3:3341–3360. [Google Scholar]

- 16.Gupta A., Joshi A., Joshi V.K. Int. J. Herb. Med. 2014;1:1–4. [Google Scholar]

- 17.Srinivasan M., Padmaja B., Nair S. J. Pharmacogn. Phytochem. 2014;2:55–59. [Google Scholar]

- 18.Lahiri P.K., Prahdan S.N. Indian J. Exp. Biol. 1964;2:219–223. [Google Scholar]

- 19.Narimaian M., Badalyan M., Panosyan V., Gabrielyan E., Panossian A., Wikman G. Phytomedicine. 2005;12:539–547. doi: 10.1016/j.phymed.2004.10.001. [DOI] [PubMed] [Google Scholar]

- 20.Gao H., Huang Y.N., Gao B., Li P., Inagaki C., Kawabata J. Food Chem. 2008;108:965–972. doi: 10.1016/j.foodchem.2007.12.002. [DOI] [PubMed] [Google Scholar]

- 21.Claeson U.P., Malmfors T., Wikman G., Bruhn J.G. J. Ethnopharmacol. 2000;72:1–20. doi: 10.1016/s0378-8741(00)00225-7. [DOI] [PubMed] [Google Scholar]

- 22.Shrivastava N., Srivastava A., Banerjee A., Nivsarkar M. J. Herb. Pharmacother. 2006;6:43–49. [PubMed] [Google Scholar]

- 23.Chaturvedi G.N., Rai N.P., Dhani R., Tiwari S.K. Ancient Sci. Life. 1983;3:19. [PMC free article] [PubMed] [Google Scholar]

- 24.Jahangir T., Khan T.H., Prasad L., Sultana S. Biol. Trace Element Res. 2006;111:217–228. doi: 10.1385/BTER:111:1:217. [DOI] [PubMed] [Google Scholar]

- 25.M. Kumar, R. Samarth, M. Kumar, S.R. Selvan, B. Saharan, A. Kumar, eCAM 4 (2007) 343–350. [DOI] [PMC free article] [PubMed]

- 26.Ascough G.D., Erwin J.E., van Staden J. Plant Cell Tiss. Organ Cult. 2009;97:1–19. [Google Scholar]

- 27.Gantait S., Kundu S. Acta Physiol. Plant. 2017;39:196. [Google Scholar]

- 28.Teixeira da Silva J.A., Kher M.M., Nataraj M. J Genet. Eng. Biotechnol. 2016;14:335–348. doi: 10.1016/j.jgeb.2016.09.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Gantait S., Kundu S. 3 Biotech. 2017;7:231. doi: 10.1007/s13205-017-0865-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Sandhu M., Wani S.H., Jiménez V. Plant Cell Tiss. Organ Cult. 2018;132:27–53. [Google Scholar]

- 31.Mandal J., Laxminarayana U. Springer plus. 2014;3:1–8. doi: 10.1186/2193-1801-3-648. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Azad M.A.K., Amin M.N., Begum F. Online J. Biol. Sci. 2003;3:172–182. [Google Scholar]

- 33.Bimal R., Shahnawaz M. J. Med. Plant Res. 2012;6:1229–1233. [Google Scholar]

- 34.Khan S., Akter S., Habib A., Banu T.A., Islam M., Khan N.F., Afrin S., Ferdousi A., Islam S. Bangladesh J. Sci. Ind. Res. 2016;51:75–80. [Google Scholar]

- 35.Khalekuzzaman M., Rahman M.S., Rashid M.H., Hossain M.S. J. Bio-Sci. 2008;16:35–39. [Google Scholar]

- 36.Roja G., Vikrant B.H., Sandur S.K., Sharma A., Pushpa K.K. Food Chem. 2011;126:1033–1038. [Google Scholar]

- 37.Lone S.A., Yadav A.S., Sharma A.K., Tafazul M., Badkhane Y., Raghuwanshi D.K. Indo Am. J. Pharma. Res. 2013;3:3341–3360. [Google Scholar]

- 38.Sil S.K., Ghosh M.K. Adv. Plant Sci. 2010;23:11–14. [Google Scholar]

- 39.Singh B., Sahu P.M., Sharma R.A. Planta. 2017;246:1125–1137. doi: 10.1007/s00425-017-2757-x. [DOI] [PubMed] [Google Scholar]

- 40.Madhukar G., Tamboli E.T., Rabea P., Ansari S.H., Abdin M.Z., Sayeed A. Pharmacogn. Mag. 2014;10:5198–5205. doi: 10.4103/0973-1296.127375. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Anand Y., Bansal Y.K. J. Phytol. Res. 2004;17:17–19. [Google Scholar]

- 42.Jayapaul K., Kavi Kishor P.B., Reddy J. In Vitro Cell. Dev. Biol. - Plant. 2005;41:682–685. [Google Scholar]

- 43.Maurya S., Singh D. Ann. Biol. Res. 2010;1:57–60. [Google Scholar]

- 44.Rashmi P.A., John R., Mathew L. Int. J. Pharm. Bio. Sci. 2012;3:B58–64. [Google Scholar]

- 45.S. Gantait, U.R. Sinniah, P.K. Das, Acta Agric. Scand., Sect. B 64 (2014) 1–12.

- 46.Jaiswal N., Verma Y., Misra P. In Vitro Cell Dev. Biol. - Plant. 2017;53:145–166. [Google Scholar]

- 47.Nath S., Buragohain A.K. Indian J. Biotechnol. 2005;4:396–399. [Google Scholar]

- 48.Murashige T., Skoog F. Physiol. Plant. 1962;15:473–497. [Google Scholar]

- 49.Amin M.N., Azad M.A.K., Begum F. Plant Tissue Cult. 1997;7:109–115. [Google Scholar]

- 50.Tejavathi D.H., Manjula B.L., Anitha P. Acta Hortic. 2010;865:367–370. [Google Scholar]

- 51.Anand Y., Bansal Y.K. Plant Biotechnol. 2002;19:159–162. [Google Scholar]

- 52.Gamborg O.L., Miller R.A., Ojima K. Exp. Cell Res. 1968;50:151–158. doi: 10.1016/0014-4827(68)90403-5. [DOI] [PubMed] [Google Scholar]

- 53.Dinesh K.S., Parameswaran S. Pharmacogn. Mag. 2009;5:359–363. [Google Scholar]

- 54.Singh B., Sharma R.A. Am. J. Phytomed. Clin. Ther. 2014;2:403–412. [Google Scholar]

- 55.Schenk R.U., Hildebrandt A.C. Can. J. Bot. 1972;50:199–204. [Google Scholar]

- 56.Gantait S., Mandal N. Int. J. Bot. 2010;6:207–219. [Google Scholar]

- 57.Gantait S., Mandal N., Bhattacharyya S., Das P.K. Int. J. Plant Dev. Biol. 2010;4:19–25. [Google Scholar]

- 58.T.A. Paz, V.A.F.F.M. dos Santos, M.C Inácio, N.B. Dias, M.S. Palma, A.M.S. Pereira, M. Furlan, Plant Cell Tiss. Organ Cult. 130 (2017) 405–416.

- 59.Panigrahi J., Gantait S., Patel I.C. 3 Biotech. 2017;7:280. doi: 10.1007/s13205-017-0882-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 60.Gantait S., Kundu S., Ali M.N., Sahu N.C. Acta Physiol. Plant. 2015;37:98. [Google Scholar]

- 61.Haque S.M., Ghosh B. Plant Cell Tiss. Organ Cult. 2016;127:71–83. [Google Scholar]

- 62.Gantait S., Kundu S., Ali M.N. Med. Plants. 2015;7:182–187. [Google Scholar]

- 63.Gantait S., Vijayan J., Majee A. Hortic. Plant J. 2017;3:41–46. [Google Scholar]

- 64.Gantait S., Kundu S., Yeasmin L., Ali M.N. J. Appl. Res. Med. Arom. Plant. 2017;4:75–81. [Google Scholar]